Feasibility and Operability of CO2 Circulation in a CO2 Storage-Enabled Geothermal System with Uncertainty Insights from Aquistore

Abstract

1. Introduction

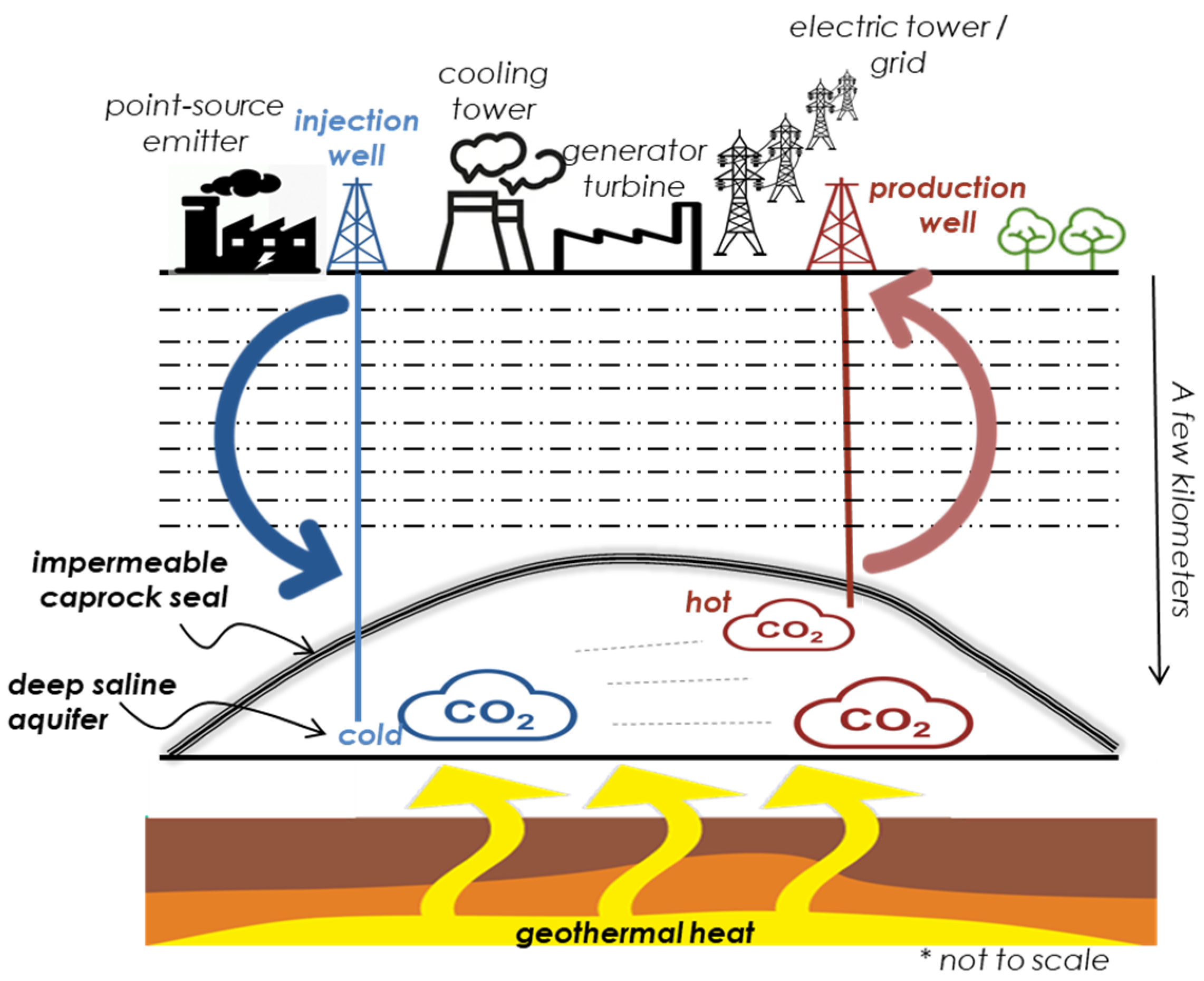

1.1. Background on CCS-Enabled Geothermal Systems

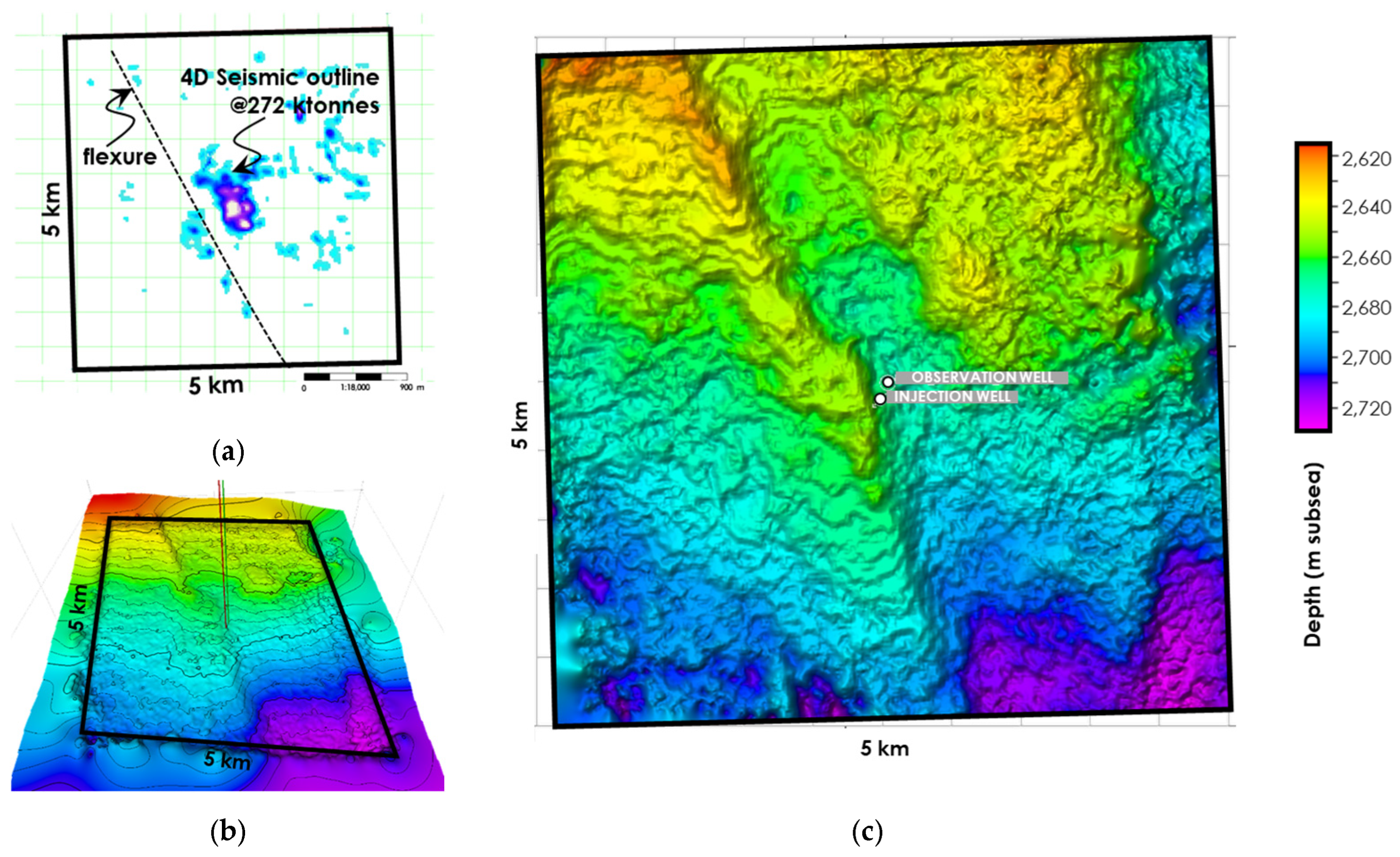

1.2. Overview of Aquistore Site and CO2 Injection History

2. Methodology

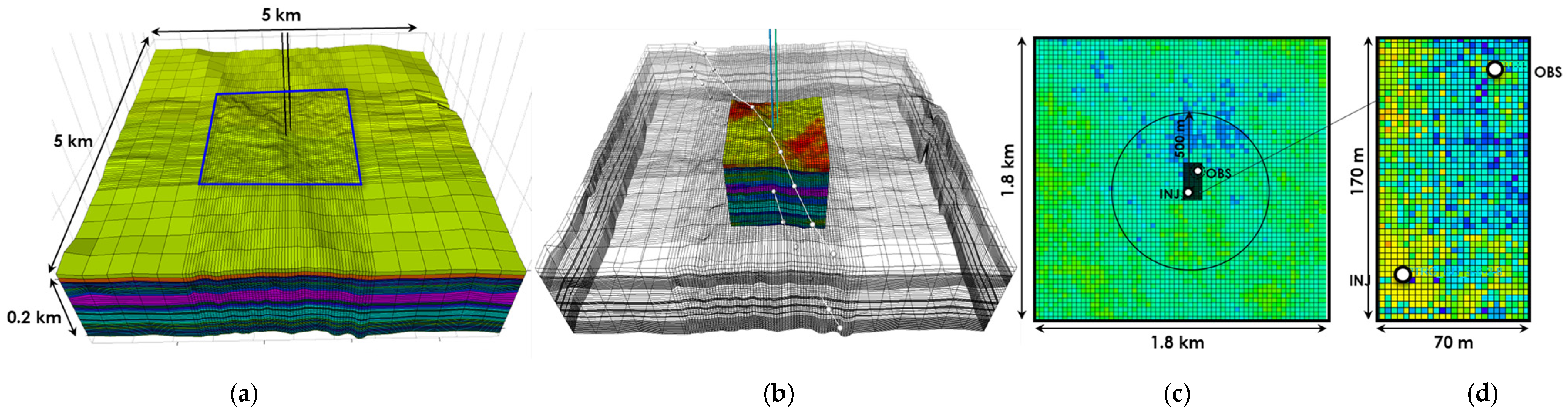

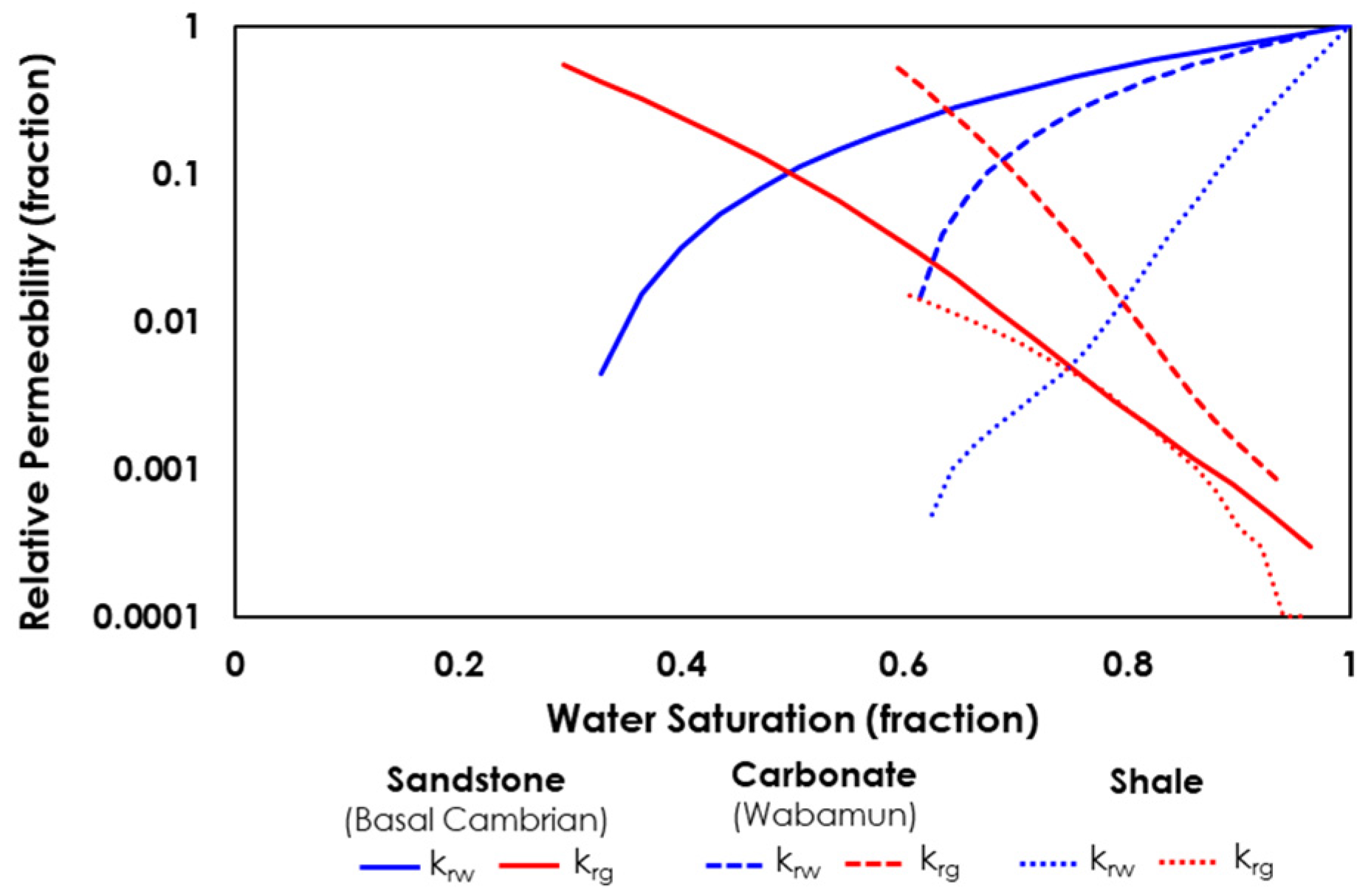

2.1. Geological Modeling Framework and Reconstruction

2.2. Dynamic Simulation Setup

2.3. Uncertainty Analysis

2.4. Wellbore Dynamics and Multiphase Flow Modeling

3. Results

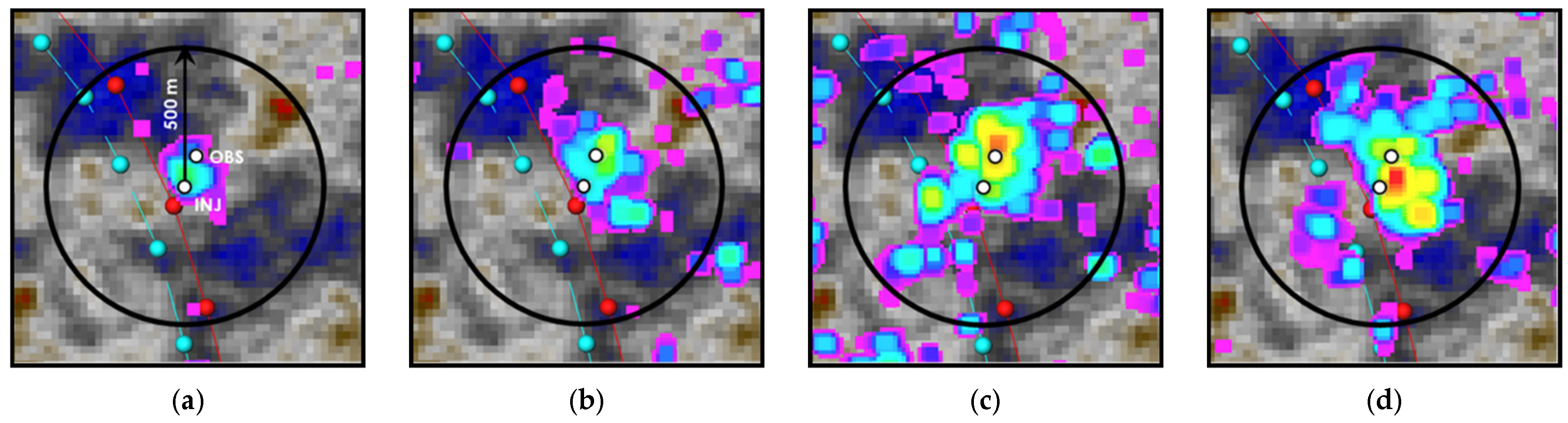

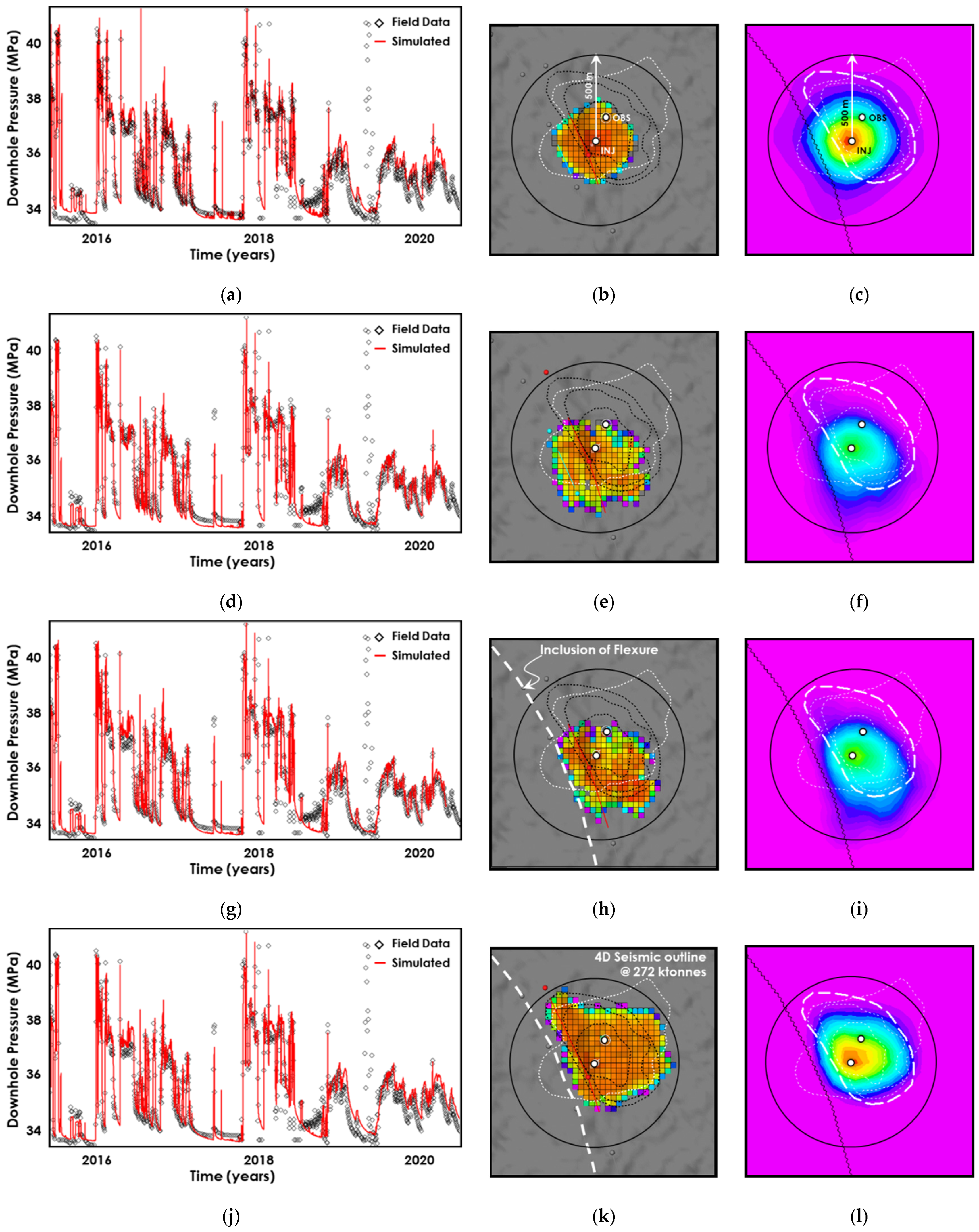

3.1. History Matching and Model Validation Using MMV Constraints

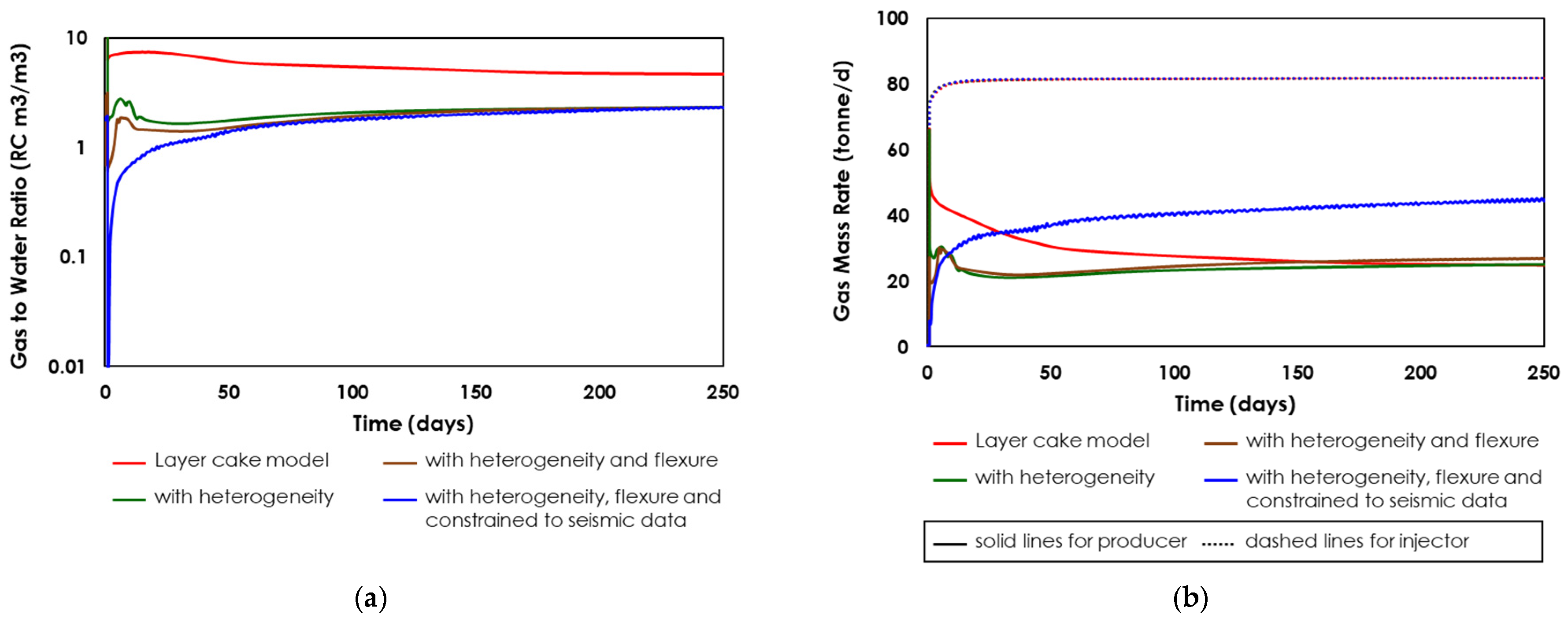

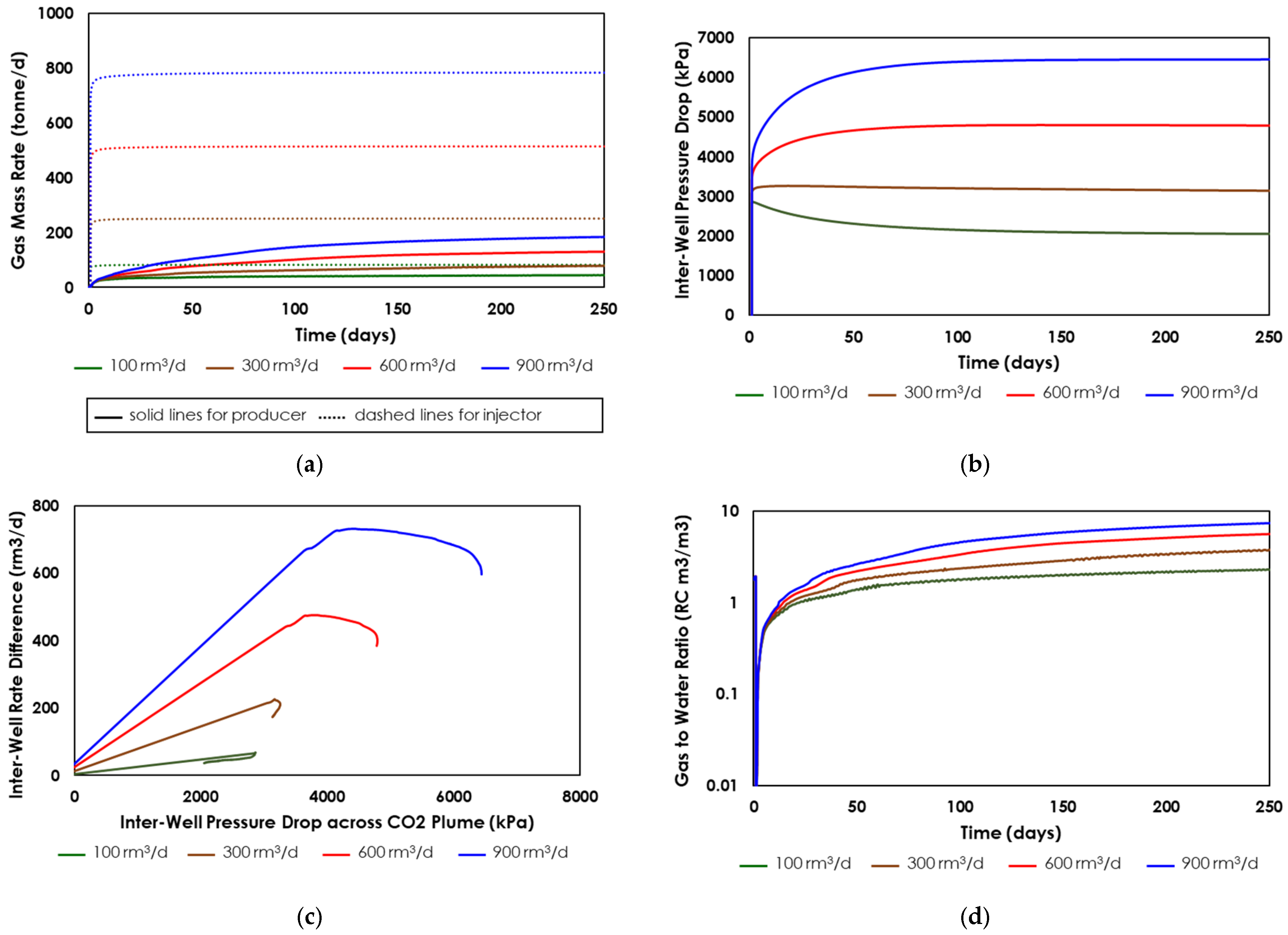

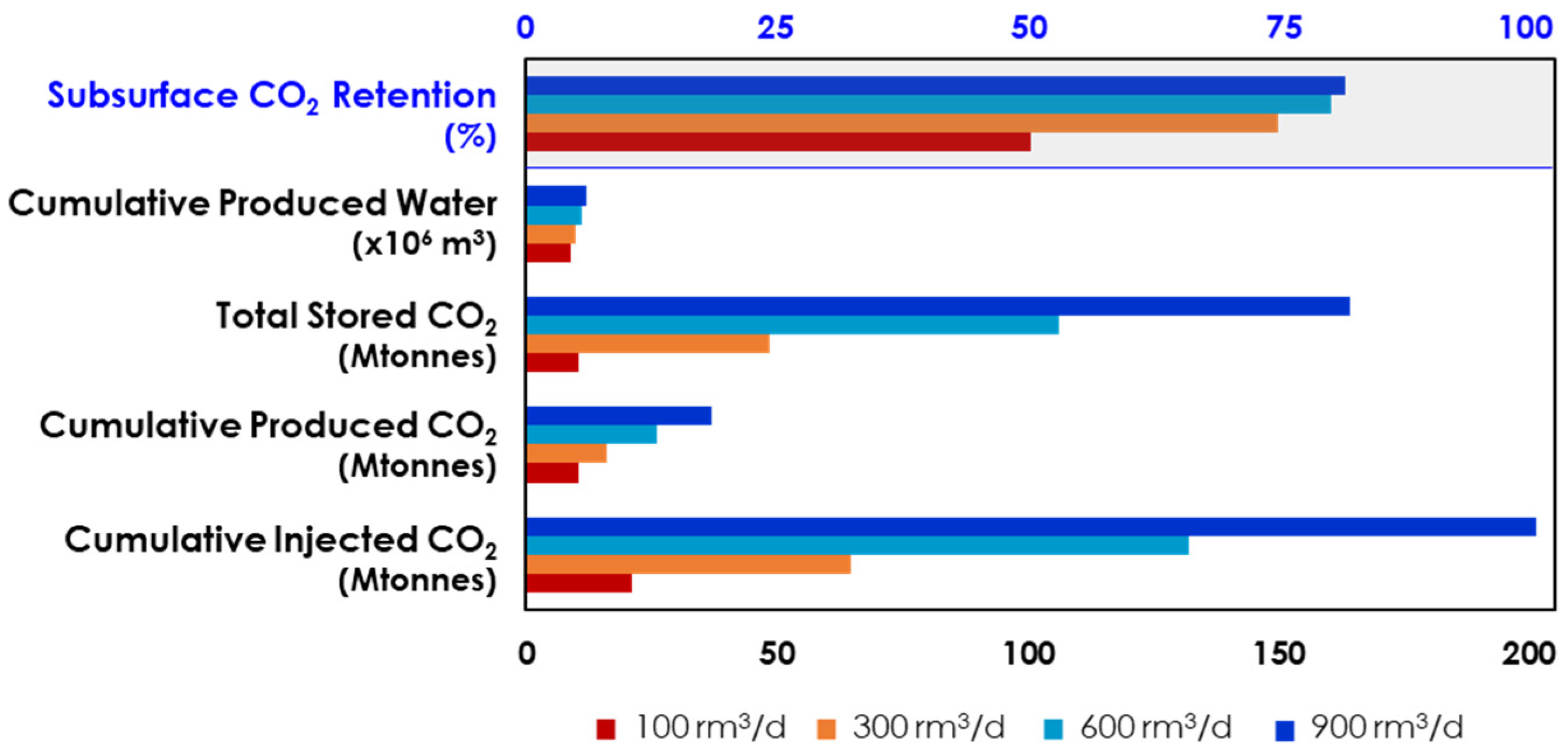

3.2. Base Case CO2 Circulation Test

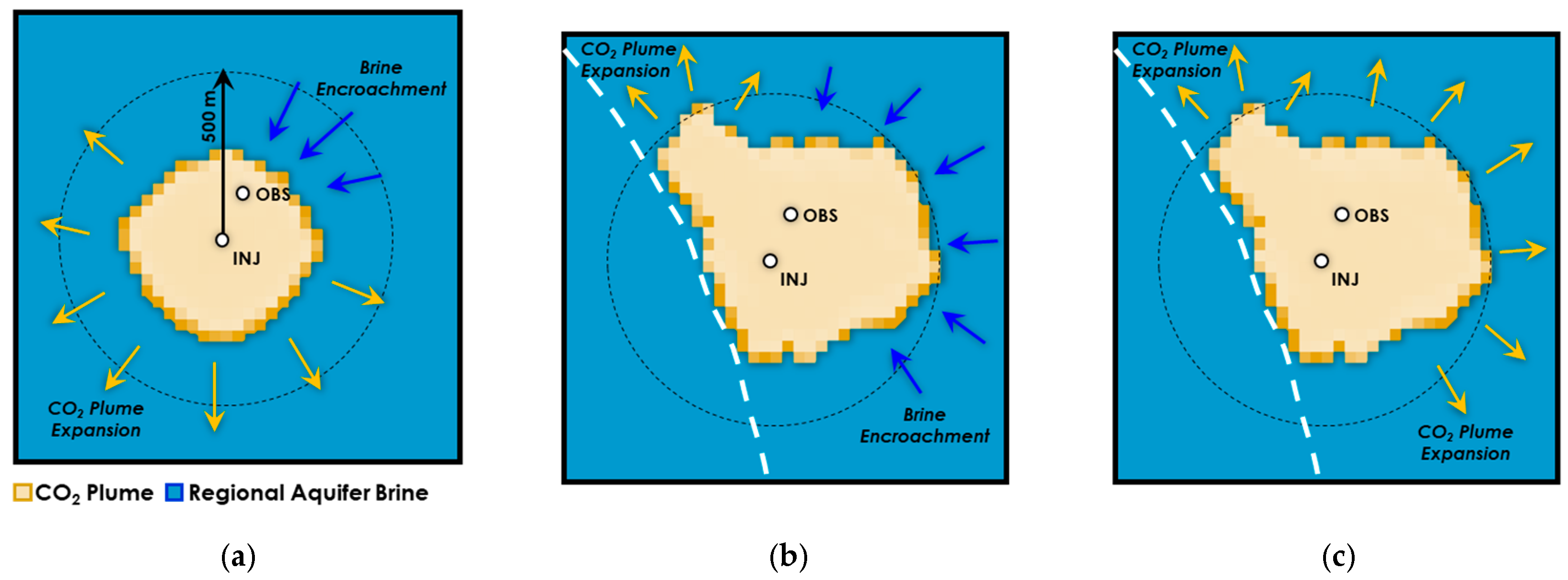

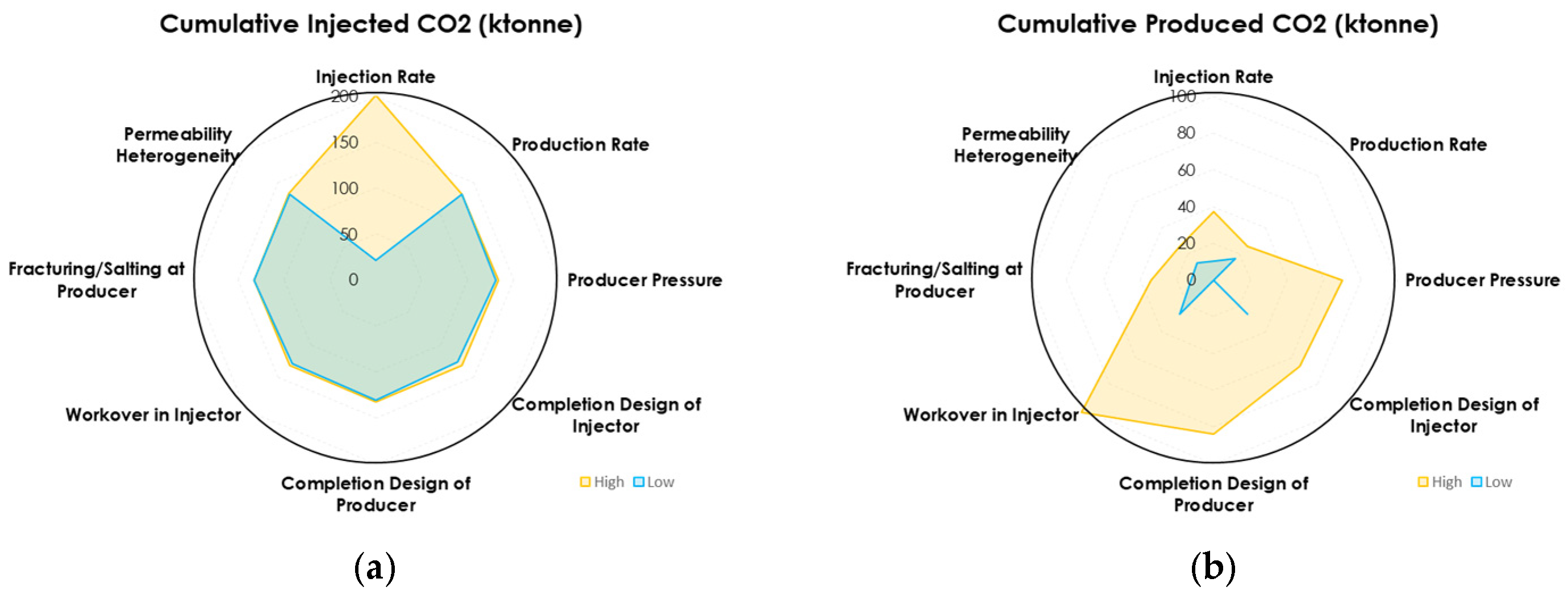

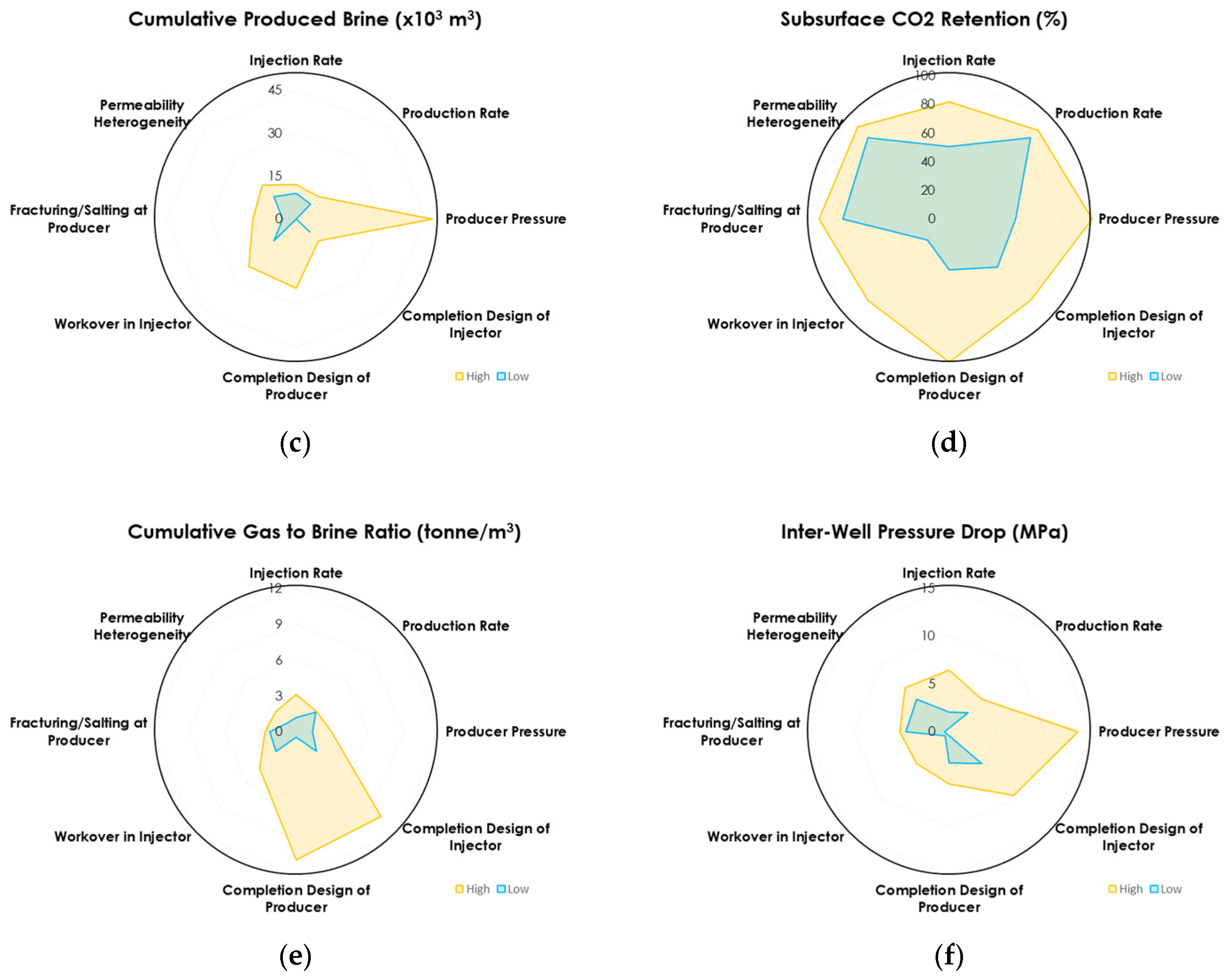

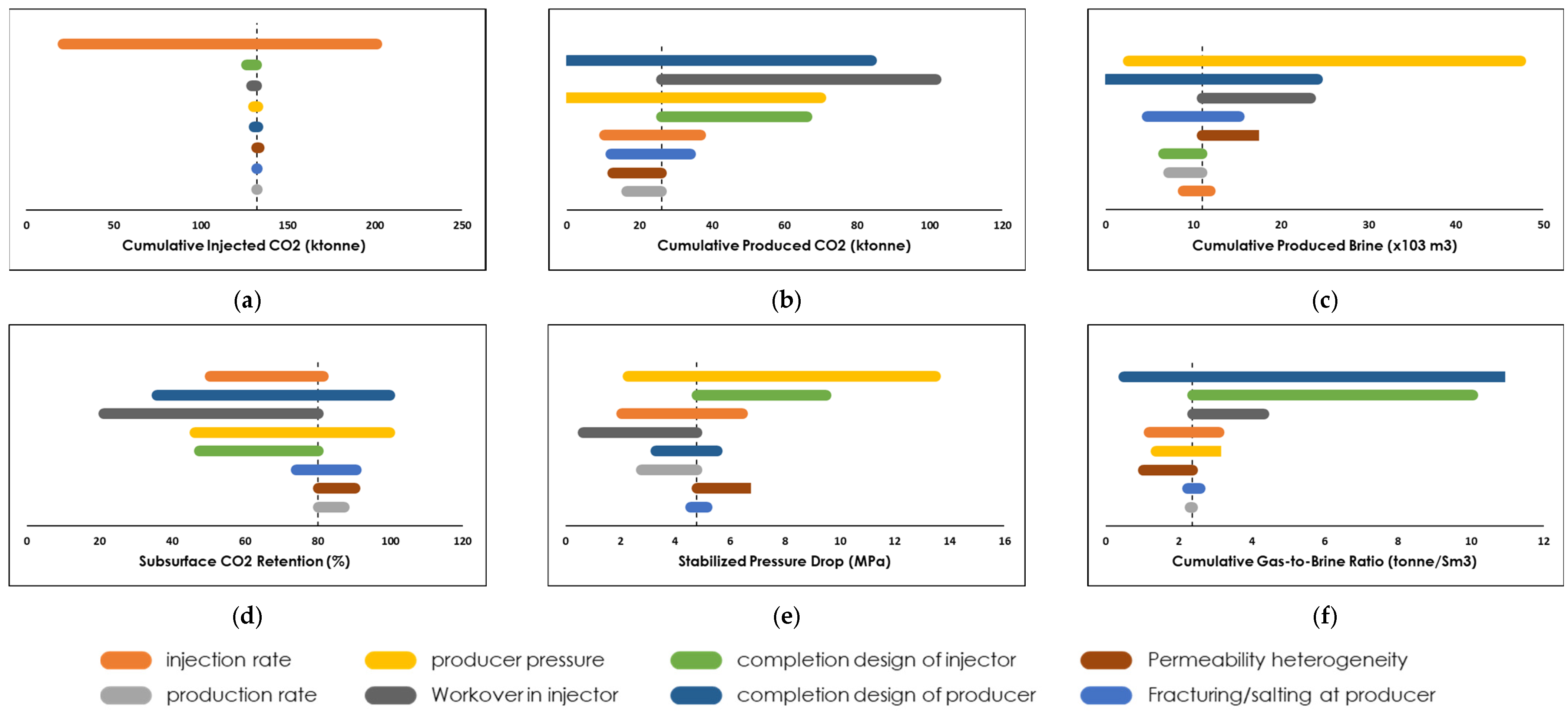

