Frequency–Temperature Characteristics of the Cellulose—Insulating Oil–Water Nanodroplet Nanocomposite Components for Diagnostic Evaluation of Power Transformer Insulation

Abstract

1. Introduction

- −

- To determine reference frequency–temperature characteristics of dielectric loss tangent and the real component of complex permittivity for pressboard moistened to 5.17 wt% and impregnated with insulating oil, for factory-new insulating oil with a moisture content below 7 ppm, and for insulating oil moistened identically to the process occurring in power transformers;

- −

- To calculate the frequency–temperature dependencies of transformer insulation (dielectric loss tangent and real and imaginary components of complex permittivity) based on the obtained reference characteristics of pressboard and oil;

- −

- To analyze the influence of insulating oil moisture content on the dielectric loss tangent and the real and imaginary components of complex permittivity of liquid–solid transformer insulation.

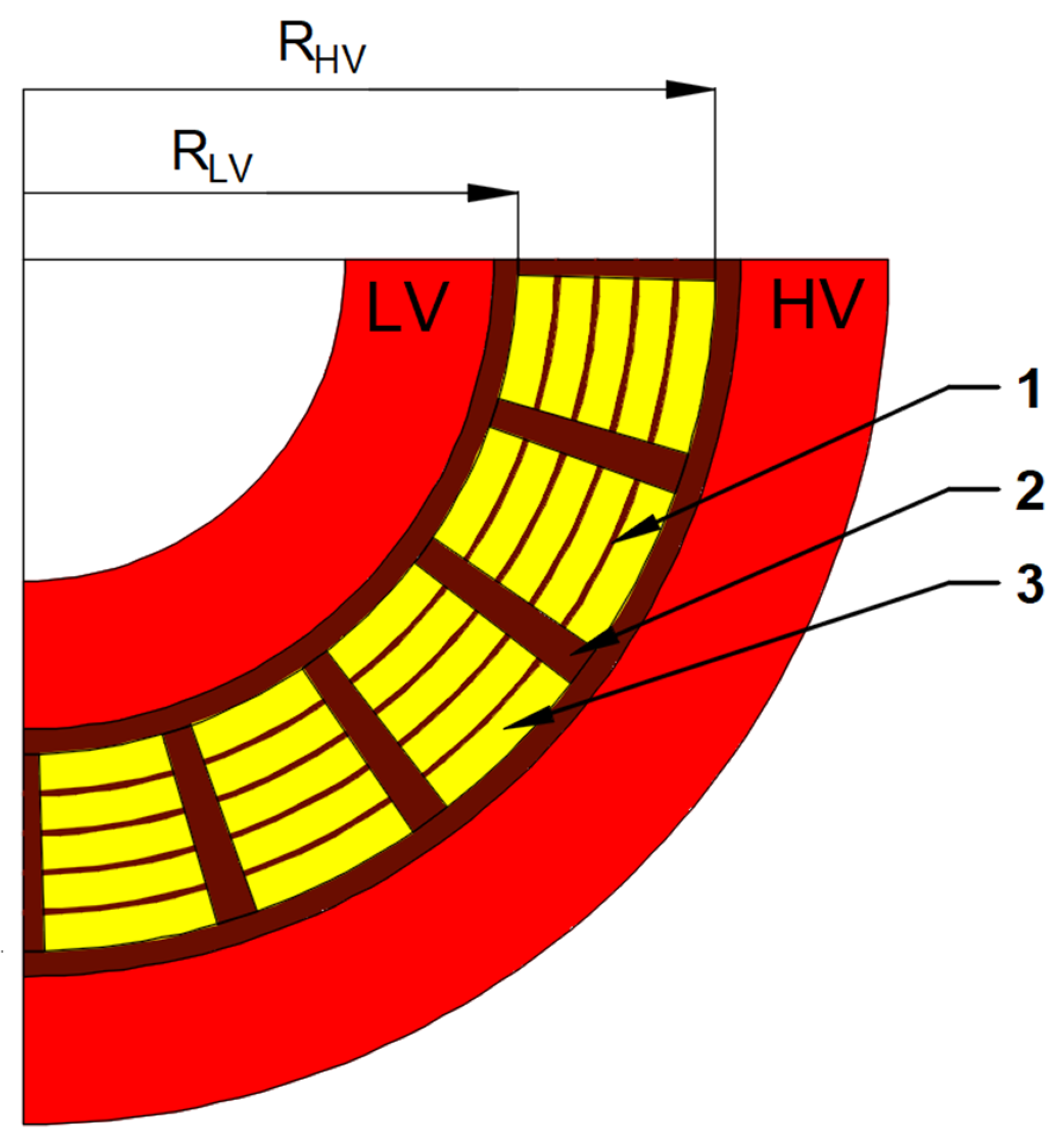

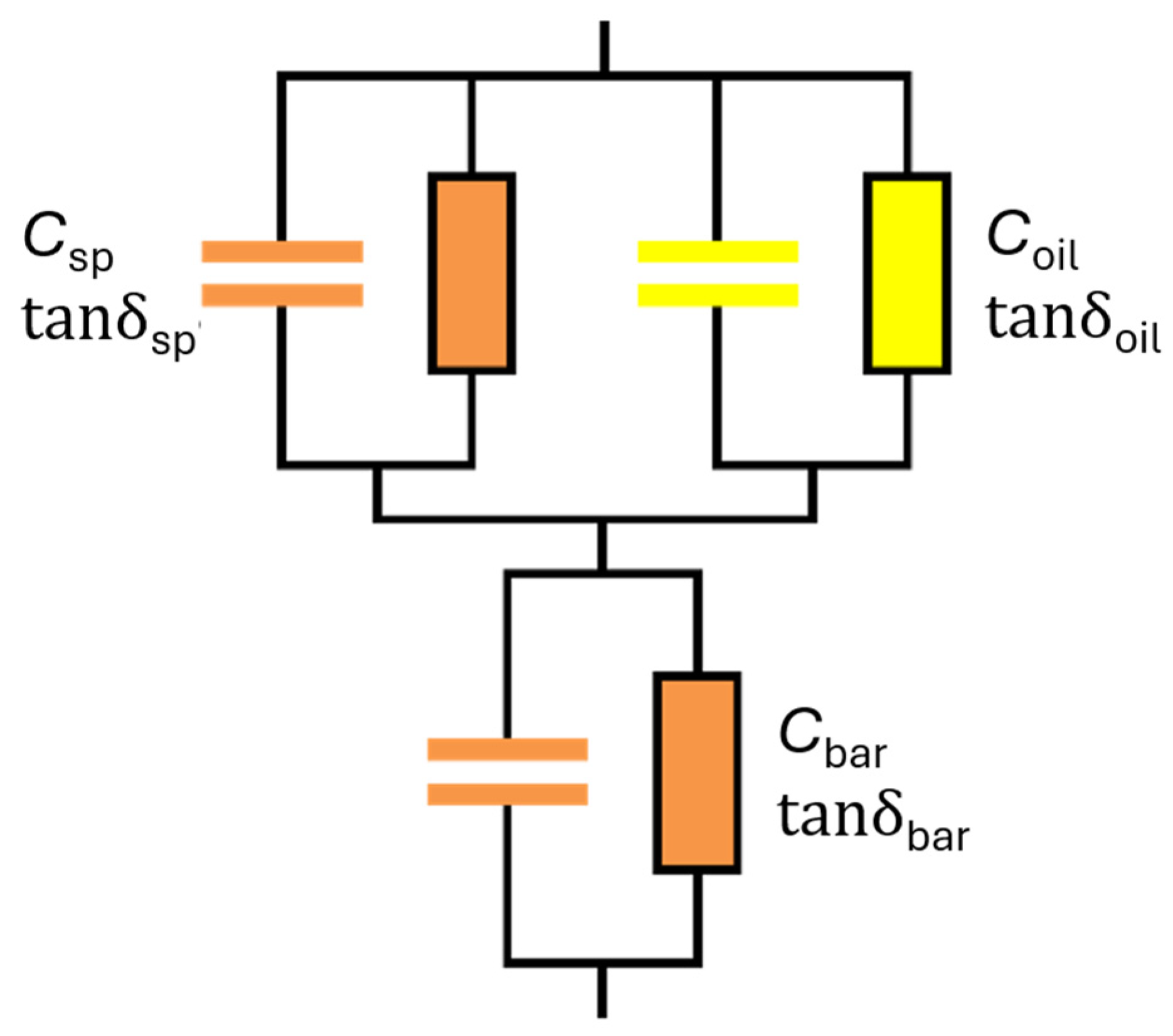

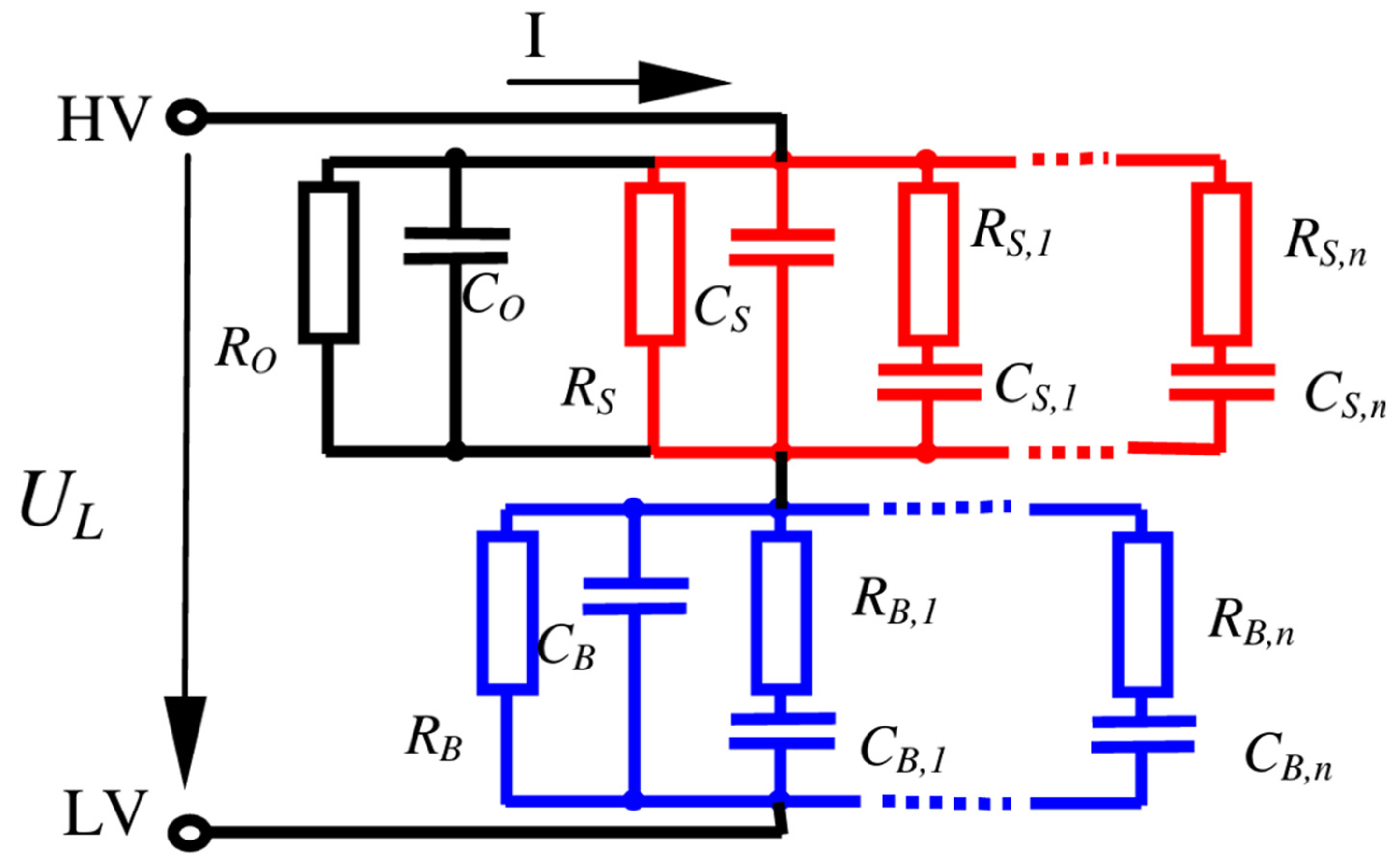

2. AC Insulation Parameters of Power Transformers: Theoretical Fundamentals

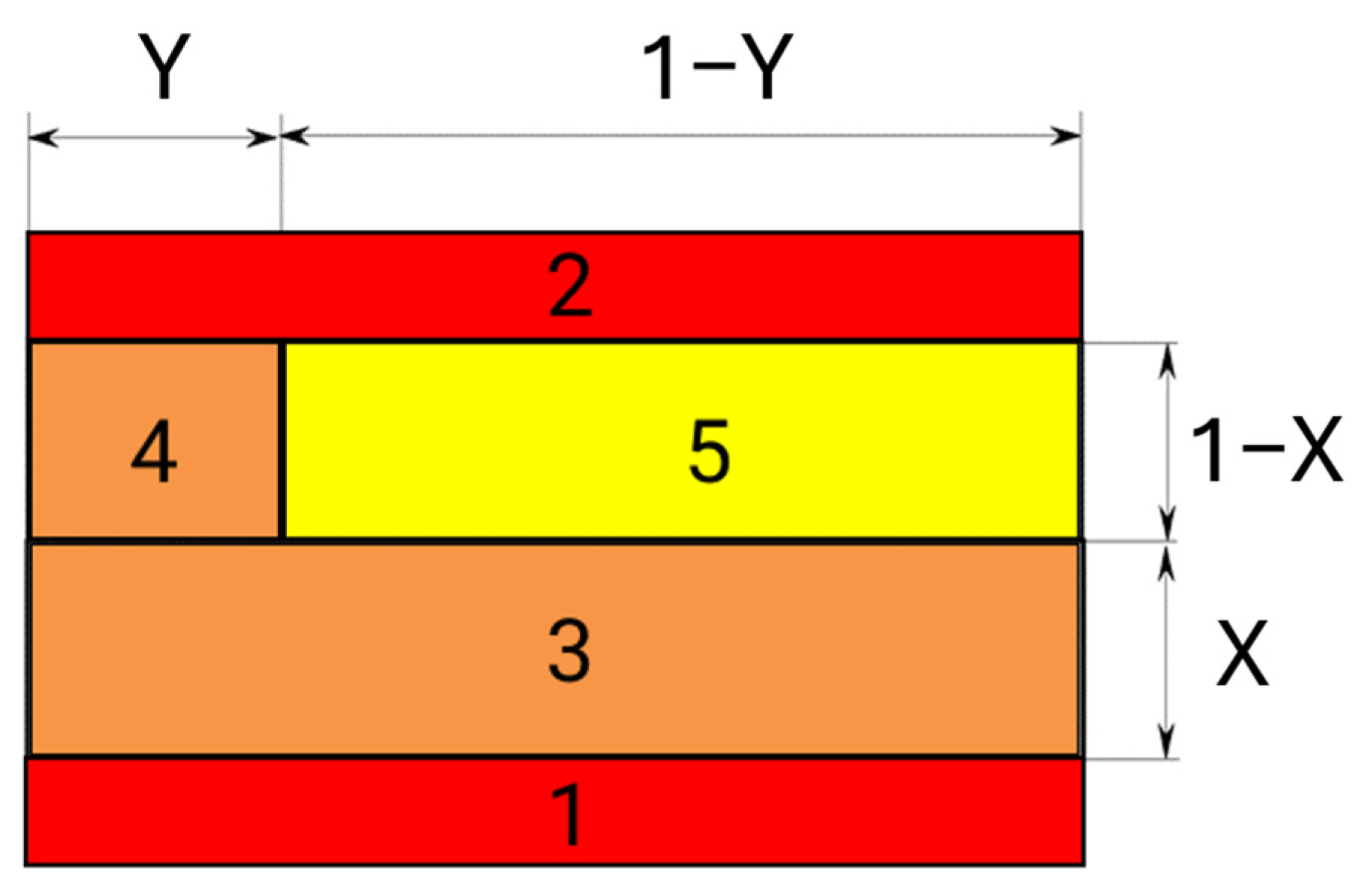

2.1. Theoretical Analysis of the AC Properties of Power Transformer Insulation Systems

