Design and Performance Evaluation of Car Seat Heat Pump for Electric Vehicles

Abstract

1. Introduction

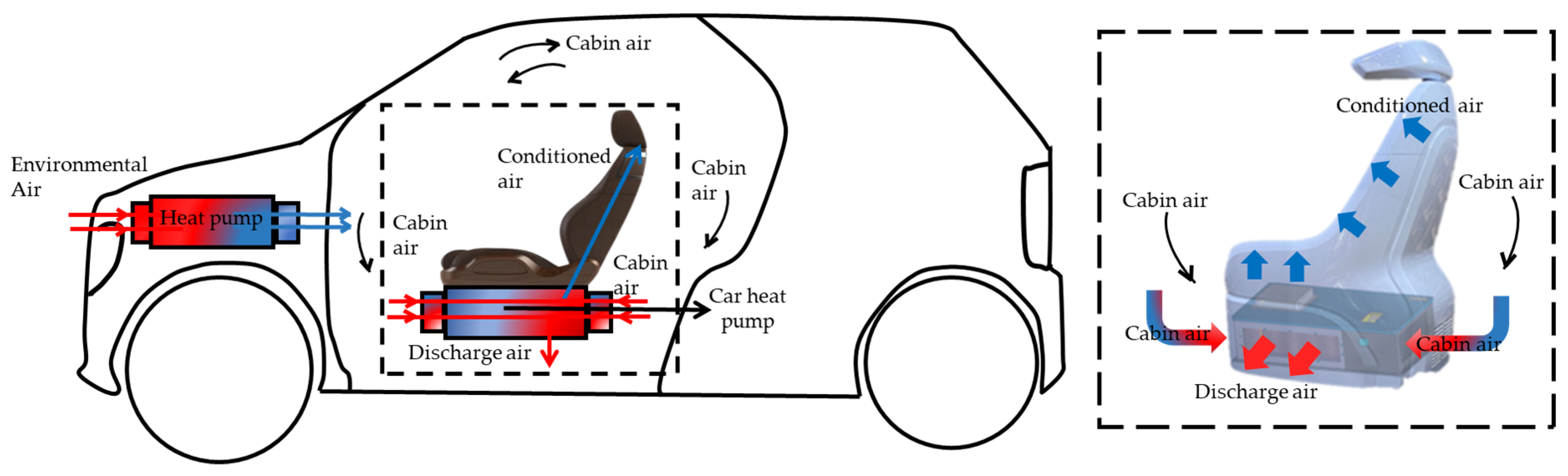

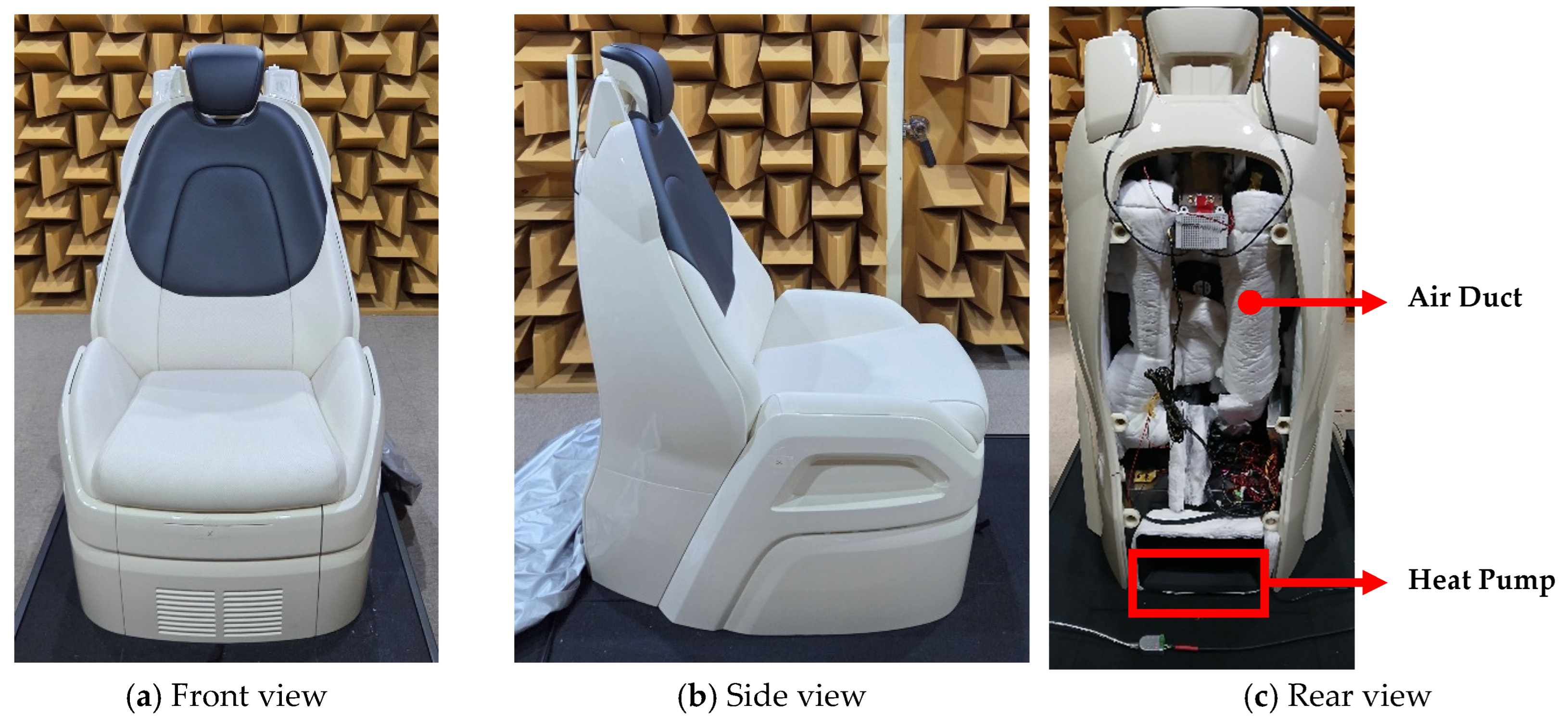

2. Development of Car Seat Heat Pump System

2.1. Heat Pump System

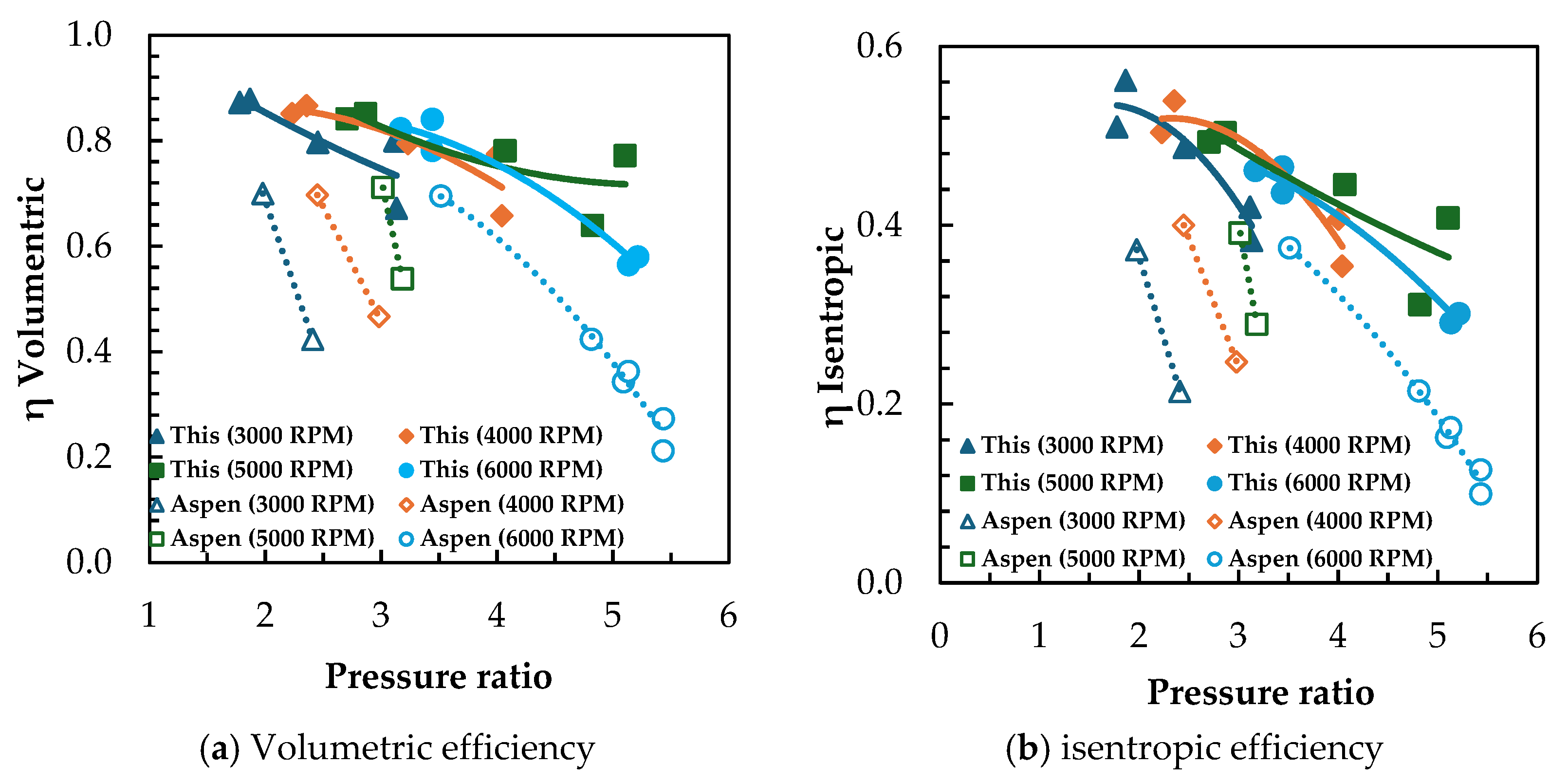

2.2. Electric Compressor

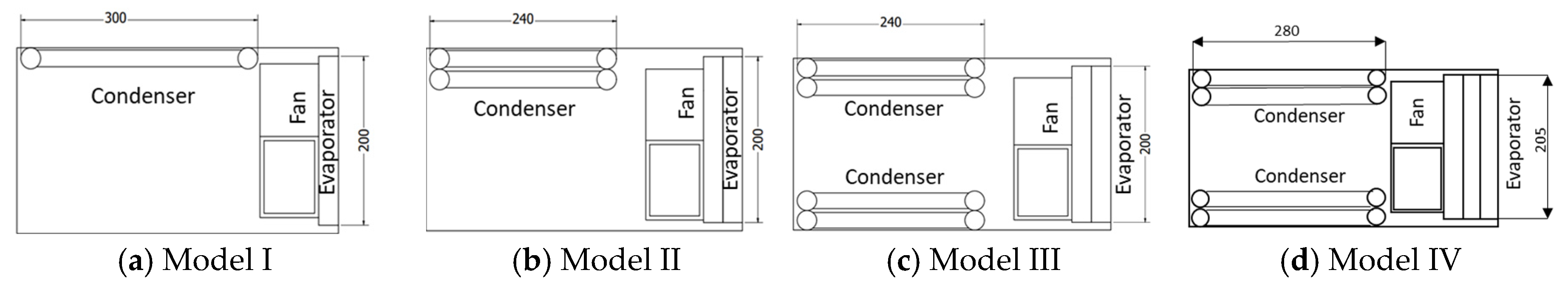