3.3. Dynamic Uncertainty Analysis of the CO2 Circulation Test

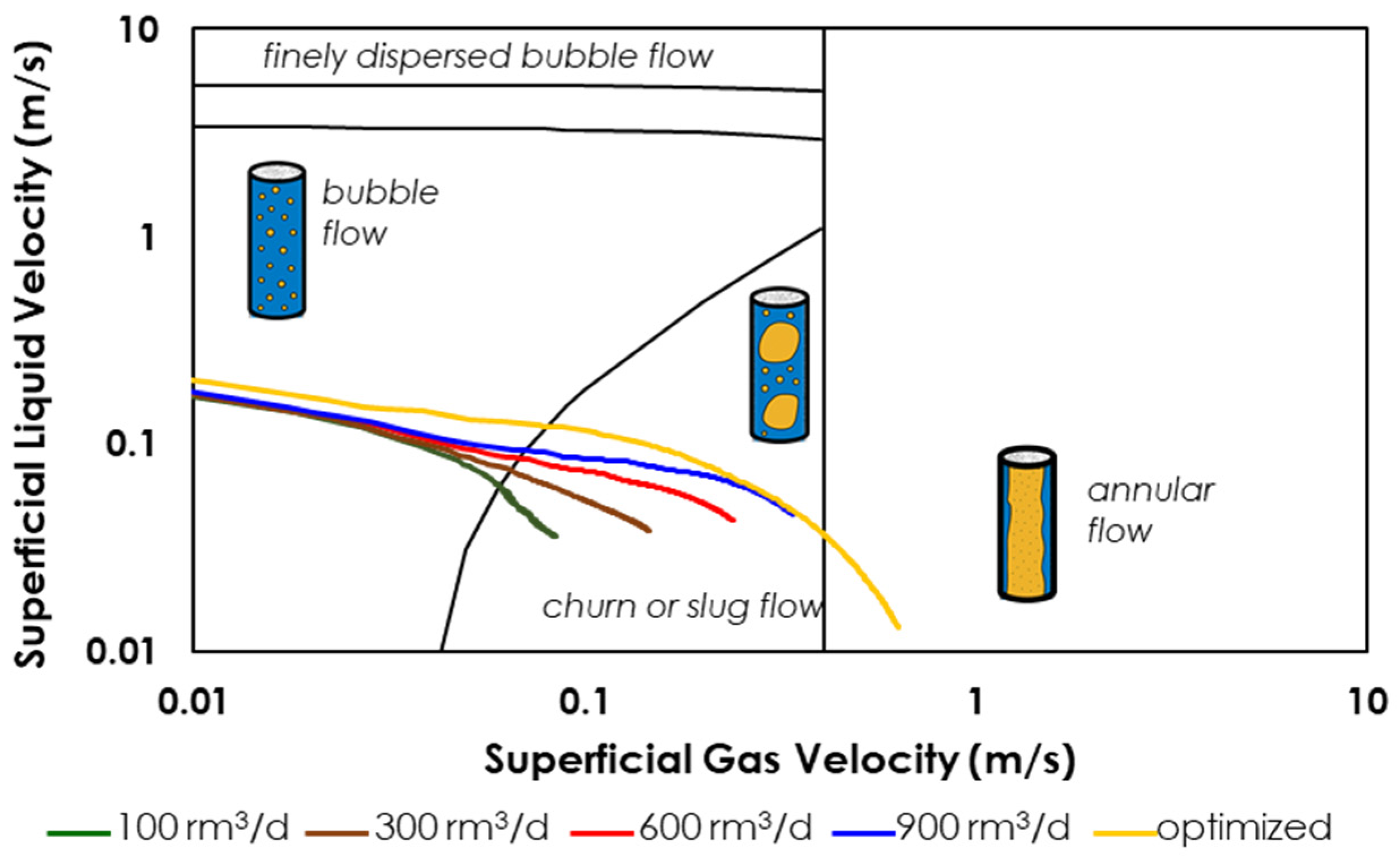

3.4. Operational Implications of Flow Regime Transition in Production Well

4. Discussion and Field Implications

- Brine production is not failure. Early brine breakthrough is transient and manageable. Surface systems must be designed to accommodate initial brine volumes without disrupting operations.

- Flow regime stability is essential. Sustaining annular flow requires precise control of production rates, bottomhole pressure, and completion geometry. Liquid loading remains a primary risk if these factors are misaligned.

- Operational flexibility outweighs limited geological uncertainty. Once the plume spans both wells, permeability variations exert minimal influence. Adaptive well design and pressure control are more impactful than subtle subsurface variability.

- Salt precipitation near the producer, particularly under high drawdown conditions, may contribute to wellbore scaling, reduced injectivity, and long-term flow assurance challenges. These risks highlight the need for near-wellbore management strategies in future CO2 circulation operations.