- (a)

- X = 1, Y = 0; X = 0, Y = 1; and X = 1, Y = 1—the entire CIGRE system consists of pressboard. For all three combinations, Equation (15) reduces to the form

- (b)

- X = 0, Y = 0. In this case, the insulation consists solely of oil. Equation (15) reduces to

- (c)

- X = 0.5, Y = 0. This corresponds to two capacitors connected in series, each with half the thickness and with an electrode area equal to that of the CIGRE capacitor. One of them has pressboard as the dielectric, while the other has oil. Equation (15) then takes the following form:

- (d)

- X = 0, Y = 0.5. This corresponds to two capacitors connected in parallel, each with the same thickness and with electrode areas equal to half of the electrode area of the CIGRE capacitor. Equation (15) reduces to

- (e)

- X = 1, Y = 0; X = 0, Y = 1; and X = 1, Y = 1, corresponding to insulation consisting only of impregnated pressboard. We obtain

- (f)

- X = 0, Y = 0, which corresponds to insulation consisting solely of oil. We obtain

- (g)

- Y = 0.5, X = 0 corresponds to two capacitors connected in parallel, each with half the electrode area and the same thickness. We obtain

- (h)

- Y = 0, X = 0.5—series connection of capacitors with half the thickness and identical electrode areas. We obtain

