Numerical Study on the Early Out-of-Plane Mechanical Response of Glass–Glass Building-Integrated Photovoltaics Exposed to Increasing Temperature and Fire

Abstract

1. Introduction

2. Modelling the Thermo-Mechanical Response of PV Systems Under Elevated Temperatures: Existing Studies

- The commercial products in use for the encapsulant (PVB or EVA) are sensitive to thermal variations, in the form of a progressive relaxation and viscoelastic response, which involves a decrease in the shear rigidity of the bonding layer, and thus affects the bending stiffness of the BIPV sandwich section [36,37,38];

- Overall, it is clear that the exposure of BIPV systems to elevated temperatures is associated with primary issues that derive from the features of the constituent materials but also depend on the reciprocal interaction of BIPV components, as well as some possible unfavorable geometrical aspects that should be properly addressed.

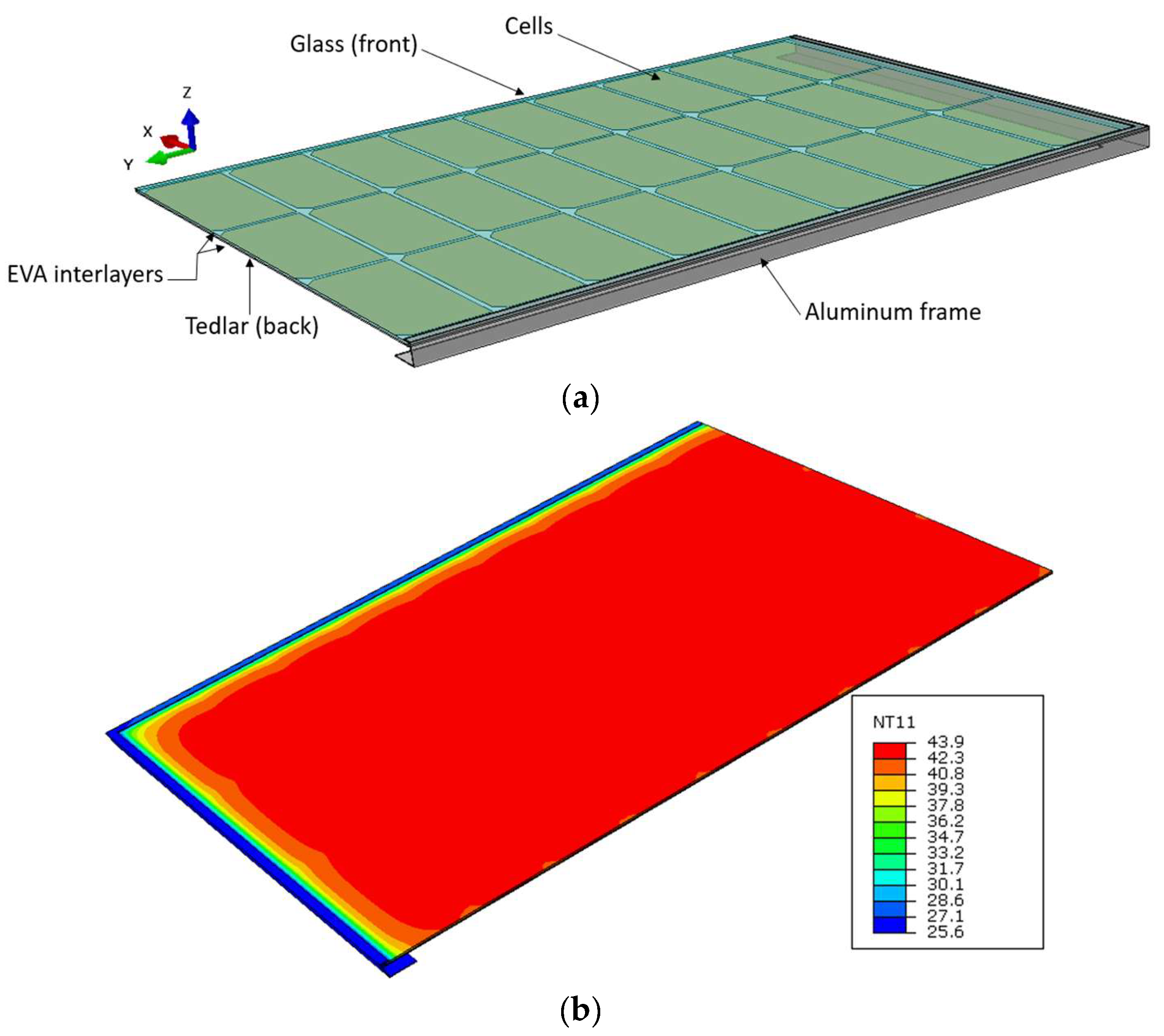

3. Present Numerical Modelling Strategy

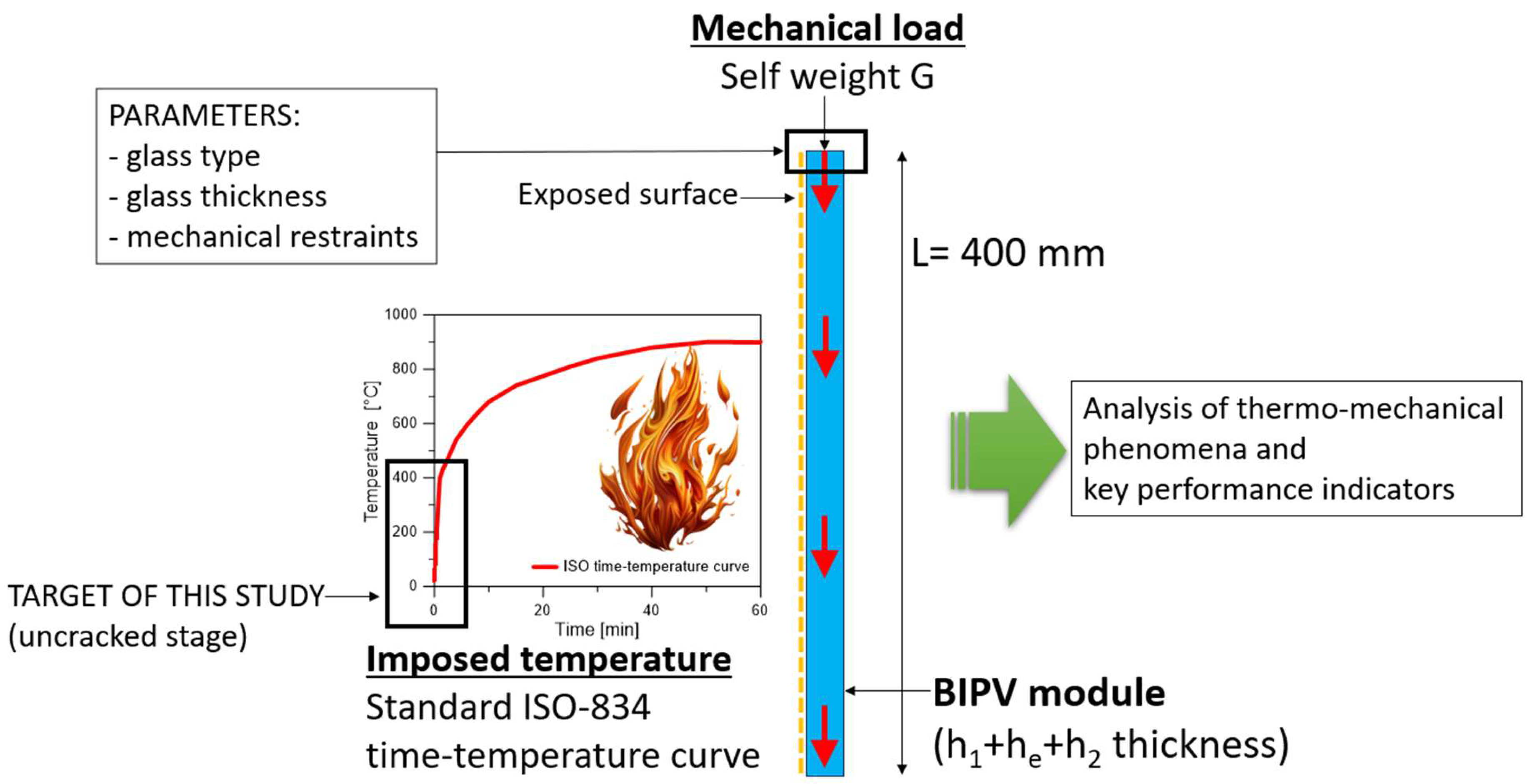

3.1. Setup, Parameters, and Goal

- (i)

- Thickness of the glass covers.

