Investigation of the Sealing and Mechanical Stability of Cap Rock for Offshore CO2 Sequestration in Saline Aquifers

Abstract

1. Introduction

2. Material and Methods

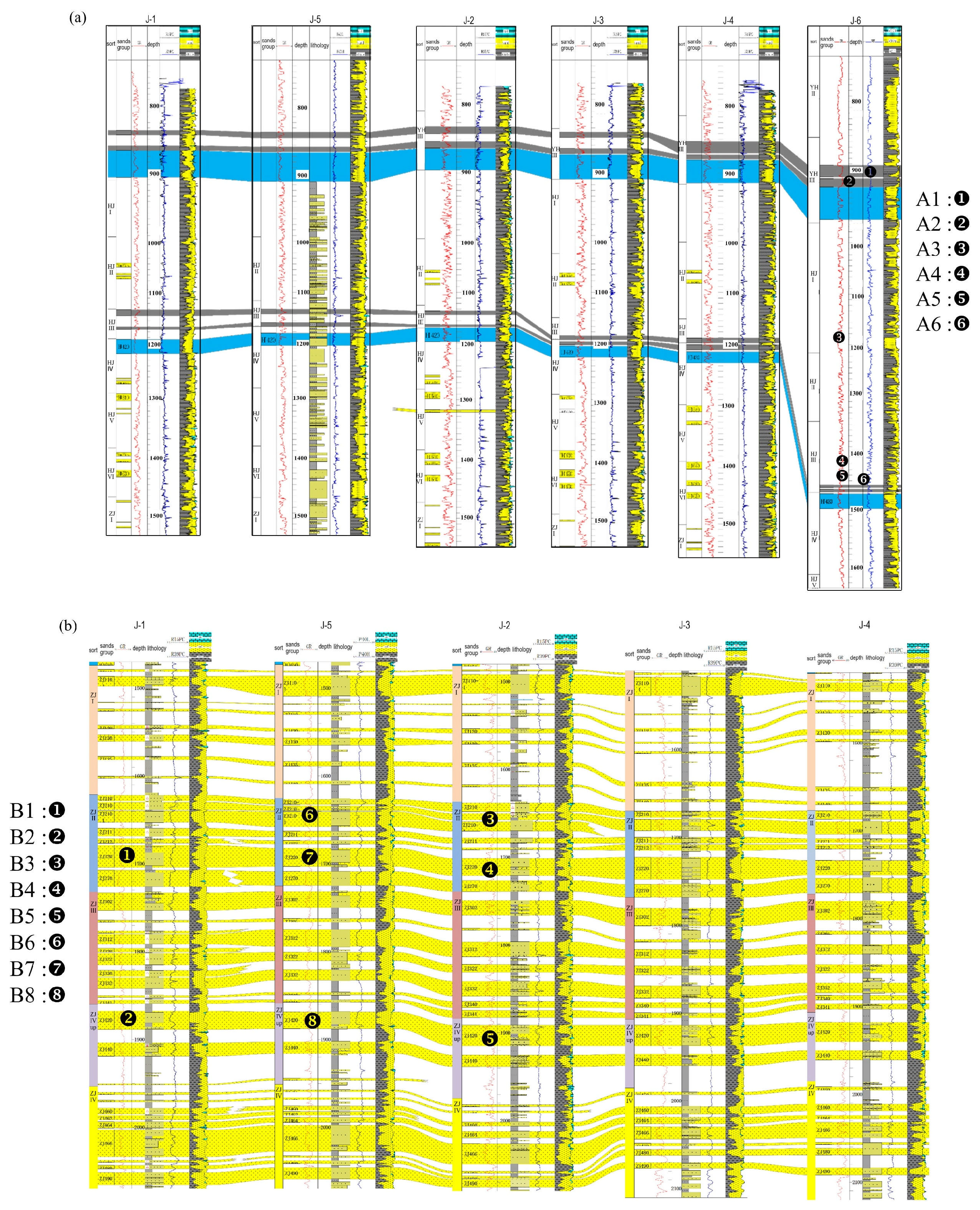

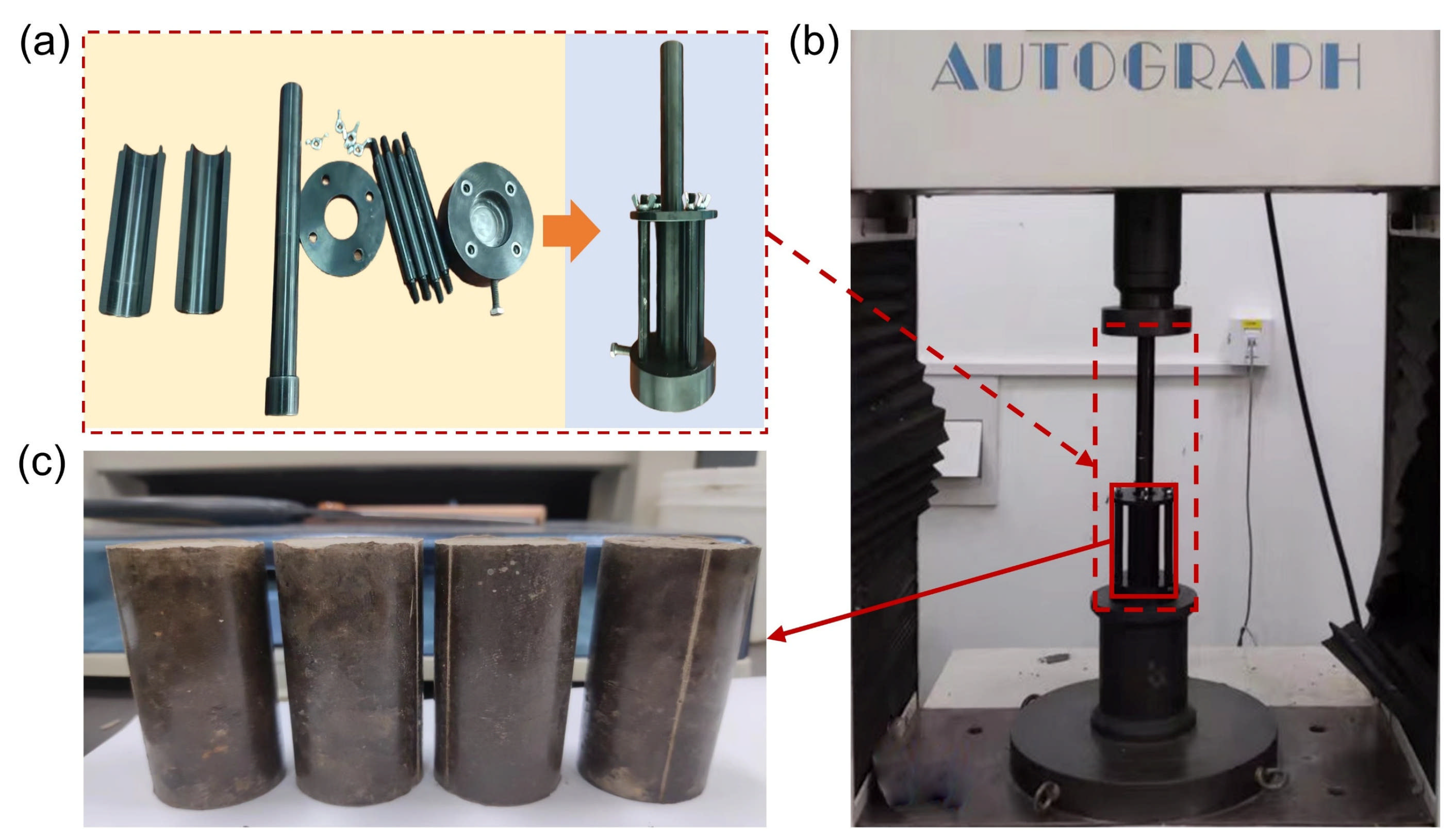

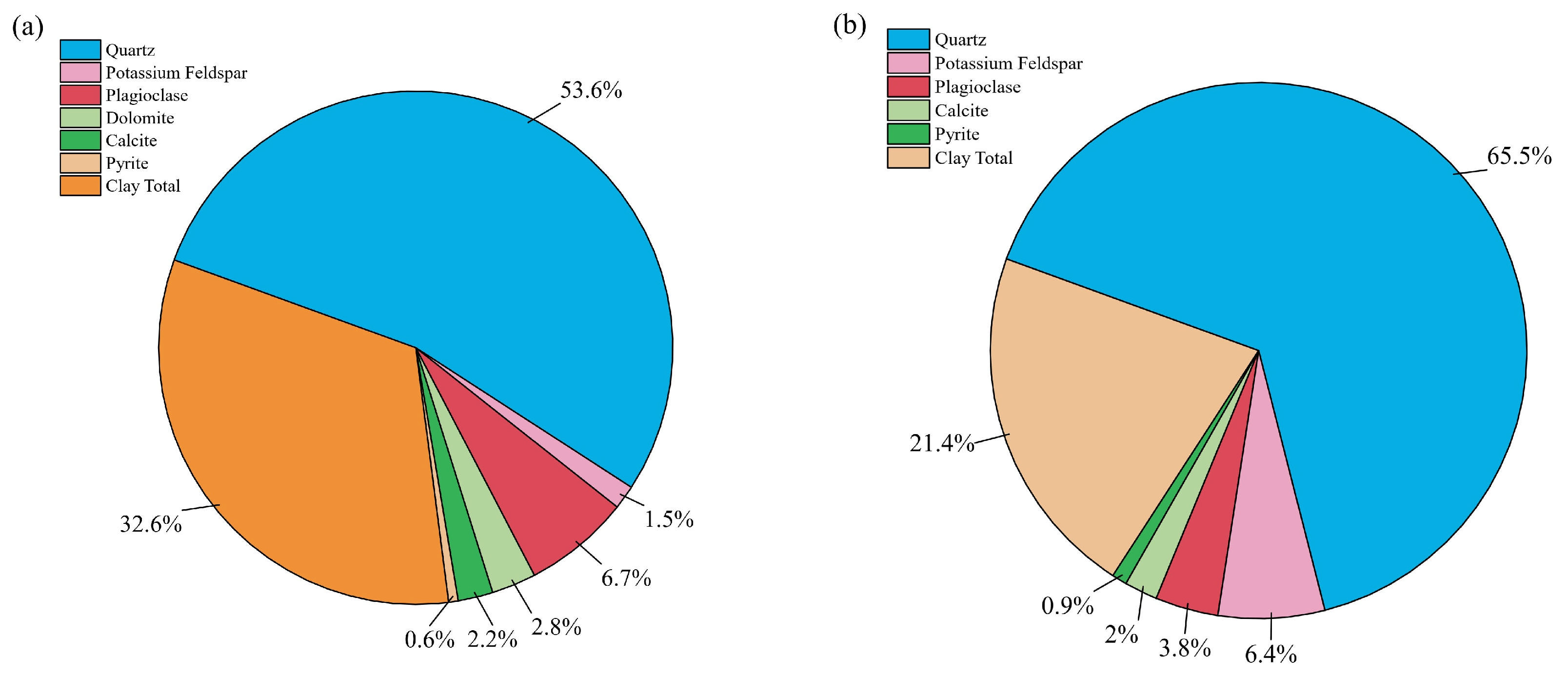

2.1. Sample Preparation

2.2. Experimental Methods

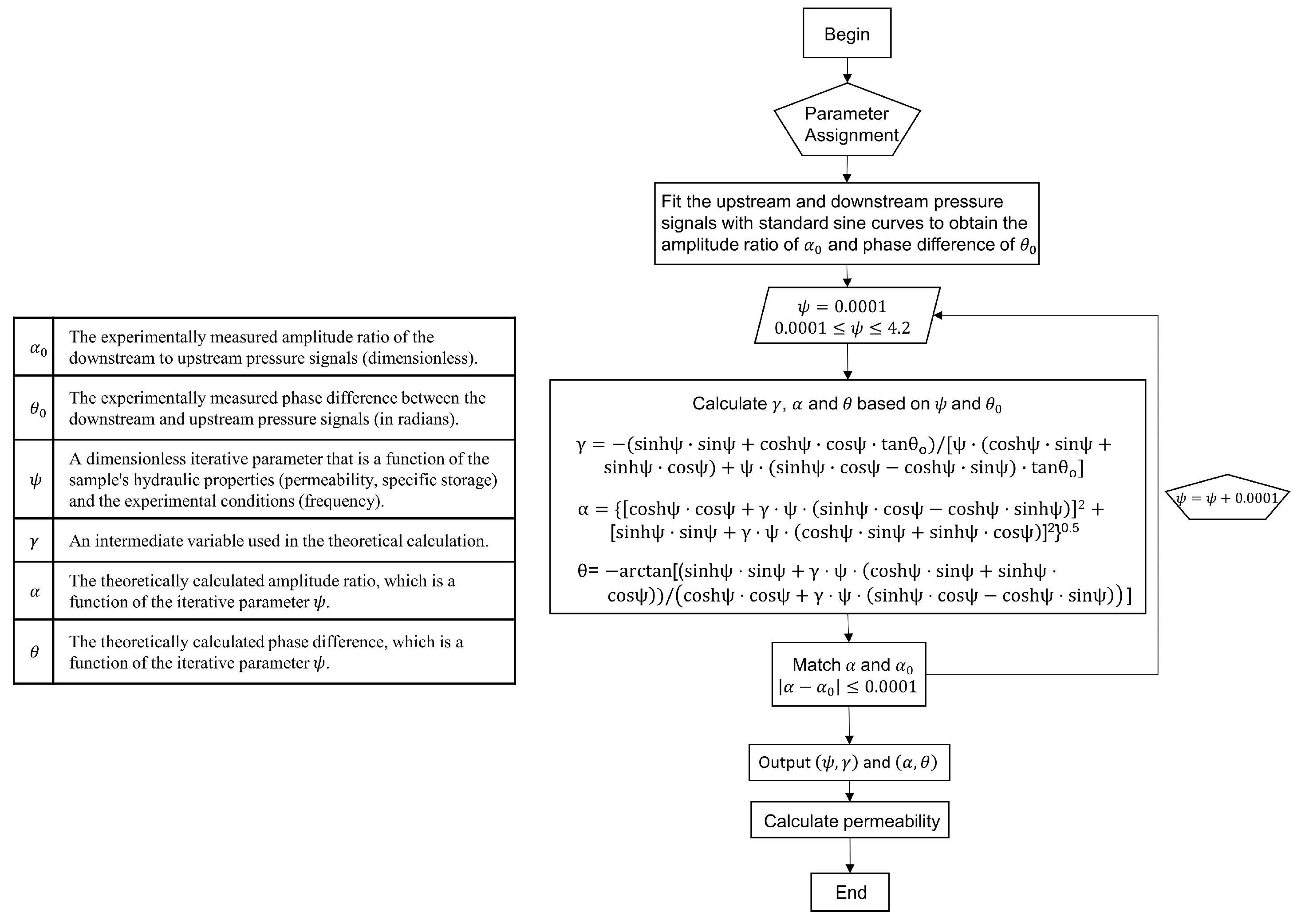

2.2.1. Permeability Measurement of Well Core Samples

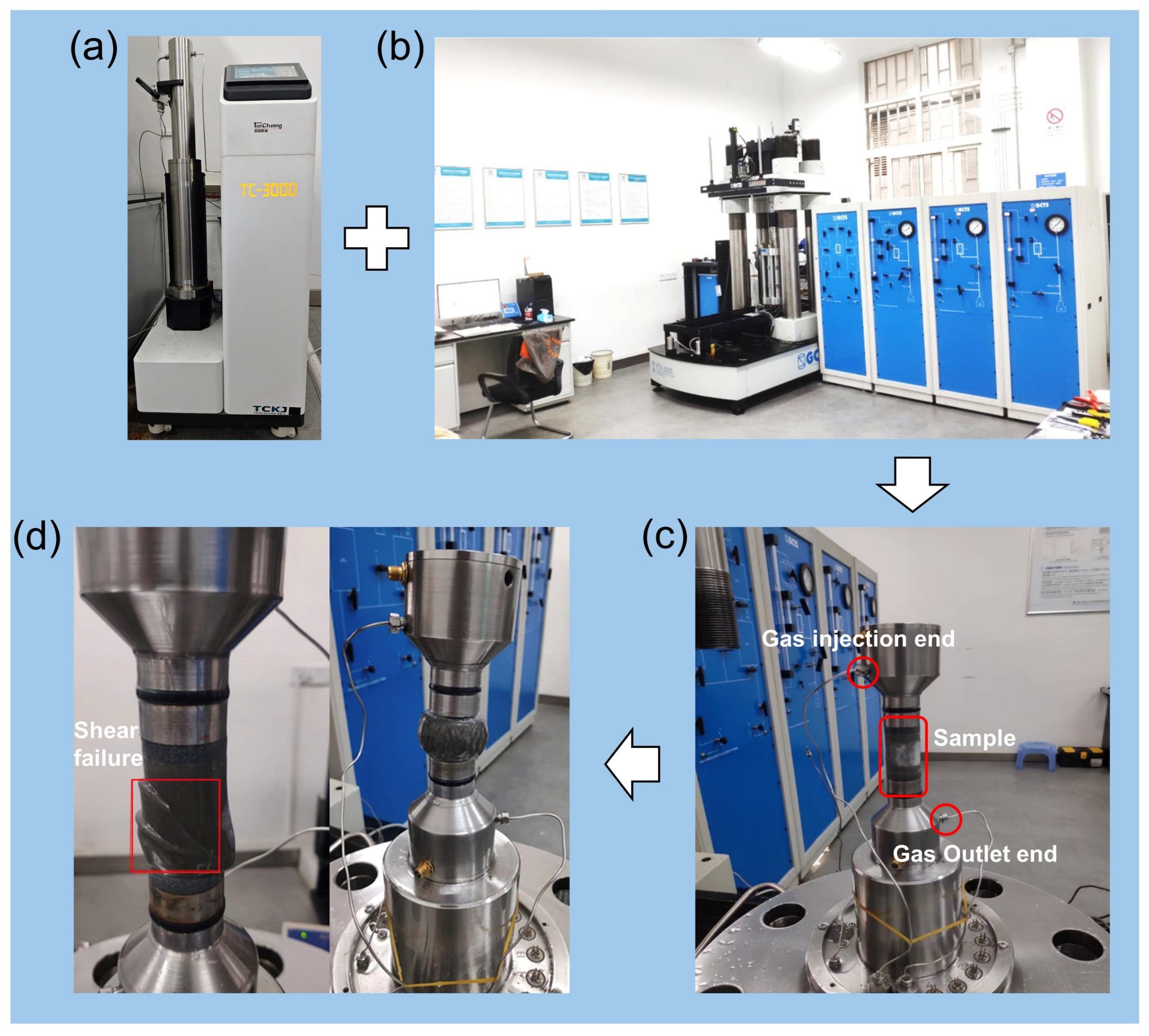

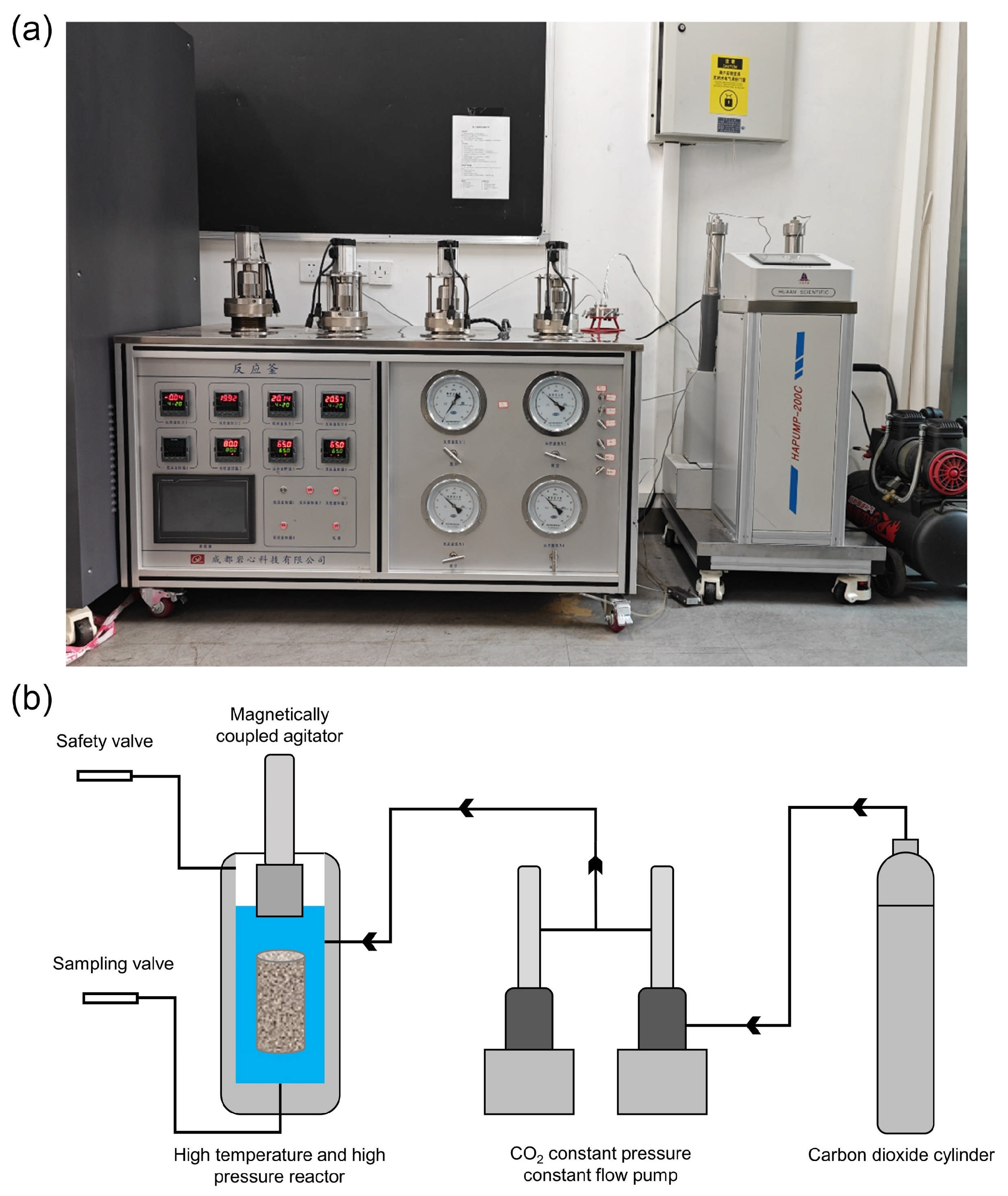

2.2.2. Supercritical CO2 Breakthrough Experiment

2.2.3. Uniaxial Compressive Strength Test

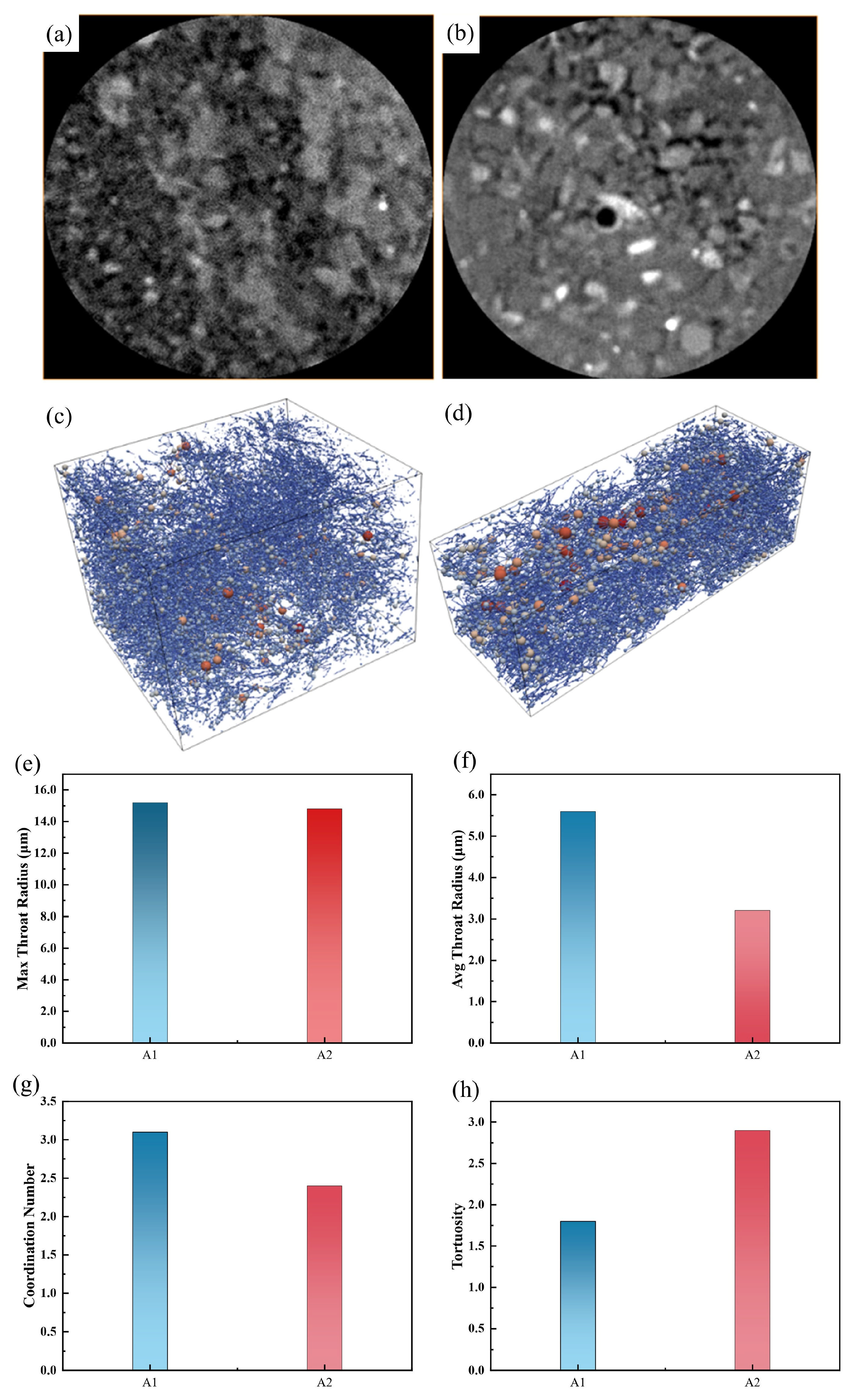

2.2.4. Micro-CT Scanning and Pore Network Modeling

3. Experimental Results

3.1. Permeability Measurement Data of Well Core Samples

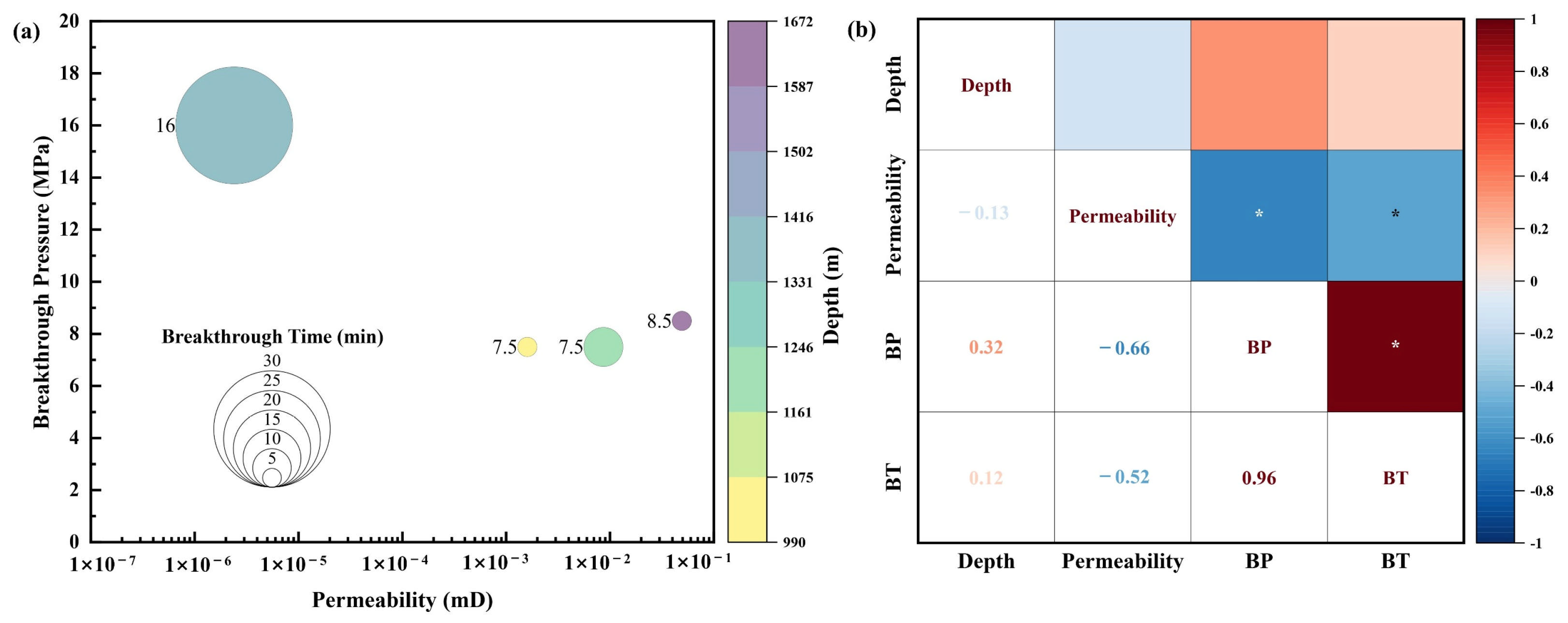

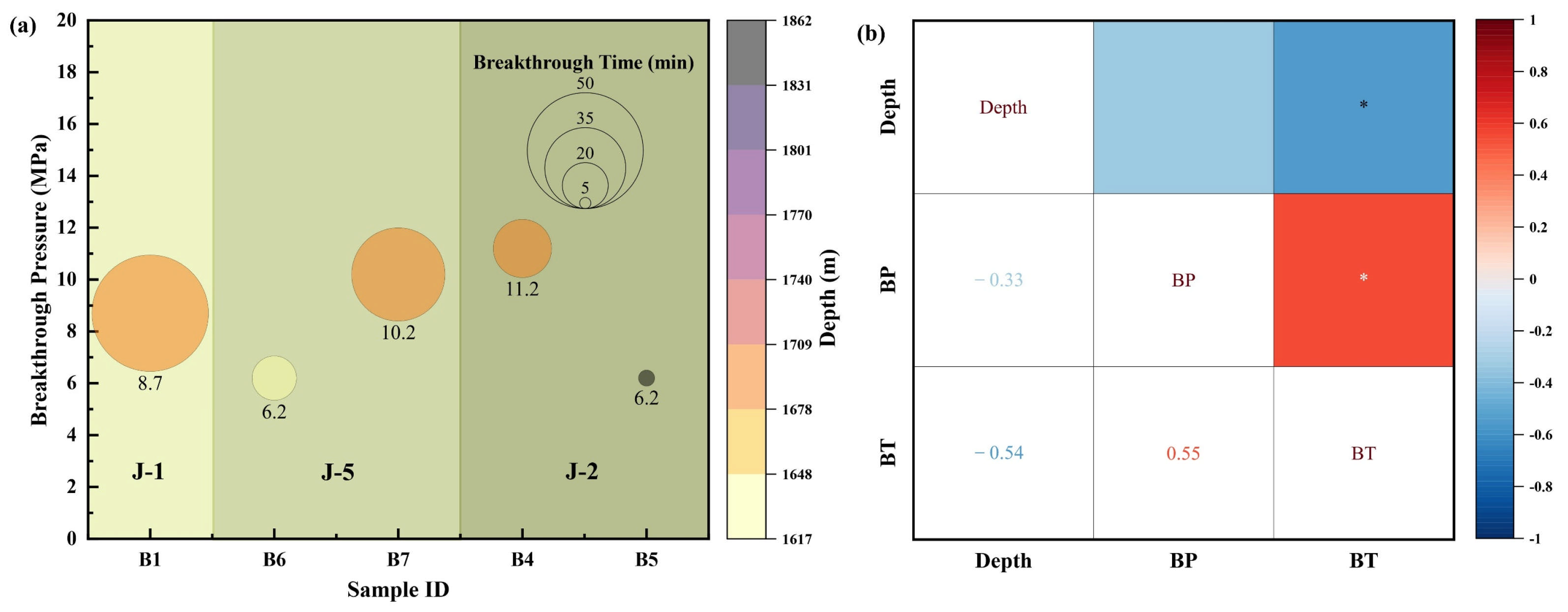

3.2. Supercritical CO2 Breakthrough Pressure Test Results

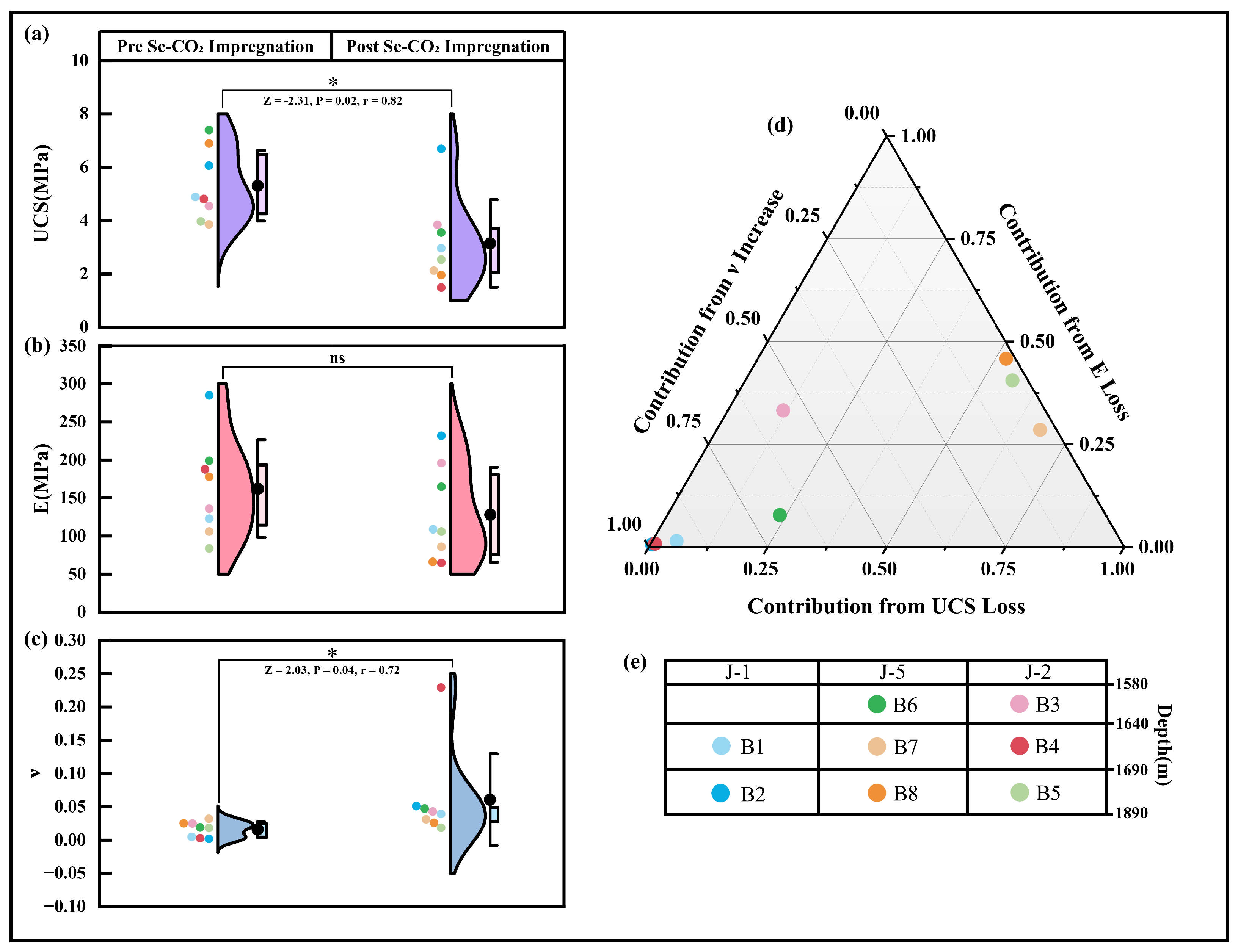

3.3. Uniaxial Mechanical Properties Test Results

4. Discussion

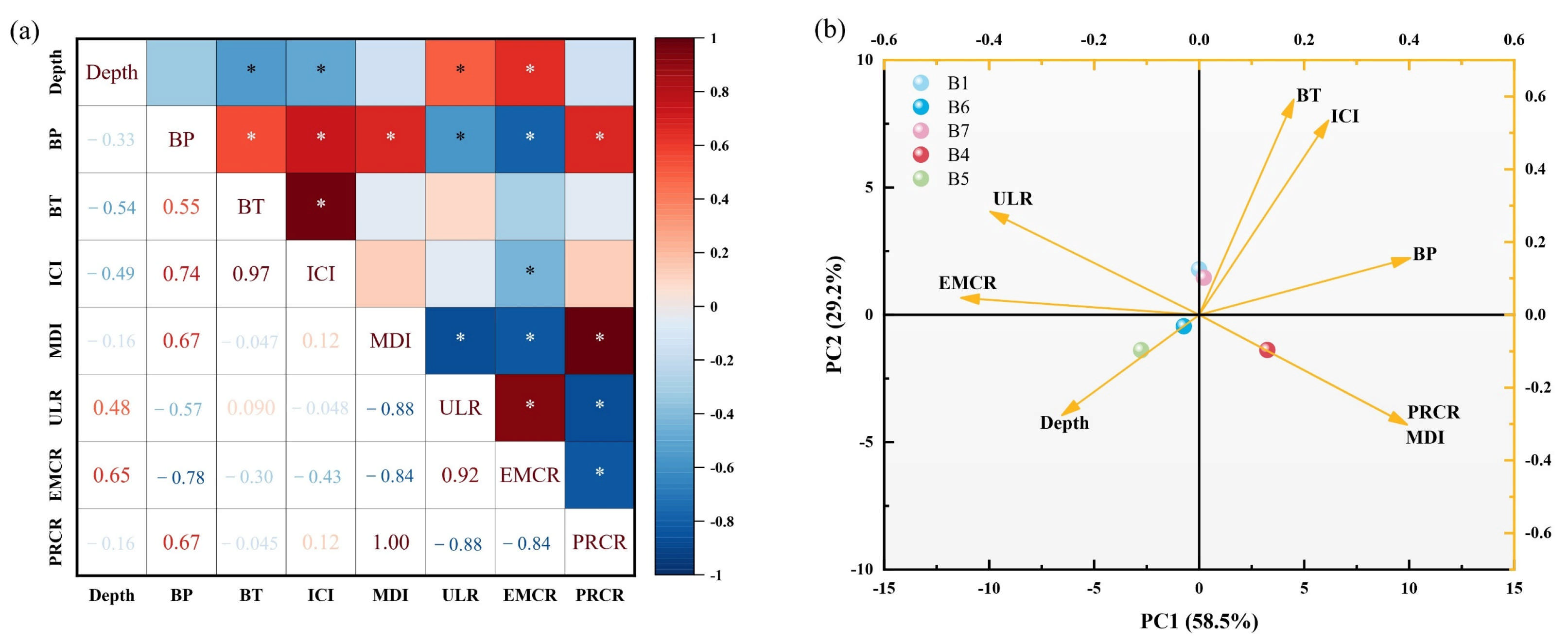

4.1. Extreme Permeability Heterogeneity and Its Diagenetic Controls

