Multi-Objective Optimization for Refined Oil Resource Allocation: Towards Energy and Carbon Saving

Abstract

1. Introduction

- At the modeling level, a full-chain MILP model for refined oil is constructed, encompassing processes from refinery production and external procurement to multimodal transportation and inventory. A distinctive feature is the introduction of a dynamic inventory coordination mechanism between external procurement sources and transit depots, specifically designed to address capacity shortages and demand fluctuations.

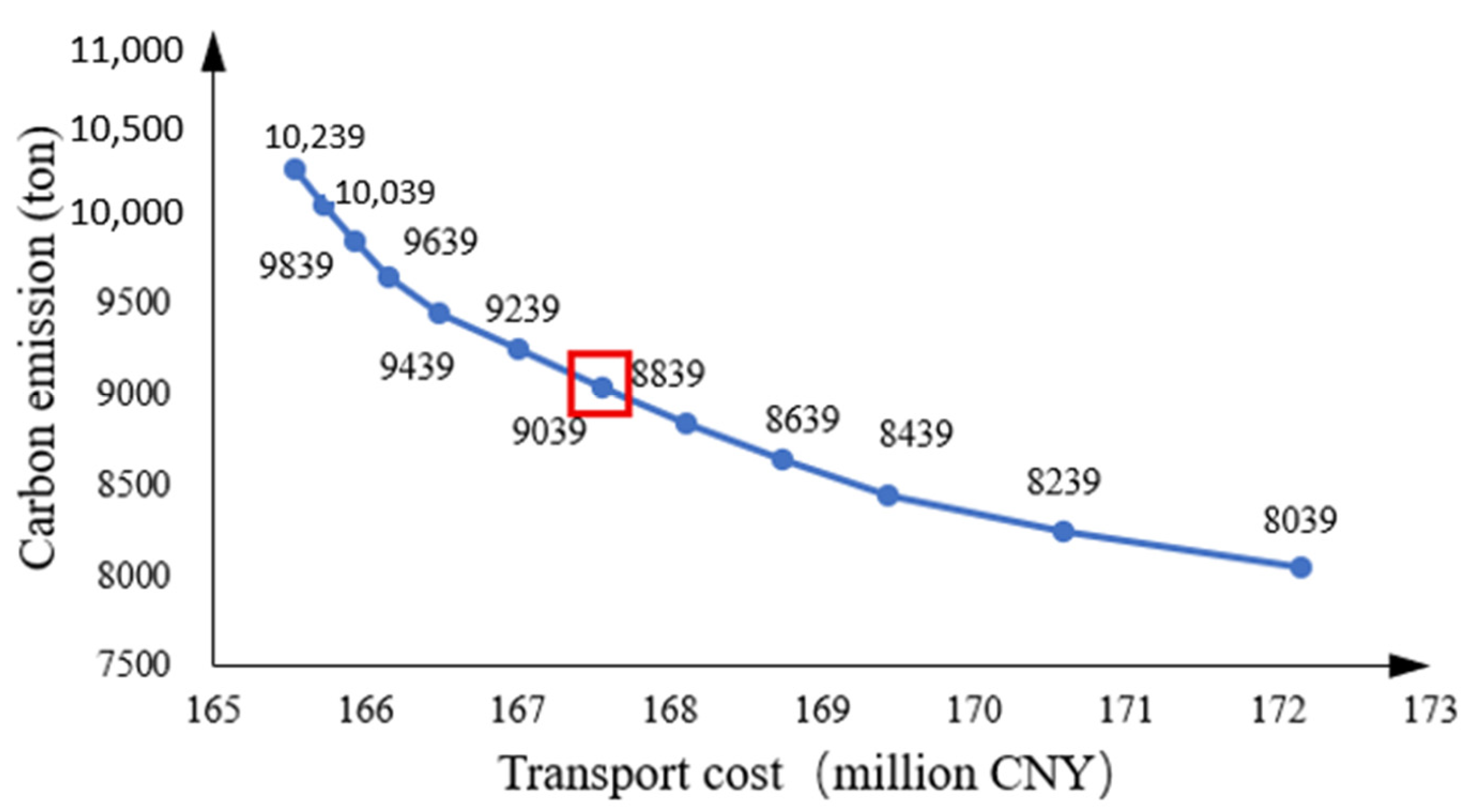

- At the algorithmic level, the ε-constraint method is adopted to resolve conflicts between economic and environmental objectives, effectively generating the complete Pareto frontier that quantifies the trade-offs.

- At the application level, this study is the first to apply the ε-constraint method to a complex multi-province, multi-node refined oil network in Central China. The application successfully quantifies the cost increments under different emission-reduction targets, providing enterprises with a clear ‘cost-emission’ trade-off map to support strategic decision-making.