- (ii)

- Glass type (AN: annealed; HS: heat-strengthened; FT: fully tempered).

- (iii)

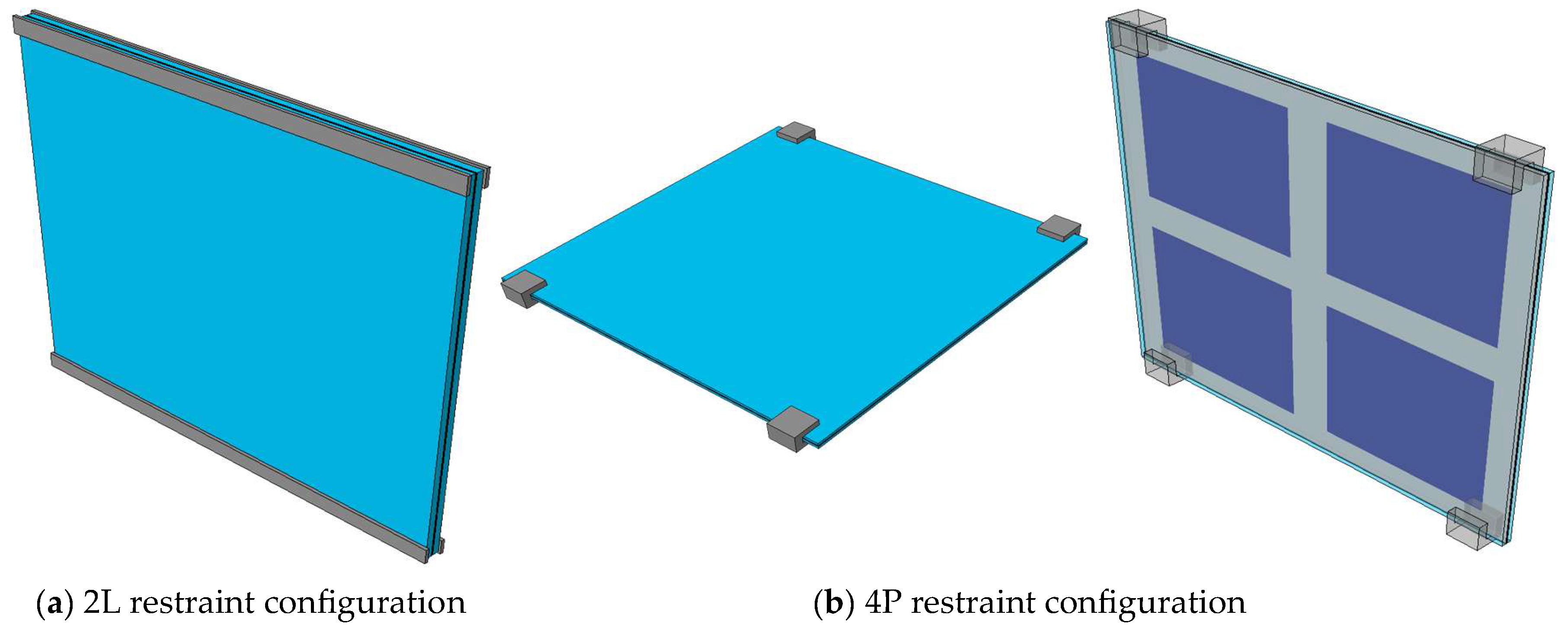

- Features of the mechanical restraints (with four (4L) or two (2L) linearly restrained edges, or four-point fixings (4P), see Figure 4). In this last case, it is important to recall that an ideally rigid bond was used at the interface between the glass covers and the metal components.

3.2. Solving Approach

- Thermal, transient “heat transfer” analysis for the BIPV system subjected to the uniformly distributed, time-varying temperature function on the exposed surface of glass (i.e., Figure 2);

- Static simulation (with input nodal temperatures varying over time, based on step 1);

- Frequency analysis (carried out on the BIPV system subjected to predefined thermal scenarios, based on the nodal temperature input from step 1).