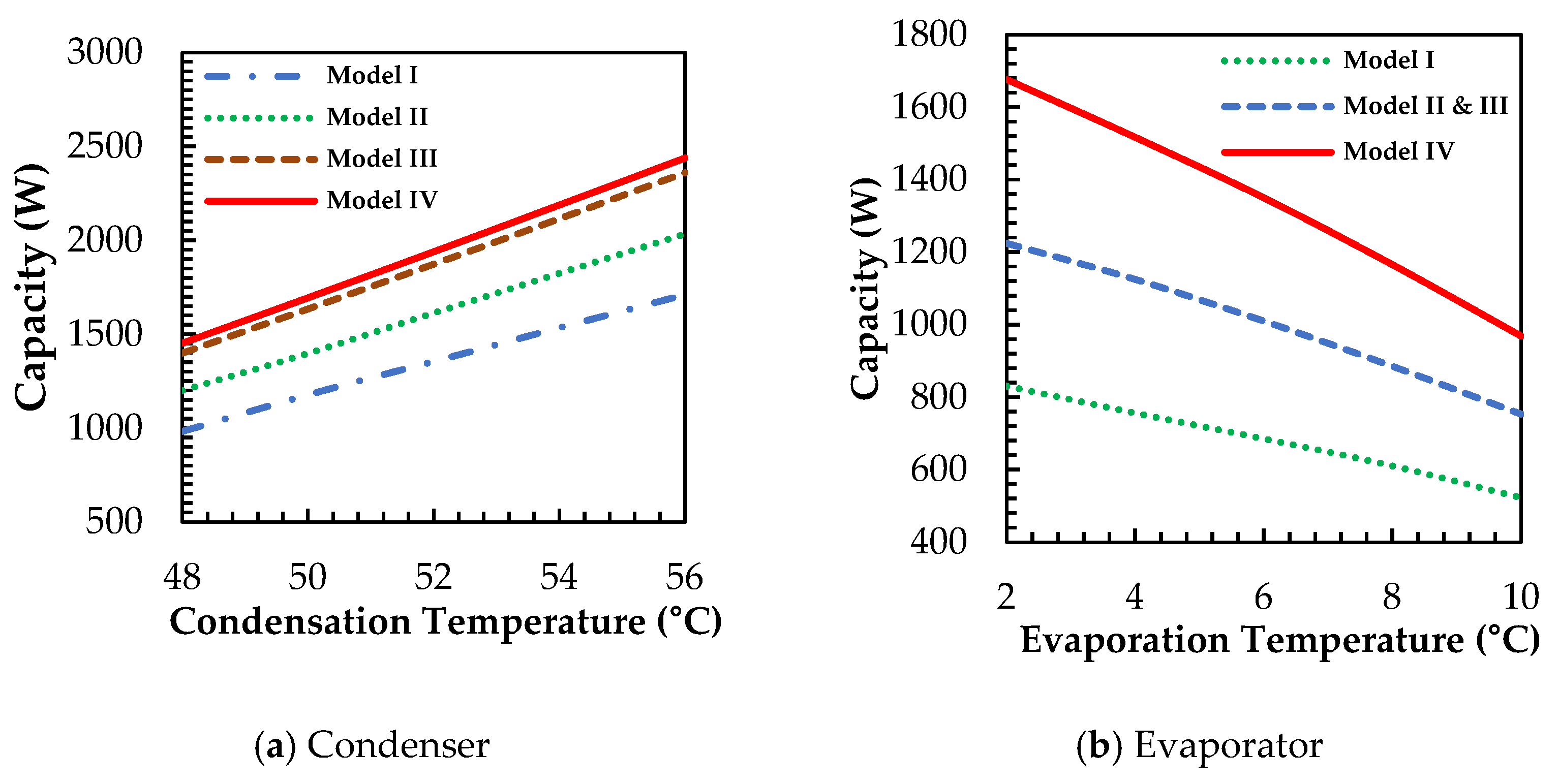

2.3. Heat Exchangers

2.4. Auxiliary Components

3. Test Setup and Conditions

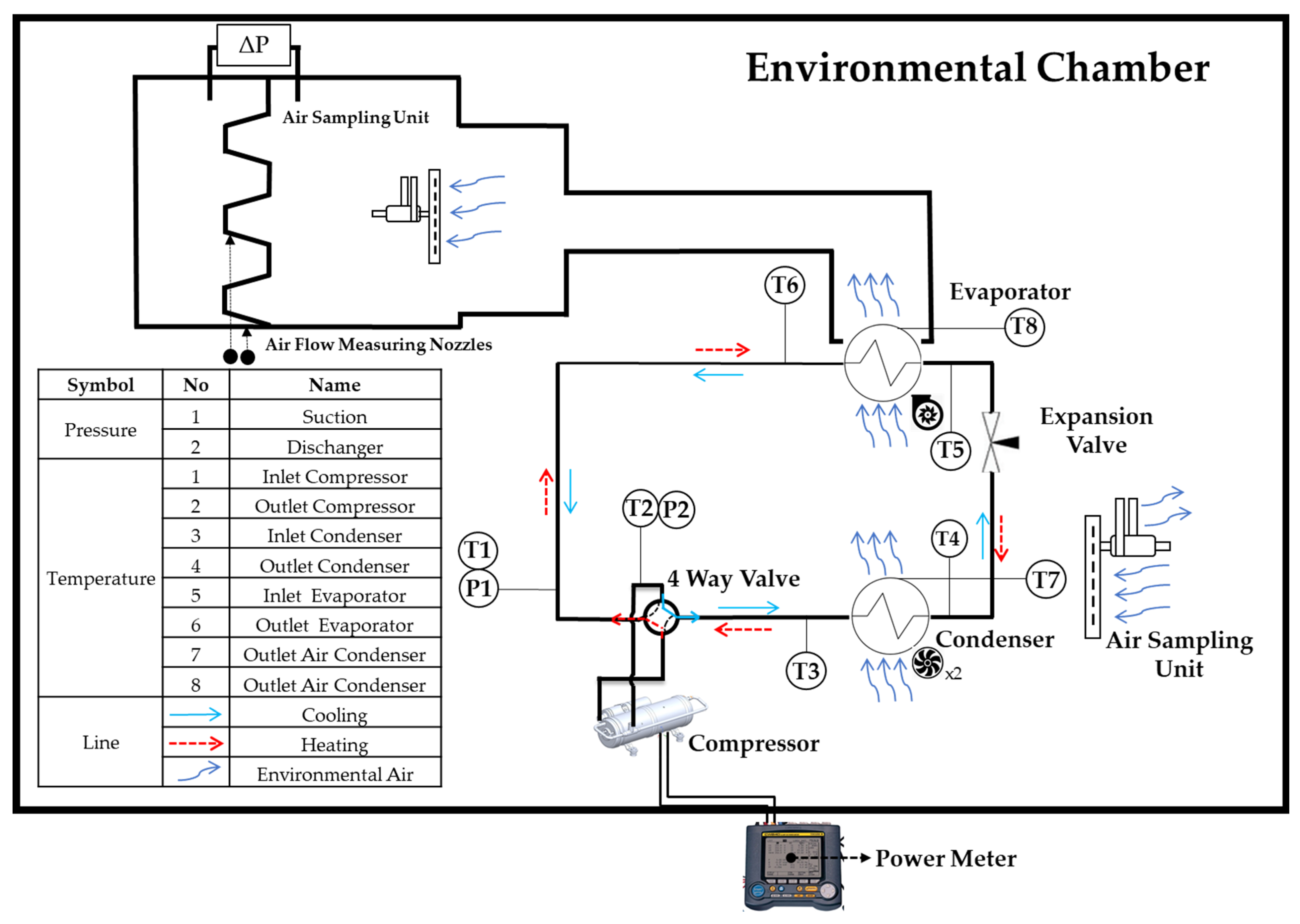

3.1. Test Setup

3.2. Test Conditions

3.3. Data Reduction

3.4. Uncertainty Analysis

4. Result and Discussion

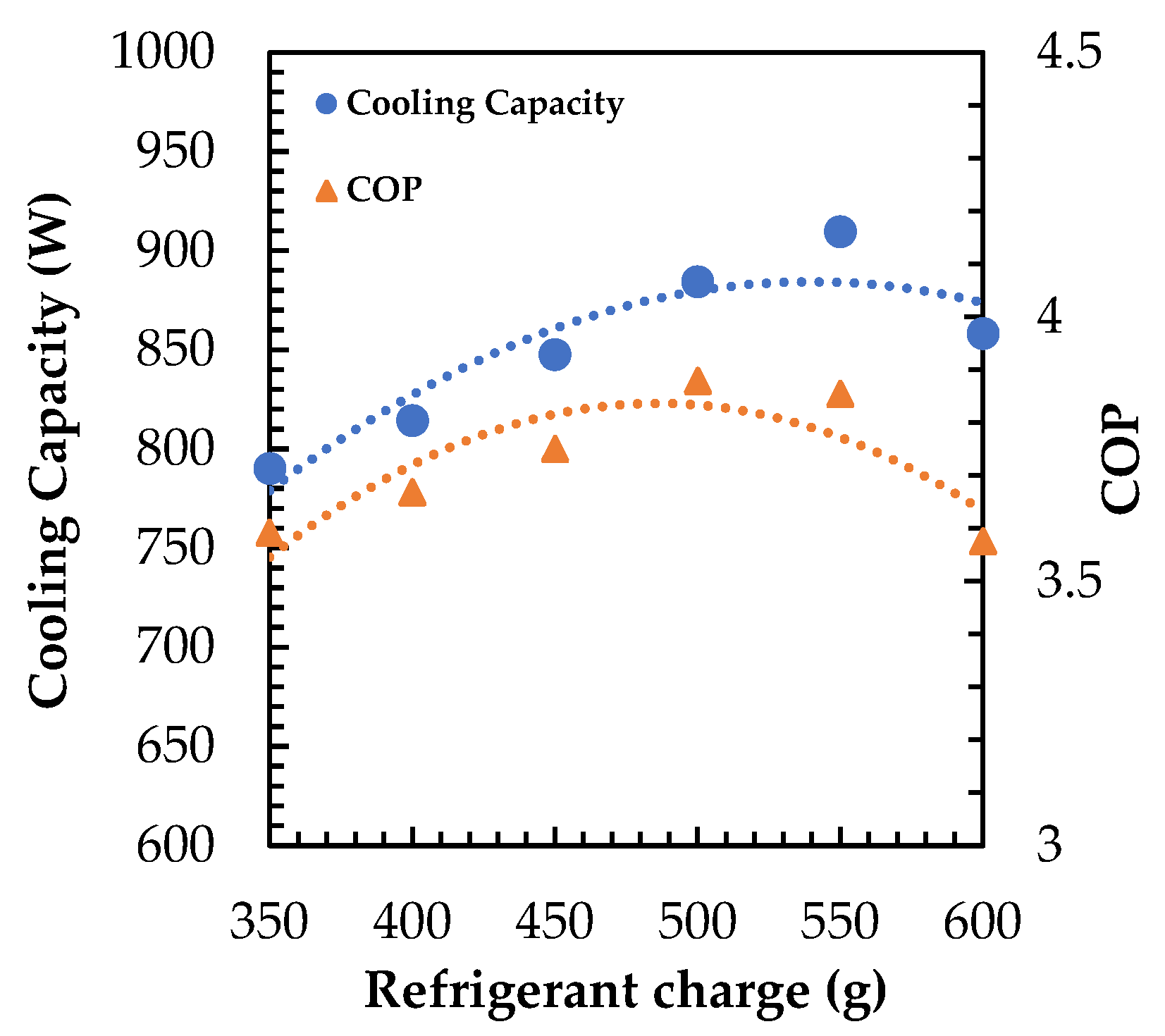

