Dynamic Behaviors and Ambient Temperature Effects of a Gas–Liquid Type Compressed CO2 Energy Storage System

Abstract

1. Introduction

- A dynamic model of GL-CCES is established, revealing the influence of transient phase transitions of CO2 in the high-pressure tank on overall system dynamics.

- The effects of ambient temperature on heat exchangers, turbomachinery, and overall performance are systematically examined, providing a theoretical basis for system optimization under different climatic conditions.

- An adaptive regulation strategy is proposed to balance flow-rate mismatches between charging and discharging, thereby improving operational stability and efficiency.

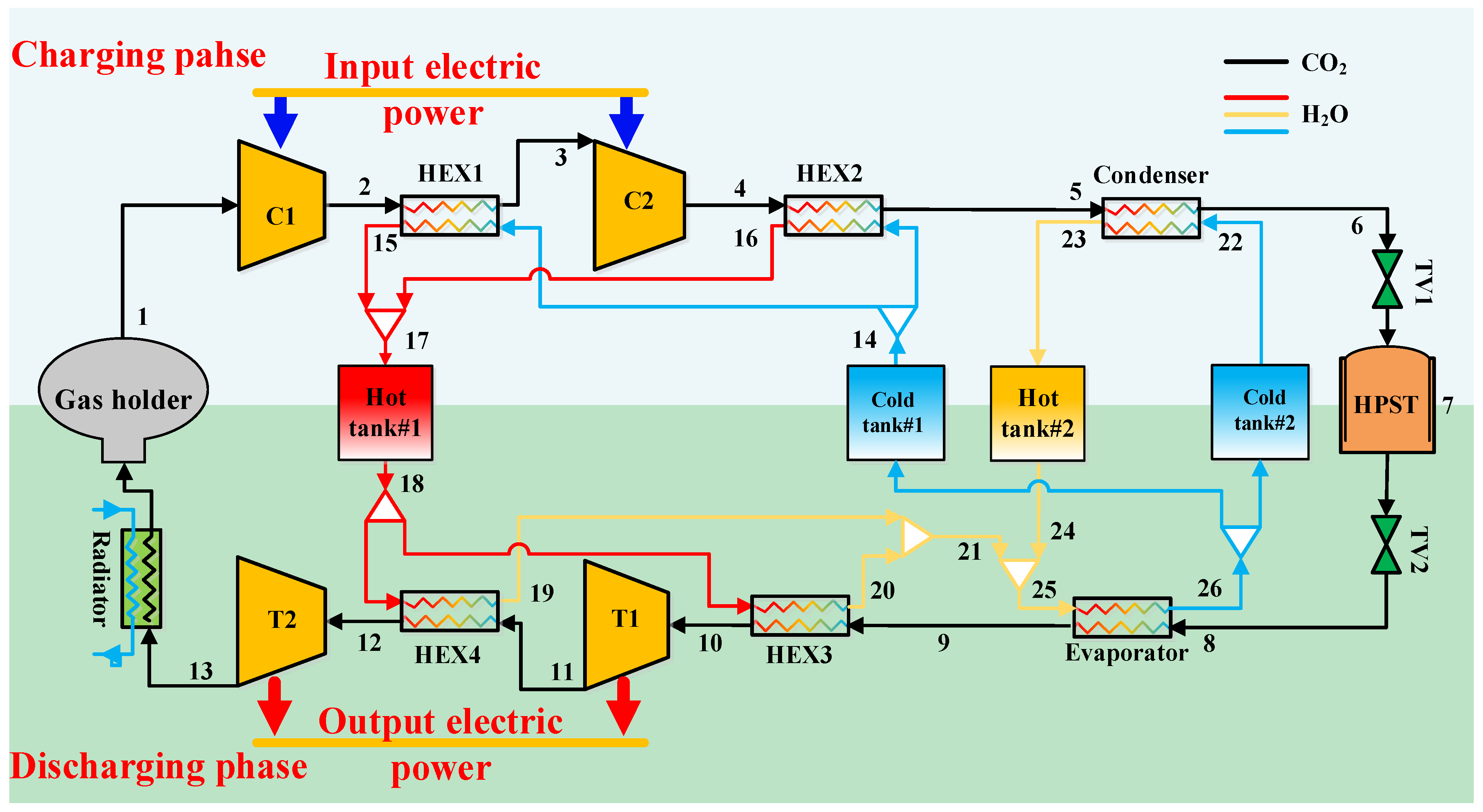

2. System Description and Assumptions

3. Mathematical Model

3.1. Steady-State Thermodynamic Modeling

3.1.1. Assumptions for the Steady-State System

- Pressure drops and heat losses in heat exchangers and connecting pipes are neglected.

- The power consumption of pumps, except for the water pump, is neglected.

- CO2 is stored in the gas tank under ambient conditions.

- Charging and discharging processes are assumed to have equal durations.

3.1.2. Thermodynamic Models of Key Components

3.2. Dynamic Modeling

3.2.1. Dynamic System Description and Assumptions

- Heat losses in heat exchangers and pipelines are neglected.

