Study on the Cutter–Granite Interaction Mechanism in High-Temperature Geothermal Wells

Abstract

1. Introduction

2. Experimental Study on Unit Rock Breaking Mechanism

2.1. Experimental Purpose

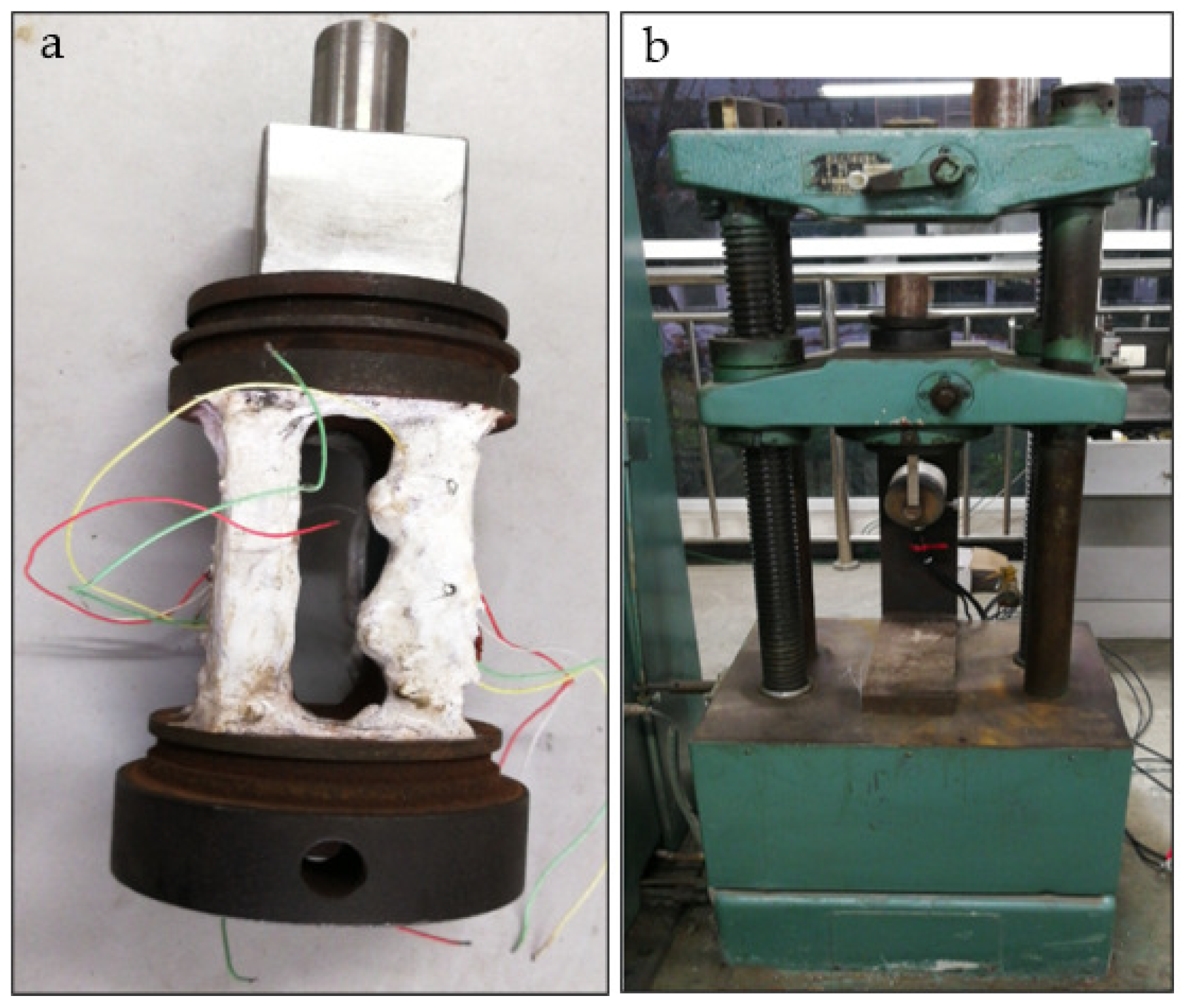

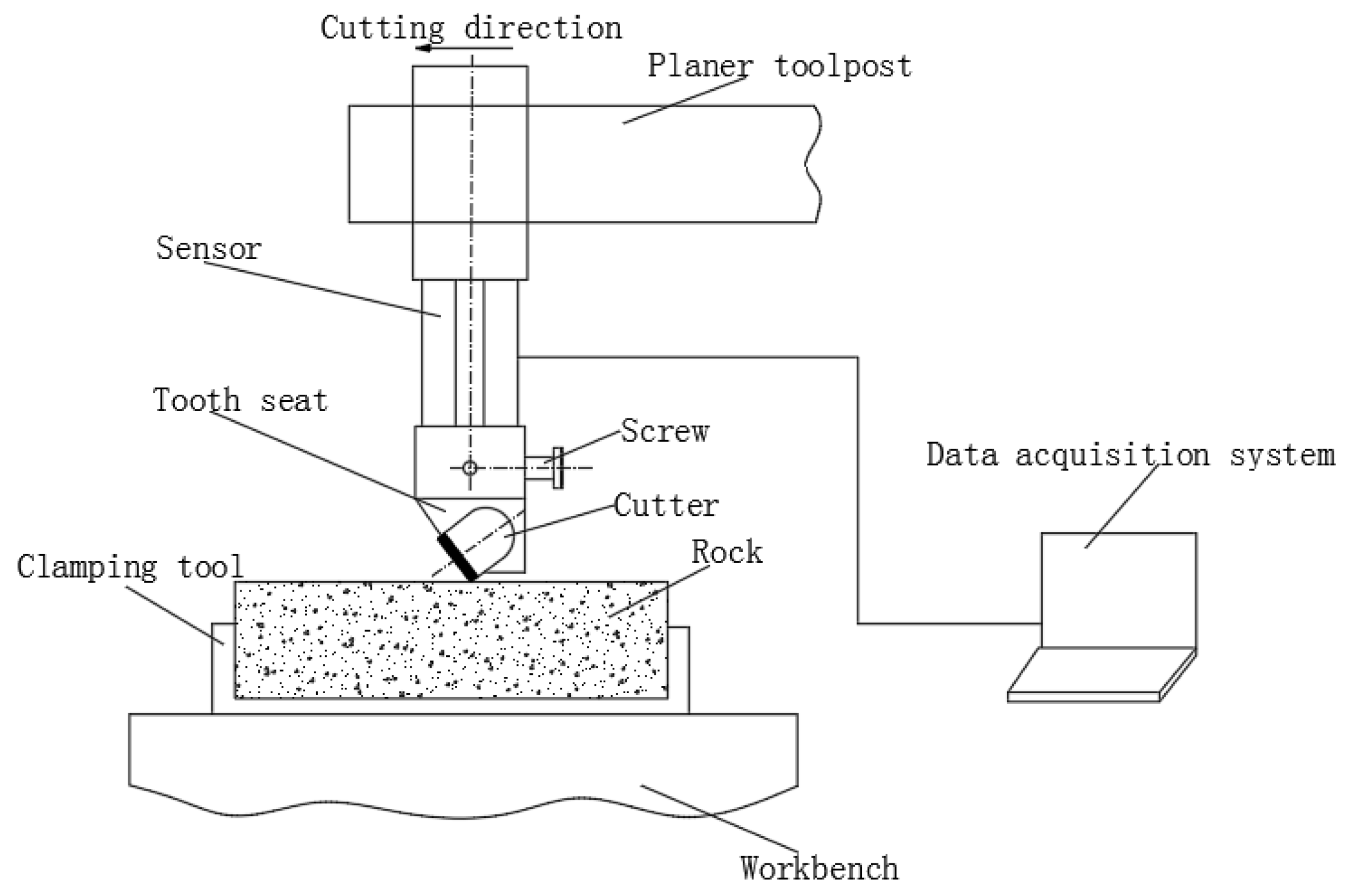

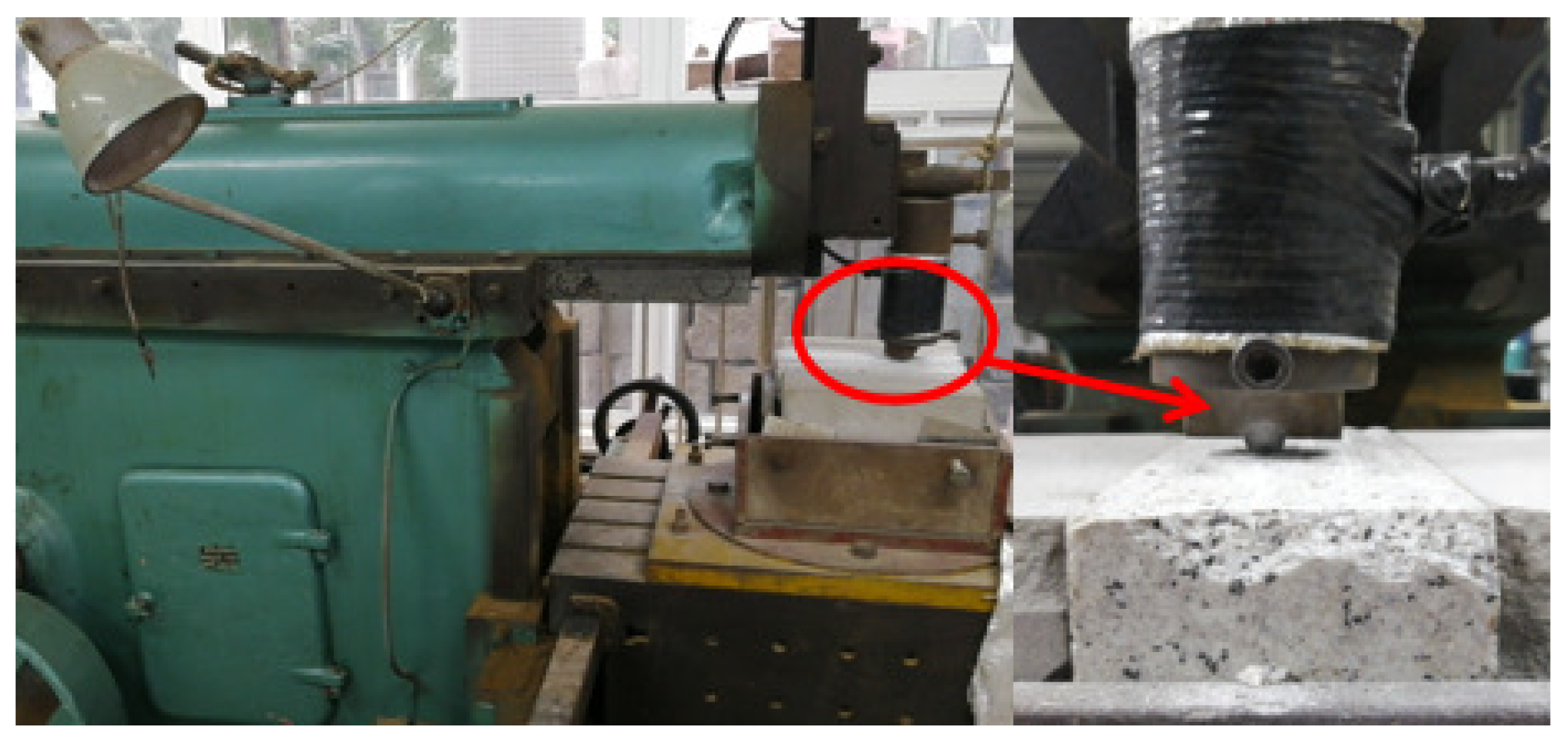

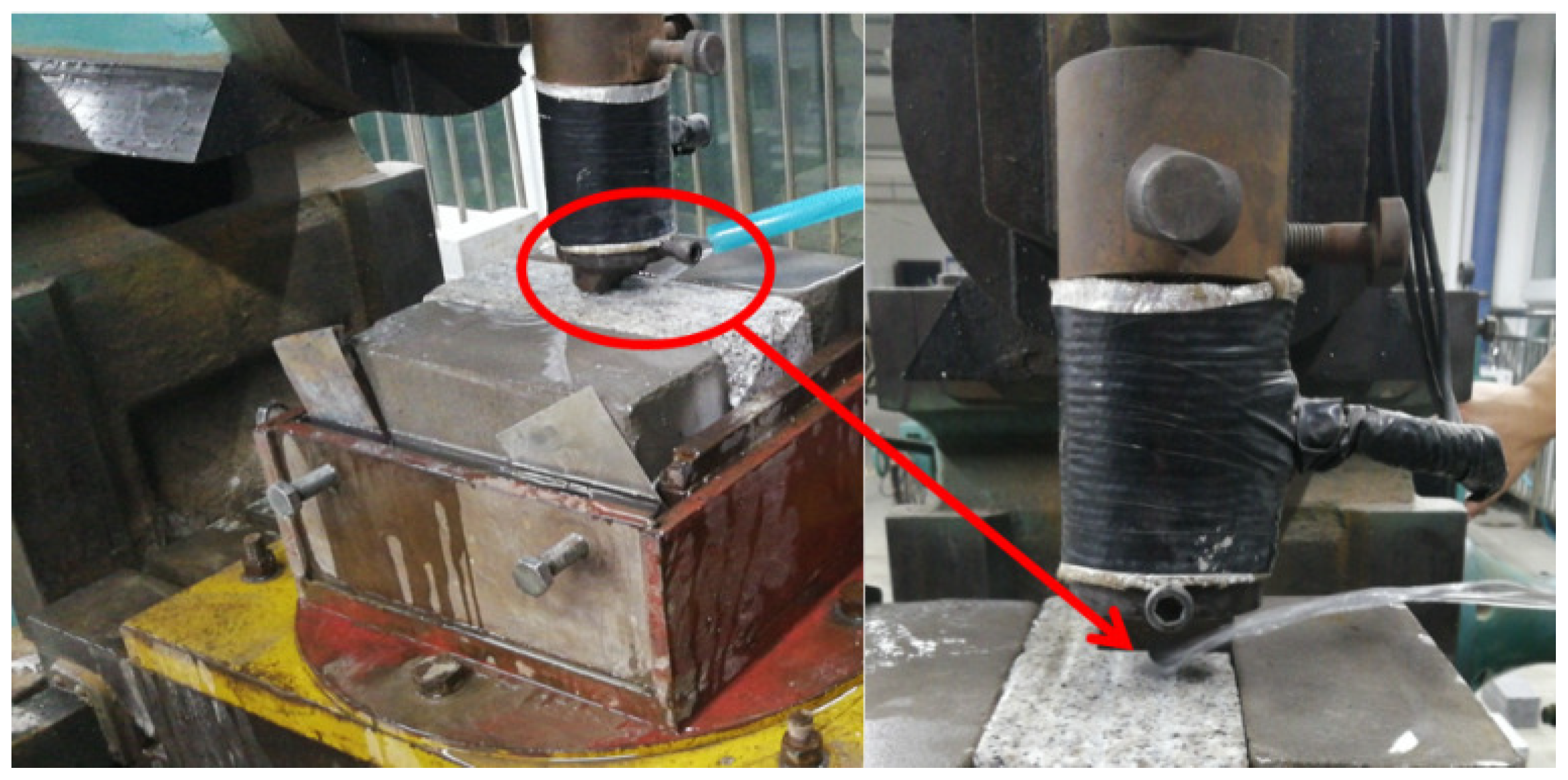

2.2. Experimental Principle and Method

- (1)

- Heat rock samples of different rock types in a high-temperature heating furnace at temperatures of 100 °C, 200 °C, 300 °C, 400 °C, and 500 °C, respectively. When taking them out, wrap them with insulating materials for heat retention.

- (2)

- Place the heated rock on the testing machine, measure its temperature with a thermometer before scraping, and then conduct the scraping experiment;

- (3)

- Place the heated rock on the testing machine, cool it immediately with water, and then conduct the scraping experiment;

- (4)

- Cool the heated rock and place it on the testing machine for scraping and cutting experiments;

- (5)

- Conduct scraping experiments on rocks using cutters with different rake angles.

