Numerical Simulation of Temperature Field Evolution and Distribution Range During Movement of Underground Coal Gasification Working Face

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental and Geological Conditions

2.2. Model and Parameters

2.2.1. Model Establishment

2.2.2. Model Parameters

- (1)

- Thermal conductivity of coal/Rock

- (2)

- Specific heat capacity of coal/Rock

- (3)

- Other parameters

2.2.3. Basic Assumptions and Heat Conduction Equation

- (1)

- The surrounding rock is a homogeneous isotropic body with no heat source inside, and the influence of pore and fissure structure on thermal conductivity is ignored.

- (2)

- The operation factors of the gasifier are not considered, and it is considered that the gasifier is always in a stable operation state, that is, the moving speed of the flame working face is unchanged.

- (3)

- The differential equation of the field variable T(x, y, t) of the transient temperature field in the Cartesian coordinate system should be as follows:

2.2.4. Mobile Grid Setting

3. Results

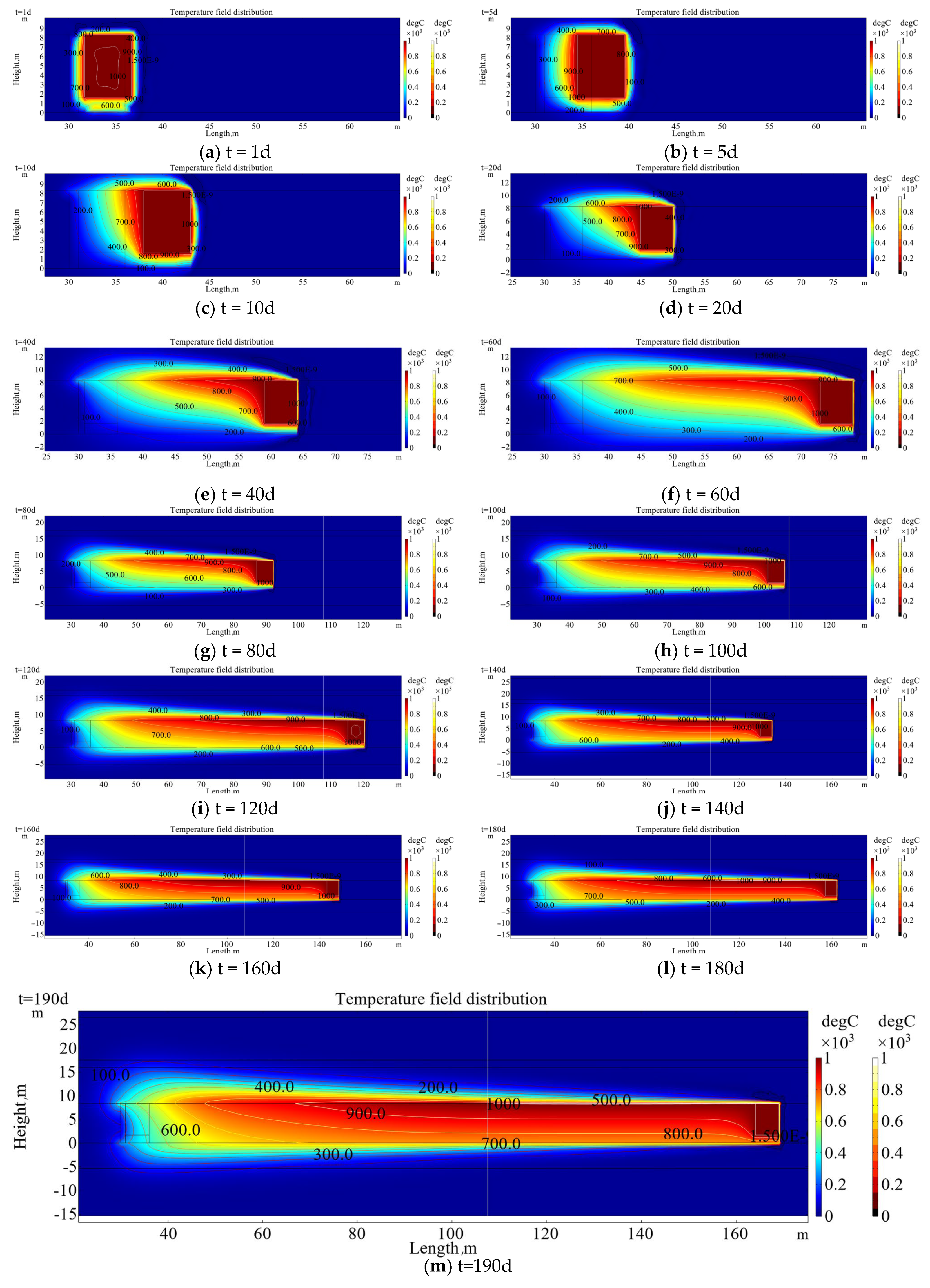

3.1. Evolution Law of Temperature Field with Advancing FWF

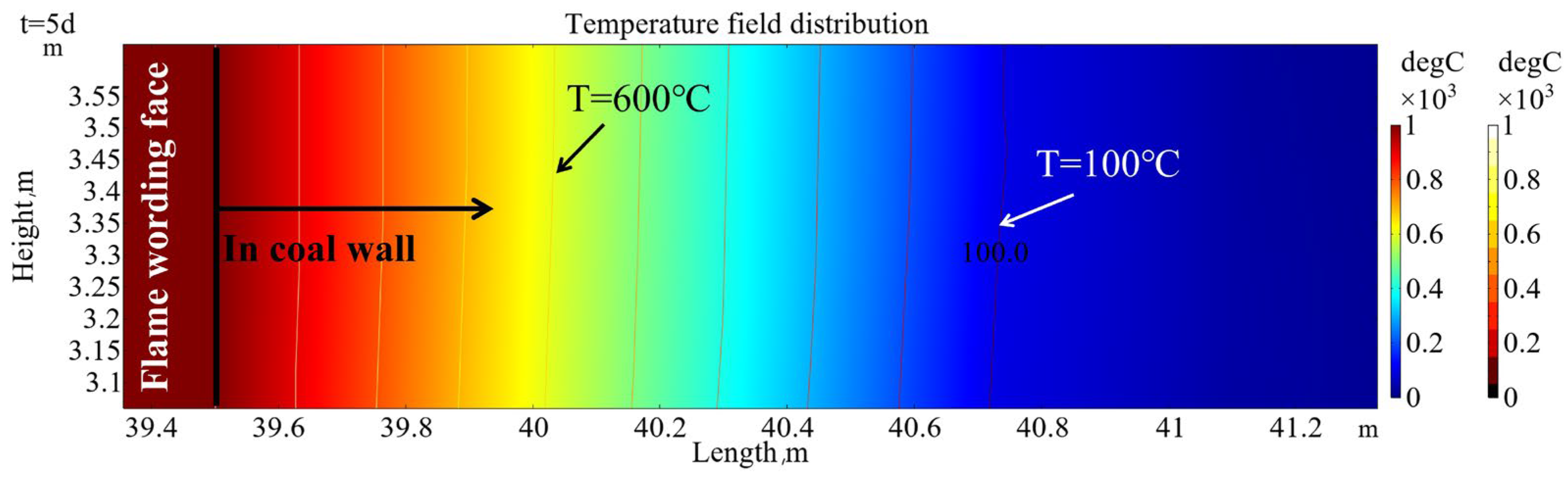

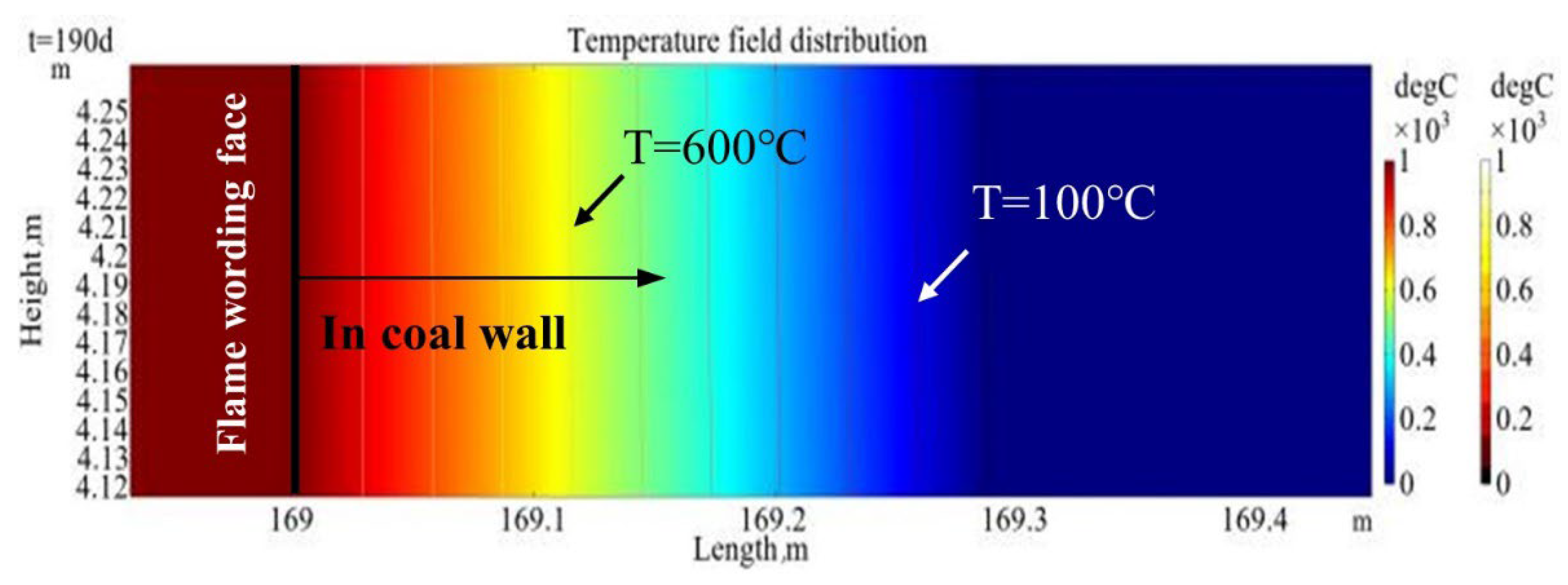

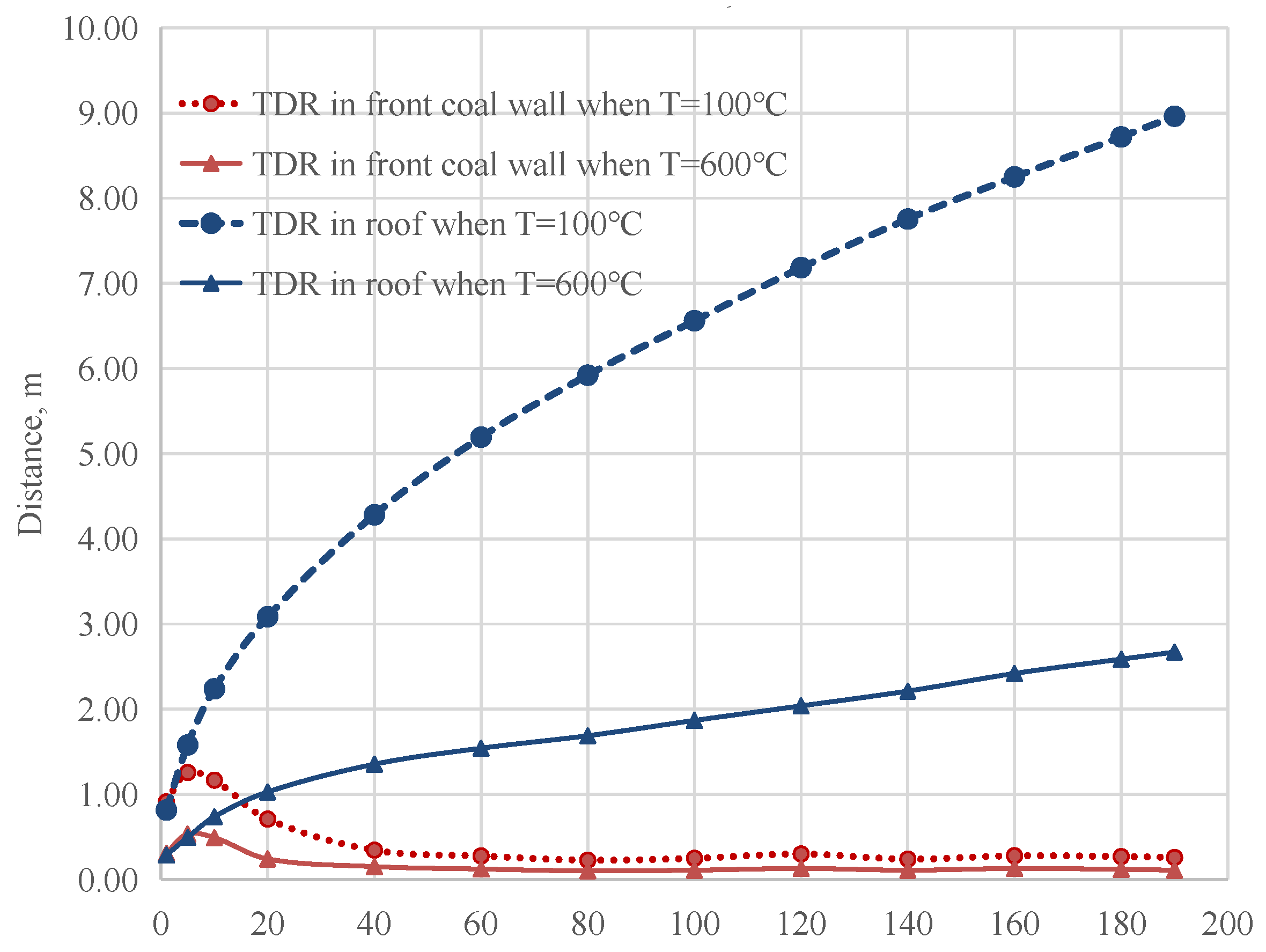

3.2. Variation Law of Temperature Distribution Range in Coal and Rock

3.2.1. Temperature Distribution Law of T = 100 °C, 600 °C and ∆T = 10 °C

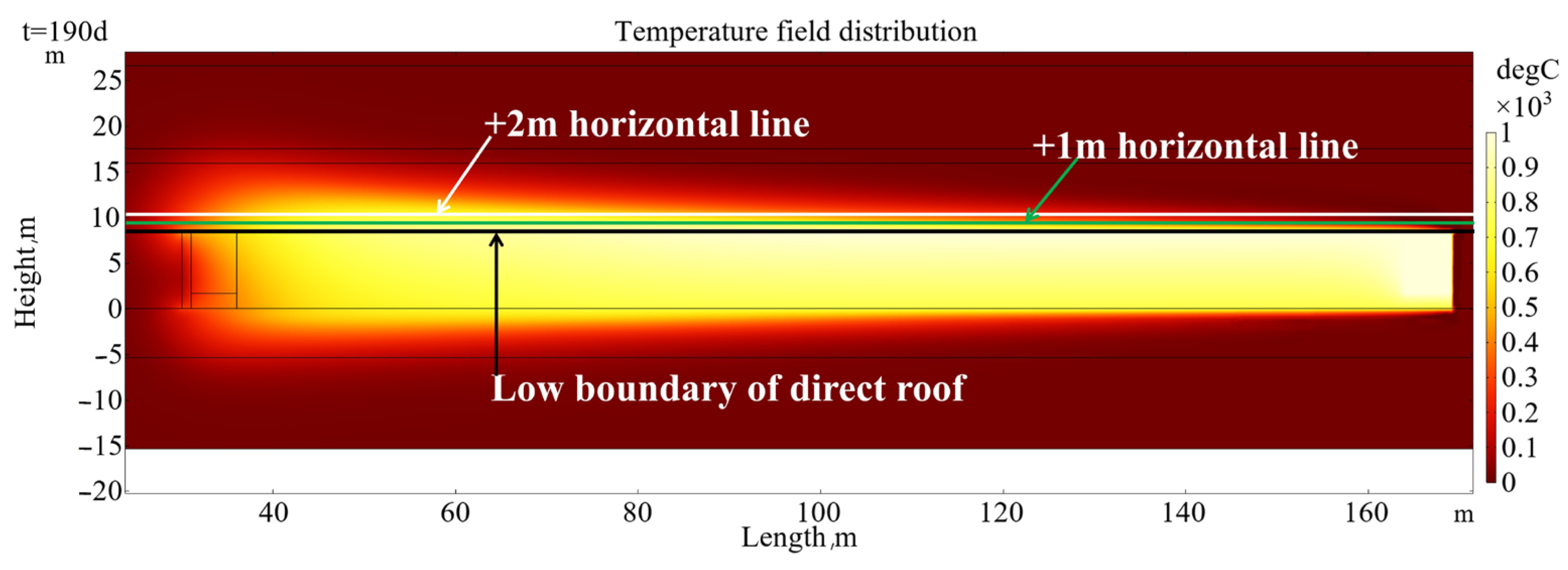

3.2.2. Temperature Distribution Law at the Lower Boundary, +1 m Position, and +2 m Position in Roof

4. Conclusions

- (1)

- The temperature distribution range curves of T = 100 °C and T = 600 °C in the front coal wall showed a nonlinear increase at first, then reached the maximum, then decreased nonlinearly, and finally gradually tended to a constant value. According to the calculation, the maximum