Impact of the Use of Predictive Cruise Control in Freight Transport on Energy Consumption

Abstract

1. Introduction

- -

- To assess the fuel-saving potential of Predictive Cruise Control (PCC) in real-world driving conditions on a mixed-terrain route;

- -

- To compare the operational characteristics (speed, engine power utilization, fuel consumption) of a heavy-duty vehicle equipped with PCC to those of a manually driven vehicle on the same route;

- -

- To quantify the impact of PCC on specific effective fuel consumption under the defined testing conditions.

2. Materials and Methods

- Arithmetic mean;

- Range;

- Mean deviation;

- Variance;

- Standard deviation.

| Simple arithmetic mean [L/100 km]; | |

| Sum of individual values [-]; | |

| Total frequency [-]. |

| Range [L/100 km]; | |

| Maximum value of the statistical set [L/100 km]; | |

| Minimum value of the statistical set [L/100 km]. |

| Mean deviation [L/100 km]; | |

| Sum of absolute values of deviations of the statistical character [L/100 km]; | |

| Total frequency [-]. |

| Variance [L/100 km]; | |

| Sum of the squared deviations of the statistical character [L/100 km]; | |

| Total frequency [-]. |

| Standard Deviation [L/100 km]; | |

| Sum of the squared deviations of the statistical character [L/100 km]; | |

| Total frequency [-]. |

| Correlation coefficient [-]; | |

| Total frequency [-]; | |

| Sum of the partial products of variables X and Y [-]; | |

| Sum of variable X [-]; | |

| Sum of variable Y [-]. |

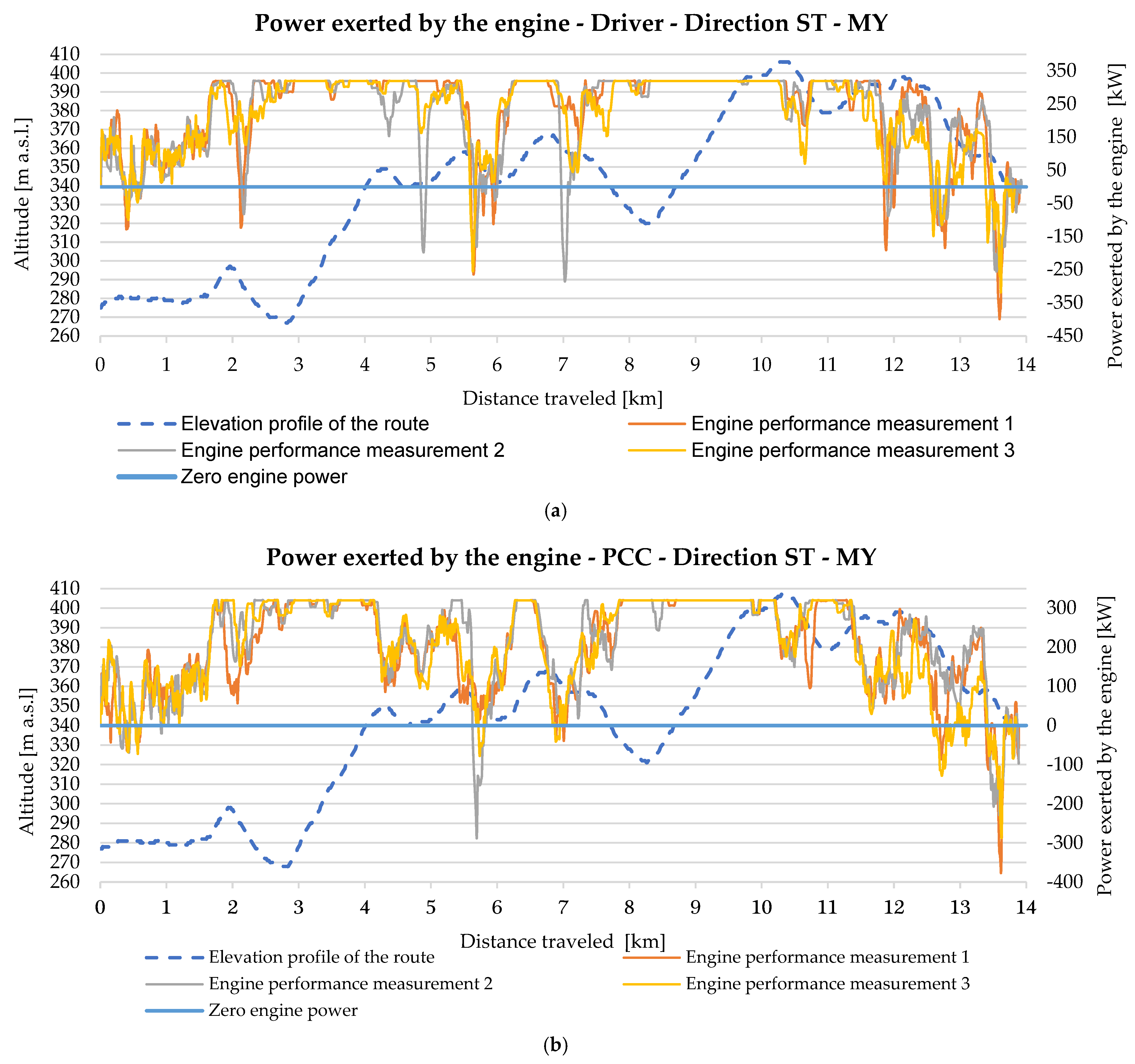

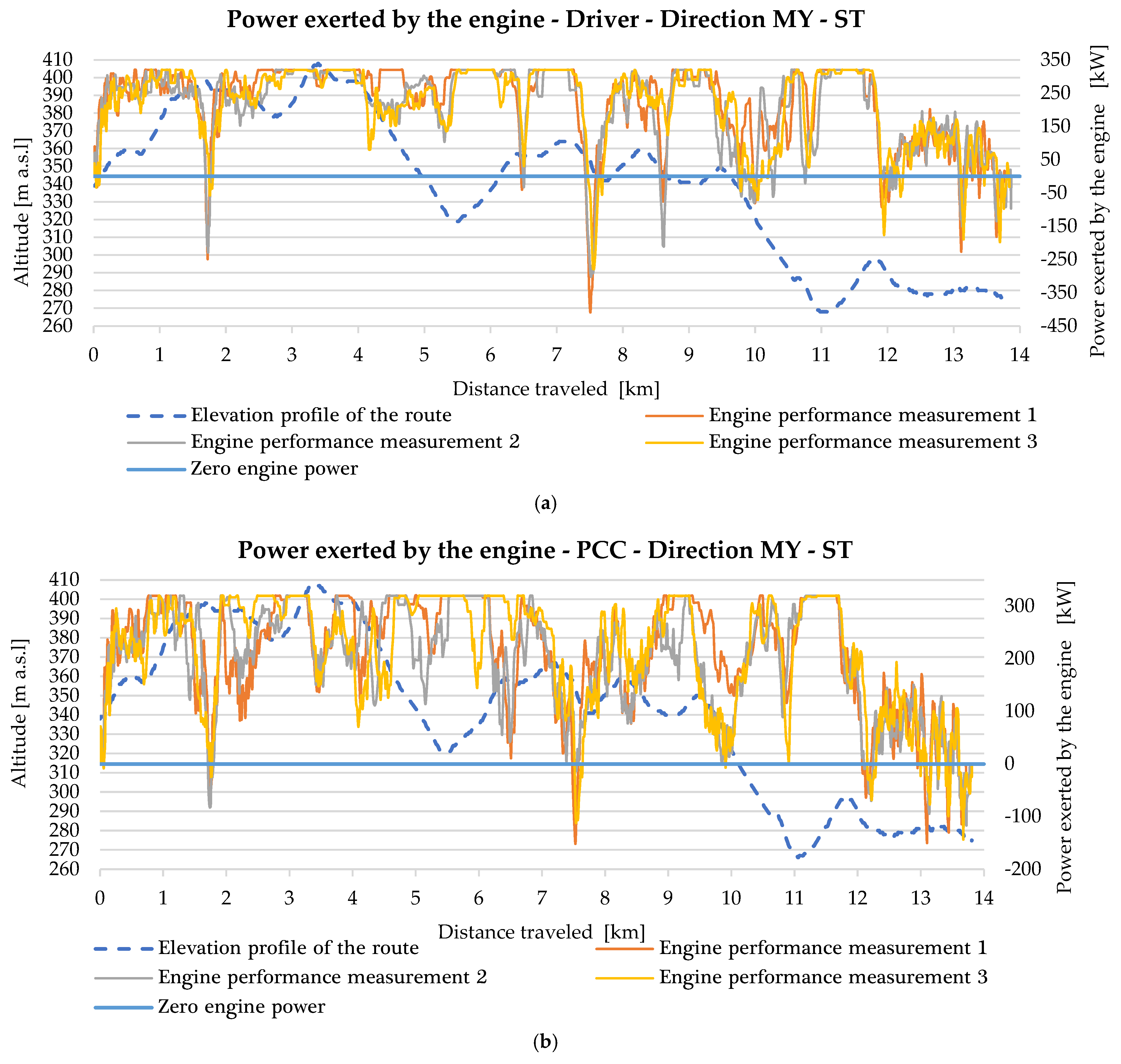

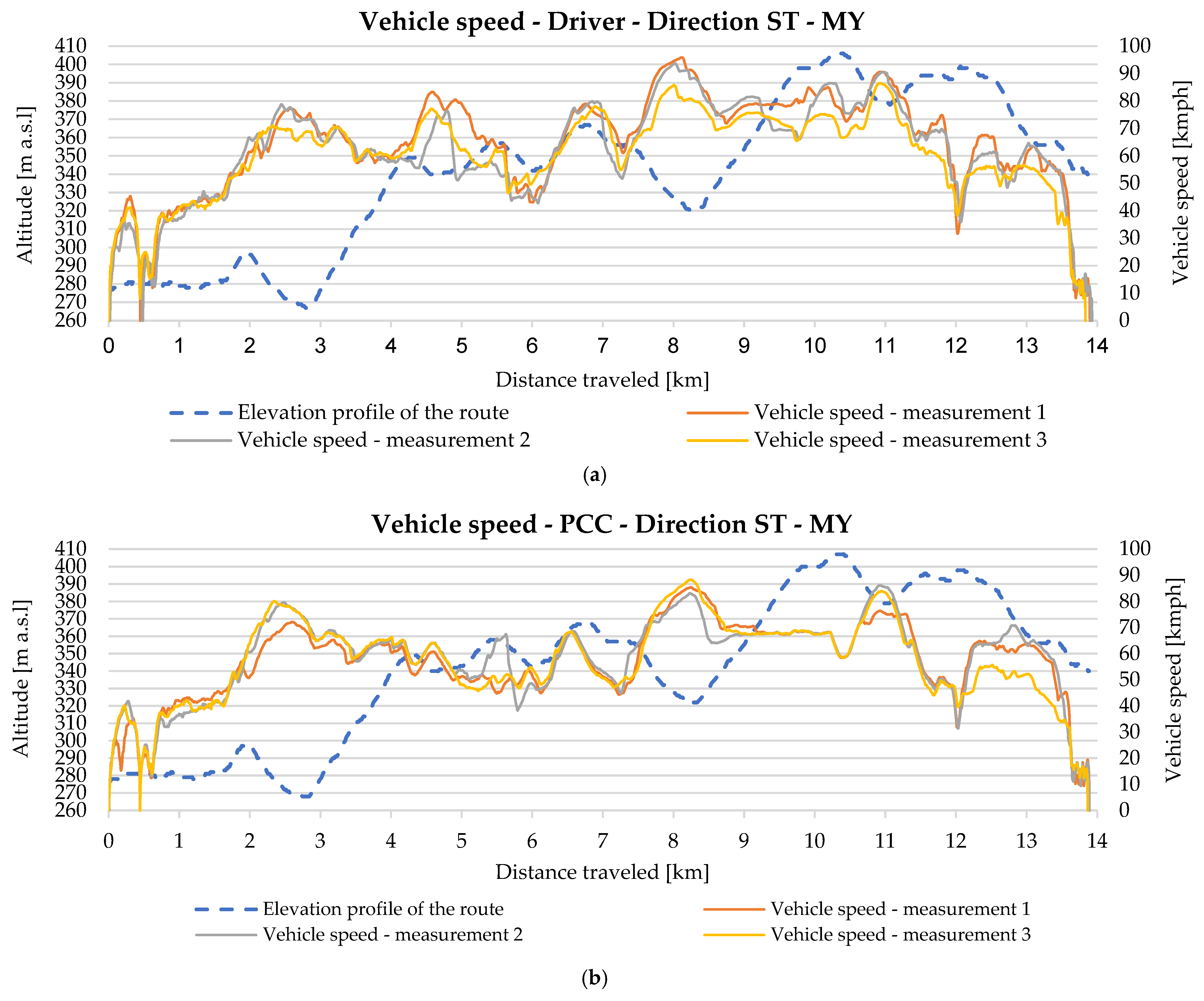