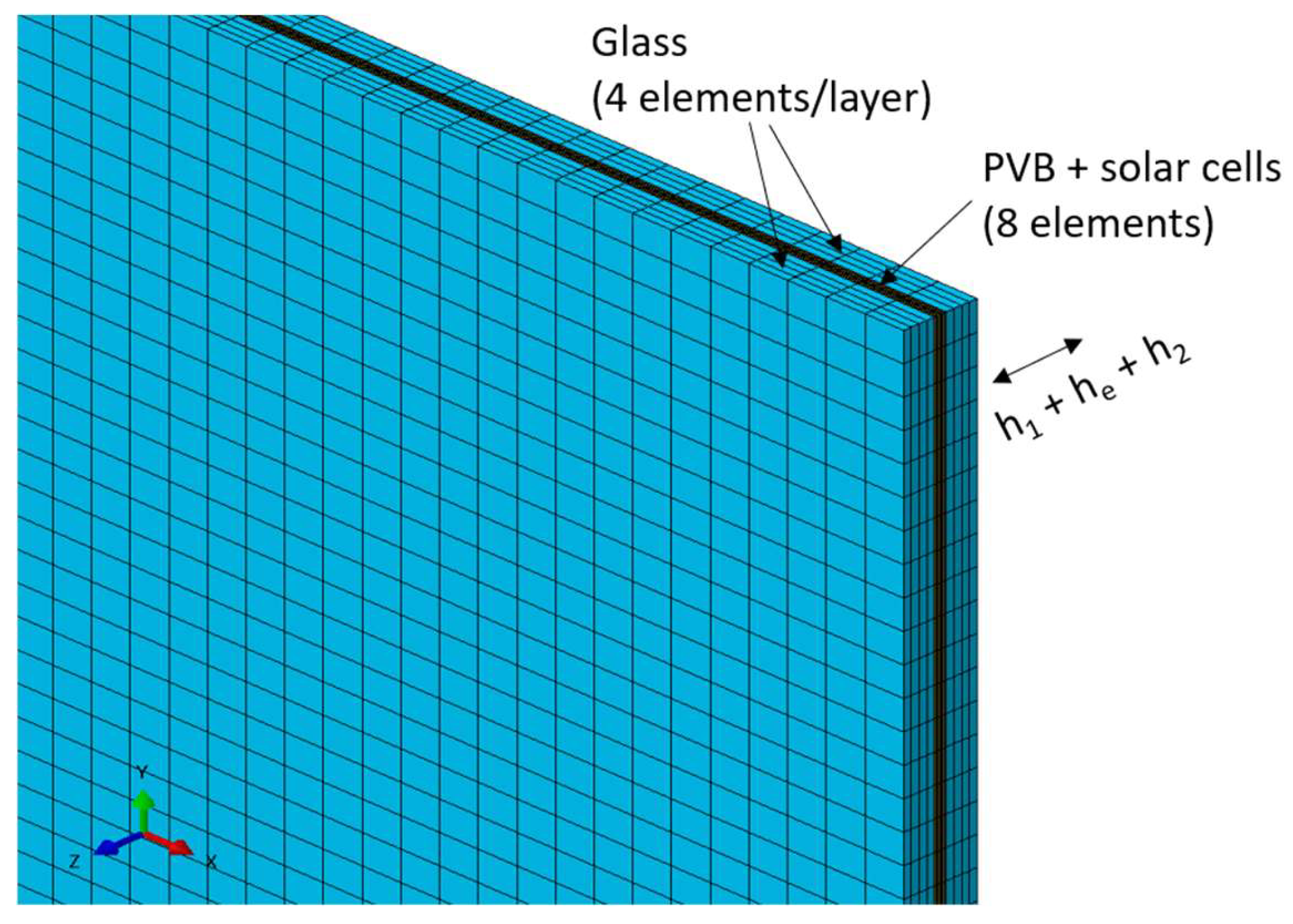

3.3. Elements, Boundaries, and Constraints

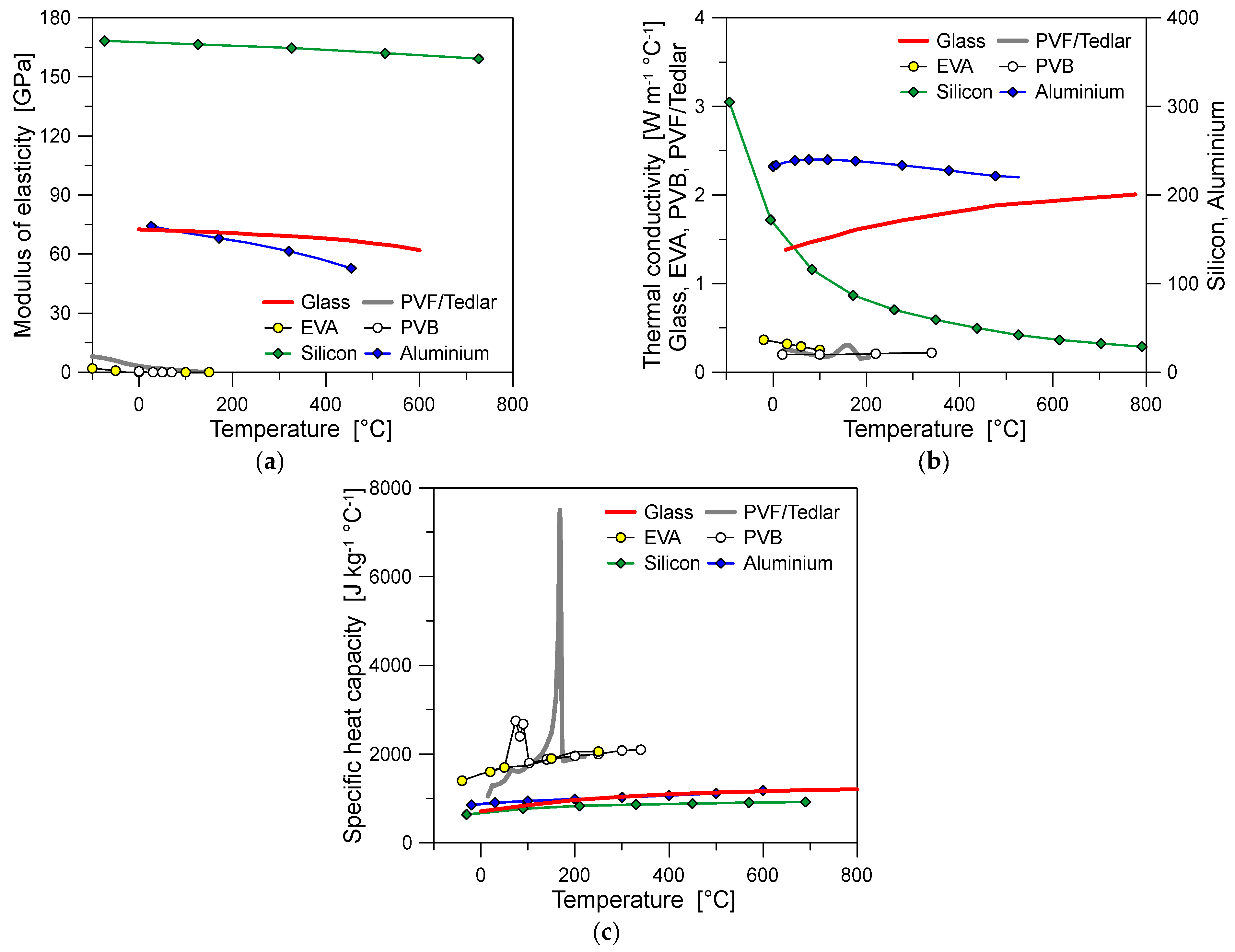

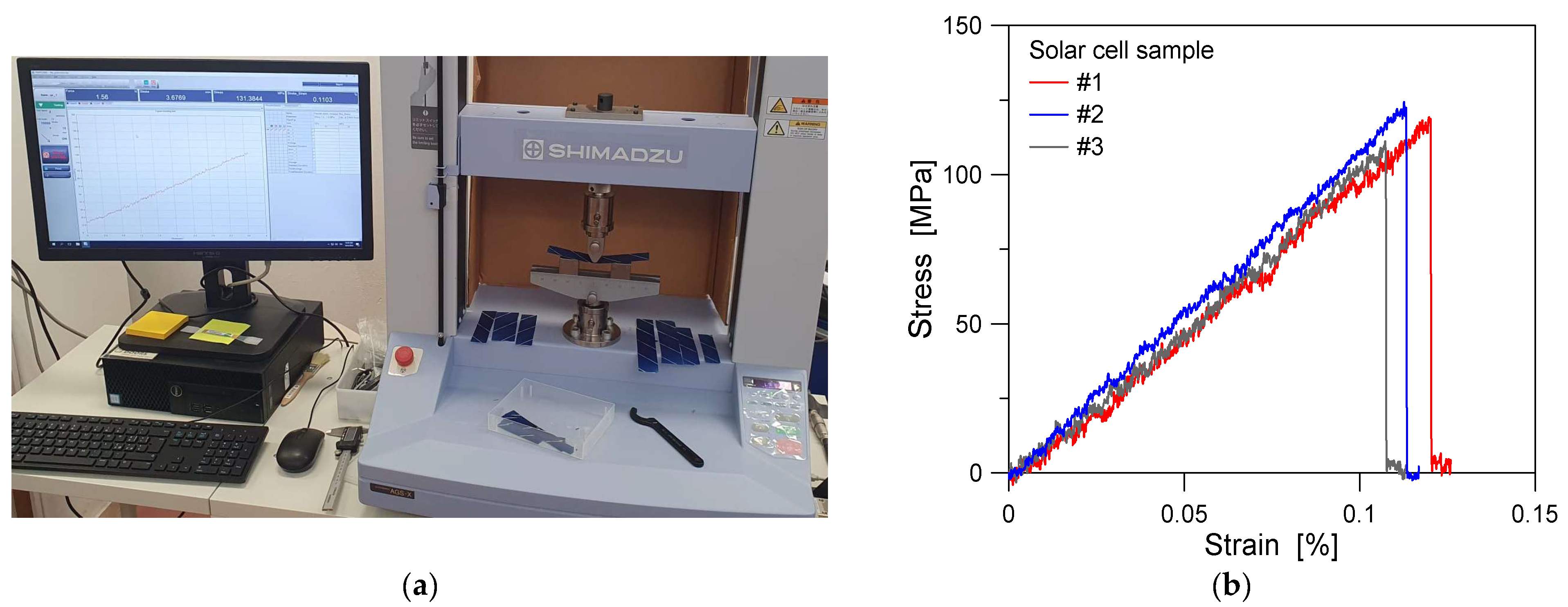

3.4. Material Properties

4. Strategy for the Thermo-Mechanical Numerical Study

4.1. Preliminary Numerical Validation

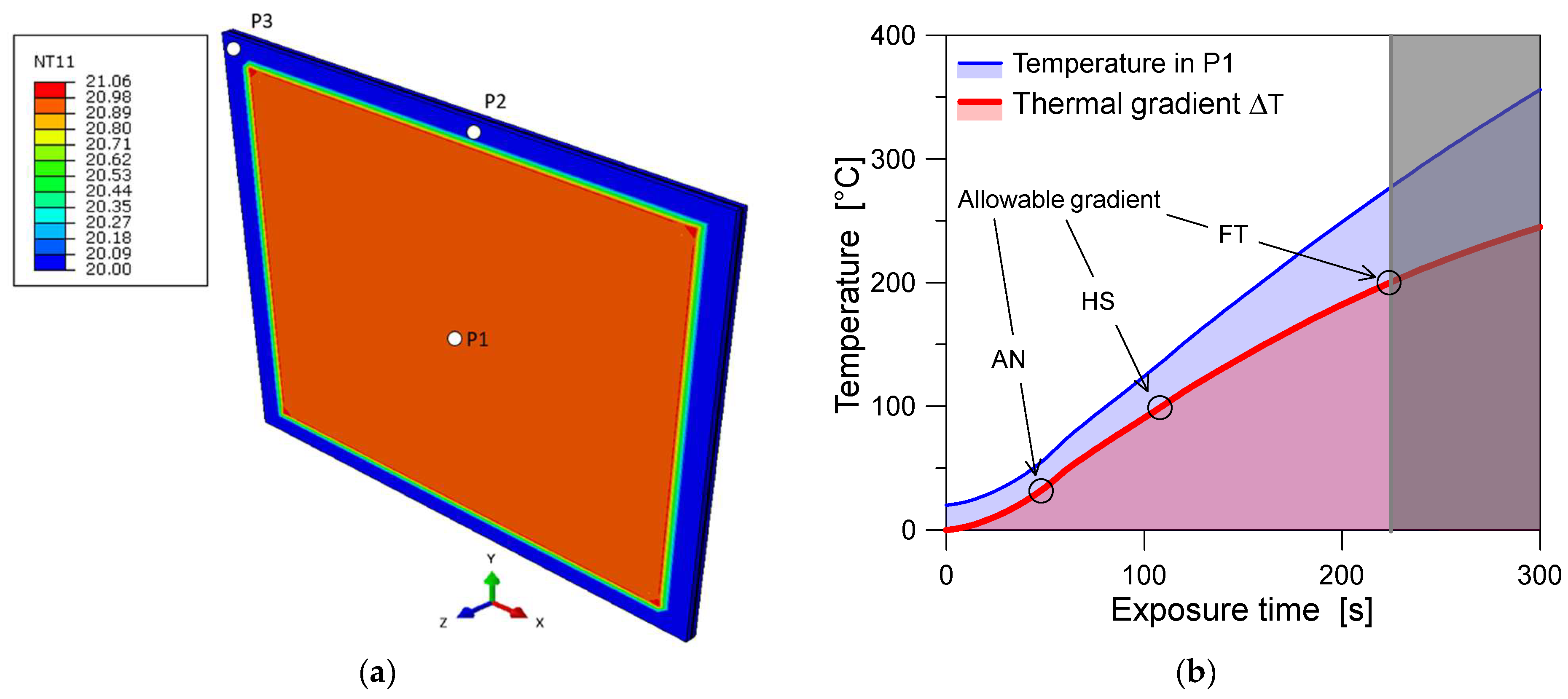

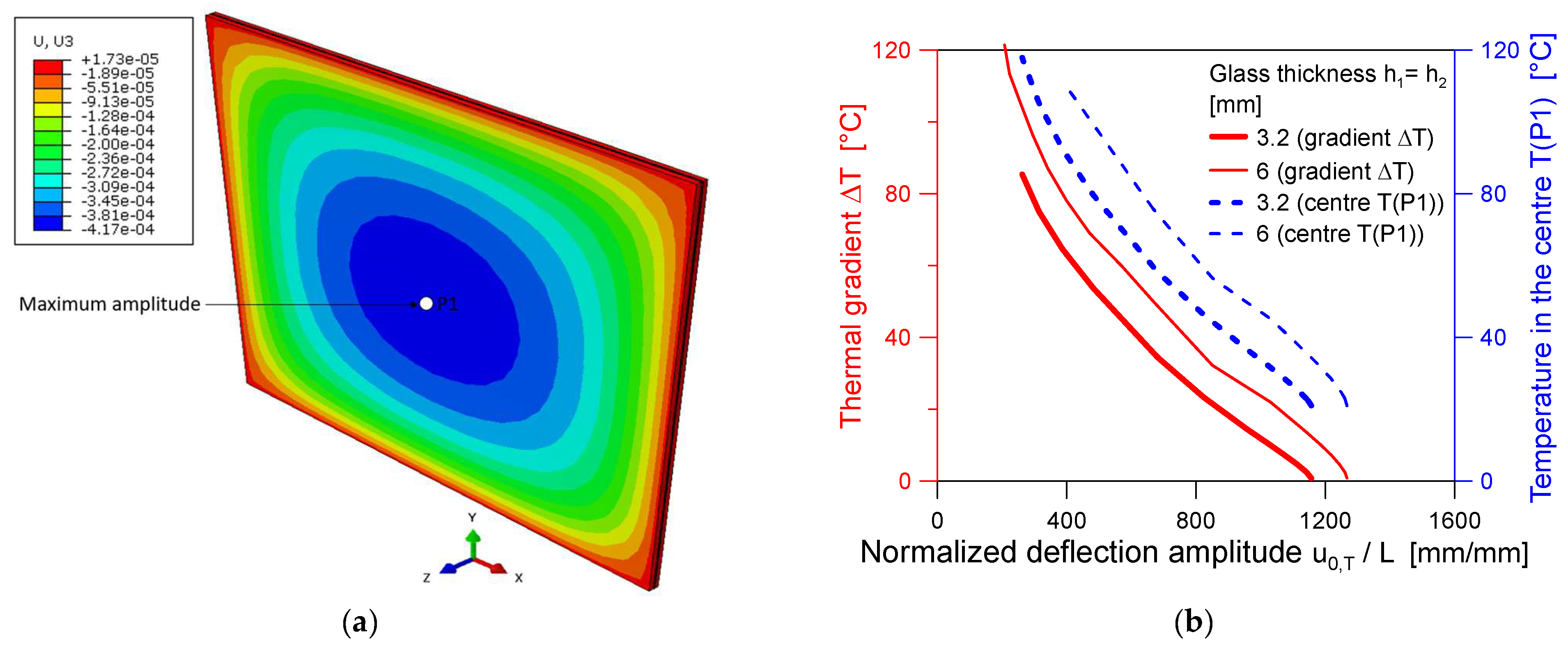

4.2. Selected Performance Indicators

- The initial geometrical imperfection (i.e., shape and amplitude) of each BIPV module, due to the imposed thermal scenarios;

