Method for Interpreting In Situ Stress Based on Pump Shutdown Pressure Drop Curves in Deep Coal Seams

Abstract

1. Introduction

2. Basic Principles of the G-Function

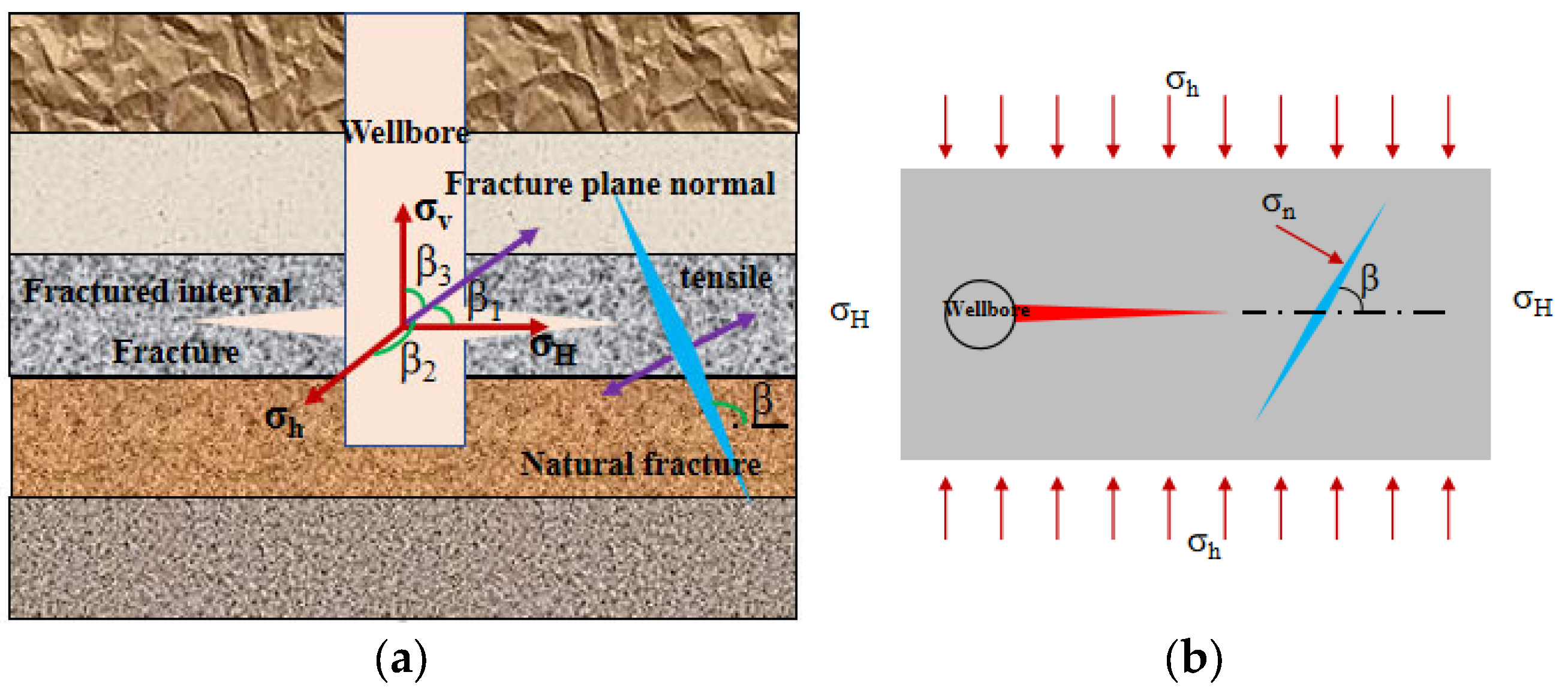

2.1. Relationship Between Closure Pressure and Horizontal Stress

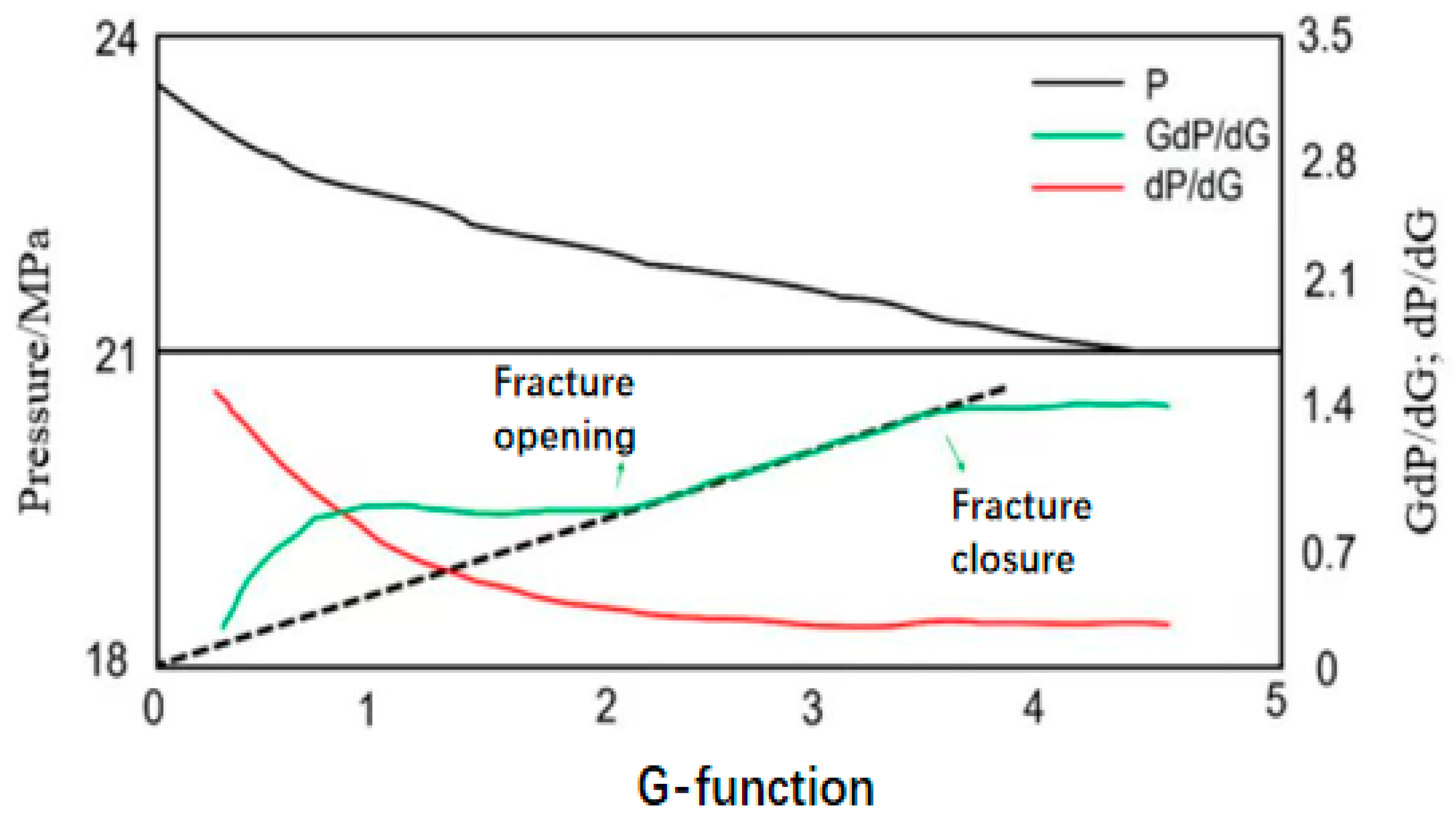

2.2. G-Function Method for Identifying Closure Point

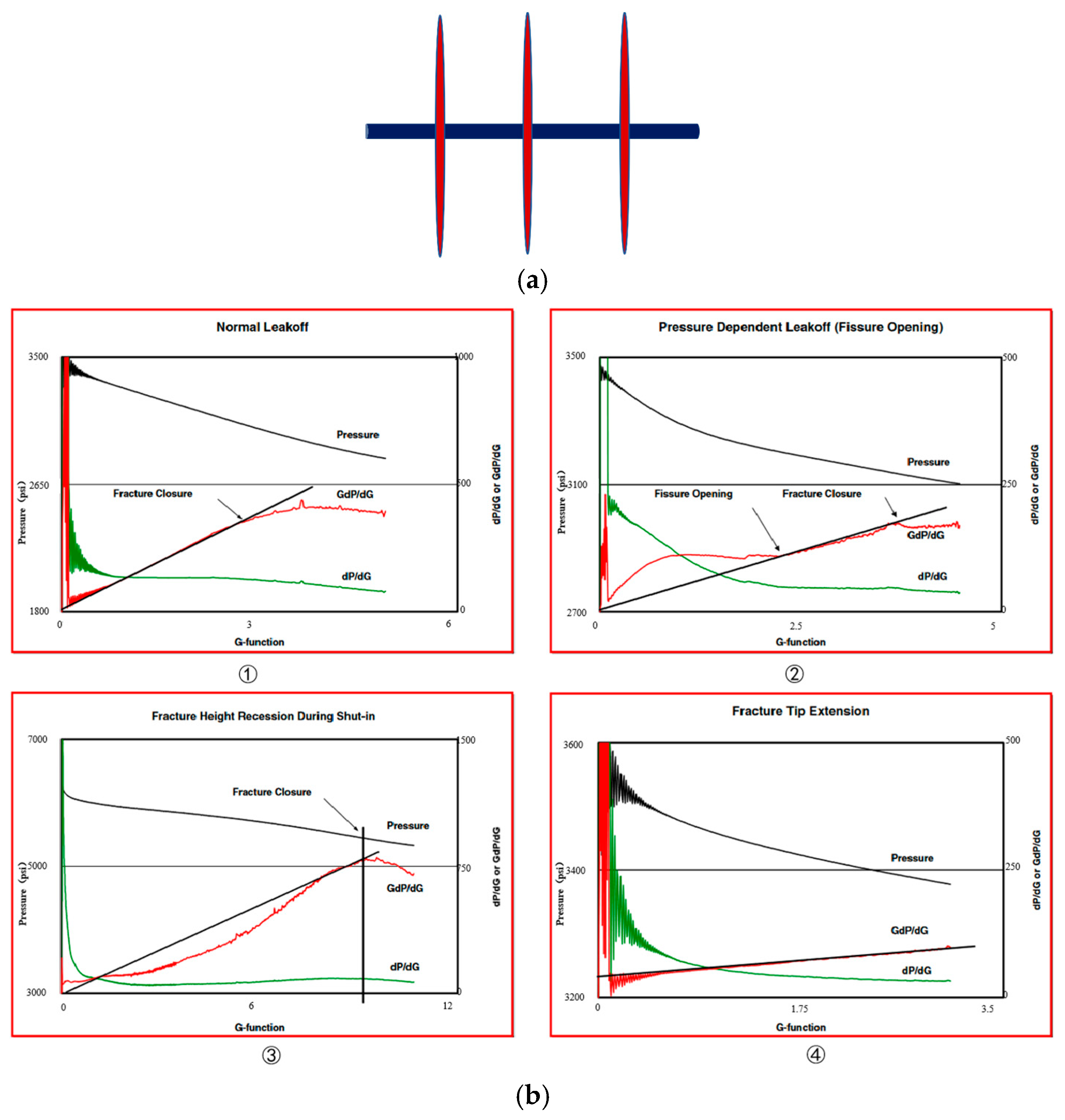

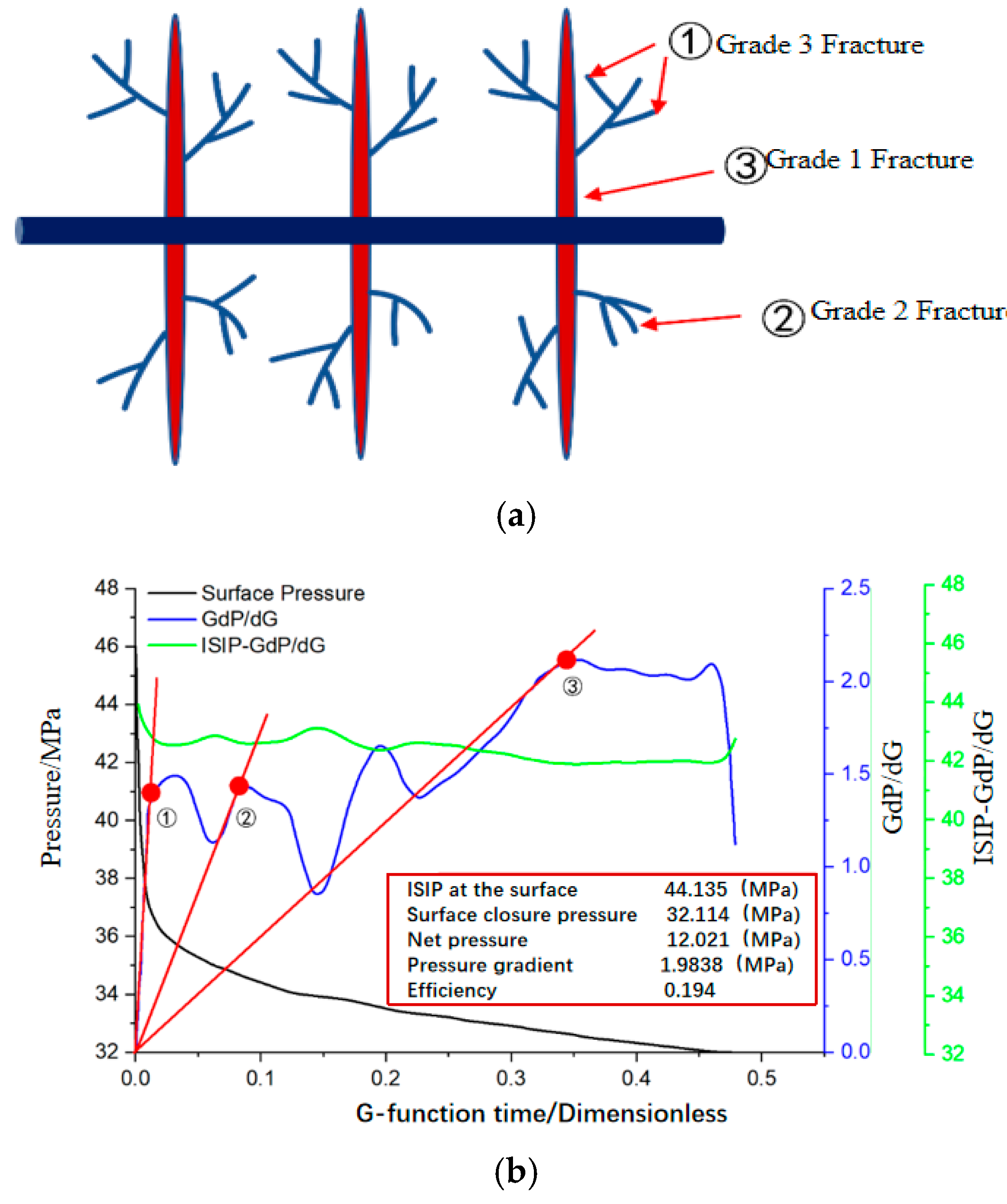

2.3. Identification of Closure Points for Fractures of Different Complexity

2.3.1. Conventional Fractures

2.3.2. Moderately Complex Fractures

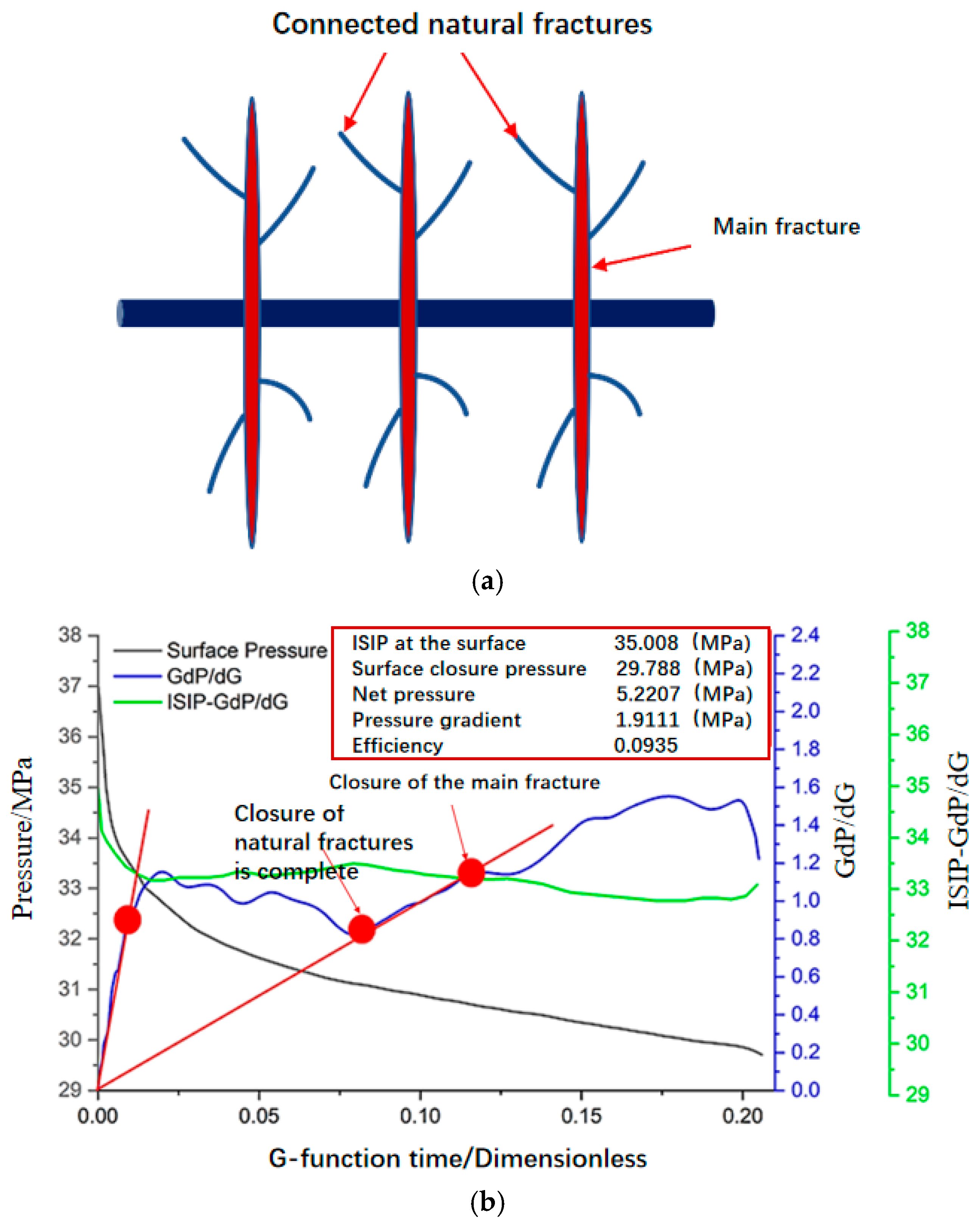

2.3.3. Complex Fractures

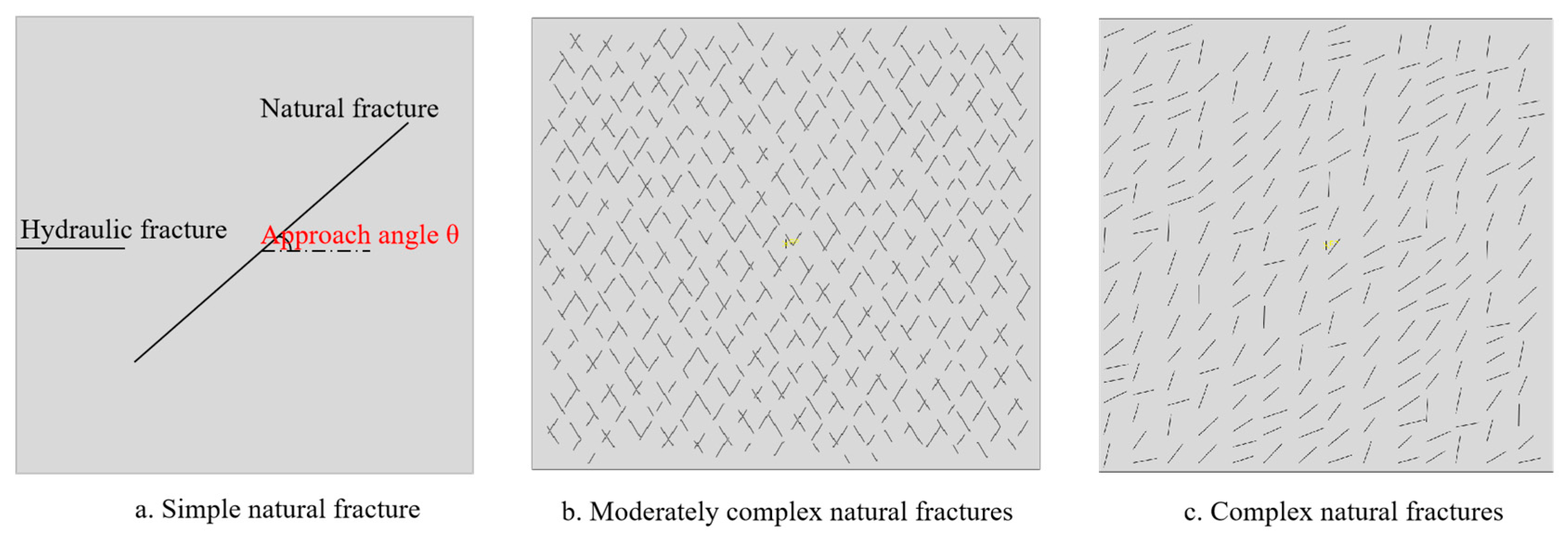

3. Numerical Simulation of Shut-In Pressure Decline for Natural Fracture Networks of Different Complexity

3.1. Model Setup

3.2. Model Parameters

