Generalized ANN Model for Predicting the Energy Potential of Heterogeneous Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection

2.2. Data Preprocessing

2.3. Statistical Analysis

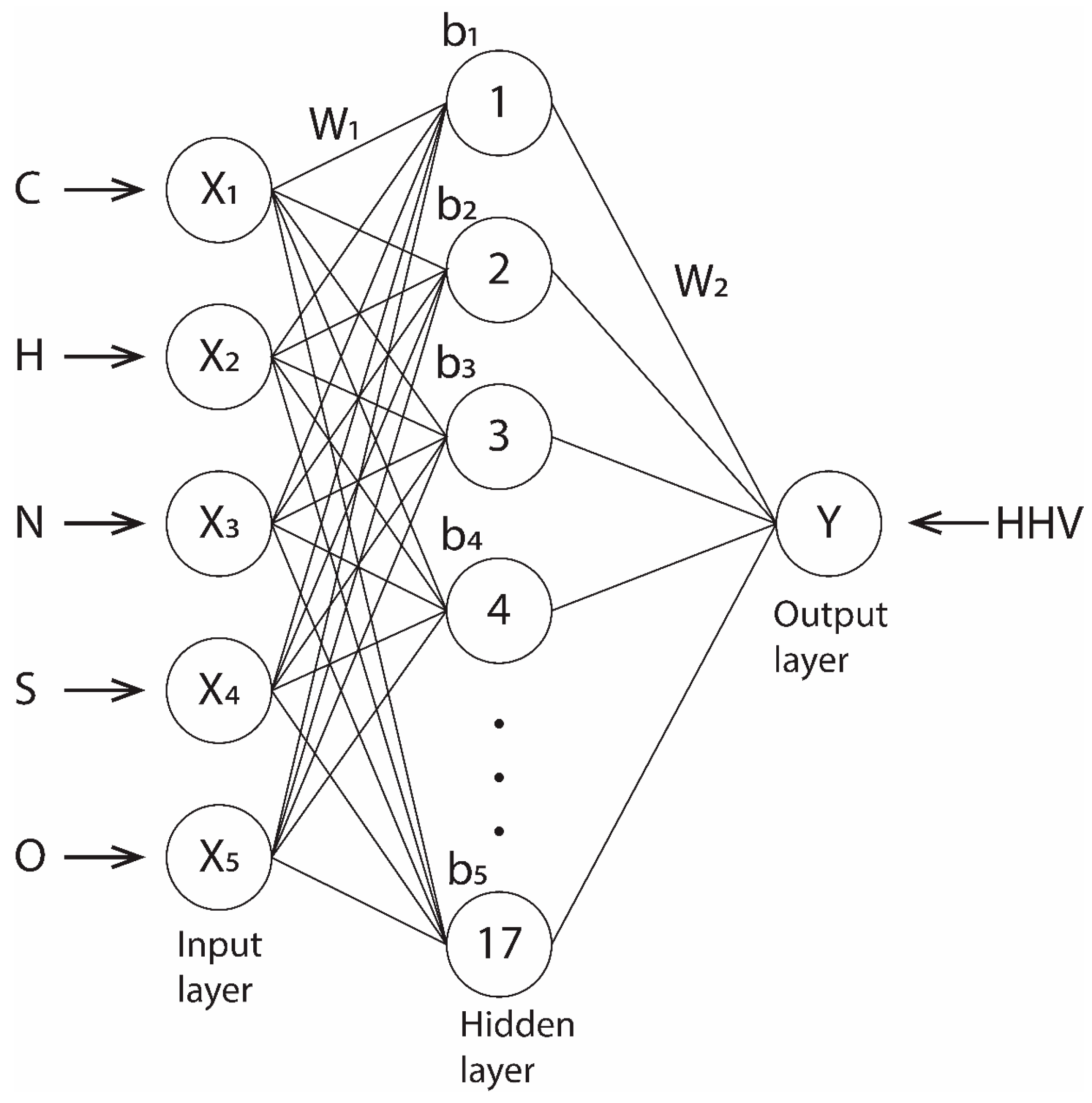

2.4. Artificial Neural Networks–Model Settings