- The power consumption of pumps is neglected.

- Heat exchange between the high-pressure tank and the environment is neglected, and changes inside the tank are treated as adiabatic.

- CO2 in the gas tank is assumed to be stored under ambient conditions, with the gas tank represented by an atmospheric module.

- Ambient temperature and pressure are assumed to be constant throughout the simulation.

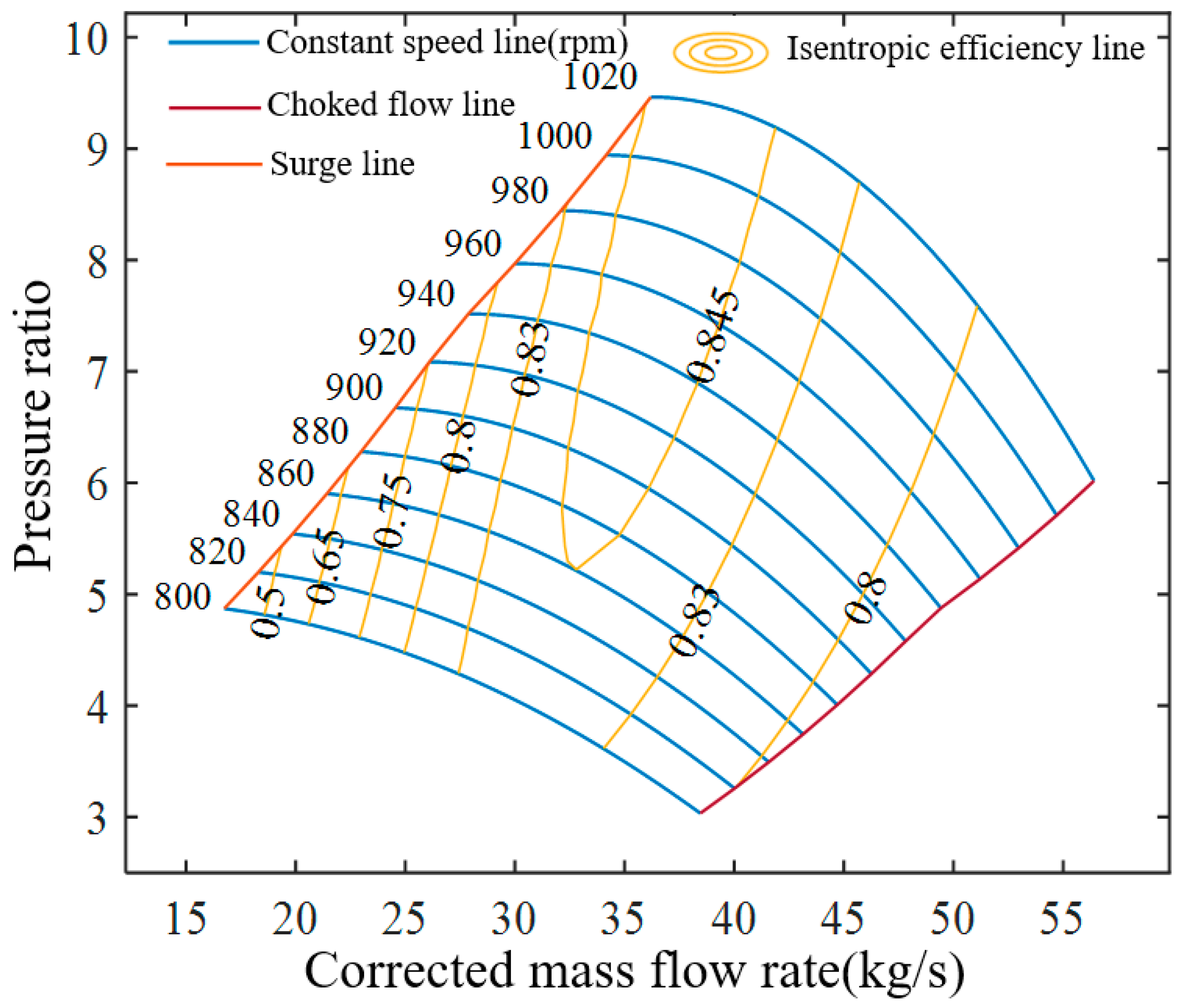

3.2.2. Compressor Module

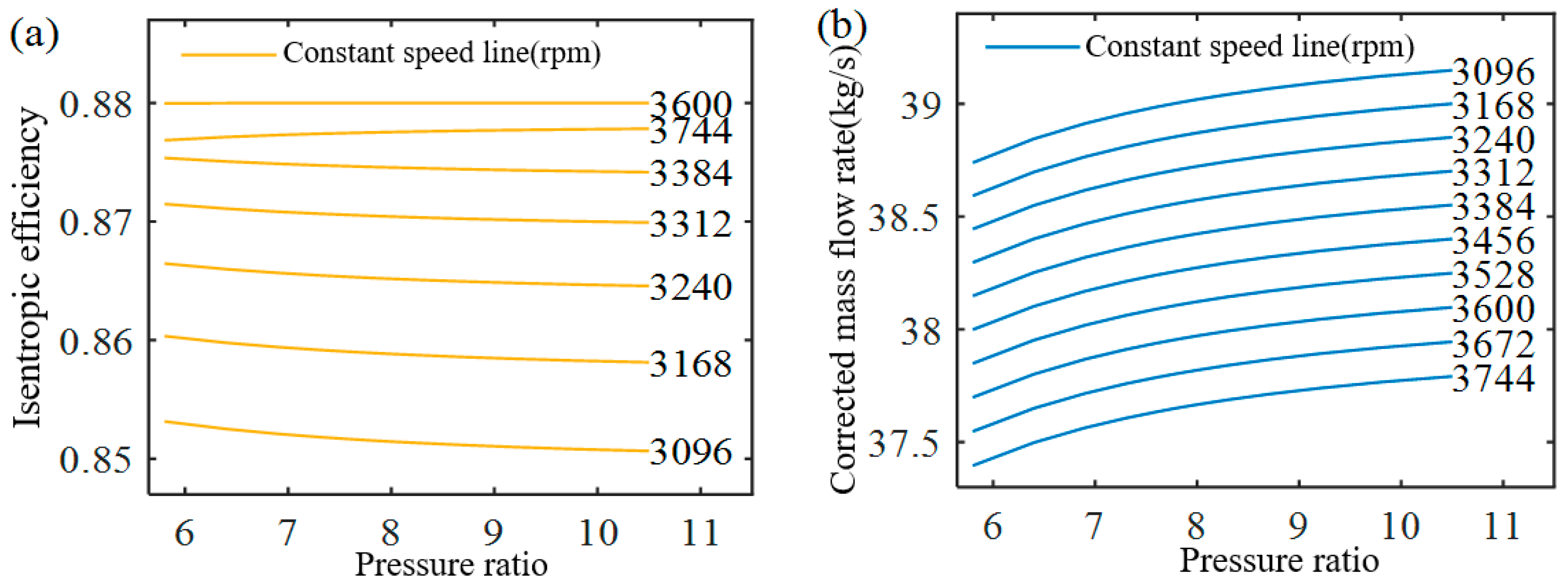

3.2.3. Expander Module

3.2.4. Heat Exchanger Module

3.2.5. High-Pressure Tank Module

