Comparative Analysis of Shaft Voltage Harmonic Characteristics in Large-Scale Generators: OEM and Excitation System Comparisons

Abstract

1. Introduction

2. Materials and Experimental Methodology

2.1. Description of Test System and Generator Parameters

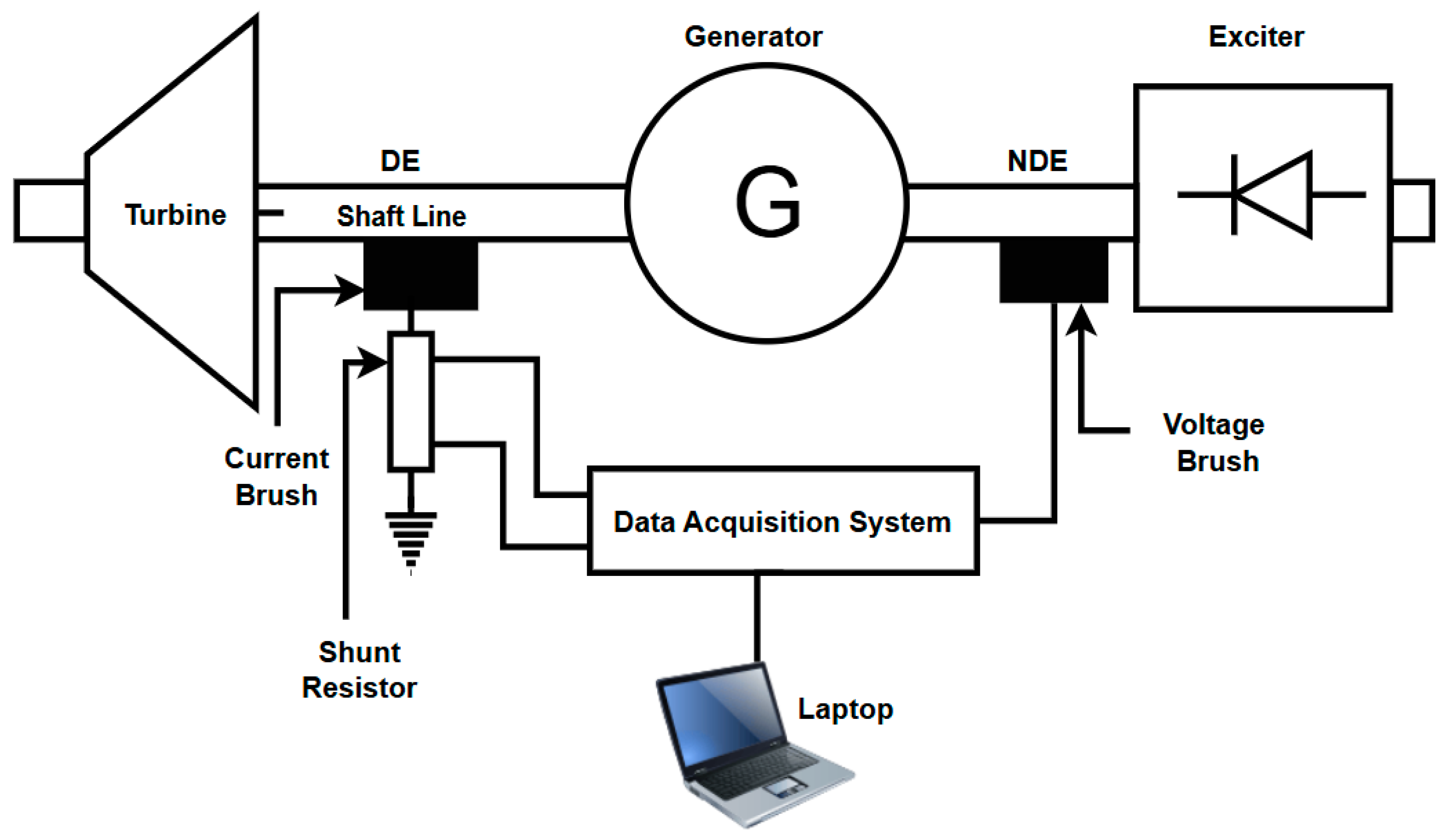

2.2. Measurement Setup Arrangement

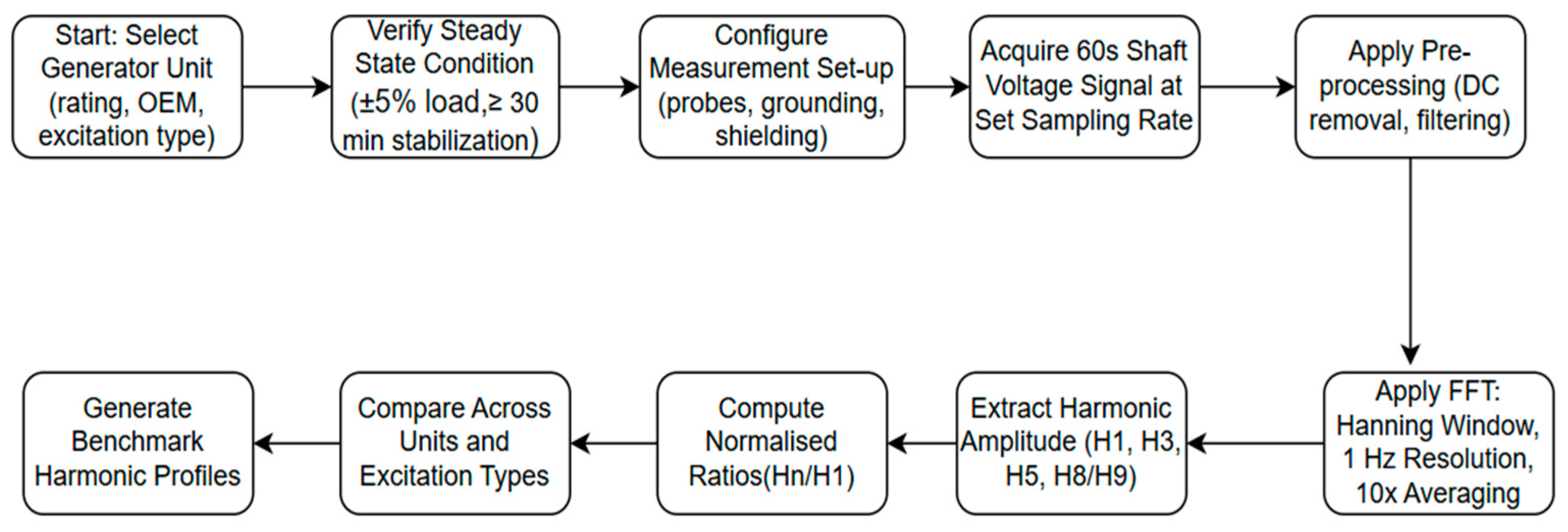

2.3. Experimental Procedure

2.4. Signal Processing and Sampling System

- Sampling rate: 1 MS/s (mega-sample per second), providing a Nyquist frequency of 500 kHz to capture transient and harmonic components up to this range.