2.5. Model Evaluation

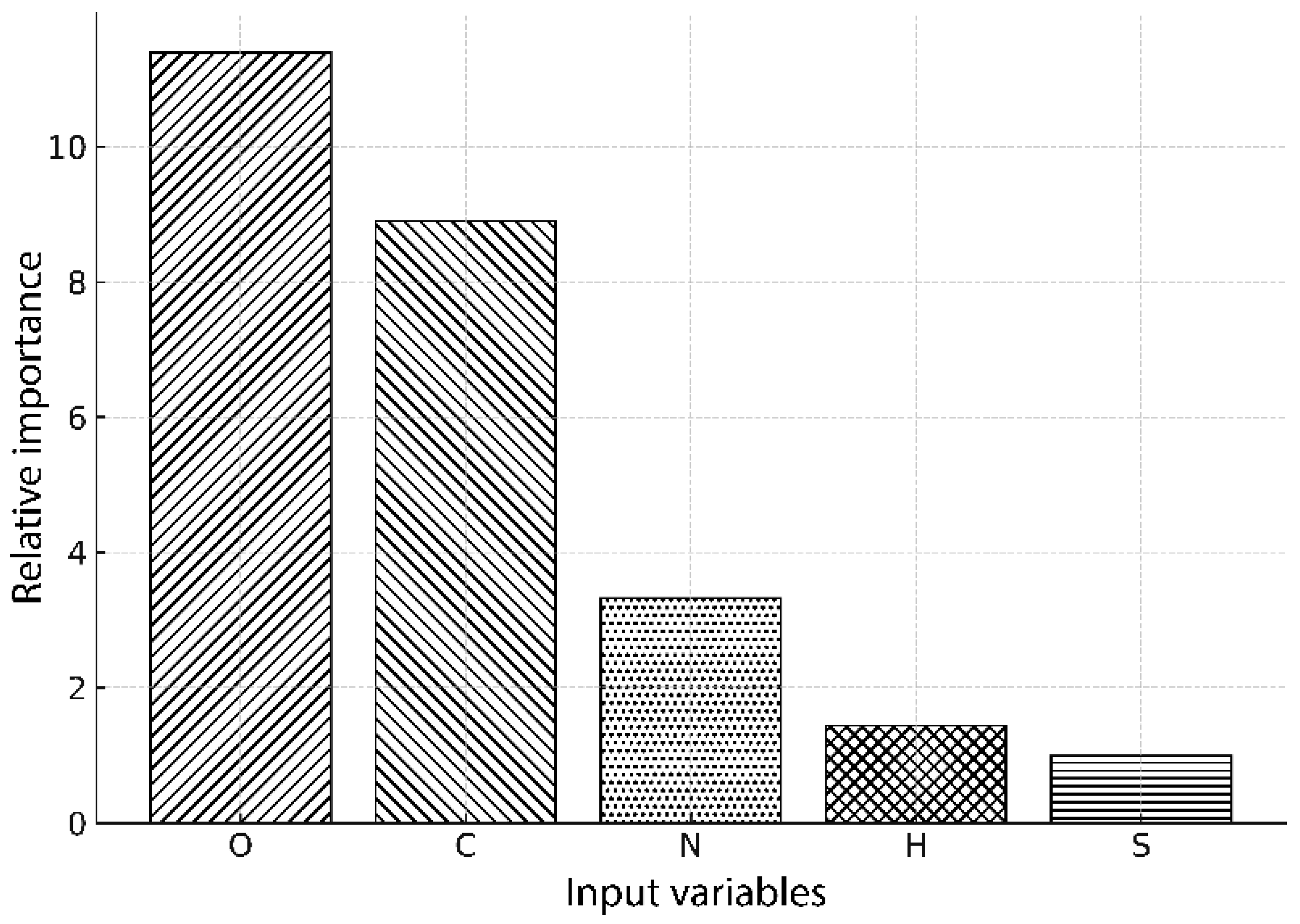

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gemar, G.; Soler, I.P.; Sánchez-Teba, E.M. Waste Management: Valorisation Is the Way. Foods 2021, 10, 2373. [Google Scholar] [CrossRef]

