Reliability, Maintenance, and Safety of Power-to-Hydrogen: Lessons Learned from an Industrial Demonstrator

Abstract

1. Introduction

1.1. Context

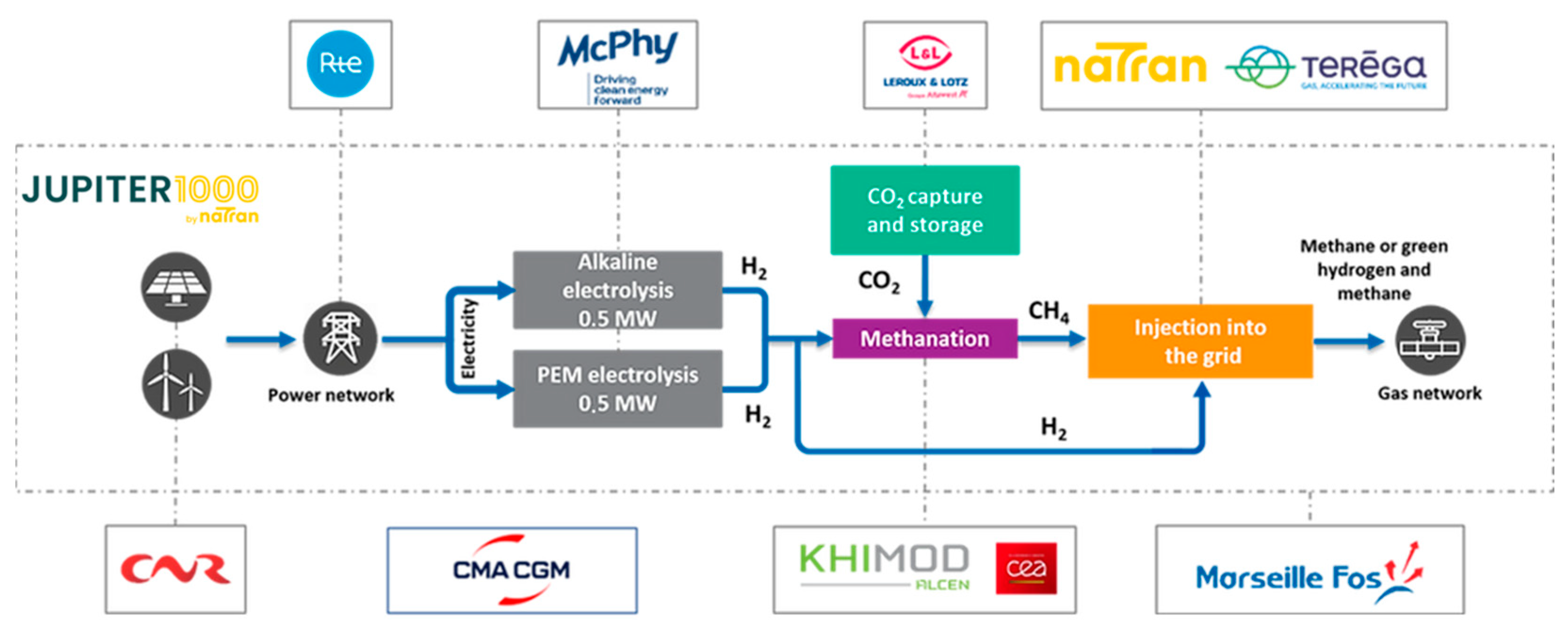

1.2. Jupiter 1000 Project

2. Reliability

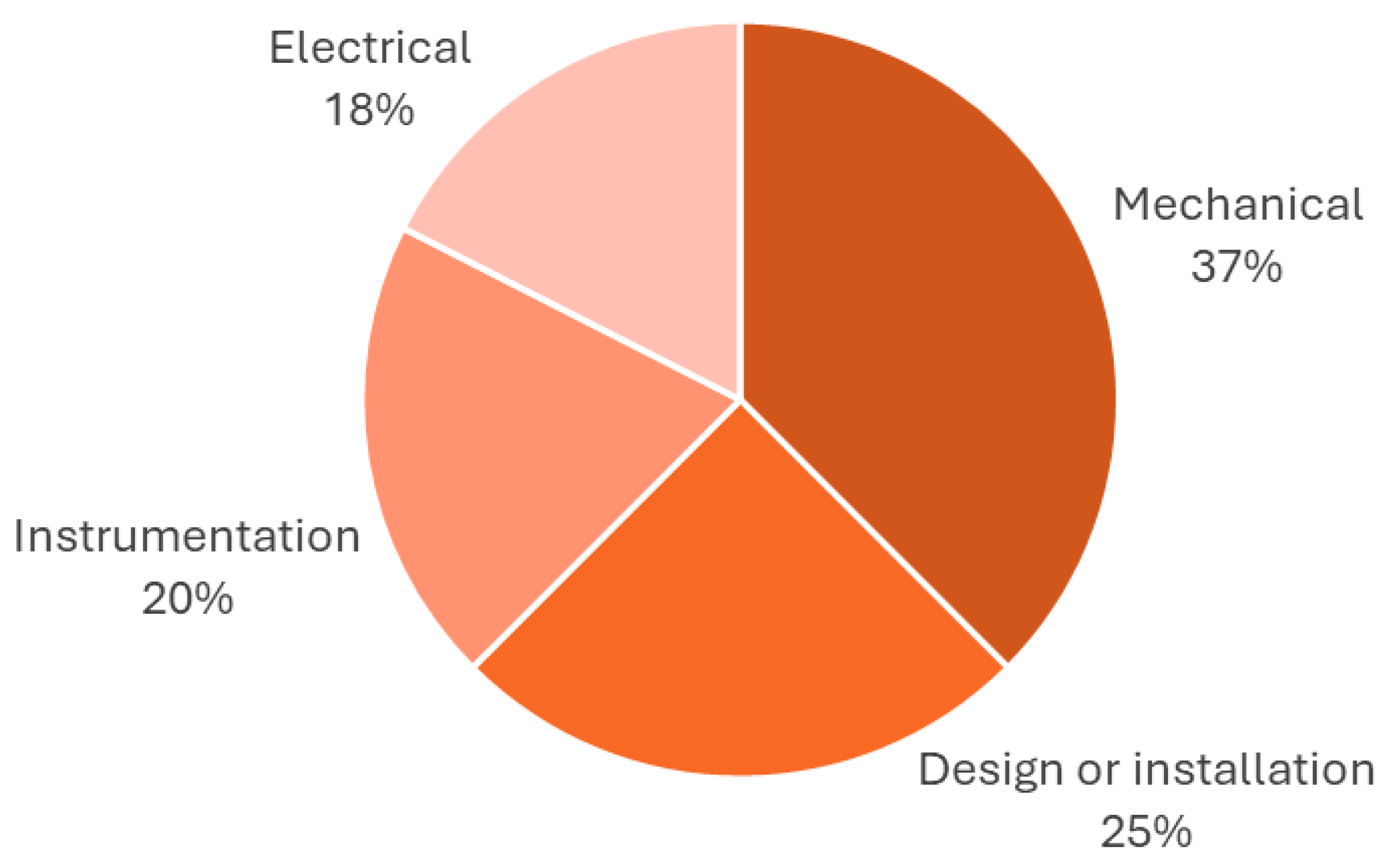

3. Maintenance

4. Safety

4.1. Managing Hydrogen Leaks

4.2. Managing the Risks of Electrolysers

4.3. Other Risks of Power-to-Gas

5. Discussion

6. Conclusions and Perspectives

6.1. Conclusions

- Reindustrialization with suppliers of materials and services (including maintenance) adapted to hydrogen, with enough specialized engineers and technicians with adequate skills;

- Reliability of hydrogen-specific materials, electrolysers and auxiliaries, compressors, and other mechanical systems;

- Creation of a specialty in reliability and risk management for hydrogen production, transmission, storage, and operation;

- Development of solutions for hydrogen safety, particularly for leak management;

- Continuing R&D efforts on hydrogen, especially to increase knowledge of hazardous phenomena, materials, monitoring, and detection.

6.2. Perspectives

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADEME | French Environment and Energy Management Agency |

| CEA | French Alternative Energies and Atomic Energy Commission |

| CFD | Computational Fluid Dynamics |

| CH4 | Methane |

| CNR | National Company of the Rhône |

| CO2 | Carbon dioxide |

| EHB | European Hydrogen Backbone |

| EU | European Union |

| GW | Gigawatt |

| H2 | (Di)hydrogen |

| MW | Megawatt |

| NH3 | Ammonia |

| PEM | Proton Exchange Membrane |

| R&D | Research and Development |

| RTE | Electricity Transmission System Operator (France) |

| TSO | Transmission System Operator |

| WOL | Wedge Opening Loading |

References

- Schiebahn, S.; Grube, T.; Robinius, M.; Tietze, V.; Kumar, B.; Stolten, D. Power to gas: Technological overview, systems analysis and economic assessment for a case study in Germany. Int. J. Hydrogen Energy 2015, 40, 4285–4294. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Brissaud, F. BE6700 V1: Power-to-Gas. Technologies, Challenges and Outlook. Available online: https://www.techniques-ingenieur.fr/en/resources/article/ti202/power-to-gas-be6700/v1 (accessed on 20 November 2025).