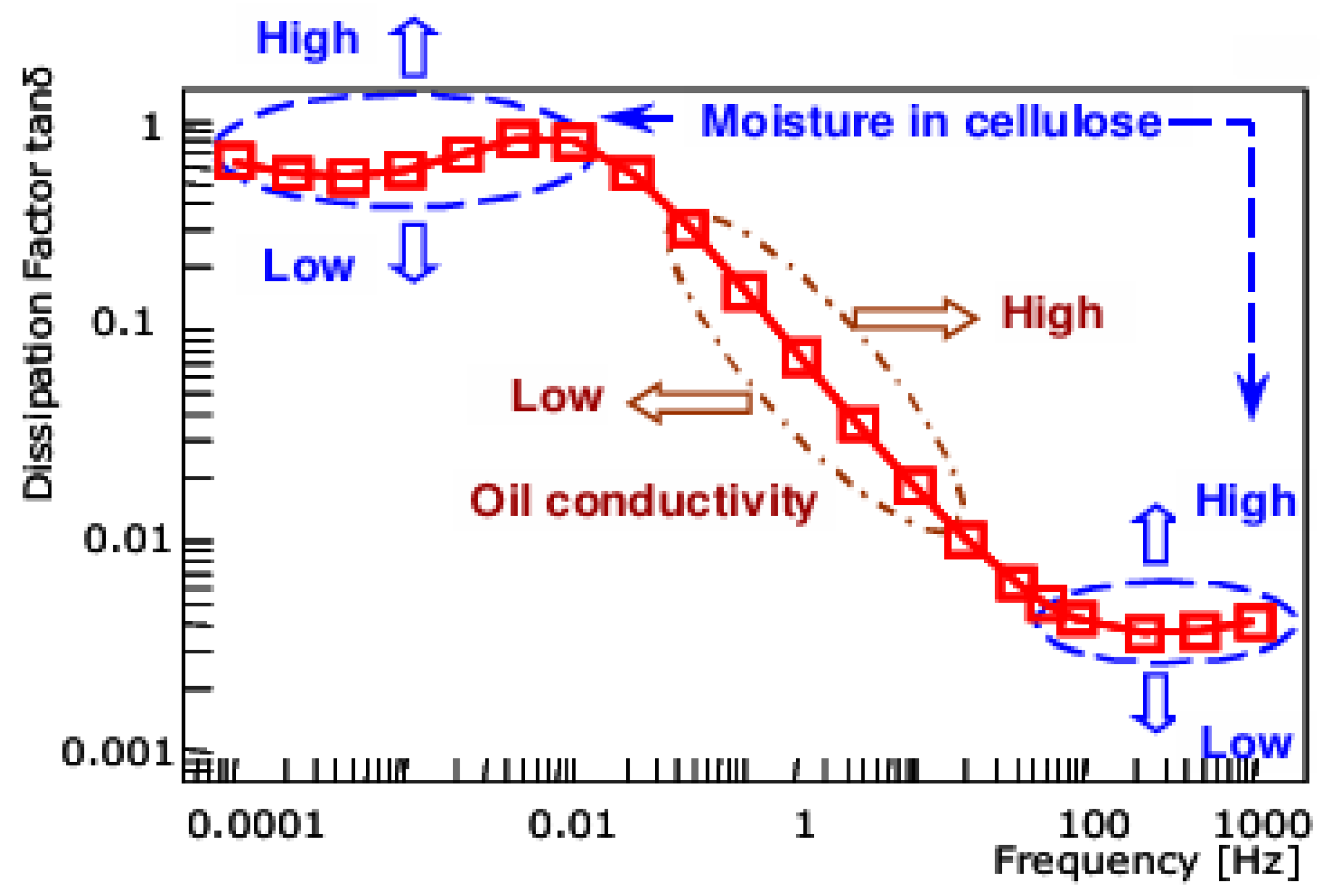

2.2. Factors Influencing the AC Parameters of Power Transformer Insulation

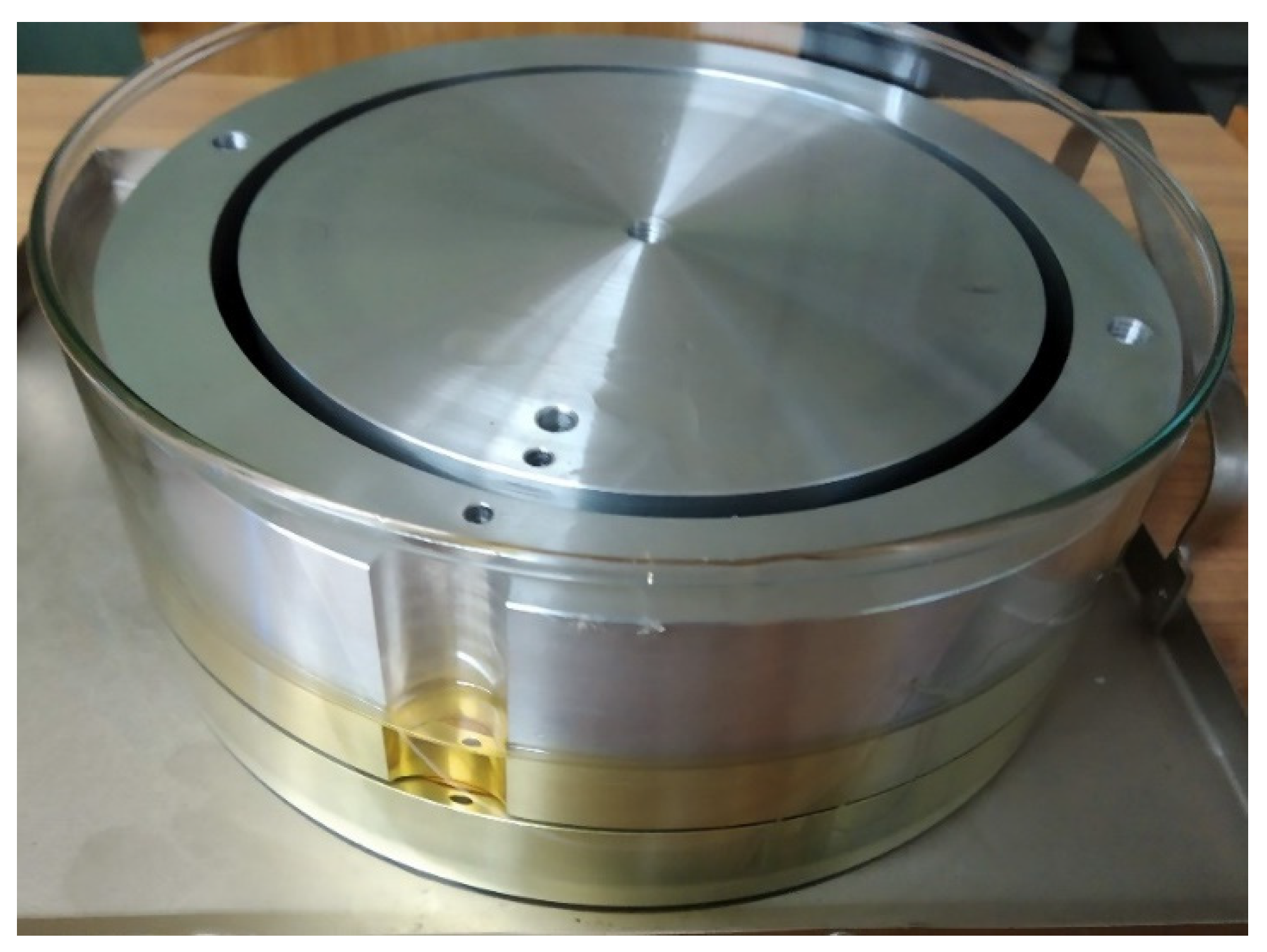

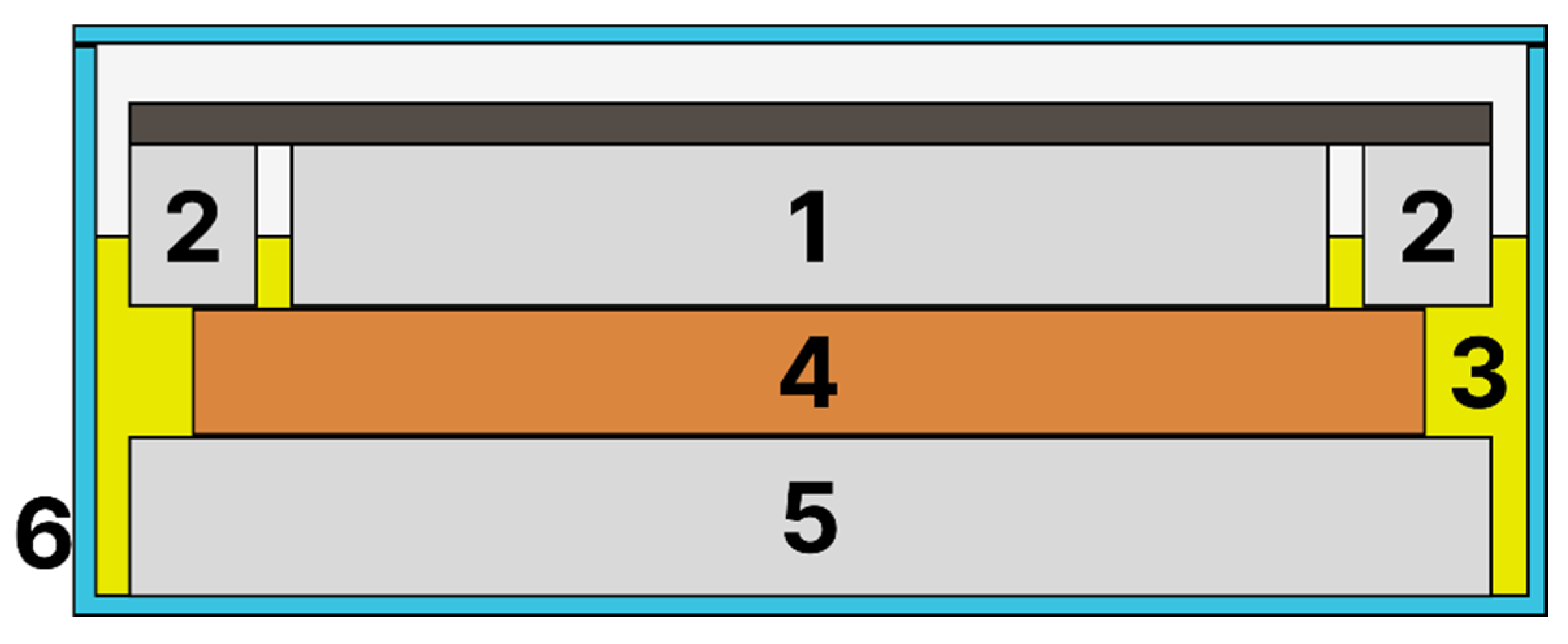

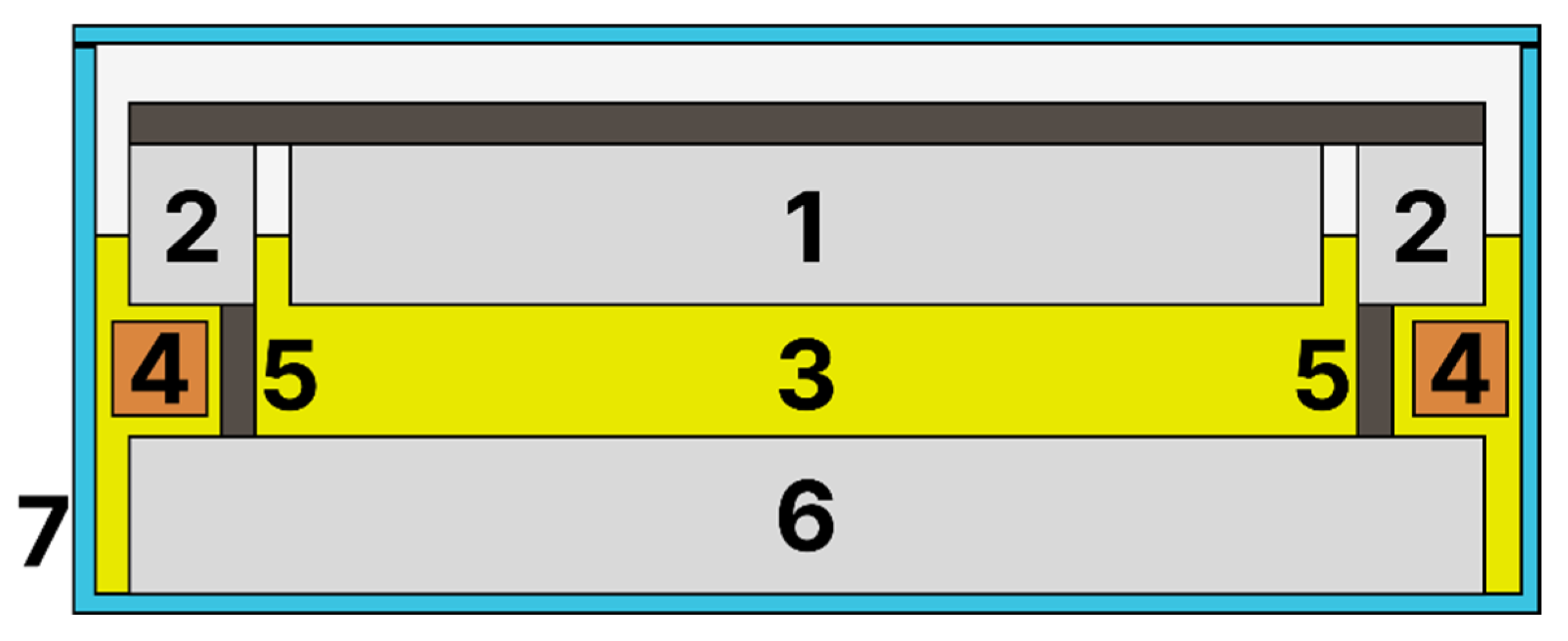

3. Materials and Methods

