Exploring the Energy Potential of Residual Biomass: A Bibliometric Analysis

Abstract

1. Introduction

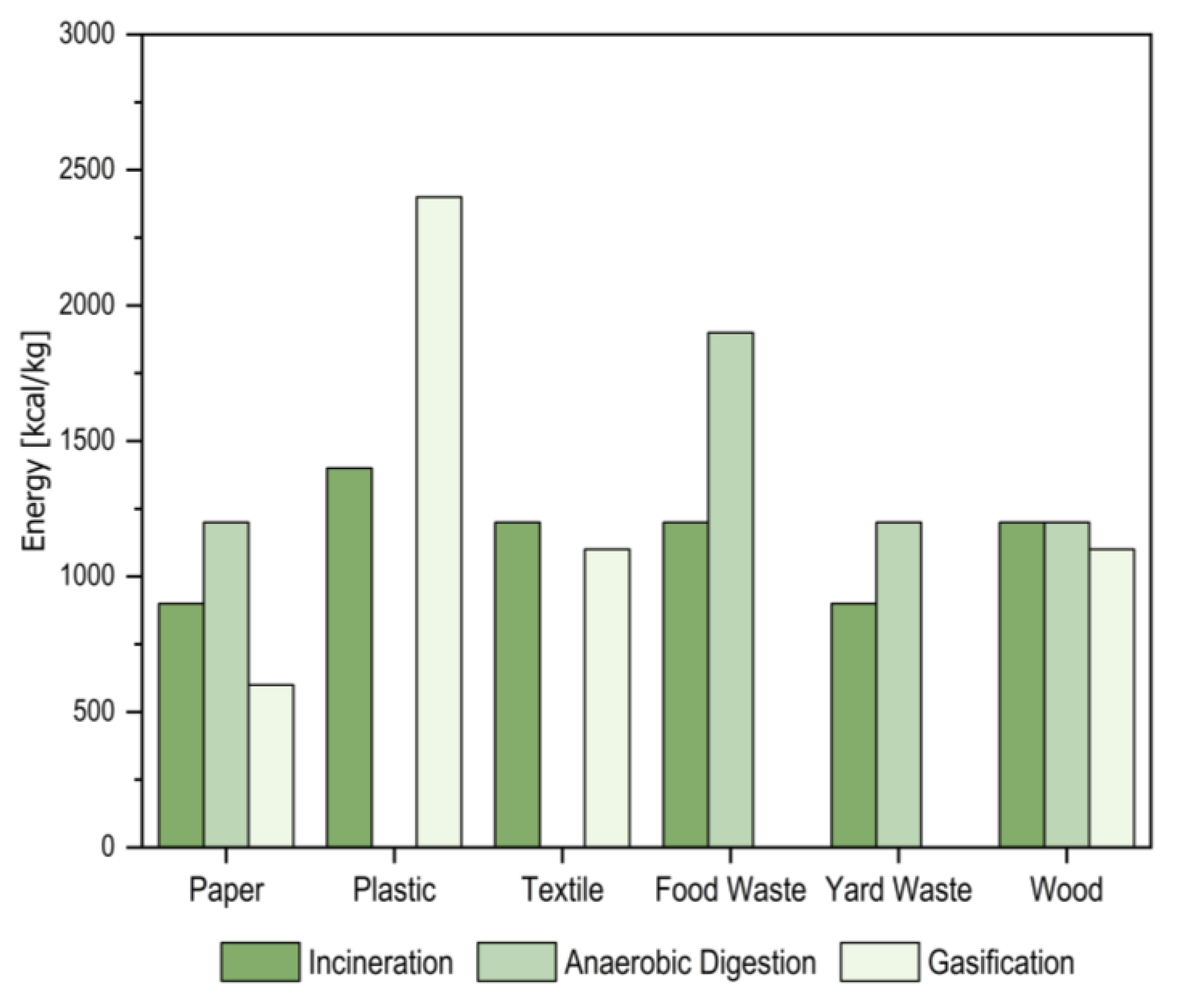

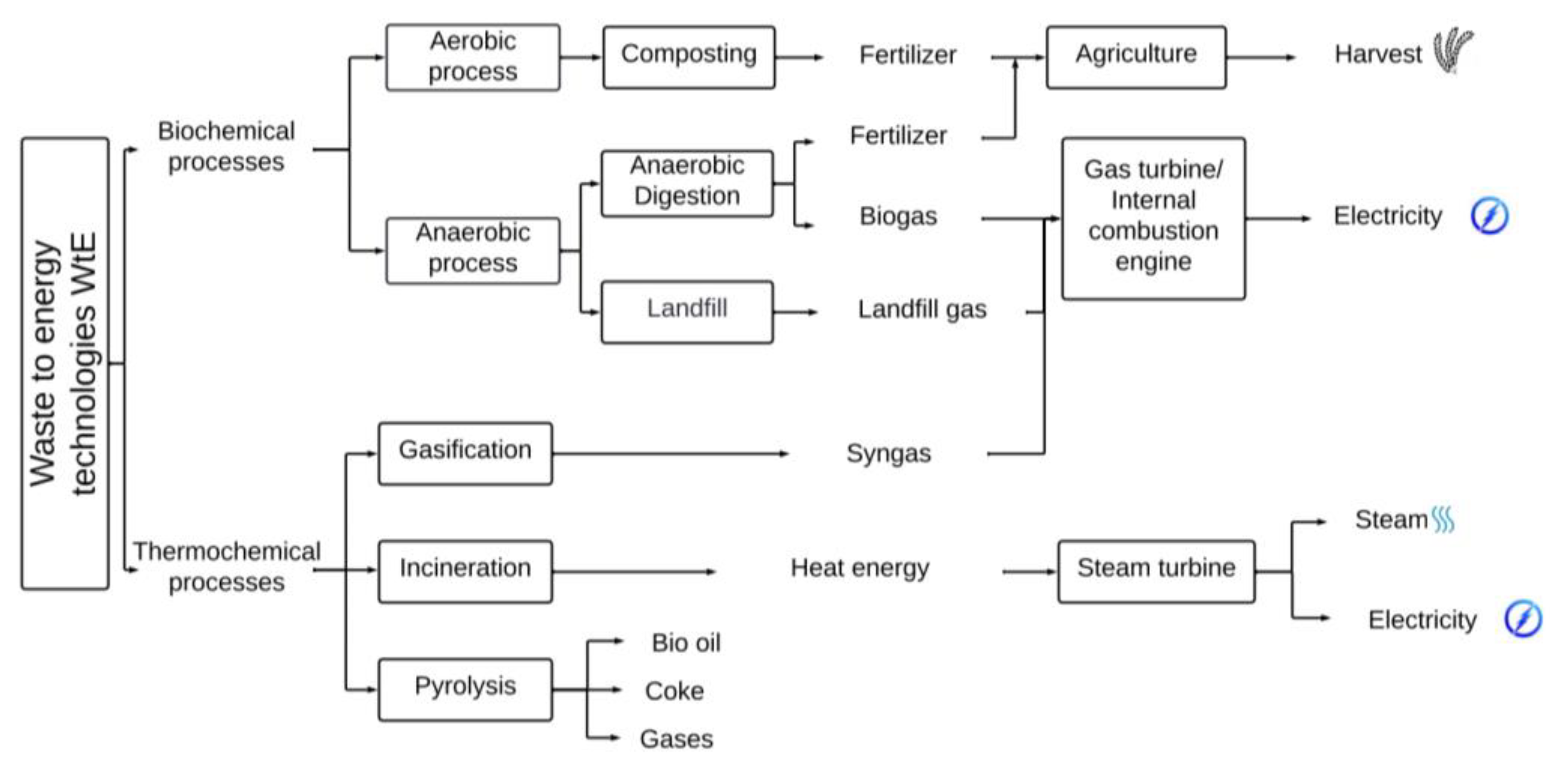

2. Waste-to-Energy Conversion Options

3. Bibliometric Analysis of Methodological References

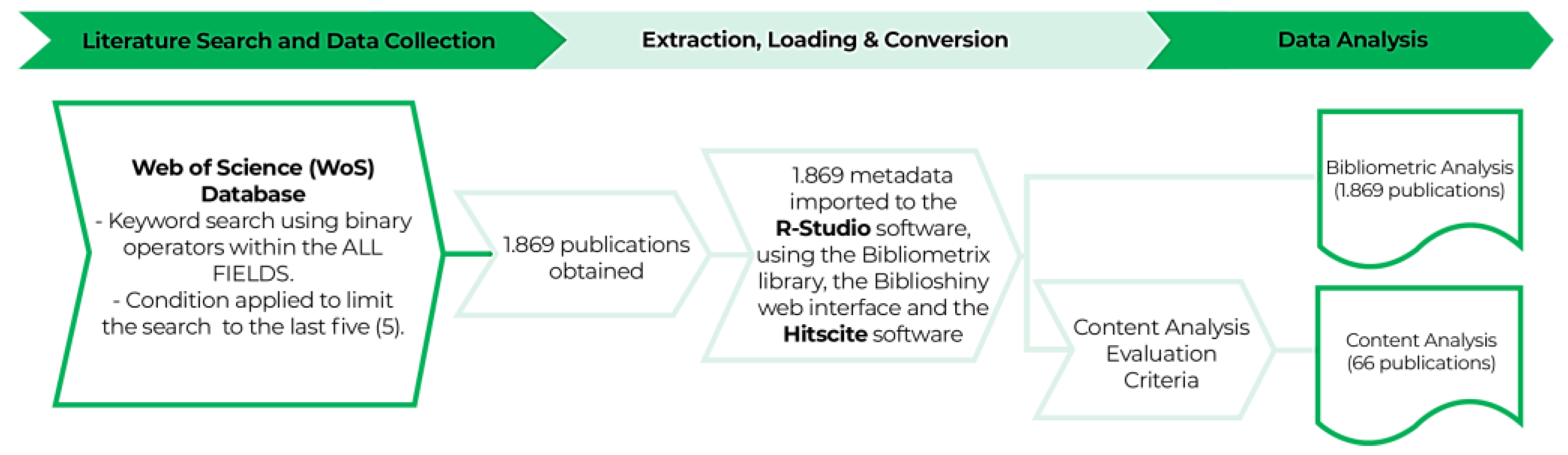

3.1. Methodological Development

3.2. Classification Method

3.3. Results Analysis

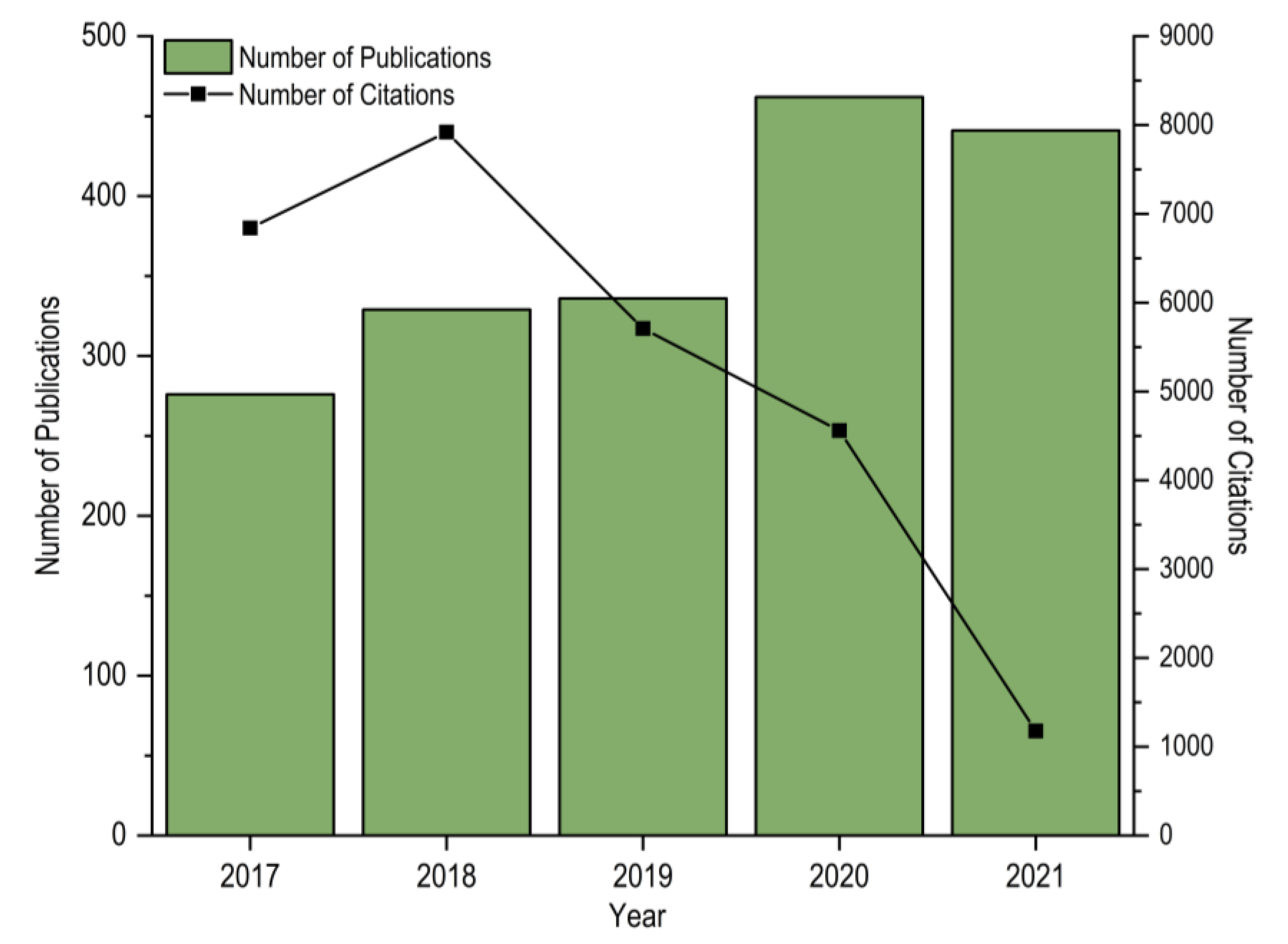

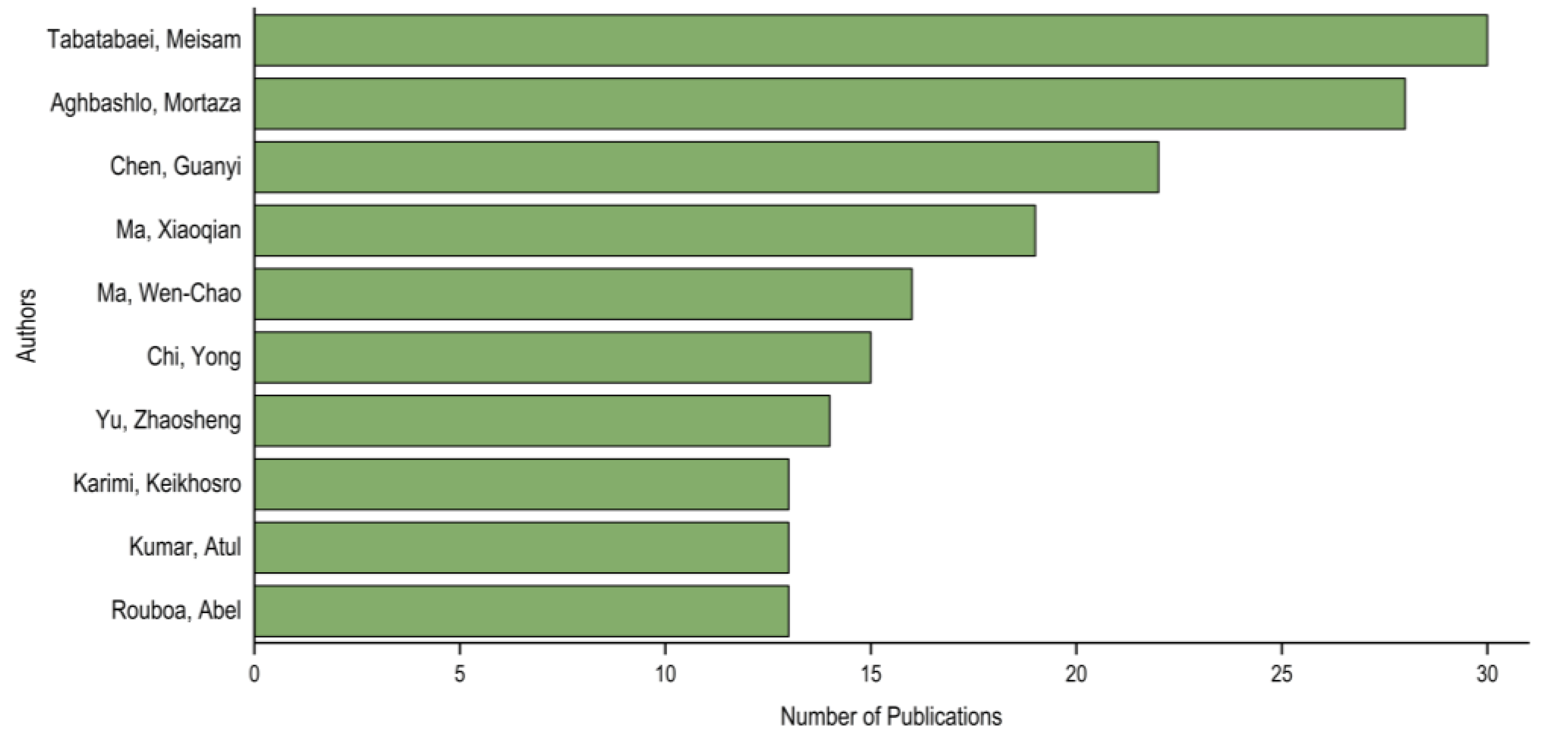

3.3.1. Top Publications and Authors

3.3.2. Top Journals

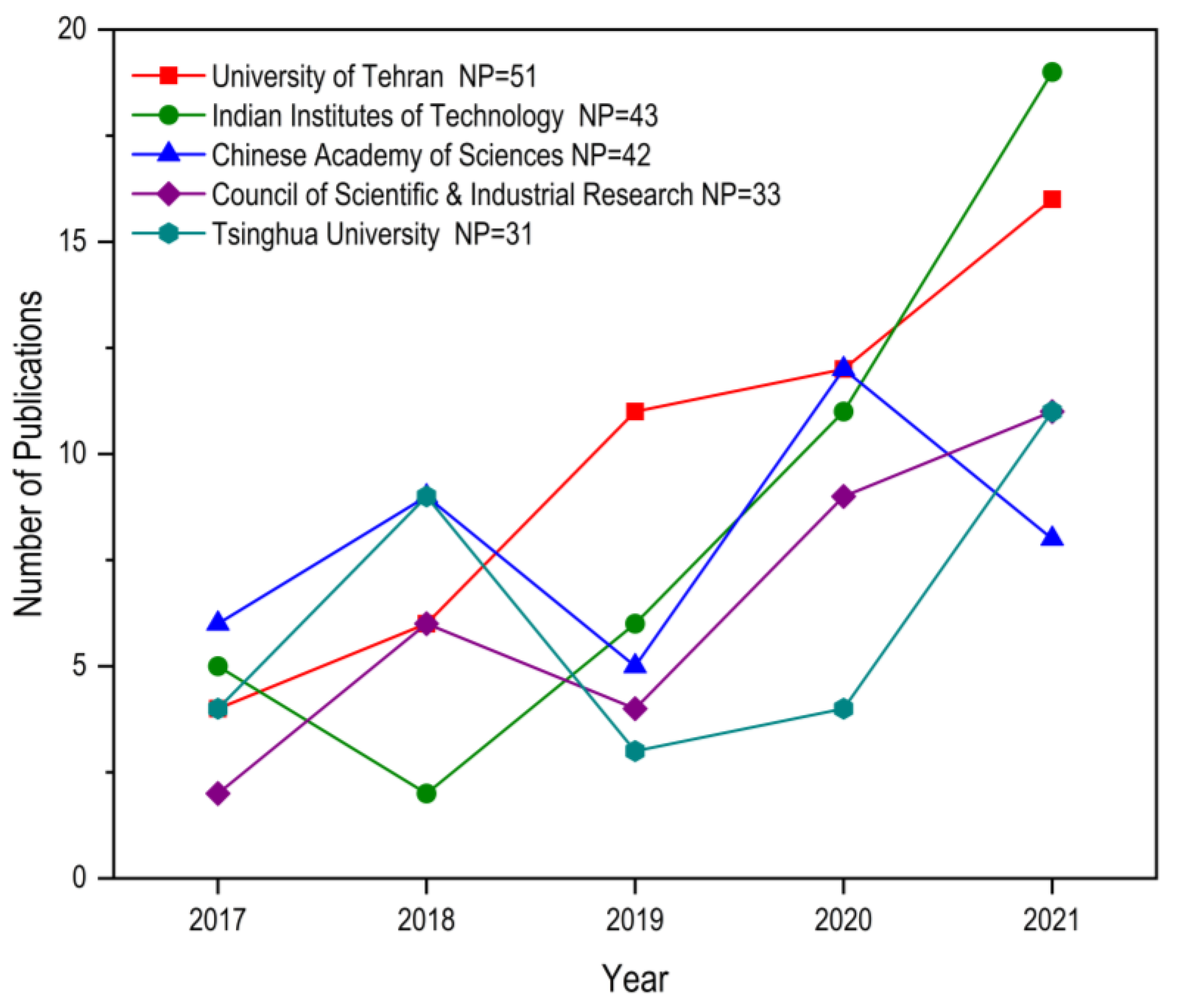

3.3.3. Contributions by Institutions

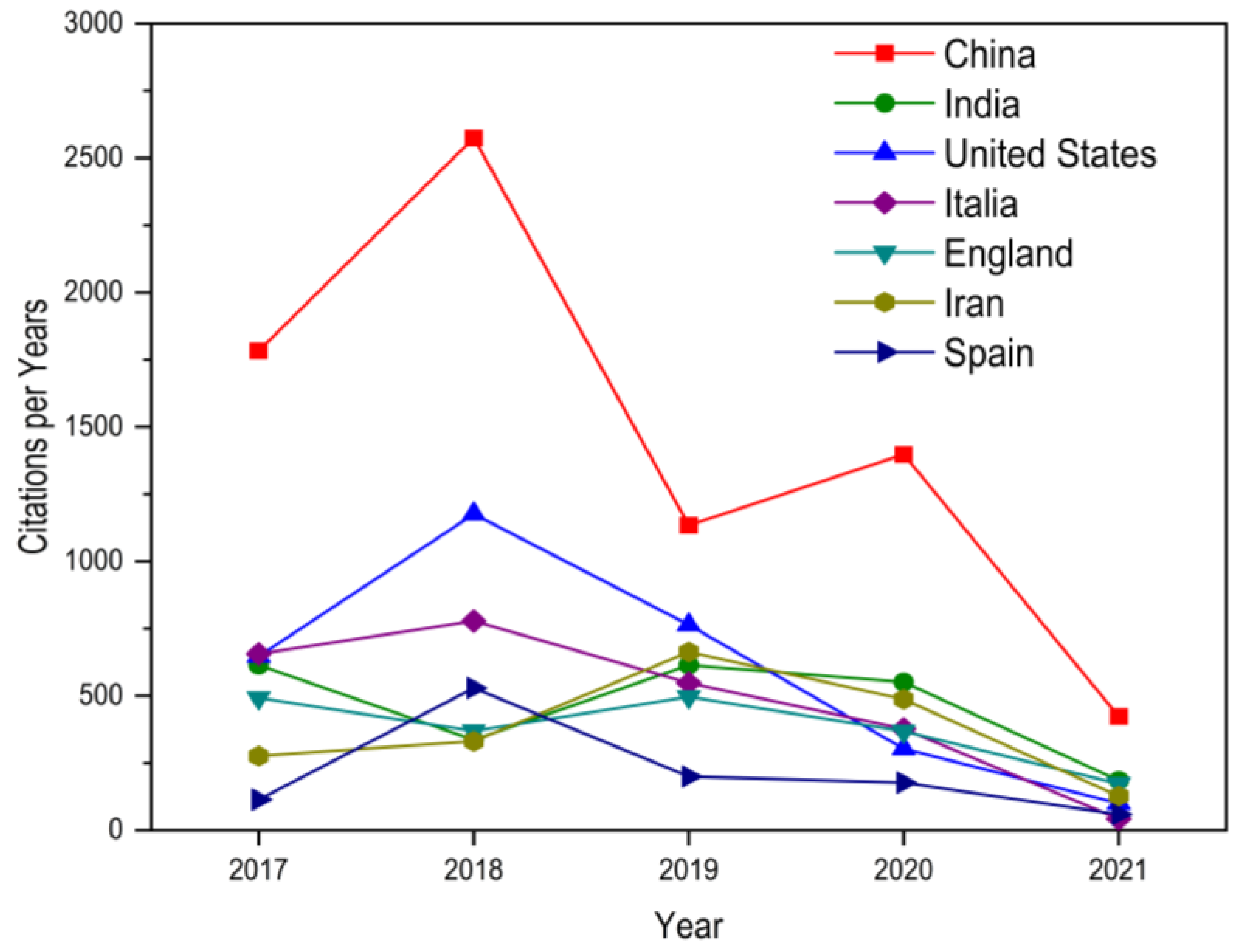

3.3.4. Contributions per Country

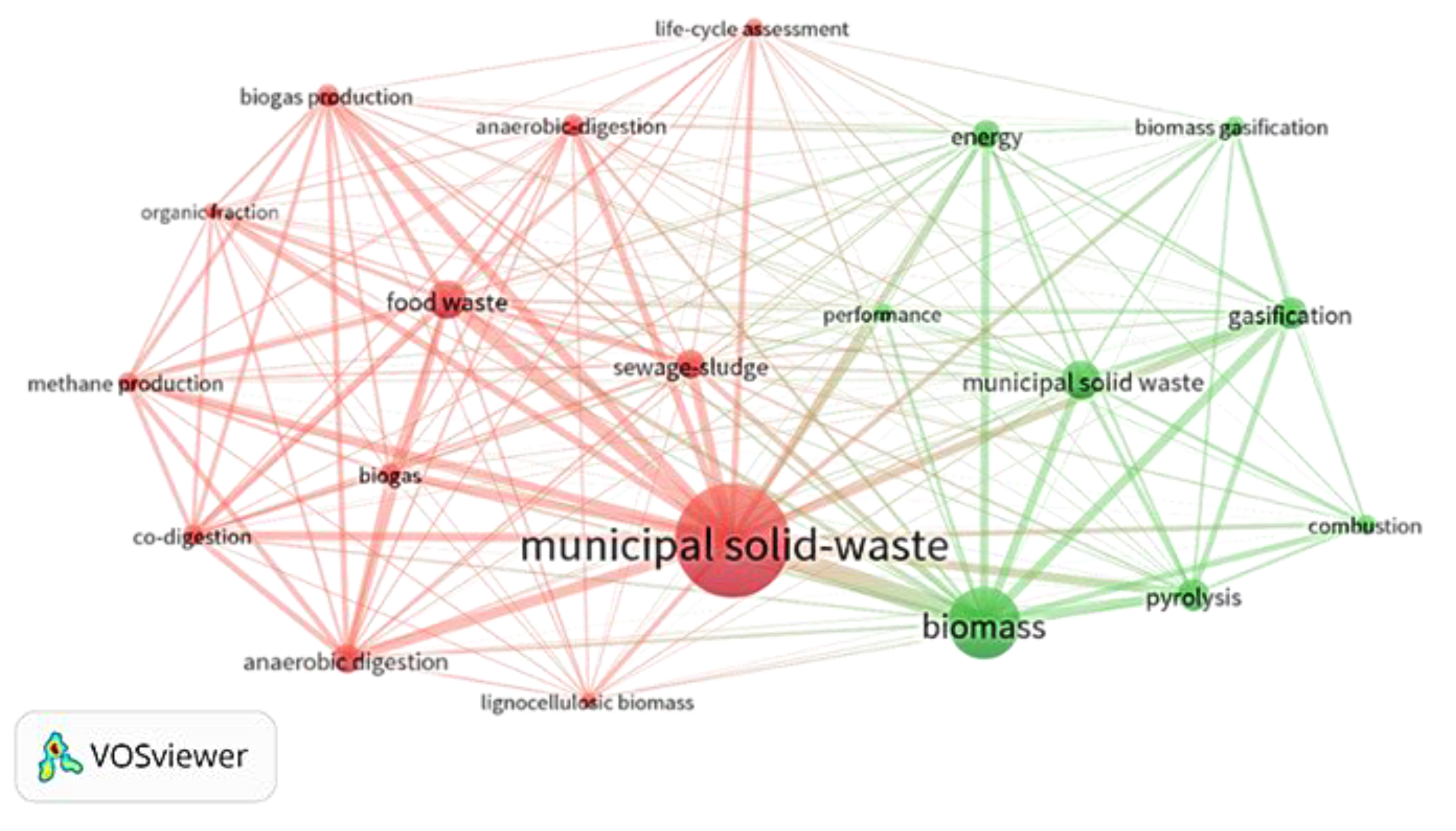

3.3.5. Keywords

3.3.6. Discussion on Selected Publications

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CRA | Corporación Autónoma Regional del Atlántico |

| WtE | Waste-to-Energy Technologies |

| AD | Anaerobic Digestion |

| GHGs | Green House Gases |

| MSW | Municipal Solid Waste |

