1. Introduction

The Paris Agreement commits all involved parties to limiting the increase in global warming to below 2 °C, preferably to 1.5 °C, compared to the pre-industrial level [

1]. The energy and the industry sector play a key role in reaching this goal since both are responsible for most of the worldwide greenhouse gas (GHG) emissions as of 2019 [

2].

The main GHG impacts of companies often result from their scope 3 activities, i.e., from indirect upstream and downstream emissions along the value chain [

3]. These GHG emissions can be influenced by different factors, such as the design of a product or the innovation of business models.

To save resources and reduce GHG emissions, transitioning to a circular economy that includes sustainable products, services, and business models as a standard is necessary [

4]. In general, the circularity of products can be increased by implementing circularity measures along the life cycle that follow so-called R-strategies: refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, and recover [

5].

For the development of tailored circularity measures for individual technologies, it is crucial to analyze and understand the environmental performance of a product in detail. The potential environmental impacts over the entire life cycle of a product can be assessed with the method of life cycle assessment (LCA). This allows identifying significant environmental impacts in a product’s life cycle and forms the baseline for the development of improvement measures [

6,

7], e.g., for increased circularity.

During a typical industrial energy sector project, there are various stages from tender planning to project-specific design and commissioning of the product. For these projects, product LCAs are usually modeled in the tender phase of a project with data sets from databases such as ecoinvent. Hence, with a project duration of multiple years, the product LCA input data sets can be outdated at the time of commissioning the product. Additionally, products in the energy sector have a lifespan of multiple decades [

8,

9,

10], meaning they are operated over a long period in the future from the time of commissioning. Since in databases such as ecoinvent, only currently available data are used [

11], parameters that will arise during or after the lifespan of the products are modeled using present-day data. Since studies show that parameters such as the energy mix will change in the future [

12,

13] and to avoid uncertainties from data that may be outdated by the time the respective life cycle stage occurs, it is necessary to reflect the future developments that could affect the environmental performance of a product already in the tender stage by conducting prospective LCAs.

Arvidsson et al. (2023) define prospective LCA (pLCA) as an “LCA that models the product system at a future point in time relative to the time at which the study is conducted” [

14].

Additionally, some parameters can be subject to change not only at one point in time, but over the lifespan of a product. A dynamic LCA (dLCA) can reflect these dynamic changes. Sohn et al. (2019) define dLCA as “an LCA that incorporates elements of temporally induced changes that affect results and interpretation of the modeled system” [

15].

To address the challenge mentioned above and accurately reflect on the environmental impacts of energy technologies to identify improvement areas in their circularity and environmental performance, it is crucial to conduct prospective and, if necessary, dynamic LCAs for products relevant to the energy sector, such as transformers.

Existing LCA studies of transformers (power and distribution), such as Guo, Gao, and Li (2022); Wang et al. (2025); and Piotrowski and Markowska (2025), showed that the operation stage has the most significant global warming potential (GWP) in the life cycle, which results from energy losses during the use [

16,

17,

18]. Piotrowski and Markowska (2025) showed in their study that by a future annual reduction of CO

2 (carbon dioxide) equivalents in the electricity mix from Poland, the carbon footprint of the operational stage of a power transformer decreases [

18]. For the future electricity mix, the authors used a linear approach derived by analyzing the emission factor data for the Polish electricity mix from the period 2018–2024. Specific future developments regarding renewable and nuclear energy have not been considered. The accuracy of the emitted CO

2 equivalents from the operation of the transformer is stated as ±10%, and the authors point out that uncertainties during the assessment of environmental impacts can impact costs and companies’ decision-making. While Piotrowski and Markowska (2025) [

18] applied a linear extrapolation of historical emission factors to estimate the future electricity mix in Poland, this approach does not account for possible policy interventions, technological breakthroughs, or structural changes in the energy system. In contrast, the present study employs an energy system model that integrates technological developments, policy scenarios, and sectoral interactions to simulate the evolution of the national electricity mix. This model-based approach enables the consideration of non-linear developments such as accelerated renewable deployment, coal phase-out, or variations in electricity demand.

The study assesses the influence of a changing German electricity mix during operation on a power transformer’s GWP by implementing dynamic prospective electricity data in different time increments for electricity use over the lifespan in an LCA of a power transformer. The development of the future electricity mix is based on an energy system model that respects, e.g., political goals, technological development, and prices of energy carriers, which are intended to increase the accuracy of the prospective data that are implemented in the industrial LCA.

