1. Introduction

Energy consumption has driven the development and adoption of sustainable technologies for various practical applications. Today, the building sector accounts for approximately 40% of the total global energy consumption, thus making it a critical area for improvement [

1]. The integration of solar energy systems into buildings is one of the most promising solutions that has been developed. These systems play an increasingly important role in reducing energy demand by producing renewable energy and enhancing energy efficiency [

2]. The Trombe wall, which consists of an outer glazed layer, an air gap, and a thermally massive inner wall with two vents positioned at the top and bottom, is a well-known example of passive solar systems [

3]. This system, when included as part of a Solar Air Heating Façade (SAHF), functions as a passive mechanism for both heating and cooling. A Trombe wall, which harnesses solar radiation and ambient temperature variations, stores energy and releases it into the indoor environment at optimal times and rates. Since architectural integration is one of the most relevant market barriers to this kind of system, this study has explored different strategies to enhance the architectural integration of Trombe wall-based SAHF, while simultaneously improving their thermal performance. One of the most effective ways of minimizing heat losses in buildings is to enhance the thermal resistance of the envelope using either opaque or transparent insulation materials. Therefore, the first strategy we considered, which involved filling the gap with translucent material, was aimed at increasing the thermal resistance of the glazed element to enhance its insulating properties. This approach significantly reduces the energy required to maintain indoor thermal comfort [

4,

5]. Several well-established solutions exist for transparent elements, including double glazing with inert gas, where argon or krypton is used between two glass panes to reduce heat [

6]. Triple glazing with low-emissivity (Low-E) coatings, which is used to obtain improved insulation, involves adding a third pane with a special coating that reflects infrared radiation, while allowing visible light to pass through. Selective-tint, double glazing further controls solar heat gains, due to the use of tinted glass, whereby a balance is achieved between thermal insulation and daylighting. Polycarbonate (PC), multiwall panels have also gained popularity in building applications, because of their lightweight nature, durability, and their resistance to fire, weather, and UV radiation. These panels are versatile and can be used in fenestration systems, continuous windows, skylights, roofs, and walls, and they offer a variety of cell geometries, colours, and thicknesses. In addition to being more cost-effective than traditional glazing, PC panels can significantly improve the thermal performance of a building, if they have been properly designed, and they can result in substantial energy savings, particularly for commercial and industrial buildings [

7]. Recent research into façade systems has involved investigating both silica-aerogel-based insulation and reflective coatings to enhance thermal performances. Buratti and Moretti [

7] investigated the integration of a granular silica-aerogel into polycarbonate (PC) multiwall panels of various thicknesses (16, 25, and 40 mm) to enhance the thermal performance of non-residential buildings. Experimental and numerical analyses have revealed that aerogel-filled PC panels can achieve a reduction of 46–68% of the U-values, compared to air-filled systems, with values ranging from 1.4 W/m

2 K for 16 mm panels to 0.6 W/m

2 K for 40 mm panels. Although light transmittance decreases as the thickness increases, the reduction is acceptable for 16 mm panels, but it is even more significant for 40 mm panels. Another advanced solution is the use of silica-aerogel, a highly insulating, translucent material that can be incorporated into glazing systems to further reduce heat losses [

8]. It in fact offers high thermal resistance, but it also requires significantly thinner layers than traditional insulation materials, and it enables a reduction in the overall thickness of a building structure. Silica-Aerogel is an ultra-lightweight, nanostructured porous material that has a three-dimensional network. Its skeletal density is approximately 2200 kg/m

3 [

9]. Because of its high porosity (it has pores ranging from 5 to 100 nm, which occupy over 90% of the total volume), the bulk density typically falls between 80 and 200 kg/m

3 [

10], although, in some cases, it can be as low as 3 kg/m

3 [

11]. This material boasts an exceptionally high specific surface area, which can reach up to 1000 m

2/g [

12]. Silica-aerogel, known to be one of the lightest and most effective insulating solid materials, exhibits a remarkably low thermal conductivity, that is, as low as 0.013 W/(m·K). This low conductivity is achieved through a combination of reduced solid and gaseous thermal conductivity, along with minimal infrared radiation transmission [

13]. The most notable advantage of silica-aerogel is that it can function as an optical filter, as it is opaque to infrared radiation but remains transparent to sunlight. The spectral and physical properties of silica-Aerogel make it highly effective in suppressing heat losses. Additionally, silica-aerogel is characterized by its non-toxicity, durability, low flammability, lightweight nature, and air permeability. Transparent silica-aerogel has recently garnered significant attention from researchers due to its exceptional insulation capabilities. It effectively prevents heat losses while allowing high solar transmission, a performance feature that has been attributed to its transparency to sunlight, opacity to infrared radiation, and extremely low thermal conductivity.