4.1. Optimal Refrigerant Charge

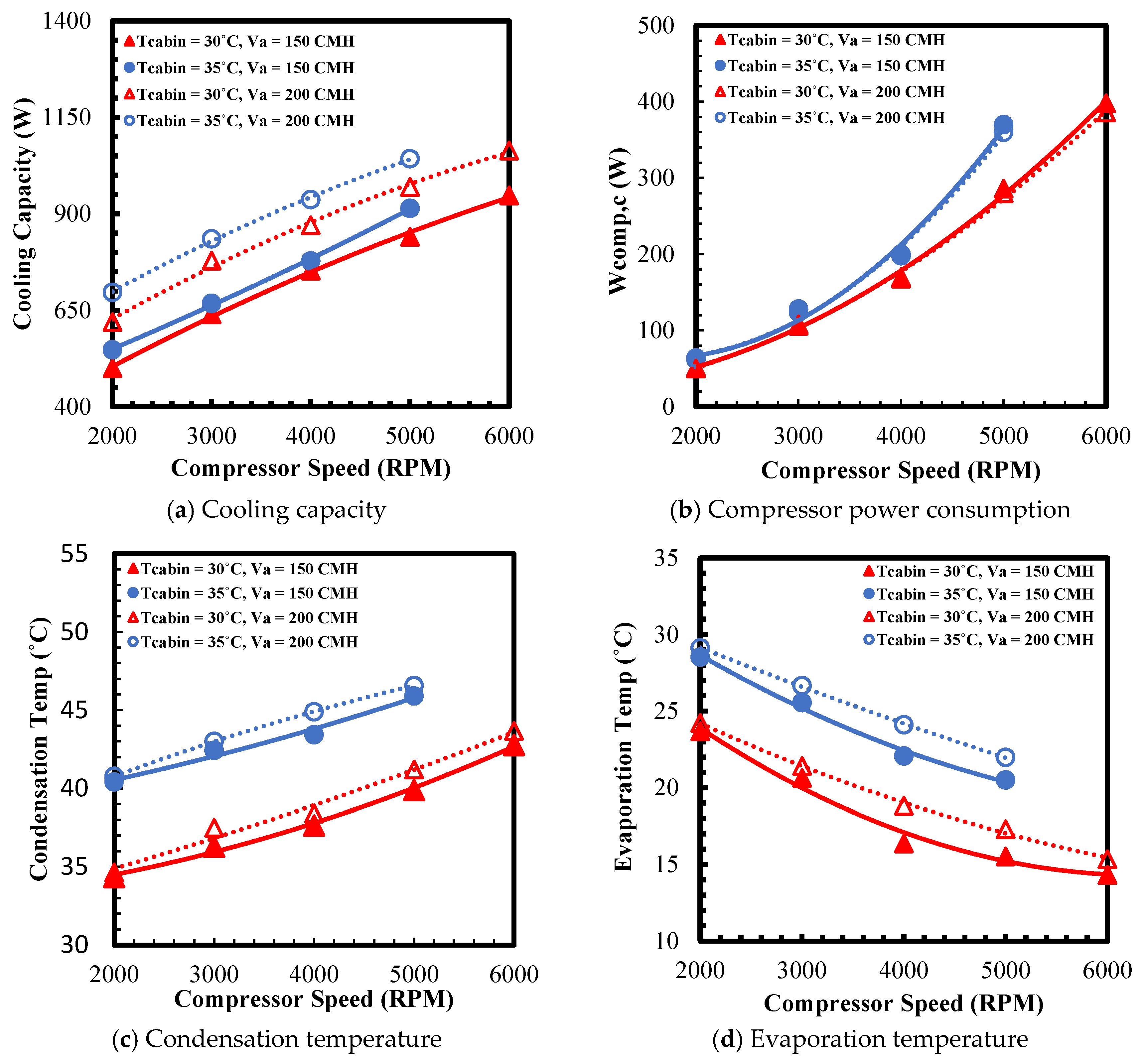

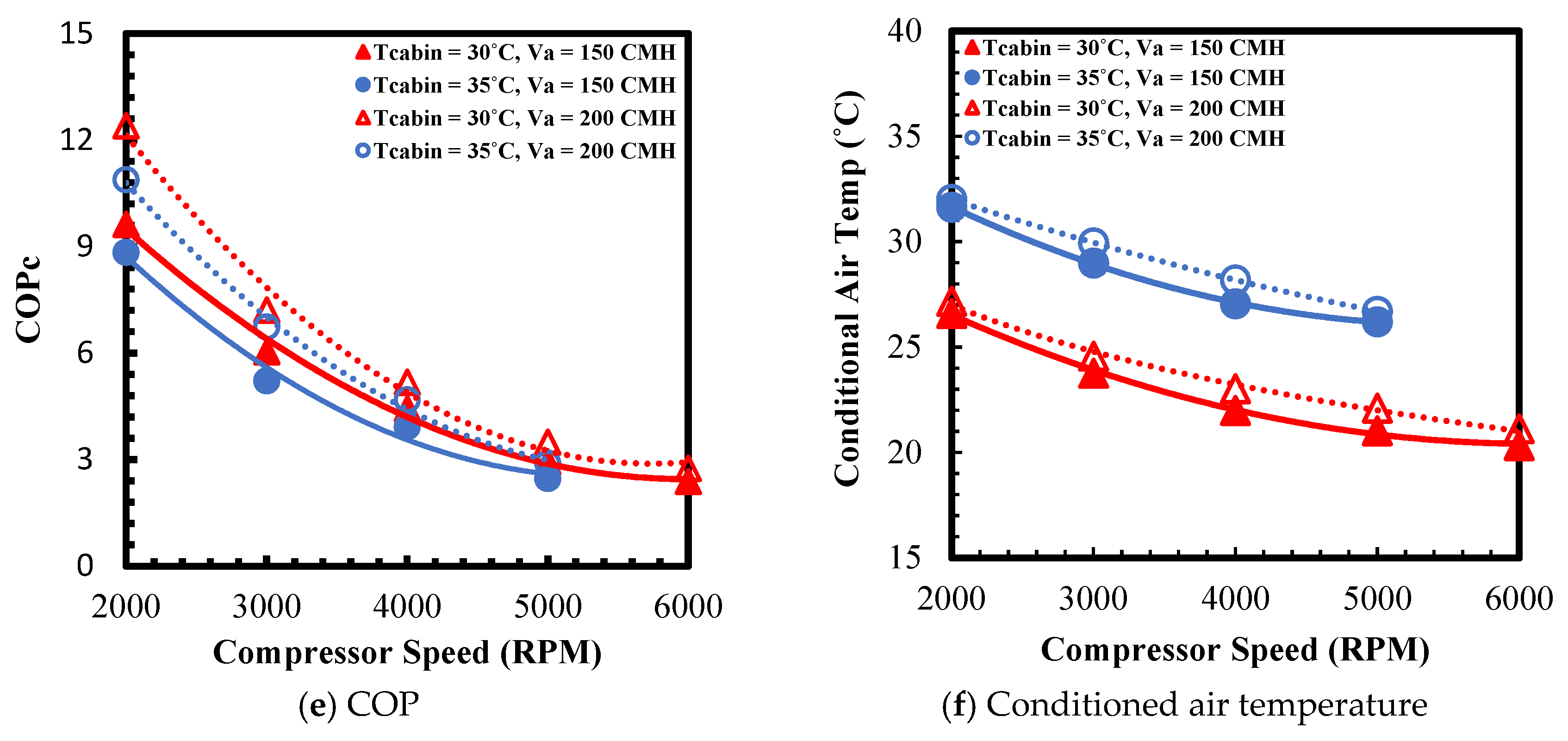

4.2. Cooling Performance

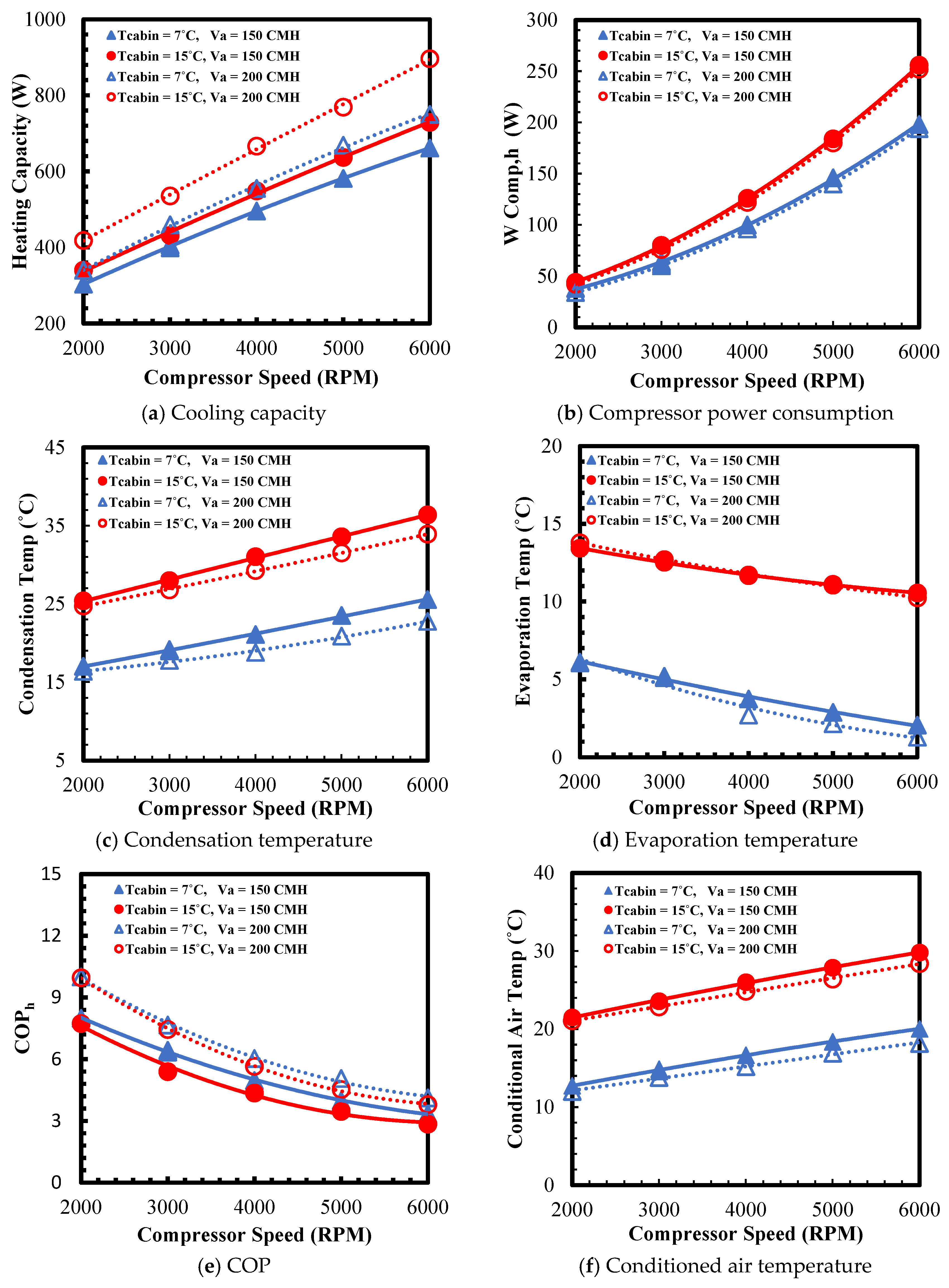

4.3. Heating Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| COP | Coefficient of Performance |

| CMH | Cubic Meter per Hour |

| HVAC | Heating, Ventilation, and Air Conditioning |