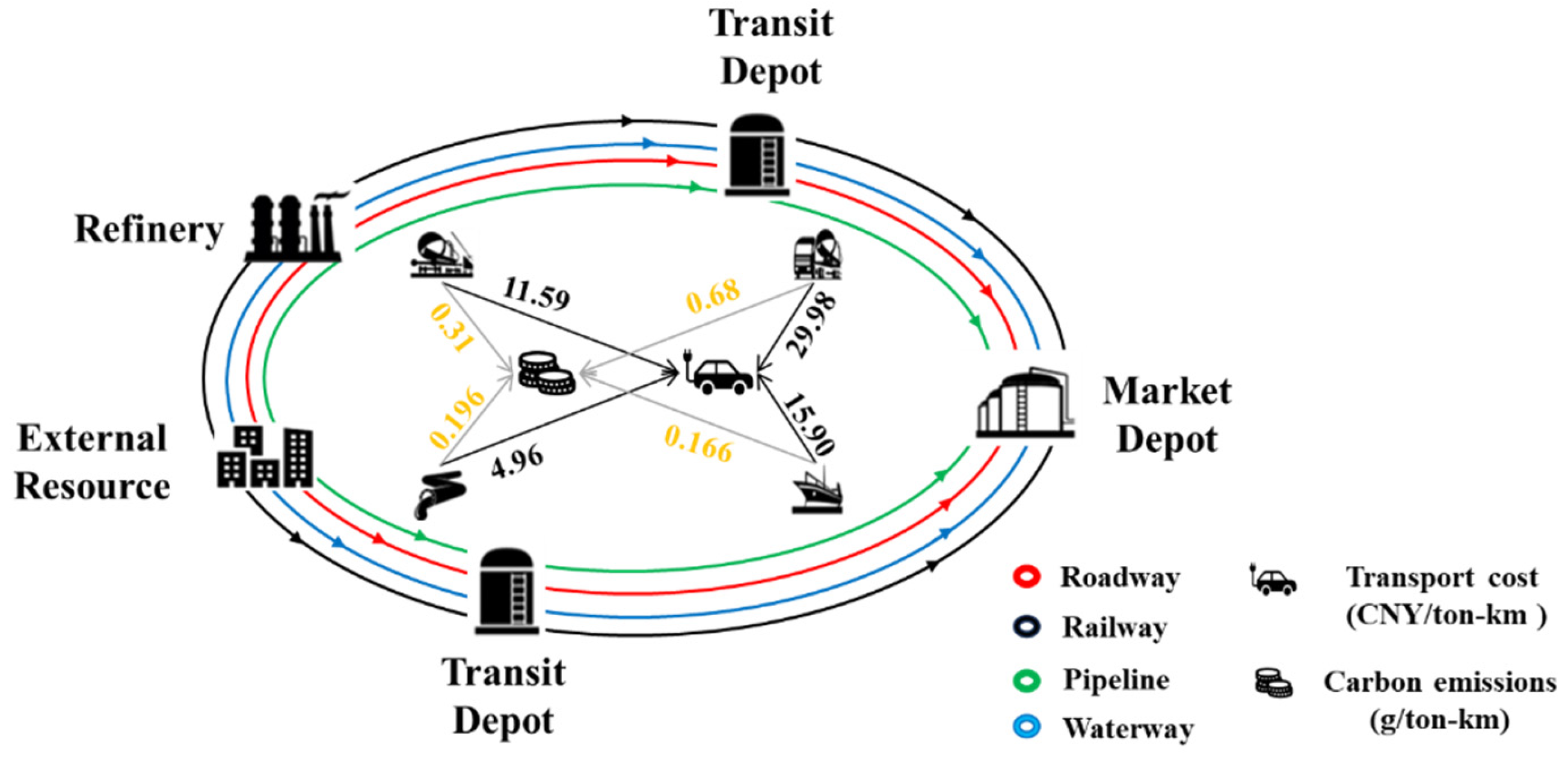

2. Problem Description

- Supply information: location, production plan, sending capacity;

- Demand information: location, demand plan, receiving capacity;

- External procurement information: location, procurement capacity;

- Transport information: transport capacity, transport time;

- Cost information: unit transport cost, production cost, inventory cost, backlog cost, stockout cost, unit external procurement cost.

- Resource allocation scheme: final sending and receiving volume, external procurement volume, backlog volume, stockout volume;

- Transport and storage scheme: transport volume and direction, inventory change;

- Other results: total cost and carbon emissions.

- All supply, demand, and inventory data are available;

- Oil losses during transport are neglected;

- Variations in transport time due to exceptional circumstances are not considered.