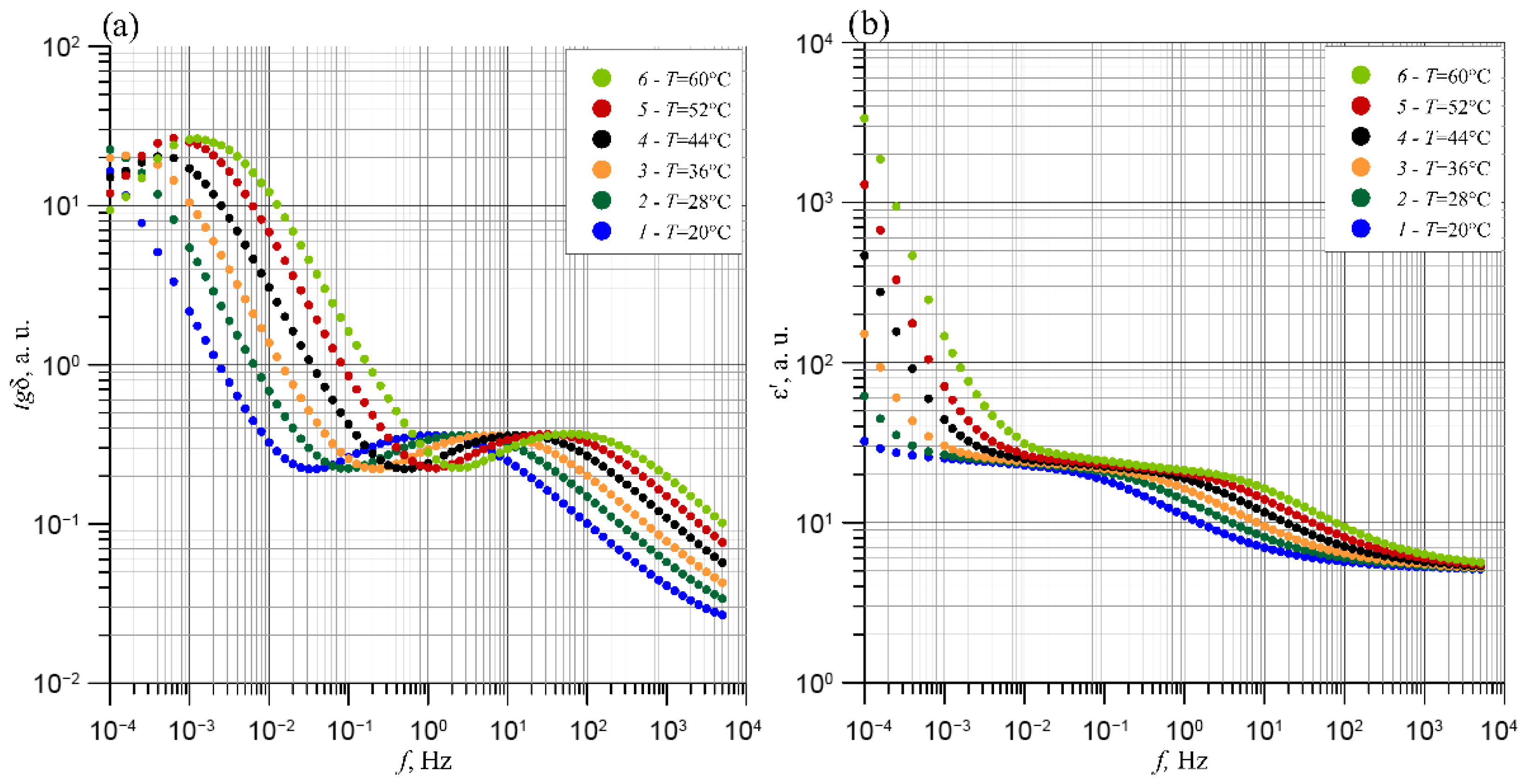

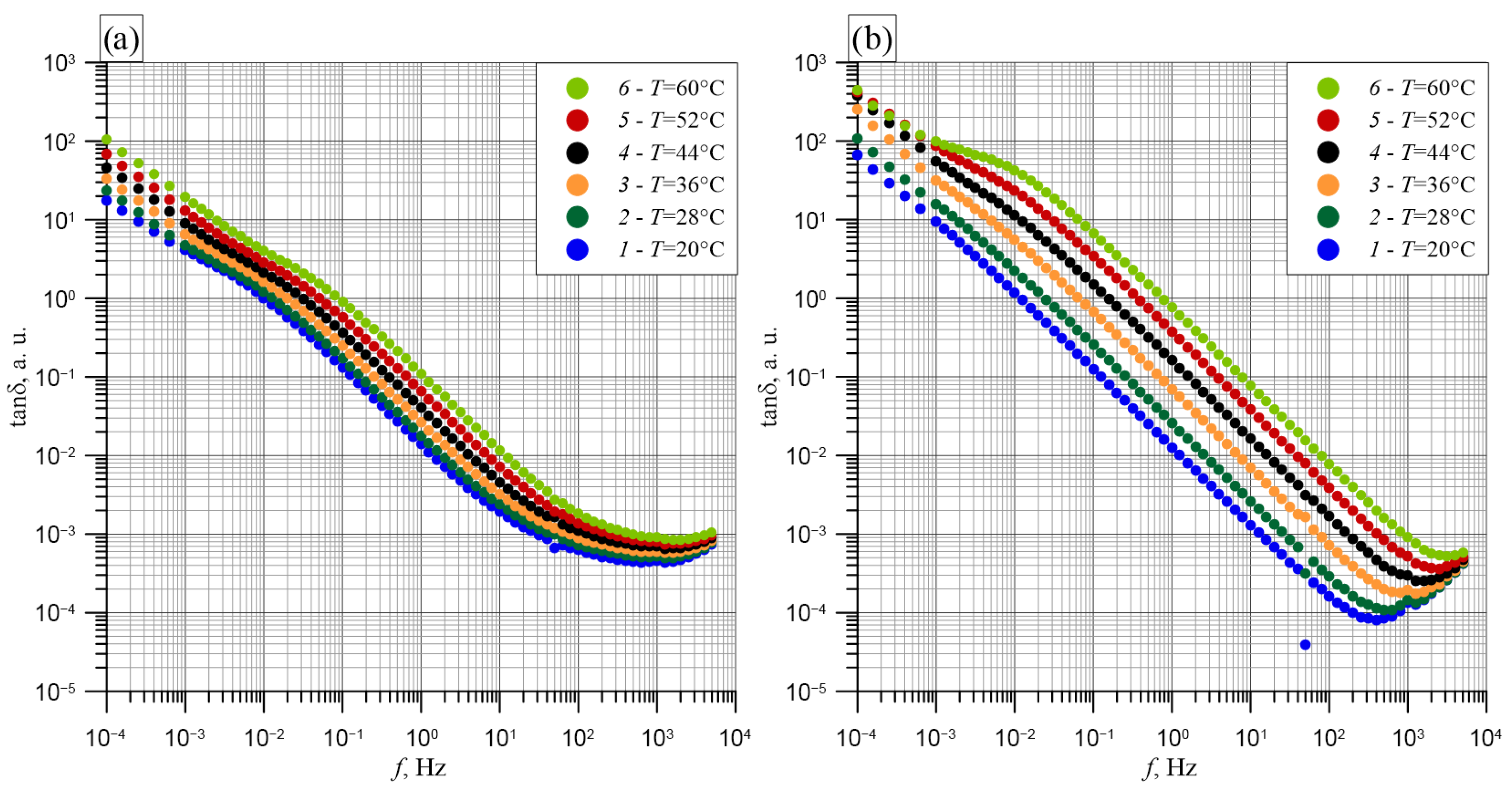

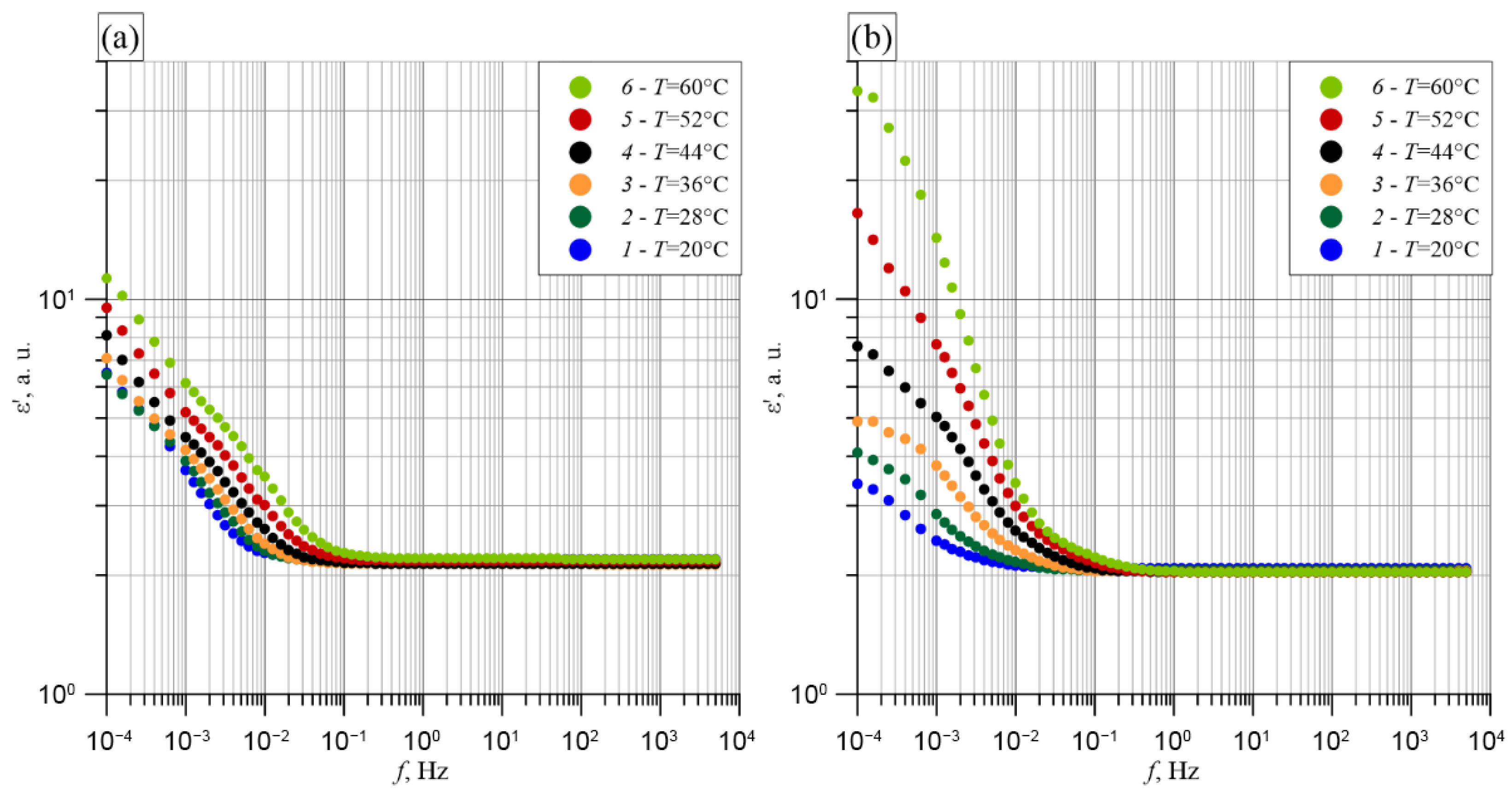

4. Frequency–Temperature Measurements of the Basic Parameters of Transformer Insulation Components

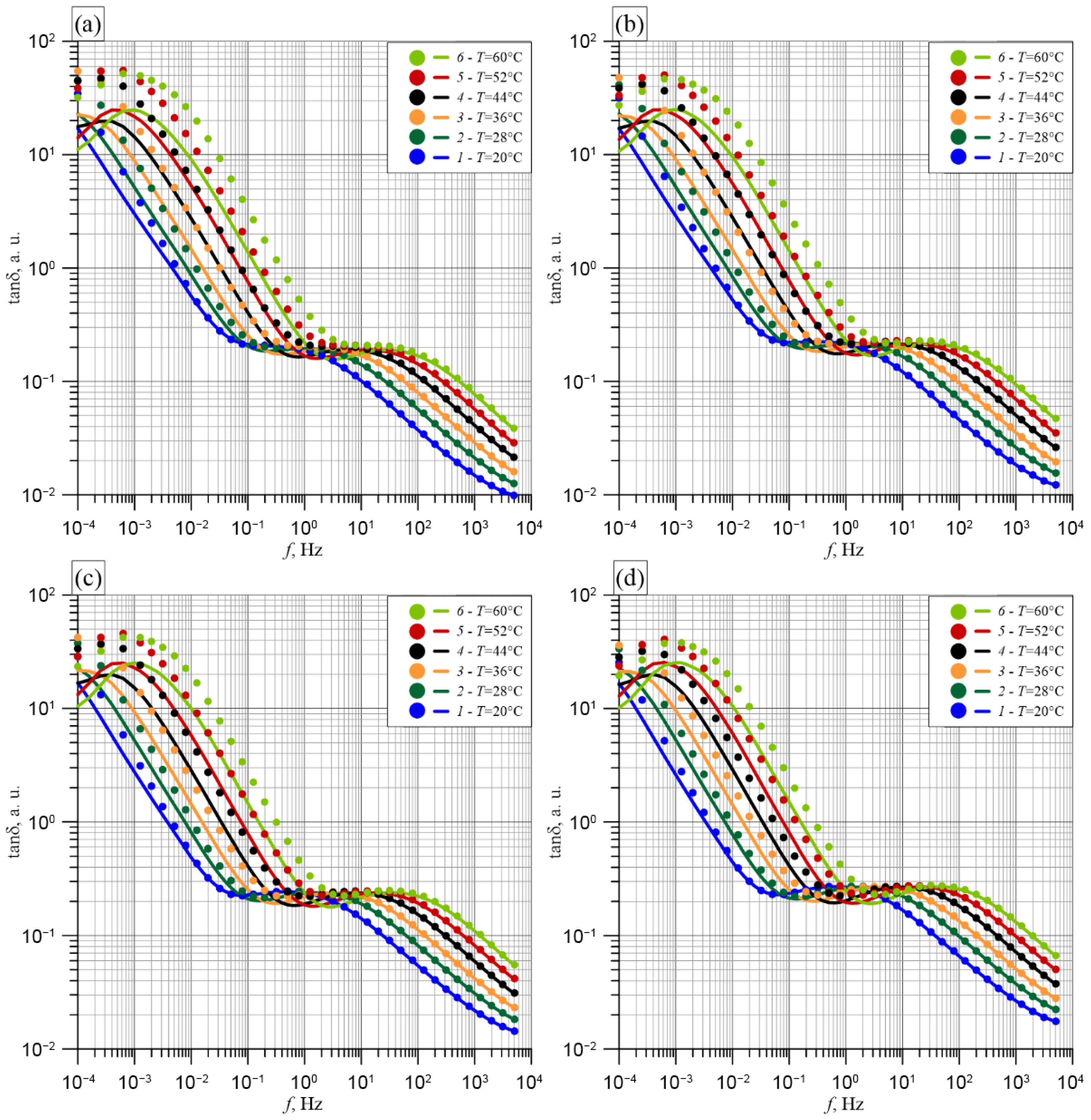