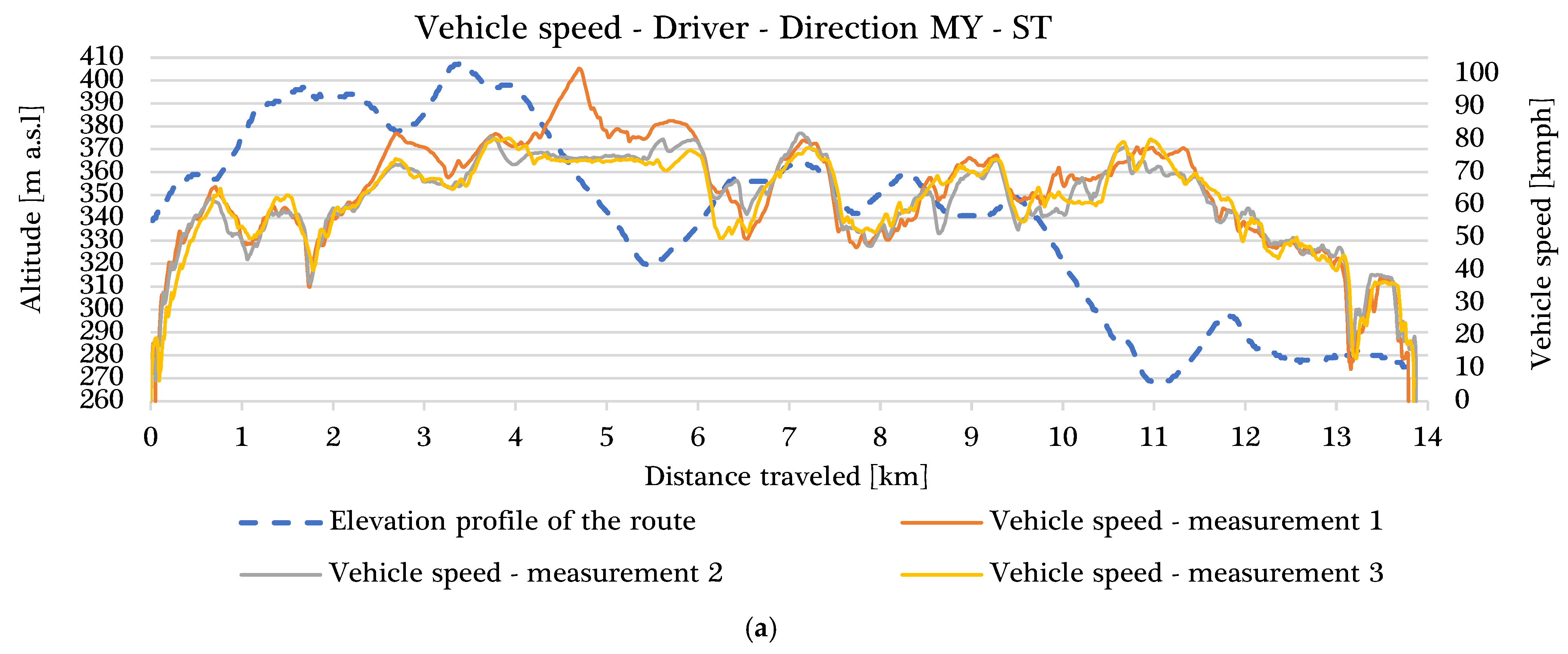

3. Results and Discussion

The Processing of Recorded Data

- In the ST-MY direction, the average fuel consumption was 37.35 L/100 km with a standard deviation of 0.32 L/100 km. The 95% confidence interval is (36.71 L/100 km, 37.99 L/100 km).

- In the MY-ST direction, the average fuel consumption was 26.43 L/100 km with a standard deviation of 2.01 L/100 km. The 95% confidence interval is (24.41 L/100 km, 28.45 L/100 km).

- In the ST-MY direction, the average fuel consumption was 31.01 L/100 km with a standard deviation of 0.23 L/100 km. The 95% confidence interval is (30.78 L/100 km, 31.24 L/100 km).

- In the MY-ST direction, the average fuel consumption was 24.41 L/100 km with a standard deviation of 0.035 L/100 km. The 95% confidence interval is (24.34 L/100 km, 24.48 L/100 km).