- Hydrate formation must be anticipated. Preventive measures, including thermal management, chemical inhibition, and flow assurance design are critical, particularly in surface infrastructure and tubing bends where CO2 clathrates may form due to localized drops in pressure and temperature. Although hydrate formation was beyond the scope of this study, thermodynamic screening indicates that such conditions are plausible under both downhole and surface scenarios. Historical evidence from the Cranfield pilot test underscores this concern, where surface-level clathrate formation disrupted flow. If not mitigated, hydrates can restrict tubing capacity, reduce injectivity, and promote secondary effects such as salt precipitation.

- The current well spacing at Aquistore (151 m) appears to balance plume development, pressure, and brine control. While optimal spacing for integrated geothermal systems such as CPG depends on heat extraction and flow recovery, this study focuses solely on circulation feasibility between two existing wells. Future well placement should consider site-specific geology and operational constraints.

5. Conclusions and Remarks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Randolph, J.B.; Saar, M.O. Combining geothermal energy capture with geologic carbon dioxide sequestration. Geophys. Res. Lett. 2011, 38, 1–7. [Google Scholar] [CrossRef]

- Hau, K.P.; Brehme, M.; Shokri, A.R.; Nickel, E.; Malakooti, R.; Chalaturnyk, R.J.; Saar, M.O. CCS Coupled with CO2 Plume Geothermal Operations: Enhancing CO2 Sequestration and Reducing Risks. Geothermics 2025, 133, 103447. [Google Scholar] [CrossRef]

- Nielsen, C.M.; Frykmana, P.; Dalhoffb, F. Synergy benefits in combining CCS and geothermal energy production. Energy Procedia 2013, 37, 2622–2628. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The Influence of Geological Factors and Transmission Fluids on the Exploitation of Reservoir Geothermal Resources: Factor Discussion and Mechanism Analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Movahedzadeh, Z.; Shokri, A.R.; Chalaturnyk, R.J.; Nickel, E.; Sacuta, N. Measurement, Monitoring, Verification and Modelling at the Aquistore CO2 Storage Site. First Break 2021, 39, 69–75. [Google Scholar] [CrossRef]