- Czekała, W.; Drozdowski, J.; Łabiak, P. Modern Technologies for Waste Management: A Review. Appl. Sci. 2023, 13, 8847. [Google Scholar] [CrossRef]

- Kumari, T.; Raghubanshi, A.S. Waste Management Practices in the Developing Nations: Challenges and Opportunities. In Waste Management and Resource Recycling in the Developing World; Elsevier: Amsterdam, The Netherlands, 2023; pp. 773–797. [Google Scholar]

- Lisbona, P.; Pascual, S.; Pérez, V. Waste to Energy: Trends and Perspectives. Chem. Eng. J. Adv. 2023, 14, 100494. [Google Scholar] [CrossRef]

- Sharma, S.; Basu, S.; Shetti, N.P.; Kamali, M.; Walvekar, P.; Aminabhavi, T.M. Waste-to-Energy Nexus: A Sustainable Development. Environ. Pollut. 2020, 267, 115501. [Google Scholar] [CrossRef]

- Adeleke, O.; Akinlabi, S.A.; Jen, T.-C.; Dunmade, I. Sustainable Utilization of Energy from Waste: A Review of Potentials and Challenges of Waste-to-Energy in South Africa. Int. J. Green Energy 2021, 18, 1550–1564. [Google Scholar] [CrossRef]

- Kalivodová, M.; Baláš, M.; Milčák, P.; Lisá, H.; Lisý, M.; Lachman, J.; Kracík, P.; Križan, P.; Vejražka, K. Determination of Higher Heating Value by Calculation Based on Elemental Analysis. Paliva 2022, 14, 8–20. [Google Scholar] [CrossRef]

- Acar, S.; Ayanoglu, A. Determination of Higher Heating Values (HHVs) of Biomass Fuels. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2012, 28, 749–758. [Google Scholar]

- Kwaghger, A.; Iortyer, L.A. The Development of Equations for Estimating High Heating Values from Proximate and Ultimate Analysis for Some Selected Indigenous Fuel Woods. Eur. J. Eng. Technol. 2017, 5, 21–33. [Google Scholar]

- Aghel, B.; Yahya, S.I.; Rezaei, A.; Alobaid, F. A Dynamic Recurrent Neural Network for Predicting Higher Heating Value of Biomass. Int. J. Mol. Sci. 2023, 24, 5780. [Google Scholar] [CrossRef]

- Kannah, R.Y.; Merrylin, J.; Devi, T.P.; Kavitha, S.; Sivashanmugam, P.; Kumar, G.; Banu, J.R. Food Waste Valorization: Biofuels and Value Added Product Recovery. Bioresour. Technol. Rep. 2020, 11, 100524. [Google Scholar] [CrossRef]

- Tyralis, H.; Papacharalampous, G.; Langousis, A. A Brief Review of Random Forests for Water Scientists and Practitioners and Their Recent History in Water Resources. Water 2019, 11, 910. [Google Scholar] [CrossRef]

- Gómez-Ramos, E.; Venegas-Martínez, F. Analítika: A Review of Artificial Neural Networks—How Well Do They Perform in Forecasting Time Series? Analítika Rev. Análisis Estadístico 2013, 6, 7–18. [Google Scholar]

- Kononenko, I. Machine Learning for Medical Diagnosis: History, State of the Art and Perspective. Artif. Intell. Med. 2001, 23, 89–109. [Google Scholar] [CrossRef]