- Average vehicle speed [kmph]—0.44;

- Number of climbed and descended speed kilometers [kmph]—0.61;

- Relative utilization of maximum engine power [%]—0.91;

- Average specific effective fuel consumption [grams per kilowatt-hour]—0.97.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACC | Adaptive Cruise Control |

| ADR | the European Agreement concerning the international carriage of Dangerous goods by Road |

| CNG | Compressed Natural Gas |

| CU | Control Unit |

| GPS | Global Positioning System |

| HVO | Hydrotreated Vegetable Oil |

| ICE | Internal Combustion Engine |

| m a.s.l. | Meters above sea level |

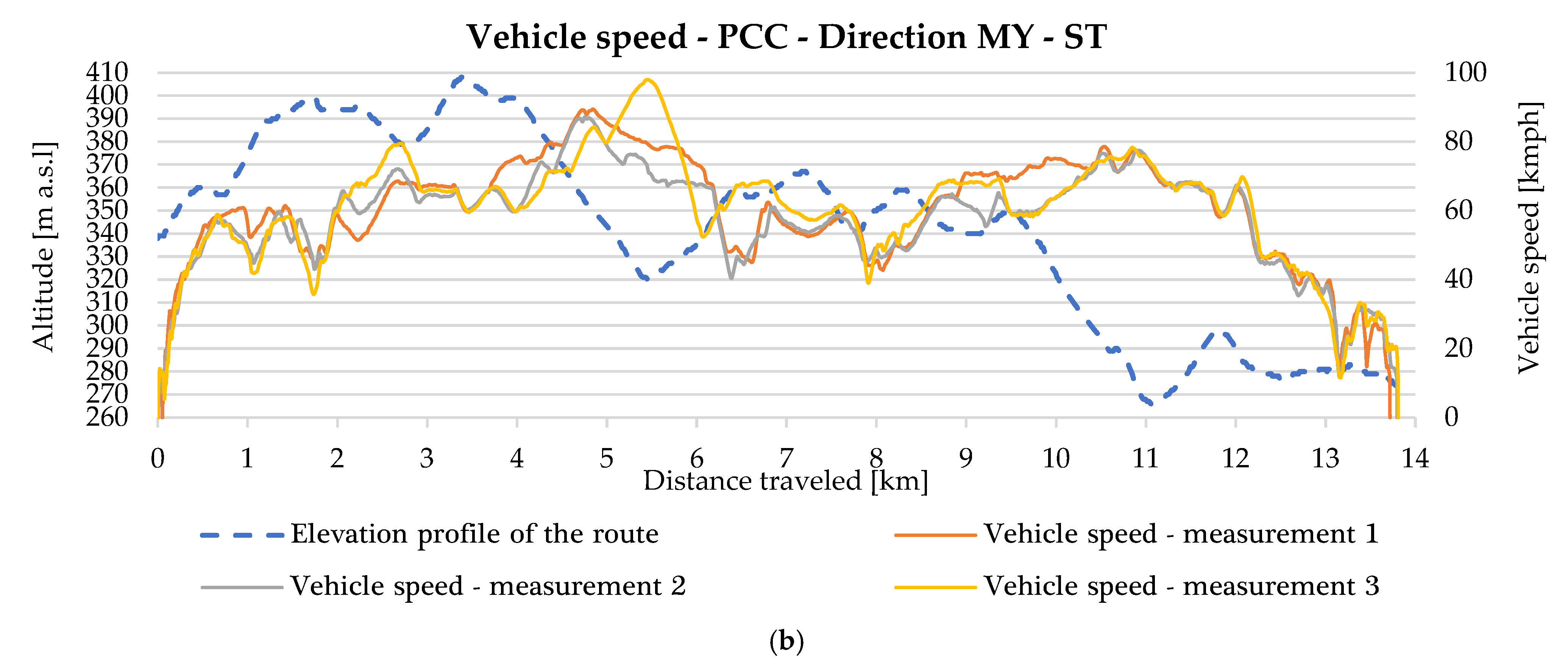

| MY-ST | Route from Myjava to Stará Tura |

| NG | Natural Gas |

| PCC | Predictive Cruise Control |

| RCCI | Reactivity Controlled Compression Ignition |

| ST-MY | Route from Stará Tura to Myjava |

References

- Borucka, A.; Kozłowski, E. Border Road Freight Traffic in the Context of the Modern Geopolitical Situation. In TRANSBALTICA XV: Transportation Science and Technology; Prentkovskis, O., Yatskiv (Jackiva), I., Skačkauskas, P., Karpenko, M., Stosiak, M., Eds.; TRANSBALTICA 2024. Lecture Notes in Intelligent Transportation and Infrastructure; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Čižiūnienė, K.; Voronavičiūtė, G.; Marinkovic, D.; Matijošius, J. Sustainable Human Resource Management in Emergencies: The Case of the Lithuanian Logistics Sector. Sustainability 2025, 17, 2591. [Google Scholar] [CrossRef]

- Bartnik, G.; Krzysiak, Z.; Samociuk, W.; Łysiak, G.; Plizga, K.; Szmigielski, M.; Nieoczym, A.; Kaliniewicz, Z.; Brumerčik, F. Dokumentowanie spełniania wymagań w obszarze bezpieczeństwa technicznego na przykładzie dystrybucji paliw ciekłych. Przem. Chem. 2017, 96, 1039–1041. [Google Scholar] [CrossRef]

- Samociuk, W.; Krzysiak, Z.; Bukova, B.; Brumercikova, E.; Bąkowski, H.; Krzywonos, L. Analiza międzynarodowego transportu produktów chemicznych w państwach Grupy Wyszehradzkiej. Przem. Chem. 2018, 97, 829–833. [Google Scholar] [CrossRef]

- Stoma, M.; Maj, G.; Dudziak, A.; Ślaska-Grzywna, B.; Piekarski, W.; Andrejko, D. Obrót produktami chemicznymi zgodnie z systemem badania bezpieczeństwa i jakości SQAS. Przem. Chem. 2015, 94, 1883–1886. [Google Scholar] [CrossRef]

- Krzysiak, Z. Profitability of Sugar Beet Production in 2023/2024 Campaign on Example of Lublin Voivodeship. In Proceedings of the 23rd International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 22–24 May 2024. [Google Scholar]

- Panoutsou, C.; Alexopoulou, E. Costs and Profitability of Crops for Bioeconomy in the EU. Energies 2020, 13, 1222. [Google Scholar] [CrossRef]

- Samociuk, W.; Krzysiak, Z.; Przystupa, K.; Zarajczyk, J. Sugar Beet Profitability in Lubelskie Province, Poland. Appl. Sci. 2025, 15, 8685. [Google Scholar] [CrossRef]

- Čižiūnienė, K.; Matijošius, J.; Liebuvienė, J.; Sokolovskij, E. Comparison of the Relative Importance of Factors Affecting the Conveyance of Bulk and Liquid Cargo. Appl. Sci. 2024, 14, 1151. [Google Scholar] [CrossRef]