2.3. Experimental Results

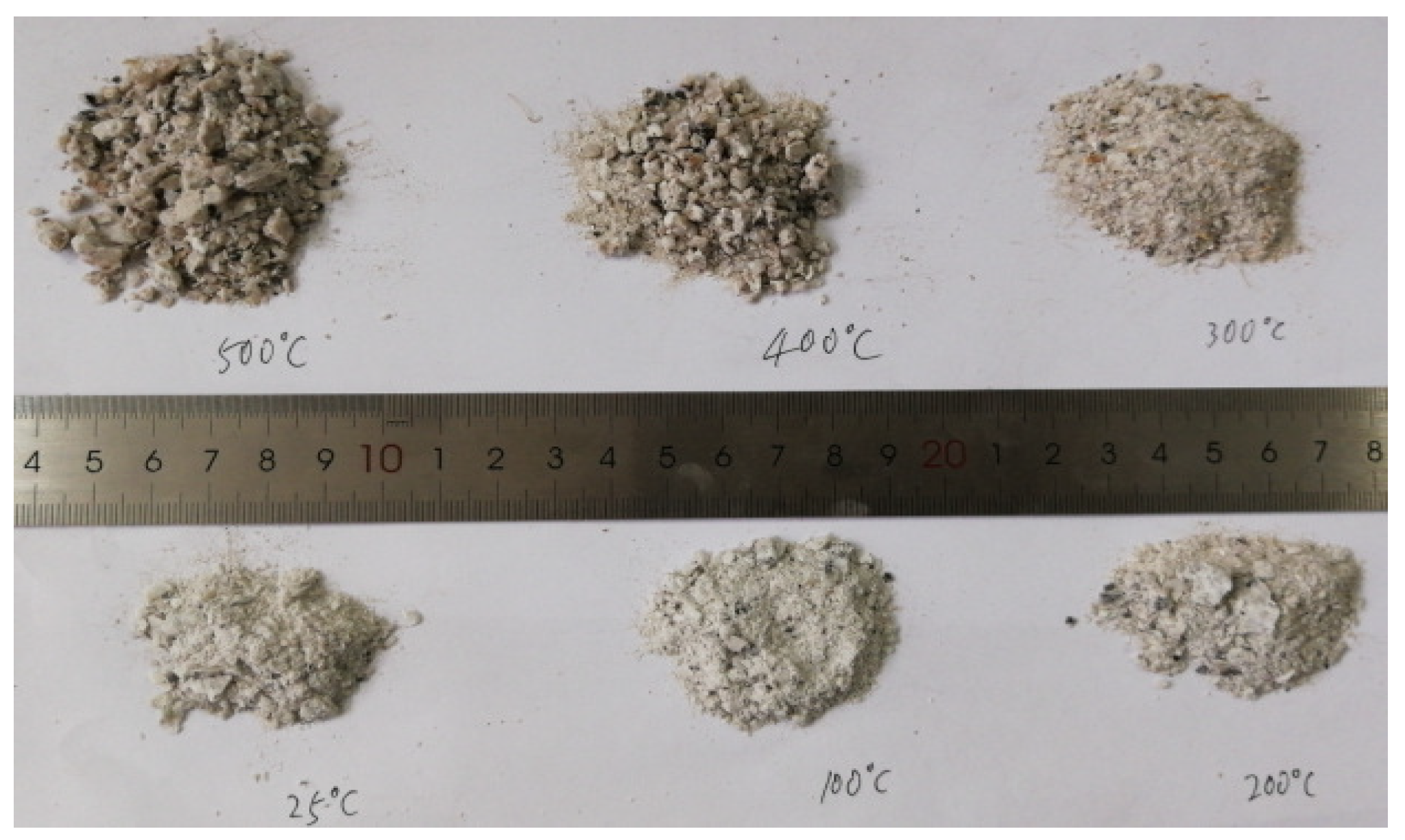

2.3.1. Single Cutter Scraping Results

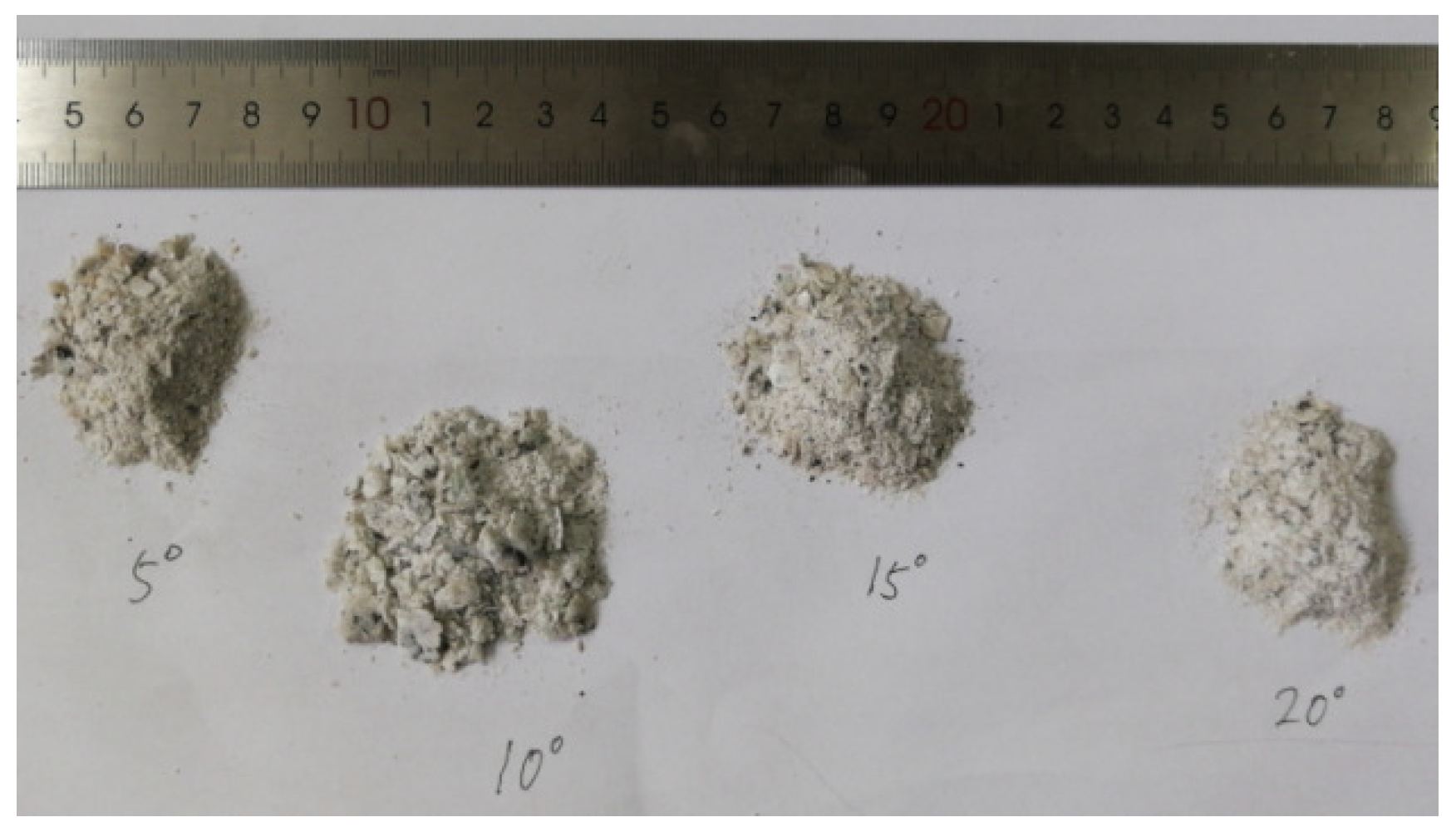

2.3.2. Single Cutter Scraping Results with Different Rake Angles

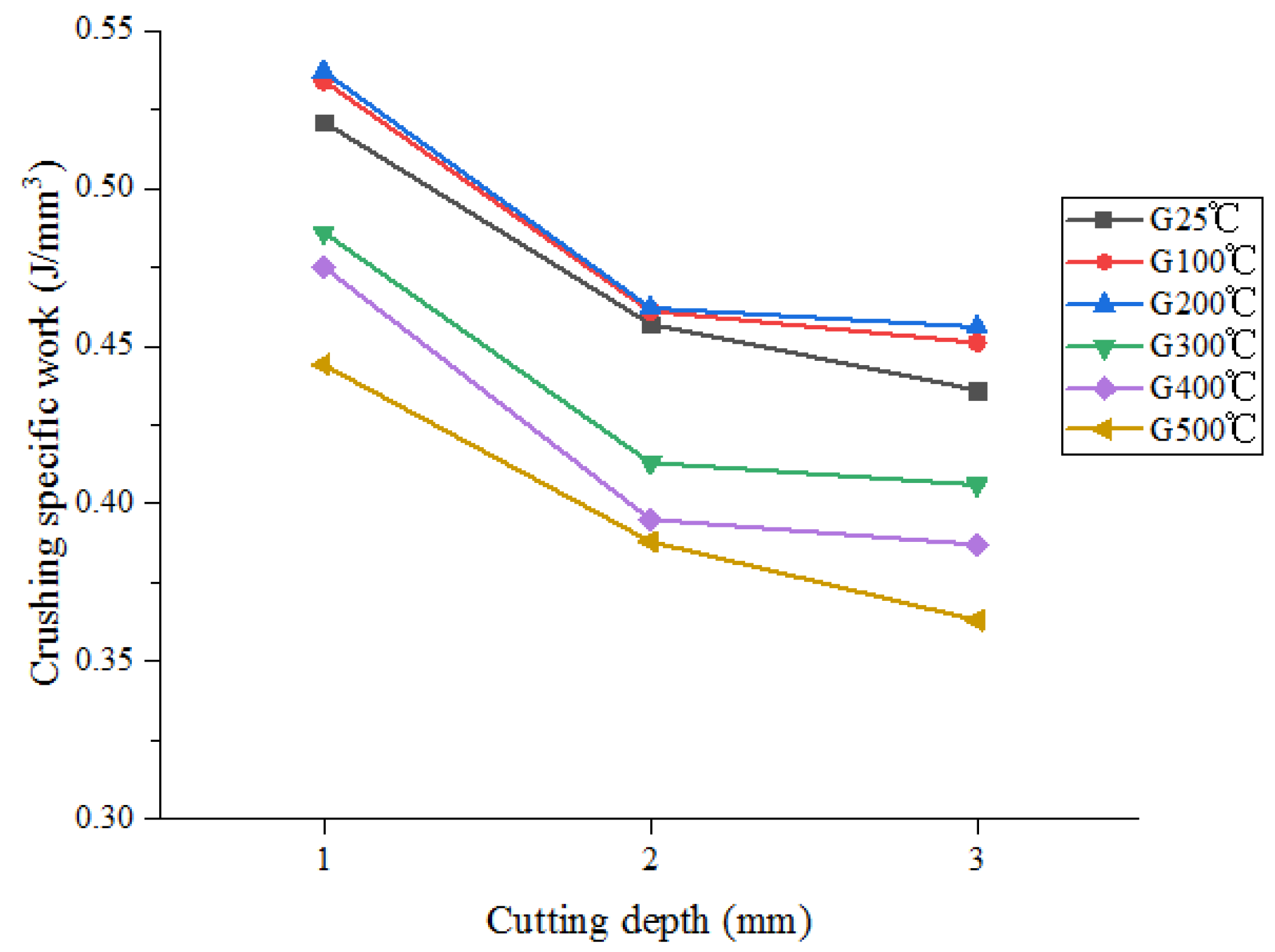

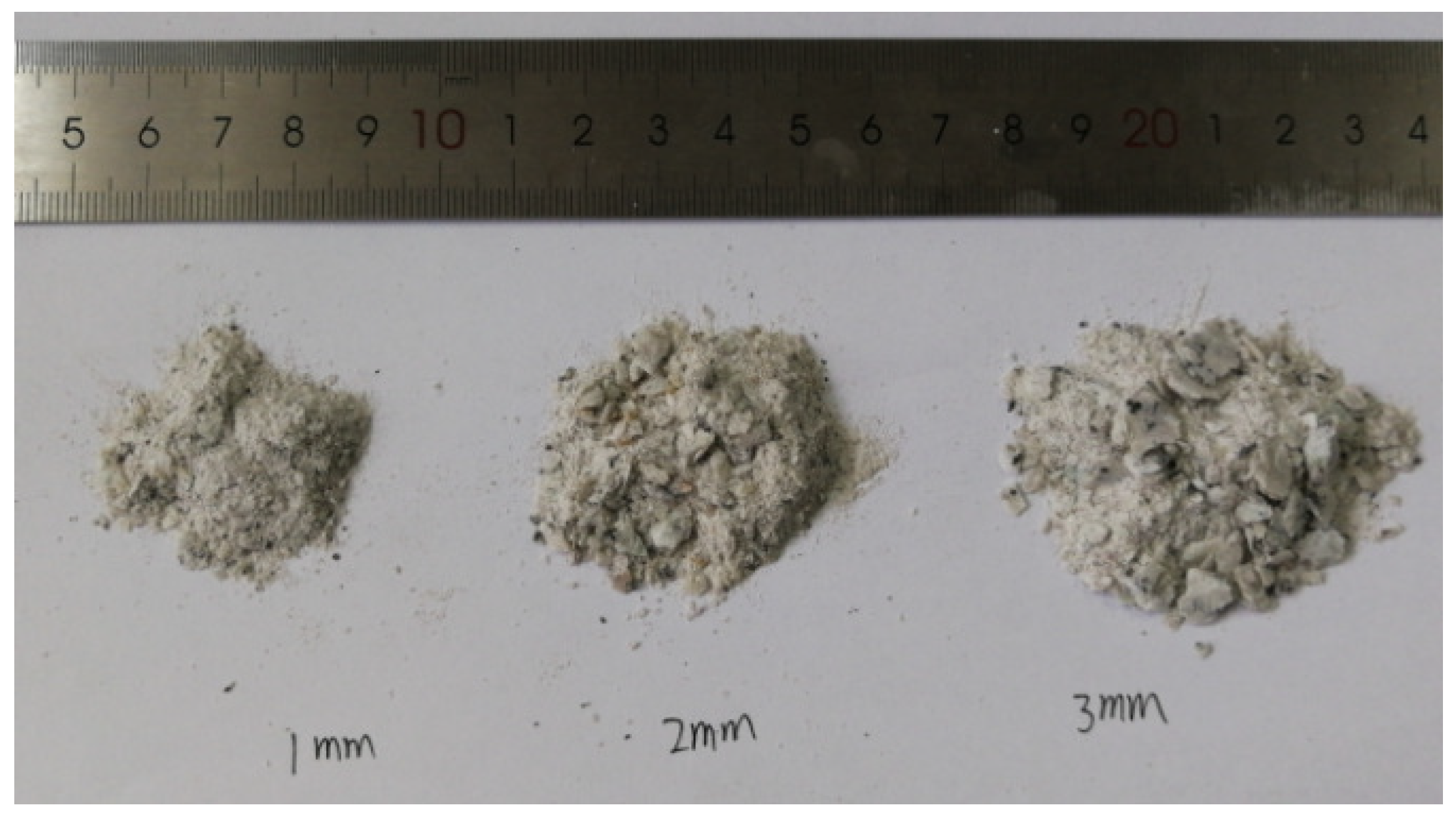

2.3.3. The Single Cutter Scraping Results with Different Cutting Depth

3. Numerical Simulation

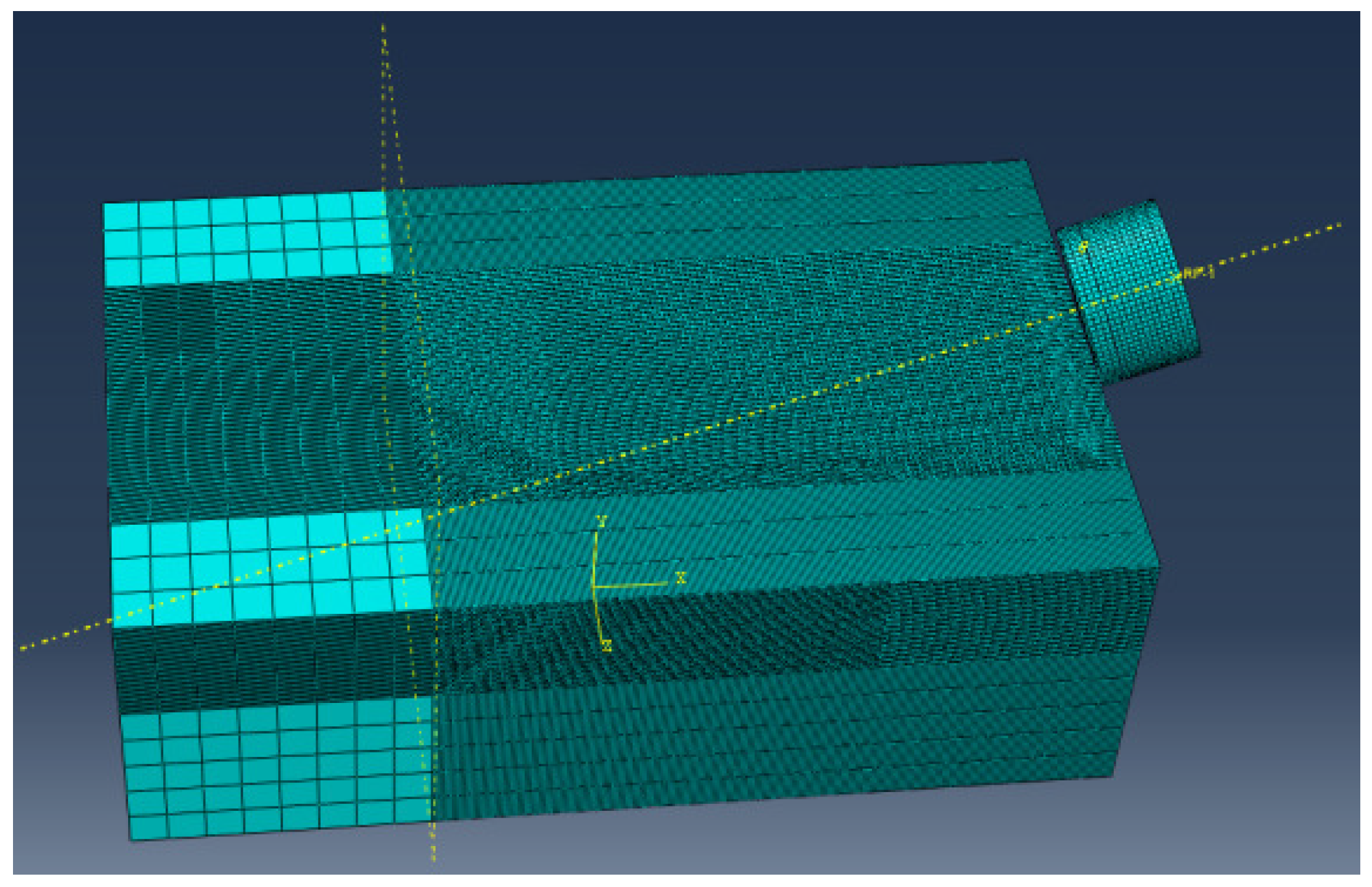

3.1. Finite Element Model

- (1)

- The rock is a homogeneous and continuous isotropic medium;

- (2)

- When the rock fails, it is immediately removed from the rock mass, ignoring its impact on subsequent drilling;

- (3)

- The hardness and strength of the cutter are higher than those of the rocks and there is no wear during the scraping process;

- (4)

- The main mode of heat transfer between the teeth and rocks is through thermal conduction, ignoring the effects of convective heat transfer and thermal radiation.

