Environmental Assessment of Hybrid Waste-to-Energy System in Ghana

Abstract

1. Introduction

2. Materials and Methods

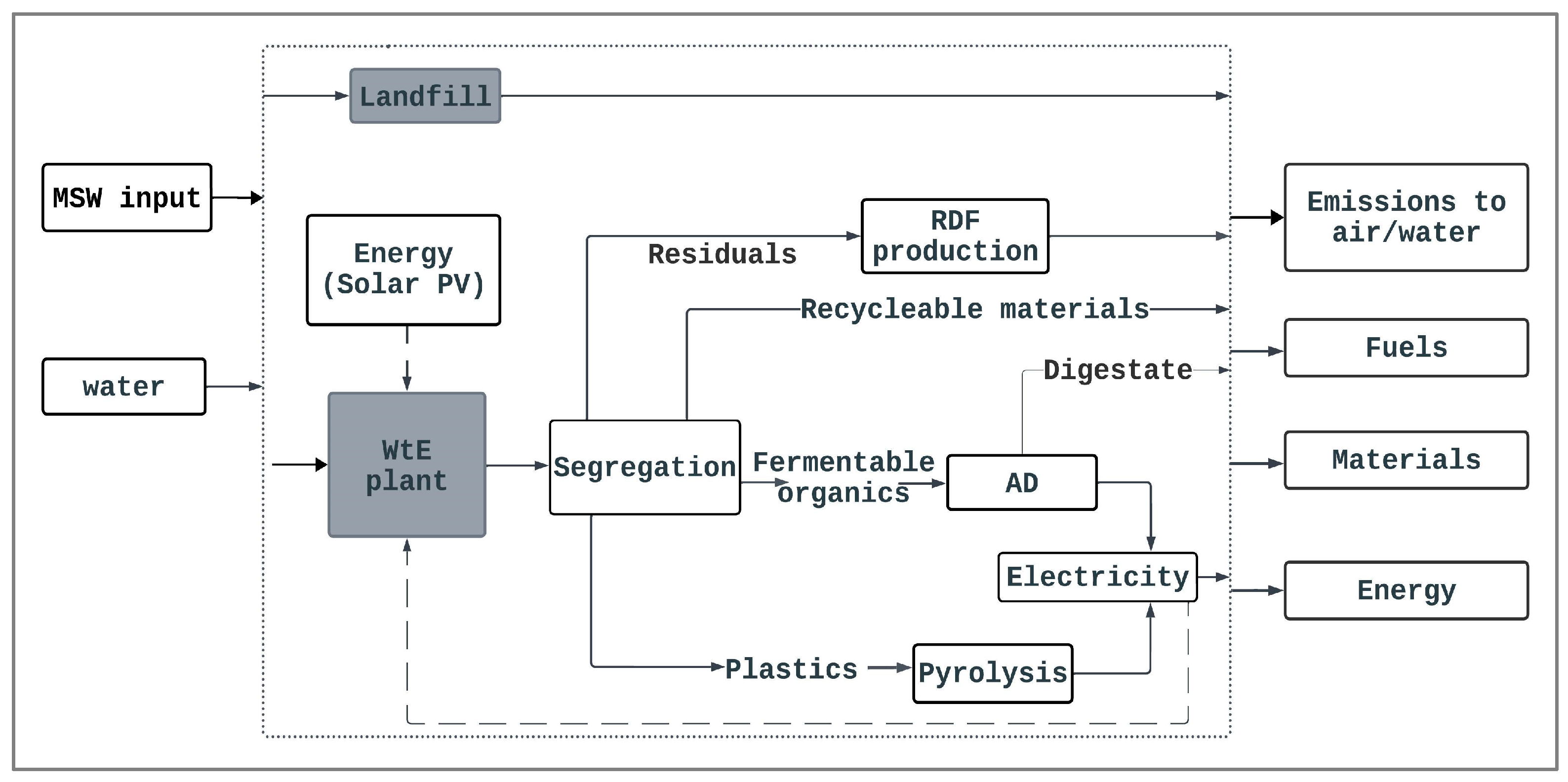

2.1. Study Scope and System Boundaries

2.2. Functional Unit

2.3. Waste Composition and Segregation

2.4. Life Cycle Inventory Analysis (LCIA)

2.4.1. Business-As-Usual (BAU)

2.4.2. Anaerobic Digestion (AD)

2.4.3. Pyrolysis