The aim of this paper is to analyze the influence on industrial LCA from considering future developments in a product’s life cycle already in a project’s tender phase by implementing dynamic prospective research data. It should be demonstrated how significantly the results of an LCA can change through this integration, and, therefore, the resolution of the product model increases, which delivers a more accurate basis to identify potential for improvement measures, e.g., for increased circularity; therefore, this supports sustainable decision-making.

Section 2 describes the framework of the LCA of a power transformer, the modeling of a future German electricity mix, and prospective scenarios for the power transformer’s operation stage.

Section 3 presents the results of the integration of the prospective research data into a power transformer’s LCA. These results are discussed in

Section 4.

Section 5 describes the conclusion of the work.

2. Materials and Methods

The following section describes the methodology for the integration of future developments in the German electricity mix during a transformer’s operation in the industrial LCA of a power transformer. First, the goal and scope of the LCA are described. Subsequently, the modeling of the future German electricity mix, as well as prospective scenarios for the transformer’s operation stage, are outlined.

2.1. Life Cycle Assessment of a Power Transformer

For this study, a life cycle assessment according to ISO 14040 and 14044 [

6,

7] for a power transformer is conducted.

The goal is the analysis of the influence on the GWP of a power transformer from implementing dynamic prospective electricity data for the operational stage. Therefore, the electricity mix in the operation stage of the transformer is varied in two scenarios (see

Section 2.3), and the results for the GWP of scenarios 1 and 2 are compared to the GWP of the baseline.

The power transformer is an example large power transformer with 300 MVA and a voltage level of 220 kV. With regard to the operational losses, the Peak Efficiency Index is met. The power transformer is manufactured in Europe. It is assumed that the power transformer is operated in Germany. The expected lifetime is 35 years [

19].

The functional unit is the transmission of electrical energy over 35 years. The reference flow for the baseline is the transmission of electrical energy over 35 years with a power transformer that uses a German electricity mix from ecoinvent 3.9.1 during operation. The reference flow for scenario 1 is the transmission of electrical energy over 35 years with a power transformer that uses a prospective German electricity mix during operation, implemented in two steps, with data from 2030 and 2050. The reference flow for scenario 2 is the transmission of electrical energy over 35 years with a power transformer that uses a prospective German electricity mix during operation, implemented in 5-year steps until 2050.