4.2. Mechanisms Underlying the Variation in Breakthrough Time

4.3. Geomechanical Weakening Mechanisms of Caprock Following scCO2-Brine-Rock Interactions

4.4. Evaluation of Cap Rock Sealing Performance for Offshore CO2 Sequestration in Saline Aquifers

4.5. Implications for Reservoir-Scale Modeling and Upscaling

5. Conclusions

- (1)

- Our results reveal extreme vertical permeability heterogeneity (10−6–10−1 mD) in Yuehai and Hanjiang Formation caprocks, driven by diagenetic processes rather than macroscopic lithology. Permeability is decoupled from scCO2 breakthrough pressure—breakthrough pressure is governed by maximum pore-throat radius, whereas breakthrough time depends on post-breakthrough pore network topology.

- (2)

- ScCO2-brine-rock interactions induce pronounced geomechanical weakening, with uniaxial compressive strength decreasing by up to 71.7% and the elastic modulus reducing, while a substantial increase in Poisson’s ratio signifies a fundamental transition from brittle to ductile behavior.

- (3)

- Hanjiang Formation Section 1 (sample A3) exhibits optimal sealing (2.41 × 10−6 mD permeability, breakthrough pressure greater than 16 MPa), ensuring secure CO2 sequestration in the underlying 1470–1500 m aquifer. Yuehai Formation Section 3 requires injection pressures less than 7.5 MPa to prevent leakage, with multi-well scenarios demanding pressure control and stability monitoring.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, G.; Shang, D.; Zhang, L.; Xie, S.; Pan, W. Short-term interactions between Longmaxi shale and carbon dioxide-based fracturing fluids. Heliyon 2024, 10, e38575. [Google Scholar] [CrossRef]

- Zhang, M.; Qiu, Y.; Li, C.; Cui, T.; Yang, M.; Yan, J.; Yang, W. A Habitable Earth and Carbon Neutrality: Mission and Challenges Facing Resources and the Environment in China—An Overview. Int. J. Environ. Res. Public Health 2023, 20, 1045. [Google Scholar] [CrossRef]

- Lu, P.; Liu, W.; Gao, C.; Zhao, J.; Bai, Y. Evaluation of carbon dioxide storage in the deep saline layer of the Ordovician Majiagou Formation in the Ordos Basin. IOP Conf. Ser. Earth Environ. Sci. 2021, 675, 012058. [Google Scholar] [CrossRef]

- Skerbisch, L.; Misch, D.; Drews, M.; Stollhofen, H.; Sachsenhofer, R.F.; Arnberger, K.; Schuller, V.; Zamolyi, A. Regional mudstone compaction trends in the Vienna Basin: Top seal assessment and implications for uplift history. Int. J. Earth Sci. 2023, 112, 1901–1921. [Google Scholar] [CrossRef]