- Coats, K.H. Geothermal Reservoir Modelling. In SPE Annual Fall Technical Conference and Exhibition; Society of Petroleum Engineers: Denver, CO, USA, 1977; p. 33. [Google Scholar] [CrossRef]

- Brown, D. A Hot Dry Rock geothermal energy concept utilizing supercritical CO2 instead of water. In Proceedings of the Twenty-Fifth Workshop on Geothermal Reservoir Engineering; Stanford University: Stanford, CA, USA, 2000; pp. 233–238. [Google Scholar]

- Schifflechner, C.; de Reus, J.; Schuster, S.; Villasana, A.C.; Brillert, D.; Saar, M.O.; Spliethoff, H. Paving the way for CO2-Plume Geothermal (CPG) systems: A perspective on the CO2 surface equipment. Energy 2024, 305, 132258. [Google Scholar] [CrossRef]

- Shokri, A.R.; Vaisblat, N.; Wigston, A.; Champollion, Y.; Hickson, C.; Chalaturnyk, R.J. Improving the Competitiveness of Geothermal Energy Exploitation through Integrated CO2 Storage in the Western Canadian Sedimentary Basin. GRC Trans. 2022, 46, 2098–2111. [Google Scholar]

- Pruess, K.; Azaroual, M. On the feasibility of using supercritical CO2 as heat transmission fluid in an Engineered Hot Dry Rock Geothermal System. In Proceedings of the Thirty-First Workshop on Geothermal Reservoir Engineering; Stanford University: Stanford, CA, USA, 2006; pp. 386–393. [Google Scholar]

- Xu, T.; Apps, J.A.; Pruess, K. Mineral sequestration of carbon dioxide in a sandstone-shale system. Chem. Geol. 2005, 217, 295–318. [Google Scholar] [CrossRef]

- Ueda, A.; Kato, K.; Ohsumi, T.; Yajima, T.; Ito, H.; Kaieda, H.; Meycalf, R.; Takase, H. Experimental studies of CO2-rock interaction at elevated temperatures under hydrothermal conditions. Geochem. J. 2005, 39, 417–425. [Google Scholar] [CrossRef]

- Zhang, L.; Cui, G.; Zhang, Y.; Ren, B.; Ren, S.; Wang, X. Influence of pore water on the heat mining performance of supercritical CO2 injected for geothermal development. J. CO2 Util. 2016, 16, 287–300. [Google Scholar] [CrossRef]

- Atrens, A.; Gurgenci, H.; Rudolph, V. Exergy analysis of a CO2 thermosiphon. In Proceedings of the Thirty-Fourth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 9–11 February 2009; pp. 1–6. [Google Scholar]