- The analysis of the evolution over time of the temperature peak and gradient on the exposed glass cover;

- The evolution of the tensile stress peaks in the exposed glass cover, as a function of the thermal exposure;

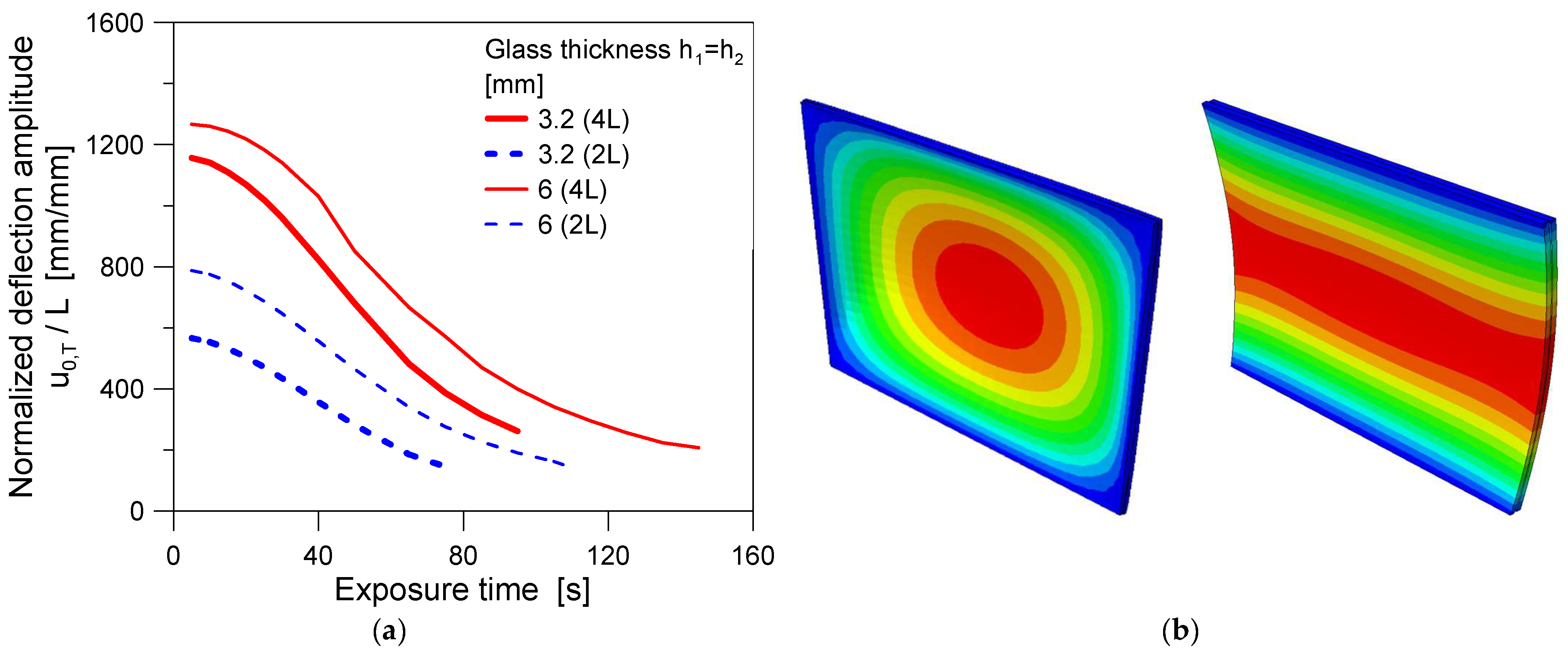

- The trend over time of the out-of-plane deflection at the center of each BIPV module, and the corresponding reaction forces at the mechanical restraints;

