1. Introduction

The continuous growth of the global population has intensified the demand for food production [

1], thereby leading to an expansion of agricultural and livestock activities worldwide. This increasing agricultural output is accompanied by the generation of large volumes of organic residues, which, if not managed properly, pose significant environmental challenges [

2]. One of the most well-established technologies regarding the treatment of such organic waste is the AD process. AD is a biological process where microorganisms degrade organic matter under oxygen-free conditions. AD simultaneously enables renewable energy generation in the form of biogas (~60% CH4, 40% CO

2, trace gases) [

3] and reduces the organic load of waste, mitigating environmental pollution. In addition, the possibility of digestate utilisation as a potential biofertilizer enables nutrient recycling, positioning AD as a key technology for advancing circular economy strategies in the agri-food sector [

4].

In recent years, poultry production has shown remarkable growth worldwide, and is expected to keep growing, as the projected increase for meat and eggs is 21% and 16.6%, respectively, by the end of 2034 [

5]. As a result, large quantities of poultry manure are produced, requiring proper treatment and management. Poultry manure constitutes a promising substrate for AD, due to its high protein content and estimated methane yield in the range of 200–360 mL CH

4 g

−1 VS [

6].

Pretreating substrates prior to AD has the potential to accelerate the hydrolysis of complex organic matter and improve overall AD process performance. Extensive research has been conducted on the application of chemical, physical, and biological pretreatments that are effective in altering the physicochemical structures and improving the biodegradability of various substrates. Among these, ultrasonication, homogenization, and thermal hydrolysis have shown effectiveness for substrates with high protein content, such as poultry manure [

7]. However, these pretreatments, especially conventional thermal hydrolysis, which is typically conducted at elevated temperatures (>100 °C), often increase the operational cost of AD due to higher energy requirements. In contrast, mild thermal hydrolysis performed at lower temperatures (50–80 °C) requires significantly less energy and can often utilise residual heat recovered from combined heat and power (CHP) units in biogas plants, thus minimizing the additional operational cost of this method [

8,

9]. Furthermore, the application of mild thermal hydrolysis enhances solubilisation of organic compounds and methane yield [

10], while simultaneously contributing to feedstock decontamination, which may affect the AD process [

11]. Thus, this pretreatment represents a potentially promising strategy to improve the AD of poultry manure.

Despite these benefits, thermal hydrolysis also increases nitrogen release, thereby influencing the total ammonium nitrogen (TAN) and free ammonia nitrogen (FAN) levels in subsequent AD stages [

12]. Thus, the use of poultry manure in the AD process poses significant challenges due to its high nitrogen content [

13]. Poultry manure contains elevated levels of proteins, uric acid, and other nitrogenous compounds that release ammonia during hydrolysis [

14]. As a result, high ammonia concentrations can inhibit methanogenic activity and compromise process stability by disturbing the methanogenic microbiome [

15]. In severe cases, provided the AD process does not collapse completely, methane production yield can decrease by more than one-third of the expected methane potential, limiting the efficient utilisation of poultry manure in full-scale AD plants [

16].

Several strategies have been proposed to mitigate ammonia inhibition in AD systems. Conventional approaches include dilution with water and co-digestion with carbon-rich substrates to increase the C/N ratio and retain a balance in the AD process [

17,

18]. However, the practical application of such strategies, which are cost-expensive and time-consuming, is also often constrained by limited availability of suitable co-substrates and the overall cost [

19]. This limitation hinders the ability to adjust the feeding mixture appropriately, resulting in feedstock storage for extended periods. Such storage conditions can result in organic matter loss and generate fluctuations in the organic loading rate (OLR), ultimately decreasing the overall energy recovery efficiency at a constant hydraulic retention time (HRT) [

20,

21]. Other approaches include physicochemical methods such as ammonia stripping, adsorption using ion-exchange materials, or chemical precipitation [

19,

22]. While these can reduce TAN concentrations, they often increase operational costs and process complexity [

23,

24], thus compromising both the energy efficiency and the economic feasibility of AD systems. These limitations collectively underline the need for alternative solutions that can stabilise and even improve the AD process without compromising the environmental and economic outputs of the full-scale AD plants.