- Resolution: 12-bit analog-to-digital conversion, providing sufficient dynamic range to detect low-level bearing current activity and voltage fluctuations associated with incipient earthing faults.

3. Test Results and Measurements

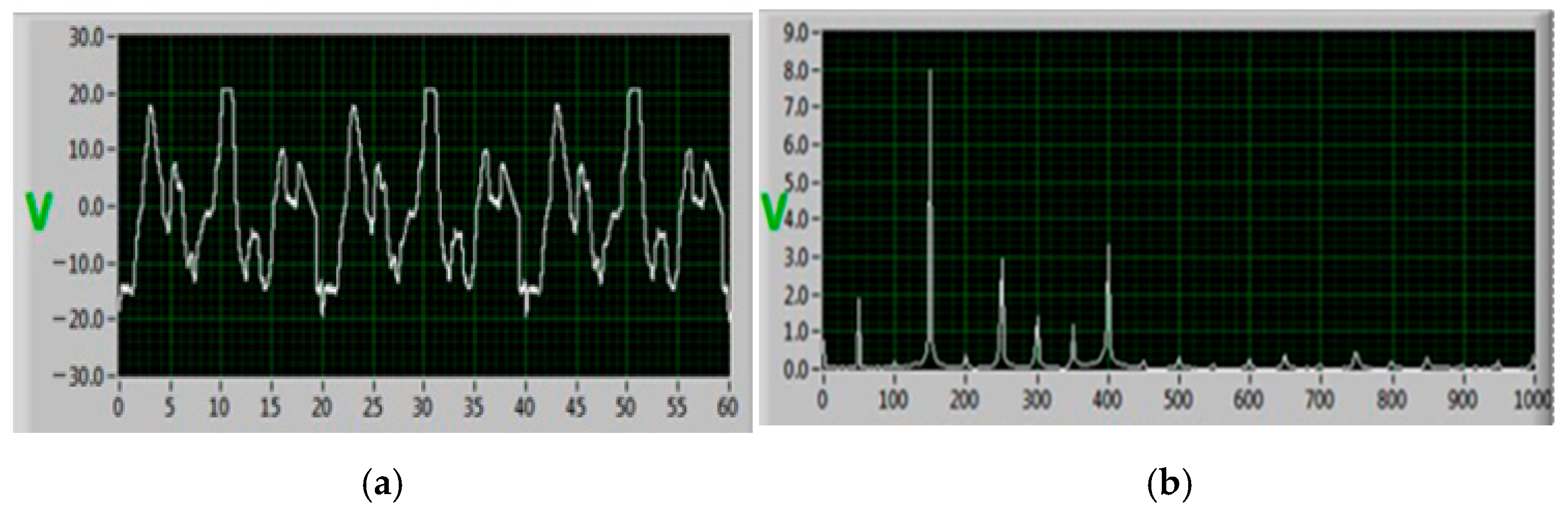

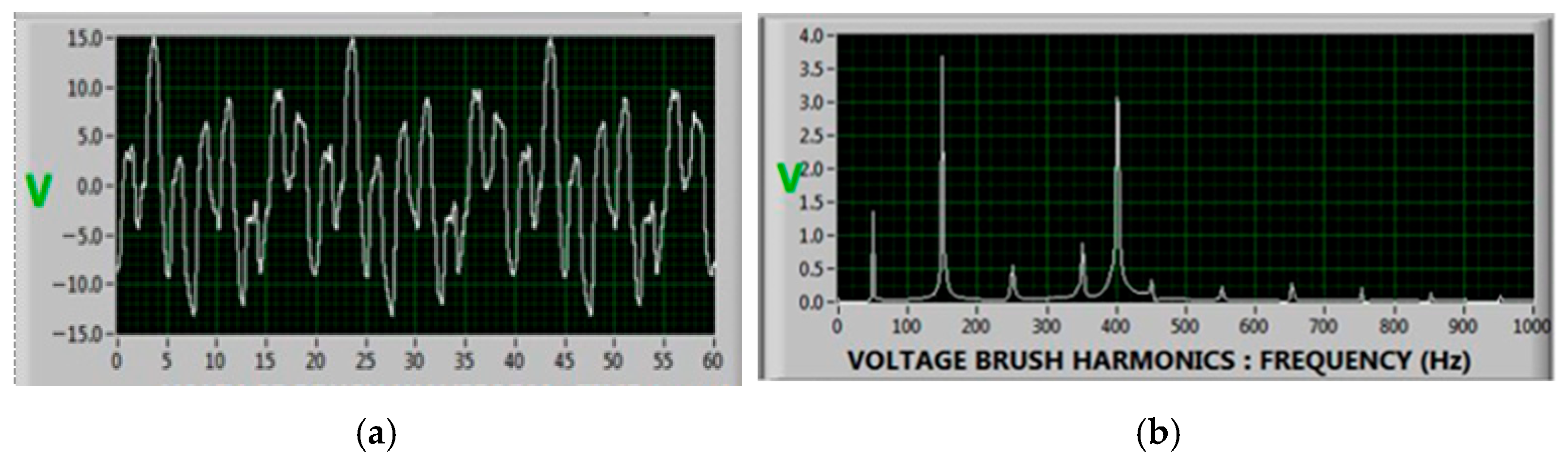

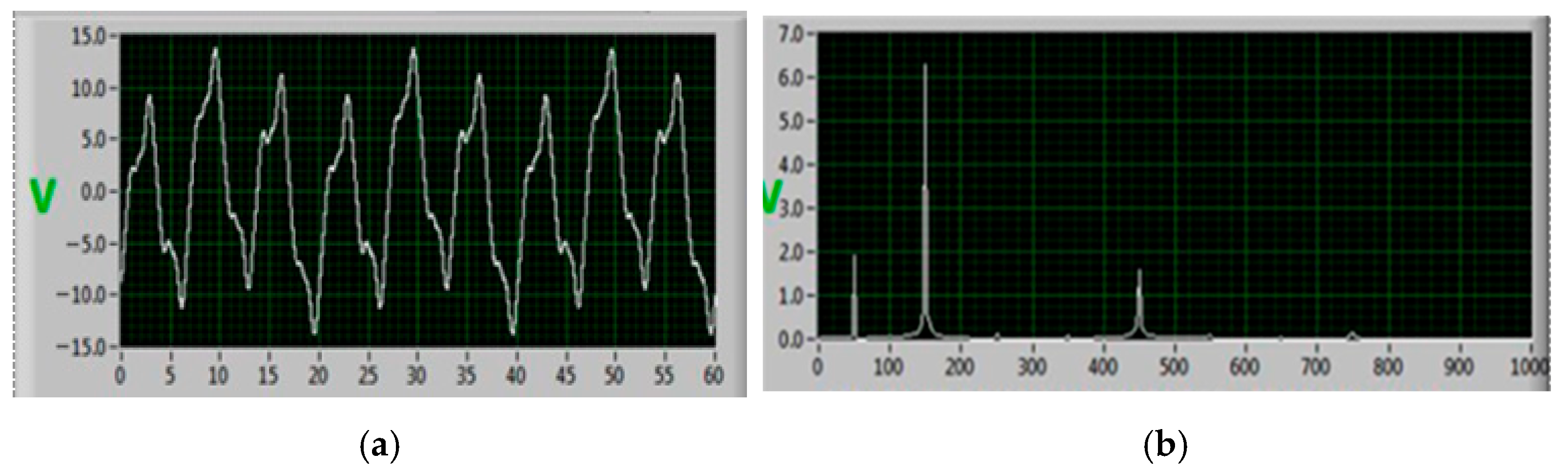

3.1. Brushless Excitation (Stations A, B, C)

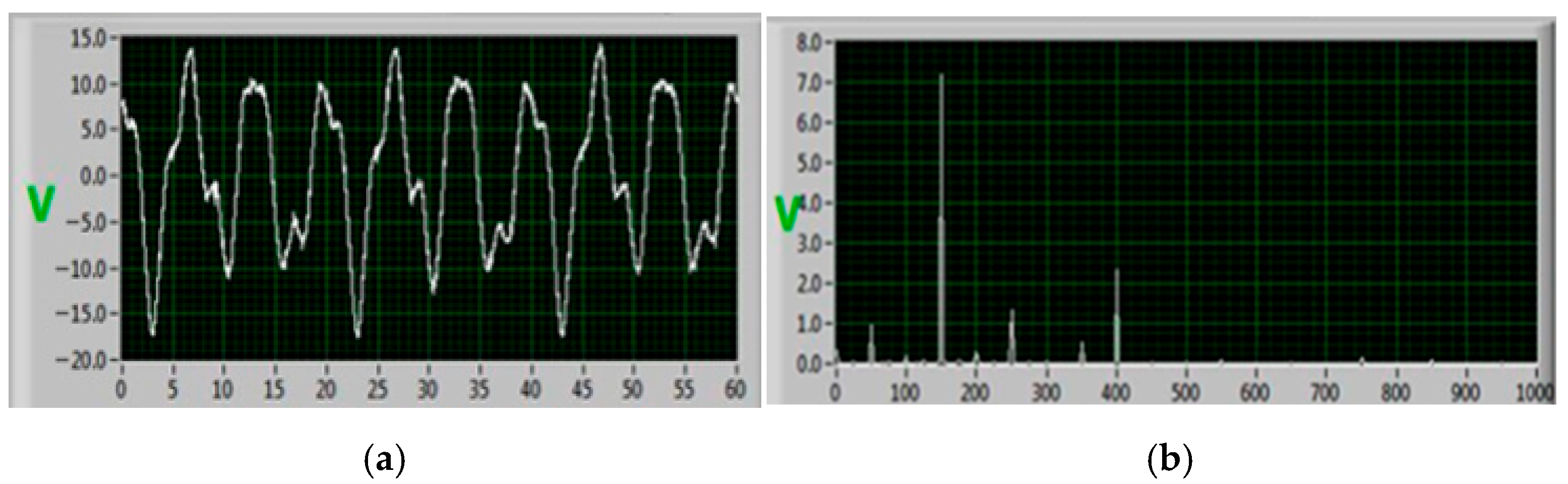

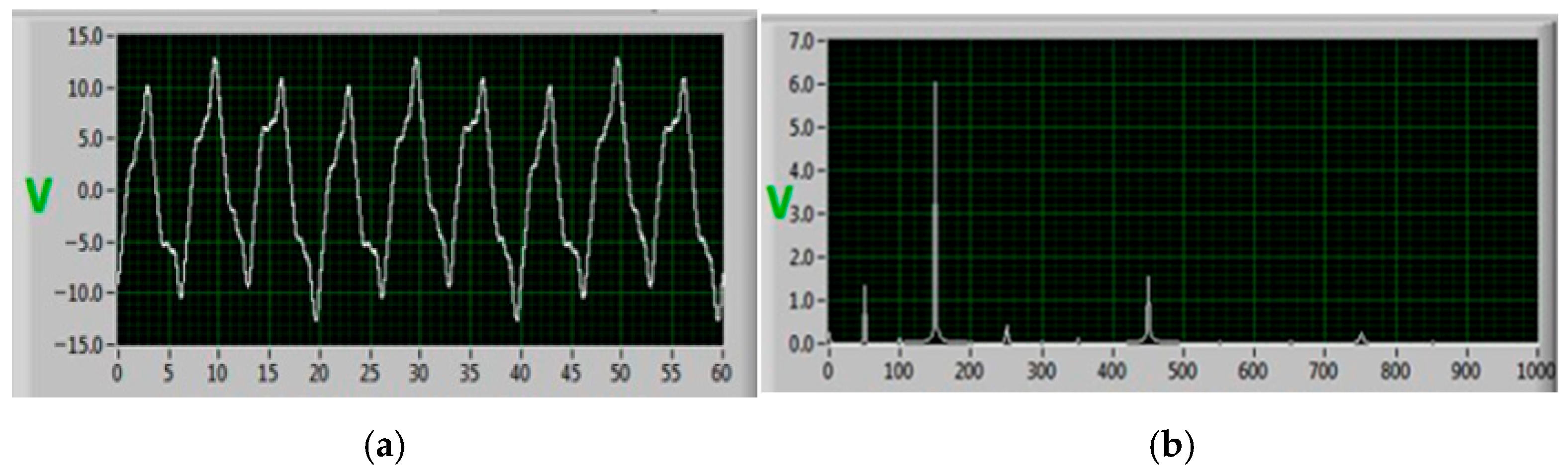

3.2. Static Excitation (Stations D and E)

3.3. Overall Comparison of Harmonic Signatures

3.4. Data-Driven Fault-Detection Framework Based on Benchmark Harmonic Maps

- Baseline reference: use benchmark harmonic profiles as labeled “healthy” signatures.

- Real-time feature extraction: acquire shaft voltage data, compute FFT or STFT-based harmonic ratios, and feed the feature vector into a trained classifier (e.g., CNN, LSTM, or ensemble tree).

- Anomaly detection: compare incoming features against the reference manifold; deviations beyond tolerance bands trigger fault flags.

- Localization and mitigation: apply model explainability or sensor fusion methods to identify which subsystem (brush gear, rectifier leg, grounding path) drives the anomaly.

- Cyber-resilience: integrate statistical residual analysis or blockchain-secured logs to detect and isolate false-data injections or spoofed sensor inputs.

