Joint Modeling of Planetary Gear Train and Bearings of Wind Turbines for Vibration Analysis of Planetary Bearing Outer Ring Looseness Fault

Abstract

1. Introduction

- (1)

- A core feature of our proposed dynamic model is the explicit incorporation of the planetary bearing’s rub-impact force. This mechanism is introduced to accurately simulate the dynamic responses induced by the outer ring looseness fault, thereby achieving a more refined joint model that surpasses the limitations of traditional modeling approaches.

- (2)

- A dynamic model of the vibration transmission path within the planetary gear train is developed and integrated. This is essential to more accurately characterize the signal modulation effects and thereby obtain a faithful representation of the system’s frequency characteristics in the simulated results.

2. Planetary Bearing Outer Ring Looseness Fault Model

2.1. Hertzian Contact Force of Planetary Bearing

2.2. Elastic-Damping Force

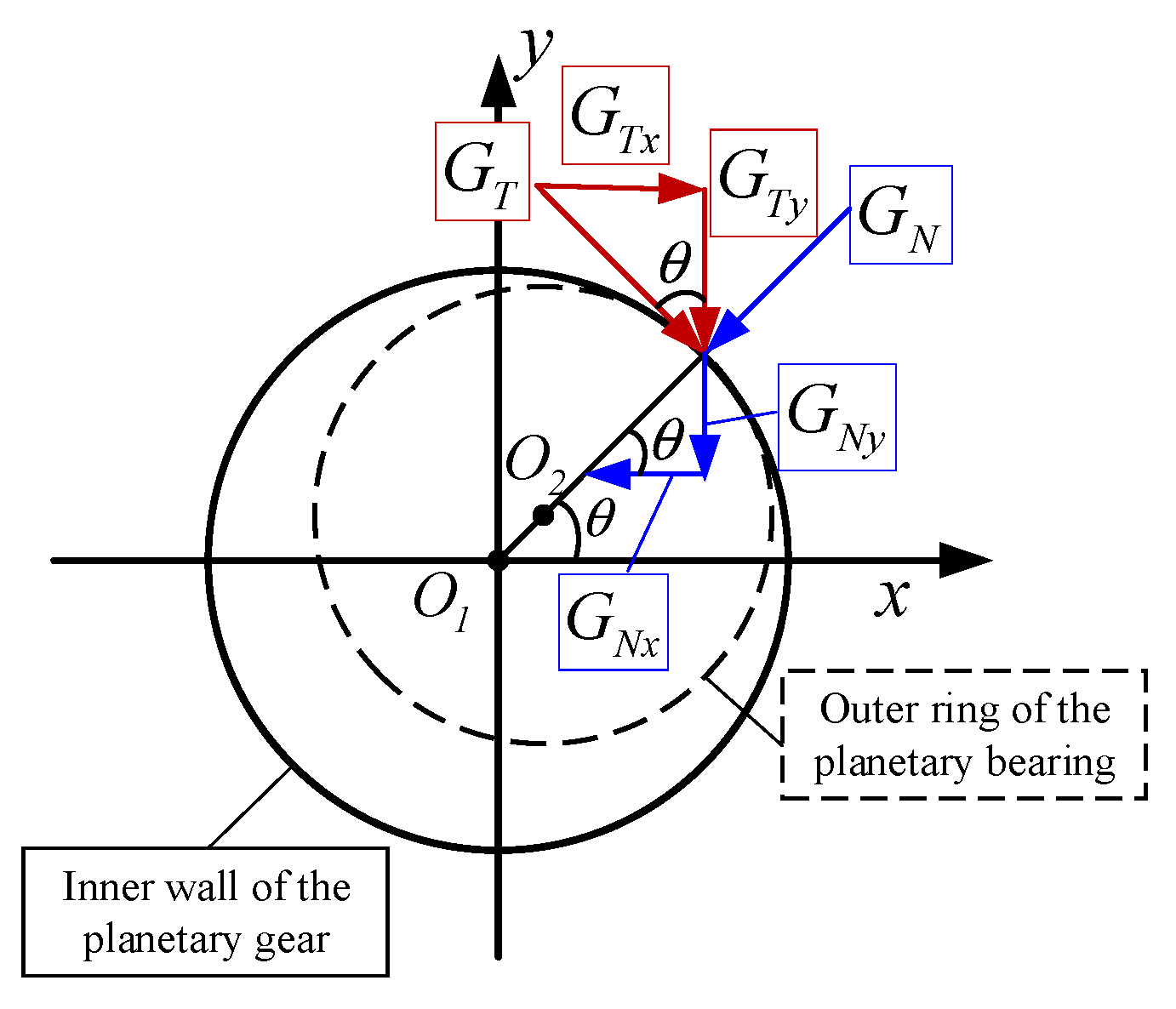

2.3. Outer Ring Looseness Fault Modeling of Planetary Bearing

2.4. Dynamic Modeling of Faulty Planetary Bearing

3. Joint Modeling of Planetary Gear Train and Bearings

3.1. Joint Dynamic Modeling

- (1)