- Wu, W.; Zoback, M.D.; Kohli, A.H. The impacts of effective stress and CO2 sorption on the matrix permeability of shale reservoir rocks. Fuel 2017, 203, 179–186. [Google Scholar] [CrossRef]

- Li, Y.; Zha, M.; Song, R.; Aplin, A.C.; Bowen, L.; Wang, X.; Zhang, Y. Microstructure and pore systems of shallow-buried fluvial mudstone caprocks in Zhanhua depression, east China inferred from SEM and MICP. Mar. Pet. Geol. 2021, 132, 105189. [Google Scholar] [CrossRef]

- Han, H.; Zhang, Q.; Lv, W.; Han, L.; Ji, Z.; Zhang, S.; Zhao, C.; Kang, H.; Sun, L.; Shen, R. Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field. Sci. Eng. Compos. Mater. 2023, 30, 20220204. [Google Scholar] [CrossRef]

- Jayasekara, D.W.; Ranjith, P.G.; Wanniarachchi, W.A.M.; Rathnaweera, T.D.; Van Gent, D. CO2-brine-caprock interaction: Reactivity experiments on mudstone caprock of South-west Hub geo-sequestration project. J. Pet. Sci. Eng. 2020, 189, 107011. [Google Scholar] [CrossRef]

- Lin, R.; Ren, L.; Zhao, J.; Tan, X.; Rasouli, V.; Wang, X.; Wu, J.; Song, Y.; Shen, C. Stress and pressure dependent permeability of shale rock: Discrete element method (DEM) simulation on digital core. J. Pet. Sci. Eng. 2022, 208, 109797. [Google Scholar] [CrossRef]

- Fujii, T.; Uehara, S.-i.; Sorai, M. Effective Confining stress Depending on Fluid Flow and Capillary Sealing Properties of Mudstones for CO2 Geological Sequestration. Energy Procedia 2014, 63, 3305–3312. [Google Scholar] [CrossRef]

- Gao, S.; Wei, N.; Li, X.; Wang, Y.; Wang, Q. Cap Rock CO2 Breakthrough Pressure Measurement Apparatus and Application in Shenhua CCS Project. Energy Procedia 2014, 63, 4766–4772. [Google Scholar] [CrossRef]

- Gao, T.; Wang, X.; Wang, H.; Gu, C.; Zhou, Z.; Yang, Z. A Study on the Breakthrough Pressure of Porous Rock Formations in Gas Storage Reservoirs. Processes 2024, 12, 2193. [Google Scholar] [CrossRef]

- Yang, W.; Bai, Y.; Sun, X.; Wang, J.; Long, G.; Li, H.; Zuo, M.; Li, H. The influence of hydrocarbon generation on the sealing capability of mudstone caprock rich in organic matter. Sci. Rep. 2024, 14, 1846. [Google Scholar] [CrossRef]