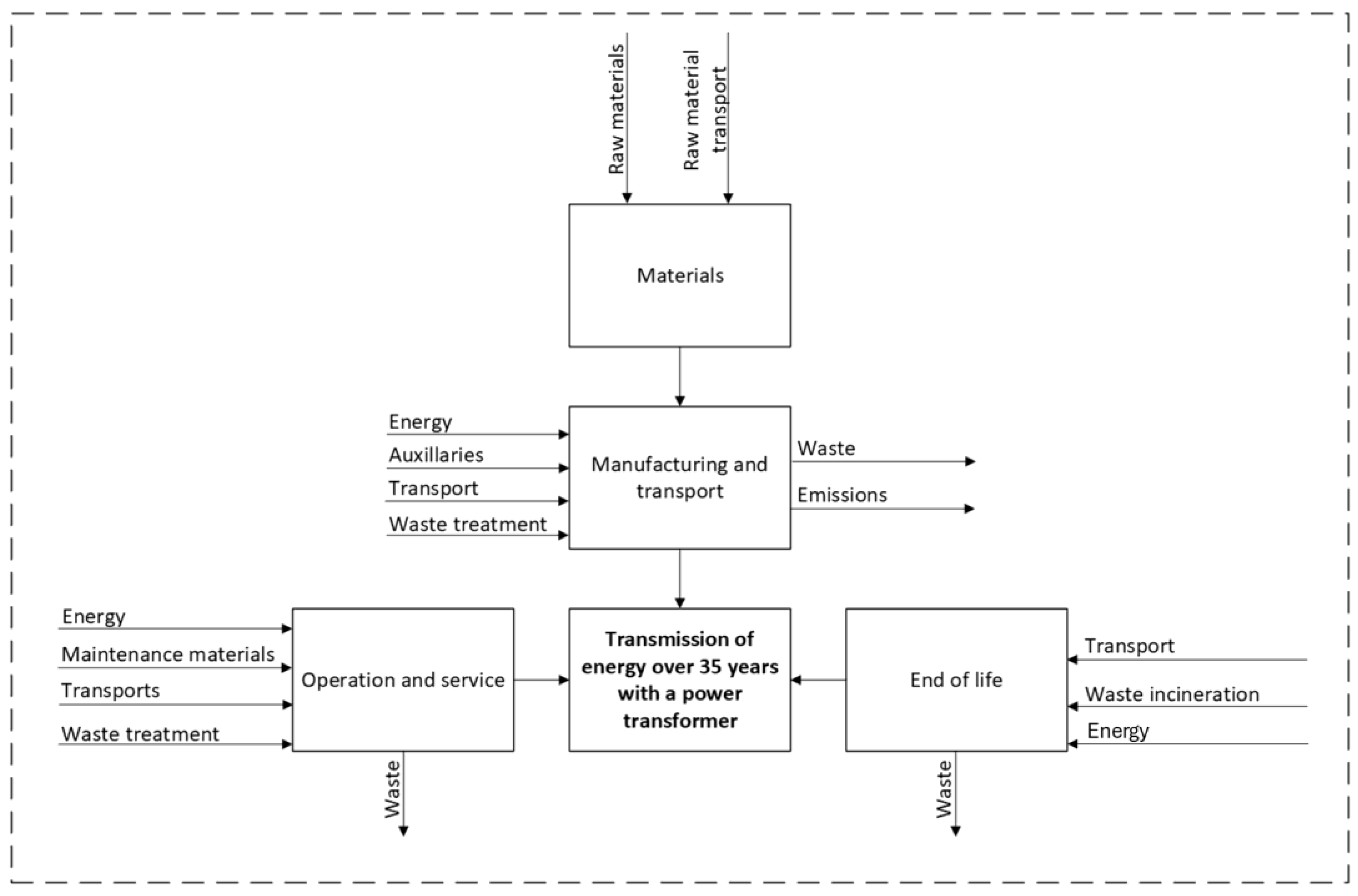

The life cycle stages, processes, and inputs and outputs included in this analysis are shown in

Figure 1.

It is assumed that the power transformer will be connected to the grid in 2025, but the LCA study is conducted already in the project’s tender stage, so, multiple years before commissioning.

All input and output data regarding material, manufacturing, and transport, as well as operation, are primary data from a transformer manufacturer. Some transport routes were estimated according to a product category rule for power transformers [

19]. The data are calculated with data from the database ecoinvent 3.9.1. It is assumed that this was the latest available database during the tender phase when the LCA was conducted. Since specific supplier data regarding the share of secondary material for the transformer’s winding copper were available, the market mix from ecoinvent was adjusted. For the end-of-life calculation, waste treatment rates from a product category rule for LCA of electronic and electrical products and systems [

20] are used as an assumption. The mass per material is multiplied by the respective or representative waste treatment rates given by the product category rule to obtain the input values for the end-of-life processes. The processes are calculated with the data from the ecoinvent 3.9.1 database according to the cut-off approach. For the energy losses of the baseline, manufacturer data are used and calculated with the German electricity data mix from ecoinvent 3.9.1 that has the reference year 2019 [

21]. Scenarios 1 and 2 use the manufacturer data for the energy losses too; the calculation is performed with emission factors from a prospective German electricity mix (see

Section 2.2).

The baseline and both scenarios are modeled with the software SimaPro 9.6, and the life cycle impact assessment uses the calculation method ReCiPe 2016 Midpoint (H) for the impact category GWP. The analysis and comparison are conducted with the Siemens Energy EcoTransparency app v.1.6.1, an internal tool for analyzing, showcasing, and comparing life cycle assessment results.

2.2. Prospective German Electricity Mix

The electricity mix for Germany is adapted to future developments that reflect a successful energy transition, meaning a reduction of GHG emissions in all European countries of 95% from 1990 to 2050. The share of each energy carrier for the electricity supply is based on the results of the solidEU from Kigle et al. (2022), which considers a reduction of GHG emissions to meet the 2 °C target [

22]. The solidEU scenario is based on the ISAaR energy system model described by Kigle et al., which provides a comprehensive representation of the European energy systems. While the solidEU scenario accurately reflects key structural trends and technological transitions, it was developed before the most recent updates in German energy policy, including the 2024 revision of the Federal Climate Action Act (Klimaschutzgesetz).