3.2.1. Boundary Conditions

3.2.2. Basic Mechanical Parameters

3.3. Simulation Results

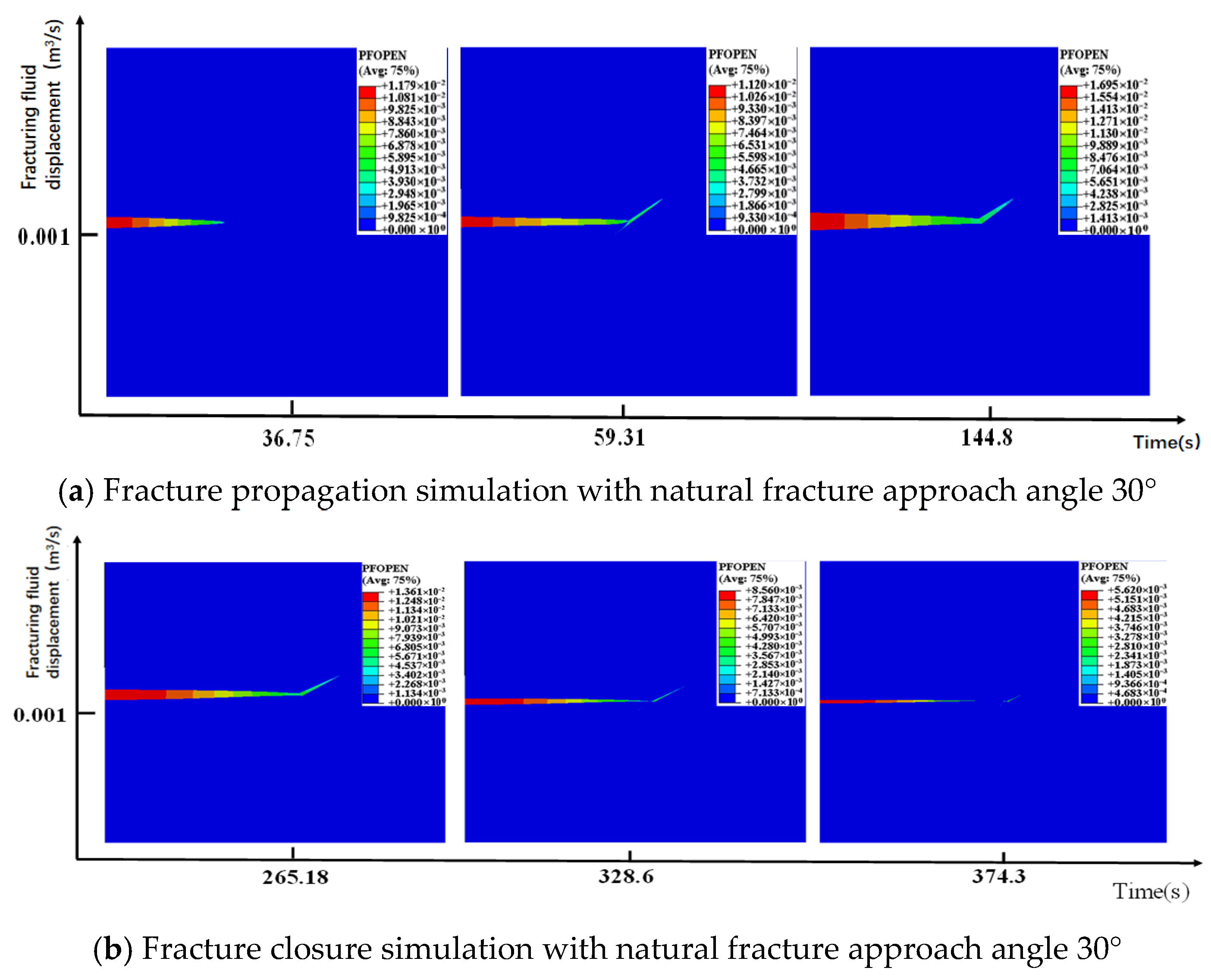

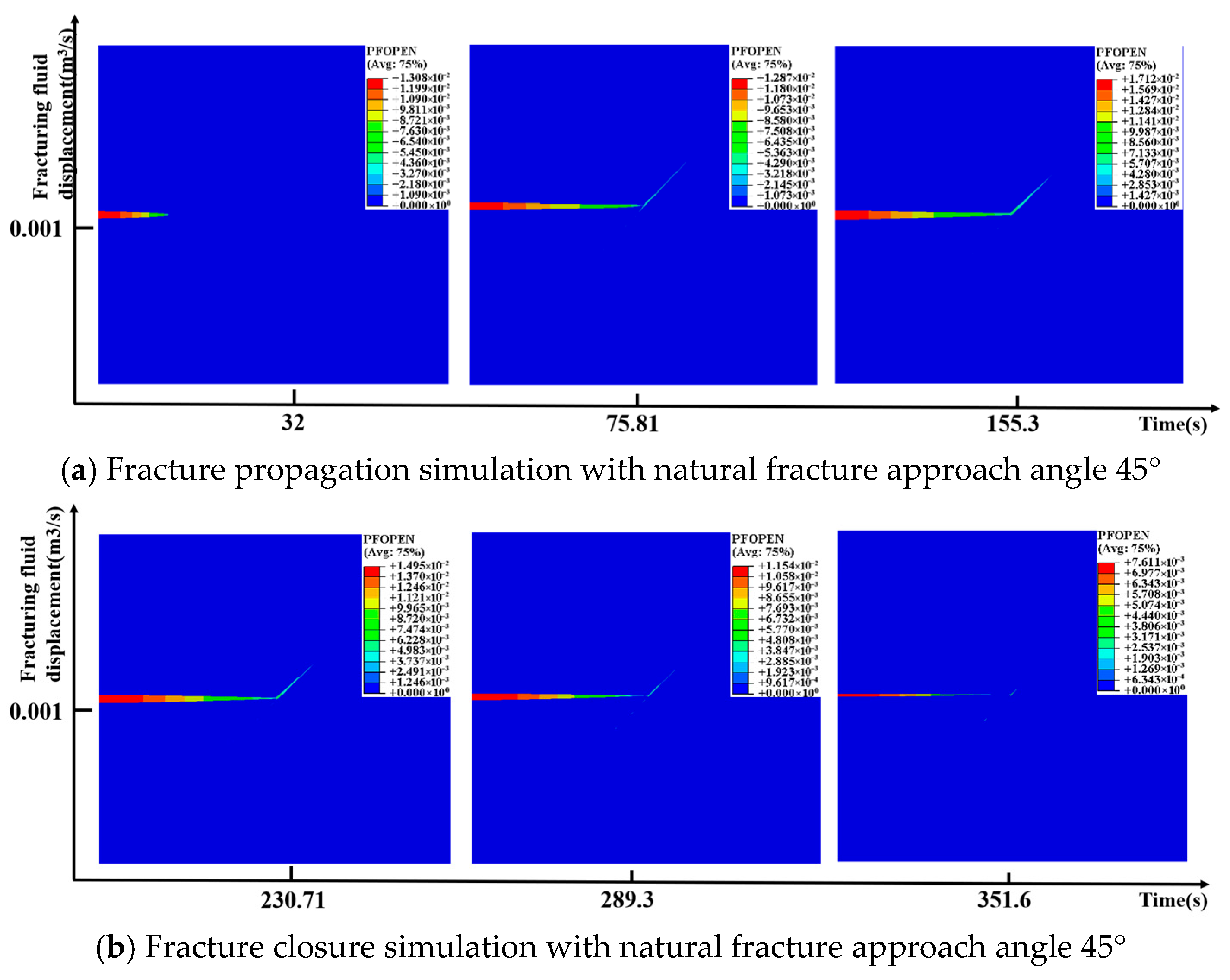

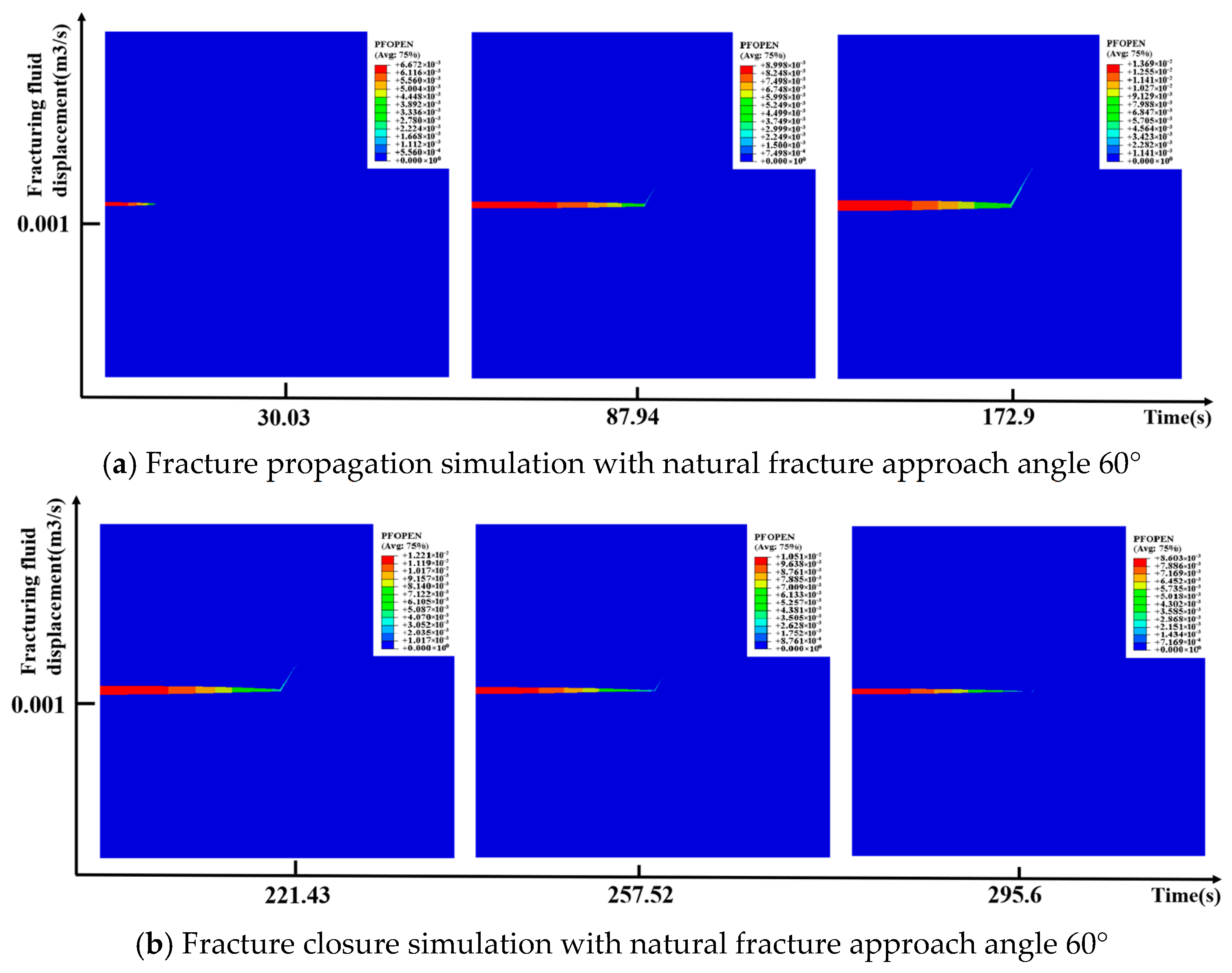

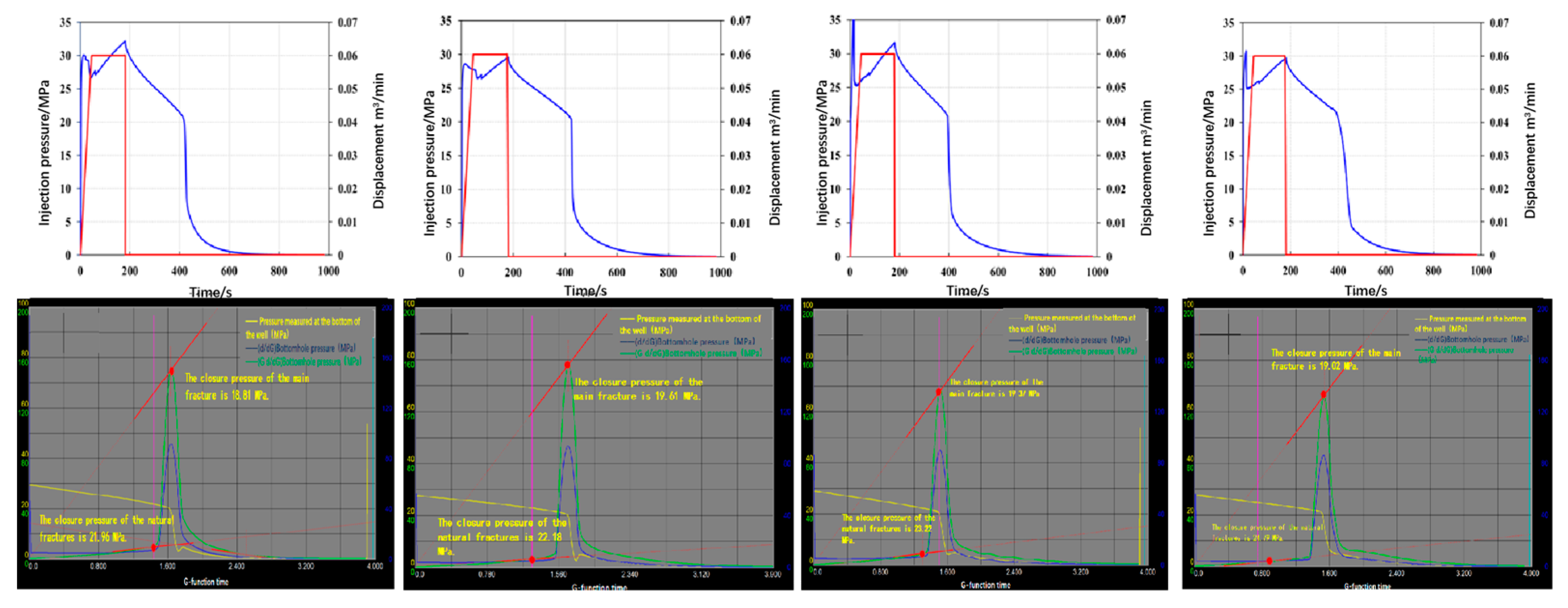

3.3.1. Simple Natural Fractures

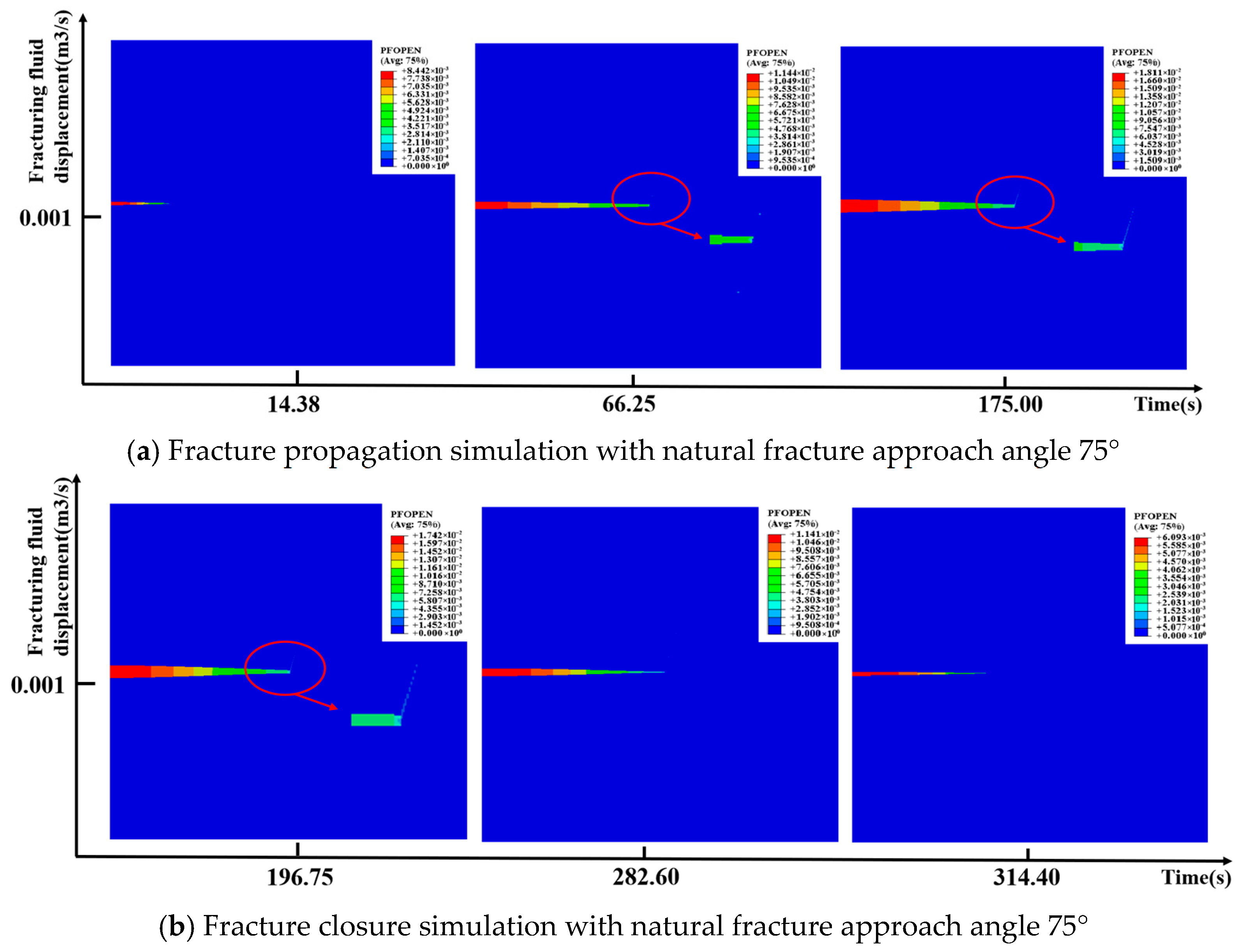

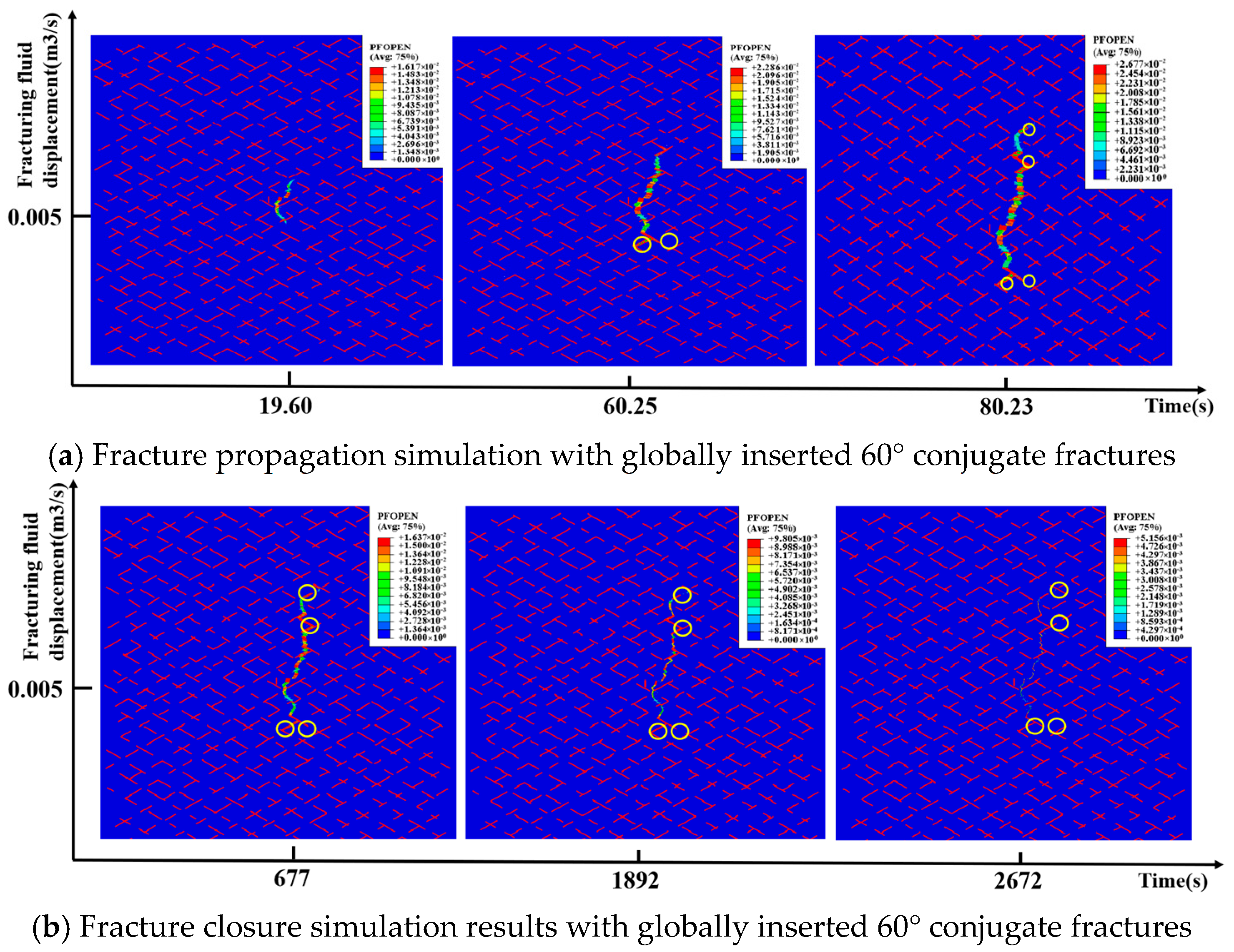

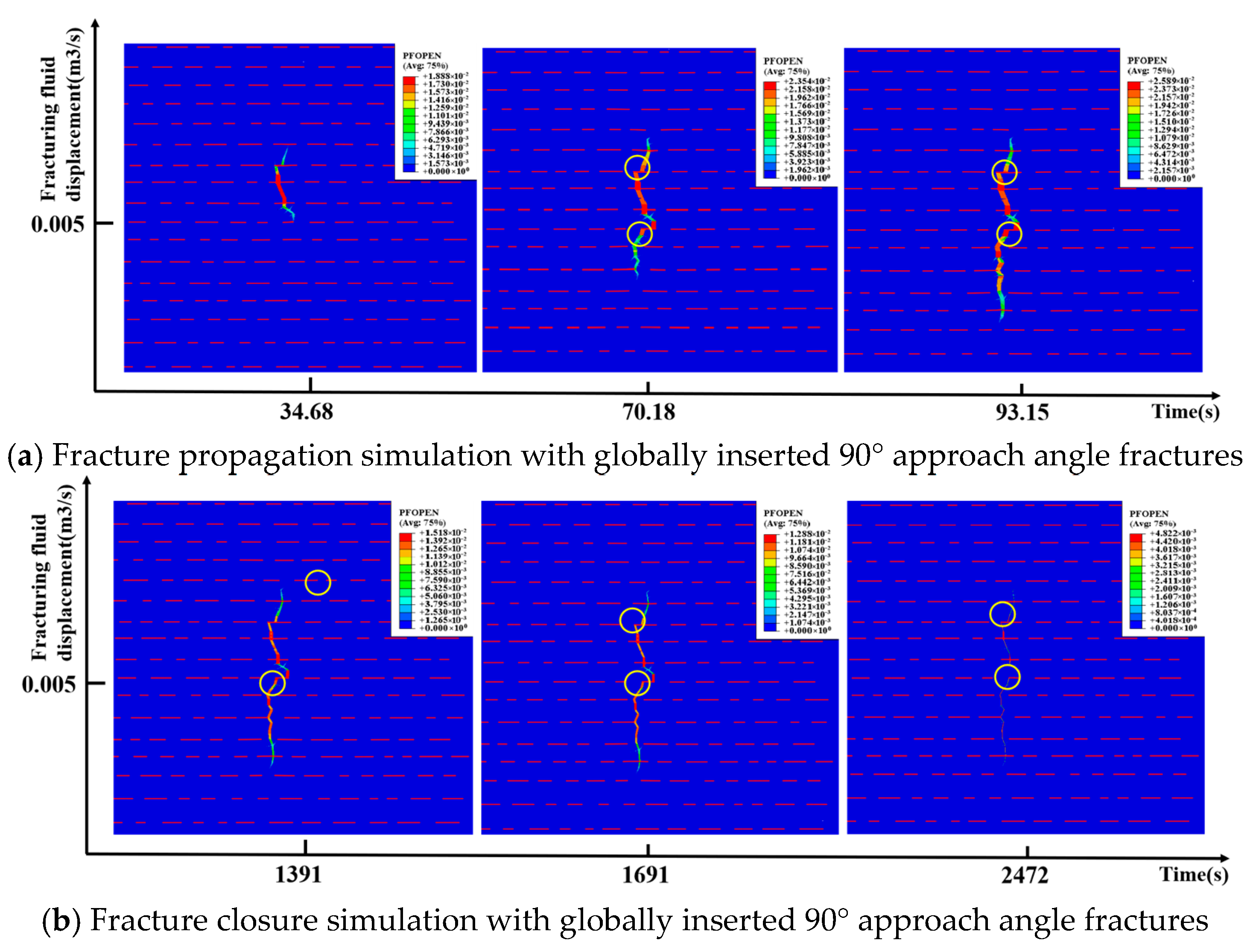

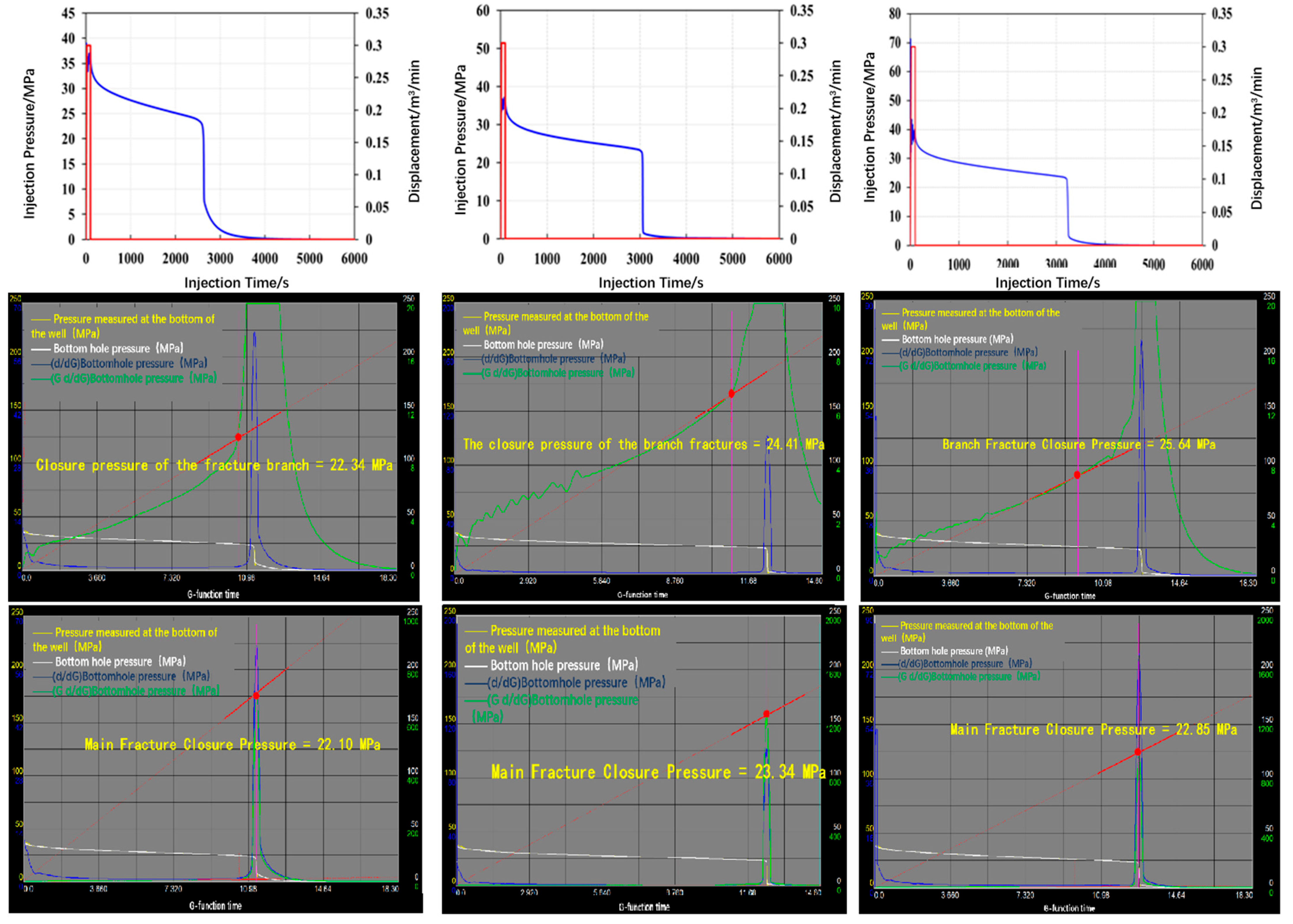

3.3.2. Moderately Complex Natural Fractures

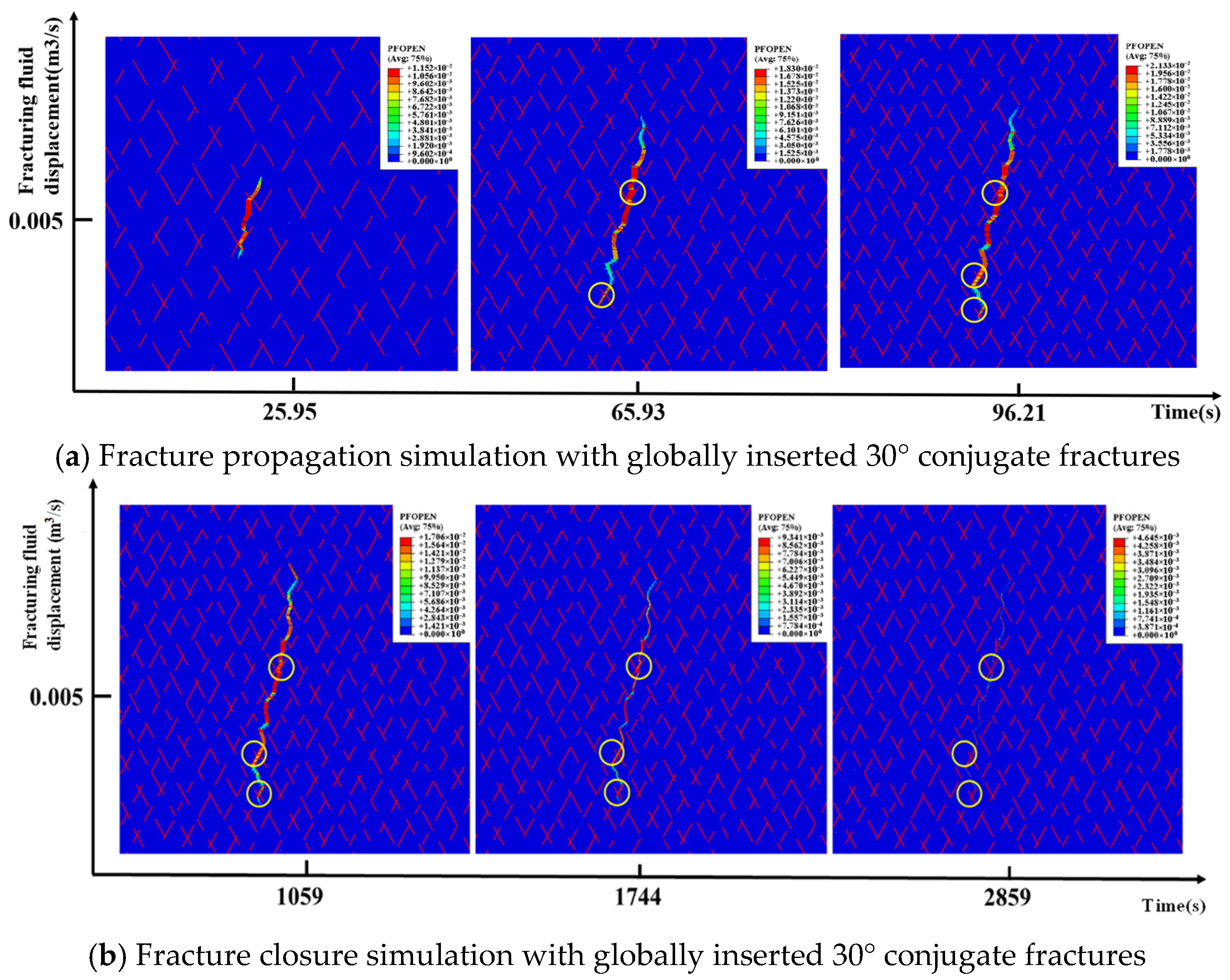

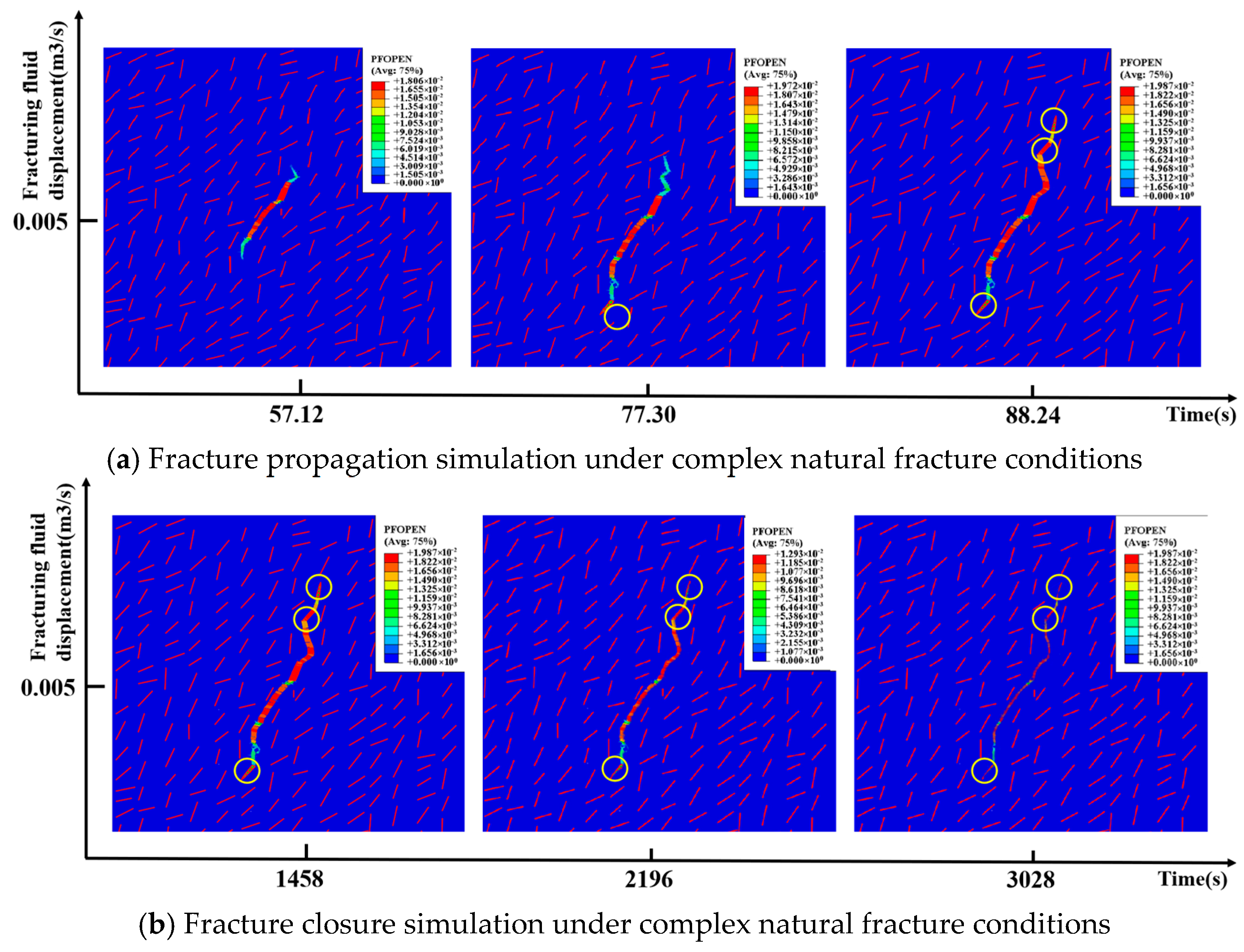

3.3.3. Complex Natural Fractures

3.3.4. Results Comparison

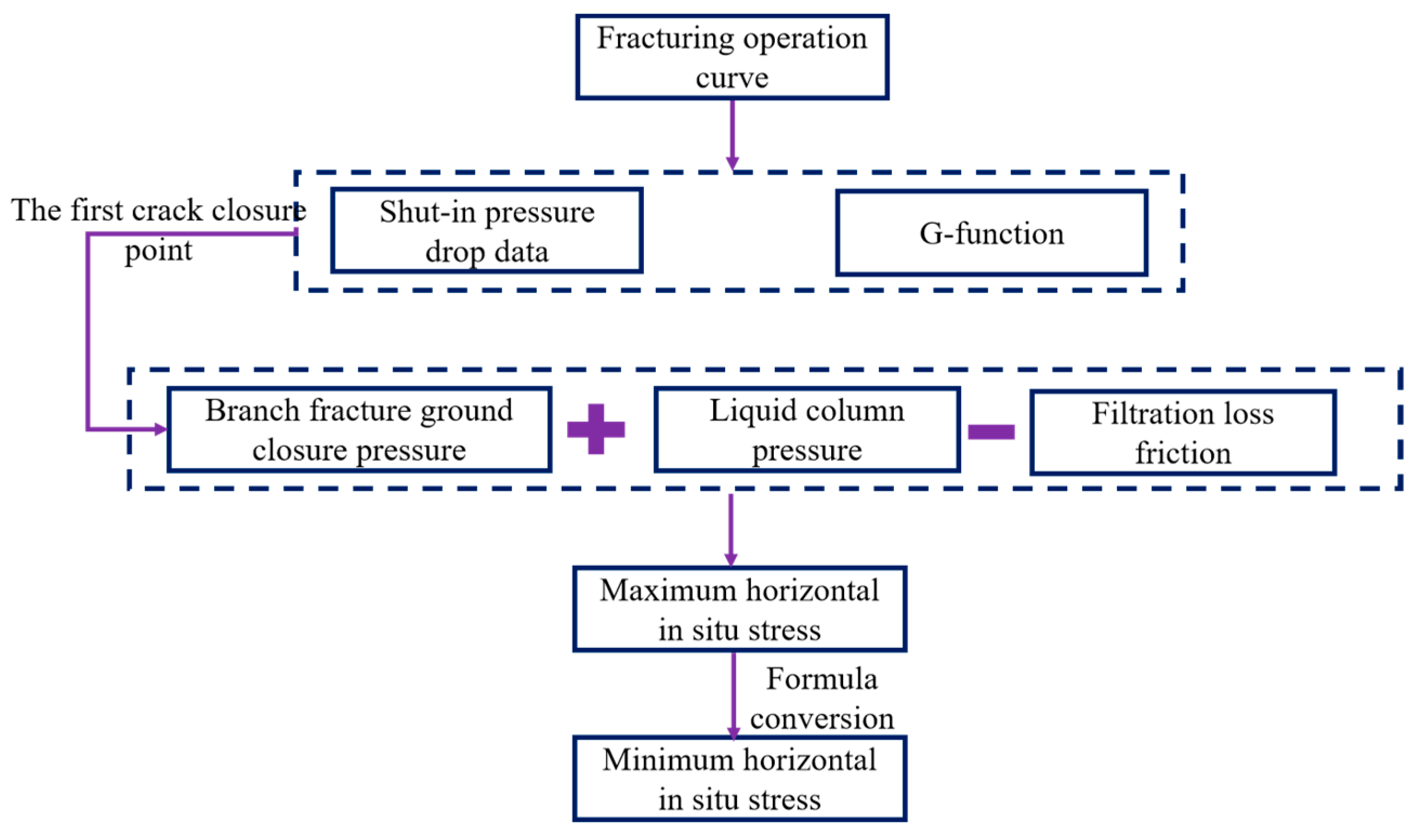

4. Calculation Method for Horizontal In Situ Stress Based on Shut-In Fracturing Curves

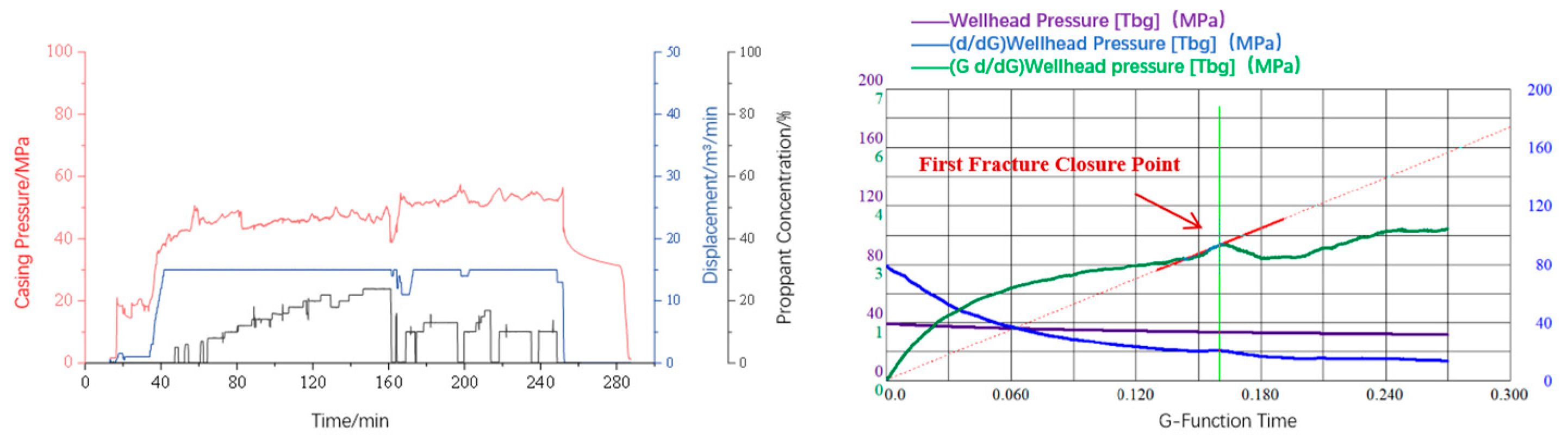

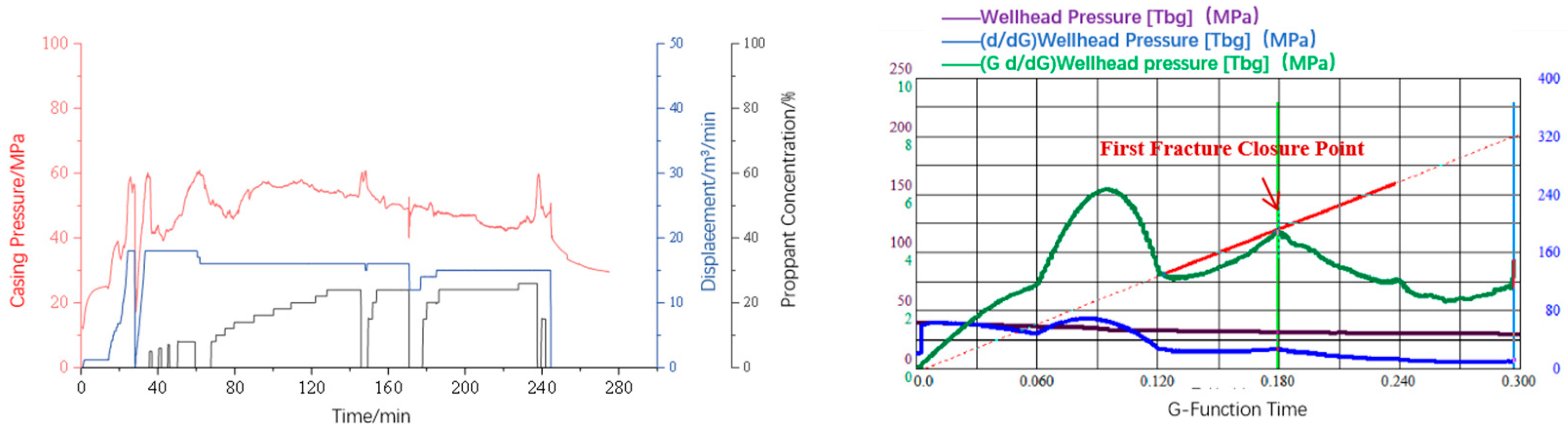