Architectural integration poses significant challenges, because it requires the balancing of technical functionality with aesthetic considerations. Indeed, integrating SAHF systems into building façades often involves trade-offs between maintaining structural integrity and achieving a visually appealing design. Additionally, there are certain material and technical constraints, such as the use of coatings and configurations that provide both high thermal efficiency and a seamless integration with diverse architectural styles. Overcoming these challenges necessitates innovative strategies that can harmonize energy efficiency with design flexibility. Therefore, the second strategy we adopted involved applying wooden lamellas with improved solar reflectance properties.

The use of lamellas as a shading device in solar façades provides both solar regulation and enhanced architectural aesthetics. Their lightweight structure, ease of installation, and natural visual appeal make them attractive design elements. When integrated into SAHF systems, lamellas introduce innovative ways of merging architecture with passive heating and cooling systems. Trombe walls, which are traditionally black to obtain an optimal heat absorption, often lack aesthetic appeal, and this can limit their market adoption. However, to address this issue, architects can explore a variety of design strategies, such as incorporating lamellas to add depth and texture, selecting advanced coatings to modify the appearance without compromising efficiency, and/or integrating materials that blend with the overall aesthetics of a building. A thoughtful orientation and choice of the materials and of the spacing of the lamella will ensure not only an improved energy performance but also durability, airflow regulation, and seamless architectural integration, which, in turn, will make SAHF systems more appealing and adaptable to diverse architectural styles.

However, to enhance their thermal performance, these lamellas require advanced surface modifications to improve their solar reflectance, mitigate overheating, and optimize the use of solar energy. Coatings or surface treatments are important to increase the ability of lamellas to reflect incident solar radiation. These coatings, which are an important innovation in building materials, offer such benefits as better energy efficiency, sustainability, improved thermal comfort, and support in managing urban microclimates [

14]. Reflective materials make use of a wide range of substances that utilize the principle of reflection for various applications across industries. Spectrally selective (SS) materials, retroreflective (RR) materials, thermochromic materials, and other specialized reflective substances are some of the most frequently used materials. As far as the coupling of silica aerogel and solar management is concerned, Zhao et al. [

15] developed a system that achieved temperatures above 473 K under real-world, weather conditions, without relying on an optical concentrator, by integrating silica-aerogel with a flat-plate solar receiver.

Qiu et al. [

16] designed an innovative parabolic trough receiver insulated with silica-aerogel, which demonstrated an efficiency improvement of 0.32–5.04%. Zhao et al. [

17] achieved a silica-aerogel with an exceptionally high solar transmittance (95%) by optimizing its microstructure to minimize scattering. Building on this advancement and utilizing aerogel, they developed a solar thermal device that could generate steam at 100 °C, and which had an efficiency of 56% under a solar irradiation of 700 W/m

2. Lv et al. [

18] examined the performance of 12 aerogel-filled glazing samples, with different average particle sizes and filling thicknesses, using a spectrophotometer. Although aerogels are commonly utilized in solar thermal absorbers, their potential applications in solar systems are still an area of ongoing exploration to address existing knowledge gaps. Furthermore, many studies have investigated various alternative reflective materials. W. Guo et al. [

19] investigated the energy-saving effects of a heat-reflective, insulating coating on exterior walls in Hangzhou, China. They conducted experimental tests in test rooms with and without the coating, and they found that the coating reduced the exterior wall surface temperatures by 8–10 °C, which resulted in an annual reduction of approximately 5.8 kWh/m

2 per month in the electricity consumption for air-conditioning. R. Levinson et al. [

20] developed methods to create non-white, solar-reflective surfaces by combining NIR-scattering pigments with reflective basecoats. These materials led to an enhancement of the reflectance of such roofing materials as metal, clay tiles, concrete, wood, and asphalt shingles.

A. Charikleia et al. [

21] evaluated the impact of advanced coatings on building façades, considering their thermal and optical properties, such as low thermal conductivity, high solar reflectance, and high emissivity. Their results revealed that the cooling loads in Athens, Greece, reduced by as much as 48.4%, and they reduced by 76.2% in Warsaw, Poland, while the heating loads decreased by 17.2% and 11.8%, respectively. S. Malz et al. [

22] explored the use of infrared, reflective, wall paint combined with heat insulation for historic brick masonry. Their results demonstrated that energy savings of 18% to 22% could be achieved under thermal comfort conditions.

Spoke 4 “Digital and Sustainable Mountains”, Research Module Interface [

23], in the framework of the NODES project, is aimed at developing novel envelope solutions that are suitable for both the energy retrofitting of existing buildings and for new buildings in mountainous areas. This study is aimed at enhancing the architectural integration of (SAHF) systems, while maintaining their thermal and solar performances (

Figure 1). Two strategies have been explored: (1) the use of a silica-aerogel infill in polycarbonate panels to increase thermal resistance, and (2) the application of coated lamellas to control solar transmission and improve visual integration. The experimental analysis involved evaluating various material configurations and lamella geometries under controlled conditions to assess their effectiveness in optimizing their energy performance and the façade aesthetics. The present research, by combining advanced insulation materials with reflective shading elements, proposes integrated solutions as a response to modern architectural demands, and it aims to contribute toward providing energy-efficient and climatically responsive building envelopes.