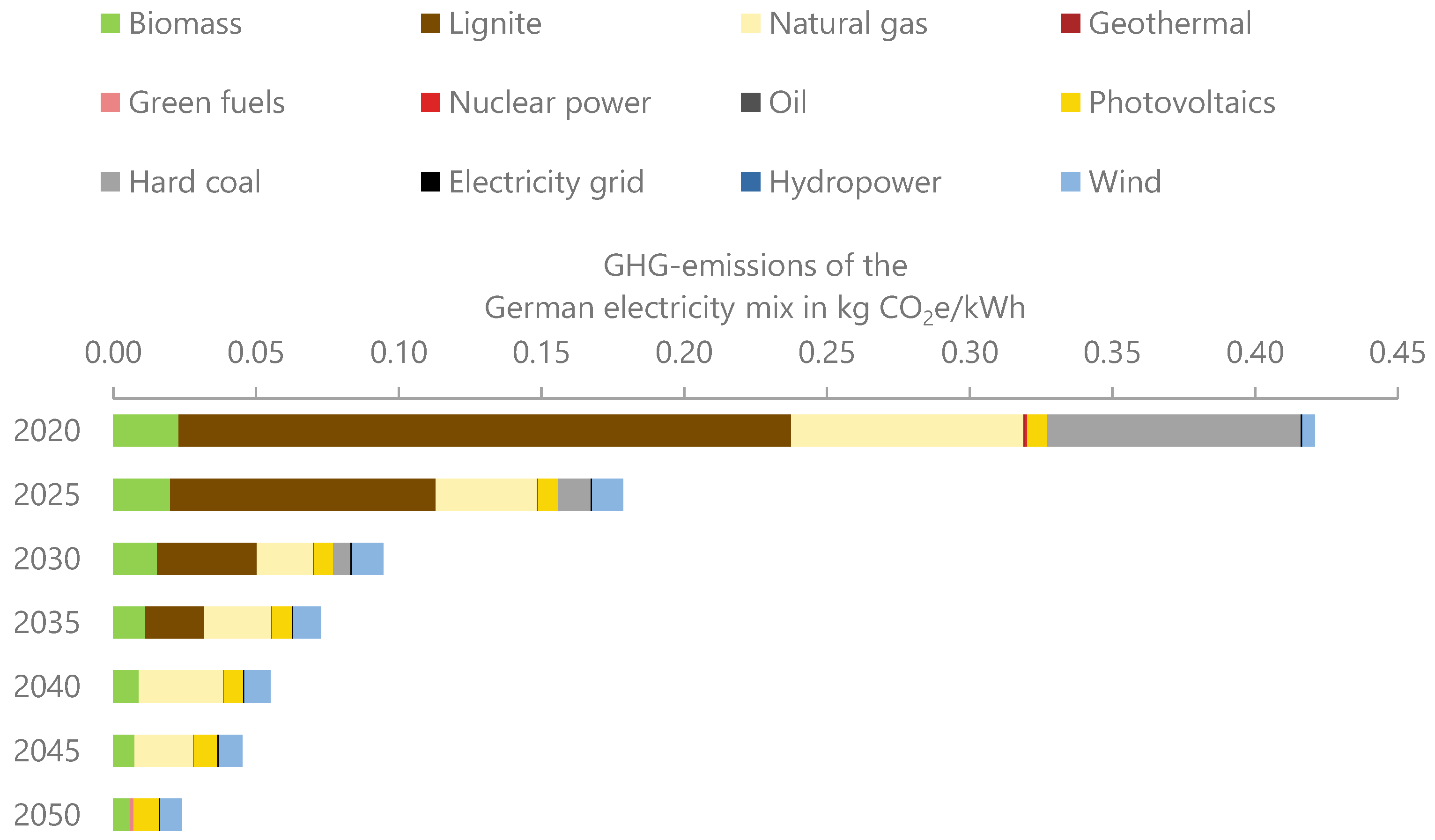

Figure 2 shows the resulting share of energy carriers.

Figure 2 illustrates that the electricity mix is becoming progressively more renewable, with the share of wind and solar power expected to rise significantly by 2050. For subsequent utilization in the LCA, the energy technologies are matched to the background database ecoinvent 3.9.1 [

23] processes, as shown in

Table 1. In some cases, the ecoinvent database uses different activities to represent one technology (e.g., for photovoltaic roof installation); all are listed in the table below.