3. Methodology

3.1. Multi-Objective Optimization Model

3.1.1. Objective Function

3.1.2. Constraints

3.2. ε-Constraint Method

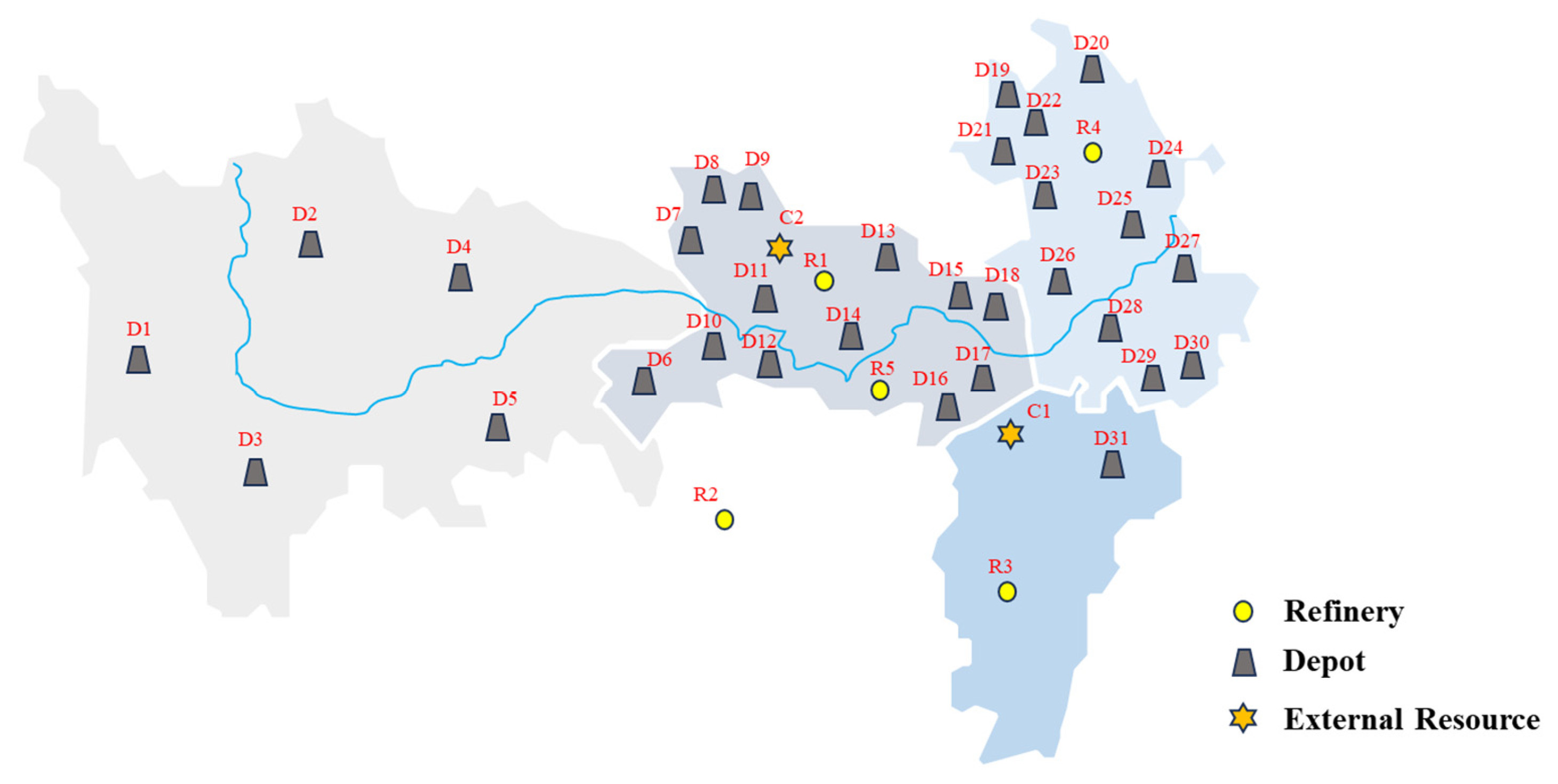

4. Case Study

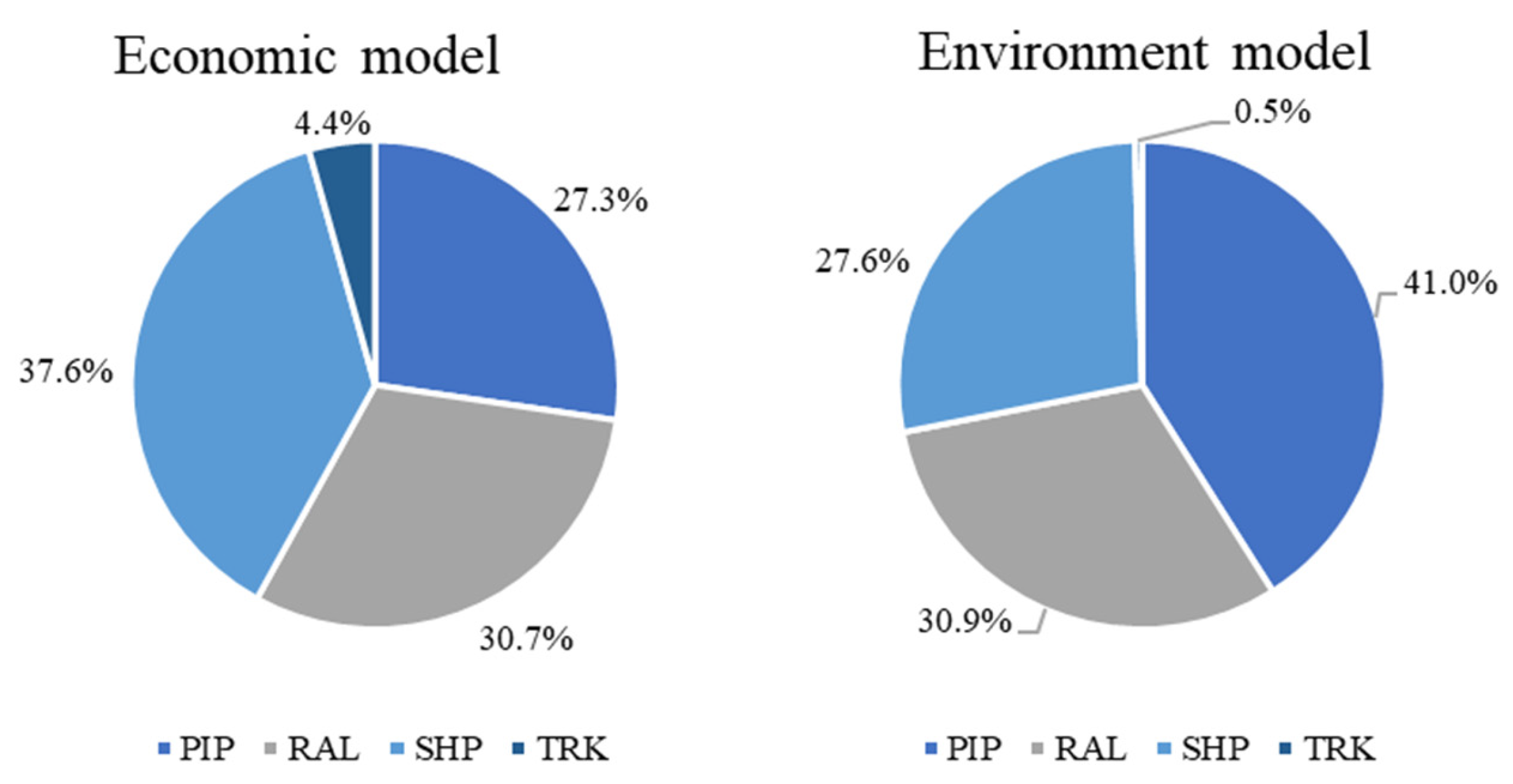

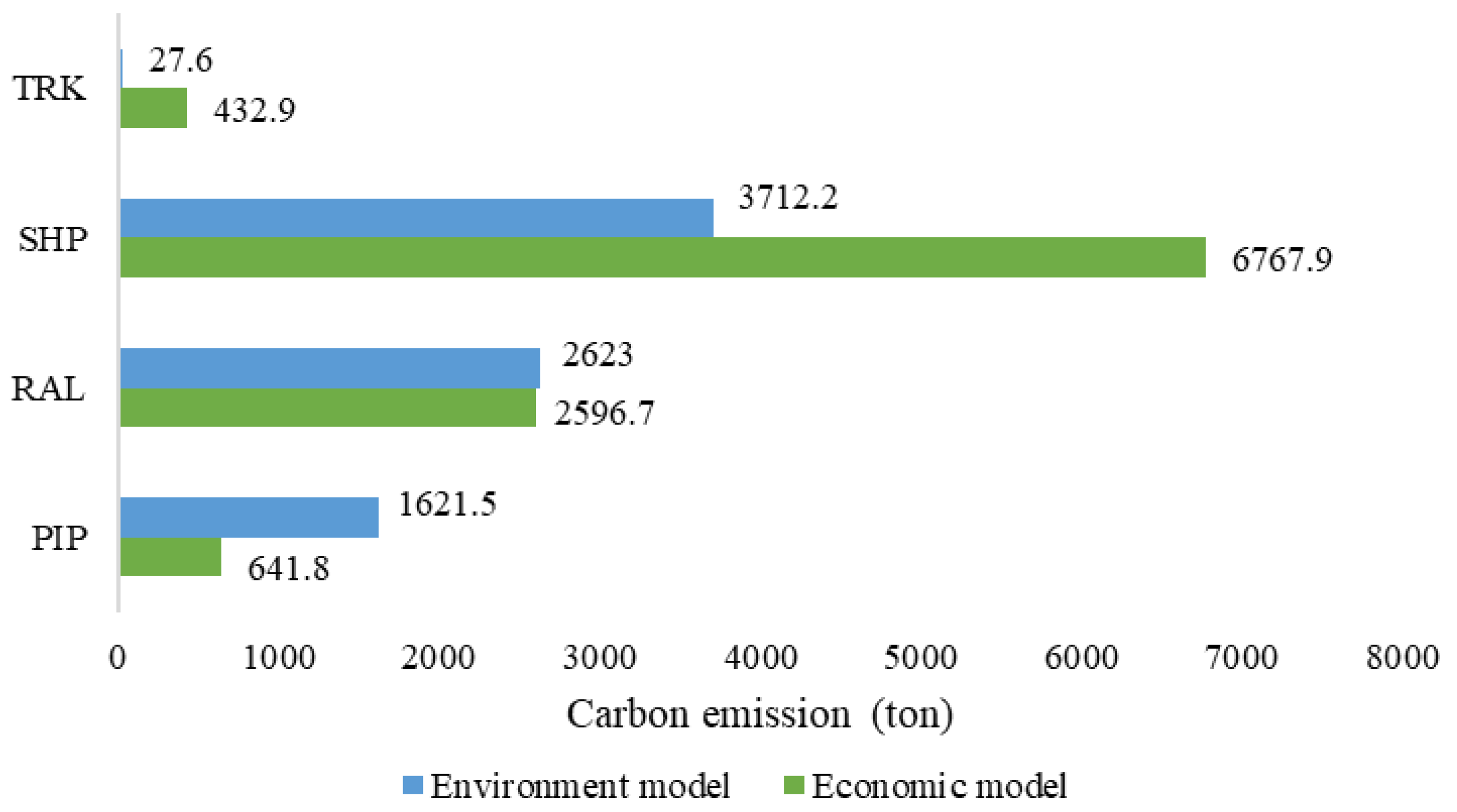

4.1. Economy and Environment Analysis

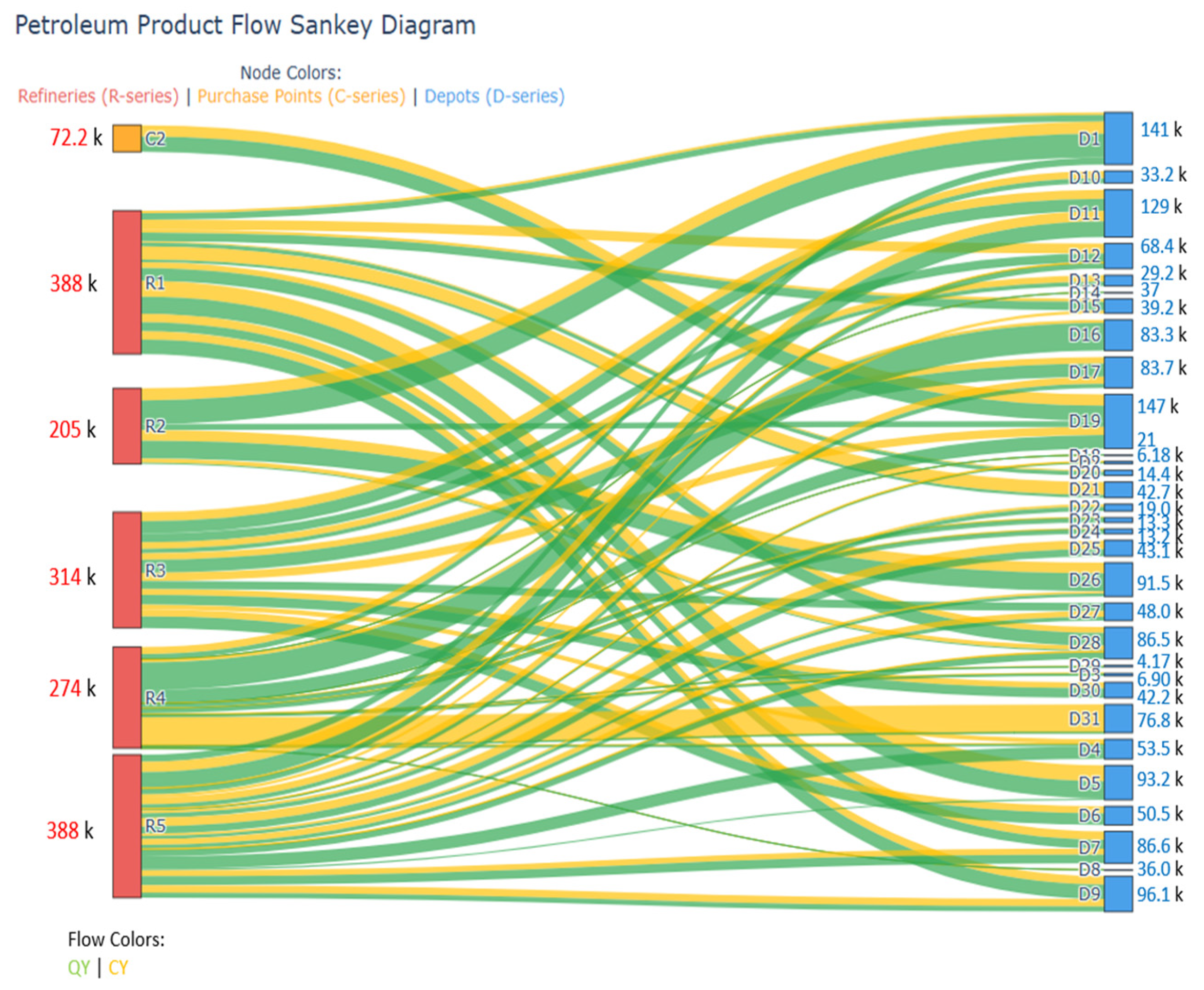

4.2. Resource Allocation Scheme

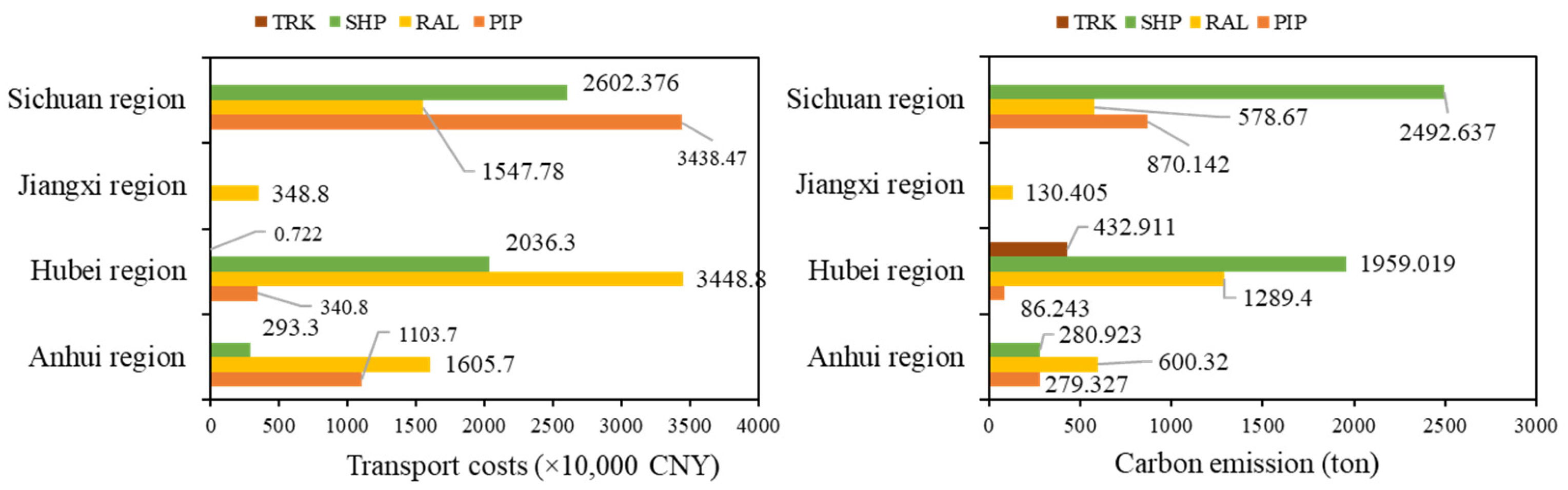

- Optimize transport structure: Increase pipeline share to 35% (currently 27.3%) in high-capacity areas such as Hubei. Although pipeline costs are slightly higher than waterway, this shift can reduce large-scale transport emissions to about 1200 tons. In high-cost regions like Sichuan, limit roadway use (currently 4.4%) and transfer flows to railway, cutting emissions by roughly 80% while lowering overall transport costs.