5. Application Example

6. Conclusions

- (1)

- Currently, it is difficult to conduct mini-fracturing tests in every deep coalbed methane well to obtain in situ formation stress. To address this issue, based on the geological characteristics of the deep coal seams in the Daning–Jixian region, a numerical model of the shut-in pressure decline for natural fracture networks of varying complexity was established using the cohesive element method on a finite element platform. The process of hydraulic fracture initiation, propagation, shut-in, and closure was simulated. The results indicate that for natural fractures, whether simple, moderately complex, or complex, when the approach angle is greater than 60°, the closure pressure of the first fracture closure point after shut-in during network fracturing in deep coal seams can be approximated as the maximum horizontal stress.

- (2)

- Based on theoretical analysis and numerical simulation results, in the context of volumetric fracturing in formations with high-angle natural fractures (where the fracture approach angle exceeds 60°), the bottomhole closure pressure of the first closure point in the fracture network after shut-in can be regarded as the maximum horizontal stress. By applying formula conversion, the minimum horizontal stress is derived. A comparison between the in situ stress interpreted from the shut-in pressure decline and the results of the acoustic emission tests shows a relative difference of less than 5%, demonstrating good applicability and accuracy.

- (3)

- Due to the narrow width and low internal pressure of high-angle branch fractures, they are less affected by proppant and the induced