Numerical Study on Thermal Deviation of High-Temperature Heating Surfaces in a Tangentially Fired Boiler Under Peak Load Regulation

Abstract

1. Introduction

2. Methods

2.1. Numerical Model

2.1.1. Turbulence Model

2.1.2. Species Model

2.1.3. Radiation Model

2.1.4. Gas–Solid Two-Phase Flow Model

2.1.5. Pulverized Coal Particle Combustion Model

- 1

- Devolatilization model

- 2

- Gas-phase combustion model

- 3

- Char combustion model

2.1.6. Solution Method

2.2. Evaluation Criteria

2.2.1. Velocity Deviation

2.2.2. Heat Absorption Deviation

3. Case Study

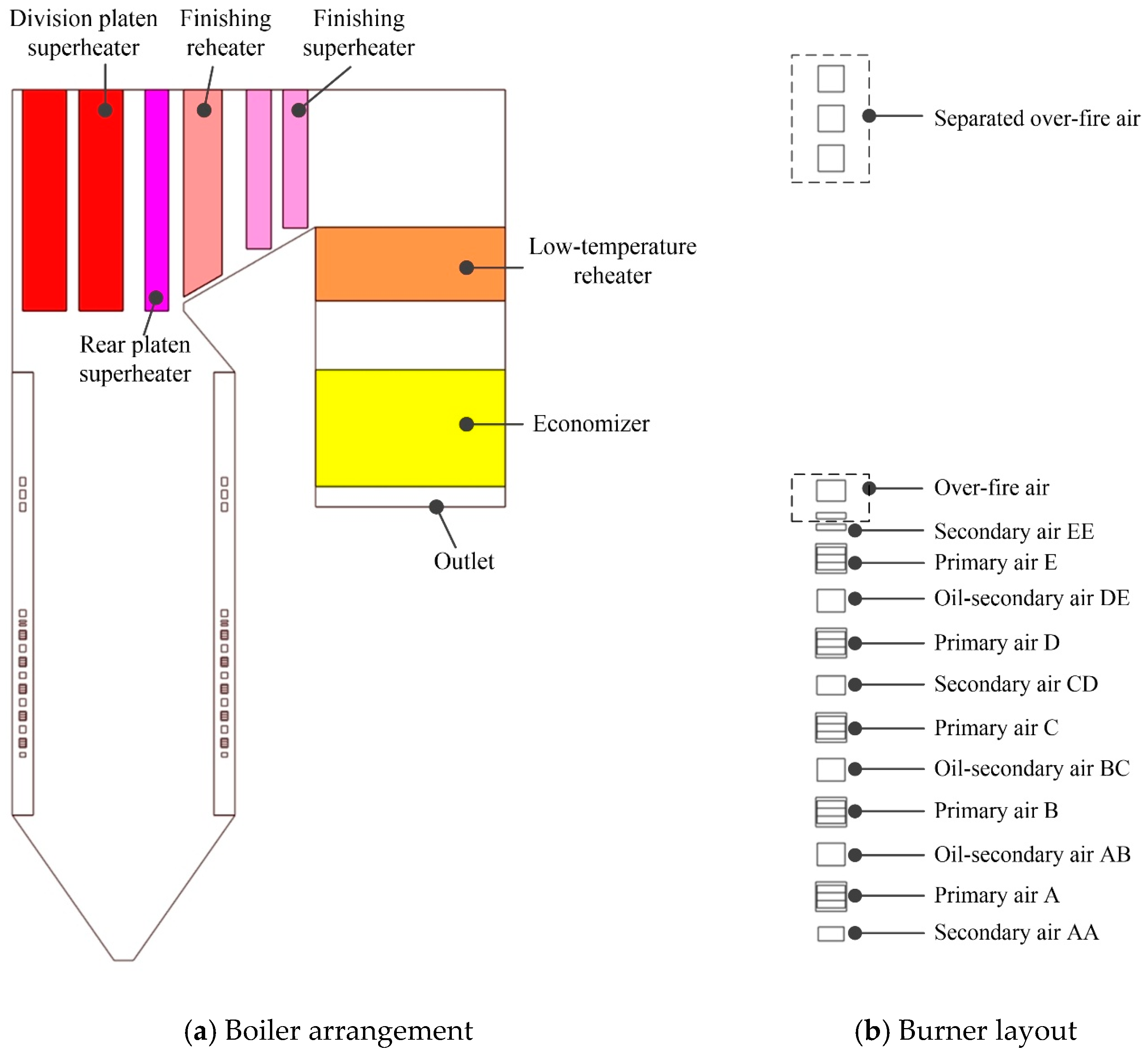

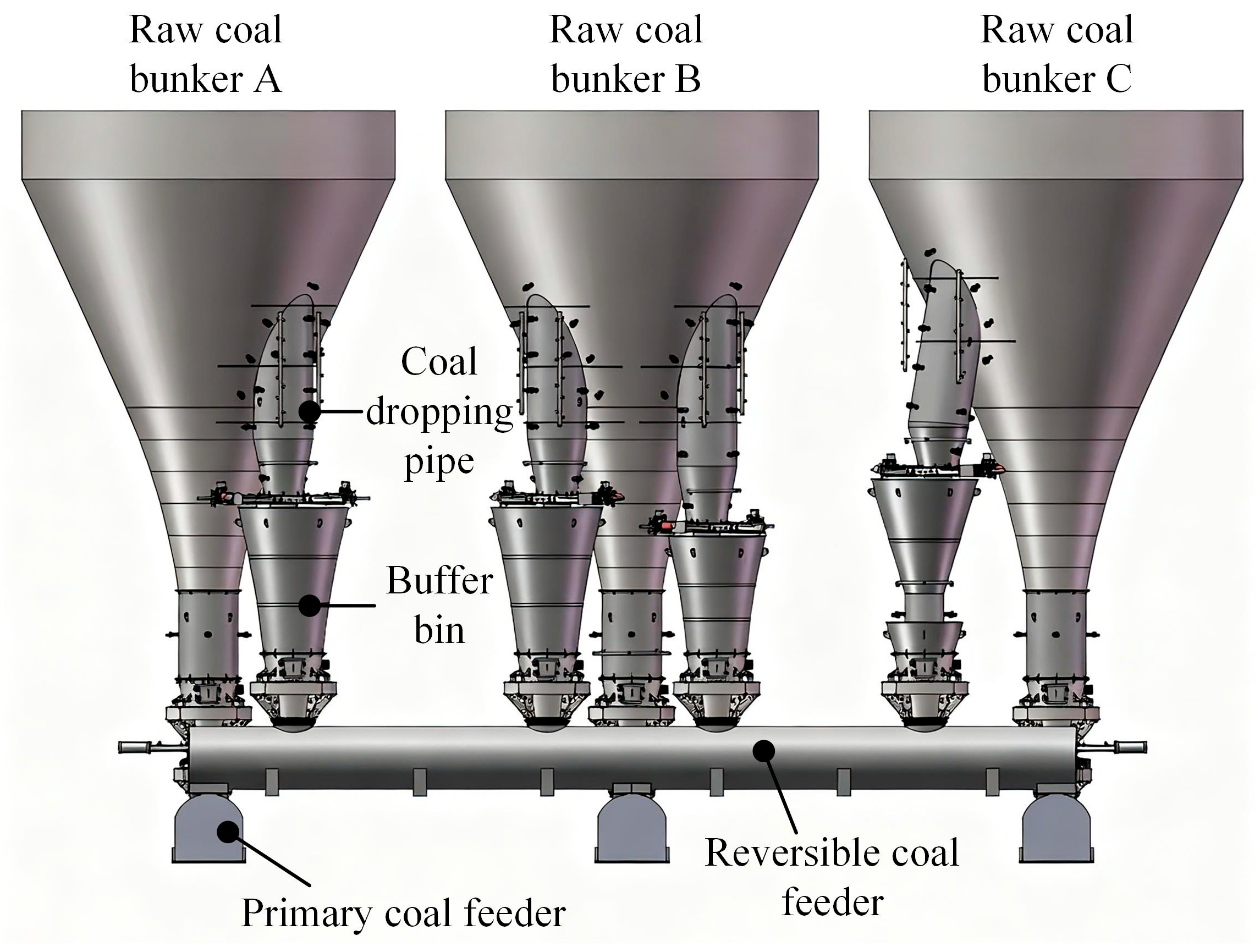

3.1. Boiler Description

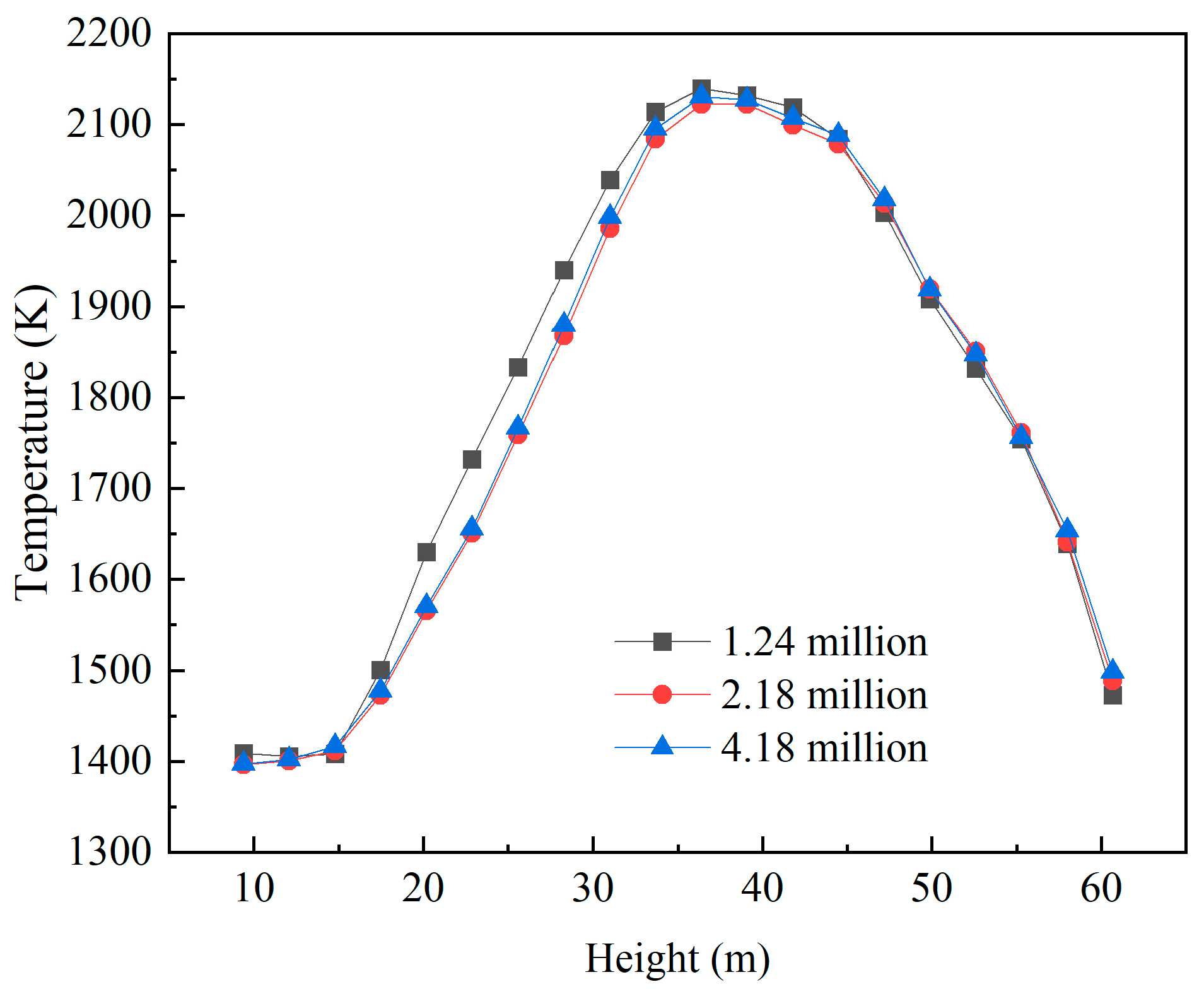

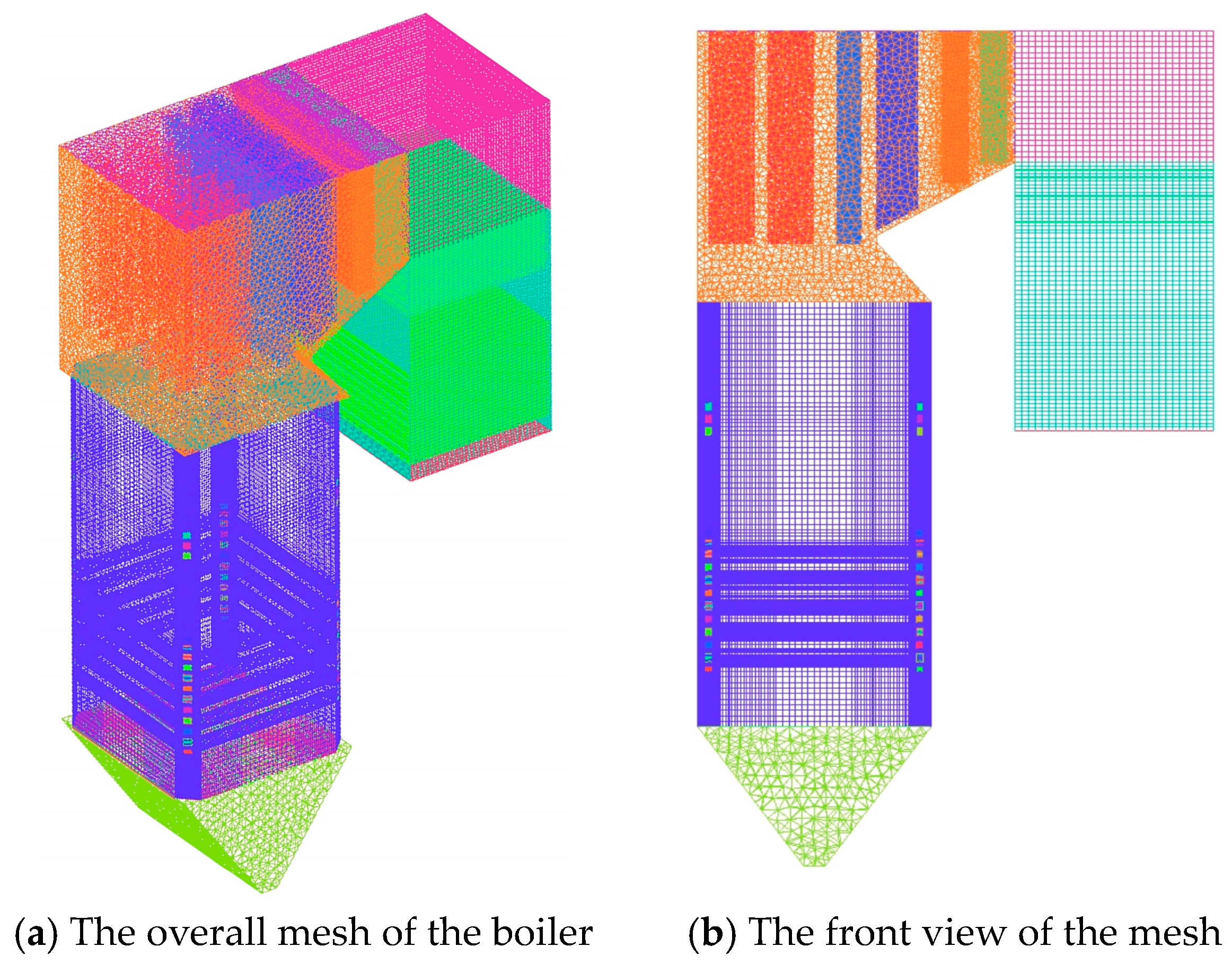

