1. Introduction

Artificial lift remains a cornerstone technology for maintaining and enhancing oil and gas production across a wide range of reservoir conditions. In scenarios where natural reservoir pressure cannot sustain its flow, artificial lift systems enable operators to prolong well life, reduce drawdown, and optimize recovery. A variety of lift methods are available, including gas lift, sucker rod pumps, progressive cavity pumps (PCPs), plunger lift, hydraulic jet pumps, and electric submersible pumps (ESPs). Each method has its niche, but ESPs have become the preferred option for high-flowrate wells, deep completions, and offshore operations, largely due to their volumetric efficiency, compact footprint, and favorable energy profile [

1,

2].

Although gas lift offers advantages in deviated or high-gas oil ratio (GOR) wells, it struggles in deeper and low-pressure conditions. Beam lift systems are constrained by rod loading and stroke limitations, while PCPs, though suitable for viscous fluids, are restricted in rate and temperature tolerance. In contrast, ESPs are capable of lifting fluids from depths exceeding 10,000 ft and delivering production rates of over 20,000 barrels of fluid per day (BFPD). Their versatility across vertical and deviated well profiles makes them highly applicable to waterflooded reservoirs, offshore developments, and high-rate land assets where space, weight, and power constraints are critical [

3].

Despite these advantages, conventional ESP installations carry significant operational burdens. The systems are typically run on jointed tubing with externally banded power cables, requiring full workover rigs for deployment or retrieval. In offshore settings, rig mobilization adds substantial cost and often results in scheduling delays. Failures in downhole components—most commonly in electrical cables, motors, or seals—frequently lead to complete system shutdown, deferred production, and extended NPT [

4].

Industry studies report that ESP systems, while improving over the years, are still susceptible to failing, with the leading failure modes including electrical degradation, thermal stress, scale deposition, and chemical attack [

5]. In high-hydrogen sulfide (H

2S) or high-chloride environments, insulation failure and metal embrittlement are particularly common and often exacerbated by pressure cycling and corrosive fluid chemistries. Scale and solids accumulation degrade pump performance and heighten the risk of sudden failure. Chemical remediation, such as continuous scale inhibition or batch acidizing, though effective, introduces additional operational complexity and cost [

6,

7].

The drive to eliminate rig dependency on ESP interventions dates back to the 1970s, and various deployment alternatives have been evaluated over the decades, including wireline-conveyed, CT-deployed, and umbilical-supported systems. While each approach addressed specific technical hurdles, they each also introduced limitations related to system integrity, sealing reliability, and surface integration. In offshore and high-pressure wells, their compatibility with well control systems remained a persistent barrier to their adoption [

8].

To address these gaps, a new generation of CDESP systems has been developed. These systems integrate high-strength, corrosion-resistant metal-jacketed cables that carry both electrical load and mechanical tension. The cables enable rigless deployment via CT injector heads, while specialized cable hanger assemblies allow electrical termination below the master valve without compromising pressure integrity or production flow [

9]. The combination system of a fully welded high-resistance alloy cable with an ESP installed in an inverted architecture and a VCHS was instrumental for rigless installations.

This evolution enables ESP deployment and retrieval using compact surface equipment, without removing the production tree or disrupting surface infrastructure. Beyond eliminating the need for a workover rig for ESP replacement, the approach has delivered notable cost and time efficiencies. The requirements of rig availability, surface infrastructure removal, wellsite preparation, overall operation duration, and production deferment were all substantially minimized. Early field trials have demonstrated strong system integrity and operational efficiency, even under corrosive and mechanically challenging conditions. Improved metallurgy, wellhead integration, and real-time monitoring compatibility positions CDESP technology as a viable long-term solution for high-risk or offshore wells [

10,

11,

12].

As production optimization continues to emphasize uptime and cost efficiency, the ability to perform ESP interventions without relying on rigs represents a critical advancement. CDESP systems offer a compelling solution for improving asset performance, reducing deferred production, and reshaping how ESPs are managed across the lifecycle of a well.

2. Technology Overview and System Architecture

The evolution of rigless CDESP systems has spanned several decades, focusing on reducing workover rigs reliance without compromising the robustness and reliability of conventional ESP performance. Since the early 1970s, the initial concepts for CDESPs have been driven by the need to streamline ESP replacement and reduce intervention costs. Early-stage designs—such as that proposed by Caycedo and Diebold (1979)—validated the concept but faced significant limitations in cable durability, surface integration, and pressure control technology [

1,

13,

14,

15,

16].

Throughout the 1990s and early 2000s, new deployment technologies such as cable-internal coiled tubing (CICT) and umbilical-based systems began to emerge. These technologies showed an evolution particularly in onshore settings. However, they still encountered persistent challenges, including limited sealing integrity, vulnerability to corrosion and splicing issues, and difficulty maintaining well control in live environments [

2,

10,

11,

12,

13,

14]. By the 2010s, advancements in corrosion-resistant materials, precision welding processes, and the adoption of standardized vertical wellhead interfaces collectively enabled the operational realization of a new generation of CDESP systems, capable of full rigless installation and retrieval under pressure [

17,

18].

2.1. Power Cable Design and Metallurgy

A critical advancement enabling modern CDESPs’ reliability is the development of the metal-jacketed power cable, as seen in

Figure 1. The figure showcases the metal-jacketed power cable design, with multiple protective layers surrounding the conductor cable. The cable’s final outer layer is a CT, which provides extra protection due to the high-strength fabrication alloy used. The cable’s design needs to account for the conductor size, multi-insulation, weight loads, overall size, and pressure rating, all while remaining airtight, small, and flexible for installations in existing completions. These specifications, which vary depending on the ESP size and voltage requirement, are shown in

Table 1. The table provides the specifications for two types of power cables designs. The smaller cable 1 ½ in. cable is designed for small series ESP 338, while the larger 1 5/8 in. cable is designed for larger ESPs up to the 562 series. In this case study, the cable was fabricated from high-alloy, corrosion-resistant materials such as Alloy 825 (UNS N08825). The cable provides a continuously welded sheath that eliminates traditional failure points such as joints and electrical splices [

2,

3,

4]. The use of Alloy 825 enables the cable to tolerate H

2S concentrations of up to 25%, under favorable thermodynamic conditions and low-chloride environments, while qualification testing has been successfully performed at 15% H

2S concentrations, under more severe conditions involving a higher temperature and an elevated chloride content. This distinction reflects the alloy’s broader corrosion resistance range and demonstrates reliable performance across varying downhole chemistries. Additionally, it offers dual functionality—supporting mechanical loads during deployment while simultaneously transmitting power to the downhole assembly. The cable’s uniform outer diameter (OD) ensures unobstructed travel through CT injectors, minimizing drag and deformation.