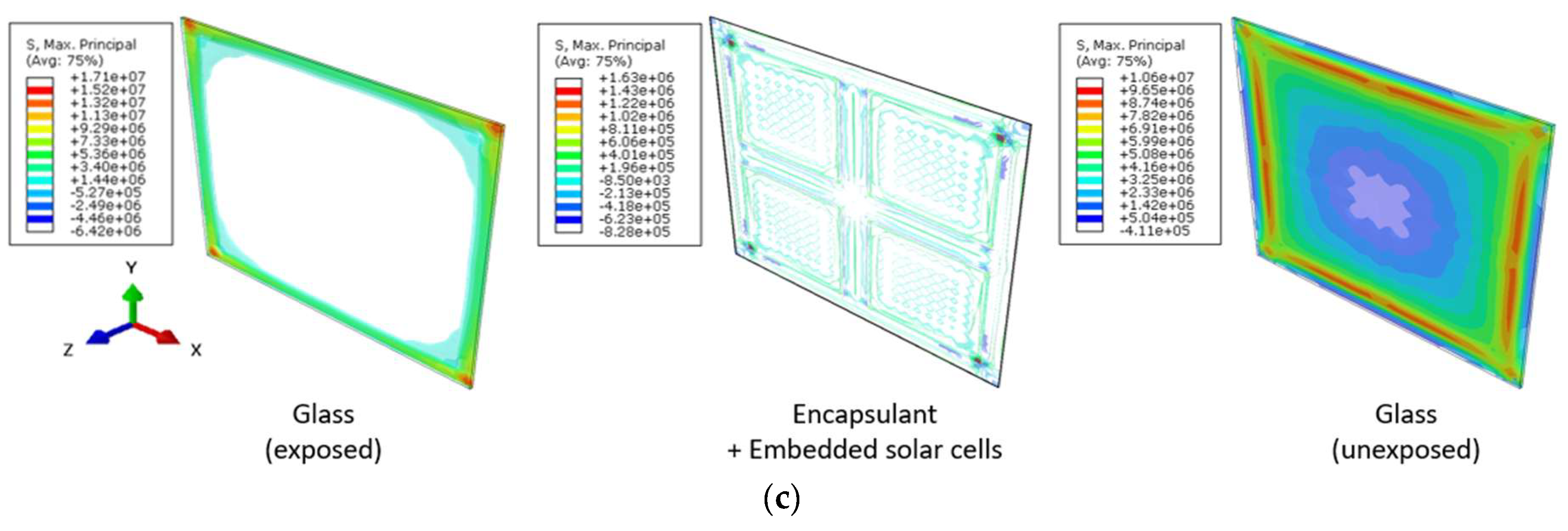

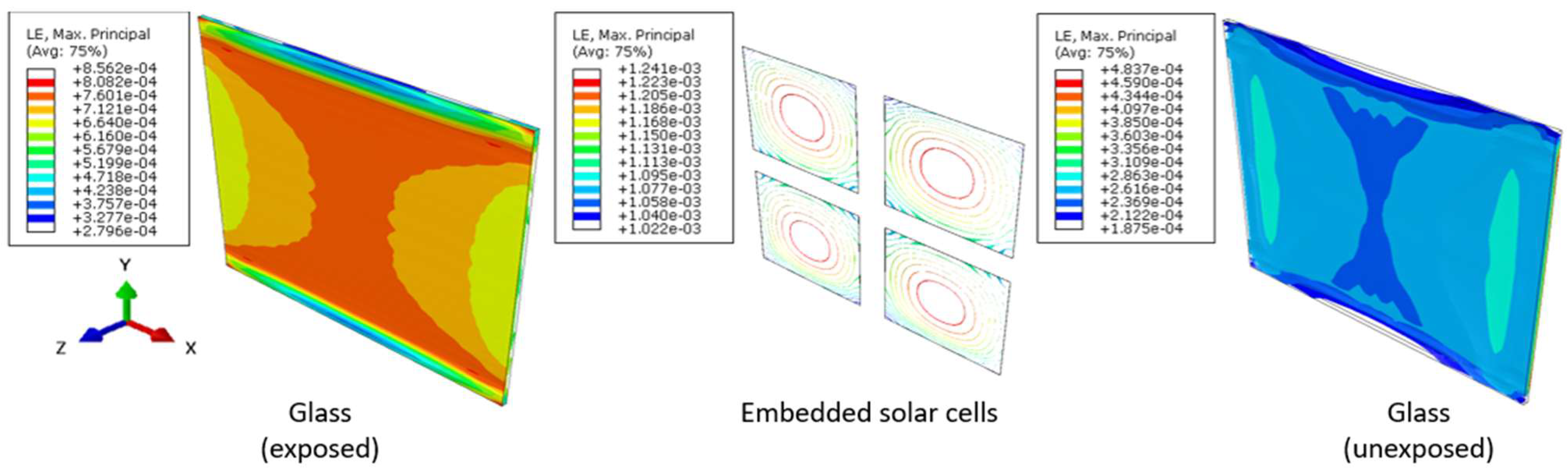

- The amplitude of the stress and strain peaks in the solar cells;

