Formation Damage in SAGD: A Review of Experimental Modelling Techniques

Abstract

1. Introduction

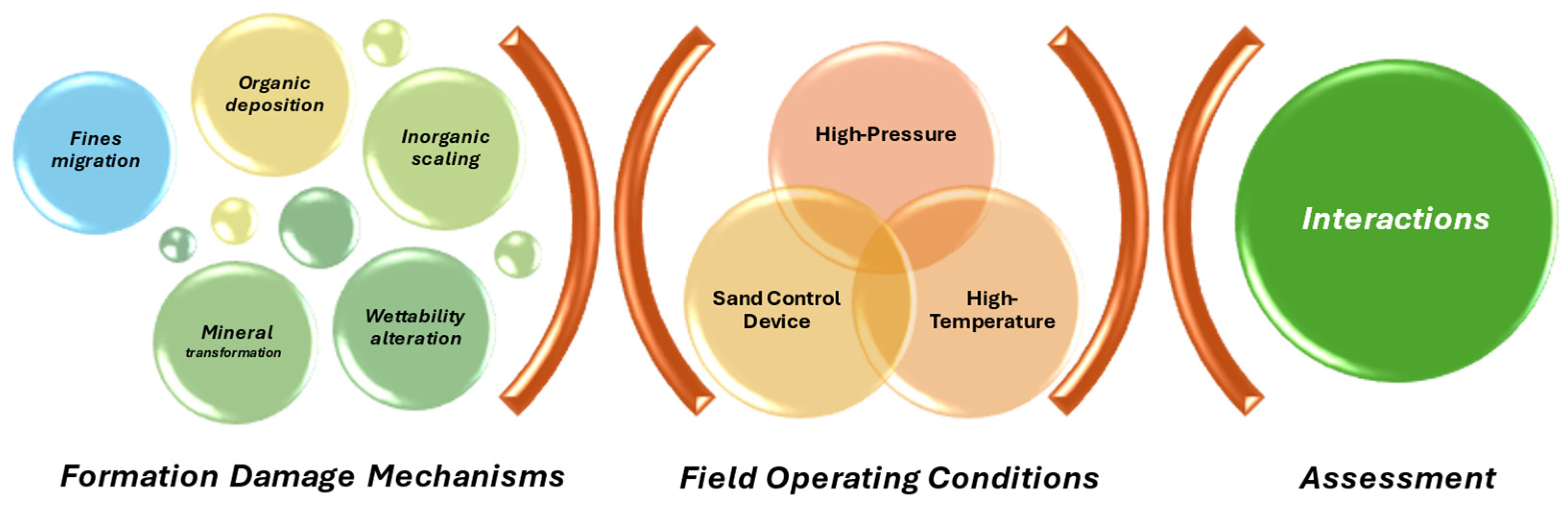

2. Formation Damage Mechanisms in SAGD

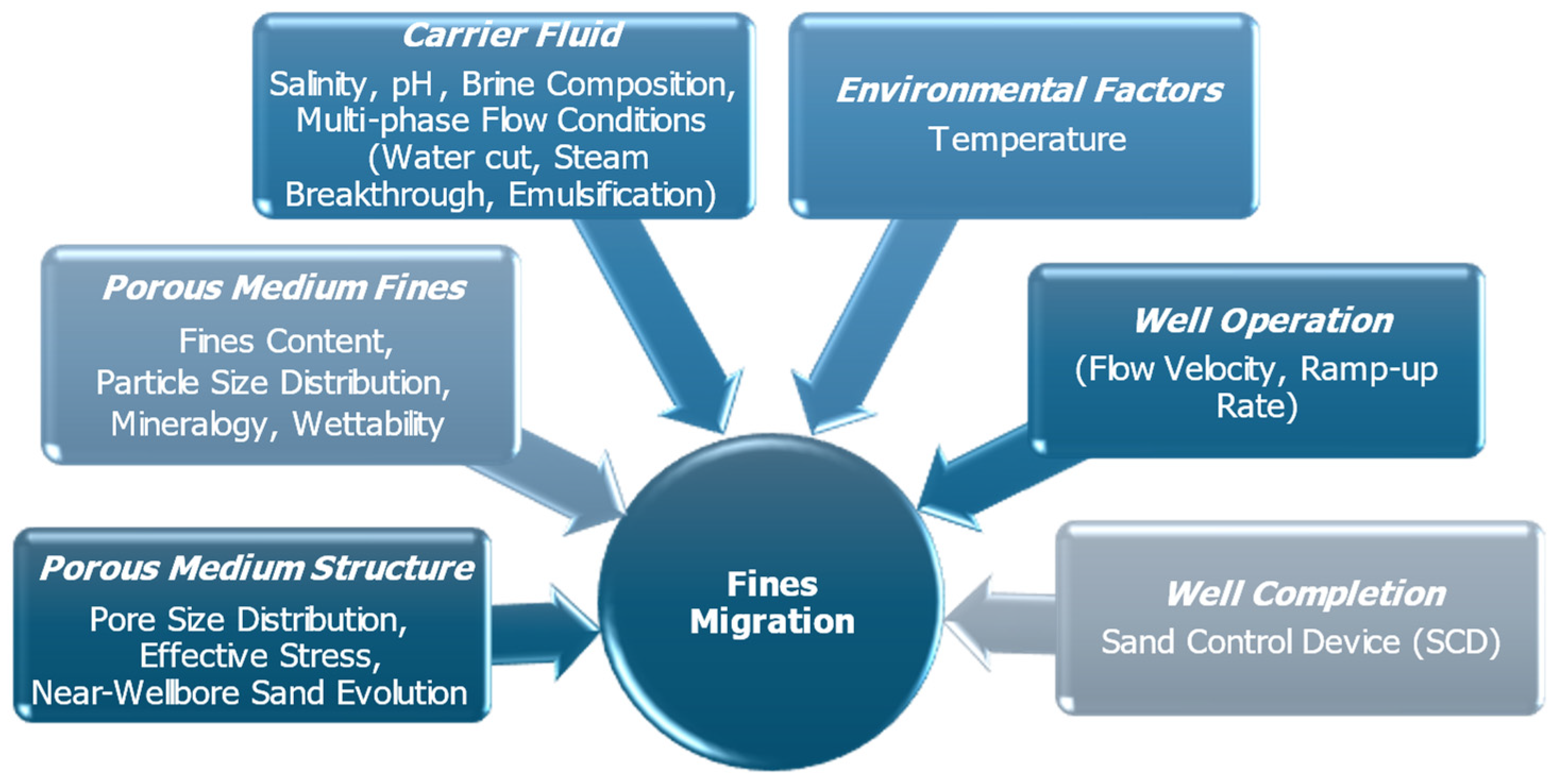

2.1. Fines Migration

2.2. Organic Deposition

2.3. Inorganic Scaling

2.4. Mineral Transformation

2.5. Wettability Alteration

3. Experimental Modelling of Formation Damage

3.1. Fines Migration

3.1.1. Fluid Characteristics

3.1.2. Fluid Flow Characteristics

3.1.3. Environmental Conditions

3.2. Organic Deposition

3.3. Inorganic Scaling

3.4. Mineral Transformation

3.5. Wettability Alteration

4. Case Studies

4.1. Case I—Lower Grand Rapids (LGR) Formation

4.2. Case II—Colony Formation (Mannville Sands)

4.3. Lessons Learned

5. Knowledge Gaps and Future Research

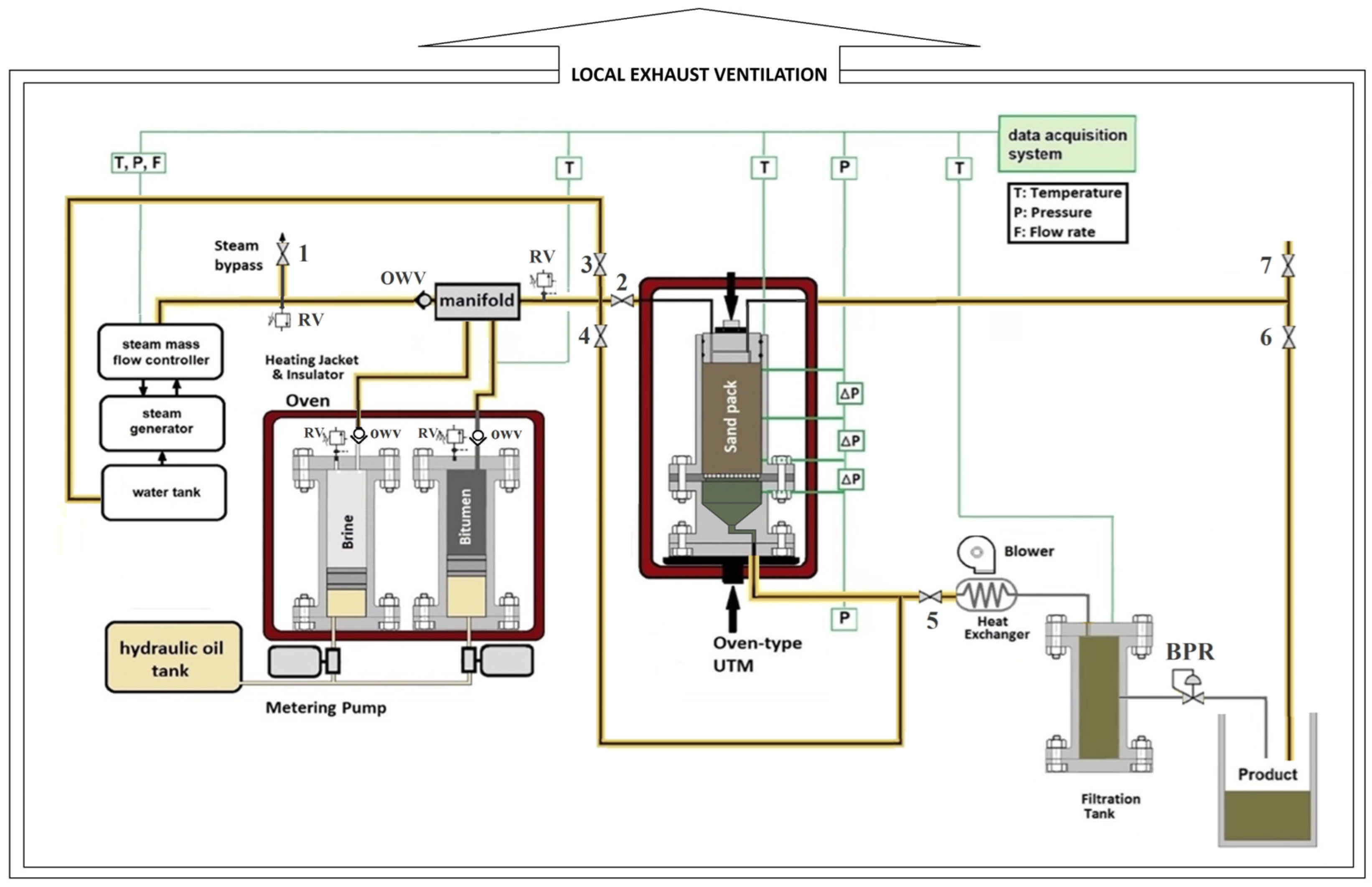

6. Proposed Testing Design for Formation Damage Assessment in Oilsands Under Field Conditions

7. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Crude Oil Forecast, Markets and Transportation; Canadian Association of Petroleum Producers-CAPP: Calgary, AB, Canada, 2022.

- Mehrotra, A.K.; Svrcek, W.Y. Viscosity of compressed Athabasca bitumen. Can. J. Chem. Eng. 1986, 64, 844–847. [Google Scholar] [CrossRef]

- Butler, R.M. Steam-assisted gravity drainage: Concept, development, performance and future. J. Can. Pet. Technol. 1994, 33, 44–50. [Google Scholar] [CrossRef]

- Butler, R. SAGD Comes Age! J. Can. Pet. Technol. 1998, 37, 9–12. [Google Scholar] [CrossRef]