2.4.4. RDF Production

2.5. Life Cycle Impact Assessment (LCA)

2.6. Interpretation of Environmental Impacts

3. Results and Discussion

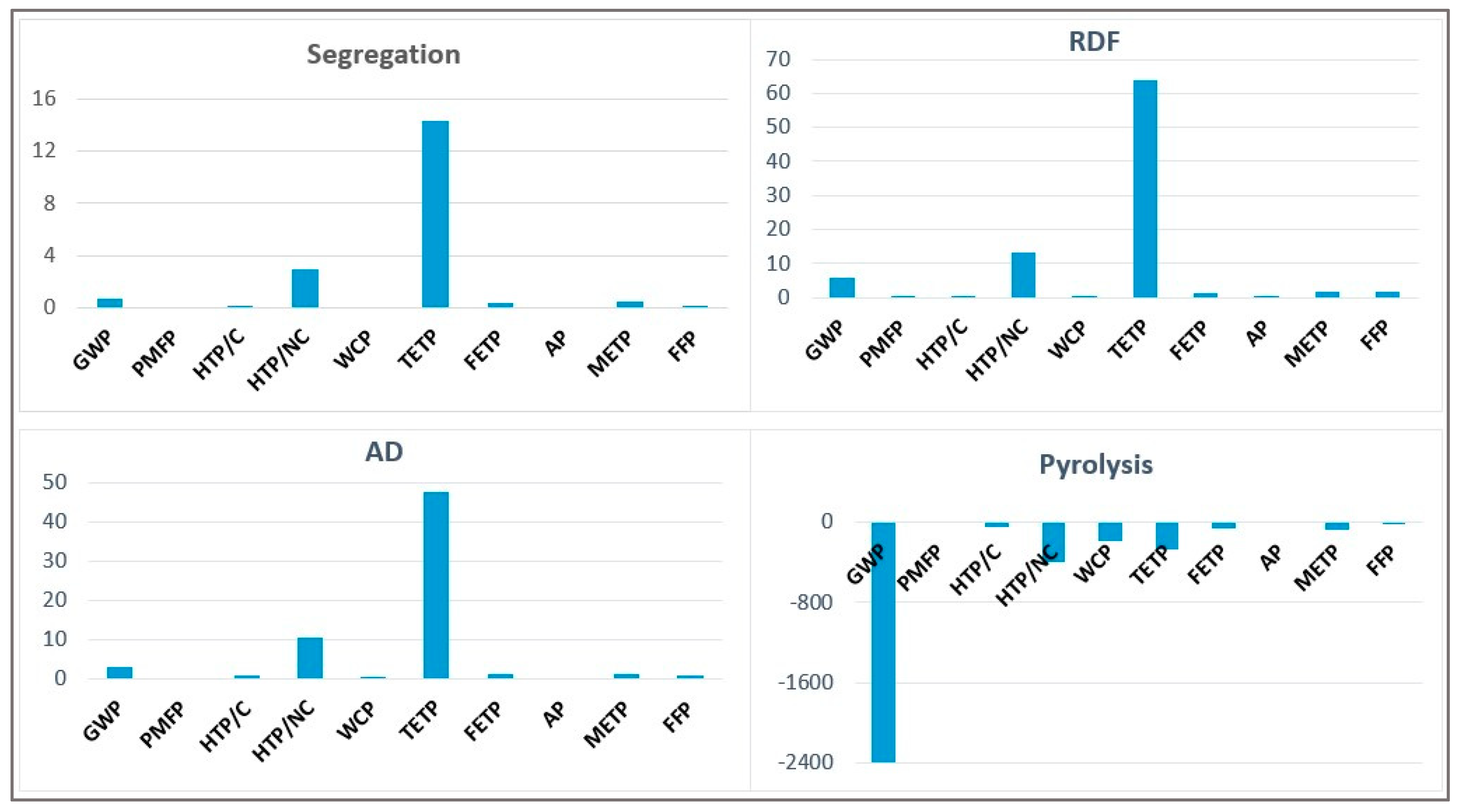

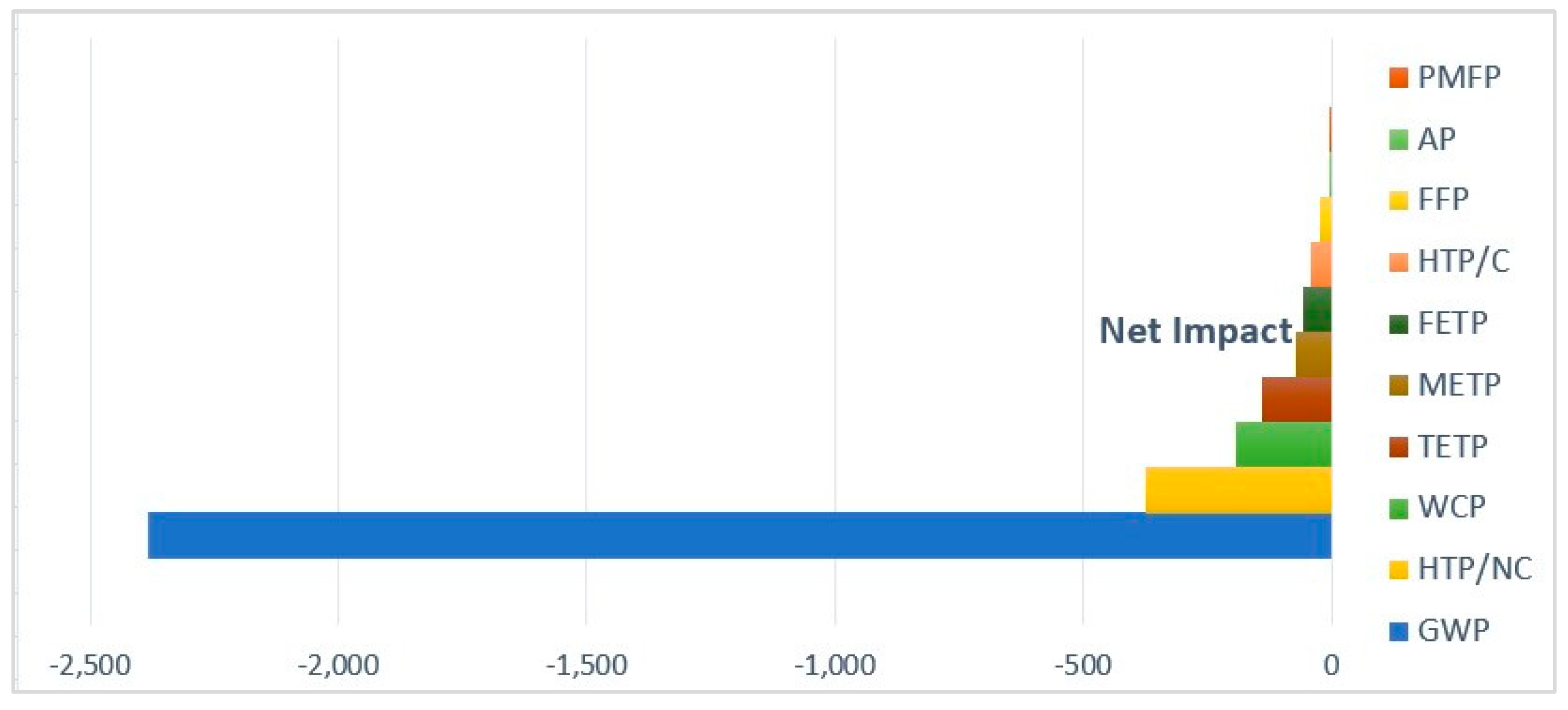

3.1. Impact Assessment of Subsystems

3.2. Impact Assessment According to Impact Categories

3.2.1. GWP

3.2.2. Toxicity Potentials

3.2.3. Water Consumption Potential