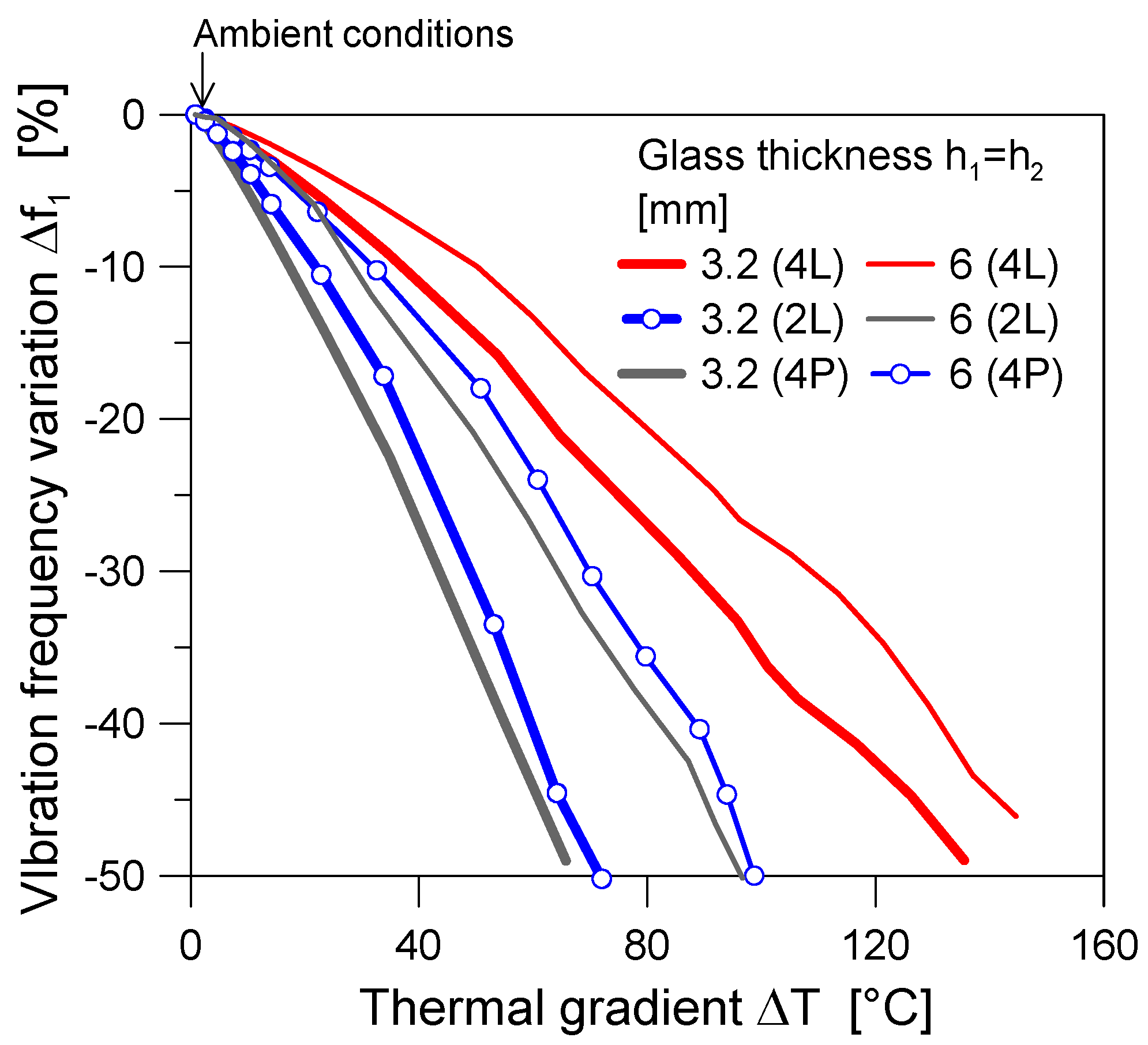

- The fundamental vibration frequency of the BIPV system when exposed to different thermal configurations.

4.3. Failure Detection Under Elevated Temperatures

- “Temperature approach”: the measured thermal gradient between the exposed and coldest regions of the glass cover subjected to progressive heating was compared to the reference limit values reported in Table 2;

- “Stress approach”: the resulting stress peaks in tension in the exposed glass cover (due to thermal and possible superimposed mechanical effects) were monitored during each analysis and compared with the nominal allowable thermal stress values reported in Table 2.

5. Numerical Results

5.1. Temperature Evolution

5.2. Thermal Exposure and Associated Mechanisms

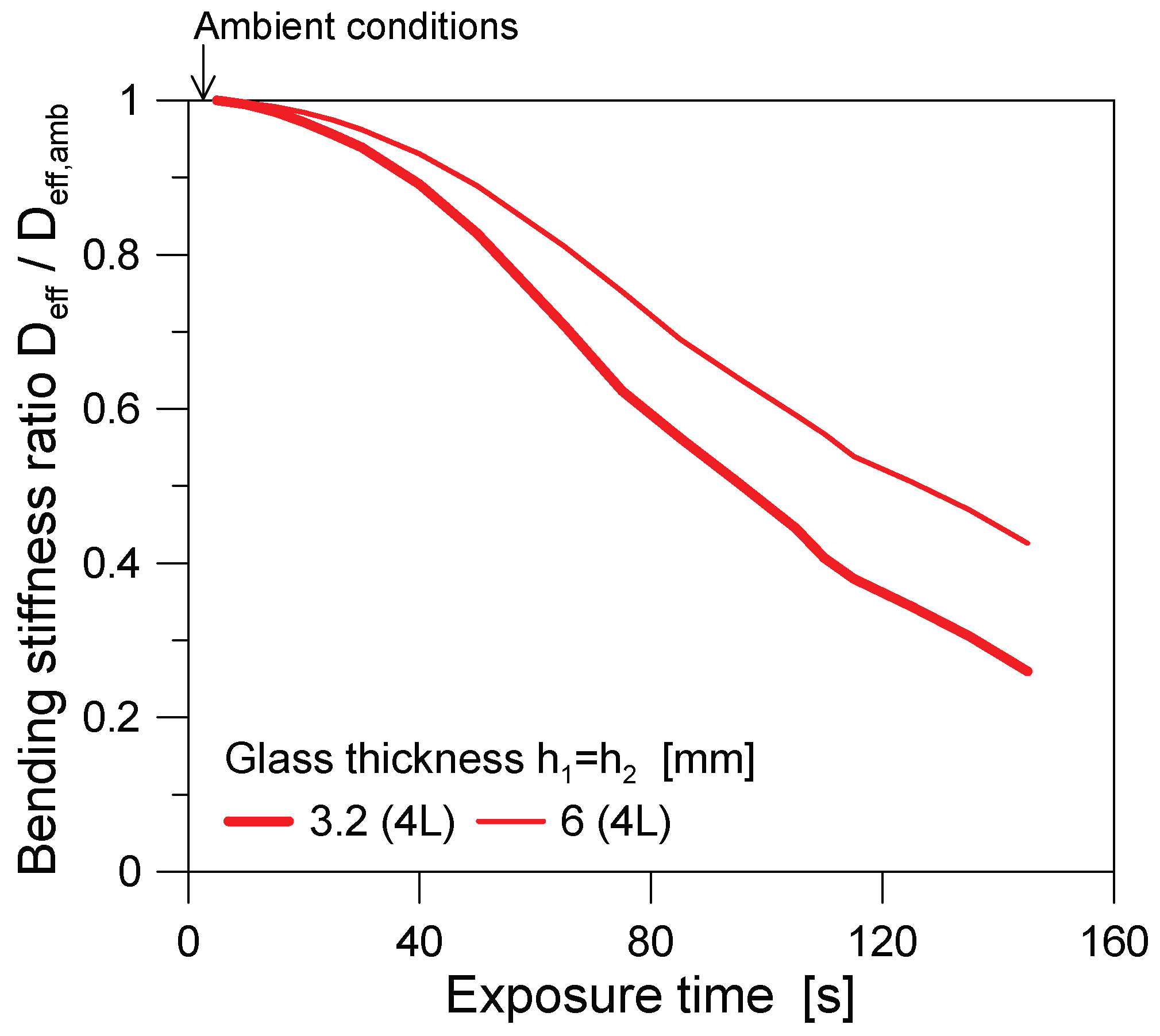

5.3. Thermal Exposure and Global Bending Stiffness

6. Conclusions and Future Studies

- Changing the glass thickness (from 3.2 + 3.2 mm to 6 + 6 mm in the present study) can minimally reduce the vulnerability and mechanical loss of capacity for similar systems.

- In particular, due to combined thermo-mechanical phenomena, the increase in glass thickness has no proportional benefits in terms of mechanical response and residual capacity under elevated temperature scenarios.

- Due to the progressive temperature spread in the size and thickness of the resisting cross-section, the associated material degradation primarily affects the encapsulant layers and has major consequences on the corresponding mechanical capacity of the system. Important stiffness reductions were numerically observed for still-moderate temperature gradients.

- The presence of different mechanical restraints (4L, 2L, or 4P, in the present study) is generally associated with minimal effects in terms of temperature spread and increase in the resisting section.

- The maximum effect of different mechanical restraints—for BIPV systems under increasing temperatures—is exploited in terms of a major degradation of the global/effective out-of-plane bending stiffness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maghrabie, H.M.; Abdelkareem, M.A.; Al-Alami, A.H.; Ramadan, M.; Mushtaha, E.; Wilberforce, T.; Olabi, A.G. State-of-the art technologies for Building-Integrated Photovoltaic Systems. Buildings 2021, 11, 383. [Google Scholar] [CrossRef]

- Abojela, Z.R.K.; Desa, M.K.M.; Sabry, A.H. Current prospects of building-integrated solar PV systems and the application of bifacial PVs. Front. Energy Res. 2023, 11, 1164494. [Google Scholar] [CrossRef]

- IEA-PVPS. Building-Integrated Photovoltaics—A Technical Guidebook; Chivelet, M., Frontini, K., Eds.; Routledge: New York, NY, USA, 2025; Available online: https://iea-pvps.org/wp-content/uploads/2025/02/Building-Integrated-Photovoltaics-Technical-Guidebook.pdf (accessed on 30 May 2025).