stress field during volumetric fracturing. As a result, their closure pressure remains relatively close to the original in situ stress. This method enables efficient and cost-effective determination of formation stress, providing valuable guidance for re-fracturing in existing wells and fracturing design in adjacent wells. The approach can be further extended to deep coal reservoirs in other blocks, offering insights for understanding deep coalbed methane reservoirs and optimizing operational techniques.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, Y. Progress on geological research of deep coalbed methane in China. Acta Pet. Sin. 2023, 44, 1791–1811. [Google Scholar]

- Yang, F.; Li, B.; Wang, K.; Wen, H.; Yang, R.; Huang, Z. Extreme massive hydraulic fracturing in deep coalbed methane horizontal wells: A case study of Linxing Block, eastern Ordos Basin, NW China. Pet. Explor. Dev. 2024, 51, 389–398. [Google Scholar] [CrossRef]

- Zeng, W.; Xu, F.; Zhang, L.; Sun, W.; Wang, Q.; Liu, Y.; Yu, L.; Ji, L.; Zeng, Q.; Zhang, K. Deep coalbed methane production technology for the eastern margin of the Ordos Basin: Advances and their implications. Coal Geol. Explor. 2024, 52, 23–32. [Google Scholar]

- Cai, D.; Cheng, S.; Li, Y.; Bai, W.; Xu, Z.; Wang, Y. Step pump injection pressure drop test to determine the morphology of formation fractures after fracturing. Oil Drill. Prod. Technol. 2023, 45, 748–755. [Google Scholar]

- Zhou, Q.; Deng, R.; Han, X.; Li, C. Evaluation on the Fracturing Effects of Tight Sandstones Based on Pump—off Pressure Drop Analysis. Spec. Oil Gas Reserv. 2017, 24, 165–169. [Google Scholar]

- Chen, Z.; Liu, S.; Zhang, B.; Peng, C.; Li, Y. Study on geostress model of coalbed methane wells in north edge of Qinshui Basin. Coal Sci. Technol. 2018, 46, 136–142. [Google Scholar]

- Jiang, J.; He, C.; Song, Q.; Jin, L.; Feng, Z.; Liu, Q.; Chu, Z.; Zhang, T. Analysis on the geological characteristics of Nantun Formation in Hailaer Oilfield based on mini-frac test. Oil Drill. Prod. Technol. 2019, 41, 636–642. [Google Scholar]

- Jing, J.; Guo, B.; Wang, X.; Li, X. Improvement and Application of Pressure Drop Analysis Method for Mini-Fracturing in Tight Reservoirs. Xinjiang Pet. Geol. 2019, 40, 371–375. [Google Scholar]

- Xiong, X.; Zhen, H.; Li, S.; Wang, H.; Zhang, L.; Song, W.; Lin, H.; Xu, F.; Li, Z.; Zhu, W.; et al. Multi-round diverting fracturing technology and its application in deep coalbed methane in the Daning-Jixian block. Coal Geol. Explor. 2024, 52, 147–160. [Google Scholar]