3.2.4. Particulate Matter Formation Potential (PMFP)

3.2.5. Terrestrial Acidification Potential

3.2.6. Fossil Resource Scarcity

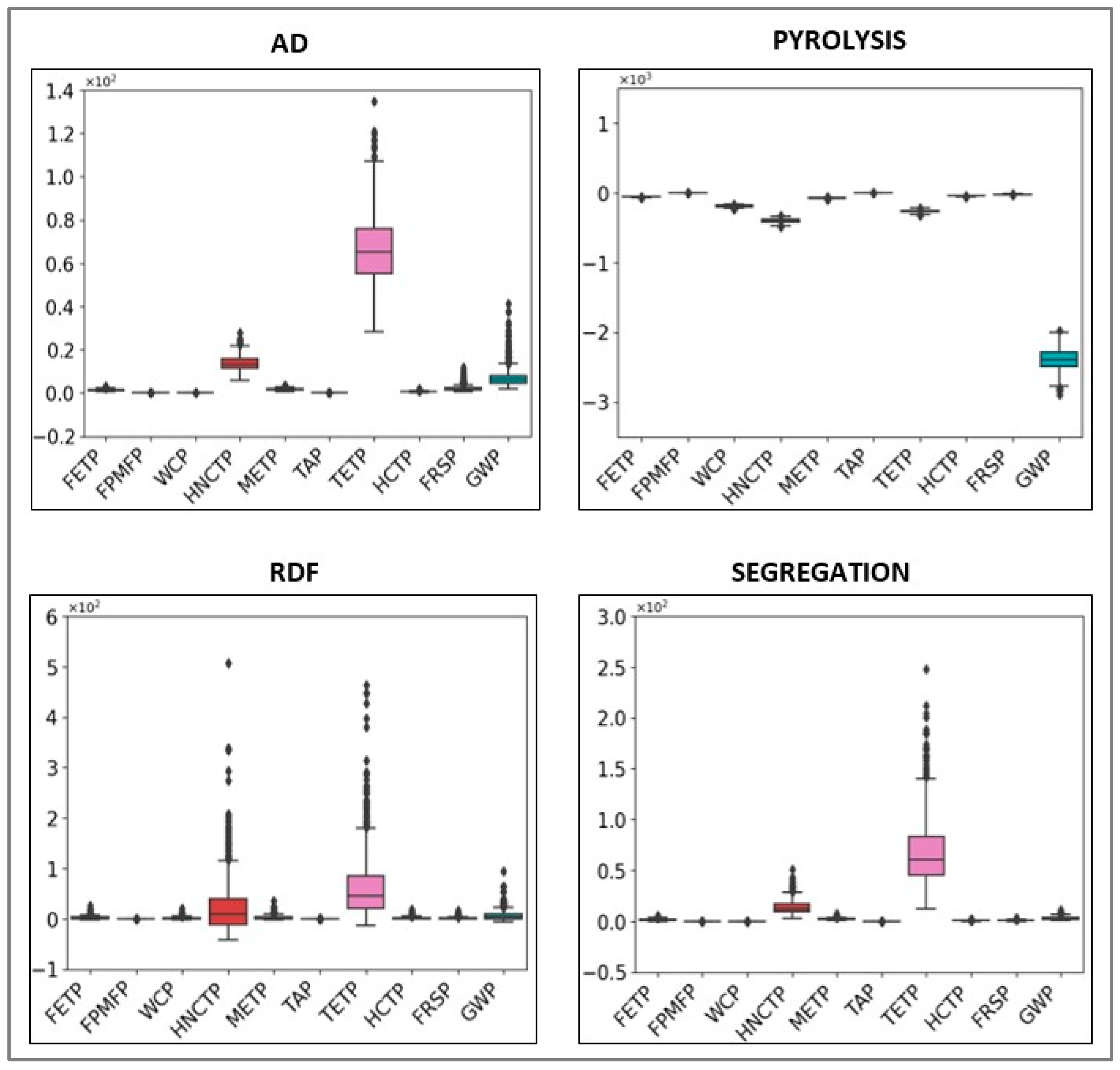

3.3. Uncertainty Analysis

3.4. Other Potential Impacts

3.5. Limitations and Recommendations

- Dedicating funding to this;

- Dedicating human resources for national coordination, such as incorporating it into the Ghana Carbon Market Office;