- Pruess, K. On production behavior of enhanced geothermal systems with CO2 as working fluid. Energy Convers. Manag. 2008, 49, 1446–1454. [Google Scholar] [CrossRef]

- Randolph, J.B.; Adams, B.; Kuehn, T.H.; Saar, M.O. Wellbore heat transfer in CO2-based geothermal systems. Geotherm Resour Counc. Trans. 2012, 36, 549–554. [Google Scholar]

- Hau, K.P.; Shokri, A.R.; Chalaturnyk, R.J.; Saar, M.O. On the Suitability of the Aquistore CCS-site for a CO2-Circulation Test. In Proceedings of the World Geothermal Congress, Reykjavik, Iceland, 21–26 May 2021. [Google Scholar]

- Garapati, N.; Randolph, J.B.; Saar, M.O. Brine displacement by CO2, energy extraction rates, and lifespan of a CO2-limited CO2-Plume Geothermal (CPG) system with a horizontal production well. Geothermics 2015, 55, 182–194. [Google Scholar] [CrossRef]

- Adams, B.M.; Kuehn, T.H.; Bielicki, J.M.; Randolph, J.B.; Saar, M.O. A comparison of electric power output of CO2 Plume Geothermal (CPG) and brine geothermal systems for varying reservoir conditions. Appl. Energy 2015, 140, 365–377. [Google Scholar] [CrossRef]

- Adams, B.M.; Kuehn, T.H.; Bielicki, J.M.; Randolph, J.B.; Saar, M.O. On the importance of the thermosiphon effect in CPG (CO2 plume geothermal) power systems. Energy 2014, 69, 409–418. [Google Scholar] [CrossRef]

- Randolph, J.B.; Saar, M.O. Coupling carbon dioxide sequestration with geothermal energy capture in naturally permeable, porous geologic formations: Implications for CO2 sequestration. Energy Procedia 2011, 4, 2206–2213. [Google Scholar] [CrossRef]

- Ezekiel, J.; Ebigbo, A.; Adams, B.M.; Saar, M.O. Combining natural gas recovery and CO2- based geothermal energy extraction for electric power generation. Appl. Energy 2020, 269, 115012. [Google Scholar] [CrossRef]

- Levy, E.K.; Wang, X.; Pan, C.; Romero, C.E.; Maya, C.R. Use of hot supercritical CO2 produced from a geothermal reservoir to generate electric power in a gas turbine power generation system. J. CO2 Util. 2018, 23, 20–28. [Google Scholar] [CrossRef]

- Delshad, M.; Kong, X.; Tavakoli, R.; Hosseini, S.A.; Wheeler, M.F. “Modeling and simulation of carbon sequestration at Cranfield incorporating new physical models. Int. J. Greenh. Gas Control 2013, 18, 463–473. [Google Scholar] [CrossRef]

- Hovorka, S.D.; Meckel, T.A.; Trevino, R.H. Monitoring a large-volume injection at Cranfield, Mississippi—Project design and recommendations. Int. J. Greenh. Gas Control 2013, 18, 345–360. [Google Scholar] [CrossRef]

- Fleming, M.R.; Adams, B.M.; Kuehn, T.H.; Bielicki, J.M.; Saar, M.O. Increased Power Generation due to Exothermic Water Exsolution in CO2 Plume Geothermal (CPG) Power Plants. Geothermics 2020, 88, 101865. [Google Scholar] [CrossRef]

- Pan, L.; Doughty, C.; Freifeld, B. How to sustain a CO2-thermosiphon in a partially saturated geothermal reservoir: Lessons learned from field experiment and numerical modeling. Geothermics 2018, 71, 274–293. [Google Scholar] [CrossRef]

- Pan, L.; Doughty, C.; Freifeld, B.; Oldenburg, C. Modeling a CO2 thermosiphon in a partially saturated reservoir using EOS7CMA. In Proceedings of the TOUGH Symposium 2015, Lawrence Berkeley National Laboratory, Berkeley, CA, USA, 28–30 September 2015. [Google Scholar]

- Freifeld, B.M.; Pan, L.; Doughty, C.; Zakem, S.; Hart, K.; Hostler, S. Demonstration of Geothermal Energy Production Using Carbon Dioxide as a Working Fluid at the SECARB Cranfield Site, Cranfield, Mississippi. In Proceedings of the 41st Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 22–24 February 2016; pp. 1–14. [Google Scholar]

- Hau, K.P. Feasibility of a CO2 Plume Geothermal (CPG) Pilot at the Aquistore (Canada) CCS site. Master’s Thesis, ETH Zürich, Zurich, Switzerland, 2020. [Google Scholar]

- White, D.J.; Hawkes, C.D.; Rostron, B.J. Geological characterization of the Aquistore CO2 storage site from 3D seismic data. Int. J. Greenh. Gas Control 2016, 54, 330–344. [Google Scholar] [CrossRef]

- Rostron, B.; White, D.J.; Hawkes, C.D.; Chalaturnyk, R.J. Characterization of the Aquistore CO2 project storage site, Saskatchewan, Canada. Energy Procedia 2014, 63, 2977–2984. [Google Scholar] [CrossRef]

- Peck, W.D.; Bailey, T.P.; Liu, G.; Klenner, R.C.L.; Gorecki, C.D.; Ayash, S.C.; Steadman, E.N.; Harju, J.A. Model Development of the Aquistore CO2 Storage Project. Energy Procedia 2014, 63, 3723–3734. [Google Scholar] [CrossRef]

- Talman, S.; Shokri, A.R.; Zambrano, G.; Chalaturnyk, R.J.; Nickel, E. Anomalous Start-Up Pressure Signals of a Bubble-Tube System for Downhole Pressure Determination at the Aquistore CO2 Injection Site. In Proceedings of the 16th Greenhouse Gas Control Technologies Conference (GHGT-16), Lyon, France, 23–24 October 2022. [Google Scholar] [CrossRef]

- Shokri, A.R.; Talman, S.; Chalaturnyk, R.J.; Nickel, E. On the Temporal Evolution of Non-Isothermal Injectivity Behaviour at an Active CO2 Injection Site. In Proceedings of the 55th US Rock Mechanics Geomechanics Symposium, Houston, TX, USA, 20–23 June 2021. [Google Scholar]

- Shokri, A.R.; Chalaturnyk, R.J.; Nickel, E. Non-Isothermal Injectivity Considerations for Effective Geological Storage of CO2 at the Aquistore Site, Saskatchewan, Canada. In SPE 196118-MS, SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Richardson, TX, USA, 2019. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Swager, L.; Pekot, L.; Piercey, M.; Will, R.; Zaluski, W. Study of operational dynamic data in Aquistore project. Int. J. Greenh. Gas Control 2018, 76, 62–77. [Google Scholar] [CrossRef]

- Talman, S.; Shokri, A.R.; Chalaturnyk, R.J.; Nickel, E. Salt Precipitation at an Active CO2 Injection Site. In Gas Injection into Geological Formations and Related Topics; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2020; pp. 183–199. [Google Scholar] [CrossRef]

- Schlumberger. Aquistore 3D—Seismic AVO Inversion and Lithology Prediction Report, PTRC Internal Report from Schlumberger; PTRC: State College, PA, USA, 2018; 34p. [Google Scholar]

- White, D.J. Prestack AVO Inversion Footprint Removal. In Aquistore Internal Report; PTRC: State College, PA, USA, 2018; 8p. [Google Scholar]

- Marfurt, K.J.; Scheet, R.M.; Sharp, J.A.; Harper, M.G. Suppression of the acquisition footprint for seismic sequence attribute mapping. Geophysics 1998, 63, 1024–1035. [Google Scholar] [CrossRef]

- White, D.J. 3D architecture of the Aquistore reservoir: Implications for CO2 flow and storage capacity. Interna-Tional J. Greenh. Gas Control 2018, 71, 74–85. [Google Scholar] [CrossRef]

- Batzle, M.; Wang, Z. Seismic properties of pore fluids. Geophysics 1992, 57, 1396–1408. [Google Scholar] [CrossRef]

- White, D.J.; Harris, K.; Roach, L.; Robertson, M. 7 years of 4D seismic monitoring at the Aquistore CO2 storage site, Saskatchewan, Canada. In Proceedings of the SEG International Exposition and Annual Meeting, San Antonio, TX, USA, 15–20 September 2019. [Google Scholar] [CrossRef]

- Xu, L.; Shokri, A.R.; Chalaturnyk, R. Implications of Structural Flexure on CO2 Plume Distribution and Long-Term Reservoir Deformation in the Canadian Aquistore CCS Project. J. Rock Mech. Geotech. Eng. 2026, in press. [Google Scholar]

- Peng, D.Y.; Robinson, D.B. A New Two-Constant Equation of State. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Zurita, R.A.A.; McCain, W.D. An efficient tuning strategy to calibrate cubic EOS for compositional simulation. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002. [Google Scholar] [CrossRef]