| EV | Electric Vehicle |

| MCHX | Microchannel Heat Exchanger |

| RTD | Resistance Temperature Detector |

| RPM | Revolutions Per Minute |

| SgRP | Seating Reference Point |

| H30 | Hip Point (SAE H-point) |

| R1234yf | 2,3,3,3-Tetrafluoropropene (refrigerant) |

| DBT | Dry Bulb Temperature |

| WBT | Wet Bulb Temperature |

| Qc | Cooling Capacity |

| Qh | Heating Capacity |

| Mass Air Flow Rate | |

| Enthalpy Air Inlet | |

| Enthalpy Air Outlet | |

| Specific Heat at Constant Pressure | |

| Temperature Air Inlet | |

| Temperature Air Outlet | |

| Coefficient of Performance of Cooling | |

| Coefficient of Performance of Heating | |

| W | Input Power (compressor) |

| GHG | Greenhouse Gas |

| CO2 | Carbon Dioxide |

| F.S | Full Scale |

| VA | Volumetric Air |

| CMH | Cubic Meter per Hour |

| W | Watt |

References

- Dong, J.; Liu, X.; Xu, X.; Zhang, S. Comparative life cycle assessment of hydrogen pathways from fossil sources in China. Int. J. Energy Res. 2016, 40, 2105–2116. [Google Scholar] [CrossRef]