2. Methodology

This study has focused on assessing the energy performance of an SAHF system through an experimental investigation of its main sub-components. Two key elements were examined: polycarbonate panels filled with silica aerogel to obtain enhanced thermal insulation, and timber lamellas coated with white paint and reflective aluminium for solar radiation control purposes. A dedicated experimental setup was developed to evaluate the thermal transmittance (U-value) and solar transmission of these façade configurations. Thermal transmittance measurements were performed using a Heat Flow Meter (HFM), in accordance with standardized procedures. An artificial sun was employed within a climatic chamber (BET-cell) to simulate solar radiation, while consistent irradiance and ambient conditions were ensured. The lamella configurations, which were designed to be integrated into large-scale Trombe wall systems, consisted of lightweight horizontal elements optimized to enhance their thermal performance, while preserving structural stability and visual quality.

2.1. Heat Balance of the External Glazed Element

The interactions between reflection, absorption, and transmission within the SAHF are illustrated in

Figure 2. When solar radiation reaches the glazed element, it is partly transmitted into the cavity and partly reflected toward the exterior environment. First, a part of this absorbed energy is re-emitted as long-wave infrared radiation from the inner surfaces of the glazed element. In addition, a considerable portion of the absorbed heat is transferred to the air by means of natural convection, thereby increasing the air temperature within the cavity and promoting a buoyancy-driven flow. This heated air creates a thermal gradient that cause continuous circulation inside the channel. Furthermore, the stored heat is also conducted toward the massive wall, thereby contributing to the overall heat balance. This conductive transfer, combined with convective and radiative exchanges, defines the net heat gain that was available to be transferred to the indoor space.

The primary objective of this configuration was to maximize the solar gains that entered the cavity of the SAHF system. When solar radiation reached the surface of the lamellas, the material properties of the coating were responsible for how the radiation was transmitted. A part of the incident solar radiation was reflected by the coated lamella surface toward the polycarbonate panel. This controlled reflection effectively redirected a portion of the solar energy that would otherwise have been lost, and it thus enhanced the solar irradiation received by the polycarbonate layer. The polycarbonate panel, in turn, transmitted a portion of this redirected radiation into the cavity. Therefore, the use of reflective top coatings, in this context, reduced the rejected solar radiation, as is typical in passive cooling strategies, and redirected and concentrated the solar energy toward the transparent façade surface, thereby improving the solar collection efficiency. This approach supported the thermal performance of the SAHF system by amplifying the movement of direct and reflected solar gains into the cavity.

A comprehensive heat balance analysis is essential to understand the energy transfer processes that occurred in the system, including the solar gains and the heat losses to the ambient environment.

Mathematically, the total heat flux Qnet that entered the cavity space was governed by the following relationship (1):

Mathematically, the total heat flux Q

net entering the cavity space is governed by the following relationship (1):

where q

sol is the heat flux that was transmitted into the interior due to solar radiation which is calculated by Equation (2) and q

TR is the heat flux that was lost to the exterior which is calculated by Equation (3).

The transmitted solar heat flux q

sol is defined as:

where g represents the solar heat gain coefficient or solar factor and I is the incident solar irradiance (W/m

2).

The heat flux lost to the exterior is expressed as:

where U represents the convective and radiative heat transfer coefficient in the interior of the SAHF, T

cav is the SAHF cavity temperature (K) and T

ext is the exterior temperature (K).

The total heat flux Q

net, can be expressed under steady state conditions, according to Equation (4):

where q

i represents the secondary heat flux that is absorbed and re-emitted.

Since it was not possible to determine the g-value of the translucent materials with low thermal conductivity due to the impossibility of shading a part of the surface of a heat flux meter sensor without locally perturbating the surface temperature the solar transmission (τ) component was used to estimate the heat balance, while the secondary flux absorbed and re-emitted into the SAHF was neglected in this analysis. This procedure can lead to an underestimation of the solar heat gains and can be only considered reliable only when the solar absorption part is marginal compared with the solar transmission part and for comparative purposes when considering different solutions.

2.2. Performance Metrics

This section presents the performance metrics and the experimental assessment methodology, focusing on the thermal performance and solar transmission characteristics of various configurations. The analysis was structured around three key performance indicators:

The Thermal Transmittance was calculated in accordance with EN ISO 6946:2017 [

24], following the simplified Formula (5):

The interior surface resistance (Rsi), equivalent to 0.13 (m2 K)/W and an exterior surface resistance (Rse), equivalent to 0,04 (m2 K)/W, were considered.

The solar transmission factor τ which indicates the percentage of solar energy transmitted through the SAHF, was calculated as (6):

where I

sample is the solar irradiation measured behind the sample and I

inc is the incident solar irradiation without sample.