- Gupta, T.K.; Raza, K. Optimization of ANN Architecture: A Review on Nature-Inspired Techniques. In Machine Learning in Bio-Signal Analysis and Diagnostic Imaging; Elsevier: Amsterdam, The Netherlands, 2019; pp. 159–182. [Google Scholar] [CrossRef]

- Muñoz-Zavala, A.E.; Macías-Díaz, J.E.; Alba-Cuéllar, D.; Guerrero-Díaz-De-León, J.A. A Literature Review on Some Trends in Artificial Neural Networks for Modeling and Simulation with Time Series. Algorithms 2024, 17, 76. [Google Scholar] [CrossRef]

- Afolabi, I.C.; Epelle, E.I.; Gunes, B.; Güleç, F.; Okolie, J.A. Data-Driven Machine Learning Approach for Predicting the Higher Heating Value of Different Biomass Classes. Clean Technol. 2022, 4, 1227–1241. [Google Scholar] [CrossRef]

- Brandić, I.; Pezo, L.; Bilandžija, N.; Peter, A.; Šurić, J.; Voća, N. Artificial Neural Network as a Tool for Estimation of the Higher Heating Value of Miscanthus Based on Ultimate Analysis. Mathematics 2022, 10, 3732. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Igwegbe, C.A.; Adeniyi, A.G. Multi-Layer Perceptron Artificial Neural Network (MLP-ANN) Prediction of Biomass Higher Heating Value (HHV) Using Combined Biomass Proximate and Ultimate Analysis Data. Model. Earth Syst. Environ. 2021, 8, 3177–3191. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, G. Study on HHV Prediction of Municipal Solid Wastes: A Machine Learning Approach. Int. J. Energy Res. 2021, 46, 3663–3673. [Google Scholar] [CrossRef]

- Mondal, C.; Pal, S.K.; Samanta, B.; Dutta, D.; Raj, S. Analysis and Significance of Prediction Models for Higher Heating Value of Coal: An Updated Review. J. Therm. Anal. Calorim. 2023, 148, 7521–7538. [Google Scholar] [CrossRef]

- Abdollahi, S.A.; Ranjbar, S.F.; Jahromi, D.R. Applying Feature Selection and Machine Learning Techniques to Estimate the Biomass Higher Heating Value. Sci. Rep. 2023, 13, 16093. [Google Scholar] [CrossRef] [PubMed]

- Kocer, A. Prediction of the Higher Heating Values of Biomass Using Machine Learning Methods Based on Proximate and Ultimate Analysis. J. Mech. Sci. Technol. 2024, 38, 1569–1574. [Google Scholar] [CrossRef]

- Das, B.K.; Kader, M.A.; Hoque, S.M.N. Energy Recovery Potential from Municipal Solid Waste in Rajshahi City by Landfill Technique. Int. J. Renew. Energy Res. 2014, 4, 349–354. [Google Scholar]

- Elwan, A.; Arief, Y.Z.; Adzis, Z.; Muhamad, N.A. Life Cycle Assessment-Based Environmental Impact Comparative Analysis of Composting and Electricity Generation from Solid Waste. Energy Procedia 2015, 68, 186–194. [Google Scholar] [CrossRef]

- Pasek, A.D.; Gultom, K.W.; Suwono, A. Feasibility of Recovering Energy from Municipal Solid Waste to Generate Electricity. J. Eng. Technol. Sci. 2013, 45, 241–256. [Google Scholar] [CrossRef]

- Fiori, L.; Basso, D.; Castello, D.; Baratieri, M. Hydrothermal Carbonization of Biomass: Design of a Batch Reactor and Preliminary Experimental Results. Chem. Eng. Trans. 2014, 37, 55–60. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Wang, Y.; Qu, L. Predicting Higher Heating Value of Sewage Sludges via Artificial Neural Network Based on Proximate and Ultimate Analyses. Water 2023, 15, 674. [Google Scholar] [CrossRef]

- Samad, N.A.F.A.; Jamin, N.A.; Saleh, S. Torrefaction of Municipal Solid Waste in Malaysia. Energy Procedia 2017, 138, 313–318. [Google Scholar] [CrossRef]