3.2. Simulation Results

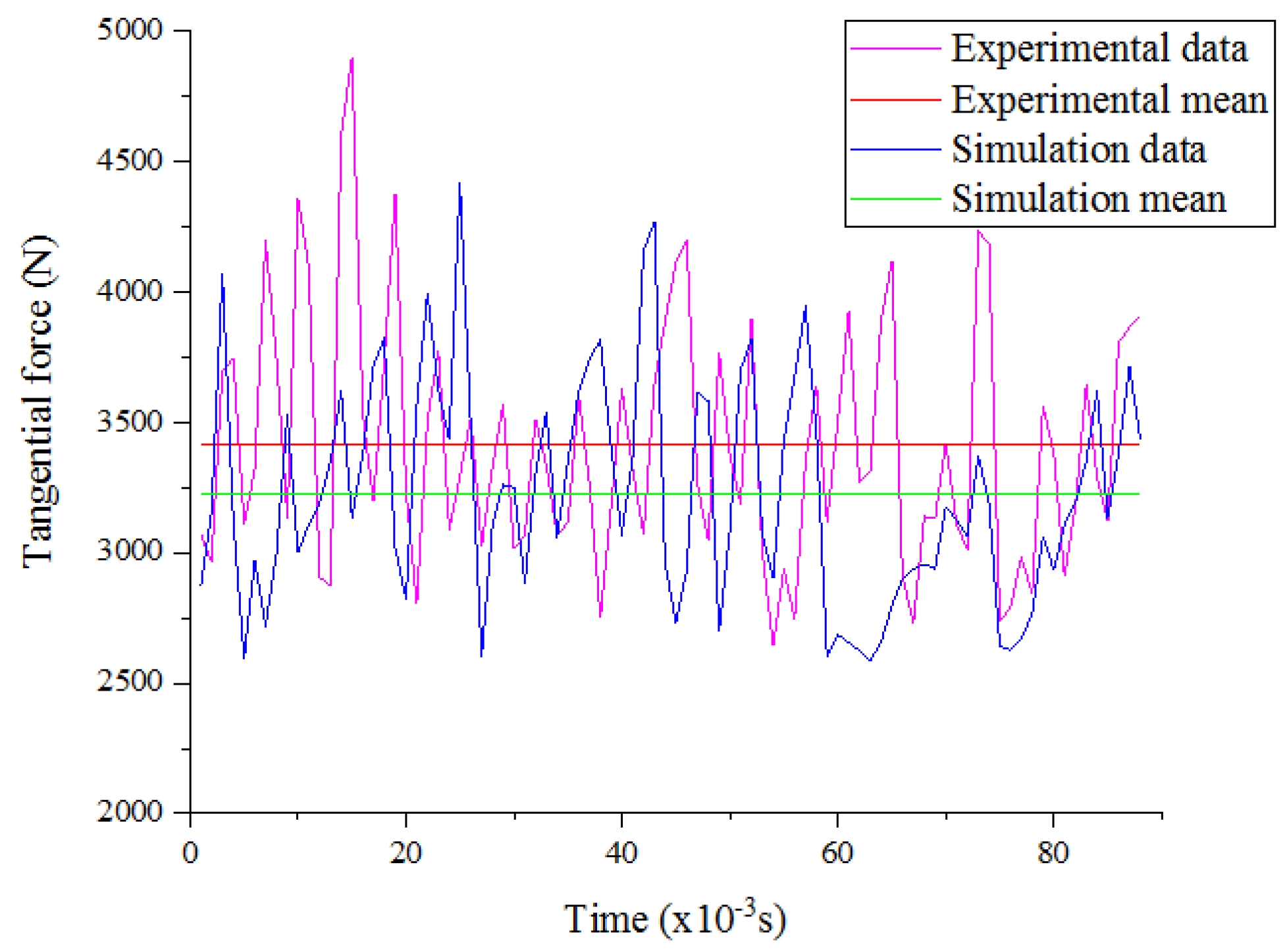

3.2.1. Model Validation

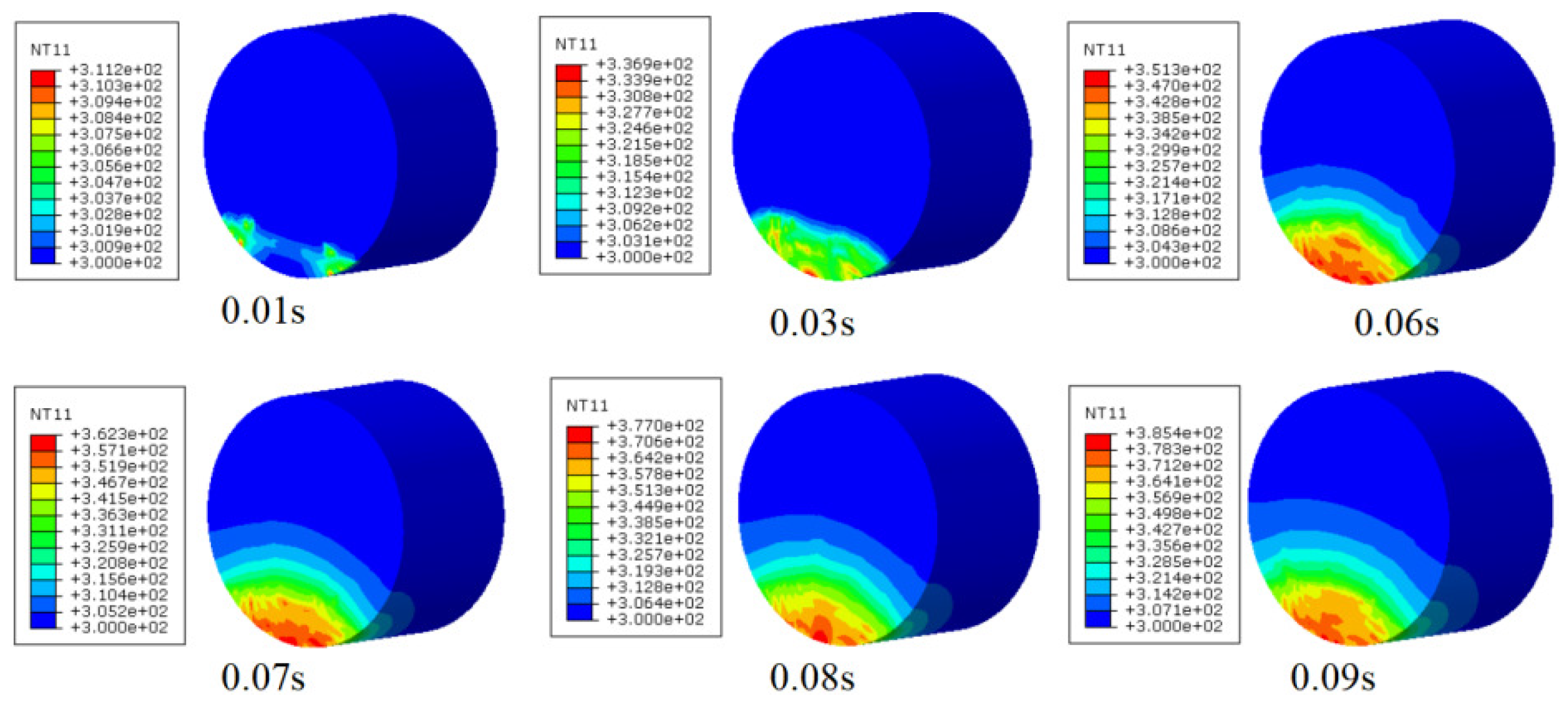

3.2.2. Study on Cutter Temperature Field

- (1)

- The cutter generates a large amount of debris and cutting heat when cutting the rock, causing the debris with a large amount of cutting heat to act on the cutter surface near the tooth edge;

- (2)

- The cutter surface temperature is a continuous accumulation process, with plastic deformation and friction heat generated near the cutter edge, resulting in the highest temperature near the cutter edge;

- (3)

- During the cutting process, the rock is squeezed and deformed and a large amount of heat generated by the deformation is transferred to the cutter, increasing the cutter surface temperature.