- Wang, F.; Xu, J.; Zhou, T.; Zhang, S. Pump-stopping pressure drop model considering transient leak-off of fracture network. Pet. Explor. Dev. 2023, 50, 416–423. [Google Scholar] [CrossRef]

- Ecnomides, J.; Nolte, G. Reservoir Stimulation Measures; Zhang, B.; Jiang, W.; Liu, L.; Zhang, R., Translators; Petroleum Industry Press: Beijing, China, 2002; pp. 189–205. [Google Scholar]

- Jin, Y.; Chen, M.; Zhang, X. Hydraulic fracturing initiation pressure models for directional wells in naturally fractured for mation. Acta Pet. Sin. 2006, 27, 124–126. [Google Scholar]

- Zhao, H.; Li, P.; Li, X.; Yao, W. Fracture propagation and evolution law of indirect fracturing in the roof of broken soft coal seams. Int. J. Coal Sci. Technol. 2024, 11, 4. [Google Scholar] [CrossRef]

- Zhao, H. Fracturing Mechanics of Unconventional Oil and Gas Reservoirs; Petroleum Industry Press: Beijing, China, 2023. [Google Scholar]

- Zhao, W.; Zhang, S.; Sun, Z.; Zhao, Y.; Yang, Y. Fracture after compression based on G function curve analysis Complexity assessment study. Sci. Technol. Eng. 2016, 16, 29–33+45. [Google Scholar]

- Wang, X. Research and Application of Fracturing Pressure Decline Analysis in Fractured Reservoir. Ph.D. Thesis, Southwest Petroleum Institute, Nanchong, China, 2005. [Google Scholar]

- Xing, L. The Methods to Analysis of Minimum Ground Stress Based on Fracture Construction Curves. Master’s Thesis, China University of Petroleum, Beijing, China, 2019. [Google Scholar]

- Nolte, K.G. Application of Fracture design Based on Pressure Analysis. SPE Prod. Eng. 1988, 3, 31–42. [Google Scholar] [CrossRef]

- Craig, D.P.; Eberhard, M.J.E.; Barree, R.D. Adapting High Permeability Leakoff Analysis to low Permeability Sands for Estimating Reservoir Engineering Parameters. In Proceedings of the SPE Rocky Mountain Regional/Low-Permeability Reservoirs Symposium and Exhibition, Denver, CO, USA, 12–15 March 2000. [Google Scholar]

- Liu, G.; Ehlig-Economides, C. Comprehensive Global Model for Before Closure Analysis of an Injection Falloff Fracture Calibration Test. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Wu, Q.; Xu, Y.; Liu, Y.; Ding, Y.; Wang, X.; Wang, T. The current situation of stimulated reservoir volume for shale in U.S. and its inspiration to China. Oil Drill. Prod. Technol. 2011, 33, 1–7. [Google Scholar]

- Zhao, H.; Luo, J.; Li, X.; Yao, W.; Ji, L.; Zhen, H. Experimental investigation into the fracture propagation behavior of horizontal well multi-stage and multi-cluster fracturing within the roof of crushed soft coal seams. Pet. Sci. 2025; in press. [Google Scholar] [CrossRef]

- Sazid, M.; Hussein, K.; Abudurman, K. Rock Stress Measurement Methods in Rock Mechanics—A Brief Overview. World Eng. Technol. 2023, 11, 252–272. [Google Scholar] [CrossRef]

- Li, C. Calculation formula of rock rupture pressure under perforation and completion conditions. Oil Drill. Prod. Technol. 2002, 2, 37–38. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, X.; Jin, Y.; Chen, M. New method for measurement of in-situ Stresses at great depth. Chin. J. Rock Mech. Eng. 2004, 14, 2355–2358. [Google Scholar]

| Parameter Name | Value | Parameter Name | Value |

|---|---|---|---|

| Elastic Modulus/GPa | 4 | Porosity | 0.02 |

| Permeability/mD | 0.01 | Fluid Loss Coefficient/m/s1/2 | 1 × 10−13 |

| Rock Tensile Strength/MPa | 1 | Rock Maximum Failure Displacement/m | 0.001 |

| Natural Fracture Tensile Strength/MPa | 0.6 | Natural Fracture Failure Opening Displacement/m | 0.0001 |

| Fracturing Fluid Viscosity/mPa·s | 5/30/60 (Simulating variable viscosity injection) | Minimum Horizontal Effective Stress/MPa | 22 |

| Fracturing Fluid Density/kg·m−3 | 1000 | Maximum Horizontal Effective Stress/MPa | 25 |

| Poisson’s Ratio | 0.30 |

| Approach Angle | 30° | 45° | 60° | 75° | |||||

|---|---|---|---|---|---|---|---|---|---|

| Closure Pressure | HF | NF | HF | NF | HF | NF | HF | NF | |

| Simple Frac | Simulated Value/MPa | 18.81 | 21.96 | 19.61 | 22.18 | 19.37 | 22.22 | 19.02 | 24.79 |

| Calculated Value/MPa | 20.00 | 21.25 | 20.00 | 22.50 | 20.00 | 23.75 | 20.00 | 24.66 | |

| Error/% | 5.95 | 3.34 | 1.95 | 1.42 | 3.15 | 6.44 | 4.90 | 0.53 | |

| Approach Angle | 30° | 60° | 90° | ||||

|---|---|---|---|---|---|---|---|

| Closure Pressure | HF | NF | HF | NF | HF | NF | |

| Moderately Complex Frac | Simulated Value/MPa | 22.10 | 22.34 | 23.34 | 24.41 | 22.85 | 25.64 |

| Calculated Value/MPa | 23.00 | 23.50 | 23.00 | 24.50 | 23.00 | 25.00 | |

| Error/% | 3.91 | 4.94 | 1.48 | 0.37 | 0.65 | 2.56 | |

| Approach Angle | 48° | 66° | 78° | ||||

|---|---|---|---|---|---|---|---|

| Closure Pressure | HF | NF | HF | NF | HF | NF | |

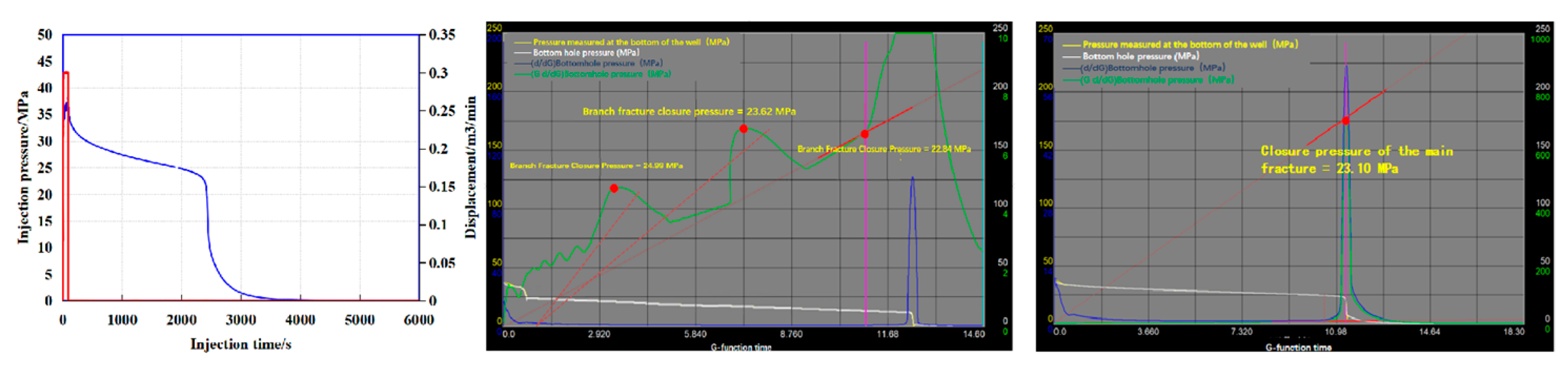

| Complex Frac | Simulated Value/MPa | 23.10 | 22.84 | 23.10 | 23.62 | 23.10 | 24.99 |

| Calculated Value/MPa | 23.00 | 23.62 | 23.00 | 24.51 | 23.00 | 24.52 | |

| Error/% | 0.40 | 4.94 | 0.40 | 3.63 | 0.40 | 1.92 | |

| Maximum Horizontal In Situ Stress/MPa | Minimum Horizontal In Situ Stress/MPa | |||||

|---|---|---|---|---|---|---|

| Well | Acoustic emission testing method | Shut-in pressure decline curve interpretation method | Relative difference/% | Acoustic emission testing method | Shut-in pressure decline curve interpretation method | Relative difference/% |

| A1 | 46.21 (Core sample No. 1) | 45.32 | 1.93 | 41.47 (Core sample No. 1) | 42.32 | 2.05 |

| 47.02 (Core sample No. 2) | 3.62 | 41.81 (Core sample No. 2) | 1.22 | |||

| A2 | 48.01 (Core sample No. 1) | 49.53 | 3.17 | 43.07 (Core sample No. 1) | 44.08 | 2.34 |

| 47.42 (Core sample No. 2) | 4.45 | 43.24 (Core sample No. 2) | 1.94 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhen, H.; Zhao, H.; Jia, Z.; Xu, F.; Sun, Y.; Zeng, W.; Zhu, Q. Method for Interpreting In Situ Stress Based on Pump Shutdown Pressure Drop Curves in Deep Coal Seams. Energies 2025, 18, 6023. https://doi.org/10.3390/en18226023

Zhen H, Zhao H, Jia Z, Xu F, Sun Y, Zeng W, Zhu Q. Method for Interpreting In Situ Stress Based on Pump Shutdown Pressure Drop Curves in Deep Coal Seams. Energies. 2025; 18(22):6023. https://doi.org/10.3390/en18226023

Chicago/Turabian StyleZhen, Huaibin, Haifeng Zhao, Zhaojie Jia, Fengyin Xu, Yanqi Sun, Wenting Zeng, and Qi Zhu. 2025. "Method for Interpreting In Situ Stress Based on Pump Shutdown Pressure Drop Curves in Deep Coal Seams" Energies 18, no. 22: 6023. https://doi.org/10.3390/en18226023

APA StyleZhen, H., Zhao, H., Jia, Z., Xu, F., Sun, Y., Zeng, W., & Zhu, Q. (2025). Method for Interpreting In Situ Stress Based on Pump Shutdown Pressure Drop Curves in Deep Coal Seams. Energies, 18(22), 6023. https://doi.org/10.3390/en18226023