distribution range of the isotherm of ∆T = 10 °C (T = 30 °C) in the roof is about 13.0 m, the maximum distribution range in the left coal pillar is about 9.0 m, and the maximum distribution range in the floor is about 10.1 m.

- (2)

- At the end of the operation of t = 190 d, the horizontal range of temperature exceeding 600 °C is x, the length range is 73 m, and the maximum temperature that can be reached at the +1 m position is about 825 °C. The temperature curve at the +2 m position in the roof is similar to the temperature curve at the +1 m position, which is in the shape of a parabola with a steep left and a gentle right. The height and width of the temperature curve gradually increase.

- (3)

- At the end of the operation, the horizontal range of the temperature above 600 °C is x, the length range is 31 m, and the maximum temperature that can be reached at the +2 m position is about 686 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Perkins, G. Underground coal gasification—Part I: Field demonstrations and process performance. Prog. Energy Combust. Sci. 2018, 67, 158–187. [Google Scholar] [CrossRef]

- Lozynskyi, V. Critical review of methods for intensifying the gas generation process in the reaction channel during underground coal gasification (UCG). Min. Miner. Depos. 2023, 17, 67–85. [Google Scholar] [CrossRef]

- Xin, L.; Wang, Z.; Wang, G.; Nie, W.; Zhou, G.; Cheng, W.; Xie, J. Technological aspects for underground coal gasification in steeply inclined thin coal seams at Zhongliangshan coal mine in China. Fuel 2017, 191, 486–494. [Google Scholar] [CrossRef]

- Perkins, G. Underground coal gasification—Part II: Fundamental phenomena and modeling. Prog. Energy Combust. Sci. 2018, 67, 234–274. [Google Scholar] [CrossRef]

- Khadse, A.; Qayyumi, M.; Mahajani, S.; Aghalayam, P. Underground coal gasification: A new clean coal utilization technique for India. Energy 2007, 32, 2061–2071. [Google Scholar] [CrossRef]

- Liu, H.; Guo, W.; Liu, S. Comparative techno-economic performance analysis of underground coal gasification and surface coal gasification based coal-to-hydrogen process. Energy 2022, 258, 125001. [Google Scholar] [CrossRef]

- Takyi, S.A.; Zhang, Y.; Si, M.; Zeng, F.; Li, Y.; Tontiwachwuthikul, P. Current status and technology development in implementing low carbon emission energy on underground coal gasification (UCG). Front. Energy Res. 2023, 10, 1051417. [Google Scholar] [CrossRef]

- Rnmesh, A.; Pkg, B. Kinetic modeling of Indian lignites pyrolysis in the context of underground coal gasification (UCG). Fuel 2021, 283, 118939. [Google Scholar]

- Leokadia, R. Vitrinite reflectance as a measure of the range of influence of the temperature of a georeactor on rock mass during underground coal gasification. Fuel 2018, 224, 94–100. [Google Scholar]