- Quan, S.; Mei, J.; Li, D.; Huang, Y.; Li, Z.; Zhu, X.; Wang, H.; Yang, X.; Zhang, M.; Kim, R.-G. A comprehensive evaluation of kinetic reaction mechanisms for NO and N2O emissions during NH3/H2 combustion across multi-temperature regimes. J. Energy Inst. 2025, 123, 102260. [Google Scholar] [CrossRef]

- Sterner, M.; Specht, M. Power-to-Gas and Power-to-X—The History and Results of Developing a New Storage Concept. Energies 2021, 14, 6594. [Google Scholar] [CrossRef]

- Faisal, S.; Gao, C. A Comprehensive Review of Integrated Energy Systems Considering Power-to-Gas Technology. Energies 2024, 17, 4551. [Google Scholar] [CrossRef]

- Smith, O.; Cattell, O.; Farcot, E.; O’Dea, R.D.; Hopcraft, K.I. The effect of renewable energy incorporation on power grid stability and resilience. Sci. Adv. 2022, 8, eabj6734. [Google Scholar] [CrossRef] [PubMed]

- Perna, A.; Moretti, L.; Ficco, G.; Spazzafumo, G.; Canale, L.; Dell’Isola, M. SNG Generation via Power to Gas Technology: Plant Design and Annual Performance Assessment. Appl. Sci. 2020, 10, 8443. [Google Scholar] [CrossRef]

- Inkeri, E.; Tynjälä, T.; Karjunen, H. Significance of methanation reactor dynamics on the annual efficiency of power-to-gas system. Renew. Energy 2021, 163, 1113–1126. [Google Scholar] [CrossRef]

- Gahleitner, G. Hydrogen from renewable electricity: An international review of power-to-gas pilot plants for stationary applications. Int. J. Hydrogen Energy 2013, 38, 2039–2061. [Google Scholar] [CrossRef]

- Wulf, C.; Linssen, J.; Zapp, P. Review of Power-to-Gas Projects in Europe. Energy Procedia 2018, 155, 367–378. [Google Scholar] [CrossRef]

- Barbaresi, A.; Morini, M.; Gambarotta, A. Review on the Status of the Research on Power-to-Gas Experimental Activities. Energies 2022, 15, 5942. [Google Scholar] [CrossRef]

- Ministère de la Transition Écologique et Solidaire. Programmation Pluriannuelle de L’énergie. 2017. Available online: https://www.ecologie.gouv.fr/politiques-publiques/programmations-pluriannuelles-lenergie-ppe (accessed on 20 November 2025). (In French)

- Brissaud, F.; Chaise, A.; Delphin, V.; Palluotto, L.; Gault, K.; Cren, J.; Seguin, V.; Lopez, C.; Bertin, M.; Ferrand, G.; et al. R&D activities on Jupiter 1000, a Power-to-Gas industrial demonstrator with electrolysis, methanation and gas injection to the gas transmission network. In Proceedings of the 28th World Gas Conference, Washington, DC, USA, 23–27 May 2022. [Google Scholar]

- Zhou, Y.; He, C. A Review on Reliability of Integrated Electricity-Gas System. Energies 2022, 15, 6815. [Google Scholar] [CrossRef]

- Sun, Y.; Mao, L.; He, K.; Liu, Z.; Lu, S. Imaging PEMFC performance heterogeneity by sensing external magnetic field. Cell Rep. Phys. Sci. 2022, 3, 101083. [Google Scholar] [CrossRef]

- Norazahar, N.; Khan, F.; Rahmani, N.; Ahmad, A. Degradation modelling and reliability analysis of PEM electrolyzer. Int. J. Hydrogen Energy 2024, 50, 842–856. [Google Scholar] [CrossRef]