- Future research focused on carrying out detailed and up-to-date studies on aspects such as national waste composition similar to that carried out in 2014 [80]. Other important areas of concern are emission factors and operation-related emissions from waste treatment activities;

- Facilitating training programs for waste management companies, research institutions, agencies and decision-makers to enhance monitoring and compliance.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- United Nations. The Sustainable Development Goals Report 2024; United Nations: New York, NY, USA, 2024. [Google Scholar]

- Ndam, S.; Touikoue, A.F.; Chenal, J.; Baraka Munyaka, J.-C.; Kemajou, A.; Kouomoun, A. Urban Governance of Household Waste and Sustainable Development in Sub-Saharan Africa: A Study from Yaoundé (Cameroon). Waste 2023, 1, 612–630. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. World Energy Transitions Outlook 2023: 1.5 °C Pathway; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023; Volume 1. [Google Scholar]

- International Energy Agency. CO2 Emissions in 2023; International Energy Agency: Paris, France, 2023; Volume 24, p. 22. [Google Scholar]

- UNFCC COP29 UN Climate Conference Agrees to Triple Finance to Developing Countries, Protecting Lives and Livelihoods. Available online: https://unfccc.int/news/cop29-un-climate-conference-agrees-to-triple-finance-to-developing-countries-protecting-lives-and (accessed on 7 December 2024).

- Ibrahim, I.D.; Hamam, Y.; Alayli, Y.; Jamiru, T.; Sadiku, E.R.; Kupolati, W.K.; Ndambuki, J.M.; Eze, A.A. A Review on Africa Energy Supply through Renewable Energy Production: Nigeria, Cameroon, Ghana and South Africa as a Case Study. Energy Strategy Rev. 2021, 38, 100740. [Google Scholar] [CrossRef]

- Williams, P.A.; Narra, S.; Antwi, E.; Quaye, W.; Hagan, E.; Asare, R.; Owusu-Arthur, J.; Ekanthalu, V.S. Review of Barriers to Effective Implementation of Waste and Energy Management Policies in Ghana: Implications for the Promotion of Waste-to-Energy Technologies. Waste 2023, 1, 313–332. [Google Scholar] [CrossRef]

- International Energy Agency; International Renewable Energy Agency; United Nations Statistics Division; World Bank; World Health Organization. Tracking SDG 7: The Energy Progress Report; The World Bank: Washington, DC, USA, 2021. [Google Scholar]

- CEWEP Waste-to-Energy Cycle. Available online: https://www.cewep.eu/waste-to-energy-cycle-2021/ (accessed on 7 December 2024).

- Khan, I.; Chowdhury, S.; Techato, K. Waste to Energy in Developing Countries-A Rapid Review: Opportunities, Challenges, and Policies in Selected Countries of Sub-Saharan Africa and South Asia towards Sustainability. Sustainability 2022, 14, 3740. [Google Scholar] [CrossRef]

- Bakkaloglu, S.; Cooper, J.; Hawkes, A. Life Cycle Environmental Impact Assessment of Methane Emissions from the Biowaste Management Strategy of the United Kingdom: Towards Net Zero Emissions. J. Clean. Prod. 2022, 376, 134229. [Google Scholar] [CrossRef]

- El Ibrahimi, M.; Khay, I.; El Maakoul, A.; Bakhouya, M. Techno-Economic and Environmental Assessment of Anaerobic Co-Digestion Plants under Different Energy Scenarios: A Case Study in Morocco. Energy Convers. Manag. 2021, 245, 114553. [Google Scholar] [CrossRef]

- Yaman, C. Investigation of Greenhouse Gas Emissions and Energy Recovery Potential from Municipal Solid Waste Management Practices. Environ. Dev. 2020, 33, 100484. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Ghana’s Fifth National Greenhouse Gas Inventory; Environmental Protection Agency: Accra, Ghana, 2022.

- Ministry of Energy. Energy Sector Recovery Program; Ministry of Energy: Accra, Ghana, 2019.

- Afful-Dadzie, A.; Mallett, A.; Afful-Dadzie, E. The Challenge of Energy Transition in the Global South: The Case of Electricity Generation Planning in Ghana. Renew. Sustain. Energy Rev. 2020, 126, 109830. [Google Scholar] [CrossRef]

- Odoi-Yorke, F.; Adu, T.F.; Ampimah, B.C.; Atepor, L. Techno-Economic Assessment of a Utility-Scale Wind Power Plant in Ghana. Energy Convers. Manag. X 2023, 18, 100375. [Google Scholar] [CrossRef]

- Kemausuor, F.; Kamp, A.; Thomsen, S.T.; Bensah, E.C.; Stergård, H. Assessment of Biomass Residue Availability and Bioenergy Yields in Ghana. Resour. Conserv. Recycl. 2014, 86, 28–37. [Google Scholar] [CrossRef]

- Afonaa-Mensah, S.; Majeed, I.B.; Odoi-Yorke, F. Advancing the Adoption of Net Metering: An Economic Assessment of Grid-Tied Solar Photovoltaic Systems in Urban Homes in Ghana. Int. J. Energy Res. 2024, 2024, 9919076. [Google Scholar] [CrossRef]

- Darmey, J.; Ahiekpor, J.C.; Narra, S.; Achaw, O.W.; Ansah, H.F. Municipal Solid Waste Generation Trend and Bioenergy Recovery Potential: A Review. Energies 2023, 16, 7753. [Google Scholar] [CrossRef]