- Okoye, C.U.; Onuba, N.L.; Ghalambor, A.; Hayatdavoudi, A. Characterization of Formation Damage in Heavy Oil Formation During Steam Injection. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 22–23 February 1990. [Google Scholar]

- Tague, J. Optimizing production in fields with multiple formation damage mechanisms. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 23–24 February 2000. [Google Scholar]

- Williamson, H.; Babaganov, A.; Romanova, U. Unlocking potential of the Lower Grand Rapids formation, Western Canada: The role of sand control and operational practices in SAGD performance. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 7–9 June 2016. [Google Scholar]

- Brand, S. Results from acid stimulation in Lloydminster SAGD applications. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 10–12 February 2010. [Google Scholar]

- McWhinney, R. Oil Sands Environmental Impacts, Study No. 143; Canadian Energy Research Institute: Calgary, AB, Canada, 2014. [Google Scholar]

- Bennion, D.B. An Overview of Formation Damage Mechanisms Causing a Reduction in the Productivity and Injectivity of Oil and Gas Producing Formations. J. Can. Pet. Technol. 2002, 41, 29–36. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Chen, Z. Hybrid Enhanced Oil Recovery Processes for Heavy Oil Reservoirs; Elsevier: Amsterdam, The Netherlands, 2021; pp. 47–89. [Google Scholar]

- Cheung, T.; Scheck, M. Novel scale remediation for Steam Assisted Gravity Drainage (SAGD) operations. In Proceedings of the SPE International Conference on Oilfield Chemistry, The Woodlands, TX, USA, 8–10 April 2013. [Google Scholar]