4. Key Findings and Discussion

- Excitation system is the dominant factor governing shaft voltage harmonics. The type of excitation architecture (brushless vs. static) essentially sets the baseline harmonic “fingerprint” of the shaft voltage. All brushless-excited machines in this study, despite spanning two different OEMs and including different rectifier pulse counts, shared a common 3rd–5th–8th harmonic pattern. In contrast, the static excitation machines consistently exhibited a 3rd–9th pattern, with the 9th harmonic (450 Hz) emerging as a distinctive feature absent in the brushless units. This convergence of spectral content within each excitation family and the persistence of that content across different manufacturers indicates that excitation topology imposes a stronger influence on the shaft voltage spectrum than machine-specific design details. In practical terms, this means that when assessing shaft voltage data, one should first classify the generator by its excitation type, as this largely determines which harmonics are expected under healthy conditions.

- In static excitation systems, the commutation process of the thyristors and the dynamic voltage regulation performed by the automatic voltage regulator (AVR) introduce characteristic harmonic components in the rotor field current. These current distortions generate fluctuating magnetic flux linkages that are electromagnetically coupled to the main shaft surface potential. In multi-pole rotor structures, the coupling path enhances the propagation of higher-order harmonics, particularly the 9th harmonic (450 Hz), which appears prominently in the shaft voltage spectrum. This mechanism explains the consistent presence of the 9th harmonic observed across all static excitation units and confirms that it originates from excitation circuit dynamics rather than mechanical asymmetry or measurement artifacts.

- The consistency of harmonic patterns within each excitation family demonstrates that the spectral characteristics identified in this study are not machine-specific but topology-specific. This indicates that the harmonic fingerprints developed here can be applied broadly across units of different OEMs, supporting their use for fleet-wide condition monitoring and baseline threshold setting.

- Baseline harmonic ratios and thresholds should be tailored to the excitation family. Because each excitation class has its own characteristic harmonic profile, a one-size-fits-all diagnostic criterion would be ineffective and could lead to misclassification of normal vs. abnormal conditions. For example, a high 8th-harmonic-to-1st-harmonic ratio (H8/H1) might be perfectly normal for a brushless unit but would be unusual for a static unit (which should exhibit H9 instead). Conversely, an elevated 9th harmonic would be a red flag in a brushless machine but is part of the normal signature for a static exciter machine. Therefore, we recommend developing family-specific diagnostic parameters. For brushless units, ratios such as H3/H1, H5/H1, and H8/H1 (3rd, 5th, and 8th harmonics relative to the fundamental) are pertinent features to monitor over time. For static exciter units, H3/H1 and H9/H1 (3rd and 9th) are more relevant metrics. In addition to these harmonic ratios, absolute shaft voltage levels and other aggregate measures (e.g., average RMS voltage, the gap between peak and average voltage, DC offset, and total harmonic distortion or the even-to-odd harmonic ratio) can provide useful information, but these too should be interpreted in the context of the appropriate baseline for that excitation family. Implementing diagnostics that are “family-aware” will improve sensitivity and specificity—for instance, avoiding false alarms on brushless machines by not applying static machine criteria, and vice versa.

- Within each family, minor design differences have second-order effects on the spectrum. The data show that generators of the same excitation class but different OEM lineages still exhibit the same dominant harmonics, with differences mainly in amplitude or secondary components. Stations A and B (both OEM H brushless) have nearly identical spectra, as expected. Station C (OEM K brushless) retains the same harmonic frequencies (150, 250, 400 Hz) as A and B, confirming that the brushless excitation design dictates those frequencies. The use of a 24-pulse exciter in C primarily affects the magnitude of the 3rd and 5th harmonics (reducing them compared to the 6-pulse cases) due to the finer rectification reducing low-order ripple, but it does not eliminate them. This illustrates that increasing the number of pulses in the exciter smooths the field current and hence attenuates lower-order induced shaft voltage harmonics [11,23], but higher-pulse systems will still share the same harmonic family. Similarly, stations D and E (static exciters, OEM K) have essentially the same spectrum; any subtle differences can be attributed to unit-specific conditions or minor control settings, but the overarching 3rd and 9th pattern is consistent. This finding is encouraging for building generalized diagnostic rules: it implies that one can develop a baseline harmonic signature for a given excitation type that applies broadly, with only minor calibration for specific designs or operating points.

- The universal presence of the 3rd harmonic and the significance of triple-n components. The 150 Hz component appears in every generator’s shaft voltage spectrum, making it a universal marker of the shaft grounding system’s response. This third harmonic often arises from inherent 3× per revolution phenomena or zero-sequence currents that circulate via the shaft ground. Its stability across different machines suggests that it can serve as a reliable indicator of the machine’s general health—any significant reduction or growth in the 150 Hz component in a given machine could signify a change in the machine’s condition (for example, improvements or deterioration in balance, or changes in the excitation system behavior). On the other hand, the presence or absence of higher triple-n harmonics (like the 9th) differentiate the families. Triple-n harmonics (multiples of 3) are zero-sequence components; in the context of a generator’s shaft, their manifestation depends on how the excitation system drives the field and how those harmonics might induce currents in the shaft ground loop. The prominence of the 9th harmonic in the static exciters confirms that the thyristor rectifier introduces a strong zero-sequence harmonic (since in a three-phase six-pulse rectifier, the 6th harmonic appears in the AC line currents, but a ripple at 300 Hz in the field current can induce a 3rd harmonic in the shaft voltage; the observed 450 Hz could be a higher-order effect or related to the generator’s two-pole rotational speed). In contrast, brushless exciters (with rotating diodes and no slip rings) do not inject such high-frequency triple-n content into the rotor circuit, so the 9th is negligible and instead an 8th harmonic (400 Hz) is observed, which likely stems from mechanical–electrical interactions (e.g., rotor slot passing effects or magnetic coupling in the stator/rotor). This difference between an 8th harmonic in brushless machines and a 9th in static machines is a distinctive diagnostic feature and should be explicitly accounted for in any monitoring scheme (for instance, by monitoring the H8/H1 ratio for brushless units versus H9/H1 for static units). Additionally, the presence of the 8th harmonic across all brushless units hints at a possible common origin related to mechanical resonance or structural coupling that deserves further investigation (e.g., rotor geometry causing an 8× harmonic). Meanwhile, the consistent 9th in static units underscores the role of excitation control in shaping the shaft voltage spectrum.