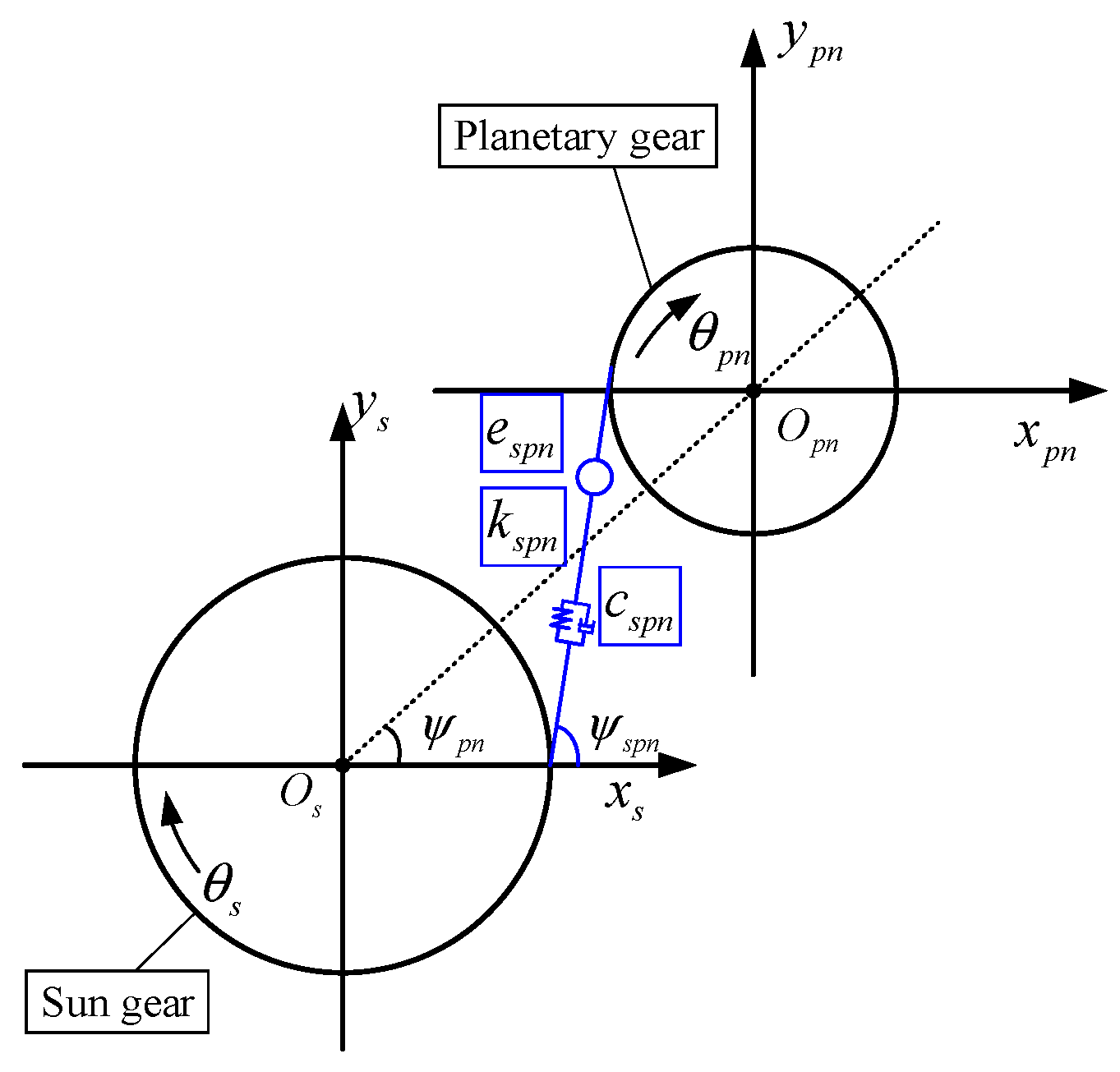

- Sun gear: The force analysis of the sun gear is proven as follows: the primary forces of the sun gear include the supporting force of the corresponding bearing and the meshing force between planetary gears and the sun gear. The dynamic model of the sun gear can be illustrated in Equation (22) [34].

- (2)

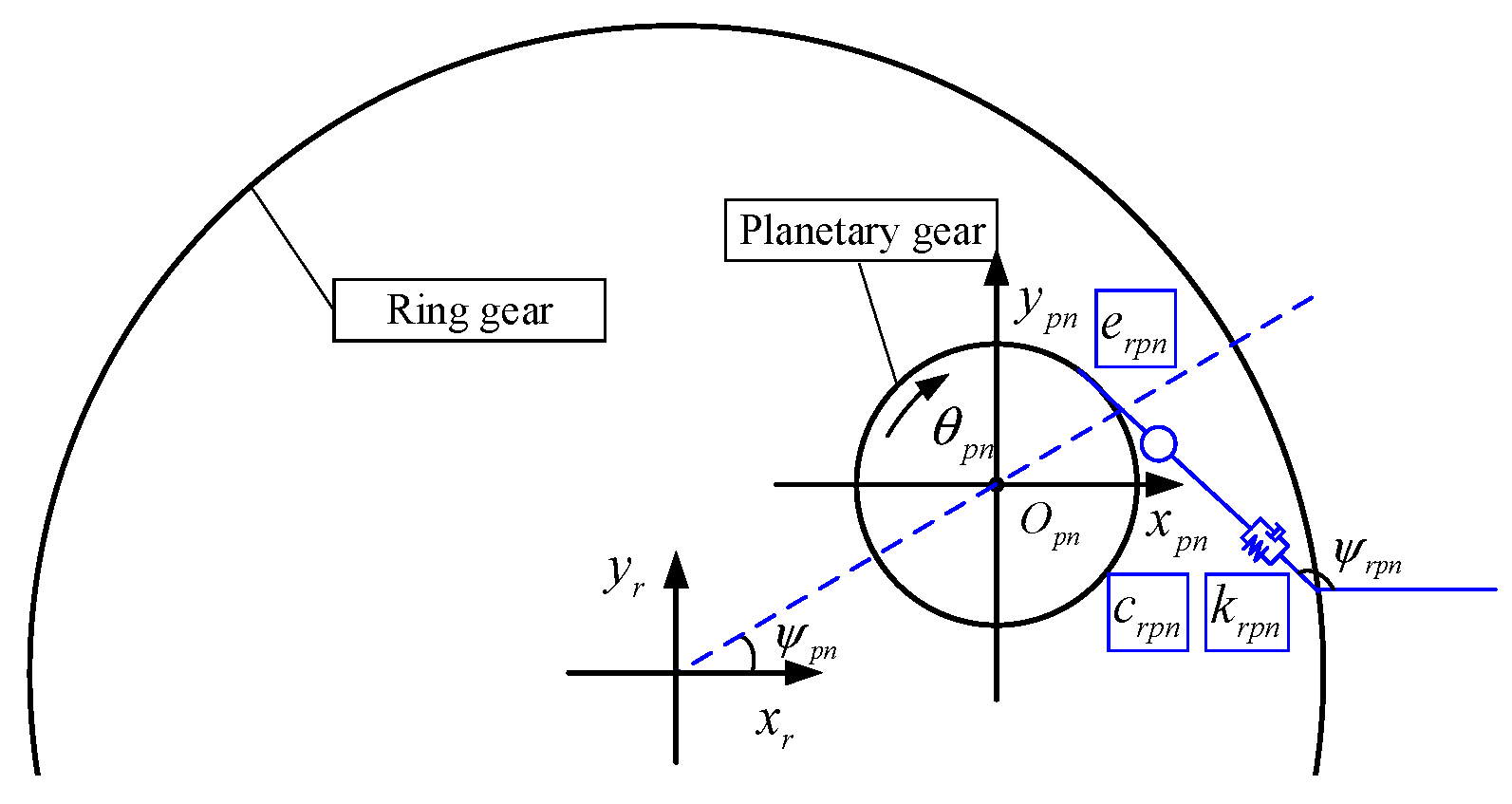

- Ring gear: The force analysis of the ring gear can be illustrated as follows: The primary forces comprise the supporting force of the fixed housing and the meshing force between the planetary gears and the ring gear. The dynamic model of the ring gear is stated in Equation (24) [34].

- (3)

- Planetary gears: The force analysis of the planetary gears can be stated as follows: The primary forces involve the meshing forces between the planetary gears, the sun gear, and the ring gear, as well as the supporting forces of the planetary bearings. The dynamic equation of the planetary gears in the normal state can be shown in Equation (26) [34].

- (4)

- Planetary carrier: The force analysis of the planetary carrier can be illustrated as follows: the primary forces include the supporting force and the reaction force of the planetary gears. The dynamic model of the planetary carrier is expressed in Equation (32) [34].