- Civan, F. Reservoir Formation Damage: Fundamentals, Modeling, Assessment, and Mitigation; Elsevier Science & Technology: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Bennion, D.B.; Gupta, S.; Gittins, S.; Hollies, D. Protocols for slotted liner design for optimum SAGD operation. J. Can. Pet. Technol. 2009, 48, 21–26. [Google Scholar] [CrossRef]

- Nghiem, L.X.; Hassam, M.S.; Nutakki, R.; George, A.E.D. Efficient modelling of asphaltene precipitation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1993. [Google Scholar]

- Ameur, Z.O.; Kudrashou, V.Y.; Nasr-El-Din, H.A.; Forsyth, J.P.; Mahoney, J.J.; Daigle, B.J. Stimulation of high-temperature steam-assisted-gravity-drainage production wells using a new chelating agent (GLDA) and subsequent geochemical modeling using PHREEQC. SPE Prod. Oper. 2019, 34, 185–200. [Google Scholar] [CrossRef]

- Boon, J.A.; Hamilton, T.; Holloway, L.; Wiwchar, B. Reaction between rock matrix and injected fluids in Cold Lake oil sand—Potential for formation damage. J. Can. Pet. Technol. 1983, 22, 55–66. [Google Scholar] [CrossRef]

- Schembre, J.M.; Tang, G.Q.; Kovscek, A.R. Wettability alteration and oil recovery by water imbibition at elevated temperatures. J. Pet. Sci. Eng. 2006, 131–148. [Google Scholar] [CrossRef]

- Amaefule, J.O.; Kersey, D.G.; Norman, D.K.; Shannon, P.M. Advances in formation damage assessment and control strategies. In Proceedings of the PETSOC Annual Technical Meeting, Calgary, AB, Canada, 12–15 June 1988. [Google Scholar]