Since in the foreground the share of each energy carrier changes over time, the background is adapted as well. Therefore, the processes from the database ecoinvent are adapted with the software tool premise [

24]. The tool uses Integrated Assessment Models (IAMs) to generate prospective versions of ecoinvent. For the implementation, one of the five so-called “Shared Socio-economic Pathways (SSPs)” must be chosen, which outlines fundamental societal developments. Additionally, pathways for the development of greenhouse gas concentrations in the atmosphere (Representative Concentration Pathways; RCPs) must be selected. These pathways determine, for example, whether the temperature increase in the considered climate scenario remains below 1.5 °C or if climate targets are not met. Also, two different IAMs are available in the premise: IMAGE and REMIND. The respective selection should be compatible with the assumptions made for the foreground model, especially the future composition of the electricity mix.

“SSP2- Peak Budget 1150” of the IAM REMIND [

25] is used for the calculation. SSP2 is chosen, as it reflects a middle-of-the-road development, which corresponds to solidEU. REMIND is chosen, as the approach of the IAM is to represent the energy sector in detail, and the most recent data was available. In REMIND, five different SSP2 pathways were available (status July 2023, premise version 1.5.0). Each represents a different temperature limit. In the two climate protection pathways SSP2-PkButdg1150 and SSP2PkBudg500, a temperature increase of 1.6–1.8 °C and 1.2–1.4 °C, respectively, is reached. SSP2-PkButdg1150 better reflects the meaning of global warming of the solidEU (2 °C), which leads to the consideration of this pathway to adapt the background database ecoinvent with the tool premise.

Figure 3 provides a detailed breakdown of emissions for electricity generation in Germany by energy source for the scenario with background adjustments.

The positive effect of the decline in fossil energy sources on the GHG intensity of the electricity mix becomes clear. However,

Figure 3 also illustrates that even in 2050, after the implementation of the energy transition and an adjustment of the background database to a climate protection situation, emissions still occur in the upstream chain of renewable energies. These residual emissions are due to various factors. On the one hand, the decarbonization of industry and the energy sector progresses at different rates in different regions of the world. On the other hand, not all economic sectors and processes are represented in the premise, so some processes are not adapted to future developments.

2.3. Scenarios for Transformer’s Operational Energy Use

Two dynamized scenarios are developed to compare the GWP of the transformer with the prospective electricity mix used for the operational losses to the GWP of the baseline. Therefore, in the scenarios, the emission factors shown in

Figure 3 are implemented for operational electricity use, substituting the data from the ecoinvent database.

As mentioned above, the German electricity mix from ecoinvent 3.9.1 is used for the baseline, assuming that these data are the latest available at the time of LCA calculation. This electricity mix refers to the reference year 2019 and was released in 2022 [

21], so before the actual connection to the grid of the transformer in 2025, and therefore reflects the time gap between tender phase and commissioning.

In scenario 1, the prospective electricity mix is implemented in the operation stage for operational energy use in two steps by using the emission factors from the years 2030 and 2050. Over the lifetime of the power transformer that is connected to the grid in 2025, the electricity mix for scenario 1 is calculated as shown in

Table 2.

This approach represents a pragmatic aggregation: the 2030 electricity data is applied for the period 2026–2045, and the 2050 data is applied thereafter. The time steps were chosen for consistency with the available data rather than to align directly with specific policy milestones. This scenario depicts that a manufacturer has only two prospective values (2030 and 2050) for the electricity mix available. The emission factor is valid for the respective year. In this study, it is always used for the four years before and the year itself. In scenario 1, the prospective data starts from the year 2026 in the 2030 mix. Thus, the year of connection (2025) is still calculated with the ecoinvent 3.9.1 electricity mix. As the next prospective value (2050) is only used from 2046, the emission factor from 2030 is also used for the operation period 2031–2045. From 2046, the emission factor from 2050 is used. Because the power transformer continues operating after 2050, the 2050 mix is used for the last nine years of operation, too.

Scenario 2 includes the prospective electricity mix even more precisely in 5-year steps in the operation stage of the power transformer, as shown in

Table 3.

Because, in this scenario, the company now has six prospective values available in 2025 where the connection to the grid takes place, the 2025 mix is used. The transformer is operated from 2026 to 2030 in the 2030 mix, from 2031 to 2035 in the 2035 mix, and continuously in 5-year steps until 2050. From 2051 to the end of life, the 2050 mix is still used, as this is the last available emission factor, but the power transformer still operates for nine years.