- Vafaie, A.; Cama, J.; Soler, J.M.; Kivi, I.R.; Vilarrasa, V. Chemo-hydro-mechanical effects of CO2 injection on reservoir and seal rocks: A review on laboratory experiments. Renew. Sustain. Energy Rev. 2023, 178, 113270. [Google Scholar]

- Lyu, Q.; Deng, J.; Shen, Y.; Ding, Y.; Shi, Y.; Feng, G.; Tan, J. Effects of supercritical CO2, water, and supercritical CO2-based water on the mechanical properties and fracturability of shale. J. Rock Mech. Geotech. Eng. 2024, 17, 3001–3017. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, X.; Jing, T.; Du, K.; Zhao, W.; Shan, Y.; Guan, Z.; Li, Z. Comparison of mineral transformation in CO2 geological storage under CO2-water-sandstone and mudstone reactions. Geoenergy Sci. Eng. 2024, 242, 213215. [Google Scholar]

- Li, Y.; Tian, H.L.; Zhuo, Z.; Sun, Y. The Potential Effect of CO2-Water-Rock Reaction on The Caprock Formation (Mudstone) Case Study. Adv. Mater. Res. 2012, 518–523, 140–143. [Google Scholar]

- Su, E.; Liang, Y.; Chang, X.; Zou, Q.; Xu, M.; Sasmito, A.P. Effects of cyclic saturation of supercritical CO2 on the pore structures and mechanical properties of bituminous coal: An experimental study. J. CO2 Util. 2020, 40, 101208. [Google Scholar] [CrossRef]