- Liu, J.; Le, W.; Zhang, X.; Gulizhaina, H.; Xuedi, C.; Lihua, H. Study on interdigital flow field structure and two-phase flow characteristics of PEM electrolyzer. Chem. Eng. Process. Process Intensif. 2024, 202, 109868. [Google Scholar] [CrossRef]

- Zeng, Z.; Ding, T.; Xu, Y.; Yang, Y.; Dong, Z. Reliability Evaluation for Integrated Power-Gas Systems with Power-to-Gas and Gas Storages. IEEE Trans. Power Syst. 2020, 35, 571–583. [Google Scholar] [CrossRef]

- Wang, S.; Hui, H.; Ding, Y.; Song, Y. Long-term reliability evaluation of integrated electricity and gas systems considering distributed hydrogen injections. Appl. Energy 2024, 356, 122374. [Google Scholar] [CrossRef]

- Wang, S.; Hui, H.; Zhai, J. Short-Term Reliability Assessment of Integrated Power-Gas Systems with Hydrogen Injections Using Universal Generating Function. IEEE Trans. Ind. Appl. 2023, 59, 5760–5773. [Google Scholar] [CrossRef]

- Brissaud, F.; Chaise, A.; Gault, K.; Soual, S. Lessons learned from Jupiter 1000, an industrial demonstrator of Power-to-Gas. Int. J. Hydrogen Energy 2024, 49, 925–932. [Google Scholar] [CrossRef]

- Upadhyay, M.; Kim, A.; Paramanantham, S.S.; Kim, H.; Lim, D.; Lee, S.; Moon, S.; Lim, H. Three-dimensional CFD simulation of proton exchange membrane water electrolyser: Performance assessment under different condition. Appl. Energy 2022, 306, 118016. [Google Scholar] [CrossRef]

- Ni, A.; Upadhyay, M.; Kumar, S.; Uwitonze, H.; Lim, H. Anode analysis and modelling hydrodynamic behaviour of the multiphase flow field in circular PEM water electrolyzer. Int. J. Hydrogen Energy 2023, 48, 16176–16183. [Google Scholar] [CrossRef]

- Kurtz, J.; Sprik, S.; Bradley, T.H. Review of transportation hydrogen infrastructure performance and reliability. Int. J. Hydrogen Energy 2019, 44, 12010–12023. [Google Scholar] [CrossRef]

- Liu, K.; He, C.; Yu, Y.; Guo, C.; Lin, S.; Jiang, J. A study of hydrogen leak and explosion in different regions of a hydrogen refueling station. Int. J. Hydrogen Energy 2023, 48, 14112–14126. [Google Scholar] [CrossRef]

- Navajas, J.; Badia, E.; Eloy Candás, C.; Sala, R.; Kingston, J.; Sato, H.; Paltrinieri, N. A comprehensive analysis of hydrogen refuelling station incidents: Unveiling contributing factors. J. Loss Prev. Process Ind. 2025, 97, 105698. [Google Scholar] [CrossRef]

- Groth, K.M.; Al-Douri, A.; West, M.; Hartmann, K.; Saur, G.; Buttner, W. Design and requirements of a hydrogen component reliability database (HyCReD). Int. J. Hydrogen Energy 2023, 51, 1023–1037. [Google Scholar] [CrossRef]

- Bouledroua, O.; Hafsi, Z.; Djukic, M.B.; Elaoud, S. The synergistic effects of hydrogen embrittlement and transient gas flow conditions on integrity assessment of a precracked steel pipeline. Int. J. Hydrogen Energy 2020, 45, 18010–18020. [Google Scholar] [CrossRef]

- Campari, A.; Ustolin, F.; Alvaro, A.; Paltrinieri, N. A review on hydrogen embrittlement and risk-based inspection of hydrogen technologies. Int. J. Hydrogen Energy 2023, 48, 35316–35346. [Google Scholar] [CrossRef]

- Li, J.; Song, F.; Zhang, X. A Review on Hazards and Risks to Pipeline Operation under Transporting Hydrogen Energy and Hydrogen-mixed Natural Gas. Sci. Technol. Energy Transit. 2024, 79, 9. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, J.; Yu, Z.; Zhang, C.; Gao, S.; Wang, P. Experimental studies and modeling of a 250-kW alkaline water electrolyzer for hydrogen production. J. Power Sources 2022, 544, 231886. [Google Scholar] [CrossRef]

- Rauls, E.; Hehemann, M.; Keller, R.; Scheepers, F.; Müller, M.; Stolten, D. Favorable Start-Up behavior of polymer electrolyte membrane water electrolyzers. Appl. Energy 2023, 330, 120350. [Google Scholar] [CrossRef]

- Académie des Sciences. L’hydrogène Aujourd’hui et Demain. 2024. Available online: https://www.academie-sciences.fr/en/node/1895 (accessed on 20 November 2025). (In French).