One promising approach is bioaugmentation, where acclimatised microbial communities are introduced into the reactor to enhance process stability under inhibitory conditions [

25]. Bioaugmentation has been successfully applied to overcome challenges such as high OLRs, accumulation of volatile fatty acids (VFA), and degradation of recalcitrant compounds, demonstrating its versatility as a process intensification tool [

26]. In the context of nitrogen-rich substrates such as poultry manure, the primary advantage of bioaugmentation is its capacity to mitigate ammonia inhibition and stabilise methanogenic pathways, particularly by reinforcing hydrogenotrophic methanogens that are more tolerant to elevated ammonia concentrations [

27,

28]. Moreover, bioaugmentation accelerates the ammonia acclimatisation period and facilitates rapid recovery following inhibitory shocks, thereby preventing long-term process destabilization [

16].

The aforementioned beneficial effects highlight the importance of carefully evaluating the combination of pretreatment methods and microbial community adaptation to maximise methane production while maintaining process stability. Despite increasing nitrogen release, mild thermal hydrolysis can be a valuable tool, combined with bioaugmentation, to improve substrate solubilisation and overall AD performance. In contrast to conventional mitigation strategies that aim to reduce or remove ammonia prior to or during AD, the present study targets stable operation under retained high ammonia concentrations, in order to simultaneously sustain and improve methane production while also generating a nitrogen-rich digestate suitable for potential subsequent nutrient recovery and biofertilizer/biostimulant production. However, to the best of our knowledge, no studies have simultaneously investigated the combined application of mild thermal hydrolysis and bioaugmentation for the anaerobic digestion of poultry manure.