3.2. Physical Model and Mesh Generation

3.3. Boundary Conditions

3.4. Simulated Operating Conditions

4. Results and Discussion

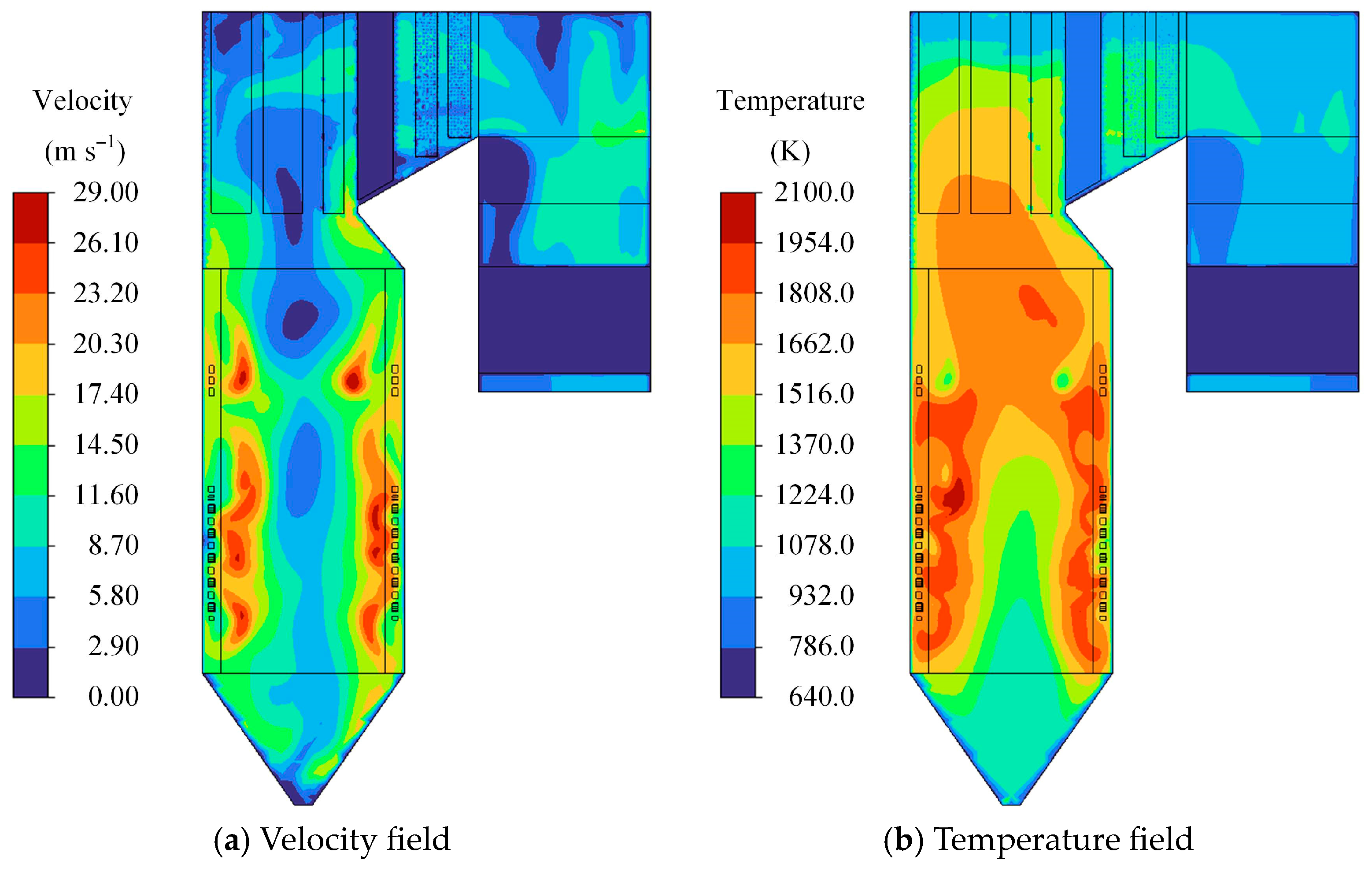

4.1. Model Validation

4.2. Velocity Deviation

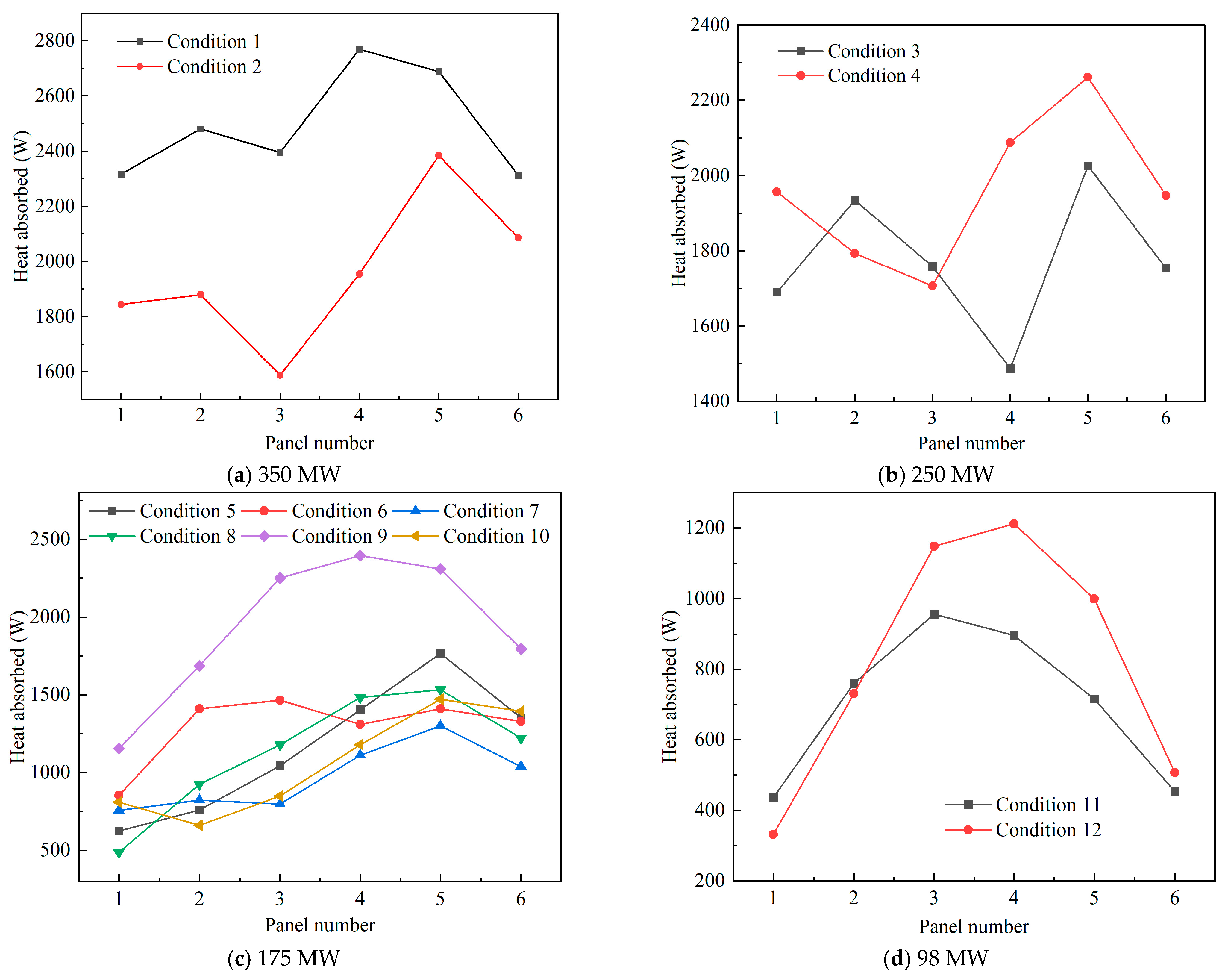

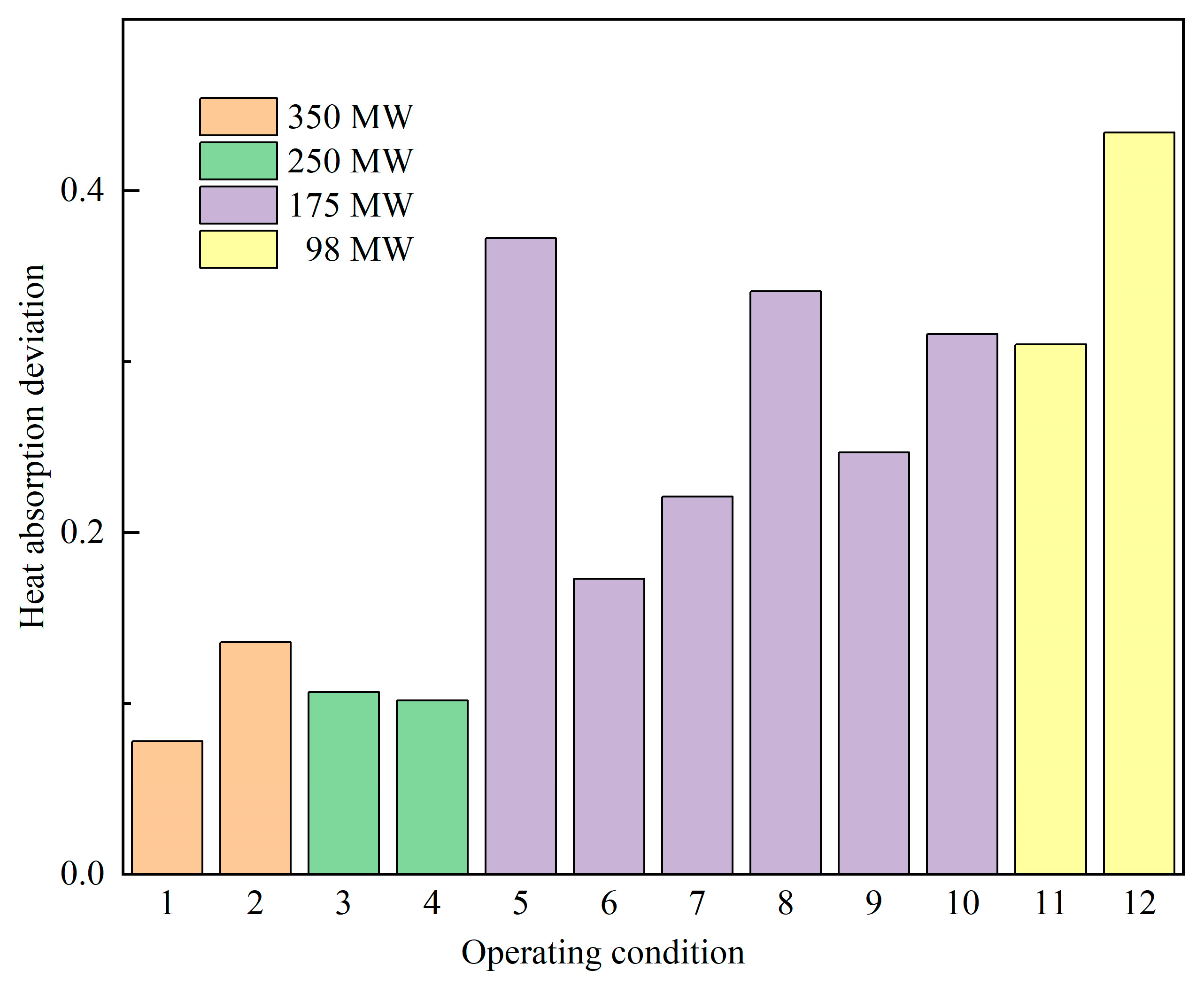

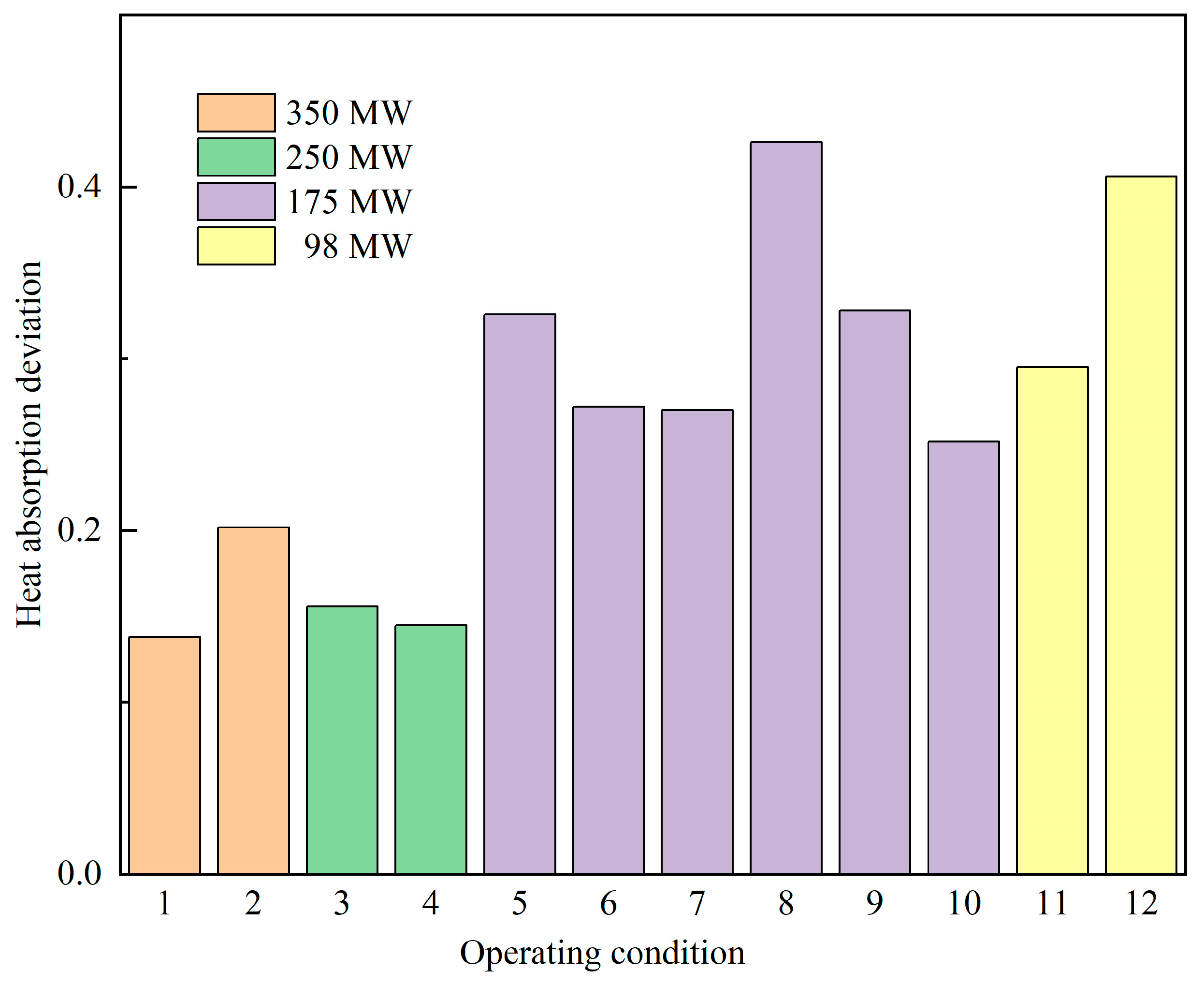

4.3. Heat Absorption Deviation