- Abledu, E.S.; Amfo-Otu, R. Contribution of Informal Sector Recycling Workers to Sustainable Landfill Management: The Case of Kpone Landfill Site in the Greater Accra Region. Appl. Res. J. 2019, 4, 1–11. [Google Scholar]

- Agyenim, F.B.; Dzamboe, P.D.; Mohammed, M.; Bawakyillenuo, S.; Okrofu, R.; Decker, E.; Agyemang, V.K.; Nyarko, E.H. Powering Communities Using Hybrid Solar–Biogas in Ghana, a Feasibility Study. Environ. Technol. Innov. 2020, 19, 100837. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Africa Waste Management Outlook; United Nations Environment Programme: Nairobi, Kenya, 2018; Volume 123, ISBN 9789280737042. [Google Scholar]

- Odoi-Yorke, F.; Abaase, S.; Zebilila, M.; Atepor, L. Feasibility Analysis of Solar PV/Biogas Hybrid Energy System for Rural Electrification in Ghana. Cogent Eng. 2022, 9, 2034376. [Google Scholar] [CrossRef]

- Mohammed, M.; Egyir, I.S.; Donkor, A.K.; Amoah, P.; Nyarko, S.; Boateng, K.K.; Ziwu, C. Feasibility Study for Biogas Integration into Waste Treatment Plants in Ghana. Egypt. J. Pet. 2017, 26, 695–703. [Google Scholar] [CrossRef]

- Osei-Appiah, N.A.; Dioha, M.O. Techno-Economic Assessment of Waste-To-Energy Technologies in Ghana. J. Sustain. Energy 2019, 10, 112–121. [Google Scholar]

- Cudjoe, D.; Nketiah, E.; Obuobi, B.; Adu-Gyamfi, G.; Adjei, M.; Zhu, B. Forecasting the Potential and Economic Feasibility of Power Generation Using Biogas from Food Waste in Ghana: Evidence from Accra and Kumasi. Energy 2021, 226, 120342. [Google Scholar] [CrossRef]

- Obuobi, B.; Adu-Gyamfi, G.; Adjei, M.; Nketiah, E. Technologies Potential and Economic Viability Analysis of Deriving Electricity from Municipal Solid Waste in Kumasi, Ghana. Energy Sustain. Dev. 2022, 68, 318–331. [Google Scholar] [CrossRef]

- Yakah, N.; Kwarteng, A.A.; Addy, C.; Yirenkyi, M.; Martin, A.; Simons, A. Techno-Economic Assessment of Municipal Solid Waste (MSW) Incineration in Ghana. Processes 2024, 12, 1286. [Google Scholar] [CrossRef]

- Asante, K.; Gyamfi, S.; Amo-boateng, M. Techno-Economic Analysis of Waste-to-Energy with Solar Hybrid: A Case Study from Kumasi, Ghana. Sol. Compass 2023, 6, 100041. [Google Scholar] [CrossRef]

- Armoo, E.A.; Narra, S.; Mohammed, M.; Boahemaa, B.; Beguedou, E.; Kemausuor, F.; Agyenim, F.B. Hybrid Waste-to-Energy Solutions within a Circular Economy Framework Directed towards Sustainable Urban Waste Management in Ghana. Sustainability 2024, 16, 4976. [Google Scholar] [CrossRef]

- Armoo, E.A.; Narra, S.; Mohammed, M.; Beguedou, E.; Kemausuor, F. Business Case for Hybrid Waste to Energy System for Ghana. In Innovations in Circular Economy and Renewable Energy in Africa; Narra, M.-M., Narra, S., Eds.; Springer: Cham, Switzerland, 2024; pp. 87–104. ISBN 978-3-031-68330-5. [Google Scholar]

- Armoo, E.A.; Mohammed, M.; Narra, S.; Beguedou, E.; Agyenim, F.B.; Kemausuor, F. Achieving Techno-Economic Feasibility for Hybrid Renewable Alternative Fuels. Energies 2024, 17, 735. [Google Scholar] [CrossRef]

- Sharma, H.; Monnier, É.; Mandil, G.; Zwolinski, P.; Colasson, S. Comparison of Environmental Assessment Methodology in Hybrid Energy System Simulation Software. Procedia CIRP 2019, 80, 221–227. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. Second Edition. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Dastjerdi, B.; Strezov, V.; Rajaeifar, M.A.; Kumar, R.; Behnia, M. A Systematic Review on Life Cycle Assessment of Different Waste to Energy Valorization Technologies. J. Clean. Prod. 2021, 290, 125747. [Google Scholar] [CrossRef]

- Elijah, E.U.; Oluwatobi Ojo, D.; Yakubu, E.A.; Ezeuzo, E.B.; Hampo, C.C.; Abubakar, A. Life Cycle Assessment (LCA) of Solid Waste Management Systems in African Countries: A Systematic Review. J. Adv. Environ. Health Res. 2023, 11, 194–204. [Google Scholar] [CrossRef]

- Mohammed, M.; Dzamboe, P.D.; Rockson, M.A.D.; Ayittah, S.; Narra, S.; Agyenim, F.B.; Joshua, K.; Boakye-Danquah, E.B.; Abdul-samii, R.; Armoo, E.A.; et al. Spatial Distribution and Resource Mobilization of Waste for a Hybrid Waste-to-Energy Plant in Ghana. In Innovations in Circular Economy and Renewable Energy in Africa; Narra, M., Narra, S., Eds.; Springer: Cham, Switzerland, 2024; pp. 43–66. ISBN 9783031683305. [Google Scholar]