- Bennion, D.B.; Thomas, F.B. Underbalanced drilling of horizontal wells: Does it really eliminate formation damage? In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 7–10 February 1994. [Google Scholar]

- Civan, F. Reservoir Formation Damage: Fundamentals, Modeling, Assessment, and Mitigation; Gulf Professional Publishing: Houston, TX, USA, 2023. [Google Scholar]

- Yuan, B.; Wood, D. Formation Damage During Improved Oil Recovery: Fundamentals and Applications; Gulf Professional Publishing: Houston, TX, USA, 2018. [Google Scholar]

- Kaiser, T.M.V.; Wilson, S.; Venning, L.A. Inflow analysis and optimization of slotted liners. SPE Drill. Complet. 2002, 17, 200–209. [Google Scholar] [CrossRef]

- Lin, F.C. Clay-Coating Reduction of Permeability During Oil-Sand Testing. Clays Clay Miner. 1985, 33, 76–78. [Google Scholar] [CrossRef]

- Khilar, K.C.; Fogler, H.S. The existence of a critical salt concentration for particle release. J. Colloid Interface Sci. 1984, 101, 214–224. [Google Scholar] [CrossRef]

- Ochi, J.; Vernoux, J.F. Permeability decrease in sandstone reservoirs by fluid injection: Hydrodynamic and chemical effects. J. Hydrol. 1998, 208, 237–248. [Google Scholar] [CrossRef]

- Bedrikovetsky, P.; Siqueira, F.D.; Furtado, C.A.; Souza, A.L.S. Modified particle detachment model for colloidal transport in porous media. Transp. Porous Media 2011, 86, 353–383. [Google Scholar] [CrossRef]

- You, Z.; Badalyan, A.; Yang, Y.; Bedrikovetsky, P.; Hand, M. Fines migration in geothermal reservoirs: Laboratory and mathematical modelling. Geothermics 2019, 77, 344–367. [Google Scholar] [CrossRef]

- Yuan, B.; Moghanloo, R.G.; Zheng, D. Analytical evaluation of nanoparticle application to mitigate fines migration in porous media. Soc. Pet. Eng. J. 2016, 21, 2317–2332. [Google Scholar] [CrossRef]

- Russell, T.; Chequer, L.; Borazjani, S.; You, Z.; Zeinijahromi, A.; Bedrikovetsky, P. Formation damage by fines migration: Mathematical and laboratory modeling, field cases. In Formation Damage During Improved Oil Recovery; Gulf Professional Publishing: Houston, TX, USA, 2018; pp. 69–175. [Google Scholar]

- Romanova, U.G.; Ma, T.; Piwowar, M.; Strom, R.; Stepic, J. Thermal Formation Damage and Relative Permeability of Oil Sands of the Lower Cretaceous Formations in Western Canada. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 9–11 June 2015. [Google Scholar]

- Yuan, H.; Shapiro, A.A. Induced migration of fines during waterflooding in communicating layer-cake reservoirs. J. Pet. Sci. Eng. 2011, 78, 618–626. [Google Scholar] [CrossRef]

- Mungan, N. Permeability reduction through changes in pH and salinity. J. Pet. Technol. 1965, 17, 1449–1453. [Google Scholar] [CrossRef]

- Khilar, K.C.; Fogler, H.S.; Ahluwalia, J.S. Sandstone water sensitivity: Existence of a critical rate of salinity decrease for particle capture. Chem. Eng. Sci. 1983, 38, 789–800. [Google Scholar] [CrossRef]

- Vaidya, R.N.; Fogler, H.S. Fines migration and formation damage: Influence of pH and ion exchange. SPE Prod. Eng. 1992, 7, 325–330. [Google Scholar] [CrossRef]

- Gabriel, G.A.; Inamdar, G.R. An experimental investigation of fines migration in porous media. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Francisco, CA, USA, 5–8 October 1983. [Google Scholar]

- Egbogah, E.O. An effective mechanism for fines movement control in petroleum reservoirs. In Proceedings of the PETSOC Annual Technical Meeting, Calgary, AB, Canada, 10–13 June 1984. [Google Scholar]

- Russell, T.; Pham, D.; Neishaboor, M.T.; Badalyan, A.; Behr, A.; Genolet, L.; Kowollik, P.; Zeinijahromi, A.; Bedrikovetsky, P. Effects of kaolinite in rocks on fines migration. J. Nat. Gas Sci. Eng. 2017, 45, 243–255. [Google Scholar] [CrossRef]

- Chequer, L.; Russell, T.; Behr, A.; Genolet, L.; Kowollik, P.; Badalyan, A.; Zeinijahromi, A.; Bedrikovetsky, P. Non-monotonic permeability variation during colloidal transport: Governing equations and analytical model. J. Hydrol. 2018, 557, 547–560. [Google Scholar] [CrossRef]

- Gruesbeck, C.; Collins, R.E. Entrainment and deposition of fine particles in porous media. Soc. Pet. Eng. J. 1982, 22, 847–856. [Google Scholar] [CrossRef]

- Rosenbrand, E.; Kjøller, C.; Riis, J.F.; Kets, F.; Fabricius, I.L. Different effects of temperature and salinity on permeability reduction by fines migration in Berea sandstone. Geothermics 2015, 53, 225–235. [Google Scholar] [CrossRef]