| RDF | Refuse Derived Fuel |

| HTC | Hydrothermal Carbonization |

References

- International Energy Agency. World Energy Outlook Special Report 2015: Energy and Climate Change; OECD/IEA: Paris, France, 2015. [CrossRef]

- Gutiérrez Vega, B.; Mendoza Rojas, O.; Cotes Prieto, D.; Viviescas, A.; Riveros Jerez, C.A. Análisis de viabilidad estructural de un sistema de generación de energía solar fotovoltaica en un relleno sanitario. Investig. Innov. Ing. 2023, 11, 173–186. [Google Scholar] [CrossRef]

- Moreno Martínez, G.; Ricardo Perdomo, I.; Mercado Martínez, I. Evaluación de la eficiencia de los residuos de plantas de sacrificio como coagulante natural. Investig. Innov. Ing. 2020, 8, 62–74. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste-to-energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. An empirical model for prediction of household solid waste generation rate—A case study of Dhanbad, India. Waste Manag. 2017, 68, 3–15. [Google Scholar] [CrossRef]

- Meza Mejía, J.E.; Hernández Rivera, L.D.; Arias Silva, D.A.; Albis Arrieta, A.R. Influencia de los parámetros operacionales en la pirólisis de biomasa con reactores Auger. Investig. Innov. Ing. 2025, 13, 97–116. [Google Scholar] [CrossRef]

- Fazeli, A.; Bakhtvar, F.; Jahanshaloo, L.; Che Sidik, N.A.; Bayat, A.E. Malaysia’s stand on municipal solid waste conversion to energy: A review. Renew. Sustain. Energy Rev. 2016, 58, 1007–1016. [Google Scholar] [CrossRef]

- Khan, D.; Kumar, A.; Samadder, S.R. Impact of socioeconomic status on municipal solid waste generation rate. Waste Manag. 2016, 49, 15–25. [Google Scholar] [CrossRef]

- Bajić, B.Z.; Dodić, S.N.; Vučurović, D.G.; Dodić, J.M.; Grahovac, J.A. Waste-to-energy status in Serbia. Renew. Sustain. Energy Rev. 2015, 50, 1437–1444. [Google Scholar] [CrossRef]

- Arafat, H.A.; Jijakli, K.; Ahsan, A. Environmental performance and energy recovery potential of five processes for municipal solid waste treatment. J. Clean. Prod. 2015, 105, 233–240. [Google Scholar] [CrossRef]