- Kwakye, S.O.; Amuah, E.E.Y.; Ankoma, K.A.; Agyemang, E.B.; Owusu, B.G. Understanding the Performance and Challenges of Solid Waste Management in an Emerging Megacity: Insights from the Developing World. Environ. Chall. 2024, 14, 100805. [Google Scholar] [CrossRef]

- Sarquah, K.; Narra, S.; Beck, G.; Bassey, U.; Antwi, E.; Hartmann, M.; Sarfo, N.; Derkyi, A.; Awafo, E.A.; Nelles, M. Characterization of Municipal Solid Waste and Assessment of Its Potential for Refuse-Derived Fuel (RDF) Valorization. Energies 2023, 16, 200. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. AP 42, Fifth Edition, Volume I Chapter 2: Solid Waste Disposal, 2.4 Municipal Solid Waste Landfills. Available online: https://www.epa.gov/air-emissions-factors-and-quantification/ap-42-fifth-edition-volume-i-chapter-2-solid-waste-0 (accessed on 4 November 2024).

- United States Environmental Protection Agency. Background Information Document for Updating AP42 Section 2.4 for Estimating Emissions from Municipal Solid Waste Landfills; United States Environmental Protection Agency: Washington, DC, USA, 2008.

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Life Cycle Assessment of Waste-to-Energy (WtE) Technologies for Electricity Generation Using Municipal Solid Waste in Nigeria. Appl. Energy 2017, 201, 200–218. [Google Scholar] [CrossRef]

- Alexander, A.; Burklin, C.; Singleton, A. Landfill Gas Emissions Model (LandGEM) Version 3.02; User’s Guide; United States Environmental Protection Agency: Washington, DC, USA, 2005.

- World Bank Group Current Climate—Ghana. Available online: https://climateknowledgeportal.worldbank.org/country/ghana/climate-data-historical (accessed on 8 December 2024).

- Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; National Greenhouse Gas Inventories Programme: Hayama, Japan, 2006. [Google Scholar]

- Intergovernmental Panel on Climate Change. Global Warming Potential Values. In Greenhouse Gas Protocol: AR6; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2024. [Google Scholar]

- United States Environmental Protection Agency. Global Methane Initiative Chapter 6. Landfill Gas Modeling. In International Best Practices Guide for Landfill Gas Energy Projects; U.S. Environmental Protection Agency: Washington, DC, USA, 2012; pp. 63–76. [Google Scholar]

- Baidoo, T.; Boakye, P.; Ama, M.; Rockson, D.; Kemausuor, F.; Narra, S. A Life Cycle Assessment of Electricity Generation from the Anaerobic Digestion of Municipal Solid Waste in Ghana. In Innovations in Circular Economy and Renewable Energy in Africa; Narra, M.-M., Narra, S., Eds.; Springer: Cham, Switzerland, 2024; ISBN 9783031683305. [Google Scholar]

- Addae, G.; Oduro-Kwarteng, S.; Fei-Baffoe, B.; Rockson, M.A.D.; Ribeiro, J.X.F.; Antwi, E. Market Waste Composition Analysis and Resource Recovery Potential in Kumasi, Ghana. J. Air Waste Manag. Assoc. 2021, 71, 1529–1544. [Google Scholar] [CrossRef]

- Krou, N.M.; Baba, G.; Akpaki, O. Estimation of the Amount of Electrical Energy Available from the Biogas Produced at the Faecal Sludge Treatment Plant in the City of Sokodé. In Proceedings of the 2nd German-West African Conference on Sustainable, Renewable Energy Systems SusRES, TH Wildau, Kara, Togo, 6 April 2021; Volume 1, pp. 77–82. [Google Scholar]

- Nielsen, M.; Nielsen, O.-K.; Thomsen, M. Emissions from Decentralised CHP Plants 2007—Energinet.Dk Environmental Project No. 07/1882. Project Report 5—Emission Factors and Emission Inventory for Decentralised CHP Production; Technical Report No. 07/1882; National Environmental Research Institute: Aarhus, Denmark, 2010. [Google Scholar]

- Bassey, U.; Bowles, A.; Fowler, G.; Tom, A.O.; Beck, G.; Narra, S.; Nelles, M.; Hartmann, M. Experimental Investigation of Products from Thermal Treatment of Real-World Mixed Single-Use and Multi-Layered Waste Plastics. Environ. Res. 2024, 247, 118244. [Google Scholar] [CrossRef] [PubMed]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Durodola, O.; Munda, J.L. Electricity Generation Potential and Environmental Assessment of Bio-Oil Derivable from Pyrolysis of Plastic in Some Selected Cities of Nigeria. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 42, 1167–1182. [Google Scholar] [CrossRef]

- Lee, R.D. Evaluating Uganda’s Waste Management System for the Production of Refuse-Derived Fuel (RDF) and Its Potential Implementation in the Country’s Growing Cement Industry. Master’s. Thesis, Technical University of Wien, Vienna, Austria, 2019. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Konig, A.; van Oers, L.; Wegener Sleeswijk, A.; Udo De Haes, H.A.; de Bruijn, J.A.; et al. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: New York, NY, USA; Boston, MA, USA; Dordrecht, The Netherlands; London, UK; Moscow, Russia, 2004; ISBN 0306480557. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Zelm, R. Van ReCiPe 2008. In A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level, 1st ed.; VROM: The Hague, The Netherlands, 2009. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Kumar, R.; He, J.; Behnia, M. Comparative Life Cycle Assessment of System Solution Scenarios for Residual Municipal Solid Waste Management in NSW, Australia. Sci. Total Environ. 2021, 767, 144355. [Google Scholar] [CrossRef]