- Implications for maintenance and anomaly detection. Establishing these baseline harmonic profiles has direct practical implications. Maintenance personnel can use the family-specific harmonic fingerprints as a reference for early anomaly detection. For example, if a brushless-excited generator that normally exhibits the 3rd, 5th, and 8th harmonic pattern suddenly shows a strong 9th or an unusual even harmonic (2nd, 4th, etc.), it would be a clear sign to investigate potential issues (such as a developing fault in the excitation system or a change in the grounding condition). In our measurements, we noted a few spectral anomalies in isolated instances—for instance, one measurement from a brushless unit showed an unusually high even 2nd harmonic (~100 Hz), and another exhibited elevated higher-order odd harmonics around 550 Hz and 750 Hz that are not part of the typical pattern. These anomalies were not observed across all units and did not correspond to any known faults at the time, but their observation suggests that such out-of-profile harmonics may indicate subtle differences or emerging issues (for example, temporary changes in brush contact or incipient insulation issues causing even-order harmonics). While a detailed analysis of these outlier harmonics is beyond the scope of this study, they highlight the value of having a baseline “envelope”—any component outside the expected set can serve as a red flag for further inspection. It is also important to consider the effect of these harmonic currents and voltages on the shaft grounding hardware: high-frequency components (like the 9th harmonic current) can cause additional heating or spark erosion at the grounding brush, and even-order harmonics can indicate asymmetrical conditions that might stress the bearings or insulation. Understanding the baseline thus not only aids in fault detection but also in assessing whether the shaft grounding system itself is operating within design limits.

- Finally, it should be noted that this study focused exclusively on healthy operating conditions. The harmonic baselines established here provide a reference against which future abnormal measurements can be compared. For instance, if a normally brushless-like spectrum begins to take on static-like features (or vice versa), it could indicate a malfunction or change in the excitation system. Developing diagnostic models that incorporate these baseline profiles can enable predictive maintenance and condition-based interventions. In future work, methods such as those presented by the authors in a recent conference paper [14], which involve using shaft voltage and current signatures to distinguish different shaft grounding fault types, could be combined with the baseline knowledge from this study. By doing so, one could create automated systems that not only detect a deviation in the harmonic pattern but also infer the likely cause (e.g., a specific type of brush wear or an excitation control issue).

- In addition to diagnostic strategies, it is worth mentioning that various measures have been explored to mitigate harmful shaft voltages and currents at their source. For example, specialized shaft grounding techniques and improved brush designs have been proposed to control stray currents [9], and there are even recommendations to install additional grounding or bypass components to limit shaft voltage buildup in large machines [14]. Active mitigation methods, such as tuned filters or modification of the excitation system to cancel out certain harmonics, have also been studied [28,29]. Moreover, the extensive body of research on inverter-driven motors provides insight into managing bearing currents. Many modeling and mitigation techniques developed for variable-frequency drive motors [30,31,32] could be adapted to help reduce shaft voltage stresses in turbo-generators. These engineering solutions (mitigation and design improvements) are complementary to the monitoring approach emphasized in this paper. While mitigation can reduce the overall level of harmful currents, monitoring remains crucial because it can alert operators to changes in the machine’s condition even when absolute levels are within nominal ranges. The baseline harmonic profiles identified for each excitation class in this work form a foundation for such monitoring systems, enabling them to distinguish between benign variations and true indicators of developing faults.

- The results obtained in this study demonstrate that excitation system topology, rather than OEM design, is the dominant factor influencing the harmonic distribution of shaft voltages in large-scale generators. Specifically, brushless excitation systems exhibit harmonic clustering around 150 Hz, 250 Hz, and 400 Hz, while static excitation systems are characterized by dominant components at 150 Hz and 450 Hz. These consistent harmonic signatures reveal that the excitation circuit configuration determines the electromagnetic coupling paths responsible for shaft potential build-up. Compared to the state of the art, the present work introduces a broader comparative dimension by analyzing multiple generator units from different OEMs under uniform measurement and operating conditions. Previous studies have typically focused on single-generator behavior or numerical simulations, offering limited generalization. In contrast, this investigation establishes a cross-fleet harmonic reference framework, enabling utilities to benchmark and compare spectral fingerprints across various excitation system types. This contribution significantly enhances the understanding of excitation-related electromagnetic phenomena and supports the development of standardized diagnostic baselines for predictive maintenance. The insights derived from this comparative framework extend the current body of knowledge by linking specific harmonic bands to the excitation architecture, thus providing an evidence-based foundation for condition-based monitoring strategies across the utility fleet and similar power utilities worldwide.

- It is acknowledged that small mechanical or electromagnetic asymmetries such as minor shaft eccentricity, brush contact variation, or local field imbalance may introduce low-level fluctuations in harmonic amplitudes even under healthy conditions. These effects are typically random and limited to less than ±10% of the baseline harmonic magnitudes, and they do not alter the overall harmonic pattern. Repeated measurements confirm that such variations remain statistically insignificant when compared to the consistent changes observed during fault progression. Consequently, the established harmonic baselines are robust to minor asymmetries, enabling reliable discrimination between normal operational variability and genuine fault-induced spectral deviations.

- Although mechanical aspects such as shaft alignment, bearing conditions, and rotor eccentricity can influence shaft voltage behavior, their contribution to the observed harmonic content is generally minor compared with that of the excitation system topology. Well-maintained generators operating under normal alignment conditions exhibit harmonic amplitudes governed primarily by excitation-induced electromagnetic coupling. Mechanical irregularities tend to produce broad-spectrum or low-level modulations without altering the dominant harmonic structure defined by the excitation circuit. However, progressive mechanical degradation such as bearing wear or eccentricity growth may gradually amplify certain low-order harmonics or introduce subharmonics, which would appear as deviations from the established baseline profiles. Consequently, mechanical effects are considered secondary but complementary diagnostic indicators relative to excitation system influences.

- The effectiveness of shielding and grounding practices has a measurable impact on the magnitude of the observed shaft voltage harmonics [9,14]. Generators equipped with low-impedance metallic grounding brushes exhibit lower overall harmonic amplitudes due to efficient current dissipation, whereas high-resistance or partially floating configurations amplify certain low-order components such as the 3rd and 5th harmonics [9,14]. Inadequate cable shielding or poor bonding can further introduce high-frequency interference originating from excitation system switching. Nevertheless, the relative harmonic pattern characteristic of each excitation topology remains unchanged, confirming that the excitation configuration governs the spectral structure, while grounding quality primarily affects amplitude scaling. Routine inspection and maintenance of earthing and shielding connections are therefore essential to preserve diagnostic accuracy.

- The condition of excitation system components has a pronounced influence on the long-term stability of harmonic characteristics. Degradation of rectifier diodes, loss of firing synchronization in thyristor bridges, or control loop instabilities can introduce asymmetry in the field current waveform, leading to changes in both the amplitude and distribution of shaft voltage harmonics. Typical indicators include the emergence of even-order components, the growth of 5th or 9th harmonics, or the appearance of low-frequency sidebands associated with voltage regulation oscillations. Although all units analyzed in this study operated with healthy and well-calibrated excitation systems, the findings suggest that monitoring harmonic ratio drift over time can serve as an effective indirect method for detecting excitation system degradation before it evolves into a failure condition.