3.2.6. Thermophysical Property Module

3.3. Model Validation

3.3.1. Validation of the Steady-State Model

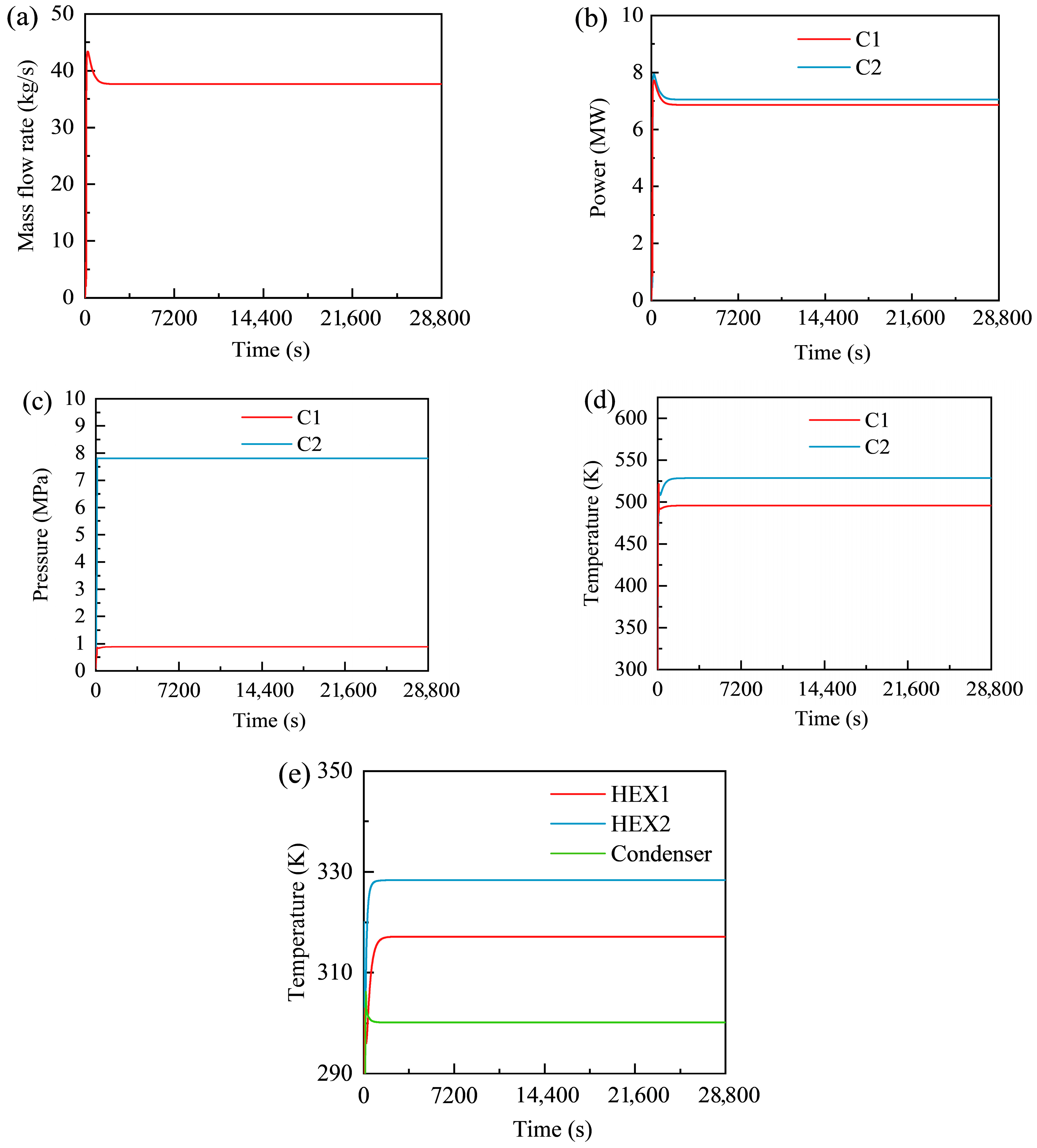

3.3.2. Validation of the Dynamic Model

4. Dynamic Characteristics of the GL-CCES System