- Zhang, D.Q.; Tan, S.K.; Gersberg, R.M. Municipal solid waste management in China: Status, problems and challenges. J. Environ. Manage. 2010, 91, 1623–1633. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.-G.; Jiang, G.-W.; Li, A.; Wang, L. Economic analysis of waste-to-energy industry in China. Waste Manag. 2016, 48, 604–618. [Google Scholar] [CrossRef] [PubMed]

- Kikuchi, R.; Gerardo, R. More than a decade of conflict between hazardous waste management and public resistance: A case study of NIMBY syndrome in Souselas (Portugal). J. Hazard. Mater. 2009, 172, 1681–1685. [Google Scholar] [CrossRef]

- Kothari, R.; Tyagi, V.V.; Pathak, A. Waste-to-energy: A way from renewable energy sources to sustainable development. Renew. Sustain. Energy Rev. 2010, 14, 3164–3170. [Google Scholar] [CrossRef]

- Charters, W.W.S. Developing markets for renewable energy technologies. Renew. Energy 2001, 22, 217–222. [Google Scholar] [CrossRef]

- Ouda, O.K.M.; Raza, S.A.; Nizami, A.S.; Rehan, M.; Al-Waked, R.; Korres, N.E. Waste to energy potential: A case study of Saudi Arabia. Renew. Sustain. Energy Rev. 2016, 61, 328–340. [Google Scholar] [CrossRef]

- Rogoff, M.J.; Screve, F. Waste-To-Energy, 3rd ed.; William Andrew Publishing: New York, NY, USA, 2019; pp. 29–56. [Google Scholar] [CrossRef]

- Tabasová, A.; Kropáč, J.; Kermes, V.; Nemet, A.; Stehlík, P. Waste-to-energy technologies: Impact on environment. Energy 2012, 44, 146–155. [Google Scholar] [CrossRef]

- Ogunjuyigbe, A.S.O.; Ayodele, T.R.; Alao, M.A. Electricity generation from municipal solid waste in some selected cities of Nigeria: An assessment of feasibility, potential and technologies. Renew. Sustain. Energy Rev. 2017, 80, 149–162. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, W. A tale of two databases: The use of Web of Science and Scopus in academic papers. Scientometrics 2020, 123, 321–335. [Google Scholar] [CrossRef]

- Salinas, L.F.C.; Ochoa, G.V.; Cardenas, Y.C. A scientometric analysis of the investigation of biomass gasification environmental impacts from 2001 to 2017. Int. J. Energy Econ. Policy 2018, 8, 223–229. Available online: https://www.econjournals.com/index.php/ijeep/article/view/5847 (accessed on 5 September 2025).