- Crenna, E.; Secchi, M.; Benini, L.; Sala, S. Global Environmental Impacts: Data Sources and Methodological Choices for Calculating Normalization Factors for LCA. Int. J. Life Cycle Assess. 2019, 24, 1851–1877. [Google Scholar] [CrossRef]

- Laurent, A.; Hauschild, M. Normalisation. In Life Cycle Impact Assessment; Hauschild, M.Z., Huijbregts, M.A.J., Eds.; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar]

- Hospido, A.; Moreira, M.T.; Martín, M.; Rigola, M.; Feijoo, G. Environmental Evaluation of Different Treatment Processes for Sludge from Urban Wastewater Treatments: Anaerobic Digestion versus Thermal Processes. Int. J. Life Cycle Assess. 2005, 10, 336–345. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.S. Catalytic Pyrolysis of Plastic Waste: Moving toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 437000. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. Assessment of Energy Recovery Potential and Analysis of Environmental Impacts of Waste to Energy Options Using Life Cycle Assessment. J. Clean. Prod. 2022, 365, 132854. [Google Scholar] [CrossRef]

- Silva, V.; Contreras, F.; Bortoleto, A.P. Life-Cycle Assessment of Municipal Solid Waste Management Options: A Case Study of Refuse Derived Fuel Production in the City of Brasilia, Brazil. J. Clean. Prod. 2021, 279, 123696. [Google Scholar] [CrossRef]

- Karlsson, N.P.E.; Hoveskog, M.; Halila, F.; Mattsson, M. Business Modelling in Farm-Based Biogas Production: Towards Network-Level Business Models and Stakeholder Business Cases for Sustainability. Sustain. Sci. 2019, 14, 1071–1090. [Google Scholar] [CrossRef]

- Ouedraogo, A.S.; Frazier, R.S.; Kumar, A. Comparative Life Cycle Assessment of Gasification and Landfilling for Disposal of Municipal Solid Wastes. Energies 2021, 14, 7032. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Economic and Environmental Assessment of Electricity Generation Using Biogas from Organic Fraction of Municipal Solid Waste for the City of Ibadan, Nigeria. J. Clean. Prod. 2018, 203, 718–735. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Emission Factor Documentation for AP-42 Section 3.1: Stationary Gas Turbines; US United States Environmental Protection Agency: Washington, DC, USA, 2000.

- Al-rumaihi, A.; Alherbawi, M.; Mckay, G. Assessing Plastic and Biomass-Based Biochar’s Potential for Carbon Sequestration: An. Front. Sustain. 2023, 4, 1200094. [Google Scholar] [CrossRef]

- Mishra, S.; Bharagava, R.N.; More, N.; Yadav, A.; Zainith, S.; Mani, S.; Chowdhary, P. Heavy Metal Contamination: An Alarming Threat to Environment and Human Health. In Environmental Biotechnology: For Sustainable Future; Sobti, R.C., Arora, N.K., Kothari, R., Eds.; Springer: Singapore, 2019; pp. 103–125. ISBN 978-981-10-7284-0. [Google Scholar]

- Akanchise, T.; Boakye, S.; Borquaye, L.S.; Dodd, M.; Darko, G. Distribution of Heavy Metals in Soils from Abandoned Dump Sites in Kumasi, Ghana. Sci. Afr. 2020, 10, e00614. [Google Scholar] [CrossRef]

- Sobti, C.R.; Arora, N.K.; Kothari, R. (Eds.) Environmental Biotechnology: For Sustainable Future; Springer: Singapore, 2019; ISBN 9789811072833. [Google Scholar]

- Fantke, P.; Aurisano, N.; Bare, J.; Backhaus, T.; Bulle, C.; Chapman, P.M.; De Zwart, D.; Dwyer, R.; Ernstoff, A.; Golsteijn, L.; et al. Toward Harmonizing Ecotoxicity Characterization in Life Cycle Impact Assessment. Environ. Toxicol. Chem. 2018, 37, 2955–2971. [Google Scholar] [CrossRef] [PubMed]

- Alengebawy, A.; Mohamed, B.A.; Jin, K.; Liu, T.; Ghimire, N.; Samer, M.; Ai, P. A Comparative Life Cycle Assessment of Biofertilizer Production towards Sustainable Utilization of Anaerobic Digestate. Sustain. Prod. Consum. 2022, 33, 875–889. [Google Scholar] [CrossRef]

- Asabea, A.; Nti, A.; Arko-mensah, J.; Botwe, P.K.; Dwomoh, D.; Kwarteng, L.; Takyi, S.A.; Acquah, A.A.; Tettey, P.; Basu, N.; et al. Effect of Particulate Matter Exposure on Respiratory Health of E-Waste Workers at Agbogbloshie, Accra, Ghana. Int. J. Environ. Res. Public Health 2020, 17, 3042. [Google Scholar] [CrossRef]

- Ghana Grid Company Limited. 2022 Electricity Supply Plan for the Ghana Power System; Ghana Grid Company Limited: Accra, Ghana, 2022. [Google Scholar]

- Ministry of Environment, Science, Technology and Innovation. Ghana: Updated Nationally Determined Contribution Under the Paris Agreement (2020–2030); Environmental Protection Agency (EPA) and the Ministry of Environment, Science, Technology and Innovation (MESTI): Accra, Ghana, 2021.