3.2. Physical Parameters Modeling in Joint Model

3.2.1. Time-Varying Mesh Stiffness and Damping Modeling

3.2.2. The Comprehensive Error Transfer Function

3.3. Transmission Path Simulation of the Signal in the Ring Gear

4. Vibration Analysis of the Proposed Model

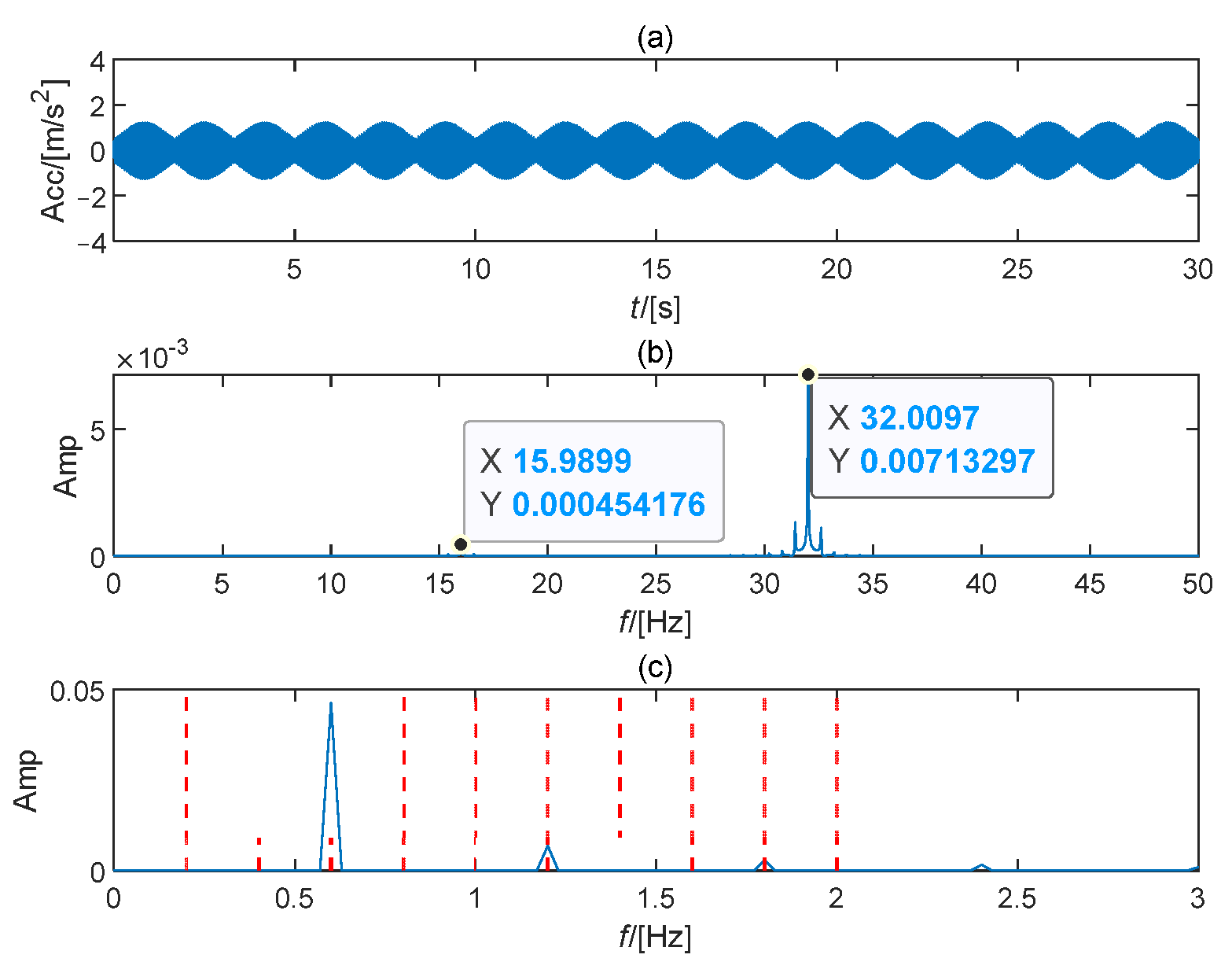

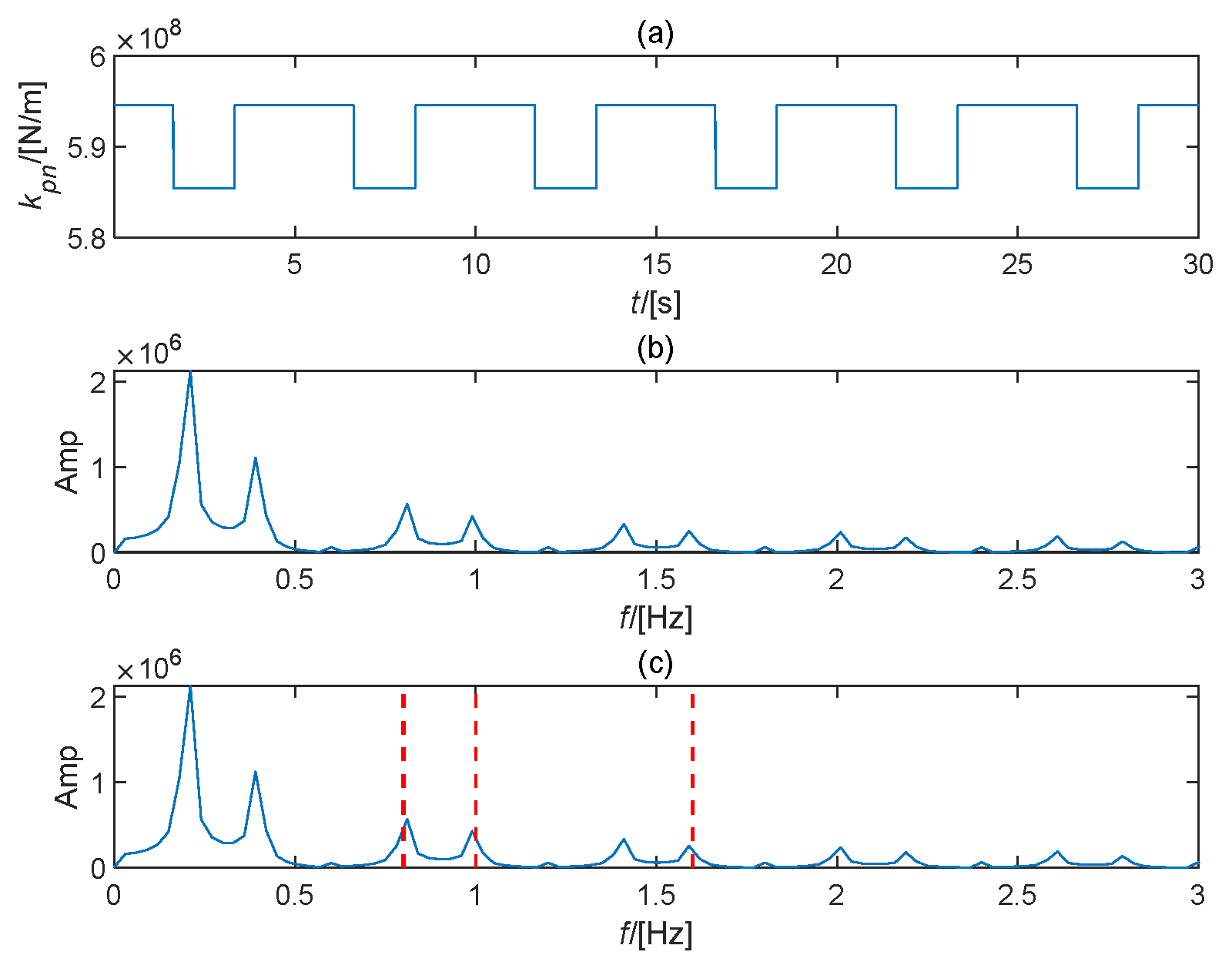

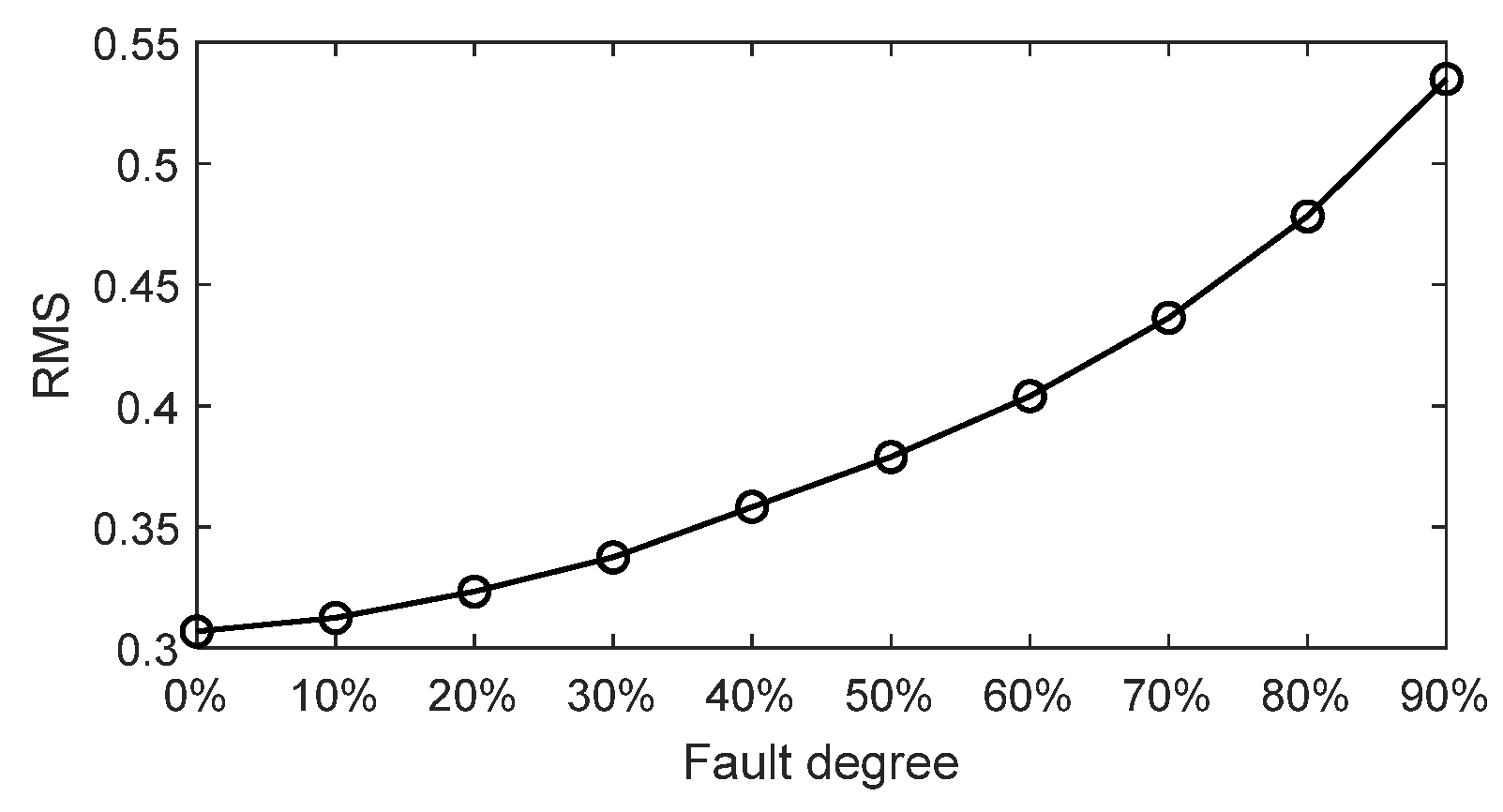

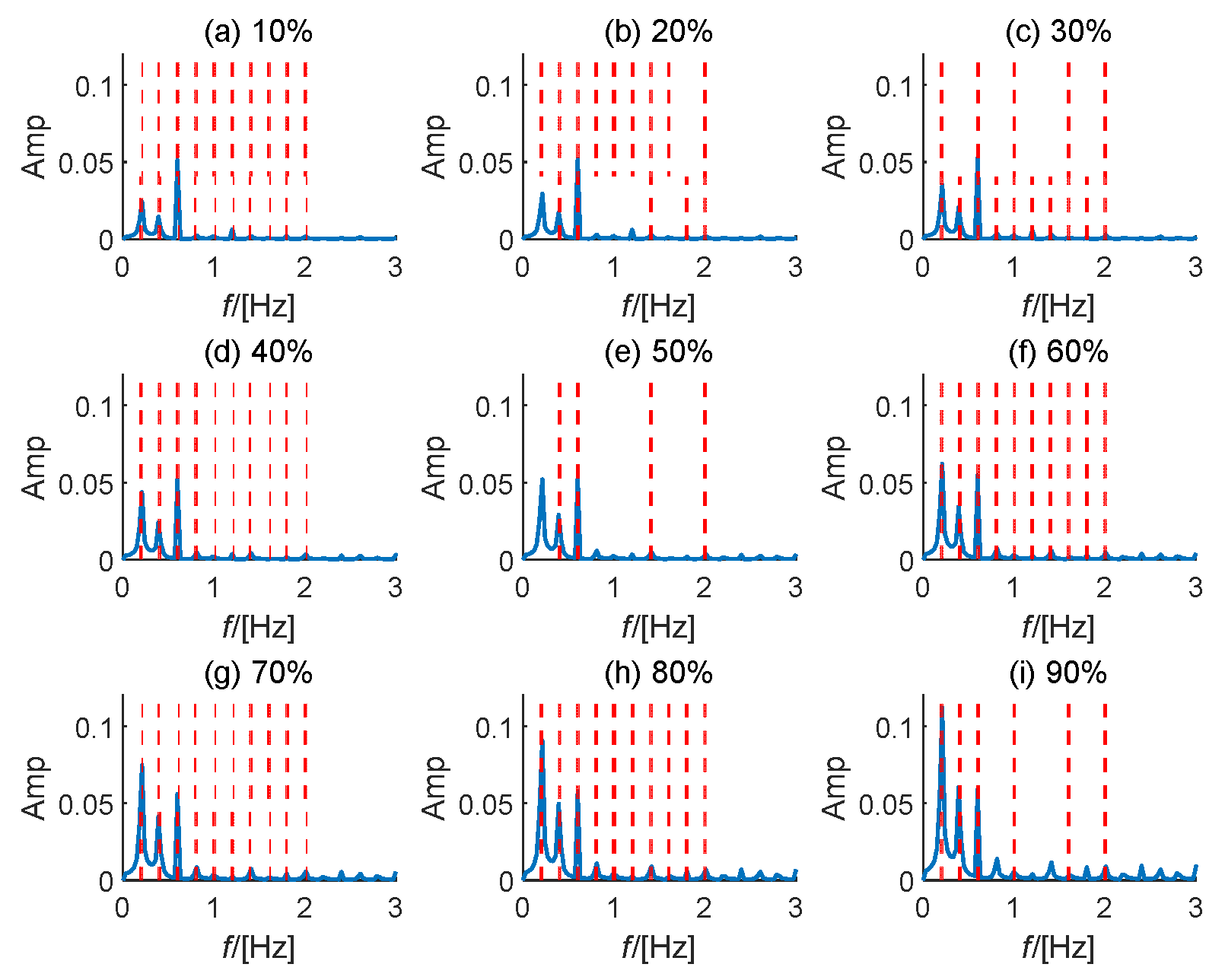

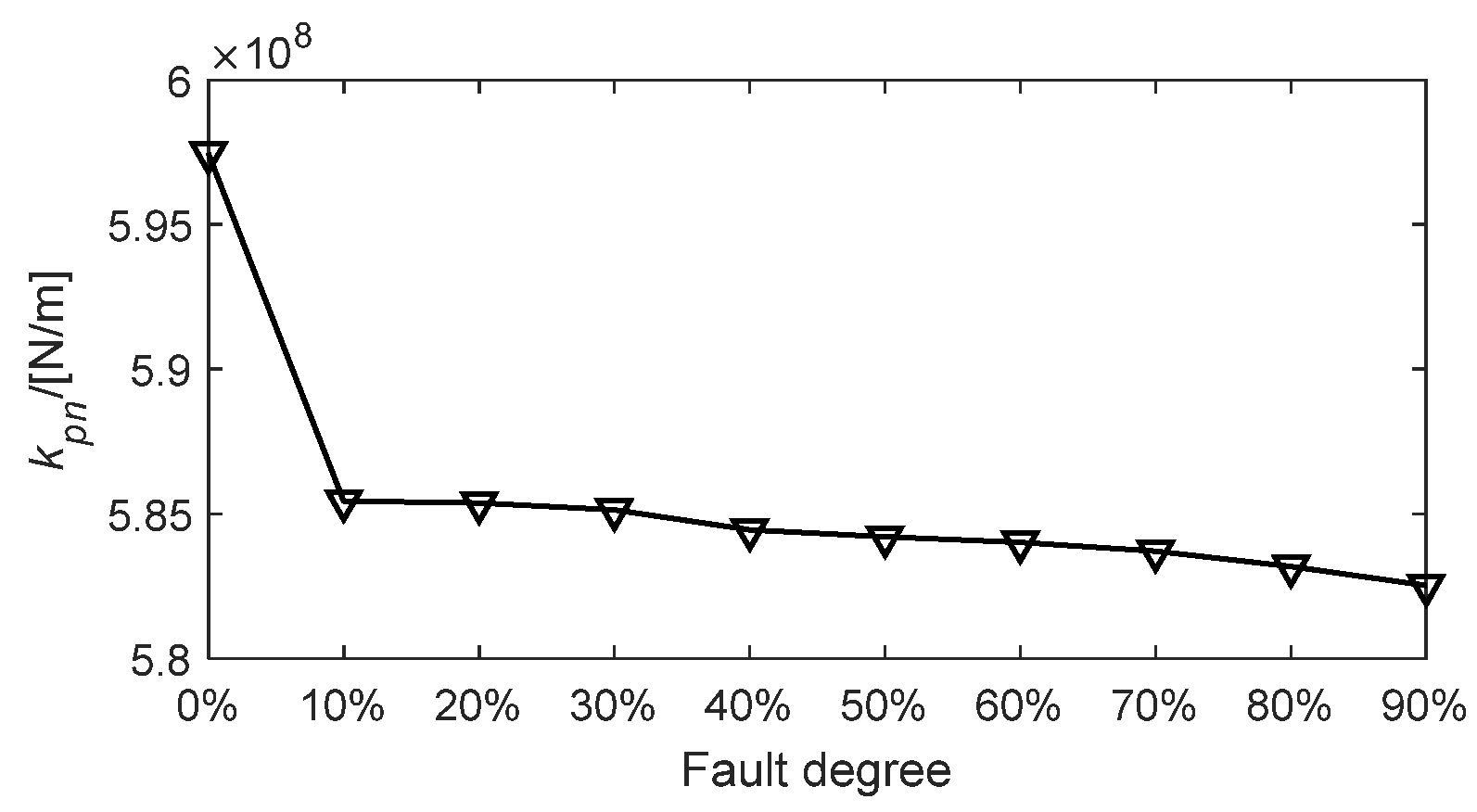

4.1. Results Analysis

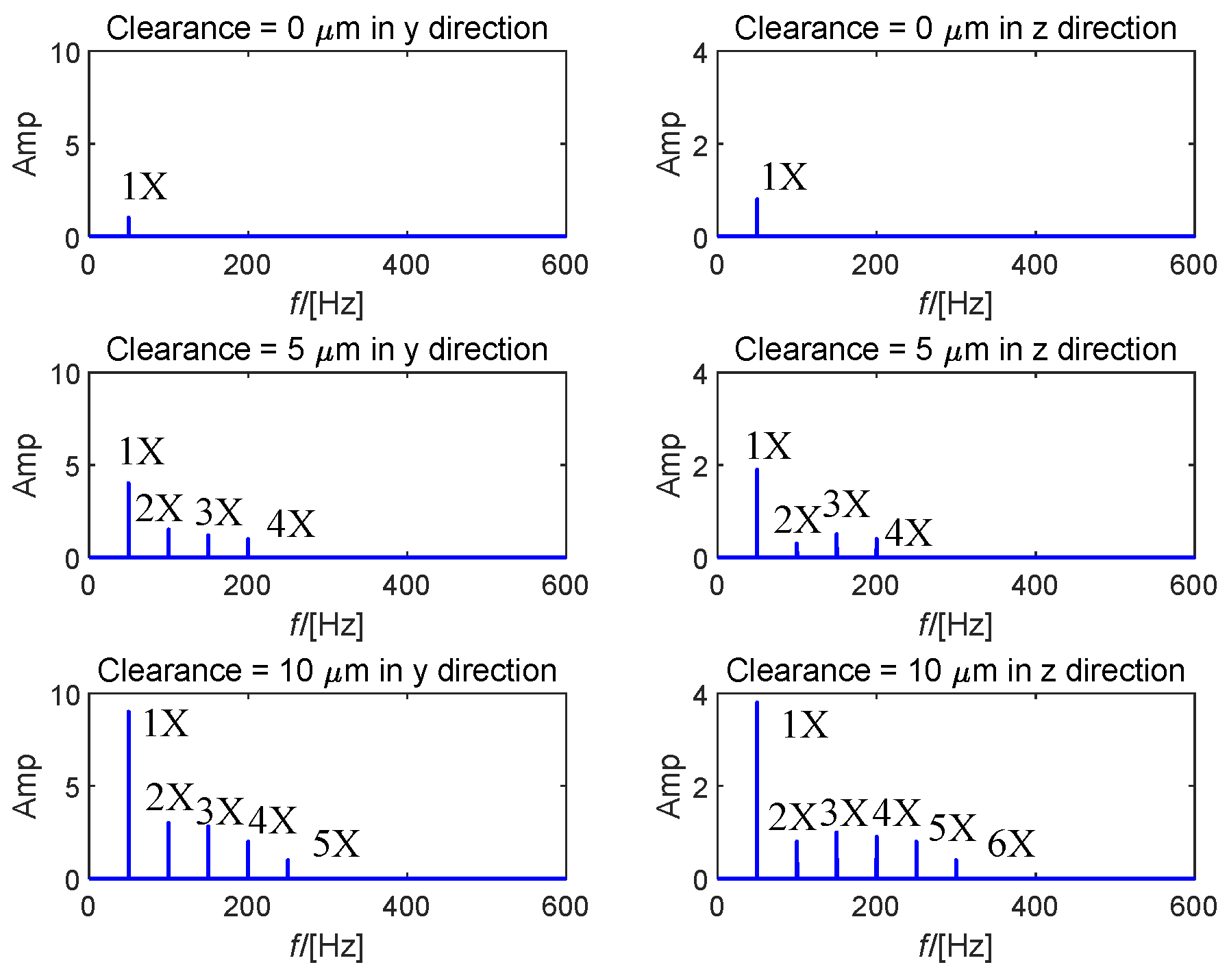