4. Discussion

The baseline calculation shows the highest GWP in the operation stage in the transformer’s life cycle, which results from electricity losses over the 35-year lifetime. This underscores the results of already existing LCA studies of transformers [

16,

17,

18]. The high GWP due to the electricity losses corresponds to the German electricity, high-voltage mix emission factor from ecoinvent 3.9.1. This emission factor was released in 2022 and refers to the reference year 2019 [

21] since it is assumed that the LCA calculation is performed in a project’s tender stage and is higher [

26] than the prospective emission factors for the German electricity mix, as shown in

Figure 3. If the LCA were to be conducted later, closer to the actual commissioning, more actual data for the electricity mix [

21], as well as other processes used for the transformer’s LCA, would become available in the updated ecoinvent database, which can influence the GWP results of the baseline. Nevertheless, the baseline cannot consider future developments in the German electricity mix, since the ecoinvent data set does not include prospective data [

21].

The advantage of considering future developments becomes clear when comparing the baseline LCA with both scenarios. It shows that the changing electricity mix has a significant influence on the calculated emissions resulting from the electricity losses and consequently on the total GWP of the power transformer. Both scenarios show a major decrease in emissions in the transformer’s operation stage by dynamically integrating prospective research data for the electricity mix. This reflects the fact that by reducing fossil energy sources until 2050, the calculated GHG emissions based on the German electricity mix will decrease in the future, as shown in

Figure 3.

According to

Figure 3, the GHG emissions of the electricity mix for Germany are decreasing fastest between 2020 and 2025 and between 2025 and 2030. This can be reflected in scenario 1, in which, from 2026, the prospective electricity mix from the year 2030 is incorporated. Hence, in the baseline from 2026, the power transformer is operated with an electricity mix with a significantly lower emission factor than the electricity mix from ecoinvent 3.9.1 (see

Table 2). The overall reduction of 85% in the operation stage for scenario 1 is further enhanced because, from 2046 until the end of the transformer’s lifetime, a prospective electricity mix with an even lower emission factor (as shown in

Figure 3) is applied in scenario 1.

Scenario 2 underlines the reduction in the GWP in the operation stage of the power transformer by the dynamic integration of the prospective research data. With an even more detailed integration of the future data in 5-year steps, the GWP reduction in the operation stage increases to 90% compared to the baseline. As in scenario 1, this is due to the fact that the power transformer in scenario 2 is operated, here from 2025, with an electricity mix with a reduced emission factor compared to the emission factor from the ecoinvent 3.9.1 electricity mix for Germany (see

Table 3). However, in scenario 2, the transformer is also operated earlier (every five years) with an electricity mix with a reduced emission factor compared to scenario 1, where the transformer is operated with the 2030 mix from the period 2026–2045. Hence, the total reduction in the operation stage of scenario 2 is even higher than in scenario 1. The further increase in reduction, however, is not that strong because the emission factor of the prospective German electricity mix from 2030 is not reduced as much as in the years prior, as can be seen in

Figure 3. Nevertheless, the further reduction in the operation stage shows clearly that through the even more detailed dynamic integration of the prospective research data, the changing German energy mix could be reflected even more precisely.

The emission factor valid for the respective year was already used in the four years before the actual year in both scenarios. This means that the power transformer is operated earlier in an energy mix with a reduced emission factor, resulting in a lower GWP for the operational energy losses in the scenarios and therefore a higher reduction compared to the baseline. Using another approach for implementing the future data would influence the results.

Furthermore, it is interesting to mention that in both scenarios, the last available prospective emission factor is from 2050, which is valid in this study for the years 2046–2050, but is also used for the remaining lifetime of the power transformer of nine years. In scenario 1, where it is assumed that only two emission factors (2030 and 2050) are available, the availability of further emission factors from 2055 and 2060 would not change the results because only the two used factors would still be integrated. With the assumption that the emission factor for the German electricity mix will further decrease between 2051–2055 and 2056–2060, and both factors are available, in scenario 2, this would result in a further reduction in the operation stage of the power transformer by using eight instead of six prospective data points for the German electricity mix. As mentioned above, the emission factor for the German electricity mix from the database will change in later versions of ecoinvent since a more current time period is considered [

21].