The Reduction Factor was used to measures how different configurations reduce the solar transmission in comparison with a reference baseline component, defined in Equation (7):

where τ

analysed component is the solar transmission factor in the tested component and τ

baseline is the solar transmission factor in the baseline component (PC without aerogel and without lamellas).

2.3. Analysed Samples

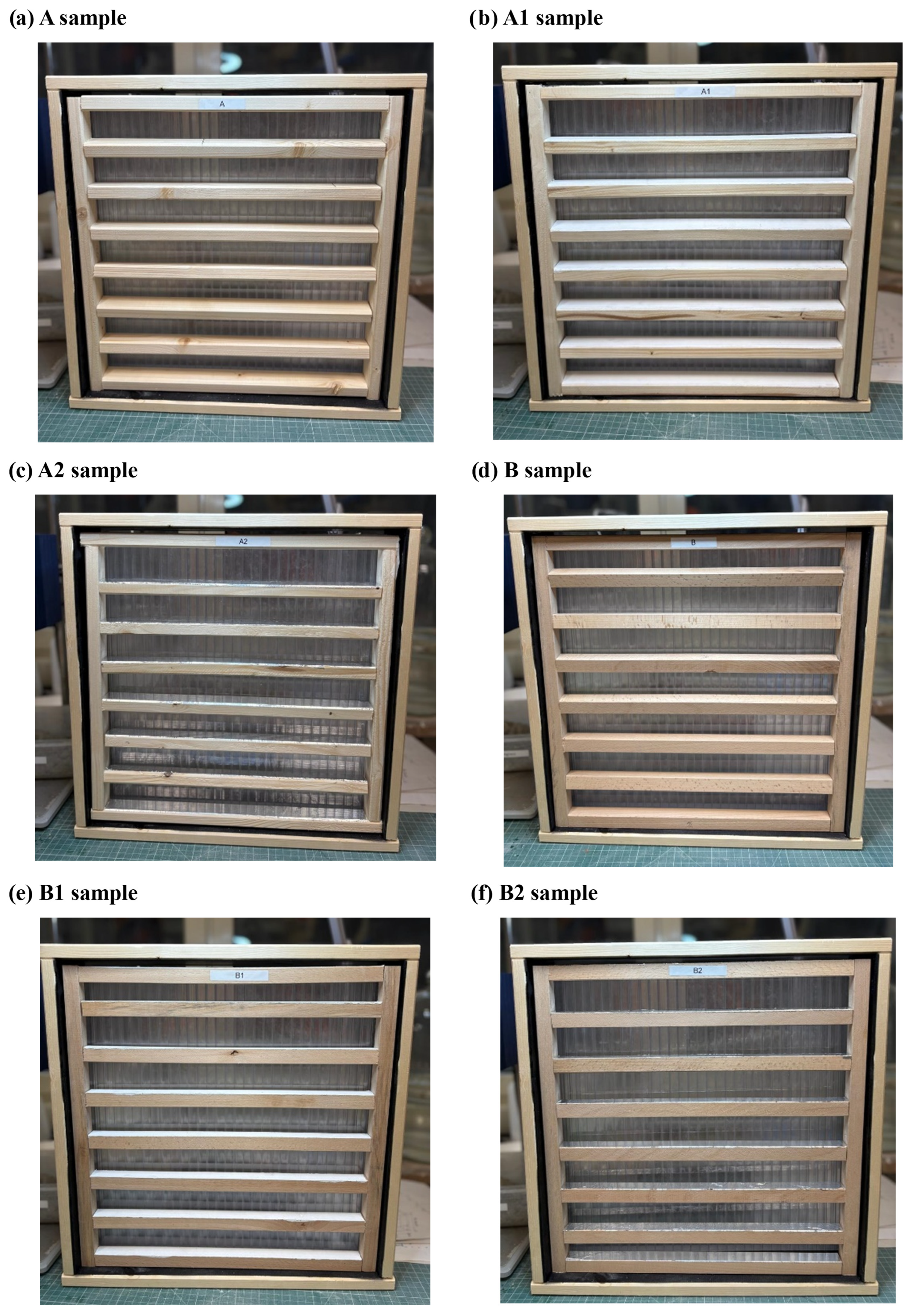

Four different multiwall polycarbonate panels were first tested and then employed to manufacture a small-scale prototype. The samples had to have a minimum measurable area of 300 × 300 mm to be tested with the HFM. Thus, 400 × 400 mm panels, with thicknesses of 20 mm, 16 mm and 10 mm, were fabricated to fulfil this requirement, (as shown in

Figure 3a).

The three panel thicknesses were selected to reproduce the typical U-values of Double-Glazing Units (DGUs), ranging from simple uncoated DGUs to argon-filled and Low-E coated systems. This allows the tested SAHF configurations to represent a realistic range of façade insulation levels, facilitating comparison with standard glazing technologies.