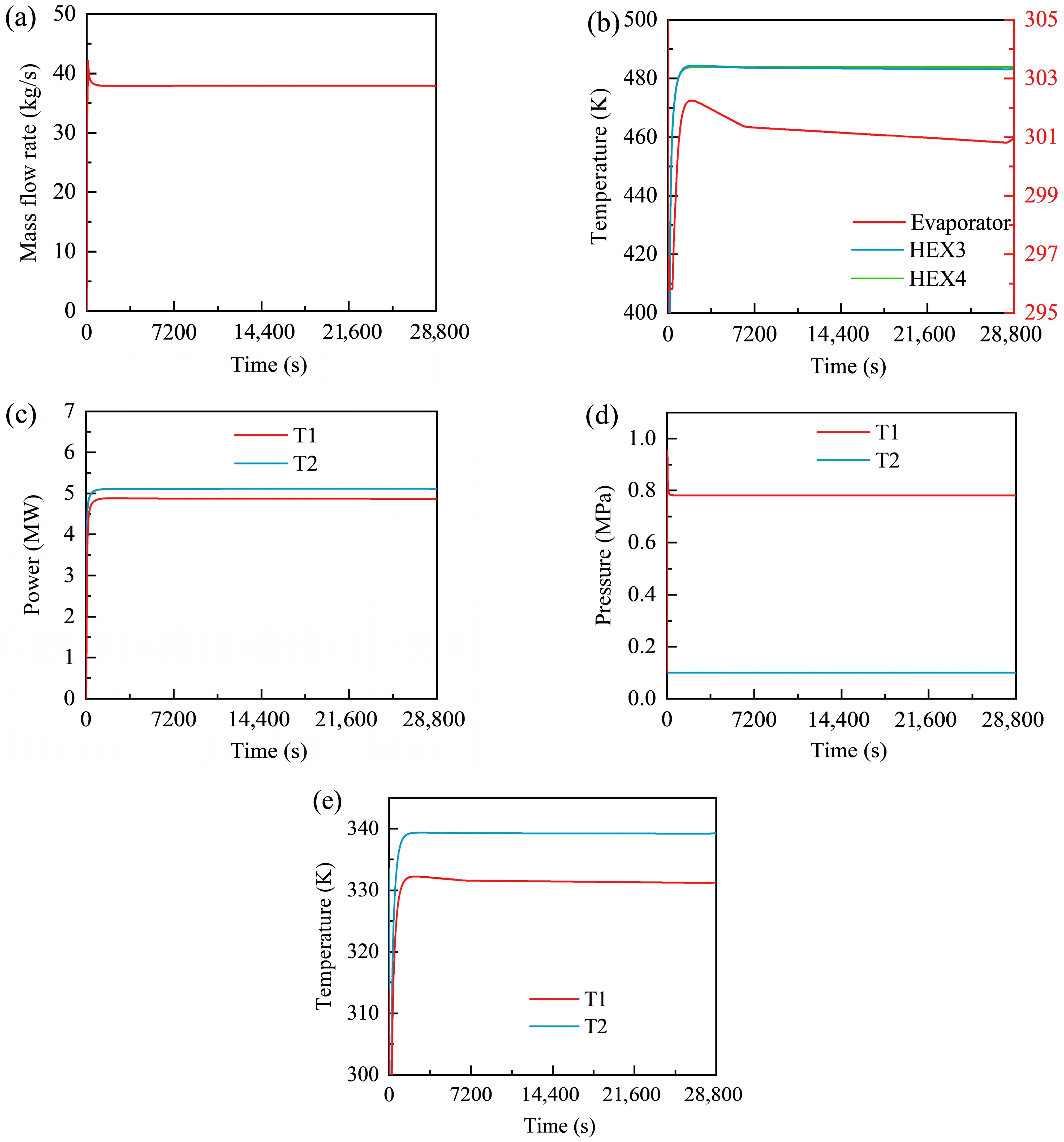

4.1. Dynamic Characteristics During the Charging Process

4.2. Dynamic Characteristics During the Discharging Process

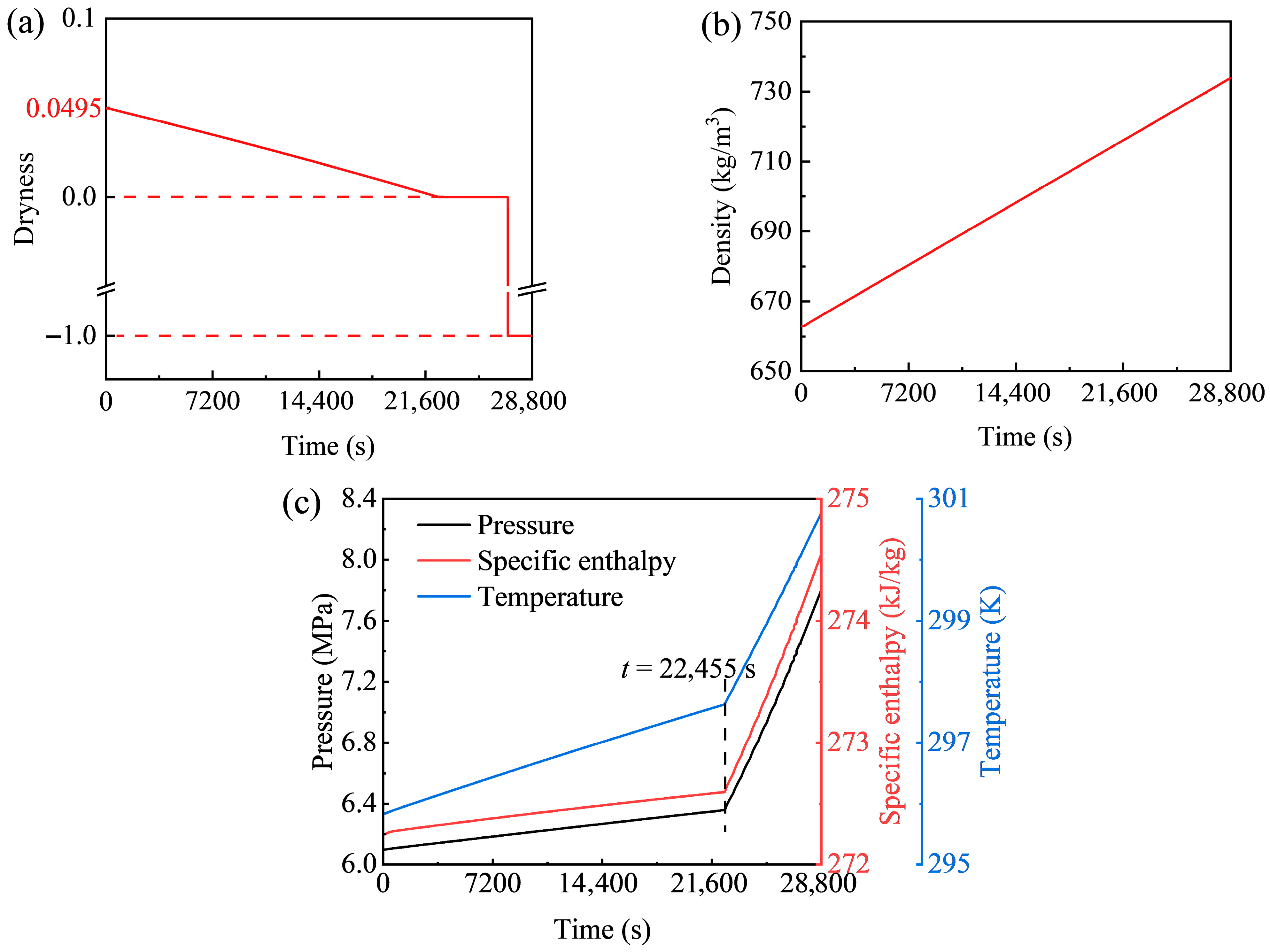