- Gañan, J.; Abdulla, A.A.-K.; Miranda, A.B.; Turegano, J.; Correia, S.; Cuerda, E.M. Energy Production by Means of Gasification Process of Residuals Sourced in Extremadura (Spain). Renew. Energy 2005, 30, 1759–1769. [Google Scholar] [CrossRef]

- Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Madissoo, M.; Pärn, L.; Virro, I.; Kikas, T. Torrefaction of Agricultural and Wood Waste: Comparative Analysis of Selected Fuel Characteristics. Energies 2021, 14, 2774. [Google Scholar] [CrossRef]

- Hu, J.; Yu, F.; Lu, Y. Application of Fischer–Tropsch Synthesis in Biomass to Liquid Conversion. Catalysts 2012, 2, 303–326. [Google Scholar] [CrossRef]

- Gerner, G.; Meyer, L.; Wanner, R.; Keller, T.; Krebs, R. Sewage Sludge Treatment by Hydrothermal Carbonization: Feasibility Study for Sustainable Nutrient Recovery and Fuel Production. Energies 2021, 14, 2697. [Google Scholar] [CrossRef]

- Enebe, N.L.; Chigor, C.B.; Obileke, K.; Lawal, M.S.; Enebe, M.C. Biogas and Syngas Production from Sewage Sludge: A Sustainable Source of Energy Generation. Methane 2023, 2, 192–217. [Google Scholar] [CrossRef]

- Zalazar-Garcia, D.; Fernandez, A.; Rodriguez-Ortiz, L.; Rodriguez, R.; Mazza, G. Sustainable Slow-Pyrolysis Simulation of 12 Lignocellulosic Bio-Wastes: CO2 Emission, Energy, and Water Consumption. IOP Conf. Ser. Earth Environ. Sci. 2022, 952, 012008. [Google Scholar] [CrossRef]

- Nhuchhen, D.; Afzal, M. HHV Predicting Correlations for Torrefied Biomass Using Proximate and Ultimate Analyses. Bioengineering 2017, 4, 7. [Google Scholar] [CrossRef] [PubMed]

- Wangikar, V.C.; Deshmukh, R.R. Data Cleaning: Current Approaches and Issues. IEEE Data Eng. Bull. 2015, 23, 3–13. [Google Scholar]

- Jamal, P.; Ali, M.; Faraj, R.H.; Ali, P.J.M. Data Normalization and Standardization: A Technical Report. Mach. Learn. Tech. Rep. 2014, 1, 1–6. [Google Scholar]

- Vinai, S. Standardization in Machine Learning. Delhi Technol. Univ. 2021, 67, 173–196. [Google Scholar]

- Ali, P.J.M. Investigating the Impact of Min-Max Data Normalization on the Regression Performance of K-Nearest Neighbor with Different Similarity Measurements. ARO Sci. J. Koya Univ. 2022, 10, 85–91. [Google Scholar] [CrossRef]

- Bhardwaj, C.A.; Mishra, M.; Desikan, K. Dynamic Feature Scaling for K-Nearest Neighbor Algorithm. arXiv 2022. [Google Scholar] [CrossRef]

- van Rossum, G.; Python Development Team. Python Tutorial Release 3.7.0, Python 3.7.0; Python Software Foundation: Beaverton, OR, USA, 2018; pp. 1–155. [Google Scholar]

- Apicella, A.; Isgrò, F.; Prevete, R. Hidden Classification Layers: Enhancing Linear Separability between Classes in Neural Networks Layers. Pattern Recognit. Lett. 2023, 177, 69–74. [Google Scholar] [CrossRef]

- Francik, S.; Łapczyńska-Kordon, B.; Pedryc, N.; Szewczyk, W.; Francik, R.; Ślipek, Z. The Use of Artificial Neural Networks for Determining Values of Selected Strength Parameters of Miscanthus × Giganteus. Sustainability 2022, 14, 3062. [Google Scholar] [CrossRef]