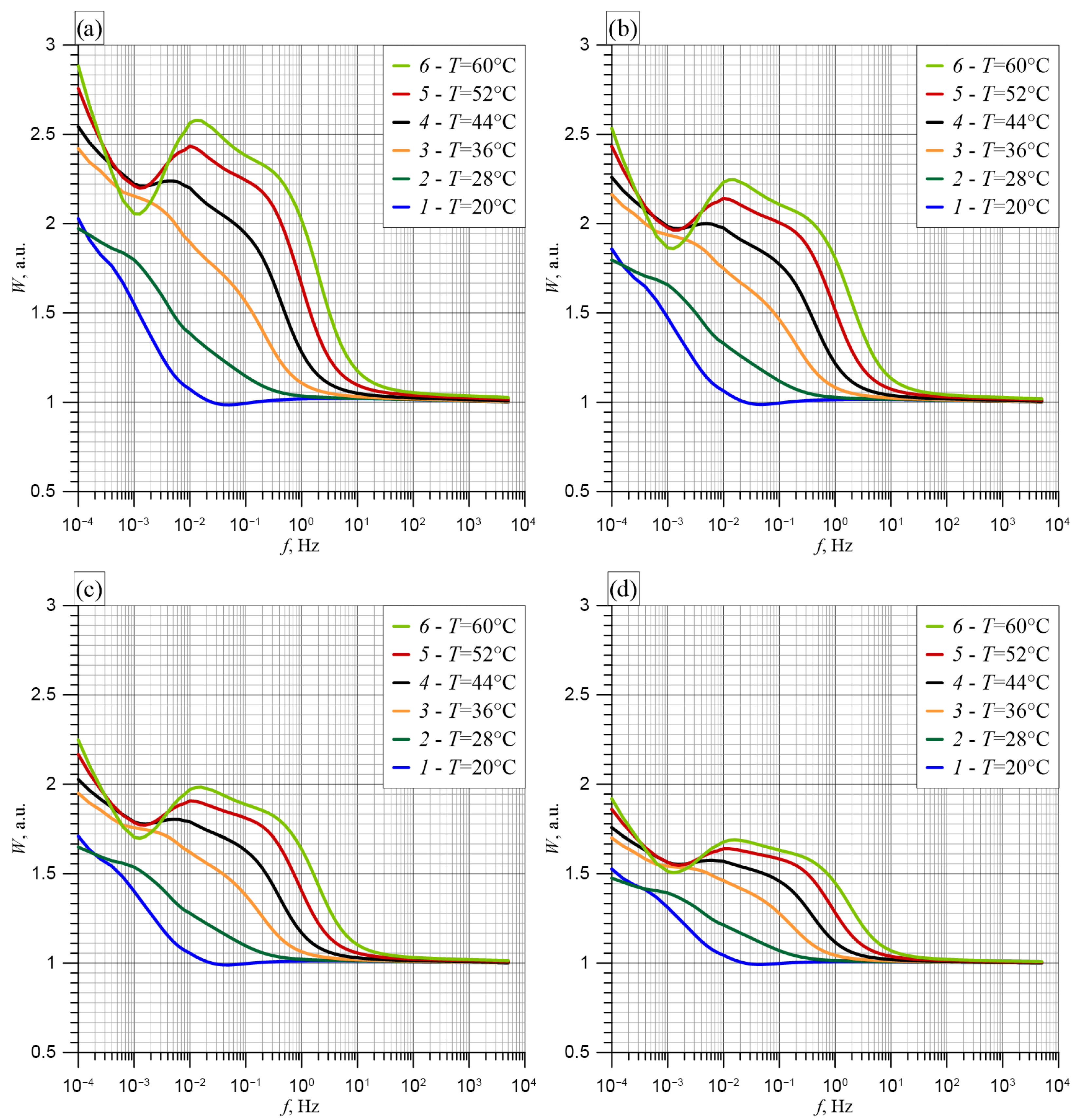

5. Calculation of the AC Parameters of the XY System of Highly Damp Insulation of Power Transformers

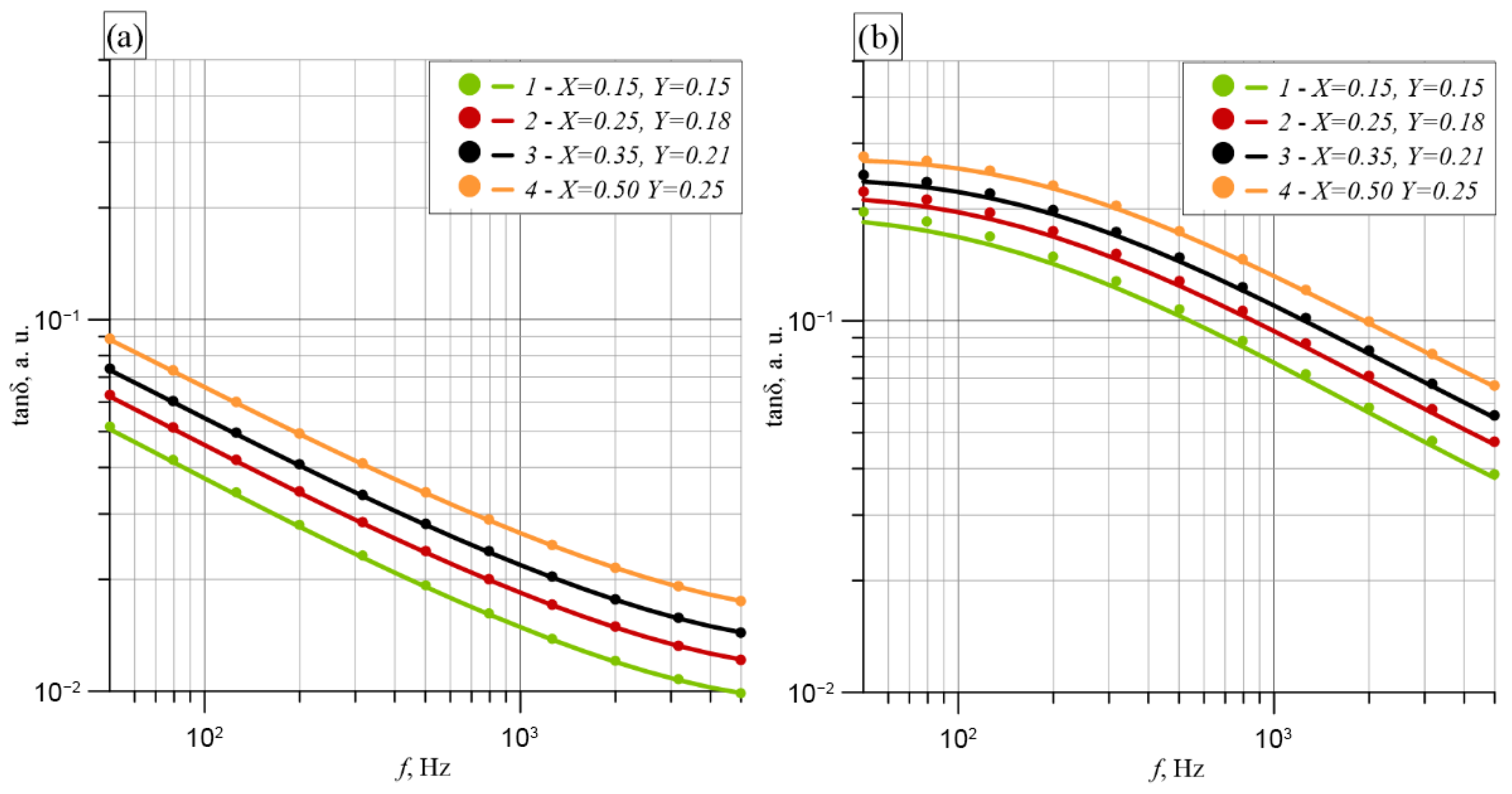

5.1. Loss Tangent

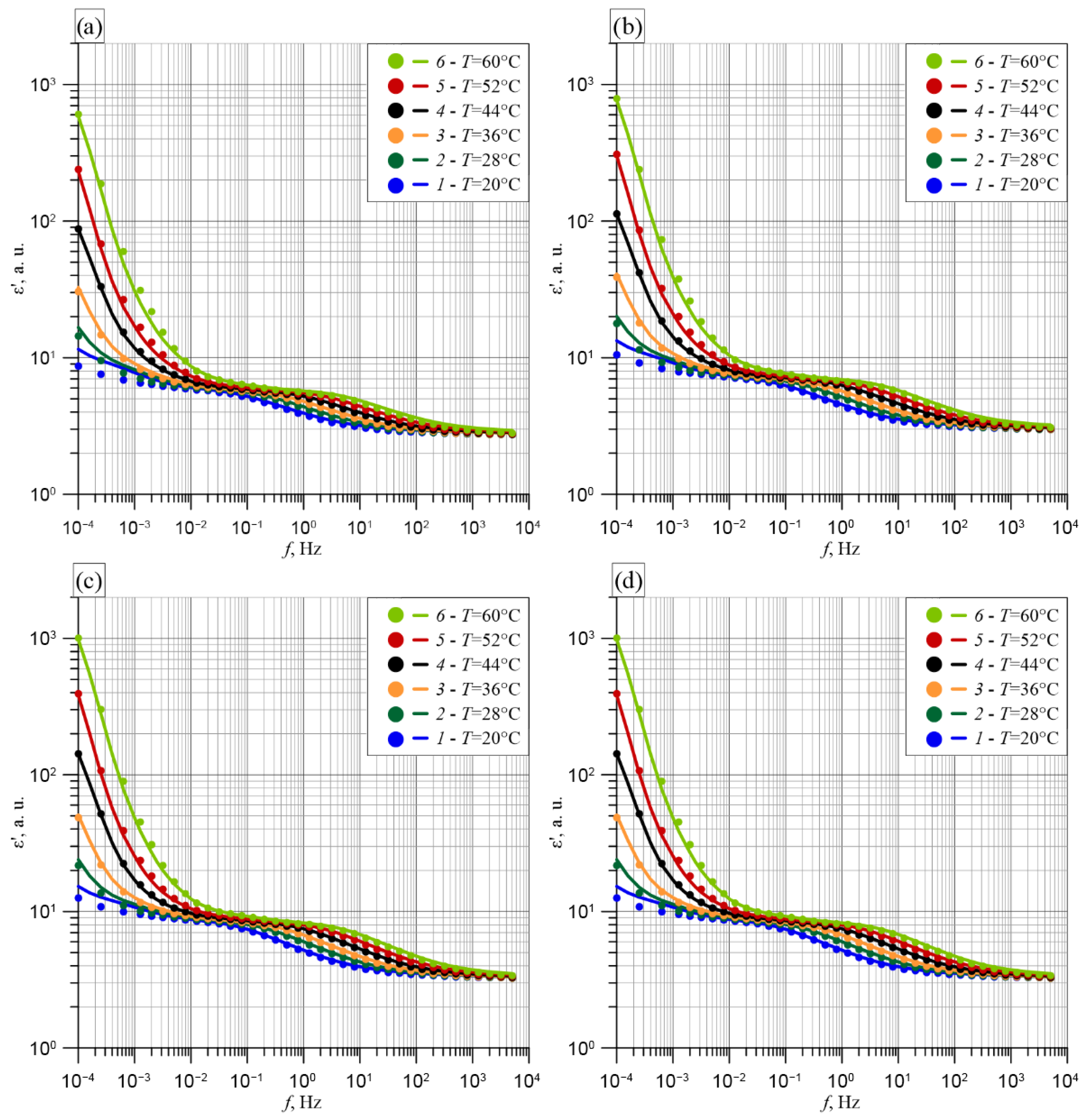

5.2. Real Part of Complex Permittivity