- Schembre, J.M.; Kovscek, A.R. Mechanism of Formation Damage at Elevated Temperature. J. Energy Resour. Technol. 2005, 127, 171–180. [Google Scholar] [CrossRef]

- Ramachandran, V.; Fogler, H.S. Plugging by hydrodynamic bridging during flow of stable colloidal particles within cylindrical pores. J. Fluid Mech. 1999, 385, 129–156. [Google Scholar] [CrossRef]

- Muecke, T.W. Formation fines and factors controlling their movement in porous media. J. Pet. Technol. 1979, 31, 144–150. [Google Scholar] [CrossRef]

- Al-Yaseri, A.; Al Mukainah, H.; Lebedev, M.; Barifcani, A.; Iglauer, S. Impact of fines and rock wettability on reservoir formation damage. Geophys. Prospect. 2016, 64, 860–874. [Google Scholar] [CrossRef]

- Das, S.K. Vapex: An efficient process for the recovery of heavy oil and bitumen. SPE J. 1998, 3, 232–237. [Google Scholar] [CrossRef]

- Haghighat, P.; Maini, B.B. Role of asphaltene precipitation in VAPEX process. J. Can. Pet. Technol. 2010, 49, 14–21. [Google Scholar] [CrossRef]

- Mukhametshina, A.; Hascakir, B. Bitumen extraction by expanding solvent-steam assisted gravity drainage (ES-SAGD) with asphaltene solvents and non-solvents. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2014. [Google Scholar]

- Leontaritis, K.J.; Amaefule, J.O.; Charles, R.E. A systematic approach for the prevention and treatment of formation damage caused by asphaltene deposition. SPE Prod. Facil. 1994, 9, 157–164. [Google Scholar] [CrossRef]

- Behbahani, T.J.; Ghotbi, C.; Taghikhani, V.; Shahrabadi, A. Experimental study and mathematical modeling of asphaltene deposition mechanism in core samples. Oil Gas Sci. Technol.–Rev. D’ifp Energ. Nouv. 2015, 70, 1051–1074. [Google Scholar] [CrossRef]

- Davies, D.K.; Vessell, R.K.; Fu, R.Y.; Mondragon, J.J.; Stepp, D.A.; Aguey, O.J. Nature, origin, treatment and control of well-bore scales in an active steamflood, Wilmington Field, California. April. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 21–24 April 1996. [Google Scholar]

- Erno, B.P.; Chriest, J.; Miller, K.A. Carbonate scale formation in thermally stimulated heavy-oil wells near Lloydminster, Saskatchewan. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Bakersfield, CA, USA, 7–8 February 1991. [Google Scholar]

- Romanova, U.G.; Ma, T. An Investigation of the Plugging Mechanisms in a Slotted Liner from the Steam Assisted Gravity Operations. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Noordwijk, The Netherlands, 5–7 June 2013. [Google Scholar]

- Gunter, W.D.; Zhou, Z.; Perkins, E.H. Modelling formation damage caused by kaolinite from 25 to 300 C in the oil sand reservoirs of Alberta. SPE Adv. Technol. Ser. 1994, 2, 206–213. [Google Scholar] [CrossRef]

- Buckley, J.S. Effective wettability of minerals exposed to crude oil. Curr. Opin. Colloid Interface Sci. 2001, 6, 191–196. [Google Scholar] [CrossRef]

- Anderson, W.G. Wettability literature survey-part 1: Rock/oil/brine interactions and the effects of core handling on wettability. J. Pet. Technol. 1986, 38, 1125–1144. [Google Scholar] [CrossRef]

- Escrochi, M.; Nabipour, M.; Ayatollahi, S.; Mehranbod, N. Wettability alteration at elevated temperatures: The consequenses of asphaltene precipitation. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 13–15 February 2008. [Google Scholar]

- Mullins, O.C.; Sheu, E.Y.; Hammami, A.; Marshall, A.G. Asphaltenes, Heavy Oils, and Petroleomics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Pang, Z.X.; Liu, H.Q.; Liu, X.L. Characteristics of formation damage and variations of reservoir properties during steam injection in heavy oil reservoir. Pet. Sci. Technol. 2010, 28, 477–493. [Google Scholar] [CrossRef]

- Crocker, M.E.; Marchin, L.M. Wettability and adsorption characteristics of crude-oil asphaltene and polar fractions. J. Pet. Technol. 1988, 40, 470–474. [Google Scholar] [CrossRef]

- Amin, J.S.; Nikooee, E.; Ayatollahi, S.; Alamdari, A. Investigating wettability alteration due to asphaltene precipitation: Imprints in surface multifractal characteristics. Appl. Surf. Sci. 2010, 256, 6466–6472. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, Q.; Raeini, A.Q.; Onaka, Y.; Iwama, H.; Takabayashi, K.; Blunt, M.J.; Bijeljic, B. Pore-scale imaging of asphaltene deposition with permeability reduction and wettability alteration. Fuel 2022, 316, 123202. [Google Scholar] [CrossRef]