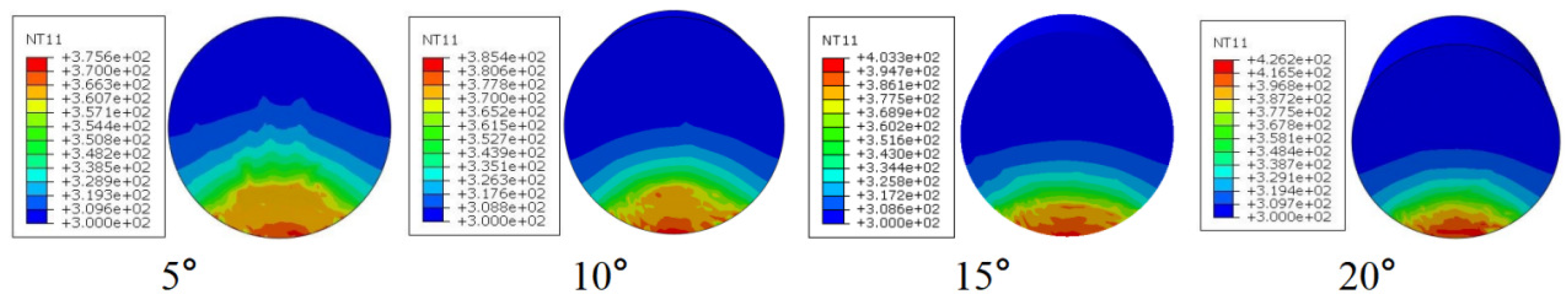

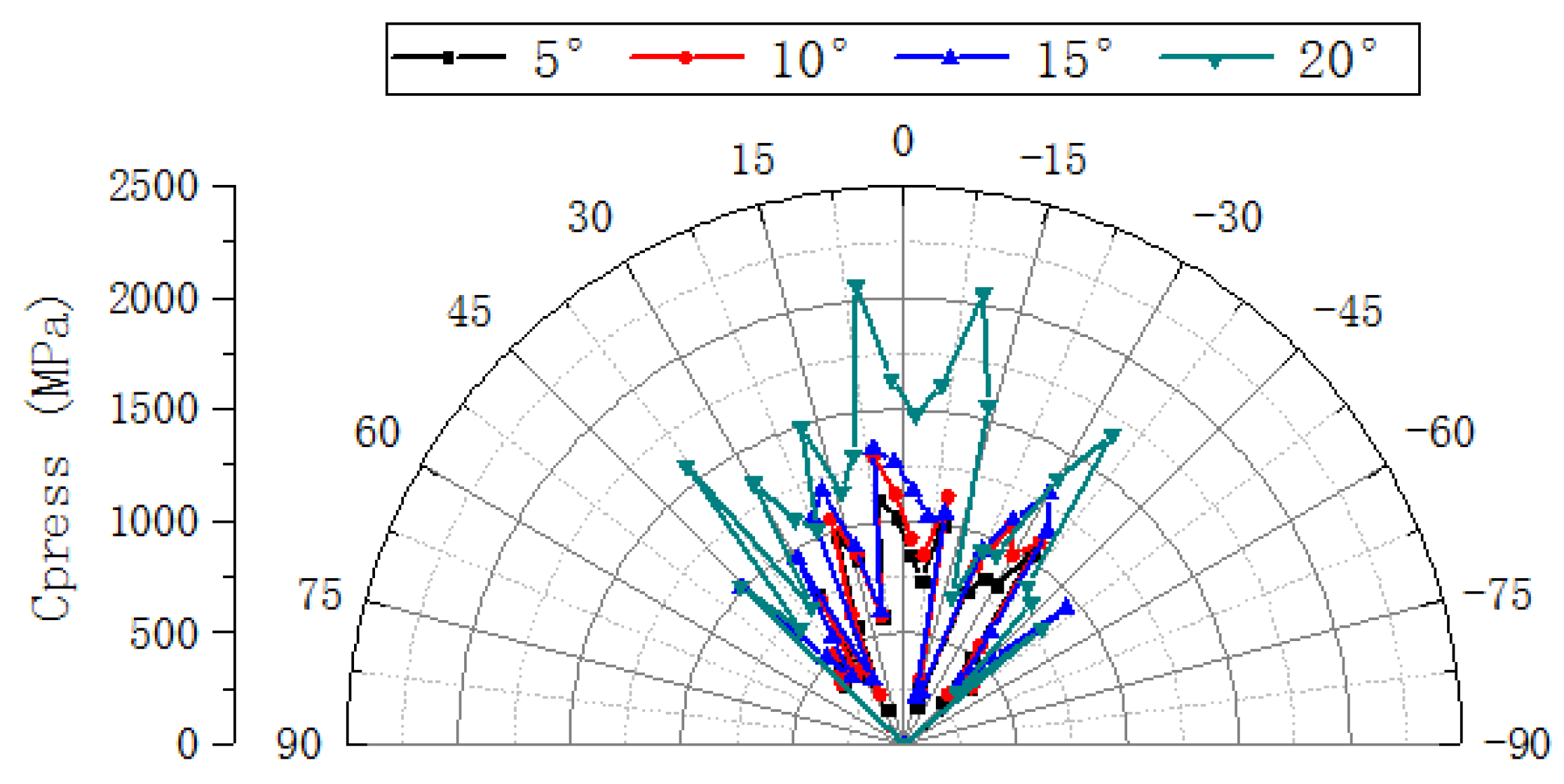

3.2.3. Study on Stress and Temperature Field of Cutter Under Different Cutting Parameters

- (1)

- The cutter stress and temperature field distribution under different rake angles

- (2)

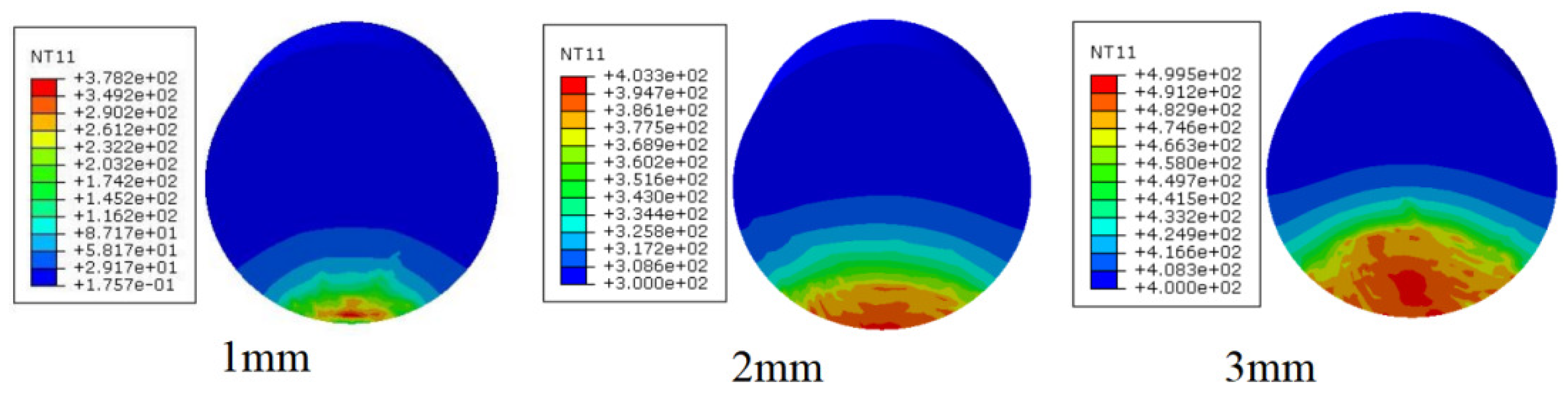

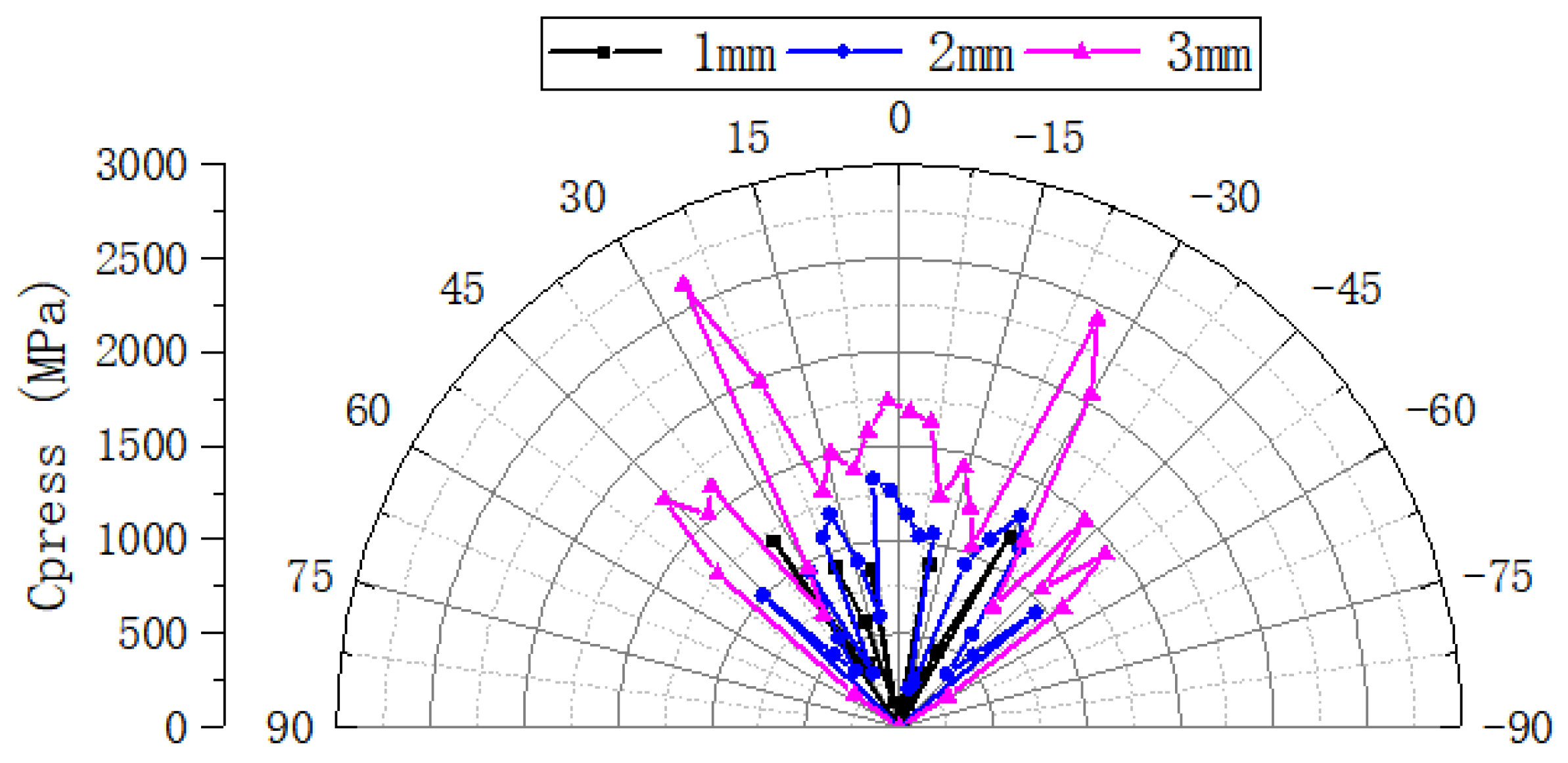

- The cutter stress and temperature field distribution under different cutting depth