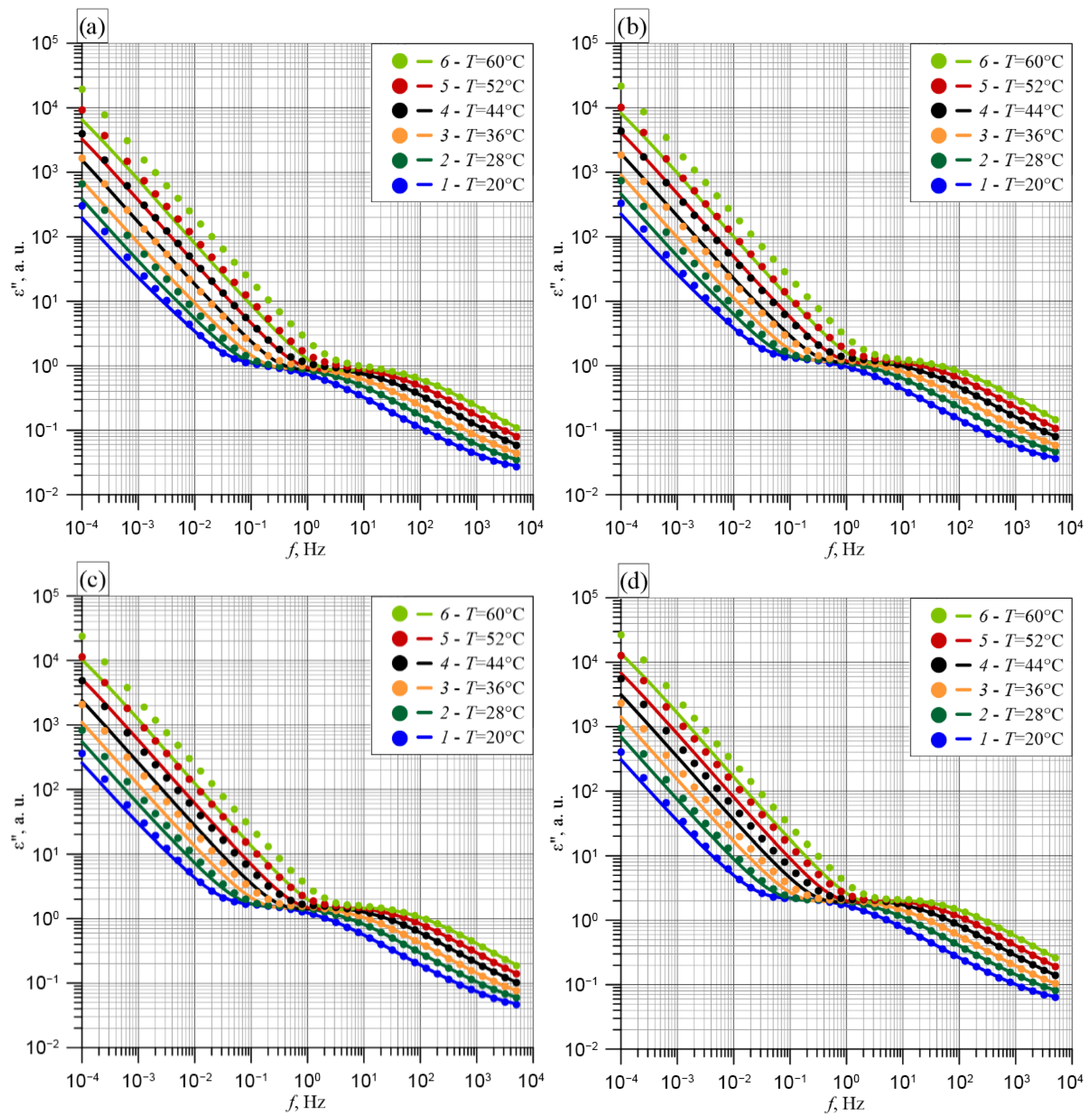

5.3. Loss Factor

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Krause, C. Power transformer insulation—History, technology and design. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1941–1947. [Google Scholar] [CrossRef]