4.2. Comparison and Explanation of Simulation Effects

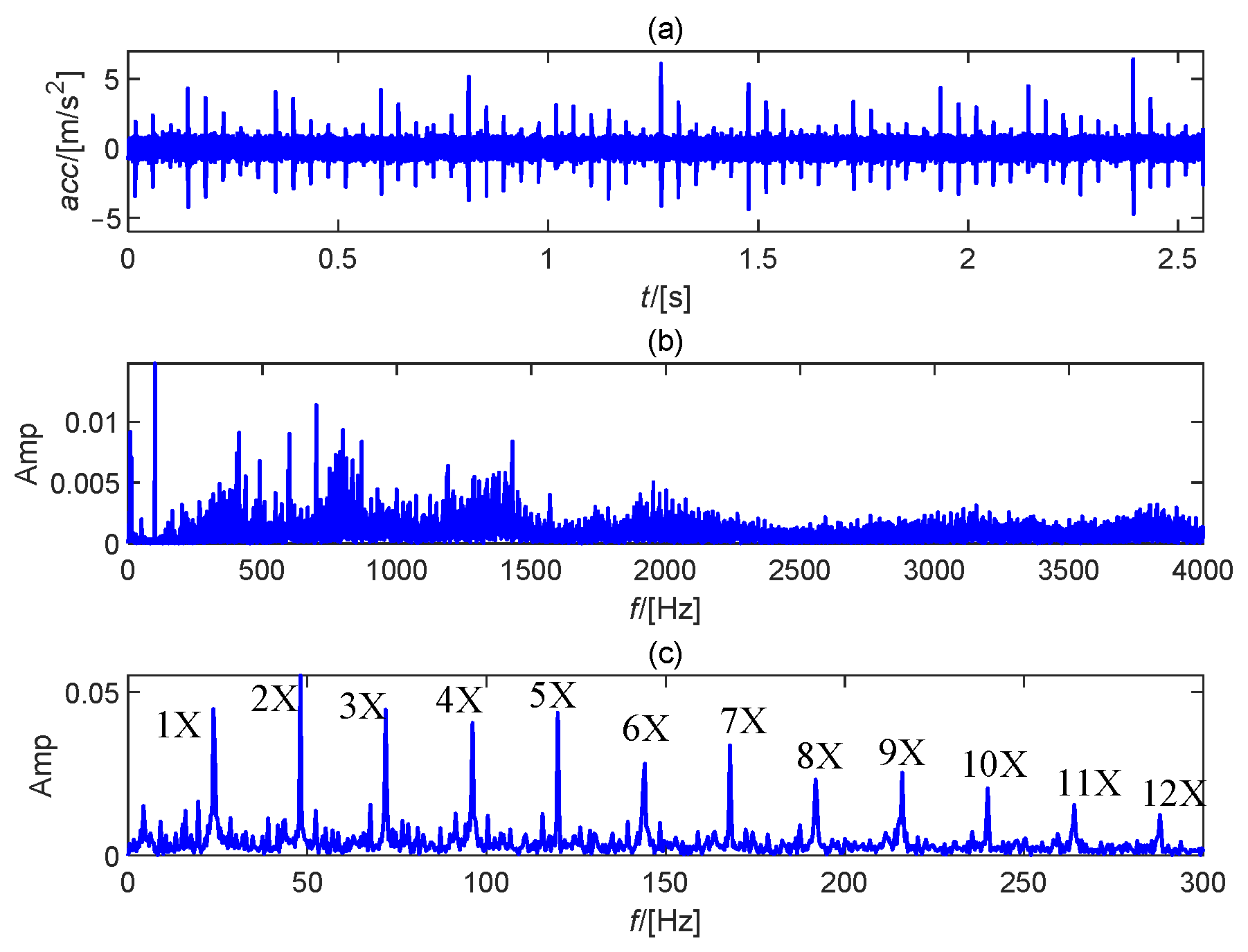

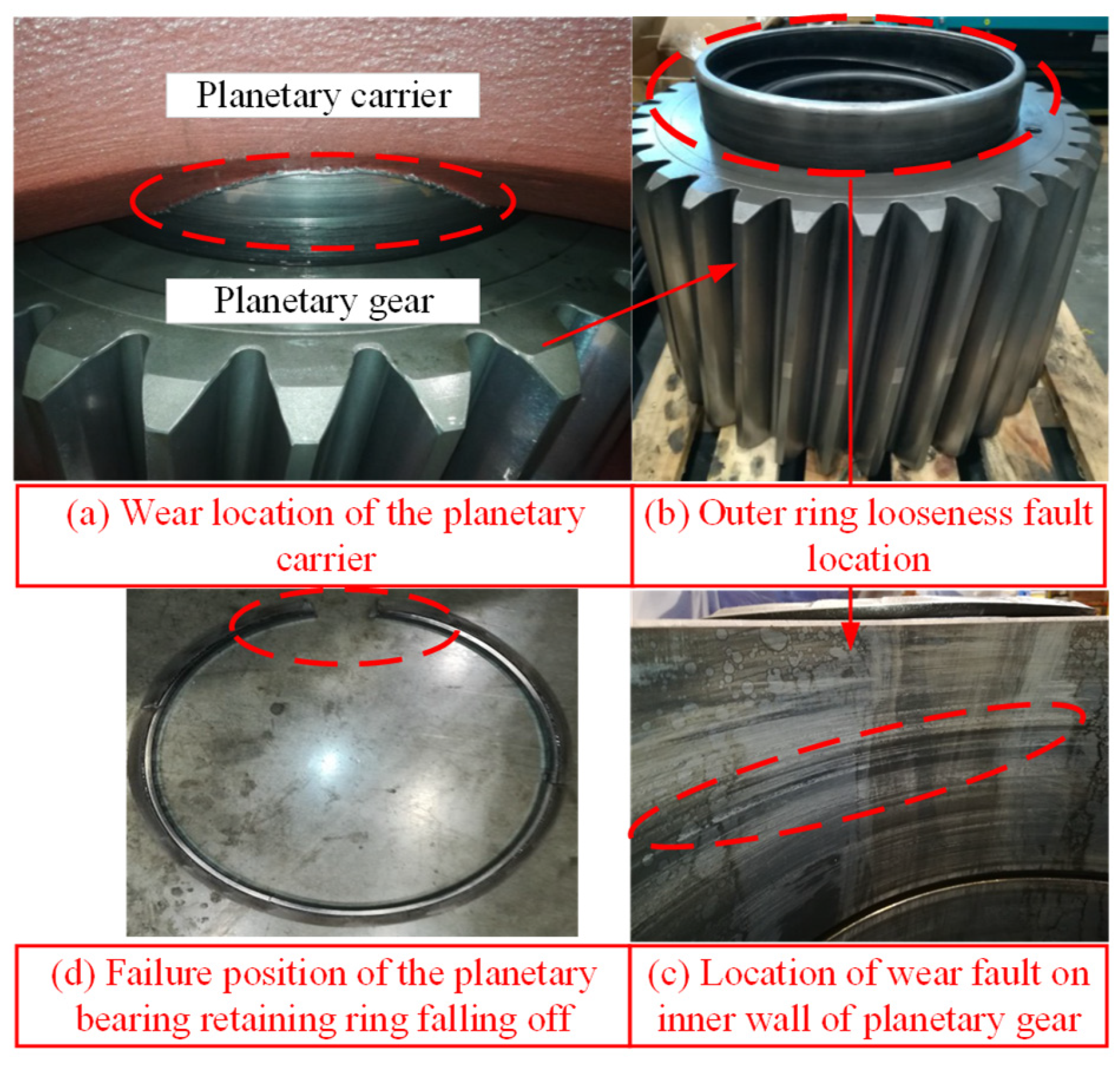

4.3. On-Site Signal Verification

5. Conclusions and Discussion

- (1)

- A new joint model was obtained, which differs from traditional dynamic modeling of bearing looseness. In this study, more detailed and practical modeling structures were considered, such as the power transmission between bearings and planetary gears and the influence of transmission paths when monitoring vibration data at acceleration measurement points.