Compared to the ecoinvent database version 3.9.1, in version 3.10.1, the emission factor for the German electricity mix decreases [

26,

27]. In version 3.11, the emission factor increases again [

26,

28]. With this insight and the assumption that the emission factors for most of the processes used for the power transformer’s LCA will also change with updates of the database, it becomes clear that the GWP reduction in both scenarios compared to the baseline will change depending on the database version that is used. So, it must be noted that not only the future developments during the lifetime of the power transformer, such as in the energy mix, but also more current data will influence the results of the power transformer’s LCA.

Furthermore, the prospective results are based on the REMIND SSP2-PkBudg1150 pathway, representing a middle-of-the-road scenario consistent with the 2 °C target. Differences across Integrated Assessment Models (e.g., IMAGE) or alternative REMIND pathways (e.g., SSP2-PkBudg500) may lead to variations in future electricity mix projections and associated environmental impacts. Therefore, the influence of Integrated Assessment Model selection should be considered as an additional source of uncertainty in prospective LCA studies and could be explored in future research.

The adaptation of the electricity mix shows that results from more scientific investigations can be included in LCAs from companies. Nevertheless, during the actual calculation, some practical limits arise. Only the resulting emission factors are transferred to the LCA model, not the entire background processes. This complicates the interpretation of the results and, e.g., the inclusion of more environmental impacts besides GWP. Especially in the context of circularity, additional impact categories must be analyzed.

As with traditional life cycle assessments, prospective life cycle assessments do not provide an absolute truth about the environmental impact of a product. In this case, only one specific electricity mix and one pathway are reflected. Numerous assumptions are made for the calculation, and hidden background data can have a significant influence on the result.

Overall, by creating both scenarios and comparing the results to the baseline, the impact of changes in the future electricity mix in Germany on a transformer’s GWP calculated in the tender stage,, could be shown in the case study. Thus, a manufacturer can use the results of scenario 2, which more accurately represent the environmental impacts during a transformer’s life cycle, as a basis for the identification of improvement measures, such as measures for increased circularity. In comparison to the baseline in scenario 2, the material phase becomes more significant, which shows the potential to develop tailor-made circularity measures, such as using materials with increased secondary share to lower the environmental impacts resulting from the materials. By communicating this, e.g., to customers, sustainable decision-making can be supported. This way, industry life cycle assessment can be influenced by the dynamic integration of research data, as demonstrated in this case study.

5. Conclusions

The purpose of this study was to analyze the influence of considering future developments in a product’s life cycle already in a project’s tender phase by implementing dynamic prospective research data on industrial LCA. The power transformer LCA conducted in this study shows significant differences in the LCA results by dynamically integrating prospective electricity data in different time increments for electricity use over the lifespan.

The integration of prospective data sets, especially on a detailed level, in the industrial LCA enables an accurate reflection of parameters that will change in the future already in the tender stage of a product. This minimizes uncertainties due to outdated data sets and significantly increases the accuracy of LCA results, which also impacts, for example, reported scope 3 emissions. It is important to note that the prospective data are developed assuming that the 2 °C target is met. Of course, there may be changes in the future, e.g., due to unforeseen events such as pandemics or wars, or non-compliance with the Paris climate agreement. Thus, in prospective data, uncertainties about future developments are still present but significantly reduced compared to the use of outdated data from databases.

The enhanced resolution of the product model allows for focusing on parameters that are actually relevant during the lifetime. This provides a more accurate basis to identify potential improvements, such as tailor-made measures to increase circularity and therefore improve the environmental performance of a product. Overall, the study highlights the benefits of dynamically implementing prospective research data for industrial LCA, thereby supporting sustainable decision-making.

Future research could build on these findings by performing a systematic uncertainty analysis, including alternative Integrated Assessment Models (e.g., IMAGE), additional REMIND pathways, or variations in prospective emission factors. Updating the analysis with more recent electricity emission data or future database versions could further assess the sensitivity of LCA results to data updates. Integrating multiple IAMs, higher temporal resolution, and explicit uncertainty quantification would allow a more comprehensive assessment of the potential impact of future electricity mixes on a transformer’s life cycle impacts. Additionally, further studies of other energy technologies and additional parameters that can change in the future, e.g., the end-of-life treatment of energy technologies, would be of high interest. Especially in the context of circularity, additional impact categories should be analyzed besides the GWP.