4. Conclusions

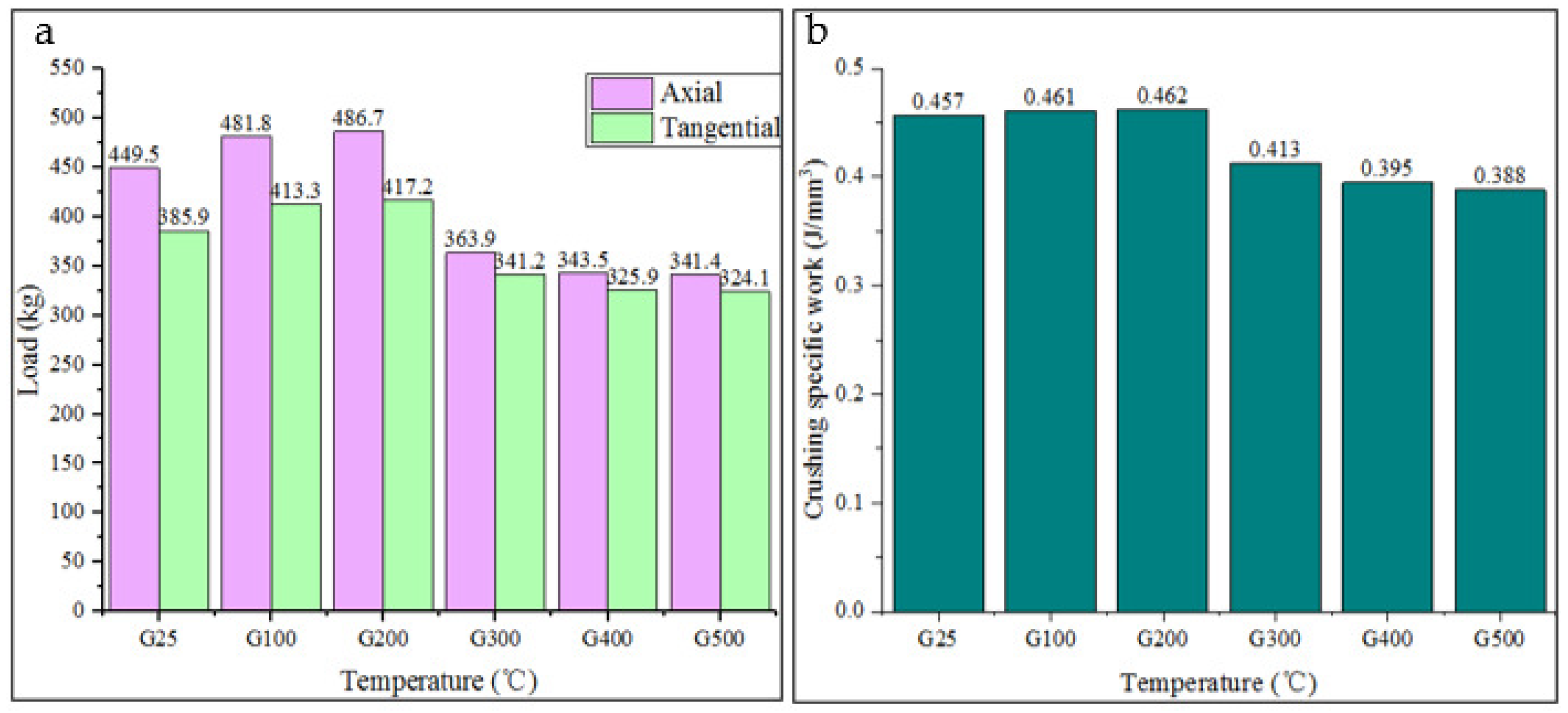

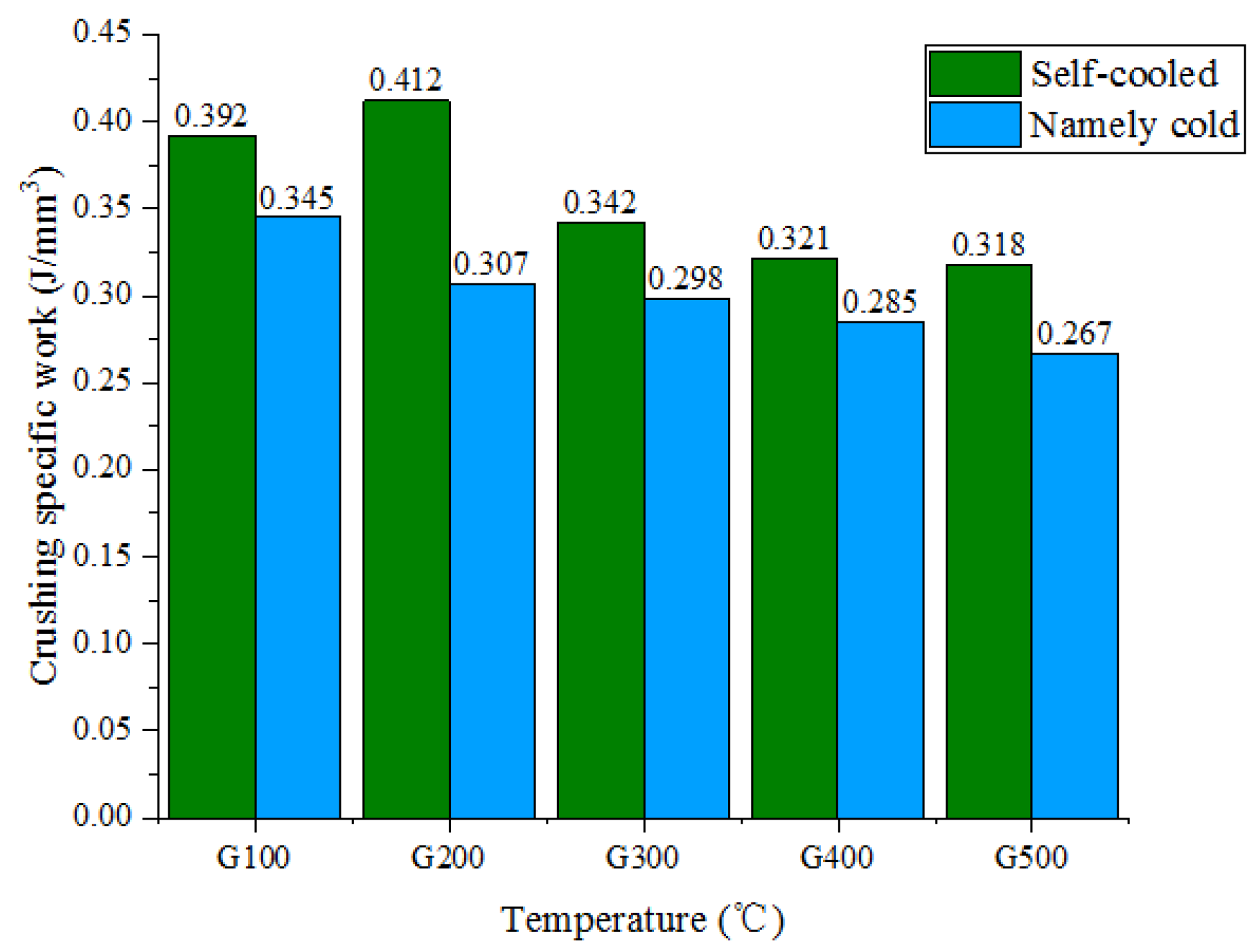

- (1)

- After exceeding a temperature of 300 °C, the specific energy consumption of rock fragmentation decreased by about 15% compared to room temperature, the axial force decreased by about 19–24%, and the tangential force decreased by about 11–16%. The specific energy consumption of rock fragmentation using the instant cooling method is about 12–25% lower than that of the self-cooling method and the rock fragmentation efficiency of the instant cooling method is higher than that of the self-cooling method. By designing water holes to reduce the cooling efficiency of rocks under immediate cooling, the strength of rocks can be reduced, further improving rock breaking efficiency.

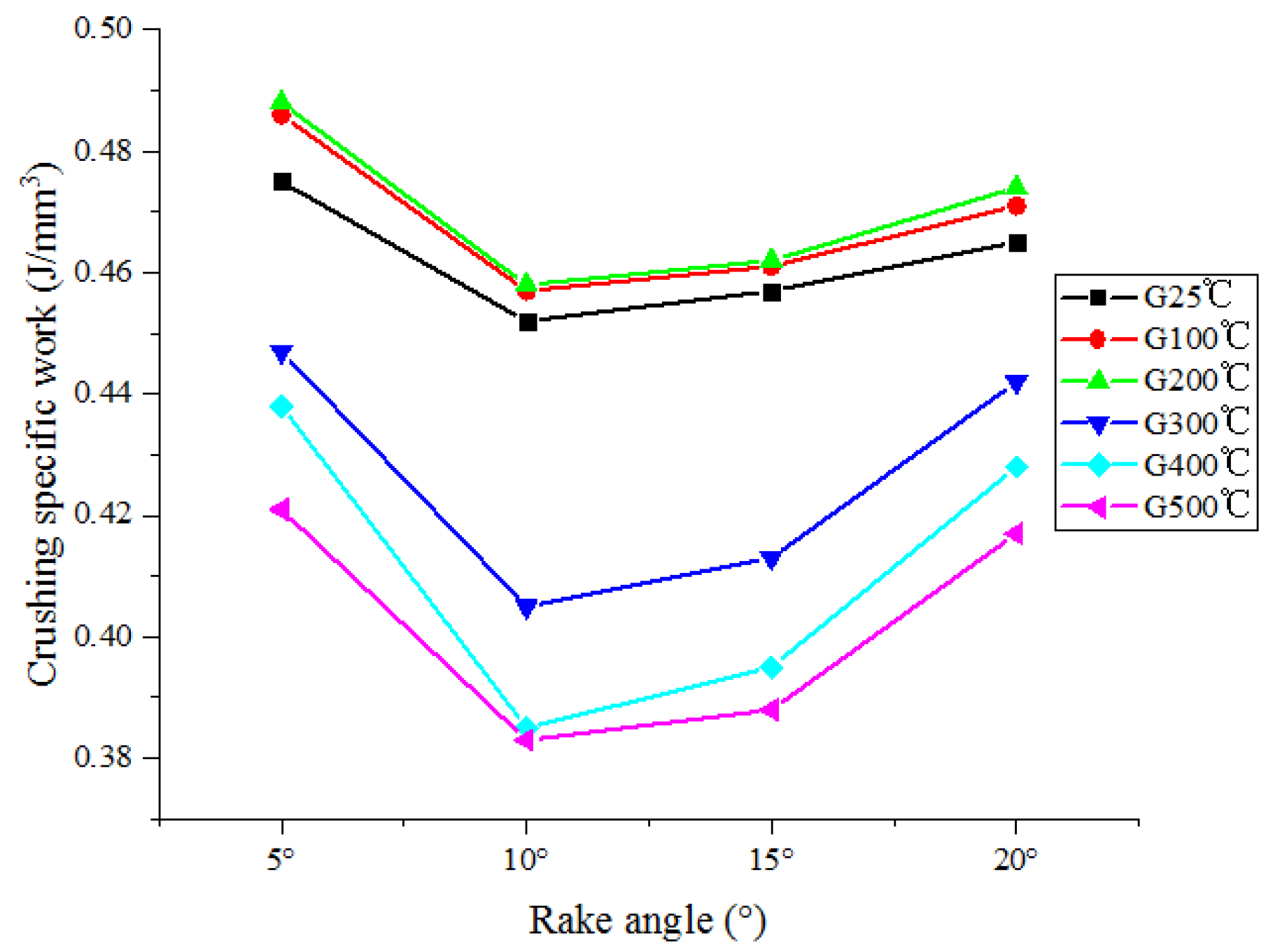

- (2)