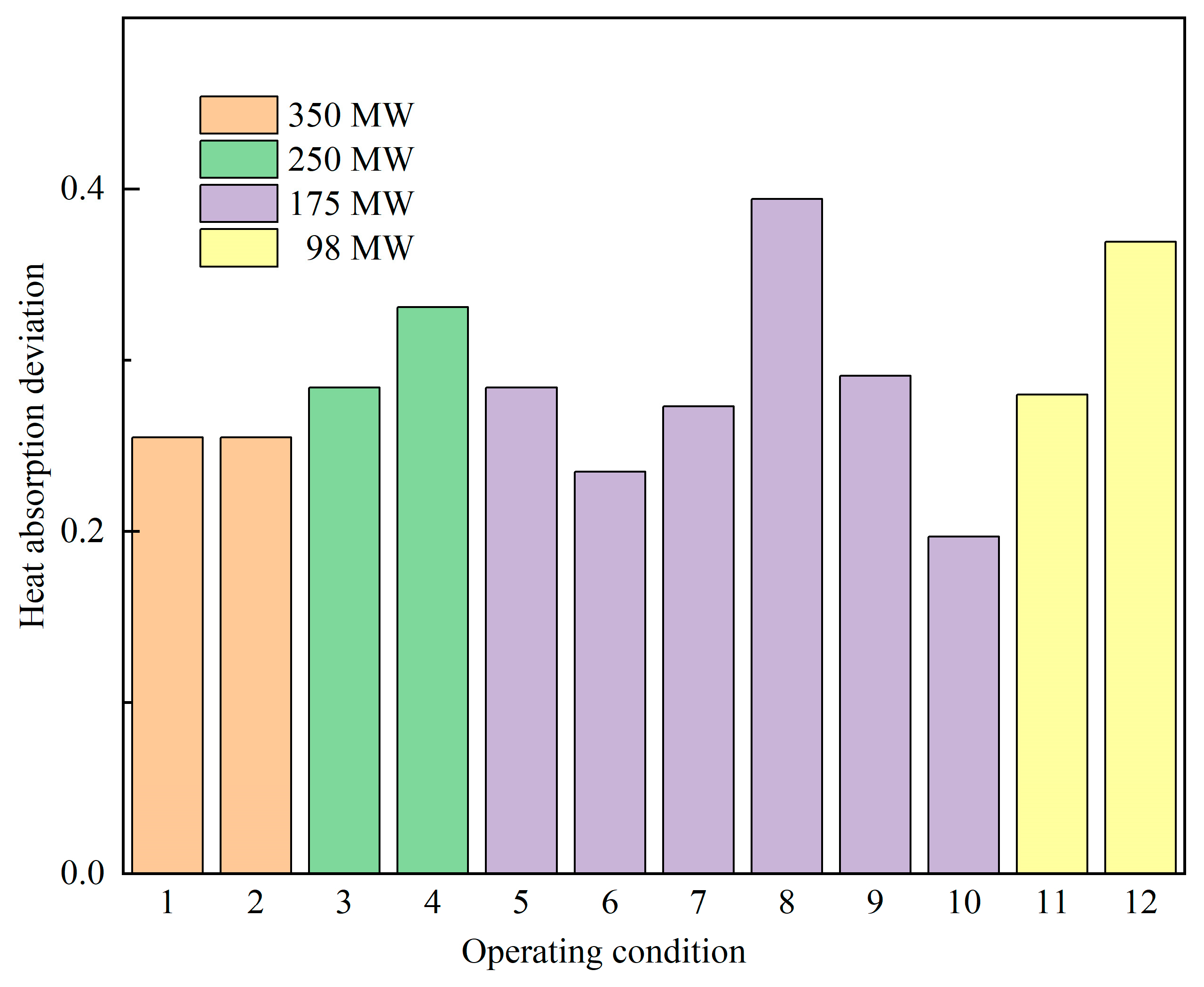

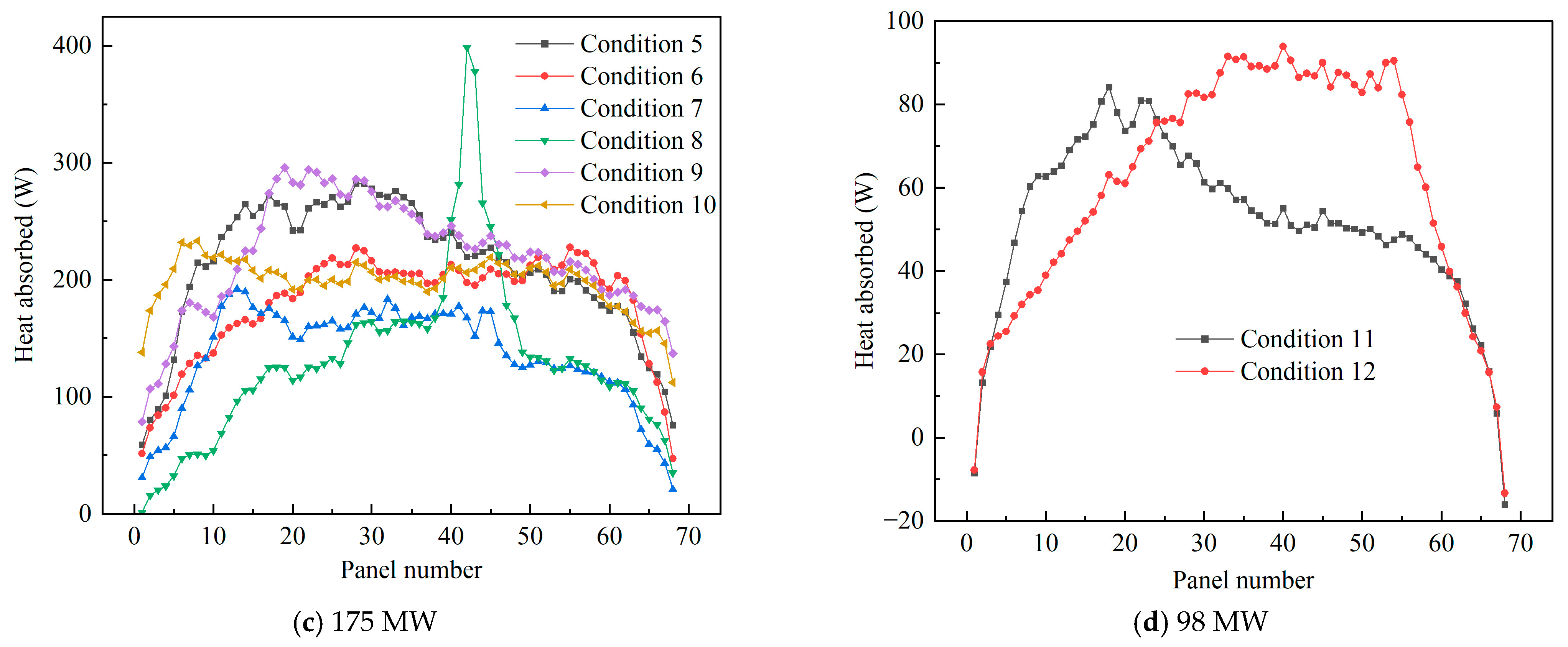

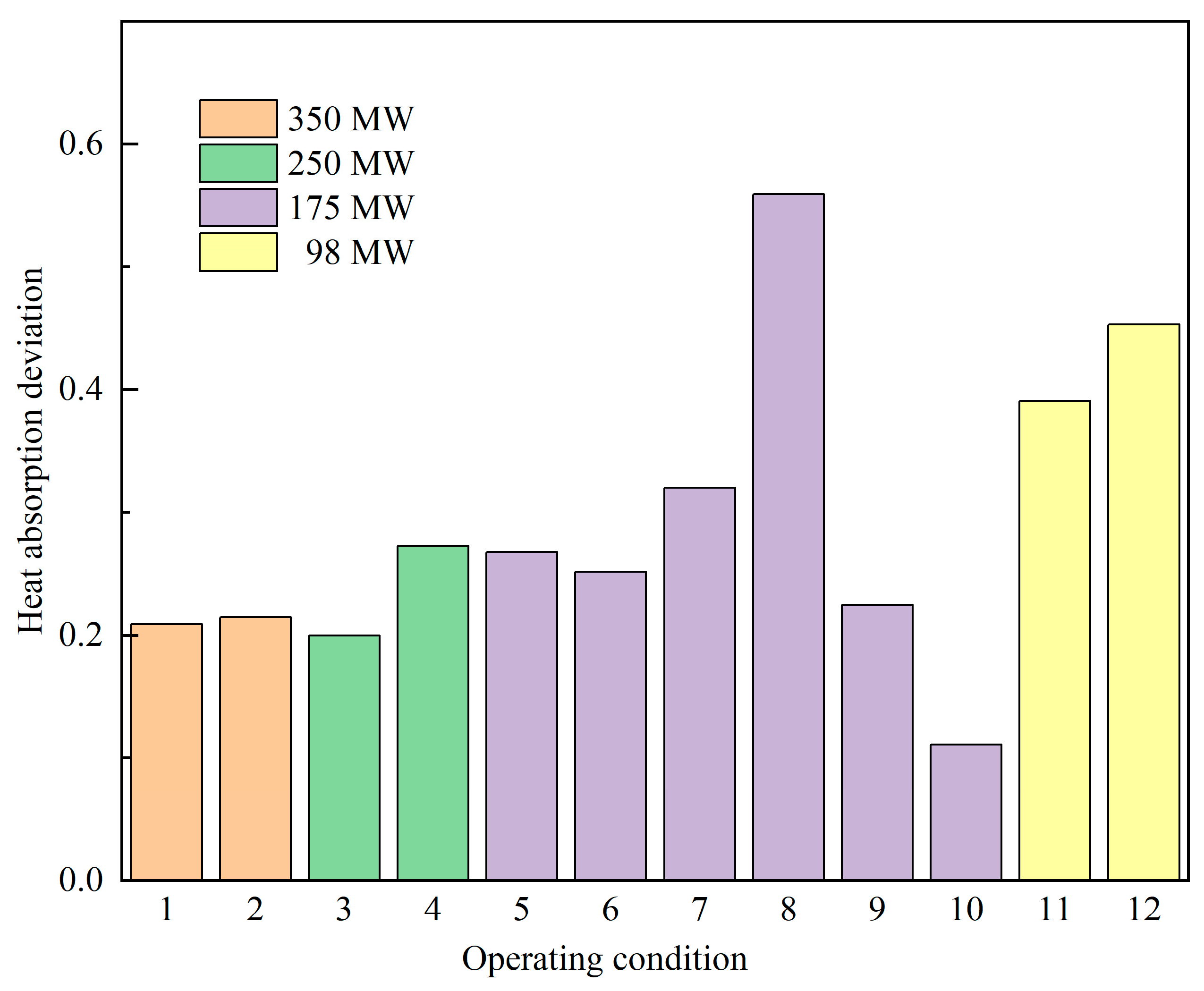

4.3.1. Division Platen Superheater

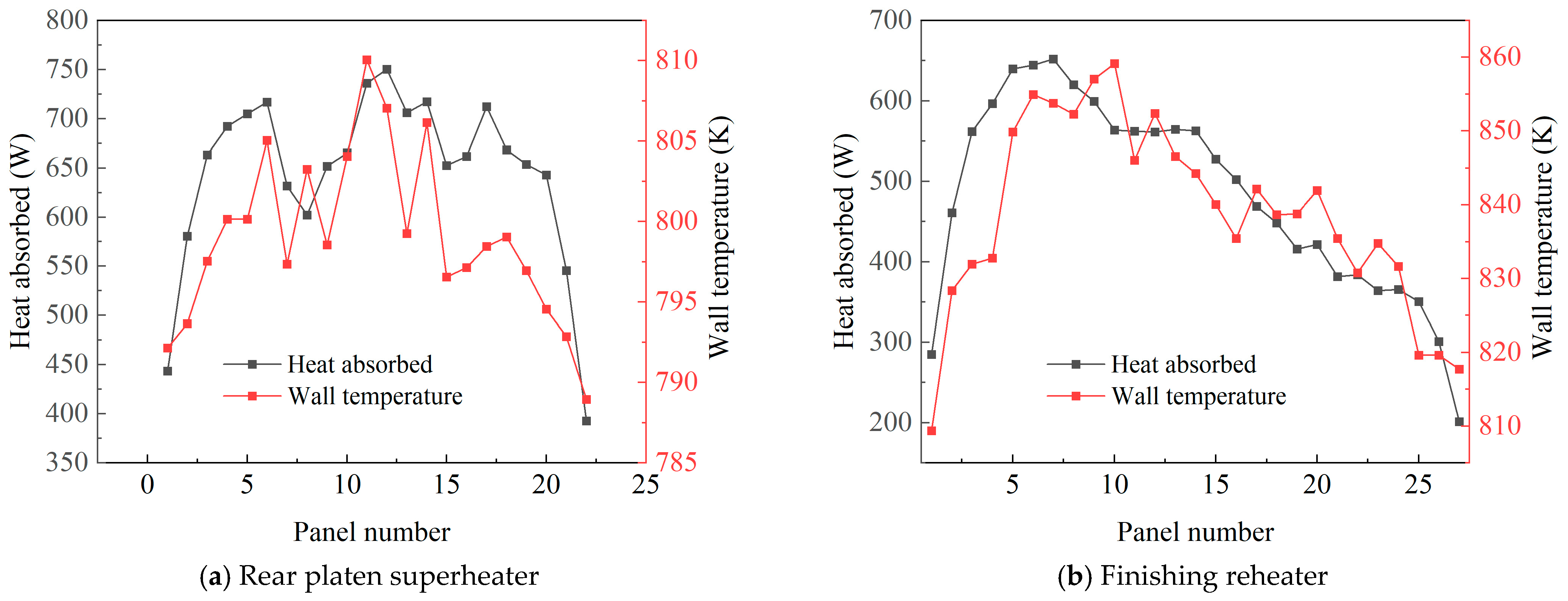

4.3.2. Rear Platen Superheater

4.3.3. Finishing Reheater

4.3.4. Finishing Superheater

4.4. Thermal Deviation Mitigation Measures

4.5. Practical Significance

5. Conclusions

- The average absolute vorticity of flue gas decreases with load reduction. Its average values at 100%, 72%, 50% and 28% loads are 0.672 s−1, 0.670 s−1, 0.563 s−1 and 0.313 s−1 respectively. However, the decrease rate is much slower than that of the load, indicating that the relative velocity deviation of the flue gas increases as the load decreases.

- With the decrease in load, the thermal deviations of the division platen superheater, rear platen superheater, finishing reheater, and finishing superheater all show an upward trend. When the load decreases from 100% to 28%, the average heat absorption deviations of these four heating surfaces increase from 0.11, 0.17, 0.26, and 0.21 to 0.37, 0.35, 0.32, and 0.42, respectively.