- Agahian, S.; Akan, T. Battle Royale Optimizer for Training Multi-Layer Perceptron. Evol. Syst. 2021, 13, 563–575. [Google Scholar] [CrossRef]

- Tufail, S.; Riggs, H.; Tariq, M.; Sarwat, A.I. Advancements and Challenges in Machine Learning: A Comprehensive Review of Models, Libraries, Applications, and Algorithms. Electronics 2023, 12, 1789. [Google Scholar] [CrossRef]

- Hussein, M.M.; Mutlag, A.H.; Shareef, H. An Improved Artificial Neural Network Design for Face Recognition Utilizing Harmony Search Algorithm. IOP Conf. Ser. Mater. Sci. Eng. 2020, 745, 012038. [Google Scholar] [CrossRef]

- Bouzeria, H.; Ghenim, A.N.; Khanchoul, K. Using Artificial Neural Network (ANN) for Prediction of Sediment Loads, Application to the Mellah Catchment, Northeast Algeria. J. Water Land Dev. 2017, 33, 47–55. [Google Scholar] [CrossRef]

- Kovačević, S.; Banjac, M.K.; Podunavac-Kuzmanović, S. Artificial Intelligence and Experimental Design: The Flywheel of Innovating Food Processing Engineering. Processes 2025, 13, 846. [Google Scholar] [CrossRef]

- Jiang, Y. Prediction of Monthly Mean Daily Diffuse Solar Radiation Using Artificial Neural Networks and Comparison with Other Empirical Models. Energy Policy 2008, 36, 3833–3837. [Google Scholar] [CrossRef]

- Chi, J.; Liu, Y.; Wang, V.; Yan, J. Performance Analysis of Three Kinds of Neural Networks in the Classification of Mask Images. J. Phys. Conf. Ser. 2022, 2181, 012032. [Google Scholar] [CrossRef]

- Hunter, J.; Dale, D.; Firing, E.; Droettboom, M. Matplotlib: Release 2.0.2 John. 2017, 1–3148. Available online: https://matplotlib.org/2.0.2/Matplotlib.pdf (accessed on 1 June 2025).

- NumPy Community. NumPy User Guide 1.22.4. 2022, 109. Available online: https://numpy.org/doc/1.22/numpy-user.pdf (accessed on 1 June 2025).

- McKinney, W. Pandas: Powerful Python Data Analysis Toolkit. Pandas—Powerful Python Data Analysis Toolkit. 2022, 1–3743. Available online: https://pandas.pydata.org/pandas-docs/version/0.7.3/pandas.pdf (accessed on 1 June 2025).

- Maqsoom, A.; Aslam, B.; Gul, M.E.; Ullah, F.; Kouzani, A.Z.; Mahmud, M.a.P.; Nawaz, A. Using Multivariate Regression and ANN Models to Predict Properties of Concrete Cured under Hot Weather. Sustainability 2021, 13, 10164. [Google Scholar] [CrossRef]

- Chai, T.; Draxler, R.R. Root Mean Square Error (RMSE) or Mean Absolute Error (MAE)?—Arguments against Avoiding RMSE in the Literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef]

- Chicco, D.; Warrens, M.J.; Jurman, G. The Coefficient of Determination R-Squared Is More Informative than SMAPE, MAE, MAPE, MSE and RMSE in Regression Analysis Evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef]

- García–Nieto, P.J.; García–Gonzalo, E.; Paredes–Sánchez, J.P. Estimation of the Coal Higher Heating Value for Energy Systems Relied on Ultimate Analysis with Machine Learning Techniques. Fuel 2023, 357, 130037. [Google Scholar] [CrossRef]

- Sedai, P.; Kalita, D.; Deka, D. Assessment of the Fuel Wood of India: A Case Study Based on Fuel Characteristics of Some Indigenous Species of Arunachal Pradesh. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 891–897. [Google Scholar] [CrossRef]