- France Hydrogène. L’hydrogène en France en 2024: Une Dynamique Industrielle. 2024. Available online: https://www.france-hydrogene.org/france-hydrogene-publie-son-rapport-annuel-lhydrogene-en-france-une-dynamique-industrielle/ (accessed on 20 November 2025). (In French).

- Cheung, A.; Tan, M. Energy Transition Investment Trends 2023; BloombergNEF: London, UK, 2023. [Google Scholar]

- Center on Global Energy Policy. National Hydrogen Strategies & Roadmaps Tracker. 2025. Available online: https://www.energypolicy.columbia.edu/wp-content/uploads/2025/02/H2-Strategies_July-2025.pdf (accessed on 20 November 2025).

- Surla, K. J 6368 V2: Hydrogen. Available online: https://www.techniques-ingenieur.fr/en/resources/article/ti452/hydrogen-j6368/v2 (accessed on 20 November 2025).

- Ocko, I.B.; Hamburg, S.P. Climate consequences of hydrogen emissions. Atmos. Chem. Phys. 2022, 22, 9349–9368. [Google Scholar] [CrossRef]

- Buttner, W.J.; Post, M.B.; Burgess, R.; Rivkin, C. An overview of hydrogen safety sensors and requirements. Int. J. Hydrogen Energy 2011, 36, 2462–2470. [Google Scholar] [CrossRef]

- Melaina, M.W.; Sozinova, O.; Penev, M. Blending Hydrogen into Natural Gas Pipeline Networks: A Review of Key Issues; NREL/TP-5600-51995; National Renewable Energy Laboratory: Golden, CO, USA, 2013. [Google Scholar]

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: A review. Renew. Sustain. Energy Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Soual, S.; Brissaud, F.; Lazrek, R. A Reliability, Durability and Safety Study of Alkaline and Polymer Electrolyte Membrane Electrolyzers. In Proceedings of the 31th European Safety and Reliability Conference, Angers, France, 19–23 September 2021. [Google Scholar]

- McPhy. Information Update Regarding the Leakage of Potassium Hydroxide in Grenzach-Wyhlen, Germany. Press Releases. 2021. Available online: https://mcphy-finance.com/images/PDF/cp/gb/2021/21.09.28.McPhy_Information_GW_EN_VDef_17h45.pdf (accessed on 20 November 2025).

- Ministère de la Transition Écologique et Solidaire. Stratégie National Bas-Carbone—La Transition Écologique et Solidaire vers la Neutralité Carbone. 2020. Available online: https://www.ecologie.gouv.fr/politiques-publiques/strategie-nationale-bas-carbone-snbc (accessed on 20 November 2025). (In French)

- French Government. Stratégie Nationale pour le Développement de L’hydrogène Décarbonée en France. 2023. Available online: https://www.ecologie.gouv.fr/sites/default/files/documents/DP%20-%20Strat%C3%A9gie%20nationale%20pour%20le%20d%C3%A9veloppement%20de%20l%27hydrog%C3%A8ne%20d%C3%A9carbon%C3%A9%20en%20France.pdf (accessed on 20 November 2025). (In French)

- French Government. Stratégie Nationale de L’hydrogène Décarbonée 2025. 2025. Available online: https://www.economie.gouv.fr/files/2025-04/strategie_nationale_hydrogene_decarbone_2025.pdf (accessed on 20 November 2025). (In French)

- European Commission. REPowerEU. 2022. Available online: https://commission.europa.eu/topics/energy/repowereu_en (accessed on 20 November 2025).

- European Hydrogen Backbone. EHB Initiative to Provide Insights on Infrastructure Development by 2030. 2023. Available online: https://ehb.eu/files/downloads/EHB-initiative-to-provide-insights-on-infrastructure-development-by-2030.pdf (accessed on 20 November 2025).

- International Energy Agency. Global Hydrogen Review 2024. 2024. Available online: https://www.iea.org/reports/global-hydrogen-review-2024 (accessed on 20 November 2025).