- Endiz, M.S. A Comparison of Battery and Hydrogen Fuel Cell Electric Vehicles for Clean Transportation. Orclever Proc. Res. Dev. 2023, 2, 10–17. [Google Scholar] [CrossRef]

- Mobasheri, R.; Aitouche, A.; Mumputu, J.B.; Li, X.; Peng, Z. Effect of Intake Charge Temperature on Oxy-Fuel Combustion in an HCCI Diesel Engine Under Different Carbon Dioxide Dilutions. J. Eng. Gas Turbines Power 2023, 145, 011012. [Google Scholar] [CrossRef]

- Khan, A.; Khattak, K.S.; Khan, Z.H.; Khan, M.A.; Minallah, N. Cyber physical system for vehicle counting and emission monitoring. Int. J. Adv. Comput. Res. 2020, 10, 181–193. [Google Scholar] [CrossRef]

- Yang, C.; Wu, H.; Guo, Y.; Hao, Y.; Wang, Z. Promoting economic and environmental resilience in the post-COVID-19 era through the city and regional on-road fuel sustainability development. NPJ Urban Sustain. 2022, 2, 33. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.S.; Park, J.; Kang, B.M.; Cho, C.-H.; Lim, H.; Won, W. Scenario-based techno-economic analysis of steam methane reforming process for hydrogen production. Appl. Sci. 2021, 11, 6021. [Google Scholar] [CrossRef]

- Pyakurel, P.; Quintal, F.; Auger, J.; Hanna, J. Analysis of carbon saving by the adoption of electric vehicles in a region where electricity generation is dominated by thermal power plants. Strateg. Plan. Energy Environ. 2020, 39, 117–130. [Google Scholar] [CrossRef]

- Akar, M.; Eker, M.; Akin, F. BLDC Motor Design and Application for Light Electric Vehicle. Afyon Kocatepe Univ. J. Sci. Eng. 2021, 21, 326–336. [Google Scholar] [CrossRef]

- Kailashkumar, B.; Elanchezhiyan, M. Powering Ahead: Current Landscape of Electric Vehicles (EV) in India. Int. J. Environ. Clim. Change 2024, 14, 639–647. [Google Scholar] [CrossRef]

- Chang, T.B.; Sheu, J.J.; Huang, J.W. High-efficiency hvac system with defog/dehumidification function for electric vehicles. Energies 2021, 14, 46. [Google Scholar] [CrossRef]

- Kulkarni, A.; Brandes, G.; Rahman, A.; Paul, S. A Numerical Model to Evaluate the HVAC Power Demand of Electric Vehicles. IEEE Access 2022, 10, 96239–96248. [Google Scholar] [CrossRef]

- Lesage, M.; Chalet, D.; Migaud, J.; Krautner, C. Holistic approach to improve cabin air quality in electric vehicles and energy savings. In Proceedings of the 36th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, ECOS 2023, Las Palmas de Gran Canaria, Spain, 25–30 June 2023; pp. 2402–2413. [Google Scholar] [CrossRef]

- Bayram, H.; Sevilgen, G.; Kılıç, M. Advances on heat pump applications for electric vehicles. Adv. Automot. Eng. 2018, 1, 79–104. [Google Scholar] [CrossRef]

- Shin, Y.H.; Ahn, S.K.; Kim, S.C. Performance characteristics of PTC elements for an electric vehicle heating system. Energies 2016, 9, 813. [Google Scholar] [CrossRef]

- Cho, C.; Kim, G.; Pyo, Y.L.W. The Development of an Energy-Efficient Heating System for Electric Vehicles; IEEE: Busan, Republic of Korea, 2016. [Google Scholar]

- Habash, R.; Ilis, G.G.; Ünal, Ş.; Saha, B.B. Enhancing COP of electric vehicle cooling systems using adsorption heat pumps. Therm. Sci. Eng. Prog. 2025, 64, 103788. [Google Scholar] [CrossRef]

- Wong, H.; Ramadhan, H.; Milhim, A.B.; Sadjadi, H. Using Charge Determination Design of Experiments to Develop Refrigerant-based Heat Pump System Charge Models. Annu. Conf. PHM Soc. 2023, 15, 1–6. [Google Scholar] [CrossRef]

- Qi, Z. Advances on air conditioning and heat pump system in electric vehicles—A review. Renew. Sustain. Energy Rev. 2014, 38, 754–764. [Google Scholar] [CrossRef]

- Sukarno, R.; Maldini, A.A.; Musyaffa, R.; Yoga, N.G.; Syaka, D.R.B. Preliminary study of the thermoelectric cooler and heat pipe application for the cooling system in cabin pickup car. J. Phys. Conf. Ser. 2024, 2866, 12090. [Google Scholar] [CrossRef]

- Zhang, T.; Ren, J.; Zhang, H. Simulation Analysis of Seat Ventilation Performance Considering Deformation during Human Occupancy. SAE Int. J. Passeng. Veh. Syst. 2025, 18, 119–132. [Google Scholar] [CrossRef]

- Kawaguchi, K.; Kase, D. Temperature Reduction in a Car Cabin under Summer Solar Radiation (Temperature Reduction around Driver’s Seat by Examination of Blowing Direction). Jpn. J. Inst. Ind. Appl. Eng. 2020, 8, 214–221. [Google Scholar] [CrossRef]

- Bayram, H.; Sevilgen, G.; İbiş, A. Otomobillerde Yenilikçi Hava Kanallı Koltuk Tasarımının Deneysel ve Sayısal Olarak İncelenmesi. Gazi Üniv. Bilim. Derg. Part C Tasarım Teknol. 2022, 10, 63–76. [Google Scholar] [CrossRef]

- SAE J1 100; Motor Vehicle Dimensions. SAE International: Warrendale, PA, USA, 1984.