- Paterson, L. Geological storage of CO2: Mechanisms and performance assessment. In Carbon Capture and Storage: Technologies and Global Contributions; Benson, S., Gale, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 145–168. [Google Scholar] [CrossRef]

- Harvey, A. Semiempirical Correlation for Henry’s Constants over Large Temperature Ranges. Am. Inst. Chem. Eng. J. 1996, 42, 1491–1494. [Google Scholar] [CrossRef]

- Rowe, A.M.; Chou, J.C.S. Pressure–Volume–Temperature-Concentration Relation of Aqueous NaCl Solutions. J. Chem. Eng. Data 1970, 15, 61–66. [Google Scholar] [CrossRef]

- Kestin, J.; Khalifa, H.E.; Correia, R.J. Tables of Dynamic and Kinematic Viscosity of Aqueous NaCl Solutions in the Temperature Range 20–150 °C and the Pressure Range 0.1–35 MPa. J. Phys. Chem. Ref. Data 1981, 10, 71–87. [Google Scholar] [CrossRef]

- Bachu, S.; Adams, J. Sequestration of CO2 in Geological Media in Response to Climate Change—Capacity of Deep Saline Aquifers to Sequester CO2 in Solution. Energy Convers. Manag. 2003, 44, 3151–3175. [Google Scholar] [CrossRef]

- Bachu, S.; Faltinson, J.; Hauck, T.; Perkins, E.; Peterson, J.; Talman, S.; Jensen, G. The Basal Aquifer in the Prairie Region of Canada—Characterization for CO2 Storage. Preliminary Report for Stage I (Phases 1 and 2); Alberta Innovates Technology Futures: Edmonton, AB, Canada, 2011.

- Bennion, D.B.; Bachu, S. Supercritical CO2 and H2S Brine Drainage and Imbibition Relative Permeability Relationships for Integral Sandstone and Carbonate Formations. In Proceedings of the Society of Petroleum Engineers Paper SPE 99326, SPE Europec/Eage Annual Conference and Exhibition, Vienna, Austria, 12–15 June 2006. [Google Scholar]

- Kurz, M.; Heebink, L.; Smith, S.; Zacher, E. Petrophysical Evaluation of Core from the Aquistore CO2 Injection Site. In Plains CO2 Reduction (PCOR) Partnership Value-Added Report for U.S. Department of Energy National Energy Technology Laboratory Cooperative Agreement No. DE-FC26-05NT42592, EERC Publication 2014-EERC-07-16; Energy & Environmental Research Center: Grand Forks, North Dakota, 2014. [Google Scholar]

- Jiang, T.; Pekot, L.J.; Jin, L.; Peck, W.D.; Gorecki, C.D. Geological Modeling and Simulation Report for the Aquistore Project. In The Plains CO2 Reduction (PCOR) Partnership Phase III, Task 1—Deliverable D93, Update 2; National Energy Technology Laboratory: Albany, Oregon, 2016. [Google Scholar]

- Roach, L.; White, D.J. Evolution of a deep CO2 plume from time-lapse seismic imaging at the Aquistore storage site, Saskatchewan, Canada. Int. J. Greenh. Gas Control 2018, 74, 79–86. [Google Scholar] [CrossRef]

- Ezekiel, J.; Adams, B.M.; Saar, M.O.; Ebigbo, A. Numerical analysis and optimization of the performance of CO2-Plume Geothermal (CPG) production wells and implications for electric power generation. Geothermics 2022, 98, 102270. [Google Scholar] [CrossRef]

- Taitel, Y.; Bornea, D.; Dukler, A.E. Modelling flow pattern transitions for steady upward gasliquid flow in vertical tubes. AIChE J. 1980, 26, 345–354. [Google Scholar] [CrossRef]

- Pereira, L.M.C.; Chapoy, A.; Burgass, R.; Tohidi, B. Interfacial tension of CO2 + brine systems: Experiments and predictive modelling. Adv. Water Resour. 2017, 103, 64–75. [Google Scholar] [CrossRef]

- Bachu, S.; Bennion, D.B. Interfacial Tension between CO2, Freshwater, and Brine in the Range of Pressure from (2 to 27) MPa, Temperature from (20 to 125) °C, and Water Salinity from (0 to 334 000) mg·L−1. J. Chem. Eng. Data 2009, 54, 765–775. [Google Scholar] [CrossRef]

- Pruess, K.; Garcia, J.E. Multiphase flow dynamics during CO2 injection into saline aquifers. Environ. Geol. 2002, 42, 282–295. [Google Scholar] [CrossRef]

- Khalaf, M.S.; Rezaei, A.; Soliman, M.Y.; Farouq Ali, S.M. Thermo-Poroelastic Analysis of Cold Fluid Injection in Geothermal Reservoirs for Heat Extraction Sustainability. In Proceedings of the 56th U.S. Rock Mechanics/Geomechanics Symposium, Santa Fe, NM, USA, 26 June 2022. [Google Scholar] [CrossRef]

| Experimental Variogram Computation | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Direction | Azimuth | Dip | Number lags | Lag distance | Search radius | Band width | Tolerance angle | Lag tolerance | Thickness |

| Vertical | NA | 90 | 8 | 25 | 200 | 50 | 45 | 50 | NA |

| Major | 0 | 0 | 8 | 250 | 2000 | 200 | 45 | 50 | 0.001 |

| Minor | 270 | 0 | 8 | 250 | 2000 | 200 | 45 | 50 | 0.001 |

| Variogram Model Fitting | |||||||||

| Type | Sill | Major range | Minor range | Vertical range | Nugget | ||||

| Spherical | 0.999 | 500 | 500 | 100 | 0.001 | ||||

| Category | Parameter | Value/Assumption |

|---|---|---|

| Reservoir | Initial reservoir pressure (kPa) | 34,129.05 at 3173 m MD |

| Pore pressure gradient (kPa/m) | 10.7 | |

| Initial reservoir temperature (°C) | 112.8 at 3173 m MD | |

| Initial water saturation (fraction) | 1 | |

| Brine salinity (ppm) | 300,000 | |

| Porosity range (fraction) | 0.002–0.105 | |

| Permeability range (mD) | 0–55 | |

| Permeability anisotropy (kv/kh) | 0.1 | |

| Reservoir boundary | Analytic infinite-acting aquifer | |

| Injection well | Max. downhole injection pressure (MPa) | 42.5 (95% of fracturing pressure) |

| CO2 injection rate (rm3/d) * | 600 (5-yr avg. max. injection rate) | |

| Downhole injection temperature (°C) | 70 (5-yr avg. injection temperature) | |

| Perforated intervals | All 4 intervals open | |

| CO2 circulation period (months) | 9 | |

| Production well | Min. downhole production pressure (MPa) | 33 |

| Max. CO2 production rate (rm3/d) * | 300 (consistent with 0.11 m ID tubing) | |

| Perforated interval | 2nd interval only (highest permeability) | |

| Additional assumptions | No fracturing and no salt precipitation around the production well |

| Uncertain Variables | Base Values | Variability Limits |

|---|---|---|

| Injection rate at injector (rm3/d) * | 600 | 100 to 900 |

| Downhole pressure at producer (MPa) | 33 | 23 to 39 MPa |

| Production rate at producer (rm3/d) * | 300 | 100 to 900 |

| Completion configurations—injector | All 4 perforated intervals | All 4 vs. 2nd interval only |

| Completion configuration—producer | 2nd perforated interval | All 4 intervals; individual interval only (1st through 4th); single layer of 2nd interval (layers 1 to 6) |

| Fracturing/salt precipitation at producer (S) | 0 (=intact) | −2 (=fractured); 0 (=intact); +2 (=slight salt); +10 (=moderate salt) |

| Localized permeability heterogeneity | Realization 0 | 8 stochastic realizations |

| Post-workover injectivity gain | 1× (=intact formation) | 10–100× enhanced permeability zone |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rangriz Shokri, A.; Chalaturnyk, R. Feasibility and Operability of CO2 Circulation in a CO2 Storage-Enabled Geothermal System with Uncertainty Insights from Aquistore. Energies 2025, 18, 6031. https://doi.org/10.3390/en18226031

Rangriz Shokri A, Chalaturnyk R. Feasibility and Operability of CO2 Circulation in a CO2 Storage-Enabled Geothermal System with Uncertainty Insights from Aquistore. Energies. 2025; 18(22):6031. https://doi.org/10.3390/en18226031

Chicago/Turabian StyleRangriz Shokri, Alireza, and Rick Chalaturnyk. 2025. "Feasibility and Operability of CO2 Circulation in a CO2 Storage-Enabled Geothermal System with Uncertainty Insights from Aquistore" Energies 18, no. 22: 6031. https://doi.org/10.3390/en18226031

APA StyleRangriz Shokri, A., & Chalaturnyk, R. (2025). Feasibility and Operability of CO2 Circulation in a CO2 Storage-Enabled Geothermal System with Uncertainty Insights from Aquistore. Energies, 18(22), 6031. https://doi.org/10.3390/en18226031