- Su, C.; Qiu, J.; Wu, Q.; Weng, L. Effects of high temperature on the microstructure and mechanical behavior of hard coal. Int. J. Min. Sci. Technol. 2020, 30, 643–650. [Google Scholar] [CrossRef]

- Akbarzadeh, H.; Chalaturnyk, R.J. Structural changes in coal at elevated temperature pertinent to underground coal gasification: A review. Int. J. Coal Geol. 2014, 131, 126–146. [Google Scholar] [CrossRef]

- Saik, P.; Berdnyk, M. Mathematical model and methods for solving heat-transfer problem during underground coal gasification. Min. Miner. Depos. 2022, 16, 87–94. [Google Scholar] [CrossRef]

- Daggupati, S.; Mandapati, R.N.; Mahajani, S.M.; Ganesh, A.; Mathur, D.K.; Sharma, R.K.; Aghalayam, P. Laboratory studies on combustion cavity growth in lignite coal blocks in the context of underground coal gasification. Energy 2010, 35, 2374–2386. [Google Scholar] [CrossRef]

- Luo, J.A.; He, J. Mechanical Characteristics of Sandstone under High Temperature and Cyclic Loading in Underground Coal Gasification. Minerals 2022, 12, 1313. [Google Scholar] [CrossRef]

- Li, M.; Wang, D.; Shao, Z. Experimental study on changes of pore structure and mechanical properties of sandstone after high-temperature treatment using nuclear magnetic resonance. Eng. Geol. 2020, 275, 105739. [Google Scholar] [CrossRef]

- Xin, L.; Wang, Z.; Huang, W.; Kang, G.; Lu, X.; Zhang, P.; Wang, J. Temperature field distribution of burnt surrounding rock in UCG stope. Int. J. Min. Sci. Technol. 2014, 24, 573–580. [Google Scholar] [CrossRef]

- Xin, L.; Cheng, W.M.; Xie, J.; Liu, W.T.; Xu, M. Theoretical research on heat transfer law during underground coal gasification channel extension process. Int. J. Heat Mass Transf. 2019, 142, 118409. [Google Scholar] [CrossRef]

- Xin, L. Study on the Overling Strata Movement by UCG Mining in Matigou Coal Mine. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2014. (In Chinese). [Google Scholar]

- Wang, J.; Wang, Z.; Xin, L.; Xu, Z.; Gui, J.; Lu, X. Temperature field distribution and parametric study in underground coal gasification stope. Int. J. Therm. Sci. 2017, 111, 66–77. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, Y.; Hou, T.; Jin, Y.; Wang, C.; Liang, J. Large-scale laboratory study on the evolution law of temperature fields in the context of underground coal gasification. Chin. J. Chem. Eng. 2020, 28, 3126–3135. [Google Scholar] [CrossRef]

- Su, F.-Q.; Zhang, T.; Wu, J.-B.; Deng, Q.-C.; Hamanaka, A.; Yu, Y.-H.; Dai, M.-J.; He, X.-L.; Yang, J.-N. Energy recovery evaluation and temperature field research of underground coal gasification under different oxygen concentrations. Fuel 2022, 329, 125389. [Google Scholar] [CrossRef]

- Yang, L. Three-Dimensional Unstable Non-linear Numerical Analysis of the Underground Coal Gasification with Free Channel. Energy Sources Part A Recovery Util. Environ. Eff. 2006, 28, 1519–1531. [Google Scholar] [CrossRef]

- Liu, X.; Guo, G.; Li, H. Thermo-mechanical coupling numerical simulation method under high temperature heterogeneous rock and application in underground coal gasification. Energy Explor. Exploit. 2020, 38, 1118–1139. [Google Scholar] [CrossRef]

- Liu, X.; Guo, G.; Li, H. Study on the propagation law of temperature field in surrounding rock of underground coal gasification (UCG) combustion cavity based on dynamic thermal parameters. Results Phys. 2019, 12, 1956–1963. [Google Scholar] [CrossRef]

- Tian, H. Development of a Thermo-Mechanical Model for Rocks Exposed to High Temperatures During Underground Coal Gasification. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2013. [Google Scholar]