- Esteves, B.; Sen, U.; Pereira, H. Influence of Chemical Composition on Heating Value of Biomass: A Review and Bibliometric Analysis. Energies 2023, 16, 4226. [Google Scholar] [CrossRef]

- Uler-Zefikj, M.; Godyń, K.; Tokarczyk, K.; Filkoski, R.V. Characterization of Municipal Solid Waste as Potential Fuel for Energy Needs. Materials 2025, 18, 2103. [Google Scholar] [CrossRef]

- Boumanchar, I.; Chhiti, Y.; Alaoui, F.E.M.; Sahibed-Dine, A.; Bentiss, F.; Jama, C.; Bensitel, M. Municipal Solid Waste Higher Heating Value Prediction from Ultimate Analysis Using Multiple Regression and Genetic Programming Techniques. Waste Manag. Res. J. A Sustain. Circ. Econ. 2018, 37, 578–589. [Google Scholar] [CrossRef]

- Kariri, E.; Louati, H.; Louati, A.; Masmoudi, F. Exploring the Advancements and Future Research Directions of Artificial Neural Networks: A Text Mining Approach. Appl. Sci. 2023, 13, 3186. [Google Scholar] [CrossRef]

- Olatunji, O.O.; Akinlabi, S.; Madushele, N.; Adedeji, P.A.; Felix, I. Multilayer Perceptron Artificial Neural Network for the Prediction of Heating Value of Municipal Solid Waste. AIMS Energy 2019, 7, 944–956. [Google Scholar] [CrossRef]

- Dashti, A.; Noushabadi, A.S.; Raji, M.; Razmi, A.; Ceylan, S.; Mohammadi, A.H. Estimation of Biomass Higher Heating Value (HHV) Based on the Proximate Analysis: Smart Modeling and Correlation. Fuel 2019, 257, 115931. [Google Scholar] [CrossRef]

- Mondal, S.; Rafizul, I.M. Predicting Calorific Value through Proximate Analysis of Municipal Solid Waste Using Soft Computing System. Discov. Appl. Sci. 2025, 7, 212. [Google Scholar] [CrossRef]

- Matveeva, A.; Bychkov, A. How to Train an Artificial Neural Network to Predict Higher Heating Values of Biofuel. Energies 2022, 15, 7083. [Google Scholar] [CrossRef]

- Veza, I.; Irianto, N.; Panchal, H.; Paristiawan, P.A.; Idris, M.; Fattah, I.M.R.; Putra, N.R.; Silambarasan, R. Improved Prediction Accuracy of Biomass Heating Value Using Proximate Analysis with Various ANN Training Algorithms. Results Eng. 2022, 16, 100688. [Google Scholar] [CrossRef]

- Adeleke, O.; Olatunji, O.O.; Jen, T.-C.; Olawuyi, I. Enhanced Prediction of Heating Value of Municipal Solid Waste Using Hybrid Neuro-Fuzzy Model and Decision Tree-Based Feature Importance Assessment. Green Energy Resour. 2025, 3, 100119. [Google Scholar] [CrossRef]

- Baziar, M.; Yousefi, M.; Oskoei, V.; Makhdoomi, A.; Abdollahzadeh, R.; Dehghan, A. Machine Learning-Based Prediction of Heating Values in Municipal Solid Waste. Sci. Rep. 2025, 15, 14589. [Google Scholar] [CrossRef]

- Kujawska, J.; Kulisz, M.; Oleszczuk, P.; Cel, W. Improved Prediction of the Higher Heating Value of Biomass Using an Artificial Neural Network Model Based on the Selection of Input Parameters. Energies 2023, 16, 4162. [Google Scholar] [CrossRef]

- Jayapal, A.; Morales, F.O.; Ishtiaq, M.; Kim, S.Y.; Reddy, N.G.S. Modeling the Higher Heating Value of Spanish Biomass via Neural Networks and Analytical Equations. Energies 2025, 18, 4067. [Google Scholar] [CrossRef]