- Rohmer, J.; Pluymakers, A.; Renard, F. Mechano-chemical interactions in sedimentary rocks in the context of CO2 storage: Weak acid, weak effects? Earth-Sci. Rev. 2016, 157, 86–110. [Google Scholar]

- Zhang, X.; Ranjith, P.G.; Lu, Y.; Ranathunga, A.S. Experimental investigation of the influence of CO2 and water adsorption on mechanics of coal under confining pressure. Int. J. Coal Geol. 2019, 209, 117–129. [Google Scholar] [CrossRef]

- Zheng, H.; Feng, X.-T.; Pan, P.-Z. Experimental investigation of sandstone properties under CO2–NaCl solution-rock interactions. Int. J. Greenh. Gas Control 2015, 37, 451–470. [Google Scholar]

- Akono, A.-T.; Dávila, G.; Druhan, J.; Shi, Z.; Jessen, K.; Tsotsis, T. Influence of geochemical reactions on the creep behavior of Mt. Simon sandstone. Int. J. Greenh. Gas Control 2020, 103, 103183. [Google Scholar] [CrossRef]

- Hu, S.; Li, X.; Bai, B.; Shi, L.; Liu, M.; Wu, H. A modified true triaxial apparatus for measuring mechanical properties of sandstone coupled with CO2-H2O biphase fluid. Greenh. Gases Sci. Technol. 2016, 7, 78–91. [Google Scholar] [CrossRef]

- Cui, G.; Wang, Y.; Rui, Z.; Chen, B.; Ren, S.; Zhang, L. Assessing the combined influence of fluid-rock interactions on reservoir properties and injectivity during CO2 storage in saline aquifers. Energy 2018, 155, 281–296. [Google Scholar] [CrossRef]

- Cui, G.; Zhang, L.; Tan, C.; Ren, S.; Zhuang, Y.; Enechukwu, C. Injection of supercritical CO2 for geothermal exploitation from sandstone and carbonate reservoirs: CO2-water-rock interactions and their effects. J. CO2 Util. 2017, 20, 113–128. [Google Scholar] [CrossRef]

- Farquhar, S.M.; Pearce, J.K.; Dawson, G.K.W.; Golab, A.; Sommacal, S.; Kirste, D.; Biddle, D.; Golding, S.D. A fresh approach to investigating CO2 storage: Experimental CO2-water-rock interactions in a low-salinity reservoir system. Chem. Geol. 2015, 399, 98–122. [Google Scholar] [CrossRef]

- Lin, H.; Fujii, T.; Takisawa, R.; Takahashi, T.; Hashida, T. Experimental evaluation of interactions in supercritical CO2-water-rock minerals system under geologic CO2 sequestration conditions. J. Mater. Sci. 2008, 43, 2307–2315. [Google Scholar]

- Park, J.; Choi, B.-Y.; Lee, M.; Yang, M. Porosity changes due to analcime in a basaltic tuff from the Janggi Basin, Korea: Experimental and geochemical modeling study of CO2-water-rock interactions. Environ. Earth Sci. 2021, 80, 81. [Google Scholar]

- Wang, T.; Wang, H.; Zhang, F.; Xu, T. Simulation of CO2-water-rock interactions on geologic CO2 sequestration under geological conditions of China. Mar. Pollut. Bull. 2013, 76, 307–314. [Google Scholar] [CrossRef]

- Zhou, X.; Sang, S.; Niu, Q.; Zhang, K.; Liu, F.; Wang, W.; Chang, J. Changes of Multiscale Surface Morphology and Pore Structure of Mudstone Associated with Supercritical CO2-Water Exposure at Different Times. Energy Fuels 2021, 35, 4212–4223. [Google Scholar] [CrossRef]

- Khosravi, M.H.; Kheirollahi, M.; Liu, B.; Gentzis, T.; Liu, K.; Morta, H.B.; Ostadhassan, M. Physico-chemo-mechanical impact of sc-CO2 on shale formations: The Bakken. Gas Sci. Eng. 2023, 112, 204945. [Google Scholar] [CrossRef]

- Berrezueta, E.; Kovacs, T.; Herrera-Franco, G.; Mora-Frank, C.; Caicedo-Potosí, J.; Carrion-Mero, P.; Carneiro, J. Laboratory studies on CO2-brine-rock interaction: An analysis of research trends and current knowledge. Int. J. Greenh. Gas Control 2023, 123, 103842. [Google Scholar] [CrossRef]

- Winhausen, L.; Amann-Hildenbrand, A.; Fink, R.; Jalali, M.; Khaledi, K.; Hamdi, P.; Urai, J.L.; Schmatz, J.; Amann, F. A comparative study on methods for determining the hydraulic properties of a clay shale. Geophys. J. Int. 2021, 224, 1523–1539. [Google Scholar] [CrossRef]

- Faulkner, D.R.; Rutter, E.H. Comparisons of water and argon permeability in natural clay-bearing fault gouge under high pressure at 20 °C. J. Geophys. Res. Atmos. 2000, 105, 16415–16426. [Google Scholar]

- Blunt, M.J.; Bijeljic, B.; Dong, H.; Gharbi, O.; Iglauer, S.; Mostaghimi, P.; Paluszny, A.; Pentland, C. Pore-scale imaging and modelling. Adv. Water Resour. 2013, 51, 197–216. [Google Scholar] [CrossRef]

- Dewhurst, D.N.; Aplin, A.C.; Sarda, J.P. Influence of clay fraction on pore-scale properties and hydraulic conductivity of experimentally compacted mudstones. J. Geophys. Res. Solid Earth 1999, 104, 29261–29274. [Google Scholar] [CrossRef]

- Bjørlykke, K. Relationships between depositional environments, burial history and rock properties. Some principal aspects of diagenetic process in sedimentary basins. Sediment. Geol. 2014, 301, 1–14. [Google Scholar] [CrossRef]

- McBride, E.F. Quartz cement in sandstones: A review. Earth-Sci. Rev. 1989, 26, 69–112. [Google Scholar] [CrossRef]

- Tyrologou, P.; Vamvaka, A.; Koukouzas, N.; Pedro, J.; Fleury, M.; Carneiro, J.; Ribeiro, C.; Ghikas, D.; Mpatsi, A.; Barradas, J.P.; et al. Progress for carbon dioxide geological storage in West Macedonia: A field and laboratory-based survey. Open Res. Eur. 2023, 3, 85. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Schlömer, S.; Krooss, B.M. Gas breakthrough experiments on fine-grained sedimentary rocks. Geofluids 2002, 2, 3–23. [Google Scholar] [CrossRef]

- Schowalter, T.T. Mechanics of secondary hydrocarbon migration and entrapment. AAPG Bull. 1979, 63, 723–760. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Schlömer, S.; Krooss, B.; Littke, R. Gas breakthrough experiments on pelitic rocks: Comparative study with N2, CO2 and CH4. Geofluids 2004, 4, 61–80. [Google Scholar] [CrossRef]

- Amann-Hildenbrand, A.; Ghanizadeh, A.; Krooss, B.M. Transport properties of unconventional gas systems. Mar. Pet. Geol. 2012, 31, 90–99. [Google Scholar] [CrossRef]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar] [CrossRef]

- Berg, S.; Ott, H.; Klapp, S.A.; Schwing, A.; Neiteler, R.; Brussee, N.; Makurat, A.; Leu, L.; Enzmann, F.; Schwarz, J.-O. Real-time 3D imaging of Haines jumps in porous media flow. Proc. Natl. Acad. Sci. USA 2013, 110, 3755–3759. [Google Scholar] [CrossRef]

- Tokunaga, T.K.; Wan, J.; Jung, J.W.; Kim, T.W.; Kim, Y.; Dong, W. Capillary pressure and saturation relations for supercritical CO2 and brine in sand: High-pressure Pc (Sw) controller/meter measurements and capillary scaling predictions. Water Resour. Res. 2013, 49, 4566–4579. [Google Scholar] [CrossRef]

- Busch, A.; Amann-Hildenbrand, A. Predicting capillarity of mudrocks. Mar. Pet. Geol. 2013, 45, 208–223. [Google Scholar] [CrossRef]