- Kar, T.; Yeoh, J.J.; Ovalles, C.; Rogel, E.; Benson, I.; Hascakir, B. The impact of asphaltene precipitation and clay migration on wettability alteration for Steam Assisted Gravity Drainage (SAGD) and expanding Solvent-SAGD (ES-SAGD). In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 9–11 June 2015. [Google Scholar]

- Moreno, L.; Babadagli, T. Multilayer organic deposition on the rock surface with different wettabilities during solvent injection for heavy-oil recovery. Can. J. Chem. Eng. 2015, 664–677. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.B.; Bennion, D.W.; Bietz, R.F. Mechanisms of formation damage and permeability impairment associated with the drilling, completion and production of low API gravity oil reservoirs. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 19–21 June 1995. [Google Scholar]

- Xu, A.; Mu, L.; Fan, Z.; Wu, X.; Zhao, L.; Bo, B.; Xu, T. Mechanism of heavy oil recovery by cyclic superheated steam stimulation. J. Pet. Sci. Eng. 2013, 111, 197–207. [Google Scholar] [CrossRef]

- Martin, J.C. A theoretical analysis of steam stimulation. J. Pet. Technol. 1967, 19, 411–418. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.; Sheppard, D. Formation damage Due to Mineral Alteration and Wettability Changes During Hot Water and Steam Injection in Clay-Bearing Sandstone Reservoirs. In Proceedings of the SPE International Symposium on Formation Damage Control, Lafayette, LA, USA, 26–27 February 1992. [Google Scholar]

- Tchobanoglous, G.; Burton, F.L. Wastewater Engineering: Treatment, Disposal, and Reuse, 3rd ed.; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Mojelsky, T.W.; Ignasiak, T.M.; Frakman, Z.; McIntyre, D.D.; Lown, E.M.; Montgomery, D.S.; Strausz, O.P. Structural features of Alberta oil sand bitumen and heavy oil asphaltenes. Energy Fuels 1992, 6, 83–96. [Google Scholar] [CrossRef]

- Goual, L.; Firoozabadi, A. Measuring Asphaltenes and Resins, and Dipole Moment in Petroleum Fluids. AIChE J. 2002, 48, 2646–2663. [Google Scholar] [CrossRef]

- Poston, S.W.; Ysrael, S.; Hossain, A.K.M.S.; Montgomery, E.F. The effect of temperature on irreducible water saturation and relative permeability of unconsolidated sands. Soc. Pet. Eng. J. 1970, 10, 171–180. [Google Scholar] [CrossRef]

- Speight, J.G. The Chemistry and Technology of Petroleum; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Yuan, B.; Moghanloo, R.; Wang, W. Using nanofluids to control fines migration for oil recovery: Nanofluids Co-injection or nanofluids pre-flush?—A comprehensive answer. Fuel 2018, 215, 474–483. [Google Scholar] [CrossRef]

- Mousavi, S.M.R.; Jafari, S.; Schaffie, M.; Norouzi-Apourvari, S. Experimental study and modeling permeability damage in porous media due to asphaltene deposition. J. Pet. Sci. Eng. 2020, 193, 107396. [Google Scholar] [CrossRef]

- Kocabas, I. Characterization of asphaltene precipitation effect on reducing carbonate rock permeability. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 9–12 June 2003. [Google Scholar]

- Sousa, A.M.; Ribeiro, T.P.; Pereira, M.J.; Matos, H.A. On the economic impact of wax deposition on the oil and gas industry. Energy Convers. Manag. 2022, 16, 100291. [Google Scholar] [CrossRef]

- Read, P.A.; Ringen, J.K. The Use of Laboratory Tests to Evaluate Scaling Problems During Water Injection. In Proceedings of the SPE Oilfield and Geothermal Chemistry Symposium, Dallas, TX, USA, 25–27 January 1982. [Google Scholar]

- Kennedy, G.C. The hydrothermal solubility of silica. Econ. Geol. 1944, 39, 25–36. [Google Scholar] [CrossRef]

- Alvarez, J.O.; Schechter, D.S. Application of wettability alteration in the exploitation of unconventional liquid resources. Pet. Explor. Dev. 2016, 43, 832–840. [Google Scholar] [CrossRef]

- Chanpura, R.A.; Hodge, R.M.; Andrews, J.S.; Toffanin, E.P.; Moen, T.; Parlar, M. A review of screen selection for standalone applications and a new methodology. SPE Drill. Complet. 2011, 26, 84–95. [Google Scholar] [CrossRef]

- Markestad, P.; Christie, O.; Espedal, A.; Rørvik, O. Selection of screen slot width to prevent plugging and sand production. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 14–15 February 1996. [Google Scholar]

- Herzig, J.P.; Leclerc, D.M.; Goff, P.L. Flow of suspensions through porous media—Application to deep filtration. Ind. Eng. Chem. 1970, 62, 8–35. [Google Scholar] [CrossRef]

- Zhong, L.; Han, X.; Yuan, X.; Liu, Y.; Zou, J.; Wang, Q. Permeability variation and its impact on oil recovery from unconsolidated sand heavy-oil reservoirs during steamflooding process. SPE Reserv. Eval. Eng. 2021, 24, 159–173. [Google Scholar] [CrossRef]