- Stojanovic, N.; Boskovic, B.; Petrovic, M.; Grujic, I.; Abdullah, O.I. The impact of accidents during the transport of dangerous good, on people, the environment, and infrastructure and measures for their reduction: A review. Environ. Sci. Pollut. Res. 2023, 30, 32288–32300. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.; Yue, M.; Qi, G.; Liu, Y.; Qian, K. Preview-based MPC for active suspension control of tank vehicle with lateral liquid sloshing suppression. Proc. I. Mech. E. Part D J. Automob. Eng. 2025, 09544070251317649. [Google Scholar] [CrossRef]

- Marienka, P.; Frančák, M.; Jagelčák, J. Evaluation of bulk cargo dynamics in the ACTS intermodal container. Nase More 2021, 68, 14–27. [Google Scholar] [CrossRef]

- Vlkovský, M. A comparison of cargo securing on laden/unladen container trucks. Int. J. Logist. Syst. Manag. 2021, 40, 510–524. [Google Scholar] [CrossRef]

- Aleksandrowicz, P.J.; Wrona, R.; Droździel, P. Problems of modelling a pedestrian collision—Selected aspects. Adv. Sci. Technol. Res. J. 2025, 19, 44–55. [Google Scholar] [CrossRef]

- Drozd, K.; Tarkowski, S.; Caban, J.; Nieoczym, A.; Vrábel, J.; Krzysiak, Z. Analysis of Truck Tractor Tire Damage in the Context of the Study of Road Accident Causes. Appl. Sci. 2022, 12, 12333. [Google Scholar] [CrossRef]

- Decker, Ž.; Tretjakovas, J.; Drozd, K.; Rudzinskas, V.; Walczak, M.; Kilikevičius, A.; Matijosius, J.; Boretska, I. Material’s Strength Analysis of the Coupling Node of Axle of the Truck Trailer. Materials 2023, 16, 3399. [Google Scholar] [CrossRef]

- Jilek, P. Design of Kinematic Coupling of the Rear Wheels of a Road Trailer. Int. J Automot. Technol. 2025, 26, 1631–1637. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, T.; Wang, H.; Wu, S.; Shao, Z. Stability Analysis of a Vehicle–Cargo Securing System for Autonomous Trucks Based on 6-SPS-Type Parallel Mechanisms. Machines 2023, 11, 745. [Google Scholar] [CrossRef]

- Bańka, M.; Droździel, P.; Nieoczym, A. Lashing methods—Mathematical basis of the process of selecting the number of lashings. In Proceedings of the 23rd International Conference, Transport Means 2019, Proceedings Part, Palanga, Lithuania, 2–4 October 2019; pp. 99–103. [Google Scholar]

- Vlkovský, M.; Veselík, P. Cargo Securing—Comparison of the Selected Trucks. Transp. Probl. 2020, 15 Pt 2, 265–274. [Google Scholar] [CrossRef]

- Vlkovský, M.; Veselík, P. Cargo securing—Comparison of different quality roads. Acta Univ. Agric. Silvic. Mendel. Brun. 2019, 67, 1015–1023. [Google Scholar] [CrossRef]

- Vlkovský, M. Impact of vehicle type and road quality on cargo securing. Commun. Sci. Lett. Univ. Zilina 2020, 22, 9–14. [Google Scholar] [CrossRef]

- Hanzl, J.; Pečman, J.; Bartuška, L.; Stopka, O.; Šarkan, B. Research on the Effect of Road Height Profile on Fuel Consumption during Vehicle Acceleration. Technologies 2022, 10, 128. [Google Scholar] [CrossRef]

- Hurtova, I.; Sejkorova, M.; Verner, J.; Sarkan, B. Comparison of electricity and fossil fuel consumption in trolleybuses and buses. Eng. Rural. Dev. 2018, 17, 2079–2084. [Google Scholar] [CrossRef]

- Kravchenko, O.; Barta, D.; Gerlici, J.; Kravchenko, K.; Rybicka, I.; Zigo, A. Environmental Problems Associated with Vehicle Braking and Their Solutions. In International Conference TRANSBALTICA: Transportation Science and Technology; Lecture Notes in Intelligent Transportation and Infrastructure; Springer: Cham, Switzerland, 2023; Part F1379; pp. 258–267. [Google Scholar]

- Lizbetin, J.; Stopka, O.; Kurenkov, P.V. Declarations regarding the energy consumption and emissions of the greenhouse gases in the road freight transport sector. Arch. Automot. Eng. 2019, 83, 59–72. [Google Scholar] [CrossRef]

- Stopka, O.; L’upták, V.; Stopková, M.; Šarkan, B.; Mašek, J. Methodology of Choosing the Most Eco-Friendly Waste Collection Truck. Promet Traffic Transp. 2025, 37, 874–887. [Google Scholar] [CrossRef]

- Warguła, Ł.; Lijewski, P.; Kukla, M. Influence of non-commercial fuel supply systems on small engine SI exhaust emissions in relation to European approval regulations. Environ. Sci. Pollut. Res. 2022, 29, 55928–55943. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Słowik, T. Comparison and assessment of emission factors for toxic exhaust components during combustion of biomass fuels. Rocz. Ochr. Srodowiska 2019, 21, 378–394. [Google Scholar]

- Bialy, M.; Wendeker, M.; Magryta, P.; Czyz, Z.; Sochaczewski, R. CFD Model of the Mixture Formation Process of the CNG Direct Injection Engine. In Proceedings of the SAE 2014 International Powertrain, Fuels & Lubricants Meeting, Birmingham, UK, 20–23 October 2014. [Google Scholar] [CrossRef]

- Milojević, S.; Gročić, D.; Dragojlović, D. CNG propulsion system for reducing noise of existing city buses. J. Appl. Eng. Sci. 2016, 14, 377–382. [Google Scholar] [CrossRef]

- Dittrich, A.; Prochazka, R.; Popelka, J.; Phu, D.N. Effect of HVO CNG dual-fuel operation mode on emissions and performance of CI engine. Eng. Rural. Dev. 2023, 22, 58–63. [Google Scholar] [CrossRef]