- Liu, J.; Iwakin, O.; Romero, C.E.; Cheng, L.; Moazeni, F.; Yao, Z.; De Saro, R.; Craparo, J. Rapid Characterization of MSW and RDF Feedstocks for Waste-to-Energy Process Using LIBS and ML Techniques. Waste Manag. 2025, 206, 115079. [Google Scholar] [CrossRef] [PubMed]

- Taki, M.; Rohani, A. Machine Learning Models for Prediction the Higher Heating Value (HHV) of Municipal Solid Waste (MSW) for Waste-to-Energy Evaluation. Case Stud. Therm. Eng. 2022, 31, 101823. [Google Scholar] [CrossRef]

- Güleç, F.; Pekaslan, D.; Williams, O.; Lester, E. Predictability of Higher Heating Value of Biomass Feedstocks via Proximate and Ultimate Analyses—A Comprehensive Study of Artificial Neural Network Applications. Fuel 2022, 320, 123944. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, S. The PSO/GA/ANN Modeling and Prediction for the Higher Heating Values of Solid Fuels: The Machine Learning Approach. Therm. Sci. 2025, 29, 2881–2897. [Google Scholar] [CrossRef]

| Descriptive Statistics ↓ | Input Variables (%) ↓ | Output Variable (MJ kg−1) ↓ | ||||

|---|---|---|---|---|---|---|

| C (%) | H (%) | N (%) | S (%) | O (%) | HHV | |

| Mean | 48.62 | 6.37 | 2.35 | 0.37 | 33.35 | 19.59 |

| Median | 45.78 | 5.90 | 0.90 | 0.13 | 37.94 | 18.75 |

| Minimum | 6.27 | 1.09 | 0.01 | 0.00 | 0.00 | 2.80 |

| Maximum | 91.53 | 14.30 | 9.98 | 9.20 | 52.84 | 46.08 |

| Std.Dev. | 14.76 | 2.24 | 2.83 | 0.91 | 13.66 | 8.35 |

| ANN Model | Performance (R2) | Error | ||||

|---|---|---|---|---|---|---|

| Training | Test | Validation | Training | Test | Validation | |

| MLP 5-17-1 | 0.94 | 0.85 | 0.86 | 2.06 | 4.96 | 3.99 |

| Dataset | R2 | RMSE | MAE | MAPE (%) |

|---|---|---|---|---|

| Train | 0.943 | 2.03 | 1.49 | 8.96 |

| Validation | 0.856 | 2.82 | 1.91 | 15.10 |

| Test | 0.85 | 3.15 | 2.30 | 16.48 |

| Overall | 0.92 | 2.36 | 1.68 | 10.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brandić, I.; Matin, A.; Špelić, K.; Jovičić, N.; Matin, B.; Grubor, M.; Voća, N. Generalized ANN Model for Predicting the Energy Potential of Heterogeneous Waste. Energies 2025, 18, 6111. https://doi.org/10.3390/en18236111

Brandić I, Matin A, Špelić K, Jovičić N, Matin B, Grubor M, Voća N. Generalized ANN Model for Predicting the Energy Potential of Heterogeneous Waste. Energies. 2025; 18(23):6111. https://doi.org/10.3390/en18236111

Chicago/Turabian StyleBrandić, Ivan, Ana Matin, Karlo Špelić, Nives Jovičić, Božidar Matin, Mateja Grubor, and Neven Voća. 2025. "Generalized ANN Model for Predicting the Energy Potential of Heterogeneous Waste" Energies 18, no. 23: 6111. https://doi.org/10.3390/en18236111

APA StyleBrandić, I., Matin, A., Špelić, K., Jovičić, N., Matin, B., Grubor, M., & Voća, N. (2025). Generalized ANN Model for Predicting the Energy Potential of Heterogeneous Waste. Energies, 18(23), 6111. https://doi.org/10.3390/en18236111