- Ashokkumar, V.; Venkatkarthick, R.; Jayashree, S.; Chuetor, S.; Dharmaraj, S.; Kumar, G.; Chen, W.-H.; Ngamcharussrivichai, C. Recent Advances in Lignocellulosic Biomass for Biofuels and Value-Added Bioproducts—A Critical Review. Bioresour. Technol. 2022, 344, 126195. [Google Scholar] [CrossRef] [PubMed]

- Alrashidi, W.; Alhazmi, S.; Sayegh, F.; Edris, S. Microalga-Based Electricity Production: A Comprehensive Review. Energies 2025, 18, 536. [Google Scholar] [CrossRef]

- Fasaei, F.; Bitter, J.H.; Slegers, P.M.; van Boxtel, A.J.B. Techno-economic evaluation of microalgae harvesting and dewatering systems. Algal Res. 2018, 31, 347–362. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Recent advances in the gasification of waste plastics. A critical overview. Renew. Sustain. Energy Rev. 2018, 82, 576–596. [Google Scholar] [CrossRef]

- Liu, W.J.; Li, W.W.; Jiang, H.; Yu, H.Q. Fates of Chemical Elements in Biomass during Its Pyrolysis. Chem. Rev. 2017, 117, 6367–6398. [Google Scholar] [CrossRef]

- Uzoejinwa, B.B.; He, X.; Wang, S.; Abomohra, A.E.-F.; Hu, Y.; Wang, Q. Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: Recent progress and future directions elsewhere worldwide. Energy Convers. Manag. 2018, 163, 468–492. [Google Scholar] [CrossRef]

- Neshat, S.A.; Mohammadi, M.; Najafpour, G.D.; Lahijani, P. Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew. Sustain. Energy Rev. 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Hu, X.; Gholizadeh, M. Biomass pyrolysis: A review of the process development and challenges from initial research up to the commercialization stage. J. Energy Chem. 2019, 39, 109–143. [Google Scholar] [CrossRef]

- Łukajtis, R.; Hołowacz, I.; Kucharska, K.; Glinka, M.; Rybarczyk, P.; Przyjazny, A.; Kamiński, M. Hydrogen production from biomass using dark fermentation. Renew. Sustain. Energy Rev. 2018, 91, 665–694. [Google Scholar] [CrossRef]

- Ubando, A.T.; Felix, C.B.; Chen, W.H. Biorefineries in circular bioeconomy: A comprehensive review. Bioresour. Technol. 2020, 299, 122585. [Google Scholar] [CrossRef] [PubMed]

- Resurchify. Waste and Biomass Valorization. 2025. Available online: https://www.resurchify.com/impact/details/19600157918 (accessed on 16 July 2025).

- Li, L.L.; Ding, G.; Feng, N.; Wang, M.H.; Ho, Y.S. Global stem cell research trend: Bibliometric analysis as a tool for mapping of trends from 1991 to 2006. Scientometrics 2009, 80, 39–58. [Google Scholar] [CrossRef]

- Lee, J.; Lin, K.-Y.A.; Jung, S.; Kwon, E.E. Hybrid Renewable Energy Systems Involving Thermochemical Conversion Process for Waste-to-Energy Strategy. Chem. Eng. J. 2023, 452 Pt 2, 139218. [Google Scholar] [CrossRef]

- Obileke, K.; Makaka, G.; Nwokolo, N. Recent Advancements in Anaerobic Digestion and Gasification Technology. Appl. Sci. 2023, 13, 5597. [Google Scholar] [CrossRef]

- Chen, H.; Song, X.; Jian, Y. Performance Assessment of a Municipal Solid Waste Gasification and Power Generation System Integrated with Absorption Heat Pump Drying. Energies 2024, 17, 6034. [Google Scholar] [CrossRef]

- Paudel, S.R.; Banjara, S.P.; Choi, O.K.; Park, K.Y.; Kim, Y.M.; Lee, J.W. Pretreatment of agricultural biomass for anaerobic digestion: Current state and challenges. Bioresour. Technol. 2017, 245, 1194–1205. [Google Scholar] [CrossRef]

- Casallas-Ojeda, M.R.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P. Identification of Factors and Variables that Influence the Anaerobic Digestion of Municipal Biowaste and Food Waste. Waste Biomass Valor. 2020, 12, 2889–2904. [Google Scholar] [CrossRef]

- Foster, W.; Azimov, U.; Gauthier-Maradei, P.; Molano, L.C.; Combrinck, M.; Munoz, J.; Esteves, J.J.; Patino, L. Waste-to-energy conversion technologies in the UK: Processes and barriers–A review. Renew. Sustain. Energy Rev. 2021, 135, 110226. [Google Scholar] [CrossRef]

- Watson, J.; Zhang, Y.; Si, B.; Chen, W.T.; de Souza, R. Gasification of biowaste: A critical review and outlooks. Renew. Sustain. Energy Rev. 2018, 83, 1–17. [Google Scholar] [CrossRef]

- Sapariya, D.D.; Patdiwala, D.U.J.; Panchal, H.; Ramana, D.P.V.; Makwana, J.; Sadasivuni, K.K. A review on thermochemical biomass gasification techniques for bioenergy production. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–34. [Google Scholar] [CrossRef]

- de Priall, O.; Gogulancea, V.; Brandoni, C.; Hewitt, N.; Johnston, C.; Onofrei, G.; Huang, Y. Modelling and experimental investigation of small-scale gasification CHP units for enhancing the use of local biowaste. Waste Manag. 2021, 136, 174–183. [Google Scholar] [CrossRef] [PubMed]

- Bhatt, M.; Wagh, S.; Chakinala, A.G.; Pant, K.K.; Sharma, T.; Joshi, J.B.; Shah, K.; Sharma, A. Conversion of refuse derived fuel from municipal solid waste into valuable chemicals using advanced thermo-chemical process. J. Clean. Prod. 2021, 329, 129653. [Google Scholar] [CrossRef]

- Lucian, M.; Volpe, M.; Gao, L.; Piro, G.; Goldfarb, J.L.; Fiori, L. Impact of hydrothermal carbonization conditions on the formation of hydrochars and secondary chars from the organic fraction of municipal solid waste. Fuel 2018, 233, 257–268. [Google Scholar] [CrossRef]

- Posso, F.; Narváez, R.A.C.; Siguencia, J.; Sánchez, J. Use of Municipal Solid Waste (MSW)-Derived Hydrogen in Ecuador: Potential Applications for Urban Transportation. Waste Biomass Valor. 2019, 10, 1529–1537. [Google Scholar] [CrossRef]

- Hsu, H.-W.; Binyet, E.; Nugroho, R.A.A.; Wang, W.-C.; Srinophakun, P.; Chein, R.-Y.; Demafelis, R.; Chiarasumran, N.; Saputro, H.; Alhikami, A.F.; et al. Toward Sustainability of Waste-to-Energy: An Overview. Energy Convers. Manag. 2024, 321, 119063. [Google Scholar] [CrossRef]