- When an excitation system is upgraded or replaced, the shaft voltage harmonic baseline must be re-established during commissioning to ensure diagnostic continuity. This involves verifying single-point grounding, brush contact condition, cable shielding, and instrument calibration, followed by acquiring multiple steady-state datasets across defined operating points (typically 25–100% load and different power factor settings). The collected signals are processed using identical FFT parameters as in the original study, and the resulting harmonic ratios such as 150/50, 250/50, 400/50, or 450/50 are averaged to derive new baseline values and variability bands. These post-upgrade signatures are then compared with pre-upgrade profiles to document structural shifts in harmonic behavior, and updated thresholds are registered in the plant monitoring system after a short verification period. This re-baselining approach ensures that the harmonic fingerprints and diagnostic limits remain accurate, repeatable, and traceable to the new excitation topology.

- Although the present analysis focused on steady-state operation, it is recognized that startup, shutdown, and transient events can significantly alter the harmonic composition of shaft voltages. During excitation ramp-up or synchronization, broadband spectral components and sidebands may appear due to rapid field current changes and magnetic flux transients. Load ramping tends to enhance low-order harmonics through increased magnetic saturation, whereas abrupt load rejections or shutdowns can introduce short-duration high-frequency components from excitation switching. These effects are temporary and dissipate once steady-state equilibrium is achieved. The steady-state harmonic baselines established in this study therefore provide an essential reference for interpreting transient harmonic behavior in future dynamic condition monitoring research.

- The present study was restricted to steady-state healthy operating conditions to establish reliable harmonic baselines; it is recognized that shaft voltage spectra can vary with generator loading and transient excitation states. Under increasing electrical load, harmonic amplitudes, particularly those at 150 Hz and 250 Hz, may intensify due to enhanced magnetic saturation and higher field current levels. Conversely, during rapid transients such as synchronization, excitation ramping, or load rejections, additional broadband or sideband components may appear, owing to electromagnetic coupling and control-system dynamics. These effects, though outside the scope of the current steady-state analysis, represent an important avenue for future work aimed at developing dynamic harmonic-based diagnostic indices for non-steady operating conditions.

- The comparative results obtained across multiple generators demonstrated stable harmonic characteristics within the same operational state, confirming the repeatability of the identified baseline profiles. Minor variations (within ±3%) were observed between measurement repetitions and are attributed to natural noise and instrumentation tolerance. Over long operational periods, however, harmonic amplitudes may gradually drift due to factors such as brush and slip ring wear, oxide film development, or changes in shaft ground resistance. Environmental parameters, including temperature and hydrogen purity, may also influence the contact resistance at the shaft interface. Although these effects were not significant within the timeframe of this study, their potential cumulative impact over the generator’s lifecycle underscores the importance of continuous harmonic trending as part of long-term condition monitoring.

- The harmonic ratios established in this study represent steady-state healthy references against which future deviations can be evaluated. Although explicit numerical thresholds for fault diagnosis were not within the present scope, experience from previous monitoring campaigns indicates that an increase exceeding roughly 30–40% in the 150 Hz/50 Hz ratio, or the appearance of pronounced high-order components above 450 Hz, may signify early brush or grounding deterioration [14]. Such limits are not universal but are derived empirically through long-term trending and correlation with inspection outcomes. The comparative harmonic baselines reported here therefore provide the quantitative foundation for defining statistically validated threshold ranges in subsequent diagnostic investigations.

- It is recognized that the harmonic content of shaft voltages may vary with generator loading and transient excitation events. Under increasing electrical load, low-order harmonic amplitudes such as the 3rd and 5th may intensify slightly due to magnetic saturation and higher field current levels, while transient states such as synchronization or sudden load rejection can introduce temporary broadband distortion or modulation sidebands. The present investigation, focused on steady-state healthy conditions, provides the necessary reference baseline against which such dynamic variations can later be quantified. Future work will extend this analysis to transient and load-dependent operating regimes to develop adaptive harmonic-based diagnostic frameworks. The overall comparative findings thus provide a practical reference for defining harmonic fingerprints under healthy conditions and serve as a foundation for future dynamic condition-based monitoring enhancements.

- It is acknowledged that low-amplitude harmonic components can be influenced by several measurement uncertainties, including electromagnetic interference, shaft-to-brush contact noise, probe impedance mismatch, and quantization errors of the acquisition system. These effects are more pronounced at frequencies above 400 Hz or when harmonic amplitudes approach the noise floor. To mitigate these influences, all measurements were performed with shielded differential probes, verified grounding, and calibration against reference voltages. Multiple FFT spectra were averaged to enhance signal-to-noise ratio, and only harmonics exceeding three times the baseline noise level were treated as diagnostically valid. The reported harmonic patterns therefore reflect stable electrical phenomena rather than artifacts of measurement noise or instrumentation bias.

- External factors such as electromagnetic interference, grid disturbances, and environmental variations can also influence shaft voltage harmonic measurements. Transients from nearby power electronic converters or grid fluctuations may introduce additional high-frequency components or amplitude modulation near the fundamental. To mitigate such effects, all measurements were performed using shielded differential probes and single-point grounding under stable grid conditions. Averaging across multiple recordings further reduced random noise influence. Consequently, the observed harmonic patterns were attributed primarily to generator and excitation behavior rather than external electrical or environmental interference.

- The accuracy of harmonic identification is inherently dependent on the sampling rate and resolution of the acquisition system. In this study, a sampling rate of 1 MS/s and 12-bit resolution were used to ensure adequate temporal and amplitude fidelity. The high sampling frequency eliminated aliasing and preserved harmonic definition up to 1 kHz, while the 12-bit depth provided a dynamic range sufficient to detect harmonics with amplitudes below 1% of the fundamental. Lower sampling rates or reduced resolution would compromise spectral clarity, particularly for weak or high-order harmonics. The chosen configuration thus represents an optimal balance between measurement precision, data volume, and computational efficiency.

- The experimental process revealed several practical challenges that can influence the accuracy of shaft voltage spectral measurements. Variations in shaft-to-ground resistance, oil film formation on slip rings, and minor eccentricities in brush contact pressure were found to introduce subtle modulation effects in the low-order harmonics. Additionally, ambient electromagnetic interference from nearby high-current busbars occasionally elevated background noise in the spectra. Although averaging and shielding minimized these effects; they highlight a key limitation of experimental generator analysis: small contact or environmental variations can obscure early warning trends in shaft voltage behavior. Recognizing and mitigating these sources of measurement uncertainty is therefore essential when establishing long-term harmonic baselines for condition monitoring.

- Although the FFT method provides a robust means of quantifying harmonic amplitudes in shaft voltage spectra, several intrinsic limitations must be considered. Finite frequency resolution may cause closely spaced harmonics or sidebands to merge, while windowing and spectral leakage can slightly distort amplitude estimates. The method also assumes stationarity, making it less effective for short-duration transients. Furthermore, weak harmonic components near the noise floor may be underestimated, and FFT analysis alone does not reveal time-dependent variations in spectral content. These limitations were mitigated in this study through long-duration sampling, windowed averaging, and noise-threshold filtering, ensuring that the derived harmonic baselines remained accurate for steady-state comparison.