- Schramm, L.L. Emulsions, Foams, and Suspensions: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Hiemenz, P.C.; Rajagopalan, R. Principles of Colloid and Surface Chemistry, Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Bedrikovetsky, P. Upscaling of stochastic micro model for suspension transport in porous media. Transp. Porous Media 2008, 75, 335–369. [Google Scholar] [CrossRef]

- Bradford, S.A.; Torkzaban, S.; Simunek, J. Modeling colloid transport and retention in saturated porous media under unfavorable attachment conditions. Water Resour. Res. 2011, 47. [Google Scholar] [CrossRef]

- Elimelech, M.; Gregory, J.; Jia, X. Particle Deposition and Aggregation: Measurement, Modelling and Simulation; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Khilar, K.C.; Fogler, H.S. Migrations of Fines in Porous Media; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1998; Volume 12. [Google Scholar]

- Civan, F.; Nguyen, V. Modeling particle migration and deposition in porous media by parallel pathways with exchange. In Handbook of Porous Media; CRC Press: Boca Raton, FL, USA, 2005; pp. 475–502. [Google Scholar]

- Sarkar, A.K.; Sharma, M.M. Fines migration in two-phase flow. J. Pet. Technol. 1990, 42, 646–652. [Google Scholar] [CrossRef]

- McCorriston, L.L.; Demby, R.A.; Eric, C.P. Study of reservoir damage produced in heavy oil formations due to steam injection. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 4 October 1981. [Google Scholar]

- Somerton, W.H.; Radke, C.J. Role of clays in the enhanced recovery of petroleum from some California sands. J. Pet. Technol. 1983, 35, 643–654. [Google Scholar] [CrossRef]

- Hajdo, L.E.; Clayton, C.A. Formation damage of an unconsolidated reservoir during steamflooding. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 7–10 February 1994. [Google Scholar]

- Liu, H.; Sang, S.; Xue, J.; Lan, T.; Xu, H.; Ren, B.; Cheng, Q. Experimental study on the velocity sensitivity of coal reservoir during coalbed methane drainage in southern Qinshui Basin. Energy Explor. Exploit. 2018, 1593–1608. [Google Scholar] [CrossRef]

- Wang, B.; Qin, Y.; Shen, J.; Wang, G.; Zhang, Q. Influence of stress and formation water properties on velocity sensitivity of lignite reservoir using simulation experiment. Fuel 2018, 224, 579–590. [Google Scholar] [CrossRef]

- Kwan, M.Y.; Cullen, M.P.; Jamieson, P.R.; Fortier, R.A. A laboratory study of permeability damage to cold lake tar sands cores. J. Can. Pet. Technol. 1989, 28, 56–62. [Google Scholar] [CrossRef]

- Coşkuner, G.; Maini, B. Effect of net confining pressure on formation damage in unconsolidated heavy oil reservoirs. J. Pet. Sci. Eng. 1990, 4, 105–117. [Google Scholar] [CrossRef]

- Shepherd, A.G.; Thomson, G.B.; Westacott, R.; Sorbie, K.S.; Turner, M.; Smith, P.C. Analysis of organic field deposits: New types of calcium naphthenate scale or the effect of chemical treatment? In Proceedings of the SPE International Oilfield Scale Conference and Exhibition, Aberdeen, Scotland, UK, 30 May–1 June 2006. [Google Scholar]

- Wang, S.; Civan, F. Modeling Formation Damage by Asphaltene Deposition During Primary Oil Recovery. ASME J. Energy Resour. Technol. 2005, 127, 310–317. [Google Scholar] [CrossRef]

- Kord, S.; Mohammadzadeh, O.; Miri, R.; Soulgani, B.S. Further investigation into the mechanisms of asphaltene deposition and permeability impairment in porous media using a modified analytical model. Fuel 2014, 117, 259–268. [Google Scholar] [CrossRef]

- Civan, F. Modified formulations of particle deposition and removal kinetics in saturated porous media. Transp. Porous Media 2016, 111, 381–410. [Google Scholar] [CrossRef]

- Mukhametshina, A.; Kar, T.; Hascakir, B. Asphaltene precipitation during bitumen extraction with expanding-solvent steam-assisted gravity drainage: Effects on pore-scale displacement. Soc. Pet. Eng. J. 2016, 21, 380–392. [Google Scholar] [CrossRef]

- Hamadou, R.; Khodja, M.; Kartout, M.; Jada, A. Permeability reduction by asphaltenes and resins deposition in porous media. Fuel 2008, 87, 2178–2185. [Google Scholar] [CrossRef]

- Thornton, S.D.; Lorenz, P.B. Role of silicate and aluminate ions in the reaction of sodium hydroxide with reservoir minerals. In Proceedings of the SPE International Symposium on Oilfield Chemistry, San Antonio, TX, USA, 4–6 February 1987. [Google Scholar]

- Thimm, H.F. Understanding the generation of dissolved silica in thermal projects: Theoretical Progress. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 13–15 June 2006. [Google Scholar]

- Tian, J.; Yan, W.; Qi, Z.; Huang, S.; Yuan, Y.; Dong, M. Cyclic Supercritical Multi-Thermal Fluid Stimulation Process: A Novel Improved-Oil-Recovery Technique for Offshore Heavy Oil Reservoir. Energies 2022, 15, 9189. [Google Scholar] [CrossRef]