- Strengthen regional coordination: For low-demand areas such as Jiangxi, source more from nearby external procurement nodes (e.g., C2) to avoid long-distance shipments. Dynamically deploy inventory through transit depots: move Sichuan’s surplus by railway to neighboring high-demand depots to reduce local roadway reliance and relieve pipeline capacity pressure.

- Apply stepped carbon constraints: Implement differentiated ε caps: tighter limits (ε = 8000 tons) for high-emission regions like Sichuan to incentivize low-carbon transport and relaxed caps (ε = 9500 tons) for low-emission regions like Jiangxi to avoid excessive cost increases.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Basic Data

| Refinery | Region | Period | GAS (×104 t) | DIE (×104 t) |

|---|---|---|---|---|

| R1 | Hubei | season | 47.4 | 28.1 |

| R2 | Hunan | season | 36.0 | 27.0 |

| R3 | Jiangxi | season | 70.0 | 42.8 |

| R4 | Anhui | season | 60.8 | 50.4 |

| R5 | Hubei | season | 626.2 | 31.5 |

| Depot | Region | Period | GAS (×102 t) | DIE (×102 t) |

|---|---|---|---|---|

| D1 | Sichuan | season | 0.8 | 767.0 |

| D2 | Sichuan | season | 0.2 | 0.1 |

| D3 | Sichuan | season | 0.4 | 41.3 |

| D4 | Sichuan | season | 407.2 | 128.3 |

| D5 | Sichuan | season | 0.2 | 0.2 |

| D6 | Hubei | season | 131.7 | 0.1 |

| D7 | Hubei | season | 263.3 | 158.8 |

| D8 | Hubei | season | 317.7 | 187.0 |

| D9 | Hubei | season | 750.0 | 83.1 |

| D10 | Hubei | season | 68.8 | 0.2 |

| D11 | Hubei | season | 0.01 | 0.2 |

| D12 | Hubei | season | 133.2 | 0.1 |

| D13 | Hubei | season | 138.5 | 193.4 |

| D14 | Hubei | season | 115.7 | 175.9 |

| D15 | Hubei | season | 1013.4 | 394.7 |

| D16 | Hubei | season | 107.5 | 36.5 |

| D17 | Hubei | season | 231.1 | 160.8 |

| D18 | Anhui | season | 558.2 | 306.4 |

| D19 | Anhui | season | 387.9 | 295.7 |

| D20 | Anhui | season | 320.1 | 160.1 |

| D21 | Anhui | season | 469.1 | 368.4 |

| D22 | Anhui | season | 38.6 | 23.2 |

| D23 | Anhui | season | 566.7 | 348.7 |

| D24 | Anhui | season | 938.2 | 530.9 |

| D25 | Anhui | season | 195.2 | 235.6 |

| D26 | Anhui | season | 120.0 | 70.0 |

| D27 | Anhui | season | 506.3 | 426.0 |

| D28 | Anhui | season | 479.0 | 386.9 |

| D29 | Anhui | season | 535.6 | 425.8 |

| D30 | Anhui | season | 73.0 | 353.6 |

| D31 | Jiangxi | season | 760.1 | 525.8 |

| Resource Node | Oil | Resource Volume (×104 t) | Unit Cost (×104 CNY/t) |

|---|---|---|---|

| C1 | GAS | 10.0 | 0.8 |

| C1 | DIE | 10.0 | 0.8 |

| C2 | GAS | 1.0 | 0.8 |

| C2 | DIE | 1.0 | 0.8 |

References

- U.S. Energy Information Administration (EIA). Short-Term Energy Outlook; U.S. Energy Information Administration: Washington, DC, USA, 2024. [Google Scholar]