- Phu, D.N.; Dittrich, A.; Prochazka, R.; Popelka, J. Evaluation of Combustion and Emission Characteristics of CI Engines Operating Dual-Fuel with BioCNG/Diesel and BioCNG/HVO. SSRG Int. J. Mech. Eng. 2024, 11, 17–26, IJME-V11I3P103. [Google Scholar] [CrossRef]

- Smigins, R.; Sondors, K.; Pirs, V.; Dukulis, I.; Birzietis, G. Studies of Engine Performance and Emissions at Full-Load Mode Using HVO, Diesel Fuel, and HVO5. Energies 2023, 16, 4785. [Google Scholar] [CrossRef]

- Yang, L.; Ji, S.; Niu, W.; Zare, A.; Hunicz, J.; Brown, R.J. Effect of split injection strategy of diesel fuel on multi-stage heat release and performance of a RCCI engine fueled with diesel and natural gas. Fuel 2024, 362, 130930. [Google Scholar] [CrossRef]

- Górski, K.; Tziourtzioumis, D.; Smigins, R.; Longwic, R. Effects of Ethanol–Diesel Blends on Cylinder Pressure, Ignition Delay, and NOx Emissions in a Diesel Engine. Energies 2025, 18, 2392. [Google Scholar] [CrossRef]

- Górski, K.; Smigins, R.; Matijošius, J.; Rimkus, A.; Longwic, R. Physicochemical Properties of Diethyl Ether—Sunflower Oil Blends and Their Impact on Diesel Engine Emissions. Energies 2022, 15, 4133. [Google Scholar] [CrossRef]

- Milojević, S.; Stopka, O.; Orynycz, O.; Tucki, K.; Šarkan, B.; Savić, S. Exploitation and Maintenance of Biomethane-Powered Truck and Bus Fleets to Assure Safety and Mitigation of Greenhouse Gas Emissions. Energies 2025, 18, 2218. [Google Scholar] [CrossRef]

- Amatnieks, K.; Šmigins, R.; Birkavs, A. Effect of Hydrogen Injection on Performance and Emissions of a Light-Duty Diesel Vehicle. In Proceedings of the Transport Means Proceedings of the International Conference, Kaunas, Lithuania, 2–4 October 2024; pp. 57–62. [Google Scholar]

- Malek, A.; Taccani, R.; Kasperek, D.; Hunicz, J. Optimization of energy management in a city bus powered by the hydrogen fuel cells. Commun. Sci. Lett. Univ. Zilina 2021, 23, E56–E67. [Google Scholar] [CrossRef]

- Ngasse Moudio, N.D.; Bian, X.-Q.; Chinamo, D.S. Liquid hydrogen carriers for clean energy systems: A critical review of chemical hydrogen storage strategies. Fuel 2026, 404, 136329. [Google Scholar] [CrossRef]

- Brumercik, F.; Lukac, M.; Krzysiak, Z.; Krzywonos, L. Model of integrated transportation system. Commun. Sci. Lett. Univ. Zilina 2017, 19, 23–26. [Google Scholar] [CrossRef]

- Dižo, J.; Blatnický, M.; Melnik, R.; Kravchenko, O. A mathematical model of operation of a semi-trailer tractor powertrain. Commun. Sci. Lett. Univ. Zilina 2022, 24, B267–B274. [Google Scholar] [CrossRef]

- Gnap, J.; Senko, S.; Kostrzewski, M.; Bridzikova, M.; Czodorova, R.; Riha, Z. Research on the relationship between transport infrastructure and performance in rail and road freight transport—A case study of Japan and selected European countries. Sustainability 2021, 13, 6654. [Google Scholar] [CrossRef]

- Korsakas, V.; Melaika, M.; Pukalskas, S.; Stravinskas, P. Hydrogen addition influence for the efficient and ecological parameters of heavy-duty natural gas Si engine. Procedia Eng. 2017, 187, 395–401. [Google Scholar] [CrossRef]

- Lovska, A.; Ishchuk, V.; Dižo, J.; Blatnický, M. Analysis of Running Properties of a Rail Multiple-Unit with a Diesel and a Hydrogen Powertrain. In International Conference TRANSBALTICA: Transportation Science and Technology; Lecture Notes in Intelligent Transportation and Infrastructure; Springer: Cham, Switzerland, 2025; Part F230; pp. 527–536. [Google Scholar]

- Rabinovich, E.; Gritsuk, I.V.; Zuiev, V.; Evgeny, E.Y.; Golovan, A.; Zybtsev, Y.; Volkov, V.; Gerlici, J.; Kravchenko, K.; Volska, O.; et al. Evaluation of the powertrain condition based on the car acceleration and coasting data. SAE Tech. Pap. 2018. [Google Scholar] [CrossRef]

- Huang, D.; Ou, J.; Yang, E.; Lin, J.; Zhang, Y. Research on a Multimode Adaptive Cruise Control Strategy with Emergency Lane-Changing Function. World Electr. Veh. J. 2023, 14, 189. [Google Scholar] [CrossRef]

- Kabasakal, B.; Üçüncü, M. The design and simulation of adaptive cruise control system. Int. J. Auto. Sci. Tech. 2022, 6, 242–256. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Y.; Sun, S. Adaptive Cruise Predictive Control Based on Variable Compass Operator Pigeon-Inspired Optimization. Electronics 2022, 11, 1377. [Google Scholar] [CrossRef]

- Wu, C.; Xu, Z.; Liu, Y. Spacing Policies for Adaptive Cruise Control: A Survey. IEEE Access 2020, 8, 50149–50162. [Google Scholar] [CrossRef]

- Yu, T.; Tang, Y.; Chen, R.; Zhao, S. Optimization of Adaptive Cruise Control Strategies Based on the Responsibility-Sensitive Safety Model. Vehicles 2025, 7, 28. [Google Scholar] [CrossRef]

- Eustace, D. Emerging Transportation Safety and Operations: Practical Perspectives. Vehicles 2024, 6, 2251–2256. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Z.; Yan, M. An Optimization Design of Adaptive Cruise Control System Based on MPC and ADRC. Actuators 2021, 10, 110. [Google Scholar] [CrossRef]