- Iglauer, S. Dissolution Trapping of Carbon Dioxide in Reservoir Formation Brine—A Carbon Storage Mechanism; INTECH Open Access Publisher: London, UK, 2011. [Google Scholar]

- Bhuiyan, M.H.; Agofack, N.; Gawel, K.M.; Cerasi, P.R. Micro-and macroscale consequences of interactions between CO2 and shale rocks. Energies 2020, 13, 1167. [Google Scholar] [CrossRef]

- Gaus, I. Role and impact of CO2–rock interactions during CO2 storage in sedimentary rocks. Int. J. Greenh. Gas Control 2010, 4, 73–89. [Google Scholar] [CrossRef]

- Zhang, Y.; Lebedev, M.; Sarmadivaleh, M.; Barifcani, A.; Iglauer, S. Change in Geomechanical Properties of Limestone Due to Supercritical CO2 Injection. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 25–27 October 2016. [Google Scholar]

- Marbler, H.; Erickson, K.P.; Schmidt, M.; Lempp, C.; Pöllmann, H. Geomechanical and geochemical effects on sandstones caused by the reaction with supercritical CO2: An experimental approach to in situ conditions in deep geological reservoirs. Environ. Earth Sci. 2013, 69, 1981–1998. [Google Scholar] [CrossRef]

- Rutqvist, J. The geomechanics of CO2 storage in deep sedimentary formations. Geotech. Geol. Eng. 2012, 30, 525–551. [Google Scholar] [CrossRef]

- Hangx, S.; van der Linden, A.; Marcelis, F.; Bauer, A. The effect of CO2 on the mechanical properties of the Captain Sandstone: Geological storage of CO2 at the Goldeneye field (UK). Int. J. Greenh. Gas Control 2013, 19, 609–619. [Google Scholar] [CrossRef]

- Liu, F.; Lu, P.; Griffith, C.; Hedges, S.W.; Soong, Y.; Hellevang, H.; Zhu, C. CO2–brine–caprock interaction: Reactivity experiments on Eau Claire shale and a review of relevant literature. Int. J. Greenh. Gas Control 2012, 7, 153–167. [Google Scholar] [CrossRef]

- Al-Ameri, W.A.; Abdulraheem, A.; Mahmoud, M. Long-term effects of CO2 sequestration on rock mechanical properties. J. Energy Resour. Technol. 2016, 138, 012201. [Google Scholar] [CrossRef]

- Rathnaweera, T.; Ranjith, P.; Perera, M. Experimental investigation of geochemical and mineralogical effects of CO2 sequestration on flow characteristics of reservoir rock in deep saline aquifers. Sci. Rep. 2016, 6, 19362. [Google Scholar] [CrossRef]

- Song, J.; Zhang, D. Comprehensive Review of Caprock-Sealing Mechanisms for Geologic Carbon Sequestration. Environ. Sci. Technol. 2012, 47, 9–22. [Google Scholar] [CrossRef]

- Ozotta, O.; Kolawole, O.; Lamine Malki, M.; Ore, T.; Gentzis, T.; Fowler, H.; Liu, K.; Ostadhassan, M. Nano- to macro-scale structural, mineralogical, and mechanical alterations in a shale reservoir induced by exposure to supercritical CO2. Appl. Energy 2022, 326, 120051. [Google Scholar] [CrossRef]

- An, Q.; Zhang, Q.; Zhang, X.; Li, X.; Yu, H.; Liu, Y. Influence of Mineralogy on Rock Mechanical Behaviour Considering Dynamic Alteration Damage Caused by scCO2: A Comparative Study on Different Rock Types. Rock Mech. Rock Eng. 2022, 55, 3129–3151. [Google Scholar] [CrossRef]

| Experimental Content | Target Hashtag | Measuring Depth (m) | Sample Type | Layer | Sample No. |

|---|---|---|---|---|---|

| Permeability test | J-6 | 905 | Well core | Yuehai Formation Section 3 | A1 |

| 929 | Yuehai Formation Section 3 | A2 | |||

| 1200 | Hanjiang Formation Section 1 | A3 | |||

| 1444 | Hanjiang Formation Section 3 | A4 | |||

| 1467 | Hanjiang Formation Section 3 | A5 | |||

| 1468 | Hanjiang Formation Section 3 | A6 | |||

| Supercritical CO2 breakthrough pressure test | J-6 | 905 | Well core | Yuehai Formation Section 3 | A1 |

| 929 | Yuehai Formation Section 3 | A2 | |||

| 1200 | Hanjiang Formation Section 1 | A3 | |||

| 1444 | Hanjiang Formation Section 1 | A4 | |||

| J-1 | 1677~1687 | Reconstituted the core | Zhujiang 220 caprock | B1 | |

| J-2 | 1684~1690 | Zhujiang 220 caprock | B4 | ||

| 1883~1890 | Zhujiang 420 caprock | B5 | |||

| J-5 | 1609~1625 | Zhujiang 210 caprock | B6 | ||

| 1677~1684 | Zhujiang 220 caprock | B7 | |||

| Uniaxial mechanical properties test | J-1 | 1677~1687 | Reconstituted the core | Zhujiang 220 caprock | B1 |

| 1859~1869 | Zhujiang 420 caprock | B2 | |||

| J-2 | 1583~1638 | Zhujiang 210 caprock | B3 | ||

| 1684~1690 | Zhujiang 220 caprock | B4 | |||

| 1883~1890 | Zhujiang 420 caprock | B5 | |||

| J-5 | 1609~1625 | Zhujiang 210 caprock | B6 | ||

| 1677~1684 | Zhujiang 220 caprock | B7 | |||

| 1858~1868 | Zhujiang 420 caprock | B8 |

| Sample No. | A1 | A2 | A3 | A4 | A5 | A6 |

|---|---|---|---|---|---|---|

| Sampling depth/m | 905 | 929 | 1200 | 1444 | 1467 | 1468 |

| Sampling layer | Yuehai Formation Section 3 | Yuehai Formation Section 3 | Hanjiang Formation Section 1 | Hanjiang Formation Section 3 | Hanjiang Formation Section 4 | Hanjiang Formation Section 4 |

| Calculate the amplitude ratio | 0.1217 | 0.4621 | 0.0082 | 0.85 | 0.8904 | 0.1024 |

| Calculate the phase difference/rad | −1.683 | −1.37 | −2.605 | −0.57 | −0.54 | −1.51 |

| Specific storage rate/10−10 Pa−1 | 0.229 | 1.811 | 0.72 | 0.24 | 1.15 | 0.022 |

| Permeability/mD | 1.6 × 10−3 | 8.64 × 10−3 | 2.41 × 10−6 | 4.93 × 10−2 | 1.97 × 10−1 | 6.72 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Chen, J.; Peng, J.; Ma, Y.; Gan, Q. Investigation of the Sealing and Mechanical Stability of Cap Rock for Offshore CO2 Sequestration in Saline Aquifers. Energies 2025, 18, 6033. https://doi.org/10.3390/en18226033

Li J, Chen J, Peng J, Ma Y, Gan Q. Investigation of the Sealing and Mechanical Stability of Cap Rock for Offshore CO2 Sequestration in Saline Aquifers. Energies. 2025; 18(22):6033. https://doi.org/10.3390/en18226033

Chicago/Turabian StyleLi, Jinsen, Jianye Chen, Jing Peng, Yueqiang Ma, and Quan Gan. 2025. "Investigation of the Sealing and Mechanical Stability of Cap Rock for Offshore CO2 Sequestration in Saline Aquifers" Energies 18, no. 22: 6033. https://doi.org/10.3390/en18226033

APA StyleLi, J., Chen, J., Peng, J., Ma, Y., & Gan, Q. (2025). Investigation of the Sealing and Mechanical Stability of Cap Rock for Offshore CO2 Sequestration in Saline Aquifers. Energies, 18(22), 6033. https://doi.org/10.3390/en18226033