The prototype utilized for the solar transmission analysis consisted of a timber frame, which was used to hold the polycarbonate panels, as shown in

Figure 4 and

Figure 5. Additionally, the frame incorporated horizontal lamellas, and it enabled different coatings, widths, and orientations to be tested. The lamella box measured 40 × 40 cm, the lamella was positioned equidistantly, with an average spacing of 3.6 cm between them, and the overall assembly thickness was kept constant at 18 cm for all tested configurations. The polycarbonate panels were positioned behind the lamellas. Furthermore, the polycarbonate layer was tested under two different conditions: unfilled polycarbonate and silica-Aerogel filled polycarbonate to evaluate the impact of aerogel in the thermal insulation and solar transmission capabilities. Moreover, three different conditions of the top faces of the lamellas were considered to obtain three design options: wood on its own (uncoated), painted in white, and coated in reflective aluminium. In addition to the coatings, the influence of the lamella width was investigated using 2 cm and 3 cm configurations, as illustrated in

Table 1, and they were evaluated in two orientations: a vertical baseline at 0° and inclined positions at 20° and 45°, to emulate the effect of different incident solar angles. Two pyranometers were placed behind the polycarbonate layer to measure the intensity of solar irradiation. At the same time, a data acquisition system recorded real-time solar transmission data.

2.4. Thermal Transmittance Measurements

The different alveolar polycarbonate samples with a multiple number of cavities and void fractions were tested in both an empty state (air cavities) and filled with aerogel. It should be mentioned that it was not possible to fill the 10 mm-thick panel (with four internal cavities) due to the limited size of the cavity; therefore, it was only tested in its empty configuration. The equivalent thermal conductivity with air cavities and the equivalent thermal conductivity with the aerogel infill were measured a Heat Flow Meter apparatus (LaserComp, Inc. © 2001-2005 Fox 600-20 Spring Street, Saugus, MA 01906, USA) illustrated in

Figure 3b, according to ASTM C518 standard [

25]. A granular CABOT aerogel (LUMIRA

® Aerogel LA1000—Frankfurt, Germany) was employed, with a thermal conductivity of 0.017–0.022 W/mK, depending on the density.

The boundary conditions considered to perform the experiments and calculations are reported in

Table 2. The repeatability of the test was proved by taking four different measures for each configuration of panels with both air cavities and aerogel infill. The test was performed twice with upwards flux direction and twice downwards. Laboratory room conditions were monitored by a Testo 175-H2 datalogger, resulting in an ambient temperature (Ta) of around 26 ± 1.5 °C and relative humidity (RH), around 34 ± 3.5%.