- Zueva, S.; Ferella, F.; Corradini, V.; Vegliò, F. Review of Organic Waste-to-Energy (OWtE) Technologies as a Part of a Sustainable Circular Economy. Energies 2024, 17, 3797. [Google Scholar] [CrossRef]

| Description | Results |

|---|---|

| Data Overview | |

| Sampling Period | 2017–2021 |

| Sources (Magazines, Books, etc.) | 388 |

| Documents | 1869 |

| Average years since publication | 1.74 |

| Average number of citations per document | 13.7 |

| Average number of citations per year per document | 4.885 |

| Document Types | |

| Papers | 1475 (78.92%) |

| Review Papers | 299 (16.00%) |

| Proceedings Paper | 87 (4.66%) |

| Editorial Material | 6 (0.32%) |

| Letters | 1 (0.05%) |

| Meeting Abstract | 1 (0.05%) |

| Authors | |

| Authors | 5818 |

| Author Participation | 8668 |

| Authors of Single-Author Documents | 41 |

| Authors of Multiple-Author Documents | 5777 |

| Author Collaboration | |

| Single-Author Documents | 46 |

| Documents per Author | 0.321 |

| Authors per Document | 3.11 |

| Co-authors per Document | 4.64 |

| Collaboration Index | 3.17 |

| Sample Size | Assessment Criteria |

|---|---|

| 66 | 25 publications with the highest number of citations |

| 16 publications from Colombia | |

| 25 most recent publications |

| No. | Document Title | Number of Citations | Reference |

|---|---|---|---|

| 1 | A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties | 349 | [25] |

| 2 | A Technological Overview of Biogas Production from Biowaste | 209 | [26] |

| 3 | Recent advances in the gasification of waste plastics. A critical overview | 205 | [27] |

| 4 | Fates of Chemical Elements in Biomass during Its Pyrolysis | 203 | [28] |

| 5 | A review of technological options of waste-to-energy for effective management of municipal solid waste | 202 | [4] |

| 6 | Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: Recent progress and future directions elsewhere worldwide | 186 | [29] |

| 7 | Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production | 181 | [30] |

| 8 | Biomass pyrolysis: A review of the process development and challenges from initial research up to the commercialization stage | 163 | [31] |

| 9 | Hydrogen production from biomass using dark fermentation | 153 | [32] |

| 10 | Biorefineries in circular bioeconomy: A comprehensive review | 145 | [33] |

| No. | Journal | Impact Factor | Number of Publications | Global Percentage | Number of Citations | Global Percentage |

|---|---|---|---|---|---|---|

| 1 | Waste and Biomass Valorization | 3.703 | 112 | 6.0 | 853 | 3.3 |

| 2 | Waste Management | 7.145 | 102 | 5.5 | 2127 | 8.3 |

| 3 | Journal of Cleaner Production | 9.297 | 95 | 5.1 | 1488 | 5.8 |

| 4 | Renewable & Sustainable Energy Reviews | 14.982 | 86 | 4.6 | 3308 | 12.9 |

| 5 | Bioresource Technology | 9.642 | 81 | 4.3 | 2096 | 8.2 |

| WtE Technology | Capital Costs (US$/Ton MSW/Year) | Operation Costs (US$/Ton MSW/Year) |

|---|---|---|

| Incineration | 400–700 | 40–70 |

| Pyrolysis | 400–700 | 50–80 |

| Gasification | 250–850 | 45–85 |

| Anaerobic Digestion | 50–350 | 5–35 |

| Gas Recovery Landfill | 10–30 | 1–3 |

| WtE Technology | Global Warming Potential () |

|---|---|

| Incineration | 424 |

| Pyrolysis and Gasification | 412 |

| Anaerobic Digestion | 222 |

| Gas Recovery Landfill | 746 |

| Technology | Contribution | Author(s) |

|---|---|---|

| Anaerobic Digestion (AD) | The energy potential of animal manure for biogas production is suboptimal due to its high nitrogen content, which lowers its C/N ratio. To address this deficiency, co-digestion with lignocellulosic waste (agricultural, forestry, municipal solids, and agro-industrial waste) compensates for the carbon deficit of the manure and improves the methane yield of the process. | [30] |

To improve the biodegradability of agricultural biomass, pretreatments are used according to the physicochemical characteristics of each raw material. The following treatments can be used:

| [39] | |

| Based on the technological surveillance methodology conducted for the 2009–2019 period in the Scopus and SciELO databases on AD studies of Biological and Food Waste, the main factors that affect the AD process were determined. The most frequently evaluated factor is related to experimental configuration, since it has the largest number of associated variables. Nevertheless, most factors have not yet been widely studied. The organic load rate and the number of stages involved in the process are the most commonly studied variables. Substrate and environmental factors follow, with pretreatment being the main studied variable. Finally, there is the inoculum, which is mainly associated with variables such as the inoculum mixture and the substrate to inoculum ratio (S/I). On the other hand, among the least studied aspects are headspace (2.16%) and retention time (3.03%). In addition, after reviewing the studies and the variables assessed, only 18% simultaneously assessed two or more variables. This analysis is useful to establish whether simultaneous interactions exist among these variables. | [40] | |

| Manure was highlighted as a significant source of ammonia, methane, and nitrogen oxide emissions, which were estimated to be 40%, 22.5%, and 28%, respectively, of total United Kingdom (UK) anthropogenic emissions. AD is a technology that can drastically reduce the potential for manure contamination compared to process absence, thus reducing approximately 90% of methane and 50% of nitrogen oxide emissions. More than 1615 TWh of electricity could be generated, since most of the 90 million tons of manure produced by the UK would be processed through biogas capture. | [41] | |

| Gasification | Three gasification agents were used: air, steam, and oxygen, which produce different gas compositions, calorific values, and yields. Based on this, the authors deduced that steam produces a greater amount of , with a higher calorific value compared to gasification by air and oxygen, thus also reducing tar content from 17% to 24% more than the other agents. Although air is the most common agent for gasification, since it is an abundant natural compound and it is easy to use, it has a major drawback: it contains approximately 79% nitrogen, which largely dilutes the resulting gas and increases its separation cost. Moreover, the re-sulting gas has a low calorific value , being constrained to the on-site generation of heat and power. Oxygen has two drawbacks: the high cost of pure oxygen and the large cost needed to separate oxygen from syngas; hence, it is often combined with steam as a gasification agent. | [42] |

| Plastic waste steam gasification produces a synthesis gas rich in , of interest both for synthesis and energy applications. Furthermore, the absence of increases the calorific value of synthesis gas in values exceeding . Despite obtaining a higher quality syngas through steam gasification of plastics, this process must overcome two main limitations: process endothermicity, and the high tar content of the final product. | [27] | |

| The combined use of biomass/waste results in higher carbon conversion, production of a large amount of gas, and reduced hazardous toxic elements. The authors also deduced that fluidized bed gasifiers are more efficient in conversion, with less tar formation compared to fixed bed gasification techniques, which is one of the main issues of using this technique. | [43] | |