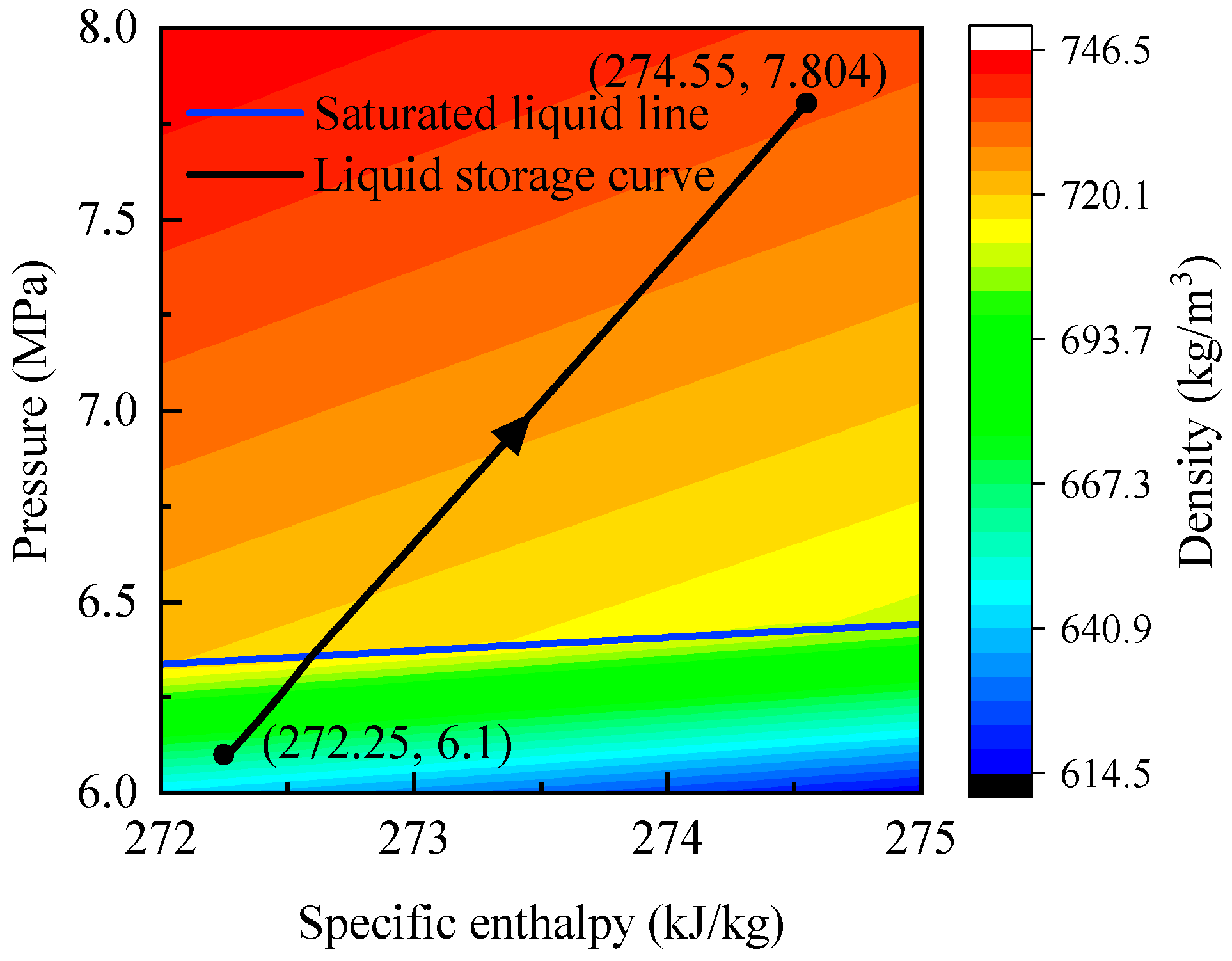

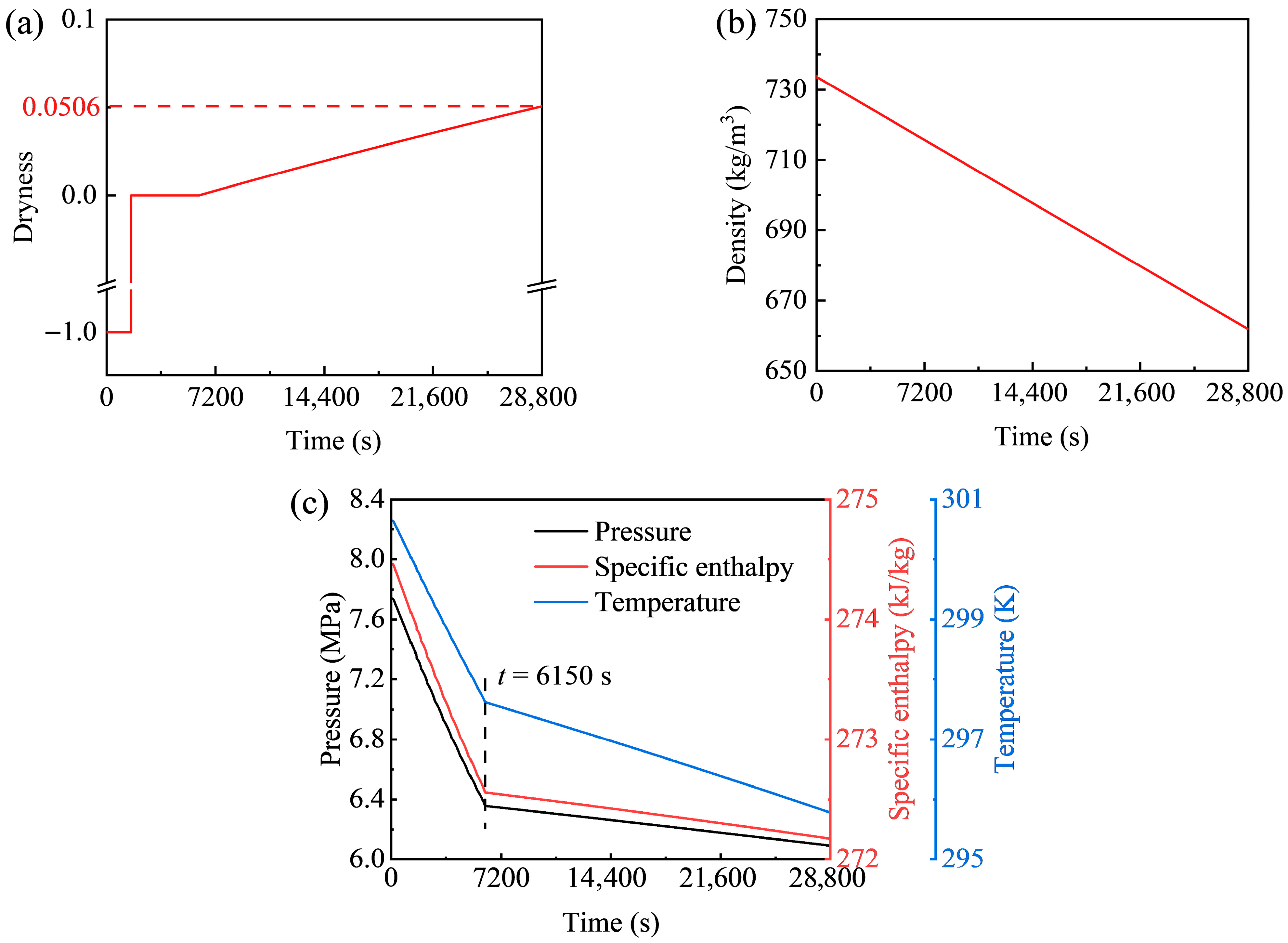

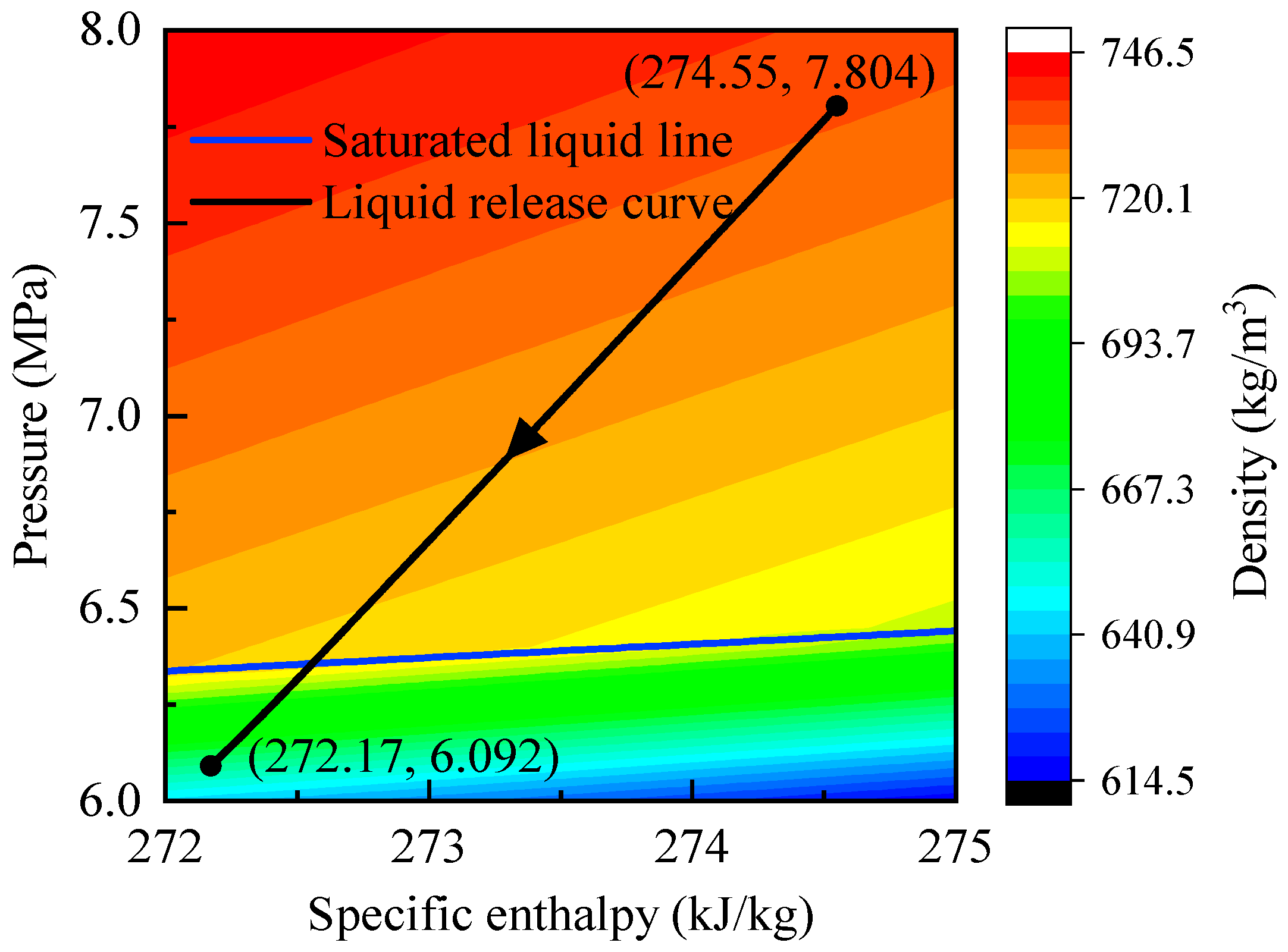

4.3. Dynamic Characteristics of the High-Pressure Storage Tank