- Under 100%, 72%, 50%, and 28% loads, from the perspective of reducing thermal deviation, the recommended mill group operation modes are ABCDE, ABCD, BCD, and ABC, respectively. This indicates that activating the lower-layer burners tends to reduce thermal deviation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Anwar, S.; Aslam, Z.; Aslam, U.; Mehmood, U.; Rana, A.G.; Mahmood, N.; Rafique, A. Advances and challenges in photocatalytic water splitting: Recent developments and trends. Fuel 2026, 404, 136280. [Google Scholar] [CrossRef]

- Magdy, G.; Shabib, G.; Elbaset, A.A.; Mitani, Y. Renewable power systems dynamic security using a new coordination of frequency control strategy based on virtual synchronous generator and digital frequency protection. Int. J. Electr. Power Energy Syst. 2019, 109, 351–368. [Google Scholar] [CrossRef]

- Qi, Y.; Liu, T.L.; Jing, L.Y. China’s energy transition towards carbon neutrality with minimum cost. J. Clean. Prod. 2023, 388, 135904. [Google Scholar] [CrossRef]

- Zhou, X.; Strunz, K.; Brown, T.; Sun, H.; Neumann, F. Multi-energy system horizon planning: Early decarbonisation in China avoids stranded assets. Energy Internet 2024, 1, 81–98. [Google Scholar] [CrossRef]

- Babosalam, S.; Kargar, S.M.; Moazzami, M.; Zanjani, S.M. Occupancy-aware energy optimization in building-to-grid systems using deep neural networks and model predictive control. J. Build. Eng. 2025, 112, 113714. [Google Scholar] [CrossRef]

- Wang, H.S.; Ding, H.L.; Ouyang, Z.Q.; Li, S.Y.; Su, K.; Chen, Q.S.; Wu, L.M. Experimental study on peak shaving operations for efficient pulverized coal combustion and working fluid coordination. Fuel 2026, 404, 136237. [Google Scholar] [CrossRef]

- Ihsan, S.; Prabowo; Widodo, W.A.; Saputra, I.; Hariana. Utilization of palm frond waste as fuel for co-firing coal and biomass in a tangentially pulverized coal boiler using computational fluid dynamic analysis. Biomass 2024, 4, 1142–1163. [Google Scholar] [CrossRef]

- Samantaray, U.; Nemalipuri, P.; Mailapalli, V.K.; Vitankar, V.; Das, H.C.; Pradhan, M.K. Computational study on the blended fuel combustion in an industrial tangentially fired boiler. Int. J. Coal Prep. Util. 2025, 1–27. [Google Scholar] [CrossRef]

- Azizah, A.N.; Amalia, R.; Satrio, D. Analysis of combustion characteristic in tangentially fired pulverized-coal boiler with tilting burner angle variation using CFD. IOP Conf. Ser. Earth Environ. Sci. 2022, 972, 012067. [Google Scholar] [CrossRef]

- Yudha, A.T.; Prayogo, B. Optimizing combustion in supercritical tangentially-fired boilers through numerical analysis and incorporating rear pass temperature optimization with the PSO algorithm. In Proceedings of the 2024 International Conference on Technology and Policy in Energy and Electric Power (ICTPEP), Bali, Indonesia, 3–5 September 2024; pp. 7–11. [Google Scholar]

- Yin, H.Y.; Jin, D.H.; Liu, X.; Li, C.; Li, X.Y.; Wang, H.Y. Prediction of the tube temperature and oxide scale formation of boiler superheater by a coupled combustion and hydrodynamic model. Int. Commun. Heat Mass Transf. 2025, 163, 108664. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Xu, T.M.; Hui, S.; Zhang, M.C. Experimental and numerical study on the flow fields in upper furnace for large scale tangentially fired boilers. Appl. Therm. Eng. 2009, 29, 732–739. [Google Scholar] [CrossRef]

- Akkinepally, B.; Shim, J.; Yoo, K. Numerical and experimental study on biased tube temperature problem in tangential firing boiler. Appl. Therm. Eng. 2017, 126, 92–99. [Google Scholar] [CrossRef]

- Li, P.; Bao, T.; Guan, J.; Shi, Z.F.; Xie, Z.X.; Zhou, Y.G.; Zhong, W. Computational analysis of tube wall temperature of superheater in 1000 MW ultra-supercritical boiler based on the inlet thermal deviation. Energies 2023, 16, 1539. [Google Scholar] [CrossRef]

- Jin, D.H.; Yan, J.W.; Liu, X.; Zhang, C.Q.; Wang, H.Y. Prediction of tube temperature distribution of boiler platen superheater by a coupled combustion and hydrodynamic model. Energy 2023, 279, 128116. [Google Scholar] [CrossRef]

- Saputra, N.A.A.; Prabowo; Setiyawan, A.; Kusuma, G.B.W.; Ishan, S.; Darmawan, A.; Hariana. Numerical analysis of burner position and EFB-coal co-firing effects on combustion performance and emissions in pulverized coal boilers. Int. J. Heat Technol. 2025, 43, 479–492. [Google Scholar] [CrossRef]

- Rawlins, B.T.; Laubscher, R.; Rousseau, P. Application of computational fluid dynamics and process modeling to investigate low-load operation of a subcritical utility-scale boiler. J. Therm. Sci. Eng. Appl. 2022, 14, 101008. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, S.; He, X.; Ding, X.; Li, W.; Liu, P. Combustion stability and NOx emission characteristics of three combustion modes of pulverized coal boilers under low or ultra-low loads. Appl. Energy 2024, 353, 121998. [Google Scholar] [CrossRef]

- Faizal, W.M.; Mazlan, N.M.; Shaukat, S.I.; Khor, C.Y.; Haidiezul, A.M.; Syafiq, A.K.M. The Convergence of computational fluid dynamics and machine learning in oncology: A review. Comput. Model. Eng. Sci. 2025, 144, 1335–1369. [Google Scholar] [CrossRef]

- Fazlizan, A.; Muzammil, W.K.; Al-Khawlani, N.A. A review of computational fluid dynamics techniques and methodologies in vertical axis wind turbine development. Comput. Model. Eng. Sci. 2025, 144, 1371–1437. [Google Scholar] [CrossRef]

- Hassan, M.H.A.; ElSherif, I.A.; El-latif, M.A.; Shaheen, M.M.; Elmesalamy, A.S.; Mahmoud, H. A comprehensive review of numerical simulation techniques for wind turbines: From computational fluid dynamics and finite element analysis to advanced turbulence modeling. Beni-Suef Univ. J. Basic Appl. Sci. 2025, 14, 92. [Google Scholar] [CrossRef]

- Maccioni, L.; Concli, F. Exploring the potential of CFD in gear jet lubrication design: A systematic literature review. Forsch. Im Ingenieurwesen-Eng. Res. 2025, 89, 121. [Google Scholar] [CrossRef]

- Sankar, G.; Kumar, D.S.; Balasubramanian, R. Computational modeling of pulverized coal fired boilers—A review on the current position. Fuel 2019, 236, 643–665. [Google Scholar] [CrossRef]

- Feng, Y.; Zhao, N.; Wang, B.; Li, Q. A method for monitoring internal temperature field distribution of transformers based on heat transfer coefficient under different operating conditions. Case Stud. Therm. Eng. 2025, 75, 107094. [Google Scholar] [CrossRef]

- Kardas, D.; Polesek-Karczewska, S.; Wardach-Swicicka, I. Integrating flow field dynamics and chemical atmosphere predictions for enhanced sulfur corrosion risk assessment in power boilers. Materials 2024, 17, 4919. [Google Scholar] [CrossRef]

- Vilakazi, L.N.; Madyira, D. Coal combustion modeling: A comparative study. Energy Sci. Eng. 2024, 12, 3465–3475. [Google Scholar] [CrossRef]

- Sun, W.J.; Zhong, W.Q.; Zhang, J.Z.; Echekki, T. Large Eddy simulation on the effects of coal particles size on turbulent combustion characteristics and NOx formation inside a corner-fired furnace. J. Energy Resour. Technol. 2021, 143, 082302. [Google Scholar] [CrossRef]

- Chetverushkin, B.N.; Olkhovskaya, O.G.; Gasilov, V.A. Stabilized scheme for calculating radiation transfer in the P1 approximation. Dokl. Math. 2024, 110, 393–398. [Google Scholar] [CrossRef]

- Rajak, U.; Panchal, M.; Verma, T.N.; Dwivedi, G. The effect of thermal radiation using different models on methane-air flames combustion modelling using CFD. Environ. Dev. Sustain. 2024, 1–23. [Google Scholar] [CrossRef]

- Sikka, A.; Singh, D.; Chander, S. An experimental and numerical study of cooling by air/water mist jet impingement at low mist loading fraction. Int. J. Therm. Sci. 2025, 212, 109788. [Google Scholar] [CrossRef]

- Dong, L.; Hu, S.W.; Wang, Y.F.; Liu, X.H.; Chen, W.; Ren, Y. Discrete simulations of combustion dynamics in coal particles: Insights into heat and mass transfer mechanisms. Particuology 2025, 105, 217–228. [Google Scholar] [CrossRef]