- (2)

- Modeling in the Matlab environment showed consistency between simulation results and mechanism research. The simulated results reveal that this fault reduces the supporting stiffness of the corresponding planetary gear, resulting in an imbalance between the gears. The looseness fault characteristic can be represented as the rotating frequency and harmonics of the planetary carrier.

- (3)

- A comparison of the results of numerical modeling and a natural experiment showed a significant degree of similarity in the primary frequency characteristics, indicating the modeling’s efficacy and ability to approximate the theoretical signal of bearing looseness in complicated planetary structures.

- (A)

- Convergence analysis: From a qualitative standpoint, this research presents a joint model based on force analysis to follow the rules of dynamics, which is an essential requirement for convergence. From a quantitative standpoint, the simulation results of this study fit the prior mechanism derivation and are similar to the primary features of on-site signals, hence proving the model’s convergence.

- (B)

- Future prospects: This study primarily focuses on joint modeling of planetary gearboxes. Wind turbines, on the other hand, have a more complicated structure, with several excitation sources to consider, including the impact of main bearings, high-speed gearbox, and other components, as well as the influence of operating conditions such as speed, load, and temperature. Therefore, a more refined model can be discussed to be closer to the characteristic frequency of the entire wind turbine in the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Parts | Parameters | Value |

|---|---|---|

| Sun gear | teeth number | 19 |

| mass | 1500 kg | |

| supporting stiffness | 2 × 108 N/m | |

| supporting damping | 1 × 105 | |

| Planetary carrier | mass | 3000 kg |

| supporting stiffness | 2 × 108 N/m | |

| supporting damping | 1 × 105 | |

| Ring gear | teeth number | 86 |

| mass | 4440 kg | |

| supporting stiffness | 2 × 108 N/m | |

| supporting damping | 1 × 105 | |

| Planetary gears | Number of planetary gear | 3 |

| teeth numbermodulus (ms = mr = mp) | 3345 mm | |

| mass | 2500 kg | |

| supporting stiffness | 5.9 × 108 N/m | |

| supporting damping | 1 × 106 | |

| average mesh stiffness (kspn = krpn) | 1 × 1010 N/m | |

| Planetary bearings | radius of inner ring | 255.1 mm |

| radius of outer ring | 340 mm | |

| width | 160 mm | |

| Number of rolling elements | 24 | |

| contact stiffness | 6 × 106 N/m | |

| Simulated signal | Sampling frequency | 5120 Hz |

| Fault frequency | 0.2 Hz | |

| Sampling duration | 30 s | |

| On-site signal | Sampling frequency | 5120 Hz |

| Fault frequency | 0.2 Hz | |

| Sampling duration | 30 s |

References

- Stanojević, M.; Tomović, R.; Ivanović, L.; Stojanović, B. Critical Analysis of Design of Ravigneaux Planetary Gear Trains. Appl. Eng. Lett. 2022, 7, 32–44. [Google Scholar] [CrossRef]

- Vasić, M.; Blagojević, M.; Stojić, B.; Dizdar, S. Design and Performance Analysis of an In-Wheel Hub Reducer. Adv. Eng. Lett. 2022, 1, 115–125. [Google Scholar] [CrossRef]

- Wang, S.; Du, J.; Li, C.; Xia, S.; Jiang, S.; Sun, J. Crack Propagation Analysis of Slewing Bearings in Wind Turbines Applying a Modified Sub-Model Technology. Eng. Fail. Anal. 2023, 153, 107556. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, X.; Yue, Y.; Wang, S.; Han, H.; Wen, M.; Wang, Q.; Cheng, P. Investigation on 3D Fatigue Crack Propagation in Pitch Bearing Raceway of Offshore Wind Turbines. Ocean. Eng. 2023, 269, 113524. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, L.; Chen, Z.; Gao, H.; Shi, Z.; Zhang, G. Dynamics Modelling and Vibration Characteristics of Urban Rail Vehicle Axle-Box Bearings with the Cage Crack. Mech. Syst. Signal Process. 2023, 205, 110870. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, B.; Xin, Q.; Niu, X.; Xie, Z.; Lu, X.; Zou, D. Analysis of Transient Lubrication and Wear Coupling Behaviors Considering Thermal Effect and Journal Misalignment for Main Bearings under Dynamic Load. Wear 2024, 554–555, 205478. [Google Scholar] [CrossRef]

- Lehmann, B.; Trompetter, P.; Guzmán, F.G.; Jacobs, G. Evaluation of Wear Models for the Wear Calculation of Journal Bearings for Planetary Gears in Wind Turbines. Lubricants 2023, 11, 364. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, B.; He, T.; Tu, L.; Xie, Z.; Zhong, N.; Zou, D. Study on Coupling Transient Mixed Lubrication and Time-Varying Wear of Main Bearing in Actual Operation of Low-Speed Diesel Engine. Tribol. Int. 2024, 191, 109159. [Google Scholar] [CrossRef]

- Wang, F.; Ling, X.; Zhang, Z.; Dai, P.; Yan, S.; Wang, L. The Effect of Fit Clearance between Outer Race and Housing on Vibration Characteristics of a Cylindrical Roller Bearing with Localized Defects. Machines 2022, 10, 415. [Google Scholar] [CrossRef]

- Yang, Y.; Ouyang, H.; Yang, Y.; Cao, D.; Wang, K. Vibration Analysis of a Dual-Rotor-Bearing-Double Casing System with Pedestal Looseness and Multi-Stage Turbine Blade-Casing Rub. Mech. Syst. Signal Process. 2020, 143, 106845. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Y.; Cao, D.; Chen, G.; Jin, Y. Response Evaluation of Imbalance-Rub-Pedestal Looseness Coupling Fault on a Geometrically Nonlinear Rotor System. Mech. Syst. Signal Process. 2019, 118, 423–442. [Google Scholar] [CrossRef]

- Jafarian, M.J.; Nazarzadeh, J. A TDF Model in Induction Machines for Loose Bearing Diagnosis by Neutral Voltage. IEEE Trans. Ind. Electron. 2020, 67, 8155–8163. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Y.-P.; Lin, J.; Han, Q.; Liu, Y. Analysis of Nonlinear Vibrations and Health Assessment of a Bearing-Rotor with Rub-Impact Based on a Data-Driven Approach. J. Sound Vib. 2022, 534, 117068. [Google Scholar] [CrossRef]

- Wang, H.; Guan, X.; Chen, G.; Gong, J.; Yu, L.; Yuan, S.; Zhu, Z. Characteristics Analysis of Rotor-Rolling Bearing Coupled System with Fit Looseness Fault and Its Verification. J. Mech. Sci. Technol. 2019, 33, 29–40. [Google Scholar] [CrossRef]