Designed for harsh service conditions, the cable is further qualified for high-chloride environments, with longevity assessments projecting a service life exceeding a decade even under cyclic pressure and corrosive completions [

1,

2,

3,

4,

5,

6,

7].

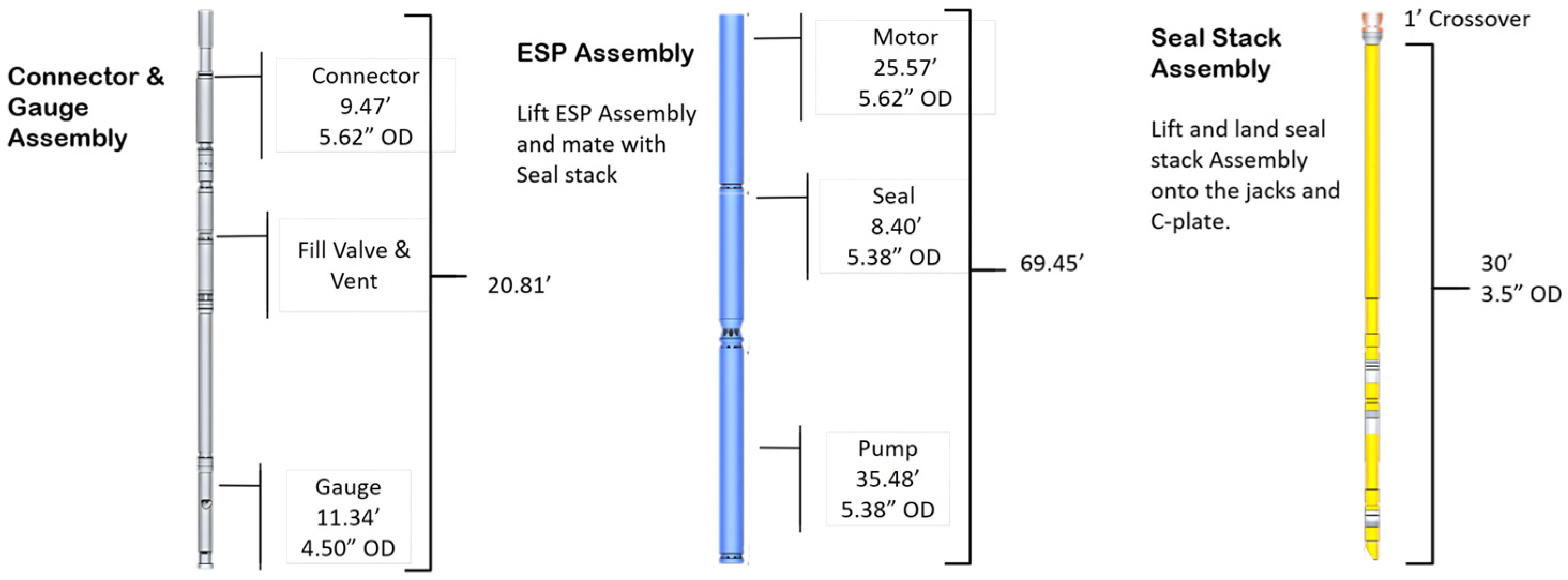

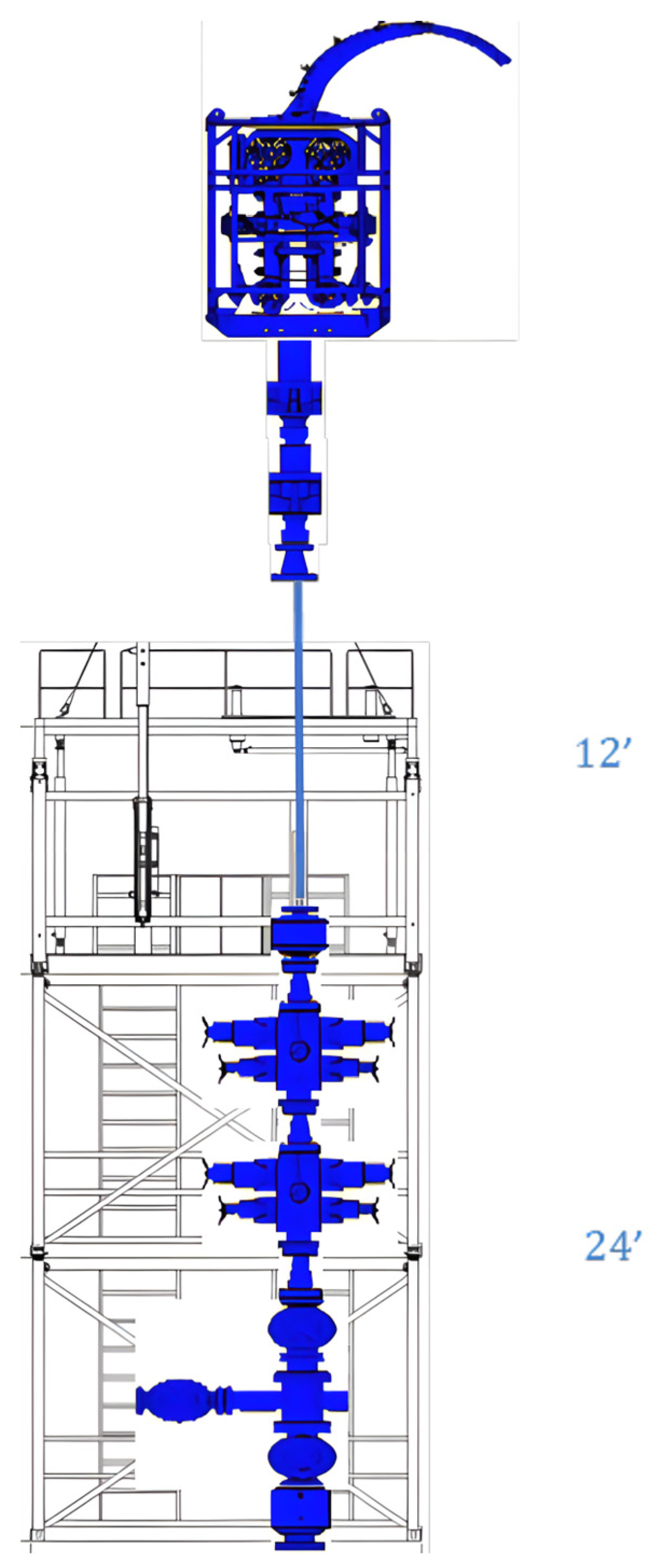

2.2. Inverted ESP Assembly

The inverted ESP configuration positions the motor above the pump, directly connected to the power cable. This eliminates the MLE, a historical weak point for electrical reliability. The power cable, which also serves as the CT cable for the ESP, is directly connected to the motor, allowing for direct power transmission without the need for cable splicing or an MLE. In contrast, standard ESP configurations typically position the motor at the bottom of the assembly, requiring an MLE located below the ESP packer. This setup necessitates cable splicing to penetrate the packer with the power cable, exposing the MLE to wellbore fluids and a corrosive environment. The bottom hole assembly (BHA) includes a CT adapter, stabilization gland, a pressure and temperature sensor, pump, motor, seal stack, and shear subs for contingency retrieval, which is shown in

Figure 2. The modular architecture improves onsite assembly efficiency and reduces manual handling risk [

6].