- Bedon, C.; Zhang, X.; Santos, F.; Honfi, D.; Kozlowski, M.; Arrigoni, M.; Figuli, L.; Lange, D. Performance of structural glass facades under extreme loads-Design methods, existing research, current issues and trends. Constr. Build. Mater. 2018, 163, 921–937. [Google Scholar] [CrossRef]

- El Fouas, C.; Hajji, B.; Gagliano, A.; Tina, G.M.; Aneli, S. Numerical model and experimental validation of the electrical and thermal performances of photovoltaic/thermal plant. Energy Convers. Manag. 2020, 220, 112939. [Google Scholar] [CrossRef]

- Johansson, F.; Gustafsson, B.E.; Stridh, B.; Campana, P.E. 3D-thermal modelling of a bifacial agrivoltaics system: A photovoltaic module perspective. Energy Nexus 2022, 5, 100052. [Google Scholar] [CrossRef]

- Honfi, D.; Sjöström, J.; Bedon, C.; Kozłowski, M. Experimental and Numerical Analysis of Thermo-Mechanical Behaviour of Glass Panes Exposed to Radiant Heatin. Fire 2022, 5, 124. [Google Scholar] [CrossRef]

- Symoens, E.; Van Coile, R.; Belis, J. Behaviour of Different Glass Elements subjected to Elevated Temperatures–State of the Art. Challenging Glass 2020, 7, 4489. [Google Scholar] [CrossRef]

- Möckel, M.; Seel, M.; Schwind, G.; Engelmann, M. Temperature distribution and stress relaxation in glass under high temperature exposition. Glass Struct. Eng. 2025, 10, 11. [Google Scholar] [CrossRef]

- Ko, Y.; Aram, M.; Zhang, X.; Qi, D. Fire safety of building integrated photovoltaic systems: Critical review for codes and standards. Indoor Built Environ. 2022, 32, 25–43. [Google Scholar] [CrossRef]

- Despinasse, M.-C.; Krueger, S. First developments of a new test to evaluate the fire behavior of photovoltaic modules on roofs. Fire Saf. J. 2015, 71, 49–57. [Google Scholar] [CrossRef]

- Stølen, R.; Li, T.; Wingdahl, T.; Steen-Hansen, A. Large- and small-scale fire test of a building integrated photovoltaic (BIPV) façade system. Fire Saf. J. 2024, 144, 104083. [Google Scholar] [CrossRef]

- Huang, Y.-C.; Lee, S.-K.; Chan, C.-C.; Wang, S.-J. Full-scale evaluation of fire-resistant building integrated photovoltaic systems with different installation positions of junction boxes. Indoor Built Environ. 2017, 17, 1259–1271. [Google Scholar] [CrossRef]

- Salmerón-Manzano, E.; Muñoz-Rodríguez, D.; Perea-Moreno, A.-J.; Hernandez-Escobedo, Q.; Manzano-Agugliaro, F. Worldwide scientific landscape on fires in photovoltaic. J. Clean. Prod. 2024, 461, 142614. [Google Scholar] [CrossRef]

- Boddaert, S.; Bonomo, P.; Eder, G.; Fjellgaard Mikalsen, R.; Ishii, H.; Kim, J.-T.; Ko, Y.; Kovács, P.; Li, T.; Olano, X.; et al. Fire Safety of BIPV: International Mapping of Accredited and R&D Facilities in the Context of Codes and Standards. Report IEA-PVPS T15-15:2023 (134 pages). 2023. Available online: https://iea-pvps.org/wp-content/uploads/2023/07/Report_IEA-PVPS_T15-15-2023_Mapping-of-Fire-Safety-Laboratories.pdf (accessed on 10 November 2025).

- Simulia. Abaqus Computer Software; Simulia: Providence, RI, USA, 2024. [Google Scholar]

- Louter, C.; Bedon, C.; Kozłowski, M.; Nussbaumer, A. Structural response of fire-exposed laminated glass beams under sustained loads; exploratory experiments and FE-Simulations. Fire Saf. J. 2021, 123, 103353. [Google Scholar] [CrossRef]

- Bedon, C.; Louter, C. Thermo-mechanical numerical analyses in support of fire endurance assessment of ordinary soda-lime structural glass elements. J. Struct. Fire Eng. 2023, 14, 522–546. [Google Scholar] [CrossRef]

- Kozlowski, M.; Bedon, C. Sensitivity to input parameters of failure detection methods for out-of-plane loaded glass panels in fire. Fire 2021, 4, 5. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Bisby, L. Comparative study of thermal breakage of annealed and tempered glazing with different thicknesses under uniform radiation conditions. Fire Saf. J. 2023, 140, 103867. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, C.; Bedon, C. Performance of photovoltaic panels with different inclinations under uniform thermal loading. Int. J. Therm. Sci. 2025, 208, 109489. [Google Scholar] [CrossRef]

- Bedon, C.; Veronese, L.; Del Bello, R.; Cella, N.; Wang, Y. Numerical Simulation of Thermal Shock for Glass-Glass BIPVs in Fire: Gaps and Challenges. In Fire Safety Engineering-Measures, Policies, and Applications; Bedon, C., Lucherini, A., Stochino, F., Eds.; Books on Demand: Norderstedt, Germany, 2025. [Google Scholar] [CrossRef]

- WSong, J.R.; Tippabhotla, S.K.; Tay, A.A.O.; Budiman, A.S. Numerical Simulation of the Evolution of Stress in Solar Cells During the Entire Manufacturing Cycle of a Conventional Silicon Wafer Based Photovoltaic Laminate. IEEE J. Photovolt. 2018, 8, 210–217. [Google Scholar]

- MSiddiqui, U.; Arif, A.F.M.; Kelley, L.; Dobowsky, S. Three-dimensional thermal modelling of a photovoltaic module under varying conditions. Sol. Energy 2012, 86, 2620–2631. [Google Scholar] [CrossRef]

- Özkalay, E.; Friesen, G.; Caccivio, M.; Bonomo, P.; Fairbrother, A.; Ballif, C.; Virtuani, A. Operating temperatures and diurnal temperature variations of modules installed in open-rack and typical BIPV configurations. IEEE J. Photovolt. 2022, 12, 133–140. [Google Scholar] [CrossRef]

- Lamaamar, I.; Tilioua, A.; Alaoui, M.A.H. Thermal performance analysis of a poly c-Si PV module under semi-arid conditions. Mater. Sci. Energy Technol. 2022, 5, 243–251. [Google Scholar] [CrossRef]

- Limane, B.; Ould-Lahoucine, C.; Diaf, S. Modeling and simulation of the thermal behavior and electrical performance of PV modules under different environment and operating conditions. Renew. Energy 2023, 219, 119420. [Google Scholar] [CrossRef]

- Zhou, J.-C.; Zhang, Z.; Liu, H.-J.; Yi, Q. Temperature distribution and back sheet role of polycrystalline silicon photovoltaic module. Appl. Therm. Eng. 2017, 111, 1296–1303. [Google Scholar] [CrossRef]

- Bosco, N.; Silverman, T.J.; Kurtz, S.R. The influence of PV module materials and design on solder joint thermal fatigue durability. IEEE J. Photovolt. 2016, 6, 1407–1412. [Google Scholar] [CrossRef]

- Lindholm, D.; Li, H.; Otnes, G.; Cattaneo, G.; Foss, S.E.; Fjaer, H. Thermomechanical fatigue of solder joint and interconnect ribbon: Impact of low lamination temperature. In Proceedings of the EU PVSEC 2021–38th European Photovoltaic Solar Energy Conference and Exhibition, Online, 6–10 September 2021; pp. 622–626. [Google Scholar]

- Dietrich, S.; Pander, M.; Sander, M.; Shulze, S.-H.; Ebert, M. Mechanical and thermo-mechanical assessment of encapsulated solar cells by Finite-Element simulation. In Proceedings of the SPIE–The International Society for Optical Engineering–Reliability of Photovoltaic Cells, Modules, Components and Systems III, San Diego, CA, USA, 1–5 August 2010. [Google Scholar]

- Noh, Y.; Lee, J. Building-integrated photovoltaic applied Bi-facial photovoltaic module structural design. Solae Energy Mater. Sol. Cells 2024, 269, 112758. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, Q.; Zhang, Y.; Wang, Q.; Sun, J. Sensitivity analysis of influencing factors on glass façade breakage in fire. Fire Saf. J. 2018, 98, 38–47. [Google Scholar] [CrossRef]