- International Energy Agency (IEA). Oil Market Report—2024 Analysis and Forecast to 2028; IEA: Paris, France, 2024. [Google Scholar]

- Wang, G.T.; Cheng, Q.W.; Zhao, W.; Liao, Q.; Zhang, H. Review on the transport capacity management of oil and gas pipeline network: Challenges and opportunities of future pipeline transport. Energy Strategy Rev. 2022, 43, 100933. [Google Scholar] [CrossRef]

- Qiu, R.; Tu, R.F.; Wei, X.M.; Zhang, H.; Gao, M.; Liao, Q.; Liang, Y. Evaluation and optimization of pipeline pricing strategies on oil product logistics in China. J. Pipeline Sci. Eng. 2024, 4, 100144. [Google Scholar] [CrossRef]

- João, N.C.; Gonçalves, M.; Carvalho, S.; Cortez, P. Operations research models and methods for safety stock determination: A review. Oper. Res. Perspect. 2020, 7, 100164. [Google Scholar] [CrossRef]

- Wei, Z.W.; Gao, M.D.; Tu, R.F.; Chang, J.; Zhang, X.; Du, M.; Yang, X.; He, W. Multimodal Transportation Optimization of Refined Oil Logistics Considering Daily Scheduling: Case from China. J. Pipeline Sci. Eng. 2024, 15, 1590. [Google Scholar] [CrossRef]

- Ibeto, C.; Ugwu, C. Exhaust Emissions from Engines Fuelled with Petrol, Diesel and their Blends with Biodiesel Produced from Waste Cooking Oil. Pol. J. Environ. Stud. 2019, 28, 3197–3206. [Google Scholar] [CrossRef]

- Jiao, Y.Q.; Qiu, R.; Liang, Y.T.; Liao, Q.; Tu, R.; Wei, X.; Zhang, H. Integration optimization of production and transportation of refined oil: A case study from China. Chem. Eng. Res. Des. 2022, 188, 39–49. [Google Scholar] [CrossRef]

- Bei, H.H.; Lin, H.; Yang, F.J.; Li, X.; Murcio, R.; Yang, T. Optimization on Multimodal Network Considering Time Window Under Uncertain Demand. IEEE Trans. Intell. Transp. Syst. 2025, 26, 11294–11312. [Google Scholar] [CrossRef]

- Li, D.; Zhang, S.J.; Xiao, Y.H. Interval Optimization-Based Optimal Design of Distributed Energy Resource Systems under Uncertainties. Energies 2020, 13, 3465. [Google Scholar] [CrossRef]

- Miehling, S.; Hanel, A.; Lambert, J.; Fendt, S.; Spliethoff, H. Energy System Optimisation using (Mixed Integer) Linear Programming. arXiv 2023, arXiv:2308.01882. [Google Scholar] [CrossRef]

- Alahmad, A.K.; Verayiah, R.; Shareef, H.; Ramasamy, A.; Ba-Swaimi, S. Optimizing renewable energy and green technologies in distribution systems through stochastic planning of distributed energy resources. Energy Convers. Manag. X 2025, 25, 100834. [Google Scholar]

- Haddad, M.; Mansour, C.; Diab, J. System dynamics modeling for mitigating energy use and CO2 emissions of freight transport in Lebanon. In Proceedings of the First GCC International Conference on Industrial Engineering and Operations Management, Riyadh, Saudi Arabia, 26–28 November 2019. [Google Scholar]

- Zhu, Z.S.; Wang, X.H.; Liu, L.J.; Hua, S. Green sensitivity in supply chain management: An evolutionary game theory approach. Chaos Solitons Fractals 2023, 173, 113595. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, Z.; Qiu, R.; Liao, Q.; Zhang, H.; Liang, Y. Multi-objective optimisation of refined oil distribution system considering distribution cost and depot utilisation rate. J. Pet. Sci. 2023, 8, 204–213. [Google Scholar]

- Ya, Z.; Han, J. Synergizing carbon trading and water management for urban sustainability: A city-level multi-objective planning framework. Appl. Energy 2024, 359, 122636. [Google Scholar]

- Jiang, W.; Yu, Q.L. Carbon emissions and economic growth in China: Based on mixed frequency VAR analysis. Renew. Sustain. Energy Rev. 2023, 183, 113500. [Google Scholar] [CrossRef]

- Wang, D.Y.; Li, Y.; Hong, J.K. Analysis of the Impact of Different Carbon Emission Reduction Subsidy Policies on Closed-Loop Supply Chain Decisions. J. Environ. Manag. 2025, 373, 123451. [Google Scholar] [CrossRef]