2.5. Solar Transmission Measurements

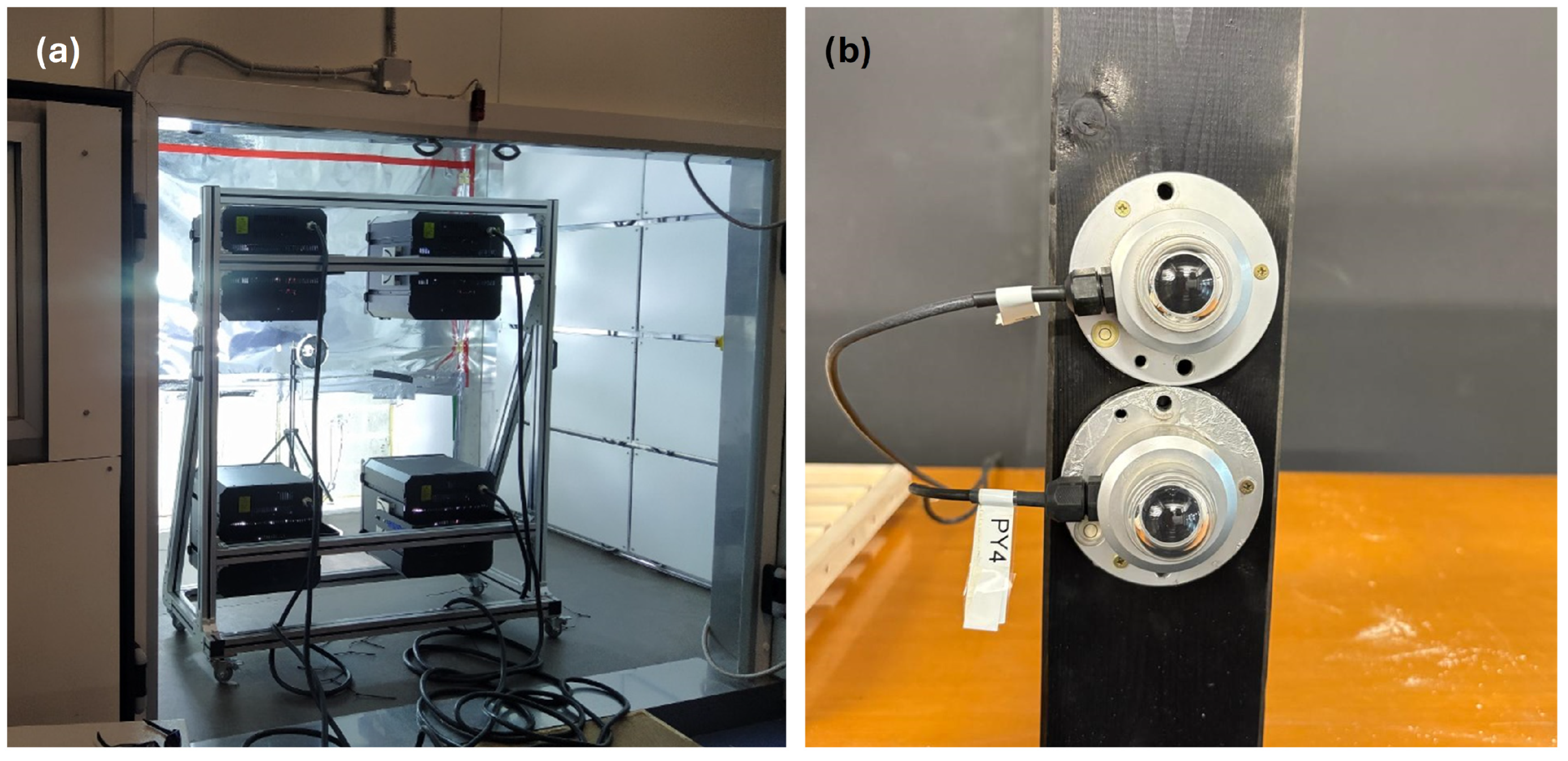

The prototype, which consisted of a lamella box and polycarbonate layer, as described in the previous section, was placed in front of the artificial sun solar radiation source during all the tests (

Figure 6a). A fixed distance of 1 m was maintained between the light source and the prototype to ensure a uniform radiation intensity over the entire surface, thereby minimizing any potential irradiance gradients.

Three tilt angles (0°, 20°, and 45°) were selected to illustrate the effect of the angular positioning on solar transmission (

Figure 7). These configurations were not intended to replicate specific real-world conditions but rather to provide a controlled framework in order to understand how different inclinations influenced the light modulation, irradiance distribution, and potential thermal gains. The study, by analysing different angles, aimed to highlight the impact of angular deviations on the performance of the system, and to offer insights into how tilt adjustments could affect energy efficiency.

The experimental set-up included an artificial sun, which was designed to replicate solar radiation under the standardized conditions shown in

Figure 8a. The lighting system was made up of lamps with a correlated colour temperature (CCT) of 6500 K, in compliance with DIN 75220:1992 [

26] and CEI EN IEC 60904-3:2020 [

27], to ensure an accurate spectral distribution for solar simulation. These lamps were coupled with symmetric parabolic reflectors to produce a high proportion of parallel light beams to promote uniform irradiance over the test surface.

The irradiated area measured at least 1200 mm × 1600 mm (height), and the irradiance intensity ranged from 1000 to 1200 W/m2 at its peak. The system was also dimmable to allow controlled adjustments of the irradiance to be made within a minimum range of 80–600 W/m2 and a maximum one of 600–1200 W/m2, depending on the test requirements.

The solar simulator satisfied the IEC 60904-9:2020 [

28] classification requirements, that is, at least Class B for a spectral match (AM1.5 spectrum), Class C for non-uniformity (±10%), and Class A for temporal instability, thereby ensuring a short-term instability (STI) of ±0.5% and long-term instability (LTI) of ±2%. These parameters confirm the suitability of the simulator for accurate and repeatable thermal and optical performance evaluations of building components under controlled conditions.

Two second class Pyranometers (Hukseflux LP02 [

29], as illustrated in

Figure 8b) were installed behind the polycarbonate layer to monitor any localized variations of the irradiance intensity with an accuracy of ±5%.

The transmitted solar intensity was continuously recorded for each configuration, with data being sampled at a frequency of 10 s. Each test was conducted over a period of approximately 15 min to allow the system to reach thermal stability. However, only the data collected during the stabilized phase, that is, in the final 5 min, were considered for the analysis to ensure accurate and consistent results. The data recorded from this period were averaged to quantify the effective solar transmission for each tilt configuration. Additionally, spatial variations in the transmitted intensity were examined to evaluate the influence of the angular positioning on the uniformity and distribution of irradiance over the surface.

All the experiments were conducted under identical lighting and environmental conditions to isolate the effects of angular variation on solar transmission. All the inclination angle configurations were experimentally tested with the PC16 polycarbonate samples.

Table 3 presents the measured global incident irradiance values and the corresponding transmitted irradiance for the different tested configurations.

The table reports the mean transmitted and incident solar irradiance values measured under stable artificial solar conditions for each configuration. The standard deviation (±SD) represents the repeatability of the measurements. The incident irradiance, monitored by a calibrated pyranometer, remained approximately constant at 982 ± 5 W/m2 during the tests.