Integrated sensors enable the continuous monitoring of downhole parameters, including pressure, temperature, voltage, current, and axis vibration. Although initial field trials encountered tubing diameter constraints that limited the pressure intake line usage, subsequent deployments incorporated hardware modifications to address this constraint [

7].

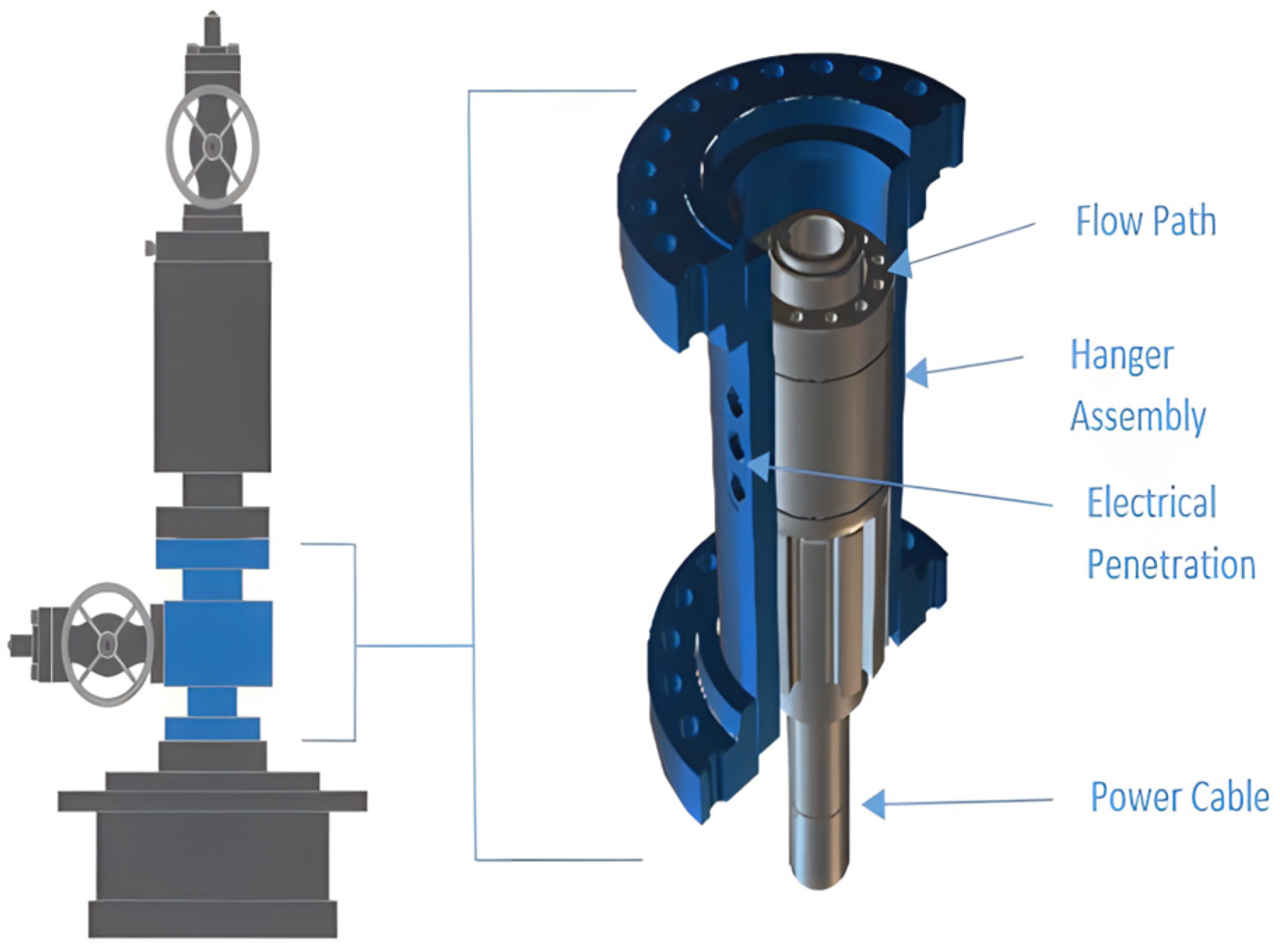

2.3. Cable Hanger and Surface Termination

The mechanical and electrical termination of the CDESP cable is achieved via a VCHS, installed between the tubing head and master valve. The VCHS allows fluids to bypass through flow channels, while sealing off electrical terminations from wellbore fluids, which is demonstrated in

Figure 3. A guided landing system ensures proper axial and rotational alignment, minimizing the risk of landing failure under load [

8].

The VCHS features a BPV (Back Pressure Valve) profile that serves as a replacement for the existing BPV profile located at the tubing hanger, which will be covered by the cable hanger after the ESP is deployed. The BPV profile is a mandatory requirement to ensure that the well can be secured at any time, allowing for wellhead valve modifications, maintenance, or complete tree replacement.

The compatibility with the standard vertical wellhead eliminates the need for any surface hardware modification, enabling faster deployment and retrieval in existing offshore infrastructure. This creates opportunity, as alternative methods of deployment specifically for offshore environment must be considered due to modifications [

19].

Figure 4 describes the VCHS which was co-developed by artificial lift providers, wellhead manufacturers, and completion teams to meet stringent requirements for load handling, electrical compatibility, and seal integrity [

9].

2.4. Well Control Integration

Rigless CDESP operations into live wells require a robust well control framework. The deployment system integrates a CT unit (CTU) with a live well blow out preventer (BOP) stack that includes annular BOPs, variable bore rams (VBRs), and slips for mechanical containment. The annular BOP can secure the well by closing its seal around any BHA profile shape, including the ESP. This component, typically only used in rig operations, provides a safe mechanism to secure the well during the CDESP rigless installation. A tailored kill fluid program ensures hydrostatic overbalance throughout the deployment, with the fluid composition selected for compatibility with the CDESP metallurgy and reservoir conditions [

10].