- Grigoriev, S.A.; Shtatniy, I.G.; Millet, P.; Porembsky, V.I.; Fateev, V.N. Description and characterization of an electrochemical hydrogen compressor/concentrator based on solid polymer electrolyte technology. Int. J. Hydrogen Energy. 2011, 36, 4148–4155. [Google Scholar] [CrossRef]

- Marciuš, D.; Kovač, A.; Firak, M. Electrochemical hydrogen compressor: Recent progress and challenges. Int. J. Hydrogen Energy 2022, 47, 24179–24193. [Google Scholar] [CrossRef]

- Zou, J.; Han, N.; Yan, J.; Feng, Q.; Wang, Y.; Zhao, Z.; Fan, J.; Zeng, L.; Li, H.; Wang, H. Electrochemical Compression Technologies for High-Pressure Hydrogen: Current Status, Challenges and Perspective. Electrochem. Energy Rev. 2020, 3, 690–729. [Google Scholar] [CrossRef]

- Aziz, M.; Amrite, A.; Raj Aryal, U.; Prasad, A.K. Electrochemical Hydrogen Separation and Compression. J. Appl. Electrochem. 2025, 55, 2369–2383. [Google Scholar] [CrossRef]

- Tuhi, F.Y.; Bucelli, M.; Liu, Y. Technical failures in green hydrogen production and reliability engineering responses: Insights from database analysis and a literature review. Int. J. Hydrogen Energy 2024, 94, 608–625. [Google Scholar] [CrossRef]

- Al-Douri, A.; Groth, K.M. Hydrogen production via electrolysis: State-of-the-art and research needs in risk and reliability analysis. Int. J. Hydrogen Energy 2024, 63, 775–785. [Google Scholar] [CrossRef]

- Li, F.; Liu, D.; Sun, K.; Yang, S.; Peng, F.; Zhang, K.; Guo, G.; Si, Y. Towards a Future Hydrogen Supply Chain: A Review of Technologies and Challenges. Sustainability 2024, 16, 1890. [Google Scholar] [CrossRef]

- Risco-Bravo, A.; Varela, C.; Bartels, J.; Zondervan, E. From green hydrogen to electricity: A review on recent advances, challenges, and opportunities on power-to-hydrogen-to-power systems. Renew. Sustain. Energy Rev. 2024, 189, 113930. [Google Scholar] [CrossRef]

- Godelier, M. Grand Flou Autour du Mégaprojet D’hydrogène vert de TotalEnergies et Engie. La Tribune. 2024. Available online: https://www.latribune.fr/climat/energie-environnement/grand-flou-autour-du-megaprojet-d-hydrogene-vert-de-totalenergies-et-engie-998255.html (accessed on 20 November 2025). (In French).

- Godelier, M. Hydrogène Vert: À la Peine, le Mégaprojet de TotalEnergies et Engie Largement Revu à la Baisse. La Tribune. 2024. Available online: https://www.latribune.fr/climat/energie-environnement/hydrogene-vert-a-la-peine-le-megaprojet-de-totalenergies-et-engie-largement-revu-a-la-baisse-1000285.html (accessed on 20 November 2025). (In French).

- GRTgaz; RTE. Enjeux du Développement des Infrastructures de Stockage et de Transport D’hydrogène Associés au Développement de L’électrolyse et Leviers D’optimisation Avec le Système électrique. 2023. Available online: https://assets.rte-france.com/prod/public/2023-08/2023-08-01-enjeux-developpement-infrastructures-stockage-transport.pdf (accessed on 20 November 2025). (In French).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brissaud, F. Reliability, Maintenance, and Safety of Power-to-Hydrogen: Lessons Learned from an Industrial Demonstrator. Energies 2025, 18, 6184. https://doi.org/10.3390/en18236184

Brissaud F. Reliability, Maintenance, and Safety of Power-to-Hydrogen: Lessons Learned from an Industrial Demonstrator. Energies. 2025; 18(23):6184. https://doi.org/10.3390/en18236184

Chicago/Turabian StyleBrissaud, Florent. 2025. "Reliability, Maintenance, and Safety of Power-to-Hydrogen: Lessons Learned from an Industrial Demonstrator" Energies 18, no. 23: 6184. https://doi.org/10.3390/en18236184

APA StyleBrissaud, F. (2025). Reliability, Maintenance, and Safety of Power-to-Hydrogen: Lessons Learned from an Industrial Demonstrator. Energies, 18(23), 6184. https://doi.org/10.3390/en18236184