- Prevost, T.A.; Oommen, T.V. Cellulose insulation in oil-filled power transformers: Part I—History and development. IEEE Electr. Insul. Mag. 2006, 22, 28–35. [Google Scholar] [CrossRef]

- Amoiralis, E.I.; Tsili, M.A.; Kladas, A.G. Transformer design and optimization: A literature survey. IEEE Trans. Power Deliv. 2009, 24, 1999–2024. [Google Scholar] [CrossRef]

- Fofana, I.; Wasserberg, V.; Borsi, H.; Gockenbach, E. Retrofilling conditions of high-voltage transformers. IEEE Electr. Insul. Mag. 2001, 17, 17–30. [Google Scholar] [CrossRef]

- Kurzweil, P.; Schell, C.; Haller, R.; Trnka, P.; Hornak, J. Environmental Impact and Aging Properties of Natural and Synthetic Transformer Oils under Electrical Stress Conditions. Adv. Sustain. Syst. 2021, 5, 2100079. [Google Scholar] [CrossRef]

- Bertrand, Y.; Hoang, L.C. Vegetal oils as substitute for mineral oils. In Proceedings of the 7th International Conference on Properties and Applications of Dielectric Materials, Nagoya, Japan, 1–5 June 2003; Volume 2, pp. 491–494. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G.; Miettinen, A.; Luengo Hendriks, C.L.; Gamstedt, E.K.; Kataja, M. Structural Characterisation of Kraft Pulp Fibres and Their Nanofibrillated Materials for Biodegradable Composite Applications. In Nanocomposites and Polymers with Analytical Methods; Scitus Academics: Wilmington, DE, USA, 2011. [Google Scholar]

- Martínez, M.; Pleite, J. Improvement of RVM test interpretation using a Debye equivalent circuit. Energies 2020, 13, 323. [Google Scholar] [CrossRef]

- Lukenda, N. Not all mineral oils are equal—Exploring the history and technology behind mineral insulating oils. Transform. Mag. 2019, 6, 112–117. [Google Scholar]

- Graczkowski, A.; Gielniak, J. Influence of impregnating liquids on dielectric response of impregnated cellulose insulation. In Proceedings of the IEEE International Conference on Solid Dielectrics-ICSD, Potsdam, Germany, 4–9 July 2010; pp. 513–516. [Google Scholar]

- Wei, Y.; Han, W.; Li, G.; Liang, X.; Gu, Z.; Hu, K. Aging Characteristics of Transformer Oil-Impregnated Insulation Paper Based on Trap Parameters. Polymers 2021, 13, 1364. [Google Scholar] [CrossRef]

- Qi, B.; Dai, Q.; Li, C.; Zeng, Z.; Fu, M.; Zhuo, R. The Mechanism and Diagnosis of Insulation Deterioration Caused by Moisture Ingress into Oil-Impregnated Paper Bushing. Energies 2018, 11, 1496. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Aging of Oil-Impregnated Paper in Power Transformers. IEEE Trans. Power Deliv. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Oommen, T.V.; Prevost, T.A. Cellulose insulation in oil-filled power transformers: Part II—Maintaining insulation integrity and life. IEEE Electr. Insul. Mag. 2006, 22, 5–14. [Google Scholar] [CrossRef]

- Fabre, J.; Pichon, A. Deteriorating Processes and Products of Paper in Oil Application to Transformers. In Proceedings of the International Conference on Large High Voltage Electric Systems, Paris, France, 3–6 November 1960; p. 137. [Google Scholar]

- Liu, J.; Zhang, H.; Geng, C.; Fan, X.; Zhang, Y. Aging Assessment Model of Transformer Insulation Based on Furfural Indicator under Different Oil/Pressboard Ratios and Oil Change. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1061–1069. [Google Scholar] [CrossRef]

- Oommen, T.V. Moisture Equilibrium in Paper Oil Systems. In Proceedings of the 16th Electrical/Electronics Insulation Conference, Chicago, IL, USA, 3–6 October 1983; pp. 162–166. [Google Scholar]

- Rahman, M.F.; Nirgude, P. Partial discharge behaviour due to irregular-shaped copper particles in transformer oil with a different moisture content of pressboard barrier under uniform field. IET Gener. Transm. Distrib. 2019, 13, 5550–5560. [Google Scholar] [CrossRef]

- Hill, J.; Wang, Z.; Liu, Q.; Krause, C.; Wilson, G. Analysing the power transformer temperature limitation for avoidance of bubble formation. High Volt. 2019, 4, 210–216. [Google Scholar] [CrossRef]

- Garcia, B.; Villarroel, R.; Garcia, D. A Multiphysical model to study moisture dynamics in transformers. IEEE Trans. Power Deliv. 2019, 34, 1365–1373. [Google Scholar] [CrossRef]

- Islam, M.M.; Lee, G.; Hettiwatte, S.N. A review of condition monitoring techniques and diagnostic tests for lifetime estimation of power transformers. Electr. Eng. 2018, 100, 581–605. [Google Scholar] [CrossRef]

- Fofana, I.; Hadjadj, Y. Electrical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 679. [Google Scholar] [CrossRef]

- Sarkar, S.; Sharma, T.; Baral, A.; Chatterjee, B.; Dey, D.; Chakravorti, S. An expert system approach for transformer insulation diagnosis combining conventional diagnostic tests and PDC, RVM data. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 882–891. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, J.; Zhang, Y.; Ma, Y.; Shen, Y.; Zhen, X.; Chen, Z. Effectiveness Analysis and Temperature Effect Mechanism on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data. Energies 2018, 11, 146. [Google Scholar] [CrossRef]

- Mishra, D.; Haque, N.; Baral, A.; Chakravorti, S. Assessment of interfacial charge accumulation in oil-paper interface in transformer insulation from polarization-depolarization current measurements. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1665–1673. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Zheng, H.; Wang, K. Feasibility of a universal approach for temperature correction in frequency domain spectroscopy of transformer insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1766–1773. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zhang, Y.; Zhang, C.; Wang, Z. Aging evaluation and moisture prediction of oil-immersed cellulose insulation in field transformer using frequency domain spectroscopy and aging kinetics model. Cellulose 2020, 27, 7175–7189. [Google Scholar] [CrossRef]

- Yang, L.; Chen, J.; Gao, J.; Zheng, H.; Li, Y. Accelerating frequency domain dielectric spectroscopy measurements on insulation of transformers through system identification. IET Sci. Meas. Technol. 2018, 12, 247–254. [Google Scholar] [CrossRef]

- Mott, N.F.; Gurney, R.W. Electronic Processes in Ionic Crystals; Clarendon Press: Oxford, UK, 1950. [Google Scholar]

- Broadbent, S.R.; Hammersley, J.M. Percolation processes: I. Crystals and mazes. Math. Proc. Cambridge Philos. Soc. 1957, 53, 629–641. [Google Scholar] [CrossRef]

- Mamunya, Y.P.; Davydenko, V.V.; Pissis, P.; Lebedev, E.V. Electrical and thermal conductivity of polymers filled with metal powders. Eur. Polym. J. 2002, 38, 1887–1897. [Google Scholar] [CrossRef]

- Koltunowicz, T.N.; Zukowski, P.; Bondariev, V.; Fedotova, J.A.; Fedotov, A.K. The effect of annealing on induction like properties of (FeCoZr)x(CaF2)(100−x) nanocomposite films produced by ion-beam sputtering in the vacuum environment. Vacuum 2015, 120, 44–50. [Google Scholar] [CrossRef]

- ISO—ISO/TS 80004-2:2015—Nanotechnologies—Vocabulary—Part 2: Nano-Objects. Available online: https://www.iso.org/standard/54440.html (accessed on 3 December 2021).

- Landau, L.D.; Lifshitz, E.M. Quantum Mechanics, 3rd ed.; Revised and Enlarged; Princeton University Press: Princeton, NJ, USA, 1977; ISBN 978-0-08-020940-1. [Google Scholar]

- Imry, Y. Introduction to Mesoscopic Physics; Oxford University Press: Oxford, UK, 2002; ISBN 9780198507383. [Google Scholar]

- Mott, N.F. Metal-Insulator Transitions; Taylor and Francis: London, UK, 1974. [Google Scholar]

- Pollak, M.; Geballe, T.H. Low-Frequency Conductivity Due to Hopping Processes in Silicon. Phys. Rev. 1961, 122, 1753. [Google Scholar] [CrossRef]

- Ravich, Y.I.; Nemov, S.A. Hopping conduction via strongly localized impurity states of indium in PbTe and its solid solutions. Semiconductors 2002, 36, 1–20. [Google Scholar] [CrossRef]

- Gerashchenko, O.V.; Ukleev, V.A.; Dyad’kina, E.A.; Sitnikov, A.V.; Kalinin, Y.E. Hopping conductivity with the “1/2” law in the multilayer nanocomposite [(Co40Fe40B20)34(SiO2)66/C]47. Phys. Solid State 2017, 59, 164–167. [Google Scholar] [CrossRef]

- Kavokin, A.; Kutrovskaya, S.; Kucherik, A.; Osipov, A.; Vartanyan, T.; Arakelyan, S. The crossover between tunnel and hopping conductivity in granulated films of noble metals. Superlattices Microstruct. 2017, 111, 335–339. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Ivashchenko, V.; Maksakova, O.; Buranich, V.; Konarski, P.; Bondariev, V.; Zukowski, P.; Skrynskyy, P.; Sinelnichenko, A.; Shelest, I.; et al. Comparative measurements and analysis of the mechanical and electrical properties of Ti-Zr-C nanocomposite: Role of stoichiometry. Measurement 2021, 176, 109223. [Google Scholar] [CrossRef]