Trip tank monitoring and surface return checks are used to detect loss or influx events. For wells with high-loss rates, deployment procedures are adjusted dynamically using surface modeling inputs and real-time rate control. The approach complies with dual-barrier principles by combining mechanical sealing and fluid-based redundancy. Optional add-ons, such as BPV adapters and bowl protectors, provide additional safeguards for the hanger assembly during deployment and retrieval [

10].

3. Field Deployment and Operational Performance

The first successful deployment of a rigless CDESP system was carried out in a high-H2S onshore well, located in a mature production region. The test site was selected due to the availability of existing surface infrastructure, well-documented reservoir properties, and a history of frequent ESP-related interventions—making it an ideal candidate for validating the technology in live well conditions. The objective was to evaluate the feasibility of rigless ESP replacement using a CTU, without removing the production tree, while maintaining strict well control standards and operational safety.

3.1. Well and Completion Design

The well was constructed with a 7 in. production casing and had previously utilized a 4½ in. tubing string. To accommodate the inverted CDESP architecture and the passage of its power cable and hanger system, the completion was reengineered to include a 7 in. × 4½ in. tubing configuration. The tubing was placed at a depth of 5183 ft MD, with a crossover to a 5 in. sealbore receptacle at 4931 ft, followed by a polished bore receptacle (PBR) and a retrievable packer. The ESP landing depth was 4920 ft MD, where the deviation angle was approximately 40°, providing an opportunity to evaluate mechanical behavior in a moderately deviated trajectory [

1].

A specially designed tubing hanger and VCHS were incorporated into the permanent completion. These components enabled mechanical load transfer and electrical termination below the master valve, while remaining compatible with a 7 1/16 in. vertical Xmas tree. The design ensured the full pass-through capability of the ESP assembly and power cable, without requiring modifications for future retrievals [

2].

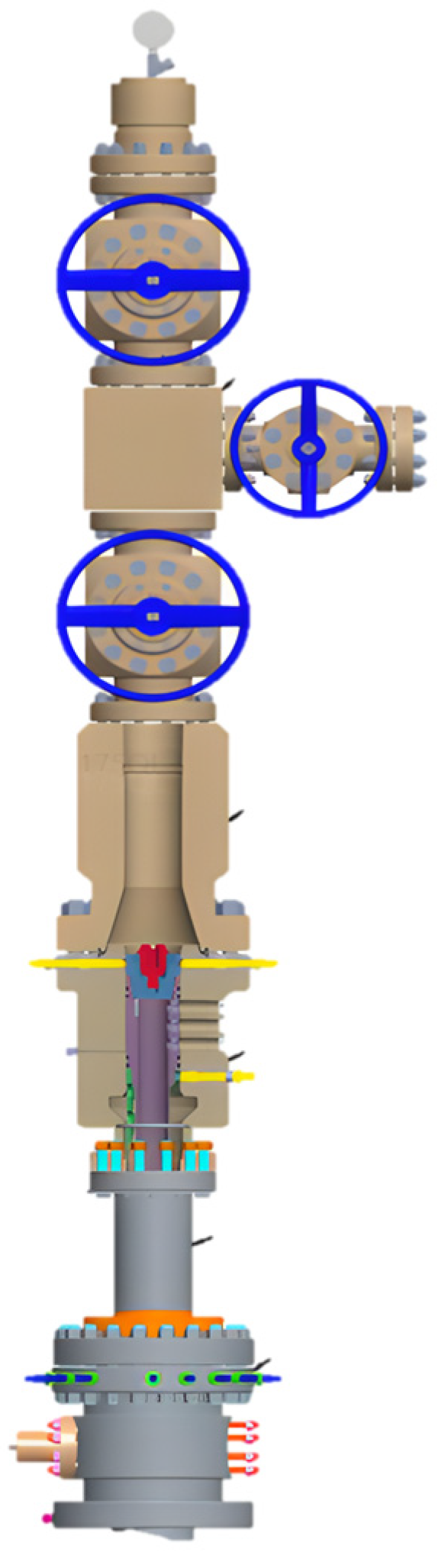

3.2. Deployment Procedure and Surface Equipment Layout

Deployment was executed using a standard CTU, equipped with a customized injector head, pressure-rated lubricator, and a well control stack that included an annular BOP, VBRs, and mechanical slips, which can be seen in

Figure 5. Moreover,

Table 2 lists each of the well control stack components, showcasing their size and pressure rating for our installation. The setup adhered to dual-barrier well control requirements. The supporting systems included a trip tank for monitoring fluid levels, kill pumps, dedicated power cable reels, and mobile cranes for lifting the segmented ESP assembly [

3].

The ESP string was pre-assembled into modular sections to streamline handling and improve deployment efficiency. The BHA included the following:

A stinger and seal stack to engage the PBR.

Redundant shear subs for contingency retrieval.

A pump, seal section, and inverted motor.

A downhole sensor for monitoring key electrical parameters.

A cable adapter for load-bearing and electrical integration.

The metal-jacketed power cable was fabricated as a continuous segment and deployed alongside the ESP modules, supporting the string’s weight while navigating the wellbore. Its consistent OD facilitated the smooth passage through the injector head and downhole completion.

Figure 6 depicts how a tower setup was utilized to accommodate the height of the rigless CDESP system, all while maintaining well barrier requirements during each phase of the operation. The deployment proceeded without mechanical interference or misalignment, aided by compatibility tests and mock-up trials performed during the pre-job phase [

4].

3.3. Well Control and Kill Fluid Strategy

The well was deemed live due to a surface pressure of 400 psi while shut in, and the presence of H

2S at concentrations above 1%. In the absence of a circulating mud system, a kill-fluid-based well control strategy was adopted. A high-density, reservoir-compatible brine was formulated to maintain a minimum 200 psi hydrostatic overbalance from the surface. The fluid was pumped continuously into the tubing-casing annulus and closely monitored using trip tanks and return flow measurements [

5].

When losses were observed, surface flowback systems enabled the real-time adjustment of fluid density and pump rates. No kicks or pressure surges were recorded, and annulus pressure remained within the target envelope. Redundant safety systems, including remote pressure monitoring, H

2S response protocols, and pressure-rated emergency shut down equipment, were in place throughout the operation [

6].