- The presence of multiple harmonic components at closely spaced frequencies can reduce spectral clarity and complicate peak identification in FFT-based analysis. When such components fall within the same resolution bandwidth, their amplitudes may combine or shift, obscuring their individual contribution to the spectrum. This challenge was mitigated in the present study by employing a 10 s sampling duration and 1 Hz spectral resolution, which ensured clear separation of major harmonic peaks. Windowing and averaging further minimized leakage and random fluctuations. For conditions where harmonics overlap dynamically, such as during excitation ripple interaction or transient states, advanced methods like zoom-FFT or wavelet-based time–frequency analysis may be used to improve resolution and ensure reliable harmonic discrimination.

- Looking ahead, the evolution of high-frequency rectifier technologies, particularly those employing terahertz (THz) semiconductor devices, offers potential to minimize excitation-induced harmonic distortion and enhance generator control precision. THz-based rectifiers exhibit superior switching speed, lower conduction loss, and improved waveform linearity, which could translate into reduced shaft voltage ripple and cleaner harmonic spectra in future excitation systems. Incorporating such advancements could therefore improve both operational efficiency and the accuracy of harmonic-based diagnostic frameworks. Recent progress in this area has been comprehensively reviewed by reference [33].

- Although this study focused exclusively on healthy operating conditions, previous investigations have shown that different fault types leave distinct harmonic ‘fingerprints’ on the shaft voltage spectrum [1,10,12,13,15]. Rotor eccentricity typically enhances odd low-order components (such as the 5th and 7th harmonics) and introduces rotational sidebands, while excitation winding or rectifier faults produce even-order and zero-sequence harmonics due to field current imbalance [1,10,21]. Brush- and grounding-related faults, in contrast, cause pronounced growth of triple-n harmonics (e.g., 3rd and 9th) and irregular broadband noise [14]. The harmonic baselines defined in this study therefore form the quantitative foundation for distinguishing such fault mechanisms in future diagnostic applications, where deviations from these reference profiles can be used to infer specific fault types with higher reliability.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mailula, K.O.; Saha, A.K. A Comprehensive Review of Shaft Voltages and Bearing Currents, Measurements and Monitoring Systems in Large Turbogenerators. Energies 2025, 18, 2067. [Google Scholar] [CrossRef]

- Datta, A.K.; Dubey, M.; Jain, S. Effect of static power supply in alternator used for short-circuit testing-observation of shaft voltage. IEEE Trans. Power Electron. 2014, 29, 6074–6080. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Mahdi, H.F. Investigation of bearing current in a Gas Turbine generator due to static excitation system. In Proceedings of the 2013 IEEE Student Conference on Research and Developement, Putrajaya, Malaysia, 16–17 December 2013. [Google Scholar]

- Costello, M.J. Shaft voltages and rotating machinery. IEEE Trans. Ind. Appl. 1993, 29, 419–426. [Google Scholar] [CrossRef]

- Buckley, G.W.; Corkins, R.J.; Stephens, R.N. The Importance of grounding brushes to safe operations of large turbine generators. IEEE Trans. Energy Convers. 1988, 3, 607–612. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.P. Damages due to shaft-potentials in modern generators. In Proceedings of the Joint International Power Conference Athens Power Tech, Athens, Greece, 5–8 September 1993. [Google Scholar]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Review on motor bearing damage Induced by bearing current. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Darques, K.; Tounzi, A.; Menach, Y.L.; Beddek, K. Analysis of shaft voltage of large turbo-generators for rotor defect detection purposes. In Proceedings of the 19th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering (ISEF), Nancy, France, 29–31 August 2019. [Google Scholar]

- Mailula, K.O.; Higgins, S.; Singh, A.; Moloi, S. Detection of Generator Earth-brush Fault Types from Shaft Voltage and Currents Measurements to monitor the performance of Earthing Brushes. In Power Generation and Electromechanical Energy Conversion (A1); CIGRE: Paris, France, 2024. [Google Scholar]

- de Canha, D.; Cronje, W.A.; Meyer, A.S.; Hoffe, S.J. Methods for diagnosing static-eccentricity in a synchronous 2 pole generator. In Proceedings of the IEEE Lausanne Power Tech 2007, Lausanne, Switzerland, 1–5 July 2007; pp. 2162–2167. [Google Scholar]

- Rankin, D.R.; Wilson, I. The use of shaft voltage to detect air gap eccentricity and shorted-turns in salient pole alternators. In Proceedings of the 1995 Seventh International Conference on Electrical Machines and Drives (Conf. Publ. No. 412), Durham, UK, 11–13 September 1995; pp. 194–197. [Google Scholar]

- Yucai, W.; Qianqian, M.; Bochong, C.C.; Yuling, H. Evaluation of dynamic and static eccentric faults in turbo generator. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 1262–1272. [Google Scholar] [CrossRef]

- Ehya, H.; Sadeghi, I.; Faiz, J. Online condition monitoring of large synchronous generator under eccentricity fault. In Proceedings of the 2017 12th IEEE Conference on Industrial Electronics and Applications (ICIEA), Siem Reap, Cambodia, 18–20 June 2017; pp. 19–24. [Google Scholar]

- Mailula, K.O.; Saha, A.K. Advanced Diagnostic Techniques for Earthing Brush Faults Detection in Large Turbine Generators. Energies 2025, 18, 3597. [Google Scholar] [CrossRef]

- Hsu, J.S.; Stein, J. Shaft signal of salient pole synchronous machines for eccentricity and short field coil detections. IEEE Trans. Energy Convers. 1994, 9, 572–578. [Google Scholar] [CrossRef]

- Nippes, P.I. Early warning of developing problems in rotating machinery as provided by monitoring shaft voltages and grounding currents. IEEE Trans. Energy Convers. 2004, 19, 340–345. [Google Scholar] [CrossRef]

- Nippes, P.I. Shaft Voltage Current Monitoring System for Early Warning and Problem Detection. U.S. Patent 6 460 013B1, 1 October 2002. [Google Scholar]

- Higgins, S. Rotating Machine Shaft Signal Monitoring Method and System. Eskom Patent US 2011/0313701 A1, 7 September 2011. [Google Scholar]

- Stone, G.; Lloyd, B.; Sasic, M. Monitoring of shaft voltages and grounding currents in rotating machines. In Proceedings of the 17th International Conference Electrical Machine Systems, Hangzhou, China, 22–25 October 2014; IEEE: Piscataway, NJ, USA, 2014. [Google Scholar]

- Torlay, J.-E.; Corenwinder, C.; Audoli, A.; Herigault, J.; Foggia, A. Analysis of shaft voltages in large synchronous generators. In Proceedings of the IEEE International Electric Machines and Drives Conference. IEMDC’99. Proceedings, Seattle, WA, USA, 9–12 May 1999; IEEE: Piscataway, NJ, USA, 1999. [Google Scholar]