- Zukowski, P.; Kołtunowicz, T.N.; Kierczyński, K.; Subocz, J.; Szrot, M.; Gutten, M. Assessment of water content in an impregnated pressboard based on DC conductivity measurements theoretical assumptions. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1268–1275. [Google Scholar] [CrossRef]

- Żukowski, P.; Kierczyński, K.; Kołtunowicz, T.N.; Rogalski, P.; Subocz, J. Application of elements of quantum mechanics in analysing AC conductivity and determining the dimensions of water nanodrops in the composite of cellulose and mineral oil. Cellulose 2019, 26, 2969–2985. [Google Scholar] [CrossRef]

- Zukowski, P.W.; Rodzik, A.; Shostak, Y.A. Dielectric constant and ac conductivity of semi-insulating Cd1-xMnxTe semiconductors. Semiconductors 1997, 31, 610–614. [Google Scholar] [CrossRef]

- Zukowski, P.; Rogalski, P.; Kierczynski, K.; Koltunowicz, T.N. Precise Measurements of the Temperature Influence on the Complex Permittivity of Power Transformers Moistened Paper-Oil Insulation. Energies 2021, 14, 5802. [Google Scholar] [CrossRef]

- Kierczynski, K.; Rogalski, P.; Bondariev, V.; Okal, P.; Korenciak, D. Research on the Influence of Moisture Exchange between Oil and Cellulose on the Electrical Parameters of the Insulating Oil in Power Transformers. Energies 2022, 15, 7681. [Google Scholar] [CrossRef]

- Subocz, J. Przewodnictwo i Relaksacja Dielektryczna Warstowywch Układów Izolacyjnych; Uczelniane, W., Ed.; Zachodniopomorski Uniwersytet Technologiczny (Szczecin) Wydaw; Uczelniane Zachodniopomorskiego Uniwersytetu Technologicznego w Szczecinie: Szczecin, Poland, 2012; ISBN 8376631136/9788376631134. [Google Scholar]

- CIGRE. Dielectric Response Methods for Diagnostics of Power Equipment; TF D1.01.09; CIGRE: Paris, France, 2002; p. 33. [Google Scholar]

- CIGRE. Dielectric Response Diagnoses for Transformer Windings; TF D1.01; CIGRE: Paris, France, 2010. [Google Scholar]

- Alekseev, B.A. A new method for detecting moisture in the insulation of transformer windings. Elektrichestvo 1959, 2, 58–63. [Google Scholar]

- Occhini, E.; Maschio, G. Electrical Characteristics of Oil-Impregnated Paper as Insulation for HV DC Cables. IEEE Trans. Power Appar. Syst. 1967, PAS-86, 312–326. [Google Scholar] [CrossRef]

- Silva, H.A.P.; Bassi, W.; Diogo, A.C.T. Non-invasive ageing assessment by means of polarization and depolarization currents analysis and its correlation with moisture content for power transformer life management. In Proceedings of the 2004 IEEE/PES Transmision and Distribution Conference and Exposition, Sao Paulo, Brazil, 8–11 November 2004; pp. 611–616. [Google Scholar] [CrossRef]

- Fan, X.; Liu, J.; Zhang, Y.; Yang, S.; Zhang, C.; Zhang, Y. A modified XY model of transformer oil–paper insulation system including non-uniform aging and conductance effect. IET Gener. Transm. Distrib. 2021, 15, 2008–2017. [Google Scholar] [CrossRef]

- Leibfried, T.; Kachler, A.J. Insulation diagnostic on power transformers using the polarisation and depolarisation current (PDC) analysis. In Proceedings of the Conference Record of the the 2002 IEEE International Symposium on Electrical Insulation, Boston, MA, USA, 7–10 April 2002; pp. 170–173. [Google Scholar] [CrossRef]

- Waygood, A. An Introduction to Electrical Science, 2nd ed.; Taylor & Francis Group: New York, NY, USA, 2019. [Google Scholar]

- Koch, M.; Tenbohlen, S.; Krüger, M.; Kraetge, A. A Comparative Test and Consequent Improvements on Dielectric Response Methods. In Proceedings of the 15th International Symposium on High Voltage Engineering, Ljubljana, Slovenia, 27–31 August 2007. [Google Scholar]

- Blennow, J.; Ekanayake, C.; Walczak, K.; García, B.; Gubanski, S.M. Field experiences with measurements of dielectric response in frequency domain for power transformer diagnostics. IEEE Trans. Power Deliv. 2006, 21, 681–688. [Google Scholar] [CrossRef]

- Ekanayake, C.; Gubanski, S.M.; Graczkowski, A.; Walczak, K. Frequency Response of Oil Impregnated Pressboard and Paper Samples for Estimating Moisture in Transformer Insulation. IEEE Trans. Power Deliv. 2006, 21, 1309–1317. [Google Scholar] [CrossRef]

- Zhang, D.; Yun, H.; Zhan, J.; Sun, X.; He, W.; Niu, C.; Mu, H.; Zhang, G.J. Insulation condition diagnosis of oil-immersed paper insulation based on non-linear frequency-domain dielectric response. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1980–1988. [Google Scholar] [CrossRef]

- Liao, R.; Liu, J.; Yang, L.; Gao, J.; Zhang, Y.; Lv, Y.D.; Zheng, H. Understanding and analysis on frequency dielectric parameter for quantitative diagnosis of moisture content in paper-oil insulation system. IET Electr. Power Appl. 2015, 9, 213–222. [Google Scholar] [CrossRef]

- Moranda, H.; Moscicka-Grzesiak, H. A Particularly Dangerous Case of the Bubble Effect in Transformers That Appeared in a Large Mass of Pressboard Heated by Mineral Oil. Energies 2025, 18, 380. [Google Scholar] [CrossRef]

- Oommen, T.V.; Lindgren, S.R. Bubble evolution from transformer overload. In Proceedings of the 2001 IEEE/PES Transmission and Distribution Conference and Exposition. Developing New Perspectives, Atlanta, GA, USA, 2 November 2001; Volume 1, pp. 137–142. [Google Scholar] [CrossRef]

- Zhao, H.; Mu, H.; Zhang, D.; DIng, N.; Wu, Y.; Zhang, G.; Tian, J.; Liang, Z. Analysis of FDS Characteristics of Oil-impregnated Paper Insulation under High Electric Field Strength Based on the Motion of Charge Carriers. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1153–1161. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zhang, Y.; Lai, B.; Jiao, J. Analysis of low-frequency polarisation behaviour for oil-paper insulation using logarithmic-derivative spectroscopy. High Volt. 2021, 6, 460–469. [Google Scholar] [CrossRef]

- Fofana, I.; Hemmatjou, H.; Meghnefi, F.; Farzaneh, M.; Setayeshmehr, A.; Borsi, H.; Gockenbach, E. On the frequency domain dielectric response of oil-paper insulation at low temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 799–807. [Google Scholar] [CrossRef]

- IEC 60814:2.0; Insulating Liquids—Oil-Impregnated Paper and Pressboard—Determination of Water by Automatic Coulometric Karl Fischer Titration. American National Standards Institute (ANSI): Washington, DC, USA, 2007.

- OMICRON electronics Asia Limited. DIRANA—The Fastest Way of Moisture Determination of Power- and Instrument Transformers and Condition Assessment of Rotating Machines; L2894; OMICRON electronics Asia Limited: Huangpu, China, 2018. [Google Scholar]

- Gubanski, S.M.; Blennow, J.; Karlsson, L.; Feser, K.; Tenbohlen, S.; Neumann, C.; Moscicka-Grzesiak, H.; Filipowski, A.; Tatarski, L. Reliable diagnostics of HV transformer insulation for safety assurance of power transmission system REDIATOOL—A european research project. In Proceedings of the 41st International Conference on Large High Voltage Electric Systems, Paris, France, 27 August–1 September 2006; CIGRE: Paris, France, 2006; p. D1-207. [Google Scholar]

- Jaya, M.; Leibfried, T.; Koch, M. Information within the dielectric response of power transformers for wide frequency ranges. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010. [Google Scholar] [CrossRef]

- Koch, M.; Prevost, T. Analysis of dielectric response measurements for condition assessment of oil-paper transformer insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1908–1915. [Google Scholar] [CrossRef]

- Bigdeli, M.; Aghajanloo, J.; Azizian, D. Estimation of Moisture in Transformer Insulation Using Dielectric Frequency Response Analysis by Heuristic Algorithms. Model. Simul. Electr. Electron. Eng. 2021, 1, 27–35. [Google Scholar] [CrossRef]

- Brncal, P.; Gutten, M. Diagnostics of Insulating Condition of Traction Transformer by Frequency Method. Transp. Res. Procedia 2021, 55, 977–982. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zukowski, P.; Kierczynski, K.; Rogalski, P.; Okal, P.; Molenda, P.; Szrot, M.; Pajak, R. Frequency–Temperature Characteristics of the Cellulose—Insulating Oil–Water Nanodroplet Nanocomposite Components for Diagnostic Evaluation of Power Transformer Insulation. Energies 2025, 18, 6176. https://doi.org/10.3390/en18236176

Zukowski P, Kierczynski K, Rogalski P, Okal P, Molenda P, Szrot M, Pajak R. Frequency–Temperature Characteristics of the Cellulose—Insulating Oil–Water Nanodroplet Nanocomposite Components for Diagnostic Evaluation of Power Transformer Insulation. Energies. 2025; 18(23):6176. https://doi.org/10.3390/en18236176

Chicago/Turabian StyleZukowski, Pawel, Konrad Kierczynski, Przemyslaw Rogalski, Pawel Okal, Pawel Molenda, Marek Szrot, and Rafal Pajak. 2025. "Frequency–Temperature Characteristics of the Cellulose—Insulating Oil–Water Nanodroplet Nanocomposite Components for Diagnostic Evaluation of Power Transformer Insulation" Energies 18, no. 23: 6176. https://doi.org/10.3390/en18236176

APA StyleZukowski, P., Kierczynski, K., Rogalski, P., Okal, P., Molenda, P., Szrot, M., & Pajak, R. (2025). Frequency–Temperature Characteristics of the Cellulose—Insulating Oil–Water Nanodroplet Nanocomposite Components for Diagnostic Evaluation of Power Transformer Insulation. Energies, 18(23), 6176. https://doi.org/10.3390/en18236176