- Reed, M.G. Gravel pack and formation sandstone dissolution during steam injection. J. Pet. Technol. 1980, 32, 941–949. [Google Scholar] [CrossRef]

- Krauskopf, K.B.; Bird, D.K. Introduction to Geochemistry; McGraw-Hill: New York, NY, USA, 1995; Volume 647. [Google Scholar]

- Pang, Z.; Liu, H. The study on permeability reduction during steam injection in unconsolidated porous media. J. Pet. Sci. Eng. 2013, 106, 77–84. [Google Scholar] [CrossRef]

- Okoye, C.U.; Onuba, N.L.; Ghalambor, A.; Hayatdavoudi, A. An Experimental Investigation of Formation Damage in Heavy Oil Reservoir During Steam Injection. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–27 February 1992. [Google Scholar]

- Okoye, C.U.; Onuba, N.L.; Ghalambor, A.; Hayatdavoudi, A. Formation damage in heavy-oil formation during steamflooding. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Lafayette, LA, USA, 4–7 November 1991. [Google Scholar]

- Rocha, J.; Klinowski, J. 29Si and 27Al magic-angle-spinning NMR studies of the thermal transformation of kaolinite. Phys. Chem. Miner. 1990, 17, 179–186. [Google Scholar] [CrossRef]

- Zhuang, Y.; Liu, X.; Xiong, H.; Liang, L. Microscopic mechanism of clay minerals on reservoir damage during steam injection in unconsolidated sandstone. Energy Fuels 2018, 32, 4671–4681. [Google Scholar] [CrossRef]

- Kudrashou, V.Y.; Nasr-El-Din, H.A. Formation damage associated with mineral alteration and formation of swelling clays caused by steam injection in sandpacks. SPE Reserv. Eval. Eng. 2020, 23, 326–344. [Google Scholar] [CrossRef]

- Levinson, A.A.; Vian, R.W. The hydrothermal synthesis of montmorillonite group minerals from kaolinite, quartz and various carbonates. Am. Mineral. J. Earth Planet. Mater. 1966, 51 Pt 1, 495–498. [Google Scholar]

- Bayliss, P.; Levinson, A.A. Low temperature hydrothermal synthesis from dolomite or calcite, quartz and kaolinite. Clays Clay Miner. 1971, 19, 109–114. [Google Scholar] [CrossRef]

- Bayliss, P.; Levinson, A.A. Mineralogical review of the Alberta oil sand deposits (Lower Cretaceous, Mannville Group). Bull. Can. Pet. Geol. 1976, 24, 211–224. [Google Scholar]

- Day, J.J.; McGlothlin, B.B.; Huitt, J.L. Laboratory study of rock softening and means of prevention during steam or hot water injection. J. Pet. Technol. 1967, 19, 703–711. [Google Scholar] [CrossRef]

- Boon, J.A. Fluid-rock interactions during steam injection. In The oil sands of Canada-Venezuela; Canadian Institute of Mining Metal: Montreal, QC, Canada, 1977; Volume 17, pp. 133–138. [Google Scholar]

- Hebner, B.A.; Bird, G.W.; Longstaffe, F.J. Fluid/pore-mineral transformations during simulated steam injection: Implications for reduced permeability damage. J. Can. Pet. Technol. 1986, 25, 68–73. [Google Scholar] [CrossRef]

- Haagh, M.E.J.; Sîretanu, I.; Duits, M.H.G.; Mugele, F. Salinity-dependent contact angle alteration in oil/brine/silicate systems: The critical role of divalent cations. Langmuir 2017, 33, 3349–3357. [Google Scholar] [CrossRef]

- Kaito, Y.; Kiriakehata, S.; Nakagawa, K.; Nakashima, H.; Izumi, T.; Yamada, T. Determination of Asphaltene Precipitation Amount under the Condition of the Solvent Assisted SAGD Process by the Application of PVT Apparatus. In Proceedings of the SPE Canada Heavy Oil Conference (Virtual), Calgary, AB, Canada, 18–19 March 2020. [Google Scholar]

- Miri, R.; Haftani, M.; Nouri, A. A review of fines migration around Steam Assisted Gravity Drainage wellbores. J. Pet. Sci. Eng. 2021, 205, 108868. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rengifo Barbosa, F.; Miri, R.; Nouri, A. Formation Damage in SAGD: A Review of Experimental Modelling Techniques. Energies 2025, 18, 871. https://doi.org/10.3390/en18040871

Rengifo Barbosa F, Miri R, Nouri A. Formation Damage in SAGD: A Review of Experimental Modelling Techniques. Energies. 2025; 18(4):871. https://doi.org/10.3390/en18040871

Chicago/Turabian StyleRengifo Barbosa, Fernando, Rahman Miri, and Alireza Nouri. 2025. "Formation Damage in SAGD: A Review of Experimental Modelling Techniques" Energies 18, no. 4: 871. https://doi.org/10.3390/en18040871

APA StyleRengifo Barbosa, F., Miri, R., & Nouri, A. (2025). Formation Damage in SAGD: A Review of Experimental Modelling Techniques. Energies, 18(4), 871. https://doi.org/10.3390/en18040871