- As the rake angle of the tool increases, the specific energy consumption for crushing rocks first decreases and then increases. When the rake angle of the tool is 10°, the specific energy consumption for crushing rocks is minimized, the amount of rock debris produced is the highest, and the particle size of the debris is the largest. Therefore, it is recommended to design the rake angle of the tool at 10° to improve the rock breaking efficiency of the cutter.

- (3)

- Considering that increasing the depth of penetration can cause uneven wear of the cutter, in order to improve rock fragmentation, within the allowable drilling parameters, the drilling parameters can be controlled to achieve a penetration depth of 2 mm to improve the rock breaking efficiency and working life of the bit.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, S.K.; Tian, F.; Li, H.; Cave, Q.; Guo, J.; Chun, H.D.; Zhang, Z.; Yu, H. Development and application of high efficiency wear-resistant PDC bits for ultra-high temperature geothermal drilling. Drill. Prod. Technol. 2010, 43, 1–3+141. [Google Scholar]

- Yang, Y.; Song, D.; Ren, H.; Huang, K.; Zuo, L. Study of a new impregnated diamond bit for drilling in complex, highly abrasive formation. J. Pet. Sci. Eng. 2019, 187, 106831. [Google Scholar] [CrossRef]

- Saito, S. Study on the durability of high temperature geothermal well bit. Transl. Prospect. Eng. 1997, 4, 57–62. [Google Scholar]

- Lukawski, M.Z.; Silverman, R.L.; Tester, J.W. Uncertainty analysis of geothermal well drilling and completion costs. Geothermics 2016, 64, 382–391. [Google Scholar] [CrossRef]

- Han, L. Preparation and Performance Research of High Thermal Stability Diamond Compact; Jilin University: Changchun, China, 2015. [Google Scholar]

- Ma, D.K. Working Mechanics of Roller Cone Bit, 2nd ed.; Petroleum Industry Press: Beijing, China, 2009. [Google Scholar]

- Song, D.; Ren, Z.; Yang, Y.; Chen, Y.; Nie, G.; Tan, L.; Peng, H.; Li, Z.; Chen, X.; Li, M.; et al. Drilling performance analysis of impregnated micro bit. Mech. Sci. 2022, 13, 867–875. [Google Scholar] [CrossRef]

- Frolova, J.V.; Ladygin, V.M.; Rychagov, S.N. Petrophysical alteration of volcanic rocks in hydrothermal systems of the kuril-kamchatla Island Arc. In Proceedings of the World Geothermal Congress, Nusa Dua, Indonesia, 25–30 April 2010. [Google Scholar]

- Simone, O.; Enel, I.; Regillion, K. New HT/HP Technology for Geothermal Application Significantly Increases On-Bottom Drilling Hours; SPE: Richardson, TX, USA, 2012; pp. 1–20. [Google Scholar]

- Song, D.D. Development and Application of PDC Bit for High Temperature Geothermal Drilling; Southwest Petroleum University: Chengdu, China, 2017. [Google Scholar]

- Denney, D. Technology applications. JPT 2009, 61, 22–27. [Google Scholar]

- Guang, X.J.; Wang, M.S.; Si, N.; Ye, H. Technical difficulties and Countermeasures of high temperature geothermal high efficiency development drilling. In Proceedings of the 18th National Exploration Engineering (Geotechnical Drilling Engineering) Technology Academic Exchange Annual Meeting, Harbin, China, 25 August 2015. [Google Scholar]

- Zuo, R.Q. Overview of international oil and gas well bit progress (III)-PDC bit development process and current situation (Part I). Explor. Eng. 2016, 43, 1–8. [Google Scholar]

- Zuo, R.Q. Overview of international oil and gas well bit development (IV)-PDC bit development process and current situation (Part II). Prospect. Eng. (Geotech. Drill. Eng.) 2016, 4, 40–48. [Google Scholar]

- Scott, D. A bit of history: Overcoming early setbacks, PDC bits now drill 90%-plus of worldwide footage. In Drilling Contractor Anthology Series—PDC Drilling Bits; IADC: Houston, TX, USA, 2015; pp. 1–7. [Google Scholar]

- Yang, Y.; Song, D.; Chen, H.; Chen, X.; Chen, L. The research on the fixation strength of tapered cone bit teeth. Eng. Fail. Anal. 2021, 124, 105318. [Google Scholar] [CrossRef]

- Zhou, D.Y.; Wang, R.H. Experimental study on rock abrasivity of PDC bit. J. Univ. Pet. (Nat. Sci. Ed.) 2003, 2, 41–43+7–6. [Google Scholar]

- Wu, Z.B.; Lv, L.T.; Wang, Y.Y. Rock breaking characteristics and temperature field change of cone PDC hybrid bit. Nat. Gas Ind. 2020, 40, 99–106. [Google Scholar]

- Luo, M.; Zhu, H.Y.; Liu, Q.Y. A v-tooth PDC bit suitable for ultra-high temperature and ultra-high pressure plastic mudstone. Nat. Gas Ind. 2021, 41, 97–106. [Google Scholar]

- Chen, L.F. “Drilling” depth and heat. China Min. News 2015, 7, 11. [Google Scholar]

- Shulyupin, A.N. Steamwater flow instability in geothermal wells. Thermo-Phys. Aeromechanics 2015, 22, 475–480. [Google Scholar] [CrossRef]

- Bill, R.; Abraham, S.; Paul, S. Successfully applying micronized cellulose to minimize lost circulation on the PUNA geothermal venture wells. In Proceedings of the Geothermal Re-Source Council, 34th Annual Meeting, Reno, NV, USA, 15–19 February 2021; pp. 1–15. [Google Scholar]

- Al-Shayea, N.A.; Khan, K.; Abduljauwad, S.N. Effects of confining pressure and temperature on mixed mode(Ⅰ-Ⅱ) fracture toughness of a lime-stone rock. Int. J. Rock Mech. Min. Sci. 2000, 37, 629–643. [Google Scholar] [CrossRef]

- Liu, Q.S.; Xu, X.C. Damage analysis of brittle rock at high temperature. Chin. J. Rock Mech. Eng. 2000, 19, 408–411. [Google Scholar]

- Xu, X.-l.; Gao, F.; Shen, X.-m.; Jin, C.-h. Research on mechanical characteristics and micropore structure of granite under high-temperature. Rock Soil Mech. 2010, 31, 1752–1758. [Google Scholar]

- Deng, H.; Zhang, M.; Deng, T.H.; Zhang, Q. Triaxial compression test of tight sandstone under high temperature and high pressure. Pet. Nat. Gas Geol. 2017, 38, 8. [Google Scholar]

- Zhao, Y.S.; Wan, Z.J.; Zhang, Y.; Qu, F.; Xie, G.; Wei, X.; Ma, W. Development of a 20MN servo controlled high-temperature and high-pressure triaxial testing machine for rock masses. J. Rock Mech. Eng. 2008, 27, 1–8. [Google Scholar]

- Zhou, C.B.; Wan, Z.J.; Zhang, Y.; Gu, B. Experimental study on hydraulic fracturing of granite under high temperature conditions. China Min. 2017, 26, 8. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Song, D.; Huang, K.; Ren, H.; Yang, Y.; Qiu, S.; Huang, Z. Study on the Cutter–Granite Interaction Mechanism in High-Temperature Geothermal Wells. Energies 2025, 18, 719. https://doi.org/10.3390/en18030719

Yang Y, Song D, Huang K, Ren H, Yang Y, Qiu S, Huang Z. Study on the Cutter–Granite Interaction Mechanism in High-Temperature Geothermal Wells. Energies. 2025; 18(3):719. https://doi.org/10.3390/en18030719

Chicago/Turabian StyleYang, Yan, Dongdong Song, Kuilin Huang, Haitao Ren, Yingxin Yang, Shunzuo Qiu, and Zequan Huang. 2025. "Study on the Cutter–Granite Interaction Mechanism in High-Temperature Geothermal Wells" Energies 18, no. 3: 719. https://doi.org/10.3390/en18030719

APA StyleYang, Y., Song, D., Huang, K., Ren, H., Yang, Y., Qiu, S., & Huang, Z. (2025). Study on the Cutter–Granite Interaction Mechanism in High-Temperature Geothermal Wells. Energies, 18(3), 719. https://doi.org/10.3390/en18030719