| The production of electricity and heat from biowaste resources in a Fluidyne Micro-Lab Class air-blown gasifier, which operates at atmospheric pressure, was also as-sessed. Poultry litter and digestate (obtained from an AD plant working with a mix-ture of animal manure and green waste) were selected for analysis. All materials were pelletized to increase their energy density. Consequently, the authors found that drying is essential for biowaste with high moisture content (50–60%), such as poultry waste, digestate, and MSW. The PCI of the Synthesis Gas produced oscillated between . In addition, agricultural and forestry waste do not require any pretreatment drying processes and can produce a useful amount of electricity. | [44] | |

| Pyrolysis | A critical review of the fate of the main chemical elements (C, H, O, N, P, Cl, S and metals) and advances in research on the emission, transformation, and distribution of pyrolysis elements was undertaken. First, the authors concluded that future work must be geared toward on-site or online detection and monitoring technologies, such as TG-FTIR-MS and Py-GC/MS, or advanced characterization techniques, such as solid carbon-13 spectroscopy nuclear magnetic resonance and synchrotron-based X-ray absorption spectroscopy, which could provide a feasible strategy to elucidate more deeply and precisely the mechanism and behaviors of lignocellulosic biomass in the pyrolysis process. Second, efficient sustainable catalysts and processes must be de-veloped to convert C, H, and O into desired products (i.e., bio-oil) and to avoid un-wanted products (i.e., tar and persistent organic pollutants). Third, any future works must ultimately predict and prevent the emission of through the development of new reducing agents or catalysts. Fourth, the development of technologies based on the calcium loop within the pyrolysis process could effectively retain N, P, S, and Cl in the biocarbon phase, and thus control their emissions in the bio-oil and gas phases. Likewise, some heavy metals, such as Cu and Ni denote catalytic effects in biomass pyrolysis to improve the final product. Finally, biomass co-pyrolysis with carbon or synthetic polymers (i.e., plastics, and rubbers) contributes to improving both the quality and the quantity of the pyrolysis oil, without having to improve the system process. | [28] |

| The study indicated that co-pyrolysis has been recognized for its ability to significantly improve the quantity and quality of pyrolysis oil, without the addition of catalysts, solvents, or hydrogen pressure to the process. On the other hand, co-pyrolysis has been considered an efficient and economical method for the production of high-grade biofuels from waste co-processing. | [29] | |

| Several biomass pretreatments have been developed, such as physical, thermal, chemical, and biological methods to improve the performance and quality of bio-oil; however, the structural configuration of raw materials and how they relate to bio-oil composition and properties must be studied further. Likewise, many researchers have developed different reactor configurations to maximize the yield of bio-oil or to improve the properties or certain specific properties thereof. Despite this, a large number of reactors still cannot fully meet the requirements of commercial pyrolysis reactors on an industrial scale, since a pyrolizer must have the ability to process versatile raw materials and accommodate low raw and reactor material requirements, as well as high heat transfer efficiency, among other aspects to reduce the operation costs and meet commercial use requirements. In this context, zeolite-based catalysts have emerged as promising agents for converting biomass into a low-oxygen fuel. Even so, they still suffer from coke fuel formation and its consequent rapid deactivation. Moreover, low bio-oil yields and carbon deficiency are the other parameters that must be considered when working with these catalysts. | [31] | |

| A pyrolysis study of different refuse derived fuel (RDF) samples was conducted in a semi-batch rotary kiln. These RDF samples were obtained from two different waste treatment plants operated by Bharuch Enviro Infrastructure Limited in the city of Ahmedabad, India, at an average feed particle size of 50 mm with different shapes. The thermal behavior of the RDF samples was studied using a thermal gravimetric analysis by heating in the presence of pure nitrogen (100 mL/min) at 20 °C/min up to 900 °C. Pure nitrogen was used to remove gaseous condensable products and air from the pyrolysis zone. The results showed that the quality of the pyrolysis product varied according to the feed composition and the operating temperature, wherein the highest oil yield (43%) was obtained with the RDF sample containing 77% of plastics at 500 °C. | [45] | |

| Other Technologies | A review of the critical Hydrothermal Carbonization (HTC) parameters was conducted, including temperature, residence time, heating speed, reagent concentration, and water quality. This review provided new perspectives that can be used to enhance the potential of this technology. The authors concluded that future work efforts must address the influence of a wide variety of organic substances contained in the biomass and identify their conversion mechanisms during the HTC process. Temperature was identified as the critical parameter governing hydrocarbon characteristics; however, more variables must be considered, such as heating rate, particle size, substrate concentration, packing ratio, catalyst addition, and liquid quality. | [25] |

| HTC from organic MSW fractions could reduce the problem of landfills and provide a sustainable source of solid fuel. The research indicated that upon increasing carbonization severity (higher temperatures and longer residence times), the solid yield and volatile hydrocarbon matter content generally decreased, while elemental carbon content increased, leading to higher heating values. However, at carbonization temperatures exceeding 260 °C, the amount of extractable “secondary” carbon decreased, after an initial increase to 220–240 °C. | [46] | |

| In Ecuador, a study assessed the energy potential of from MSW considering thermochemical (gasification combined with steam reform-ing) and electrochemical (gasification combined with electrolysis) paths for their conversion. This study also proved the feasibility of satisfying the energy demand of urban public transportation in 91% of the country with derived from MSW. Here, the authors offered very promising benefits, including a solution to the problem of final MSW disposal, with an improvement in urban transport infrastructure and its corresponding environmental indicators. | [47] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceballos-Sandoval, J.; Pulido-Rojano, A.D.; Rincón-Laurens, H.; Villalobos-Toro, B.; Ospino-Toro, O.; Rincón-Laurens, R.; Restrepo-Vieco, J. Exploring the Energy Potential of Residual Biomass: A Bibliometric Analysis. Energies 2025, 18, 6009. https://doi.org/10.3390/en18226009

Ceballos-Sandoval J, Pulido-Rojano AD, Rincón-Laurens H, Villalobos-Toro B, Ospino-Toro O, Rincón-Laurens R, Restrepo-Vieco J. Exploring the Energy Potential of Residual Biomass: A Bibliometric Analysis. Energies. 2025; 18(22):6009. https://doi.org/10.3390/en18226009

Chicago/Turabian StyleCeballos-Sandoval, Jairo, Alexander D. Pulido-Rojano, Hegel Rincón-Laurens, Bertha Villalobos-Toro, Oscar Ospino-Toro, Ray Rincón-Laurens, and Javier Restrepo-Vieco. 2025. "Exploring the Energy Potential of Residual Biomass: A Bibliometric Analysis" Energies 18, no. 22: 6009. https://doi.org/10.3390/en18226009

APA StyleCeballos-Sandoval, J., Pulido-Rojano, A. D., Rincón-Laurens, H., Villalobos-Toro, B., Ospino-Toro, O., Rincón-Laurens, R., & Restrepo-Vieco, J. (2025). Exploring the Energy Potential of Residual Biomass: A Bibliometric Analysis. Energies, 18(22), 6009. https://doi.org/10.3390/en18226009