- Mu, H.; Li, L.; Mei, M.; Zhao, Y. A Hierarchical Control Scheme for Adaptive Cruise Control System Based on Model Predictive Control. Actuators 2023, 12, 249. [Google Scholar] [CrossRef]

- Borneo, A.; Miretti, F.; Misul, D.A. Fuel Efficiency Optimization in Adaptive Cruise Control: A Comparative Study of Model Predictive Control-Based Approaches. Appl. Sci. 2024, 14, 9833. [Google Scholar] [CrossRef]

- Grabowski, Ł.; Sochaczewski, R.; Biały, M. Deep learning long short-term memory methods for instantaneous fuel consumption prediction: Experimental study and comparison of modeling strategies. Adv. Sci. Technol. Res. J. 2025, 19, 197–209. [Google Scholar] [CrossRef]

- Kalašová, A.; Čulík, K.; Skřivánek-Kubíková, S. The interaction between a driver and intelligent transport systems. Acta Polytech. CTU Proc. 2022, 39, 16–22. [Google Scholar] [CrossRef]

- Grencik, J.; Barta, D.; Brezani, M.; Molnar, D. Energy Consumption and Travel Time as Important Factors for Deciding on the Mode of Transport—Case Study from Slovakia. In International Conference TRANSBALTICA: Transportation Science and Technology; Lecture Notes in Intelligent Transportation and Infrastructure; Springer: Cham, Switzerland, 2023; Part F1379; pp. 518–527. [Google Scholar]

- Małek, A.; Marciniak, A.; Kroczyński, D. Defining Signatures for Intelligent Vehicles with Different Types of Powertrains. World Electr. Veh. J. 2025, 16, 135. [Google Scholar] [CrossRef]

- Šarkan, B.; Loman, M.; Senko, Š.; Richtář, M.; Gołębiowski, W. Change in engine power in the event of electronic components failures. Arch. Automot. Eng. 2022, 98, 40–55. [Google Scholar] [CrossRef]

- Loman, M.; Šarkan, B. Determination of the deviation of the on-board computer in the vehicle when determining the average fuel consumption. Arch. Automot. Eng. 2021, 91, 25–35. [Google Scholar] [CrossRef]

- Melders, L.; Smigins, R.; Birkavs, A. Recent Advances in Vehicle Driver Health Monitoring Systems. Sensors 2025, 25, 1812. [Google Scholar] [CrossRef]

- Sajdl, J. Predictive Adaptive Cruise Control. Available online: https://www.autolexicon.net/en/articles/prediktivni-adaptivni-tempomat/ (accessed on 5 June 2025).

- Gáspár, P.; Németh, B. Predictive Cruise Control for Road Vehicles Using Road and Traffic Information; Springer: Cham, Switzerland, 2019; p. 226. ISBN 978-3-030-04115-1. [Google Scholar]

- Vehicle Registration Certificate MAN TGX 18.470 4x2 LL SA. Available online: https://autoline.info/-/sale/truck-tractors/MAN/TGX-18-470-4X2-LL-SA-MEGA--25112217255940077000 (accessed on 4 October 2025).

- Predictive Driving—Smart Savings. Available online: https://www.man.eu/de/en/truck/assistance-systems/gps-assisted-cruise-control/man-efficientcruise.html (accessed on 21 July 2025).

- Internet Map Application Mapy.cz. Available online: https://sk.mapy.cz/zakladni?x=19.4402339&y=48.8084443&z=8 (accessed on 25 February 2025).

- Google Earth Pro Internet Mapping Application. Available online: https://earth.google.com/web/ (accessed on 25 February 2025).

- Borneo, A.; Zerbato, L.; Miretti, F.; Tota, A.; Galvagno, E.; Misul, D.A. Platooning Cooperative Adaptive Cruise Control for Dynamic Performance and Energy Saving: A Comparative Study of Linear Quadratic and Reinforcement Learning-Based Controllers. Appl. Sci. 2023, 13, 10459. [Google Scholar] [CrossRef]

- Piao, C.; Gao, J.; Yang, Q.; Shi, J. Adaptive cruise control method based on hierarchical control and multi-objective optimization. Trans. Inst. Meas. Control. 2023, 45, 1298–1312. [Google Scholar] [CrossRef]

- Weißmann, A.; Görges, D.; Lin, X. Energy-optimal adaptive cruise control combining model predictive control and dynamic programming. Control Eng. Pract. 2018, 72, 125–137. [Google Scholar] [CrossRef]

| Direction | ST- MY | MY- ST | ST- MY | MY- ST | ST- MY | MY- ST | ST- MY | MY- ST | ST- MY | MY- ST |

|---|---|---|---|---|---|---|---|---|---|---|

| OC1 | 52.1 | 49.5 | 5.9 | 15.5 | 2.0 | 6.1 | 5.8 | 43.9 | ±2.4 | ±6.6 |

| OC2 | 384.3 | 363.7 | 75.0 | 27.0 | 32.9 | 10.9 | 1217.6 | 137.6 | ±34.9 | ±11.7 |

| OC3 | −384.3 | −363.7 | −75.0 | −27.0 | 32.9 | 10.9 | 1217.6 | 137.6 | ±34.9 | ±11.7 |

| OC4 | 29.9 | 18.9 | 8.3 | 6.9 | 3.1 | 3.0 | 11.8 | 10.2 | ±3.4 | ±3.2 |

| OC5 | 106.3 | 75.4 | 16.4 | 12.2 | 5.8 | 31.0 | 45.4 | 25.9 | ±6.7 | ±2.6 |

| OC6 | 37.4 | 26.4 | 0.6 | 3.6 | 0.2 | 1.5 | 0.1 | 2.7 | ±0.3 | ±1.6 |

| Legend: | ||||||||||

| Arithmetic mean | OC1 | Average vehicle speed [km/h] | ||||||||

| Range | OC2 | Average number of uphill speed kilometers [km/h] | ||||||||

| Mean deviation | OC3 | Average number of downhill speed kilometers [km/h] | ||||||||