- Compressor Aspen. June 2023. Available online: https://www.aspencompressor.com/copy-of-horizontal-compressors (accessed on 2 October 2025).

- Kim, H.; Al Hakiem, F.Z.; Park, S.H. Development of Low Noise and High Efficiency Small Refrigerant Compressor Technology for Indoor Mounted Local Air-Conditioning and Optimization of Small Heat Pump System. 2025 Summer Academic Conference. Available online: http://conf2025s.sarek.or.kr/ (accessed on 23 October 2025).

- Center for Environmental Energy Engineering (CEEE); CoilDesigner|Center for Environmental Energy Engineering; Center for Environmental Energy Engineering, University of Maryland. Available online: https://ceee.umd.edu/software/coildesigner (accessed on 20 November 2025).

- Jiang, H.; Aute, V.; Radermacher, R. CoilDesigner: A general-purpose simulation and design tool for air-to-refrigerant heat exchangers. Int. J. Refrig. 2006, 29, 601–610. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the Uncertainties in Experimental Results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Elarusi, A.; Attar, A.; Lee, H. Optimal Design of a Thermoelectric Cooling/Heating System for Car Seat Climate Control (CSCC). J. Electron. Mater. 2017, 46, 1984–1995. [Google Scholar] [CrossRef]

- Su, C.; Dong, W.; Deng, Y.; Wang, Y.; Liu, X. Numerical and Experimental Investigation on the Performance of a Thermoelectric Cooling Automotive Seat. J. Electron. Mater. 2018, 47, 3218–3229. [Google Scholar] [CrossRef]

| Safety Limit | Values |

|---|---|

| Max condensing temp. range (°C) | 71 |

| Max discharge temp. range (°C) | 100 |

| Max ambient temp. range (°C) | 49 |

| Max dome temp. (°C) | 100 |

| Max operation pressure (MPa) | 2.4 |

| Name | Aspen [24] | This Study [25] |

|---|---|---|

| Type | Horizontal | Horizontal |

| Width (mm) | 122.1 | 120.1 |

| Height (mm) | 79.5 | 80.1 |

| Length (mm) | 316.4 | 295.3 |

| Displacement (cc/rev) | 5.6 | 5.7 |

| Max. Speed (rpm) | 6500 | 6000 |

| Refrigerant | R1234yf | R1234yf |

| Weight (kg) | 2.4 | 2.4 |

| Rated Power | 440 W | 440 W |

| Operating Voltage (V) | 48 | 48 |

| Name | Evaporator | Condenser | |

|---|---|---|---|

| Heat Exchanger | Width (mm) | 60 | 53 |

| Height (mm) | 150 | 130 | |

| Length (mm) | 205 | 280 | |

| Number of rows | 3 | 2 | |

| Tube | Length (mm) | 118 | 230 |

| Width (mm) | 16 | 20 | |

| Thickness (mm) | 1.3 | 1.4 | |

| Spacing (mm) | 9.3 | 9.4 | |

| Number/row | 12 | 22 | |

| Position | vertical | horizontal | |

| Pass distribution | 10/10/10/10/10/10 | 6/6/6/6 | |

| Fin | Type | Louver | Louver |

| Width (mm) | 16 | 18 | |

| Height (mm) | 8.1 | 8.1 | |

| Pitch (mm) | 1.3 | 1 | |

| Parameters | Cooling | Heating |

|---|---|---|

| Inlet air temperature (Tdry (°C)/Twet (°C)) | 30/22, 35/26 | 15/11, 7/6 |

| Conditioned air flow rate (CMH) | 150, 200 | 150, 200 |

| Compressor rotational speed (RPM) | 2000~6000 | 2000~6000 |

| Parameter | Measurement | Uncertainty |

|---|---|---|

| Dry bulb RTD | Air dry temperature | ±0.25 °C of calibration |

| Wet bulb RTD | Air wet temperature | ±0.25 °C of calibration |

| Pressure transducer | Pressure in refrigerant pipes | ±0.25% of F.S |

| Nozzle differential pressure | Pressure drop at nozzle | ±0.25% of F.S |

| Power meter | Compressor power consumption | ±0.3% of F.S |

| Result of measurement | 10.17% | |

| Result of measurement | 12.50–14.00% | |

| Result of measurement | 10.47–10.50% | |

| Result of measurement | 1.28–8.12% | |

| Result of measurement | 0.84–4.72% | |

| Result of measurement | 14.06–14.90% | |

| Result of measurement | 10.53–11.48% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhammad, A.H.; Fauzan; Hakiem, F.Z.A.; Kim, H.; Park, S.H.; Chang, Y.S. Design and Performance Evaluation of Car Seat Heat Pump for Electric Vehicles. Energies 2025, 18, 6197. https://doi.org/10.3390/en18236197

Muhammad AH, Fauzan, Hakiem FZA, Kim H, Park SH, Chang YS. Design and Performance Evaluation of Car Seat Heat Pump for Electric Vehicles. Energies. 2025; 18(23):6197. https://doi.org/10.3390/en18236197

Chicago/Turabian StyleMuhammad, Alfarabi Habil, Fauzan, Faris Zaiem Al Hakiem, HyunJung Kim, Sung Hoon Park, and Young Soo Chang. 2025. "Design and Performance Evaluation of Car Seat Heat Pump for Electric Vehicles" Energies 18, no. 23: 6197. https://doi.org/10.3390/en18236197

APA StyleMuhammad, A. H., Fauzan, Hakiem, F. Z. A., Kim, H., Park, S. H., & Chang, Y. S. (2025). Design and Performance Evaluation of Car Seat Heat Pump for Electric Vehicles. Energies, 18(23), 6197. https://doi.org/10.3390/en18236197