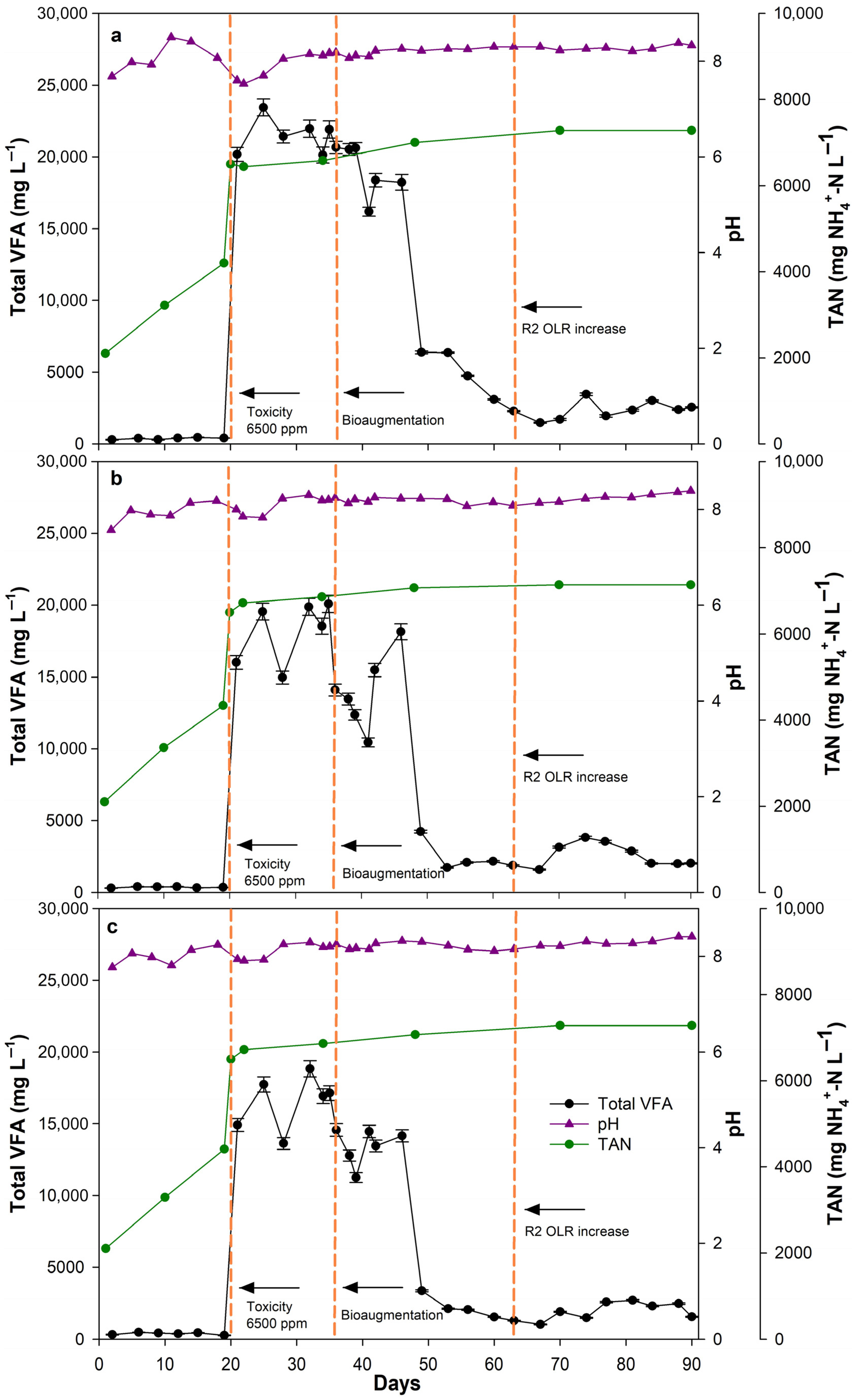

The overall aim of this study was to enhance methane production from poultry manure in mesophilic AD through the combined application of mild thermal hydrolysis and a robust bioaugmentation strategy with an ammonia-acclimatised inoculum. To achieve this aim, the effect of thermal hydrolysis was assessed under different operating conditions on TAN release and methane potential, to determine the most suitable poultry manure pretreatment conditions for the CSTR experiments. The most promising conditions were then applied to the feedstock used in the CSTR reactors, which were subsequently subjected to extremely high ammonia stress (>6500 mg NH4+-N L−1), to induce ammonia inhibition conditions. Bioaugmentation with ammonia-acclimatised inoculum was then tested as a stabilization and enhancement strategy under these conditions. Finally, a secondary aim was to assess continuous AD process robustness, adaptive capacity, and enhanced performance of the already bioaugmented CSTR reactor at extremely high ammonia concentrations (7280 mg NH4+-N L−1), by increasing the OLR.

4. Conclusions

This study demonstrated that the combined application of mild thermal hydrolysis pretreatment and bioaugmentation with ammonia-acclimatised inoculum is an effective strategy to overcome extreme ammonia inhibition in the continuous AD of nitrogen-rich poultry manure. Mild thermal hydrolysis at 70 °C for 60 min enhanced substrate biodegradability, resulting in the highest methane yield during batch assays. Bioaugmentation with ammonia-acclimatised inoculum successfully restored methane production, achieving up to 93% and 100% recovery of pre-inhibition and ammonia-toxicity yields, respectively under extreme ammonia levels (>7000 mg NH4+-N L−1). The results of this study indicate several avenues for future research and practical application. Further investigations should examine the long-term operational stability and microbial community dynamics of hydrolysed and bioaugmented systems, as well as assess the scalability and economic feasibility of this integrated approach in full-scale AD plants. Beyond enhanced methane recovery, the resulting nitrogen-rich digestate represents a valuable co-product with potential for nutrient recovery and valorisation. Given its elevated ammonium and residual organic content, such digestate can be processed into biofertilizers and biostimulants, contributing to nutrient recycling and aligning with the principles of the circular economy. Integrating bioaugmentation strategies with digestate valorisation could therefore enable a closed-loop, resource-efficient system that supports renewable energy generation, sustainable agriculture, and greenhouse gas mitigation within the broader bioenergy framework. Thus, a full techno-economic, energy feasibility, and scale-up assessment of the proposed integrated strategy at industrial scale is identified as a critical objective for future research. This assessment requires long-term operational data, and could include thermal pretreatment, large-scale production of ammonia-acclimatised inoculum, operational requirements, potential coupling with digestate nitrogen recovery processes, and energy input calculations.