| Variance | OC4 | Relative utilization of maximum engine power [%] | ||||||||

| Standard deviation | OC5 | Average specific effective fuel consumption [g/kWh] | ||||||||

| OC6 | Average fuel consumption [L/100 km] | |||||||||

| Direction | ST- MY | MY- ST | ST- MY | MY- ST | ST- MY | MY- ST | ST- MY | MY- ST | ST- MY | MY- ST |

|---|---|---|---|---|---|---|---|---|---|---|

| OC1 | 48.4 | 48.0 | 4.6 | 4.7 | 1.8 | 1.7 | 3.9 | 3.8 | ±2.0 | ±1.9 |

| OC2 | 345.3 | 318.3 | 43.0 | 25.0 | 15.8 | 8.9 | 317.6 | 105.6 | ±17.8 | ±10.3 |

| OC3 | −345.3 | −318.3 | −43.0 | −25.0 | 15.8 | 8.9 | 317.6 | 105.6 | ±17.8 | ±10.3 |

| OC4 | 22.0 | 14.4 | 3.3 | 4.8 | 1.3 | 7.6 | 2.0 | 4.2 | ±1.4 | ±2.0 |

| OC5 | 90.8 | 69.4 | 6.8 | 1.9 | 2.4 | 0.7 | 7.8 | 0.7 | ±2.8 | ±0.8 |

| OC6 | 31.0 | 24.4 | 0.4 | 0.1 | 0.2 | 0.03 | 0.03 | 0.001 | ±0.2 | ±0.03 |

| Legend: | ||||||||||

| Arithmetic mean | OC1 | Average vehicle speed [km/h] | ||||||||

| Range | OC2 | Average number of uphill speed kilometers [km/h] | ||||||||

| Mean deviation | OC3 | Average number of downhill speed kilometers [km/h] | ||||||||

| Variance | OC4 | Relative utilization of maximum engine power [%] | ||||||||

| Standard deviation | OC5 | Average specific effective fuel consumption [g/kWh] | ||||||||

| OC6 | Average fuel consumption [L/100 km] | |||||||||

| Operational Characteristic | Direction | Average Value | Difference | ||

|---|---|---|---|---|---|

| Driver | PCC | Absolute | Relative [%] | ||

| Vehicle speed [kmph] | ST-MY | 52.1 | 48.4 | 3.7 | 7.10 |

| MY-ST | 49.5 | 48.0 | 1.5 | 3.03 | |

| ST-MY-ST | 50.83 | 48.17 | 2.66 | 5.23 | |

| Number of uphill speed kilometers [kmph] | ST-MY | 384.3 | 345.3 | 39 | 10.15 |

| MY-ST | 363.7 | 318.3 | 45.4 | 12.48 | |

| ST-MY-ST | 374 | 332 | 42 | 11.23 | |

| Number of downhill speed kilometers [kmph] | ST-MY | −384.3 | −345.3 | −39 | 10.15 |

| MY-ST | −363.7 | −318.3 | −45.4 | 12.48 | |

| ST-MY-ST | 374 | −332 | −42 | 11.23 | |

| Relative utilization of the maximum engine power [%] | ST-MY | 29.9 | 22.0 | 7.9 | 26.42 |

| MY-ST | 18.9 | 14.4 | 4.5 | 23.81 | |

| ST-MY-ST | 24.43 | 18.23 | 6.2 | 25.38 | |

| Specific effective fuel consumption [g/kWh] * | ST-MY | 106.3 | 90.8 | 15.5 | 14.58 |

| MY-ST | 75.4 | 69.4 | 6 | 7.96 | |

| ST-MY-ST | 90.83 | 80.09 | 10.74 | 11.82 | |

| Fuel consumption [L/100 km] | ST-MY | 37.4 | 31.0 | 6.4 | 17.11 |

| MY-ST | 26.4 | 24.4 | 2 | 7.58 | |

| ST-MY-ST | 31.89 | 27.21 | 4.68 | 14.68 | |

| Ranking | Operational Characteristic | Normalized Importance Weight [-] | |

|---|---|---|---|

| P1 | Average vehicle speed [kmph] | 1/15 | |

| P2a | Number of uphill speed kilometers [kmph] | 1/15 | (2/15) |

| P2b | Number of downhill speed kilometers [kmph] | 1/15 | |

| P3 | Relative utilization of the maximum engine power [%] | 3/15 | |

| P4 | Average specific effective fuel consumption [g/kWh] | 4/15 | |

| P5 | Average fuel consumption [L/100 km] | 5/15 | |

| Σ 15 | Σ 1 | ||

| Direction | Final Number of Assigned Points | Difference | ||

|---|---|---|---|---|

| Driver [-] | PCC [-] | Absolute | Relative [%] | |

| ST-MY | 101.46 | 88.17 | 13.29 | 13.10 |

| MY-ST | 84.52 | 74.80 | 9.72 | 11.50 |

| ST-MY-ST | 92.99 | 81.48 | 11.51 | 12.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skrúcaný, T.; Vrábel, J.; Rakyta, A.; Kassai, F.; Caban, J. Impact of the Use of Predictive Cruise Control in Freight Transport on Energy Consumption. Energies 2025, 18, 6171. https://doi.org/10.3390/en18236171

Skrúcaný T, Vrábel J, Rakyta A, Kassai F, Caban J. Impact of the Use of Predictive Cruise Control in Freight Transport on Energy Consumption. Energies. 2025; 18(23):6171. https://doi.org/10.3390/en18236171

Chicago/Turabian StyleSkrúcaný, Tomáš, Ján Vrábel, Andrej Rakyta, Filip Kassai, and Jacek Caban. 2025. "Impact of the Use of Predictive Cruise Control in Freight Transport on Energy Consumption" Energies 18, no. 23: 6171. https://doi.org/10.3390/en18236171

APA StyleSkrúcaný, T., Vrábel, J., Rakyta, A., Kassai, F., & Caban, J. (2025). Impact of the Use of Predictive Cruise Control in Freight Transport on Energy Consumption. Energies, 18(23), 6171. https://doi.org/10.3390/en18236171