- Lu, W.B.; Xiao, Q.; Jiao, Z.P.; Jiang, Q.; Mu, Y.; Hou, K.; Yu, X.; Guo, S.; Jia, H. Multi-objective Optimal Operation of District Integrated Energy System. IEEE Sustain. Power Energy 2020, 11, 1505–1510. [Google Scholar]

- Shao, T.; Wang, J.; Wang, R.; Chow, D.; Nan, H.; Zhang, K.; Fang, Y. Multi-Objective Optimization for the Energy, Economic, and Environmental Performance of High-Rise Residential Buildings in Areas of Northwestern China with Different Solar Radiation. Appl. Sci. 2024, 14, 6719. [Google Scholar] [CrossRef]

- Delfino, F.; Ferro, G.; Robba, M.; Rossi, M. An Energy Management Platform for the Optimal Control of Active and Reactive Powers in Sustainable Microgrids. IEEE Trans. Ind. Appl. 2019, 55, 7146–7156. [Google Scholar] [CrossRef]

- Ji, H.; Wang, C.; Li, P.; Song, G.; Yu, H.; Wu, J. Quantified analysis method for operational flexibility of active distribution networks with high penetration of distributed generators. Appl. Energy 2019, 239, 706–714. [Google Scholar] [CrossRef]

- Han, J.M.; Wang, J.J.; Zhou, Y.; Lu, X. Distributed energy systems: Multi-objective optimization and evaluation under different operational strategies. J. Clean. Prod. 2021, 280, 124050. [Google Scholar] [CrossRef]

- Dong, Y.C.; Wang, C.; Zhang, H.L.; Zhou, X. A novel multi-objective optimization framework for optimal integrated energy system planning with demand response under multiple uncertainties. Inf. Sci. 2024, 663, 120252. [Google Scholar] [CrossRef]

- Wang, J.S.; Ren, X.X.; Li, T.; Zhao, Q.; Dai, H.; Guo, Y.; Yan, J. Multi-objective optimization and multi-criteria evaluation framework for the design of distributed multi-energy system: A case study in industrial park. J. Build. Eng. 2024, 88, 109138. [Google Scholar] [CrossRef]

- Xing, X.K.; Yan, Y.M.; Zhang, H.R.; Long, Y.; Wang, Y.; Liang, Y. Optimal design of distributed energy systems for industrial parks under gas shortage based on augmented ε-constraint method. J. Clean. Prod. 2019, 218, 782–795. [Google Scholar] [CrossRef]

- Chen, W.X.; Ren, H.T.; Zhou, W.J. Review of multi-objective optimization in long-term energy system models. Glob. Energy Interconnect. 2023, 6, 645–660. [Google Scholar] [CrossRef]

- Qiu, R.; Zhang, H.R.; Guo, X.Y.; Zhou, X.; Guo, Z.; Liao, Q.; Liang, Y. A multi-scenario and multi-objective scheduling optimization model for liquefied light hydrocarbon pipeline system. Chem. Eng. Res. Des. 2019, 141, 566–579. [Google Scholar] [CrossRef]

- Qiu, R.; Zhang, H.R.; Zhou, X.Y.; Guo, Z.; Wang, G.; Yin, L.; Liang, Y. A multi-objective and multi-scenario optimization model for operation control of CO2-flooding pipeline network system. J. Clean. Prod. 2020, 247, 119157. [Google Scholar] [CrossRef]

- Mavrotas, G. Effective implementation of the ε-constraint method in Multi-Objective Mathematical Programming problems. Appl. Math. Comput. 2009, 213, 455–465. [Google Scholar] [CrossRef]

- Wang, B.H.; Liang, Y.T.; Zheng, T.C.; Yuan, M.; Zhang, H. Optimisation of a downstream oil supply chain with new pipeline route planning. Chem. Eng. Res. Des. 2019, 145, 300–313. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Dong, B.; Bao, Z.; Fu, G.; Lu, J.; Qi, Z.; Li, H.; Qiu, R. Multi-Objective Optimization for Refined Oil Resource Allocation: Towards Energy and Carbon Saving. Energies 2025, 18, 6075. https://doi.org/10.3390/en18226075

Chen J, Dong B, Bao Z, Fu G, Lu J, Qi Z, Li H, Qiu R. Multi-Objective Optimization for Refined Oil Resource Allocation: Towards Energy and Carbon Saving. Energies. 2025; 18(22):6075. https://doi.org/10.3390/en18226075

Chicago/Turabian StyleChen, Jingjun, Bozhuo Dong, Zhen Bao, Guangtao Fu, Jingkai Lu, Zhengfang Qi, Haochong Li, and Rui Qiu. 2025. "Multi-Objective Optimization for Refined Oil Resource Allocation: Towards Energy and Carbon Saving" Energies 18, no. 22: 6075. https://doi.org/10.3390/en18226075

APA StyleChen, J., Dong, B., Bao, Z., Fu, G., Lu, J., Qi, Z., Li, H., & Qiu, R. (2025). Multi-Objective Optimization for Refined Oil Resource Allocation: Towards Energy and Carbon Saving. Energies, 18(22), 6075. https://doi.org/10.3390/en18226075