3.4. Operational Results and Benchmarking

The full deployment and ESP landing were completed in less than 24 h, a significant reduction compared to the 10–14 days typically required for rig-based ESP replacements. Surface termination was completed while keeping the production tree in place, validating the compatibility of the VCHS with standard wellhead configurations [

7].

Post-installation, the ESP was brought online and stabilized at over 5000 BFPD. Downhole sensors provided continuous pressure, temperature, and current monitoring, which helped ensure stable operation and CDESP reliability. No evidence of scale buildup, electrical instability, or gas interference was observed during the initial runtime.

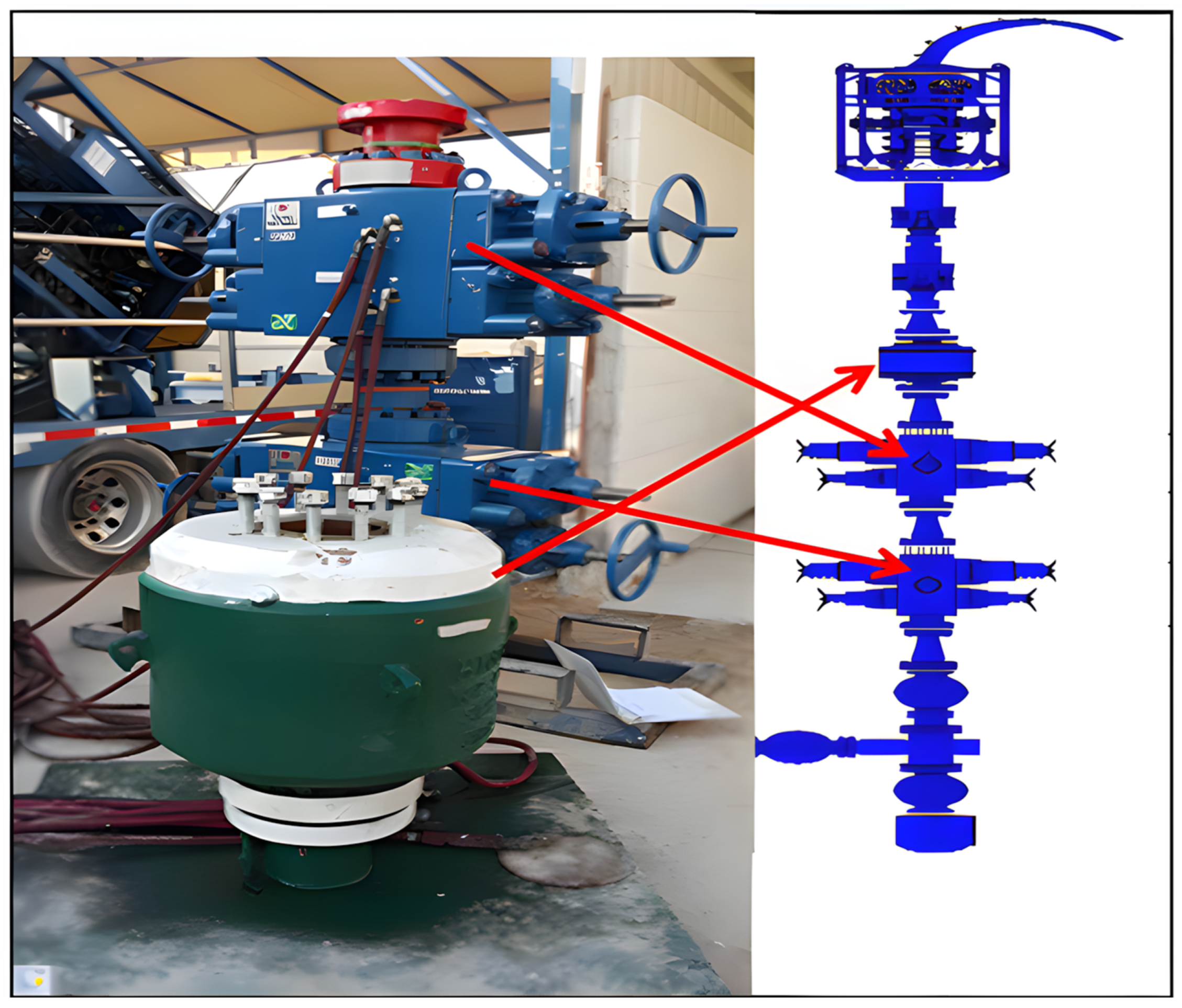

3.5. Retrieval and Redeployment

After more than two years of continuous operation, the ESP was proactively retrieved using the original CTU setup. The purpose was to evaluate the CDESP components physically, both externally and internally, once the retrieval was completed without incident. The system had been running for an extended period under reservoir conditions. The temperature exceeded 150 °F, while the pressure exceeded 2000 psi. Additionally, the well where the CDESP was installed had a very harsh environment, with H

2S exceeding 1%, chloride above 90,000 ppm, and TDS exceeding 110,000 ppm.

Figure 7 shows the tower system, compared to the permanent well platform utilized for the deployment, demonstrating the rig up height required to accommodate the CDESP system to satisfy safety requirements. The inspection of the BHA and power cable revealed minimal normal wear; no external corrosion or electrical damage were detected. The system was refurbished, bench-tested, and successfully redeployed in the same well, requiring no changes to the surface or downhole hardware. The same cable was used with a new ESP section and redeployed in the well. This successful run cycle confirmed the mechanical durability, reusability, and long-term integrity of the CDESP system under field operating conditions [

8].