- Zhang, J.; Prationo, W.; Zhang, L.; Zhang, Z. Computational fluid dynamics modeling on the air-firing and oxy-fuel combustion of dried Victorian brown coal. Energy Fuels 2013, 27, 4258–4269. [Google Scholar] [CrossRef]

- Ghose, P.; Sahoo, T.K.; Sahu, A.K. Pulverized coal combustion computational modeling approach: A review. Proc. Inst. Mech. Eng. Part A J. Power Energy 2023, 237, 797–818. [Google Scholar] [CrossRef]

- Ezzahra, L.F.; Abdallah, B.; Senda, A.; Sadiki, A.; Chrigui, M. Full-scale cfd study of swirl number effect on particle and flow behavior in interaction with combustion dynamics inside coal pulverized burner. Heat Transf. Res. 2023, 54, 79–95. [Google Scholar] [CrossRef]

- Wartha, E.M.; Haugen, N.E.; Karchniwy, E.; Bösenhofer, M.; Harasek, M.; Lovås, T. The effect of turbulence on the conversion of coal under blast furnace raceway conditions. Fuel 2023, 331, 125840. [Google Scholar] [CrossRef]

- Aydın, A.; Engin, T.; Kılıç, S. Design and optimization of a combi boiler heat exchanger: A CFD-based approach. Appl. Therm. Eng. 2024, 257, 124178. [Google Scholar] [CrossRef]

- Yan, L.; Yan, J.; Pu, J.; Song, Y.; Wu, X.; Lu, X. Study on superheater wall temperature in a 1000 MW ultra-supercritical power plant under flexible load operations. Case Stud. Therm. Eng. 2025, 74, 106994. [Google Scholar] [CrossRef]

- Du, J.; Li, Y.; Zhao, Y.; Da, Y.; Che, D. Numerical study of supercritical opposed wall-fired boiler furnace temperature and high-temperature heating surface stress under variable load operation. Energies 2024, 17, 663. [Google Scholar] [CrossRef]

- Skalak, Z. A remark on the regularity criterion for the Navier–Stokes equations in terms of one directional derivative of the velocity. Nonlinear Anal. Real World Appl. 2026, 87, 104437. [Google Scholar] [CrossRef]

- Jalilibal, Z.; Amiri, A.; Castagliola, P.; Khoo, M.B.C. Monitoring the coefficient of variation: A literature review. Comput. Ind. Eng. 2021, 161, 107600. [Google Scholar] [CrossRef]

- Chong, P.A.; Zhu, X.L.; Li, J.N.; Li, X.; Deng, L. Investigation on hydrodynamic performance and wall temperature of water-cooled wall in 1000 MW boiler under low-load conditions. Energies 2024, 17, 5751. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Zhang, W.; Wang, H.; Deng, L.; Che, D. Coupled modeling of combustion and hydrodynamics for a 1000 MW double-reheat tower-type boiler. Fuel 2019, 255, 115722. [Google Scholar] [CrossRef]

- Zhang, G.H.; Fan, Y.B.; Yang, R.S.; Li, S.H. Application of the Rosin-Rammler function to describe quartz sandstone particle size distribution produced by high-pressure gas rapid unloading at different infiltration pressure. Powder Technol. 2022, 412, 117982. [Google Scholar] [CrossRef]

- Zhu, M.; Lu, H.; Zhao, W.; Huang, S.; Chang, X.; Dong, L.; Kong, D.; Jing, X. A numerical study of ash deposition characteristics in a 660MW supercritical tangential boiler. Adv. Theory Simul. 2023, 6, 2300133. [Google Scholar] [CrossRef]

- Zima, W.; Taler, J.; Gradziel, S.; Trojan, M.; Cebula, A.; Oclon, P.; Dzierwa, P.; Taler, D.; Rerak, M.; Majdak, M.; et al. Thermal calculations of a natural circulation power boiler operating under a wide range of loads. Energy 2022, 261, 125357. [Google Scholar] [CrossRef]

- Chen, G.; Li, Z.; Zhang, H.; Huang, L.; Liu, Z.; Fan, W. Influences of ultra-low load operation strategies on performance of a 300 MW subcritical bituminous coal boiler. Appl. Therm. Eng. 2024, 256, 124037. [Google Scholar] [CrossRef]

- Qin, M.; Liu, D.Y.; Wu, S.H.; Cao, Q.X. Numerical simulations on flow characteristics of flue gas in furnace with four-wall tangential firing. Combust. Sci. Technol. 2017, 189, 2135–2153. [Google Scholar] [CrossRef]

- Chong, P.; Li, J.; Zhu, X.; Jing, D.; Deng, L. Numerical Study on Combustion Characteristics of a 600 MW boiler under low-load conditions. Processes 2024, 12, 2496. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Y.G.; Zou, L.; Bai, Y.Y.; Shen, T.; Wei, Y.W.; Li, F.X.; Zhao, Q.X. Numerical investigation of stable combustion at ultra-low load for a 350 MW wall tangentially fired pulverized-coal boiler: Effect of burner adjustments and methane co-firing. Appl. Therm. Eng. 2024, 246, 122980. [Google Scholar] [CrossRef]

| Proximate Analysis (%) | Elemental Analysis (%) | Qnet,ar (MJ kg−1) | |||||

|---|---|---|---|---|---|---|---|

| war(A) | war(M) | war(C) | war(H) | war(O) | war(N) | war(S) | |

| 13.75 | 18.00 | 53.97 | 3.32 | 9.92 | 0.40 | 0.64 | 19.94 |

| Condition Number | Load (MW) | Mill Group Operation Mode | Coal Feed Rate (t h−1) | Total Air Flow Rate (t h−1) |

|---|---|---|---|---|

| 1 | 349.29 | ABCDE | 159.83 | 1307.7 |

| 2 | 349.42 | ABCE | 150.16 | 1273.47 |

| 3 | 250.14 | ABCD | 121.97 | 943.28 |

| 4 | 250.65 | ACDE | 125.62 | 1150.09 |

| 5 | 174.42 | ABC | 98.19 | 660.67 |

| 6 | 174.93 | BCD | 92.84 | 603.29 |

| 7 | 174.74 | ABD | 85.29 | 736.98 |

| 8 | 174.16 | ADE | 82.65 | 782.59 |

| 9 | 174.38 | ACD | 93.84 | 631.12 |

| 10 | 175.38 | ABCD | 99.07 | 667.63 |

| 11 | 94.07 | ABC | 47.08 | 394.81 |

| 12 | 97.79 | ABD | 46.65 | 413.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, D.; Kong, J.; Qin, B.; Pan, F.; Duan, W.; Yang, J.; Deng, L. Numerical Study on Thermal Deviation of High-Temperature Heating Surfaces in a Tangentially Fired Boiler Under Peak Load Regulation. Energies 2025, 18, 6046. https://doi.org/10.3390/en18226046

Yuan D, Kong J, Qin B, Pan F, Duan W, Yang J, Deng L. Numerical Study on Thermal Deviation of High-Temperature Heating Surfaces in a Tangentially Fired Boiler Under Peak Load Regulation. Energies. 2025; 18(22):6046. https://doi.org/10.3390/en18226046

Chicago/Turabian StyleYuan, Dianhong, Junfeng Kong, Bin Qin, Feng Pan, Weihao Duan, Jiahui Yang, and Lei Deng. 2025. "Numerical Study on Thermal Deviation of High-Temperature Heating Surfaces in a Tangentially Fired Boiler Under Peak Load Regulation" Energies 18, no. 22: 6046. https://doi.org/10.3390/en18226046

APA StyleYuan, D., Kong, J., Qin, B., Pan, F., Duan, W., Yang, J., & Deng, L. (2025). Numerical Study on Thermal Deviation of High-Temperature Heating Surfaces in a Tangentially Fired Boiler Under Peak Load Regulation. Energies, 18(22), 6046. https://doi.org/10.3390/en18226046