4. Heat Balance Estimation and Performance Evaluation of SAHF

A simplified steady-state heat balance model was used to estimate the net thermal performance of the different SAHF configurations (Equation (4)). The model is intended to capture the main energy exchanges within the façade, while neglecting solar absorption and heat emission inside the cavity. Thermal inertia and non-uniform solar distribution are also not considered, consistent with the simplified steady-state assumption.

We referred to a full-scale monitoring campaign carried out on an SAHF Trombe wall during the 2023–2024 heating season in Turin (Italy) to ensure that the assessment reflected realistic operating conditions [

31]. We estimated

Qnet, which is the net heat gain of the SAHF cavity, using these reference values for each tested configuration, thereby accounting for the absorbed solar radiation and the thermal losses to the exterior. This approach allowed us to evaluate whether the configuration that had been validated at a small-scale could maintain sufficiently good performance under real-scale conditions. Although these estimations do not fully replicate conditions or long-term measurements, they provide a reliable framework that can be used to verify the thermal suitability of each configuration for building integration purposes, and they are intended as an initial criteria to select the most promising solutions for future integrations at a larger scale.

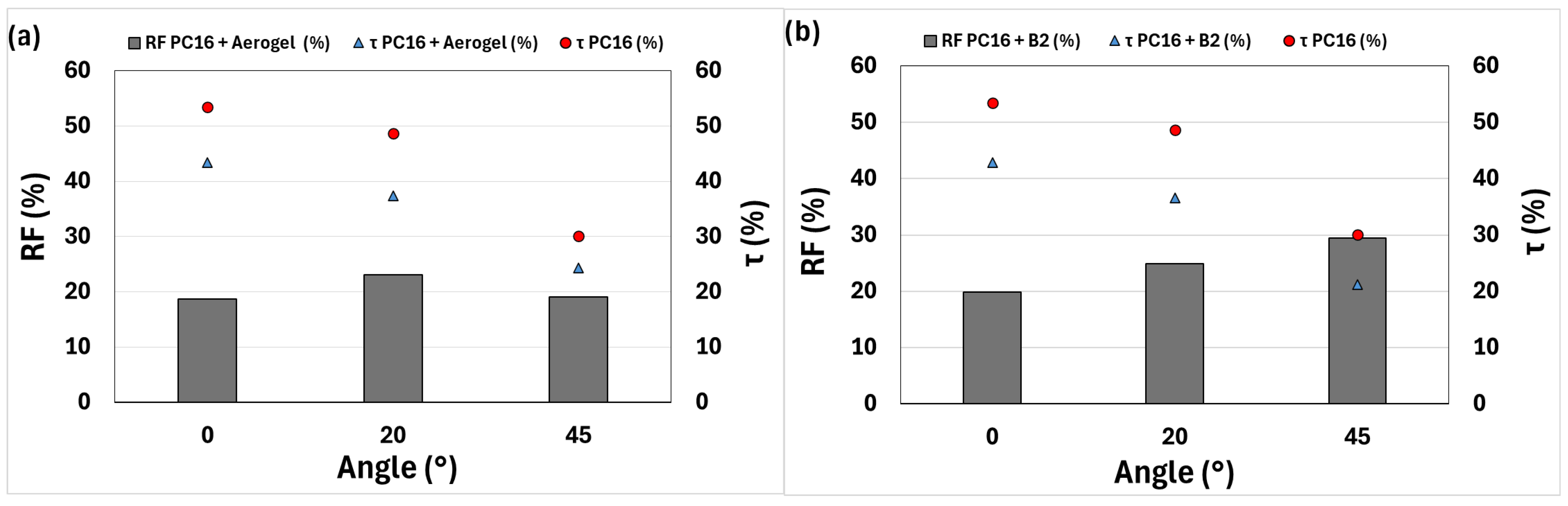

The first graph (

Figure 14a) illustrates the cumulative frequency distribution of the air temperature differences (ΔT) between the solar façade cavity and the outdoor environment. It shows that ΔT remained below 6 °C, which corresponds to nocturnal or low solar radiation conditions, during approximately 30% of the monitoring period. The median ΔT value is around 11 °C. Moreover, 90% of the values are below 20 °C.

The second graph (

Figure 14b) presents the cumulative frequency distribution of the incident solar radiation measured over the same period. About 30% of the radiation values are below 100 W/m

2, thereby reflecting frequent low-radiation conditions. The median value is approximately 250 W/m

2, while 90% of the irradiance values remain below 500 W/m

2.

Finally,

Figure 14c refers to the cumulative distribution of solar radiation during daytime hours and reveals that 60% of the data correspond to irradiance levels below 600 W/m

2, thereby highlighting the stronger impact of solar gains during daytime.