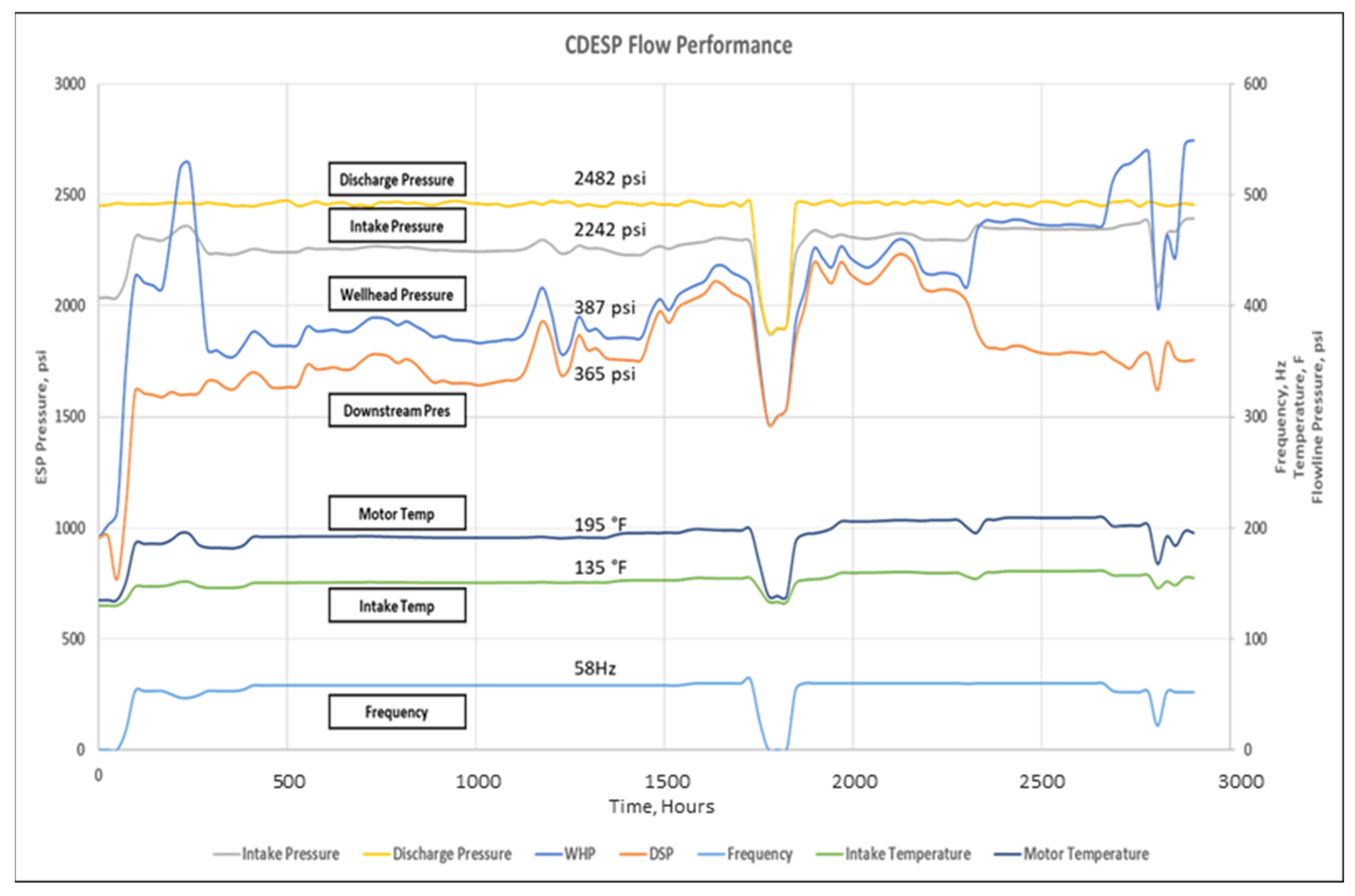

3.6. CDESP Flow Performance

The CDESP system was then operated after redeployment with the same power cable, utilizing a similarly refurbished ESP to demonstrate the capability of the system to run with readily available units. The system was able to flow continuously with no issues to the ESP or flow performance for almost 3000 h. A single shutdown was executed to demonstrate the capability of remote access to the pump system at the midpoint.

Figure 8 displays the real-time parameters for the well after the deployment, showcasing the ESP intake and discharge pressure, intake and motor temperature, frequency, wellhead pressure, and flowline downstream pressure. During this testing period, the CDESP achieved a maximum flowrate of 7000 BFPD. Continuous monitoring included axial vibration, pump and motor efficiency, electrical insulation, and flow envelope performance. The analysis indicated that the CDESP’s operational behavior closely matched neighboring conventional ESPs, with notable improvement in electrical insulation, which remained consistent with initial installation values after two years of operation. However, the available real-time monitoring architecture did not archive historical data for these parameters, as it was primarily configured for well-performance monitoring, as displayed in

Figure 8.

4. Comparative Evaluation and Lessons Learned

The successful field deployment of the CDESP system served not only as a demonstration of rigless ESP capability but also as a benchmark for evaluating its performance relative to conventional systems. Key metrics, such as deployment time, reliability, cost, and operational safety, were assessed using job data, inspection reports, and real-time monitoring feedback.

4.1. Time and Cost Efficiency

The most significant operational advantage was the drastic reduction in deployment time. While traditional ESP replacement typically takes 10 to 14 days, factoring in rig mobilization, tree removal, tubing handling, and reinstallation, the CDESP was installed and commissioned in under 24 h, without altering the production tree.

Rigless deployment eliminated several high-cost activities, including the following:

Rig mobilization and fuel logistics.

Crew mobilization and accommodations.

Well site modification to accommodate rig size.

Deferred production losses due to prolonged downtime.

Although the initial capital cost for CDESP hardware, including the metal-jacketed cable, VCHS, and surface termination gear, is higher, at roughly 30%, this cost was offset after the first successful intervention. The value proposition strengthens over time, especially when redeployment, reduced NPT, and uninterrupted production are factored into long-term field economics [

2]. This advantage becomes even more pronounced in offshore applications, where high rig installation costs amplify the economic benefit of fully rigless installation and retrieval systems. Furthermore, the ability to replace ESPs earlier using our rigless CDESP system can significantly mitigate deferred production costs. For instance, assuming an oil price of USD 60 /bbl and an average production rate of 2000 BPFD, the estimated monthly cost of deferred production can be substantial, at approximately 3.6 million USD per month. Given that rig-based workover ESP replacements can sometimes take several months to schedule, the economic benefits of our rigless CDESP system can be considerable, potentially saving millions of USD in lost revenue just by minimizing production downtime.

4.2. System Reliability and Component Integrity

The CDESP system operated continuously for more than two years before being retrieved and redeployed. Several design factors contributed to its performance under high-deviation and corrosive conditions:

Compared to rig-deployed systems, which often suffer from electrical faults or scale-related failures, the CDESP system demonstrated marked resilience and consistency [

6].

4.3. Operational Safety and Intervention Simplicity

By avoiding rig operations, the CDESP deployment model significantly reduced health, safety, and environmental (HSE) risks, as follows:

No exposure to rig floor hazards or heavy-lift tasks.

Minimal personnel onsite, reducing total manhours.

No Xmas tree disassembly or pressurized equipment modification.

No flowline disassembly.

Full control of annular pressure via CTU and kill fluid management.

This simplified profile made the system particularly suitable for remote, unmanned, or sour service environments, where minimizing surface complexity is critical [

7].