- Miezah, K.; Obiri-Danso, K.; Kádár, Z.; Fei-Baffoe, B.; Mensah, M.Y. Municipal Solid Waste Characterization and Quantification as a Measure towards Effective Waste Management in Ghana. Waste Manag. 2015, 46, 15–27. [Google Scholar] [CrossRef]

- Dery, P.; Benefoh, D. Ghana’s Report on the Implementation of Article 6 of the Paris Agreement; Ghana’s Carbon Market Office: Accra, Ghana, 2023.

- Hang, M.; Geyer-Klingeberg, J.; Rathgeber, A.W. It Is Merely a Matter of Time: A Meta-Analysis of the Causality between Environmental Performance and Financial Performance. Bus. Strategy Environ. 2019, 28, 257–273. [Google Scholar] [CrossRef]

| Input Variable | Value | Units | Details | Reference |

|---|---|---|---|---|

| Precipitation | 1318.34 | mm/yr | Regional annual average for Ashanti Region (1990–2021) | [46] |

| Methane correction factor | 0.8 | - | Default for deep, unmanaged landfills | [47] |

| Temperature | 26.98 | °C | Regional annual average for Ashanti Region (1990–2021) | [46] |

| Methane fraction in landfill gas | 50 | % | Default | [47] |

| Flow Direction | Parameter | Units | Value |

|---|---|---|---|

| 1. Bio-digestion | |||

| Inputs | Organic waste | tons | 1.00 |

| Electricity (solar PV) | kWh | 38.45 | |

| Heat (CHP) | kWh | 237.80 | |

| Water (groundwater) | m3 | 0.37 | |

| Outputs | Methane | m3 | 62.14 |

| Digestate | tons | 0.88 | |

| Methane (emissions) | kg | 1.34 | |

| 2. Cogeneration | |||

| Input | Methane | m3 | 62.14 |

| Outputs | Electricity | kWh | 216.20 |

| Avoided heat | kWh | 237.80 | |

| Carbon monoxide | kg | 5.16 × 10−9 | |

| N2O | kg | 0.0012 | |

| NOx | kg | 0.16 | |

| SO2 | kg | 0.02 | |

| Flow Direction | Parameter | Units | Value |

|---|---|---|---|

| 1. Pretreatment | |||

| Inputs | Waste–plastic mixture | tons | 1.00 |

| Water (well) | m3 | 0.15 | |

| Electricity | kWh | 1.00 × 10−5 | |

| Outputs | Waste–plastic mixture | tons | 0.95 |

| Wastewater | m3 | 0.165 | |

| 2. Pyrolysis | |||

| Inputs | Waste–plastic mixture | tons | 0.95 |

| Electricity (solar PV) | kWh | 0.009 | |

| Outputs | Bio-oil | tons | 0.75 |

| Char | tons | 0.05 | |

| Syngas | m3 | 0.13 | |

| 3. Cogeneration | |||

| Inputs | Bio-oil | tons | 0.75 |

| Outputs | Electricity | kWh | 0.0033 |

| Heat | kWh | 0.0093 | |

| Carbon dioxide (non-fossil) | kg | 2.15 | |

| N2O | kg | 0.0003 | |

| Methane (non-fossil) | kg | 0.0001 | |

| NO2 | kg | 0.0039 | |

| SO2 | kg | 0.0209 | |

| Flow Direction | Parameter | Units | Value |

|---|---|---|---|

| Inputs | Residual materials | tons | 1.00 |

| Electricity (solar PV) | kWh | 51.58 | |

| Outputs | RDF pellets | tons | 0.95 |

| Heat (loss) | kWh | 33.0 | |

| Trace particles | kg | 0.05 |

| Impact Categories | Relevance to the Study | Link to Endpoint Impact | Unit |

|---|---|---|---|

| GWP | Risk to human health and ecosystem | Human health | kgCO2eq |

| PMFP | Increase in respiratory diseases | kg PM2.5 eq | |

| HTP/C | Increased risk of carcinogenic diseases | kg 1,4-DCB | |

| HTP/NC | Increase in other diseases | kg 1,4-DCB | |

| WCP | Reduced access for consumptive uses | m3 | |

| TETP | Risk to terrestrial spp. | Ecosystems | kg 1,4-DCB |

| FETP | Risk to freshwater spp. | kg 1,4-DCB | |

| AP | Risk to terrestrial spp. | kg SO2 eq | |

| METP | Risk to marine life | kg 1,4-DCB | |

| FFP | Increased scarcity and cost of extraction | Resource availability | kg oil eq |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Armoo, E.A.; Baidoo, T.; Mohammed, M.; Agyenim, F.B.; Kemausuor, F.; Narra, S. Environmental Assessment of Hybrid Waste-to-Energy System in Ghana. Energies 2025, 18, 595. https://doi.org/10.3390/en18030595

Armoo EA, Baidoo T, Mohammed M, Agyenim FB, Kemausuor F, Narra S. Environmental Assessment of Hybrid Waste-to-Energy System in Ghana. Energies. 2025; 18(3):595. https://doi.org/10.3390/en18030595

Chicago/Turabian StyleArmoo, Ekua Afrakoma, Theophilus Baidoo, Mutala Mohammed, Francis Boateng Agyenim, Francis Kemausuor, and Satyanarayana Narra. 2025. "Environmental Assessment of Hybrid Waste-to-Energy System in Ghana" Energies 18, no. 3: 595. https://doi.org/10.3390/en18030595

APA StyleArmoo, E. A., Baidoo, T., Mohammed, M., Agyenim, F. B., Kemausuor, F., & Narra, S. (2025). Environmental Assessment of Hybrid Waste-to-Energy System in Ghana. Energies, 18(3), 595. https://doi.org/10.3390/en18030595