- Hoffe, S.J. Synchronous Generator Fault Diagnosis Using Shaft Signal Measurements. Master’s Thesis, School of Electrical and Information Engineering, University of the Witwatersrand, Johannesburg, South Africa, 2006. [Google Scholar]

- Wu, Y.; Li, Y.; Li, H. Diagnosis of turbine generator typical faults by shaft voltage. In Proceedings of the IEEE Industry Applications Society Annual Meeting, Las Vegas, NV, USA, 7–11 October 2012. [Google Scholar]

- Ammann, C.; Posedel, Z.; Joho, R.; Reichert, K. Shaft voltages in generators with static excitation systems—Problems and Solutions. IEEE Trans. Energy Convers. 1988, 3, 409–419. [Google Scholar] [CrossRef] [PubMed]

- Mailula, K.O.; Saha, A.K. A Deep Learning-Based Diagnostic Framework for Shaft Earthing Brush Faults in Large Turbine Generators. Energies 2025, 18, 3793. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep Learning Algorithms for Bearing Fault Diagnostics—A Comprehensive Review. IEEE Access 2020, 8, 29857–29881. [Google Scholar] [CrossRef]

- Datta, A.K.; Dubey, M.; Jain, S. Study of shaft voltage & bearing currents in electrical machines. In Proceedings of the 2012 IEEE Students’ Conference on Electrical, Electronics and Computer Science, Bhopal, India, 1–2 March 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Wang, X.; Zhu, H.; Luo, X.; Guan, X. Data-Driven-Based Detection and Localization Framework Against False Data Injection Attacks in DC Microgrids. IEEE Internet Things J. 2025, 12, 36079–36093. [Google Scholar] [CrossRef]

- Ogasawara, S.; Akagi, H.; Ayano, H. An active circuit for cancellation of common-mode voltage generated by a PWM inverter. IEEE Trans. Power Electron. 1998, 13, 835–841. [Google Scholar] [CrossRef]

- Ogasawara, S.; Zhang, S.; Akagi, H. Configurations and characteristics of active canceling and compensating circuits for reducing commonmode voltage generated by voltage-source PWM inverters. In Proceedings of the Conference Record of the 2000 IEEE Industry Applications Conference. Thirty-Fifth IAS Annual Meeting and World Conference on Industrial Applications of Electrical Energy (Cat. No.00CH37129), Rome, Italy, 8–12 October 2000; pp. 57–65. [Google Scholar]

- Muetze, A. On a New type of Inverter-Induced bearing current in large drives with one journal bearing. IEEE Trans. Ind. Appl. 2010, 46, 240–248. [Google Scholar] [CrossRef]

- Bjekić, M.; Rosić, M.; Bozic, M.; Stojanovic, D. Analysis of mitigation techniques for bearing currents in PWM inverter drives. Metal. Int. 2013, 18, 91–97. [Google Scholar]

- Muetze, A.; Binder, A. Calculation of circulating bearing currents in Machines of Inverter-Based Drive Systems. IEEE Trans. Ind. Electron. 2007, 54, 932–938. [Google Scholar] [CrossRef]

- Citroni, R.; Di Paolo, F.; Livreri, P. Progress in THz Rectifier Technology: Research and Perspectives. Nanomaterials 2022, 12, 2479. [Google Scholar] [CrossRef] [PubMed]

| Power Stations | Power Rating MW | Number of Poles | Years in Service | Original Equipment Manufacturer (OEM) | Excitation System Design |

|---|---|---|---|---|---|

| Power Station A | 600 | 2 | 35 | (OEM H) | Brushless Excitation (6 pulse) |

| Power Station B | 600 | 2 | 41 | (OEM H) | Brushless Excitation (6 pulse) |

| Power Station C | 657 | 2 | 29 | (OEM K) | Brushless Excitation (24 pulse) |

| Power Station D | 846 | 2 | 8 | (OEM K) | Static Excitation (6 pulse) |

| Power Station E | 794 | 2 | 10 | (OEM K) | Static Excitation (6 pulse) |

| Station | Excitation Design | OEM Lineage | Dominant Features (Baseline FFT) | Harmonic Amplitude (Vrms) | Normalized Harmonic Ratios (%)—H3/H1, H5/H1, H8/H9/H1 | Diagnostic Implication | Observation |

|---|---|---|---|---|---|---|---|

| A | Brushless 6-pulse | H-family | H3 (150 Hz) H5 (250 Hz), H8 (400 Hz) | 0.28/0.22/0.15 | 12.0/9.4/6.4 | Use {H3/H1, H5/H1, H8/H1} as baselines; track attenuation/distortion under faults | Typical six-pulse brushless spectrum with strong 3rd and 5th; 8th indicates mechanical coupling |

| B | Brushless 6-pulse | H-family | Same triad H3 (150 Hz) H5 (250 Hz), H8 (400 Hz) | 0.30/0.23/0.16 | 12.5/9.7/6.6 | Family-consistent thresholds; OEM differences are second-order | Nearly identical to A due to shared OEM and design |

| C | Brushless 24-pulse | K-family | Same triad H3 (150 Hz) H5 (250 Hz), H8 (400 Hz) despite OEM change | 0.26/0.19/0.13 | 11.1/7.6/5.3 | Topology > OEM: brushless signature persists across designs | Shows the same harmonic families as A and B but with reduced third and fifth harmonic amplitudes |

| D | Static 6-pulse | K-family | H3 (150 Hz) H9 (450 Hz) | 0.31/0.29 | 12.8/12.0 | Use {H3/H1, H9/H1}; different baseline from brushless units | Static exciters introduce triple-n harmonics beyond the third |

| E | Static 6-pulse | K-family | H3 + H9 reproduced | 0.30/0.28 | 12.4/11.7 | Family baseline is stable; enables family-specific alarms | Very similar to D; family baseline stable; use H3/H1 and H9/H1 for condition trend analysis |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mailula, K.O.; Saha, A.K. Comparative Analysis of Shaft Voltage Harmonic Characteristics in Large-Scale Generators: OEM and Excitation System Comparisons. Energies 2025, 18, 6128. https://doi.org/10.3390/en18236128

Mailula KO, Saha AK. Comparative Analysis of Shaft Voltage Harmonic Characteristics in Large-Scale Generators: OEM and Excitation System Comparisons. Energies. 2025; 18(23):6128. https://doi.org/10.3390/en18236128

Chicago/Turabian StyleMailula, Katudi Oupa, and Akshay Kumar Saha. 2025. "Comparative Analysis of Shaft Voltage Harmonic Characteristics in Large-Scale Generators: OEM and Excitation System Comparisons" Energies 18, no. 23: 6128. https://doi.org/10.3390/en18236128

APA StyleMailula, K. O., & Saha, A. K. (2025). Comparative Analysis of Shaft Voltage Harmonic Characteristics in Large-Scale Generators: OEM and Excitation System Comparisons. Energies, 18(23), 6128. https://doi.org/10.3390/en18236128