- Bedon, C. Structural Glass Systems under Fire: Overview of Design Issues, Experimental Research, and Developments. Adv. Civ. Eng. 2018, 2017, 2120570. [Google Scholar] [CrossRef]

- Sabsabi, A.; Youssef, M.A.; El-Fitiany, S.F.; Vedrtnam, A. Simplified structural analysis of framed ordinary non-tempered glass panels during fire exposure. Fire Saf. J. 2021, 122, 103357. [Google Scholar] [CrossRef]

- El-Din, N.M.S.; Sabaa, M.W. Thermal degradation of poly(vinyl butyral) laminated safety glass. Polym. Degrad. Stab. 1995, 47, 238–288. [Google Scholar] [CrossRef]

- Pelayo, F.; Lamela-Rey, M.J.; Muniz-Calvente, M.; Lopez-Aenlle, M.; Alvarez-Vazquez, A.; Fernandez-Canteli, A. Study of the time-temperature-dependent behaviour of PVB: Application to laminated glass elements. Thin-Walled Struct. 2017, 119, 324–331. [Google Scholar] [CrossRef]

- Suwen, C.; Xing, C.; Xiqiang, W. The mechanical behaviour of polyvinyl butyral at intermediate strain rates and different temperatures. Constr. Build. Mater. 2018, 182, 66–79. [Google Scholar] [CrossRef]

- Li, Y.; Xie, L.; Zhang, T.; Wu, Y.; Sun, Y.; Ni, Z.; Zhang, J.; He, B.; Zhao, P. Mechanical analysis of photovoltaic panels with various boundary conditions. Renew. Energy 2020, 145, 242–260. [Google Scholar] [CrossRef]

- Hartley, J.Y.; Owen-Bellini, M.; Truman, T.; Maes, A.; Elce, E.; Ward, A.; Khraishi, T.; Robert, S.A. Effects of photovoltaic module materials and design on module deformation under load. IEEE J. Photovolt. 2020, 10, 838–843. [Google Scholar] [CrossRef]

- Bedon, C.; Pavan Massi, A. Non-destructive vibration-based monitoring analysis of PV modules with encapsulant degradation by frequency change. Measurement 2024, 236, 115096. [Google Scholar] [CrossRef]

- ISO 834-1:2020; Fire-Resistance Tests–Elements of Building Construction. International Organization of Standardization (ISO): Geneve, Switzerland, 2020.

- Sahli, M.; Correia, J.P.M.; Ahzi, S.; Touchal, S. Thermomechanical investigation of PV panels behaviour under NOCT conditions. In Proceedings of the IESEC–International Renewable and Sustainable Energy Conference 2017, Tangier, Morocco, 4–7 December 2017. [Google Scholar] [CrossRef]

- Evans, D.L. Simplified method for predicting photovoltaic array output. Sol. Energy 1981, 27, 555–560. [Google Scholar] [CrossRef]

- Beinert, A.J.; Leidl, R.; Sommeling, P.; Eitner, U.; Aktaa, J. FEM-Based development of novel back contact PV modules with ultra-thin solar cells. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference, Amsterdam, The Netherlands, 25–29 September 2017. [Google Scholar]

- Jia, Y.; Zhang, J. Thermal conductivity of ethylene-vinyl acetate copolymers with different vinyl acetate contents dependent on temperature and crystallinity. Thermochim. Acta 2022, 708, 179141. [Google Scholar] [CrossRef]

- Desai, P.D. Thermodynamic properties of iron and silicon. J. Phys. Chem. Ref. Data 1985, 15, 967–983. [Google Scholar] [CrossRef]

- Morris, R.G.; Hust, J.G. Thermal conductivity measurements of silicon from 30° to 425 °C. Phys. Rev. 1961, 14, 1426–1430. [Google Scholar] [CrossRef]

- Liu, Z. Temperature-dependent elastic constants and Young’s modulus of silicon single crystal. In Proceedings of the Mechanical Engineering Design of Synchrotron Radiation Equipment and Instrumentation (MEDSI2020), Chicago, IL, USA, 26–29 July 2021. [Google Scholar] [CrossRef]

- Zhao, L.; Maynadier, A.; Nelias, D. Stiffness and fracture analysis of photovoltaic grade silicon plates. Int. J. Solids Struct. 2016, 97–98, 355–369. [Google Scholar] [CrossRef]

- Salama, A.M.; Rowe, W.M.; Yasui, R.K. Stress Analysis and Design of Silicon Solar Cell Arrays and Related Material Properties; JPL Technical Report 32-1552; Jet Propulsion Laboratory, California Institute of Technology: Flintridge, CA, USA, 1972. [Google Scholar]

- Vosteen, L.F. Effect of Temperature on Dynamic Modulus of Elasticity of Some Structural Alloys; NACA TN 4348; Technical Note 4348; National Advisory Committee of Aeronautics: Washington, DC, USA, 1958. [Google Scholar]

- Doležel, I.; Karban, P.; Kropík, P.; Pánek, D. Accurate control of position by induction-heating produced thermoelasticity. IEEE Trans. Magn. 2010, 46, 2888–2891. [Google Scholar] [CrossRef]

- prEN Thstr:2004; Glass in Building: Thermal Stress Calculation Method. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- Galuppi, L.; Franco, A.; Bedon, C. Architectural Glass under Climatic Actions and Fire: Review of State of the Art, Open Problems and Future Perspectives. Buildings 2024, 13, 939. [Google Scholar] [CrossRef]

| Glass Type | Glass Thickness [mm] | Encapsulant | Mechanical Restraints | Thermal Exposure |

|---|---|---|---|---|

| AN or HS or FT * | h1 = h2 = 3.2 * or 6 | PVB * he = 1.52 mm * | Linear on four edges (4L) * or two edges (2L), or four-point fixings (4P) | Uniform distribution; time-varying ISO 834 function (Figure 2) |

| Edges | ||||

|---|---|---|---|---|

| Glass Type | As-Cut or Arrissed | Smooth Ground | Polished | |

| Allowable thermal gradient [°C] | Float (<12 mm) | 35 | 40 | 45 |

| Heat-strengthened | 100 | |||

| Tempered | 200 | |||

| Allowable thermal stress [MPa] | Float (<12 mm) | 20.34 | 23.24 | 26.15 |

| Heat-strengthened | 58.10 | |||

| Tempered | 116.20 | |||

| Glass Thickness [mm] | Size [m2] | Expected Failure Time [s] |

|---|---|---|

| h1 = h2 = 6 (FT glass) | 1.046 × 1.719 | 347 numerical (ABAQUS) 375 experimental (furnace test) (data from [22]) |

| h1 = h2 = 6 | 0.4 × 0.4 | 220 (FT glass)—present numerical study |

| 110 (HS glass)—present numerical study | ||

| 55 (AN glass)—present numerical study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bedon, C.; Wang, Y.; Cozzarini, L.; Del Bello, R.; Fasan, M. Numerical Study on the Early Out-of-Plane Mechanical Response of Glass–Glass Building-Integrated Photovoltaics Exposed to Increasing Temperature and Fire. Energies 2025, 18, 6037. https://doi.org/10.3390/en18226037

Bedon C, Wang Y, Cozzarini L, Del Bello R, Fasan M. Numerical Study on the Early Out-of-Plane Mechanical Response of Glass–Glass Building-Integrated Photovoltaics Exposed to Increasing Temperature and Fire. Energies. 2025; 18(22):6037. https://doi.org/10.3390/en18226037

Chicago/Turabian StyleBedon, Chiara, Yu Wang, Luca Cozzarini, Riccardo Del Bello, and Marco Fasan. 2025. "Numerical Study on the Early Out-of-Plane Mechanical Response of Glass–Glass Building-Integrated Photovoltaics Exposed to Increasing Temperature and Fire" Energies 18, no. 22: 6037. https://doi.org/10.3390/en18226037

APA StyleBedon, C., Wang, Y., Cozzarini, L., Del Bello, R., & Fasan, M. (2025). Numerical Study on the Early Out-of-Plane Mechanical Response of Glass–Glass Building-Integrated Photovoltaics Exposed to Increasing Temperature and Fire. Energies, 18(22), 6037. https://doi.org/10.3390/en18226037