4.4. Lessons Learned and Overcoming Challenges

The deployment, retrieval, and operation of the CDESP system were not without challenges, but the team successfully mitigated them. During the course of the project, several unforeseen difficulties were encountered, including unexpected wellbore conditions, equipment malfunctions, and operational complexities. However, through a combination of careful planning, effective problem-solving, and collaboration among the project team, these challenges were successfully overcome. The solutions and mitigations applied to address these issues not only ensured the successful completion of the project but also provided valuable insights and lessons learned that can be applied to future CDESP deployments. The following key learnings were identified:

Surface compatibility: Thorough pre-job validation of hanger, cable, and tree interfaces proved essential. Future deployments should retain this modular design philosophy.

Sensor limitations: Pressure intake line use was constrained by tubing ID. Completion design should accommodate full sensor access.

Cable handling: Maintaining consistent tension and avoiding torsion was key to safe deployment. Refinements in spooling controls are recommended for extended-reach wells.

Kill fluid control: Real-time monitoring of loss rates was critical. Pre-deployment modeling of brine compatibility and loss scenarios added significant value.

Contingency design: Though not needed, the shear subs and retrieval profiles built into the BHA ensured operational flexibility.

Cross-team coordination: Execution success was supported by strong planning across CTU operators, lift engineers, and vendors. Early-stage collaboration should be standard.

These lessons will inform broader deployment strategies and highlight the importance of standardization, training, and continuous design adaptation in rigless ESP operations [

8].

5. Future Applications and Development Pathways

The successful deployment, extended operation, and rigless retrieval of the CDESP system highlight its potential to reshape ESP management across a diverse range of well environments. As operators continue to prioritize uptime, cost reduction, and safety, CDESP technology is poised for broader adoption especially in offshore, remote, and other high-risk settings.

5.1. Offshore and Marginal Field Applications

Offshore environments represent a key opportunity for CDESP implementation. Traditional ESP replacements offshore often require jack-up rigs or heavy-lift vessels, which are costly, logistically intensive, and schedule-constrained. In contrast, CDESP systems can be installed and retrieved using light intervention vessels or barge-mounted CTUs, significantly reducing the cost, complexity, and HSE exposure [

1].

CDESP technology also holds a strong value in marginal fields and late-life assets, where conventional intervention economics may not justify continued production. By enabling lower-cost interventions and a faster turnaround, the technology supports extended production life and improves the return on investment for wells approaching economic limits.

5.2. Rapid Redeployment and Inventory Optimization

The modularity and reusability of CDESP assemblies enable their rapid redeployment across multiple wells. Provided the downhole environment permits, a single ESP unit type can be cycled between wells with limited refurbishment. This supports centralized inventory management strategies, where high-value ESP components are rotated across a field or asset portfolio to maximize utilization and reduce idle time.

Over time, this approach lays the foundation for dynamic ESP fleet management, allowing operators to proactively move equipment based on reservoir conditions, production demand, or maintenance schedules, improving responsiveness and reducing lead times.

5.3. Integration with Digital Oilfield Initiatives

CDESP systems are inherently well-suited for integration into digital oilfield architectures. Downhole sensors continuously capture parameters such as intake and discharge pressures, pump and motor temperatures, current, vibration, and motor health. These data streams can be integrated into analytics platforms for real-time performance tracking, predictive maintenance, and automated alerts [

2].

Such integration supports condition-based monitoring, enhances the surveillance of unmanned assets, and enables the data-driven optimization of artificial lift performance. Combined with machine learning algorithms or digital twin models, CDESP-equipped wells can achieve greater efficiency with fewer manual interventions. Furthermore, by leveraging artificial intelligence and machine learning, operators can identify early warning signs of ESP degradation, predict potential failures, and proactively plan for replacement, thereby minimizing production downtime and reducing the risk of unexpected failures, ultimately leading to more reliable and optimized artificial lift operations.

5.4. Design Enhancements and Standardization

To facilitate broader deployment across diverse well conditions, ongoing development efforts are focusing on the following:

Compact ESP formats: Reducing system OD and length to ensure compatibility with tight or deviated wellbores. Allowing the BHA to be deployed inside the CT lubricator in a closed system that is similar to normal CT operations, eliminating the need for complex well-killing operations.

Sensor redundancy: Adding multiple sensor arrays for improved diagnostics and reliability.

Improved retrieval mechanics: Enhancing shear subs, anchors, and fishing profiles to support contingency operations.

High-temperature applications: Advancing insulation and material systems to expand thermal operating limits.

Integrated surface packages: Developing turnkey deployment kits with built-in power, control, and well control functionality.

In parallel, industry collaborations are progressing toward standardized components such as power cables, hanger interfaces, and surface termination connections to streamline integration and ensure cross-vendor compatibility [

3].

5.5. Regulatory and Safety Considerations

Wider adoption of CDESP will require alignment with regulatory frameworks, particularly for live well interventions involving high-voltage terminations below the master valve. Areas of focus include well control barriers, retrieval protocols, and abandonment procedures.

Initial projects have demonstrated that CDESP can operate safely within existing guidelines, provided that appropriate procedures, personnel training, and containment systems are in place. Moving forward, operators and regulators will need to develop specific standards for rigless ESP systems to ensure consistency, safety, and quality management across deployments.

6. Conclusions

The successful development and field validation of the CDESP system mark a pivotal shift in artificial lift strategy. By eliminating the need for rig-based interventions, CDESP technology significantly reduces operational downtime, enhances safety, and lowers intervention costs, particularly in offshore, remote, and sour-service environments. The system achieved over two years of continuous runtime, followed by a rigless retrieval and redeployment, confirming its long-term mechanical and electrical integrity.

As digital integration and field standardization continue to evolve, CDESP systems offer a scalable, high-performance alternative to traditional ESPs, supporting improved uptime, asset utilization, and operational agility.

The key conclusions are as follows:

Rigless CDESP deployment reduces intervention time from several weeks to under 24 h.

Field-proven reliability was demonstrated over two years in harsh well conditions.

Inverted ESP design and metal-jacketed cable improved the durability and removed common failure points.

Real-time data enhances monitoring, diagnostics, and proactive maintenance.

CDESP systems support digital integration, efficient redeployment, and safer intervention logistics.

Author Contributions

Conceptualization, M.M.R. and T.A.A.; methodology, K.M.M. and M.B.W.; validation, M.B.W., K.M.M. and M.M.R.; formal analysis, T.A.A.; investigation, K.M.M.; resources, K.M.M.; data curation, M.B.W.; writing—original draft preparation, M.M.R.; writing—review and editing, T.A.A.; visualization, M.M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to acknowledge Mohammed Aleissa for his contribution to the field operation.