A representative range of environmental conditions was defined, on the basis of these cumulative distributions, to support the heat balance estimation. Specifically, solar radiation values of 150 W/m2, 250 W/m2, and 400 W/m2 were selected to reflect the low, medium, and high irradiance scenarios that were observed during the winter monitoring campaign. Similarly, air temperature differences (ΔT) of 5 °C, 15 °C, and 25 °C were chosen to represent a gradient from minimal to substantial thermal differentials between the façade cavity and the outdoor environment.

At (0°) incidence angle (

Figure 15): At 150 W/m

2, PC16 showed 69 W/m

2 of average heat gains for ΔT = 5 °C, but dropped to 24 W/m

2 for ΔT = 25 °C. The PC16 + Aerogel reached 28 W/m

2 for ΔT = 25 °C, thereby slightly improving the performance. The lamellas significantly reduced the performance, with B1 at –8 W/m

2 and B2 at 8 W/m

2, thus confirming the dominance of heat losses for low irradiance. At 250 W/m

2, PC16 recorded 100 W/m

2 for ΔT = 15 °C, while PC10 + Aerogel achieved the highest value (127 W/m

2), thus underlining the benefit of Aerogel in reducing losses. The lamella configurations remained lower, with B2 at 73 W/m

2, and they outperform B1 (25 W/m

2). The gains were at a maximum of a 400 W/m

2: PC10 + Aerogel reached 240 W/m

2 for ΔT = 5 °C, a result that was significantly above that of PC16 (202 W/m

2). B2 maintained its reliable performance (138 W/m

2 for ΔT = 15 °C), while B1 remained less effective (96 W/m

2).

At (20°) incidence angle (

Figure 16): At 150 W/m

2, PC16 reached 17 W/m

2 of average heat gains for ΔT = 25 °C, while PC16 + Aerogel recorded 19 W/m

2 and B2 fell to –1 W/m

2. At 250 W/m

2, PC16 achieved 139 W/m

2 for ΔT = 25 °C, while Aerogel improved by about 112 W/m

2. B2 remained competitive at 90 W/m

2 and was once again more performant than B1 (65 W/m

2). At 400 W/m

2, PC16 showed 183 W/m

2 for ΔT = 5 °C, but PC16 + Aerogel demonstrated a higher efficiency at 112 W/m

2 for ΔT = 25 °C. B2 show slightly lower performance with 90 W/m

2 of average heat gains, whereas B1 underperformed

At (45°) incidence angle (

Figure 17): At 150 W/m

2, PC16 provided 34 W/m

2 of average heat gains for ΔT = 5 °C, but dropped to –11 W/m

2 for ΔT = 25 °C. Aerogel mitigated the loss (−1 W/m

2), while B2 showed the lowest value (−24 W/m

2). At 250 W/m

2, PC16 showed 139 W/m

2 for ΔT = 25 °C, while it reached 112 W/m

2 with Aerogel. B2 remained lower (90 W/m

2), although it was still more performant than B1. At 400 W/m

2, PC16 reached 183 W/m

2 for ΔT = 5 °C and 139 W/m

2 for ΔT = 25 °C. Aerogel performed in a similar manner, that is, from 142 to 112 W/m

2, while B2 indicated from 135 to 90 W/m

2, thereby showing the strongest shading effect for the high tilt angles.

A consistent trade-off emerged for all the incidence angles between thermal insulation and solar transmission. The Silica-Aerogel configurations demonstrated clear advantages at higher temperature differences. The lamella component, that is, the white-coated lamella (B1), provided limited benefits, whereas the aluminium-coated lamella (B2) performed always better than B1, as it redirected part of the incident radiation into the cavity, especially for intermediate ΔT values. The solar gains were maximized for normal incidence (0°), while the differences between materials were more pronounced, with PC10 + Aerogel showing the best performance under high irradiance. Overall, Qnet decreased for realistic tilted angles (20° and 45°), due to a reduced solar penetration, but the relative benefits of Silica-Aerogel insulation and the reflective lamellas became more evident, thereby underlining their role in enhancing energy efficiency.

To complement the analysis of solar heat gains, a simplified steady-state approach was applied to quantify the conductive heat losses during daytime and nighttime periods. The method assumes constant temperature differences between the cavity and the exterior of 15 °C for daytime and 9 °C for nighttime, which correspond to the monitored average temperature gradients in Turin during the winter season of [

31]. The durations of 8.5 h and 15.5 h were selected based on the average seasonal daylight hours and nighttime hours, respectively. The energy balance was calculated considering a 20° solar incidence angle, which represents the average winter solar altitude in Turin, ensuring a more realistic assessment of the system’s performance. This calculation isolates the conductive component of thermal exchange to enable a 24 h energy balance, combining both solar gains and heat losses. As shown in

Table 4, the Aerogel-filled panels exhibit the lowest energy losses throughout the day and night.

It should be noted that this simplified heat balance model presents some limitations, as detailed in

Section 4. However, despite these simplifications, this approach provides a reliable framework that can be used to compare different SAHF configurations under realistic climatic conditions.