- Nan, G.; Yao, J.; Chen, X.; Jiang, S. Coupling Dynamics of Pedestal Looseness and Impact-Rub for Rotor System with Nonlinear Support. Adv. Mech. Eng. 2024, 16, 16878132231222907. [Google Scholar] [CrossRef]

- Xu, H.; Wang, P.; Ma, H.; Yang, Y.; Li, X.; Luo, Z.; Han, Q.; Wen, B. Dynamic Behaviors and Contact Characteristics of Ball Bearings in a Multi-Supported Rotor System under the Effects of 3D Clearance Fit. Mech. Syst. Signal Process. 2023, 196, 110334. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, Y.; Du, W.; Jiang, L.; Yu, W. Dynamic Characteristic Analysis of a Gear-Rotor-Bearing Coupling System Considering Bearing Fit. Nonlinear Dyn. 2025, 113, 2131–2154. [Google Scholar] [CrossRef]

- Liu, P.; Wang, L.; Ma, F.; Zheng, D.; Wu, J.; Li, Z. Influence of Assembly Clearance on Vibration Characteristics of Angular Contact Ball Bearings in the Thermal Environment. Tribol. Int. 2023, 181, 108317. [Google Scholar] [CrossRef]

- Yin, J.; Meng, X.; Cheng, S.; Fang, X.; Fan, X. Tribo-dynamics modeling and analysis of planetary gear bearing systems in wind turbines considering sun-planetary-ring helical gear mesh and elastic deformation effects. Tribol. Int. 2024, 200, 110059. [Google Scholar] [CrossRef]

- Xu, H.; Ren, H.; Qin, D. Dynamic characteristics of the planetary gear system with rolling bearing. Multibody Syst. Dyn. 2023, 59, 171–191. [Google Scholar] [CrossRef]

- Wang, P.; Xu, H.; Ma, H.; Han, H.; Yang, Y. Effects of three types of bearing misalignments on dynamic characteristics of planetary gear set-rotor system. Mech. Syst. Signal Process. 2022, 169, 108736. [Google Scholar] [CrossRef]

- Zhang, B.; Teng, W.; Tang, S.; Peng, D.; Fang, Q.; Ma, Z. Sparsity-assisted energy decoupling model for fault detection of planetary ring gear in wind turbines. Mech. Syst. Signal Process. 2025, 238, 113235. [Google Scholar] [CrossRef]

- Nie, Y.; Lu, H.; Chen, X.; Li, G.; Zhang, C.; Wang, L.; Li, F. Interpreting vibration characteristics of planetary gearboxes for condition monitoring based on a novel transfer path effect model. Nonlinear Dyn. 2025, 113, 9351–9371. [Google Scholar] [CrossRef]

- Jing, H.; Zhen, D.; Feng, G.; Liang, X.; Zhang, H.; Gu, F. Improved Transfer Path Effect Model Considering Frequency Attenuation for Planetary Gear Train with Sun Gear Fault. Shock. Vib. 2025, 1, 1559627. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Tang, S.; Xu, J.; Shi, B.; Liu, Y. Vibration Analysis for Fault Detection of Wind Turbine Drivetrains-A Comprehensive Investigation. Sensors 2021, 21, 1686. [Google Scholar] [CrossRef]

- Zhou, P.; Du, M.; Chen, S.; He, Q.; Peng, Z.; Zhang, W. Study on Intra-Wave Frequency Modulation Phenomenon in Detection of Rub-Impact Fault. Mech. Syst. Signal Process. 2019, 122, 342–363. [Google Scholar] [CrossRef]

- Harris, T.A. Essential Concepts of Bearing Technology; Taylor & Francis: Abingdon, UK, 2006; pp. 199–212. [Google Scholar]

- Xue, S.; Wang, C.; Howard, I.; Lian, P.; Chen, G.; Wang, Y.; Yan, Y.; Xu, Q.; Shi, Y.; Jia, Y.; et al. The diagnostic analysis of the fault coupling effects in planet bearing. Eng. Fail. Anal. 2019, 108, 104266. [Google Scholar] [CrossRef]

- Chen, G.; Qu, M. Modeling and Analysis of Fit Clearance between Rolling Bearing Outer Ring and Housing. J. Sound Vib. 2019, 438, 419–440. [Google Scholar] [CrossRef]

- Cao, H.; Shi, F.; Li, Y.; Li, B.; Chen, X. Vibration and Stability Analysis of Rotor-Bearing-Pedestal System Due to Clearance Fit. Mech. Syst. Signal Process. 2019, 133, 106275. [Google Scholar] [CrossRef]

- Mao, Y.; Wang, L.; Zhang, C. Influence of Ring Deformation on the Dynamic Characteristics of a Roller Bearing in Clearance Fit with Housing. Int. J. Mech. Sci. 2018, 138–139, 122–130. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, A.; Qin, D.; Lim, T.C.; Shu, R.; Lin, X.; Meng, F. A Coupling Dynamics Analysis Method for a Multistage Planetary Gear System. Mech. Mach. Theory 2017, 110, 27–49. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Xia, M. A Dynamic Model for the Planetary Bearings in a Double Planetary Gear Set. Mech. Syst. Signal Process. 2023, 194, 110257. [Google Scholar] [CrossRef]

- Liang, X. Dynamics Based Vibration Signal Modeling and Fault Detection of Planetary Gearboxes; University of Alberta: Edmonton, AB, Canada, 2016. [Google Scholar]

- Liu, J.; Pang, R.; Ding, S.; Li, X. Vibration Analysis of a Planetary Gear with the Flexible Ring and Planet Bearing Fault. Measurement 2020, 165, 108100. [Google Scholar] [CrossRef]

- Kong, Y.; Wang, T.; Chu, F. Meshing Frequency Modulation Assisted Empirical Wavelet Transform for Fault Diagnosis of Wind Turbine Planetary Ring Gear. Renew. Energy 2019, 132, 1373–1388. [Google Scholar] [CrossRef]

- Wang, T.; Chu, F.; Han, Q. Fault Diagnosis for Wind Turbine Planetary Ring Gear via a Meshing Resonance Based Filtering Algorithm. ISA Trans. 2017, 67, 173–182. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Wang, R.; Fu, D.; Zhao, N.; Ma, X. Joint Modeling of Planetary Gear Train and Bearings of Wind Turbines for Vibration Analysis of Planetary Bearing Outer Ring Looseness Fault. Energies 2025, 18, 5938. https://doi.org/10.3390/en18225938

Zhou C, Wang R, Fu D, Zhao N, Ma X. Joint Modeling of Planetary Gear Train and Bearings of Wind Turbines for Vibration Analysis of Planetary Bearing Outer Ring Looseness Fault. Energies. 2025; 18(22):5938. https://doi.org/10.3390/en18225938

Chicago/Turabian StyleZhou, Chuandi, Ruiming Wang, Deyi Fu, Na Zhao, and Xiaojing Ma. 2025. "Joint Modeling of Planetary Gear Train and Bearings of Wind Turbines for Vibration Analysis of Planetary Bearing Outer Ring Looseness Fault" Energies 18, no. 22: 5938. https://doi.org/10.3390/en18225938

APA StyleZhou, C., Wang, R., Fu, D., Zhao, N., & Ma, X. (2025). Joint Modeling of Planetary Gear Train and Bearings of Wind Turbines for Vibration Analysis of Planetary Bearing Outer Ring Looseness Fault. Energies, 18(22), 5938. https://doi.org/10.3390/en18225938