Conflicts of Interest

All authors were employed at the current company Saudi Aramco. The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

| BFPD | barrels of fluid per day |

| BHA | bottom hole assembly |

| BOP | blow out preventer |

| BPV | back pressure valve |

| CDESP | cable deployed electrical submersible pump |

| CT | coiled tubing |

| CTU | coiled tubing unit |

| ESP | electrical submersible pump |

| GOR | gas oil ratio |

| H2S | hydrogen sulfide |

| ID | inner diameter |

| MLE | motor lead extension |

| NPT | non-productive time |

| OD | outer diameter |

| PBR | polished bore receptacle |

| PCP | progressive cavity pump |

| VBR | variable bore rams |

| VCHS | vertical cable hanger spool |

References

- Winarno, M.B.; Said, R.; Shawly, A.S.; Mutairi, K.M.; Rafie, M.M.; Roth, B.A.; Yahya, S. Rigless Deployment of Innovative Electrical Submersible Pumping System for First Time Worldwide. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017. [Google Scholar] [CrossRef]

- Roth, B.A.; Xiao, J.J.; Abdelaziz, M.; Mack, J.; Sarawaq, Y.; Reid, R.; Helvenston, A. Field Deployment of a Rigless Cable Deployed ESP Using a Vertical Wellhead. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 6–9 March 2017. [Google Scholar] [CrossRef]

- Roth, B.A.; Xiao, J.J.; Abdelaziz, M.; Mack, J.; Sarawaq, Y.; Reid, R.; Helvenston, A. Field Deployment of a Rigless Cable-Deployed Electric Submersible Pump Using a Vertical Wellhead. SPE Prod. Oper. 2018, 33, 437–448. [Google Scholar] [CrossRef]

- Roth, B.A.; Xiao, J.J.; Windiarto, Y.; Al-Hadrami, N.; Al-Qahtani, N.F.; Sarawaq, Y. Advancing Electric Submersible Pump Alternative Deployment Technology: An Overview and Case Study. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar] [CrossRef]

- Abdelaziz, M.; Lastra, R.; Xiao, J.J. ESP Data Analytics: Predicting Failures for Improved Production Performance. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017. [Google Scholar] [CrossRef]

- Winarno, M.B.; Eissa, M.A.; Mutairi, K.M. Success Story of Retrieval and Reinstallation of the First New Technology Rigless Cable Deployed ESP System. In Proceedings of the SPE Middle East Artificial Lift Conference and Exhibition, Manama, Bahrain, 25–26 October 2022. [Google Scholar] [CrossRef]

- Jassem, H.; Mehmood, S.; Al-Mutairi, K.; Al-Shawly, A. Operational Excellence Initiative Contributes Towards Enhanced ESP System Reliability, Longer Run Life, and Sustained Oil Production. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019. [Google Scholar] [CrossRef]

- Brown, K.E. Overview of Artificial Lift Systems. J. Pet. Eng. 1982, 34, 2384–2396. [Google Scholar] [CrossRef]

- Manning, F.S.; Thompson, R.E. Oilfield Processing of Petroleum; Volume 2—Crude Oil; PennWell Publishing Company: Tulsa, OK, USA, 1995; ISBN 9780878143542. [Google Scholar]

- Mahmoud, A.M. Cable Deployed ESP-TransCoil-Retrieval. In Proceedings of the SPE Middle East Artificial Lift Conference and Exhibition, Manama, Bahrain, 25–26 October 2022. [Google Scholar] [CrossRef]

- Xiao, J.; Winarno, M.; Eissa, M.; Mahmoud, A. Overcoming Deployment and Retrieval Challenges with Killed Well Cable Deployed Electric Submersible Pump Systems–Lessons Learned from Five Years of CDESP History. In Proceedings of the SPE Eastern Europe Subsurface Conference, Kyiv, Ukraine, 23–24 November 2021. [Google Scholar] [CrossRef]

- Al Munif, E.H.; Banjar, H.M.; Ejim, C.E.; Xiao, J. ESP Deployment Cable Demonstrates Resilience in the Face of Corrosion Challenges in Harsh Downhole Environments. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2023. [Google Scholar] [CrossRef]

- Xiao, J.; Roth, B.; Lastra, R.; Sarawaq, Y.; Mack, J. Cable Concept Evaluation for ESP Rigless Deployment. In Proceedings of the SPE Middle East Artificial Lift Conference and Exhibition, Manama, Bahrain, 30 November–1 December 2016. [Google Scholar] [CrossRef]

- Romero, M.; Fardan, A.; Bespalov, E.; Alsiemat, M. Successful Field Trial Deployment of ESP Rigless Technology in the Middle East: A Step Forward to Reduce Well Intervention Expenditure. In Proceedings of the SPE Middle East Artificial Lift Conference and Exhibition, Manama, Bahrain, 28–29 November 2018. [Google Scholar] [CrossRef]

- Caycedo, L.; Diebold, J.B. An Artificial Lift System That Utilizes Cable Suspended Electrical Submersible Pumps. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 23–26 September 1979. [Google Scholar] [CrossRef]

- Patterson, J.C.; Wiess, J.; Brookbank, E.B.; Bebak, K.T. Cable Internal, Coiled Tubing Deployed Submersible Pump Installation. In Proceedings of the SPE/ICoTA Coiled Tubing Roundtable, Houston, TX, USA, 5–6 April 2000. [Google Scholar] [CrossRef]

- Drozdov, A.N.; Malyavko, E.A.; Alekseev, Y.L.; Robin, A.V.; Alekseev, A.I.; Stefomirov, A.V.; Ageev, S.R. The Use of Umbilicals as a New Technology of Artificial-Lift Operation of Oil and Gas Wells without Well Killing when Workover. In Proceedings of the SPE Russian Oil & Gas Exploration & Production Technical Conference, Moscow, Russia, 16–18 October 2012. [Google Scholar] [CrossRef]

- Ward, I.; Lynn, C.; Shaw, R.; Hervo, S. Coiled Tubing Material Selection for Velocity Strings in Sour Brine Service. In Proceedings of the SPE/ICoTA Coiled Tubing and Well Intervention Conference and Exhibition, The Woodlands, TX, USA, 25–26 March 2014. [Google Scholar] [CrossRef]

- Rizza, G.; Pilone, S.; Bespalov, E.; Drablier, D.; Okassa, F.D.; Tita, G.E. Successful First Offshore Fully Retrievable ESP System Installation in Congo. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2013. [Google Scholar] [CrossRef]

- Robison, C.; Cox, D. Alternate Methods for Installing ESP’s. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1992. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).