- Jowkar, A.; Sereshki, F.; Najafi, M. A new model for evaluation of cavity shape and volume during Underground Coal Gasification process. Energy 2018, 148, 756–765. [Google Scholar] [CrossRef]

- Wan, Z. Study on Thermal-Mechanical Coupling Process of Heterogeneous Rock Mass and Channel’s Stability of Underground Coal Gasification. Ph.D. Thesis, China University of Science and Technology, Xuzhou, China, 2006. [Google Scholar]

- Lu, Y.; Wang, L.; Tang, F.; He, Y. Fracture evolution of overlying strata over combustion cavity under thermal-mechanical interaction during underground coal gasification. J. China Coal Soc. 2012, 37, 1292–1298. (In Chinese) [Google Scholar]

- Zhang, L.; Mao, X.; Liu, R.; Li, Y.; Yin, H. Meso-structure and fracture mechanism of mudstone at high temperature. Int. J. Min. Sci. Technol. 2014, 24, 433–439. [Google Scholar] [CrossRef]

| Coal Rock Category | Thermal Conductivity, W/(m•°C) | Density kg/m3 | Constant Pressure Specific Heat Capacity J/(kg•°C) |

|---|---|---|---|

| Coal seam 3 | 0.65 | 1450 | 1000 |

| Siltstone | 1.56 | 2300 | 920 |

| Medium-grained sandstone | 1.36 | 2350 | 900 |

| Fine-grained sandstone | 1.42 | 2350 | 910 |

| Ash layer | 0.178 | 963 | 900 |

| Coal gas | 0.025 | 1.15 | 10 |

| In Front of Coal Wall/m | In Roof/m | |||

|---|---|---|---|---|

| Time/d | T = 100 °C | T = 600 °C | T = 100 °C | T = 600 °C |

| 1 | 0.91 | 0.31 | 0.82 | 0.29 |

| 5 | 1.26 | 0.53 | 1.58 | 0.50 |

| 10 | 1.17 | 0.49 | 2.24 | 0.74 |

| 20 | 0.71 | 0.24 | 3.09 | 1.03 |

| 40 | 0.34 | 0.15 | 4.28 | 1.35 |

| 60 | 0.28 | 0.12 | 5.19 | 1.54 |

| 80 | 0.23 | 0.10 | 5.92 | 1.69 |

| 100 | 0.25 | 0.11 | 6.56 | 1.87 |

| 120 | 0.30 | 0.13 | 7.18 | 2.04 |

| 140 | 0.24 | 0.11 | 7.76 | 2.21 |

| 160 | 0.28 | 0.13 | 8.25 | 2.42 |

| 180 | 0.27 | 0.12 | 8.72 | 2.59 |

| 190 | 0.26 | 0.11 | 8.96 | 2.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Liu, J.; Xin, L.; Li, W.; Fan, J.; Wang, X.; Ma, Y.; Cheng, W.; Sui, J.; Niu, M. Numerical Simulation of Temperature Field Evolution and Distribution Range During Movement of Underground Coal Gasification Working Face. Energies 2025, 18, 931. https://doi.org/10.3390/en18040931

Li W, Liu J, Xin L, Li W, Fan J, Wang X, Ma Y, Cheng W, Sui J, Niu M. Numerical Simulation of Temperature Field Evolution and Distribution Range During Movement of Underground Coal Gasification Working Face. Energies. 2025; 18(4):931. https://doi.org/10.3390/en18040931

Chicago/Turabian StyleLi, Wei, Jian Liu, Lin Xin, Wei Li, Jianguo Fan, Xianmin Wang, Yan Ma, Weimin Cheng, Jiancai Sui, and Maofei Niu. 2025. "Numerical Simulation of Temperature Field Evolution and Distribution Range During Movement of Underground Coal Gasification Working Face" Energies 18, no. 4: 931. https://doi.org/10.3390/en18040931

APA StyleLi, W., Liu, J., Xin, L., Li, W., Fan, J., Wang, X., Ma, Y., Cheng, W., Sui, J., & Niu, M. (2025). Numerical Simulation of Temperature Field Evolution and Distribution Range During Movement of Underground Coal Gasification Working Face. Energies, 18(4), 931. https://doi.org/10.3390/en18040931