4.4. Performance Evaluation Under Design Condition

4.5. Effect of Ambient Temperature on the Performance of the GL-CCES System

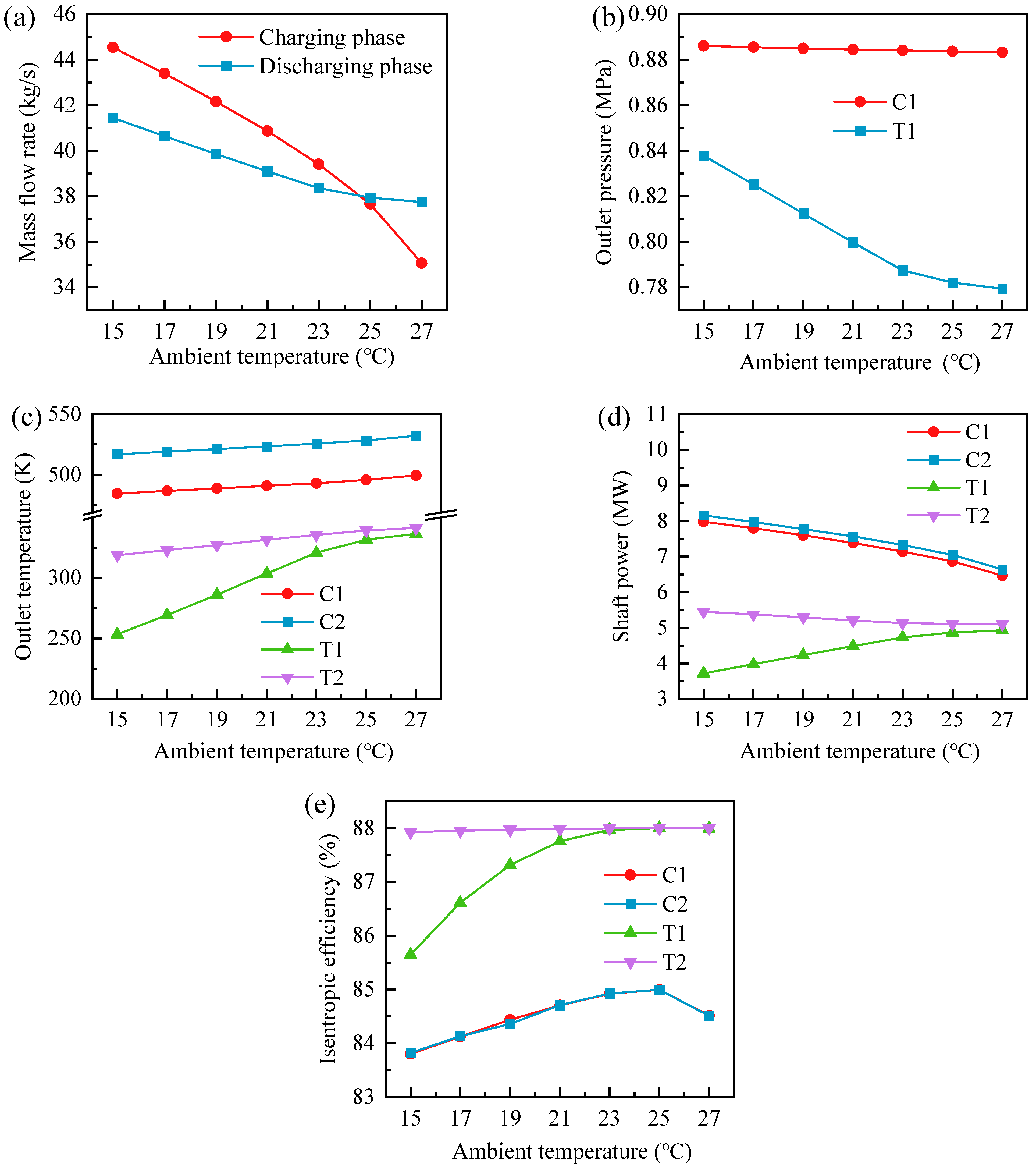

4.5.1. Effect on Turbomachinery

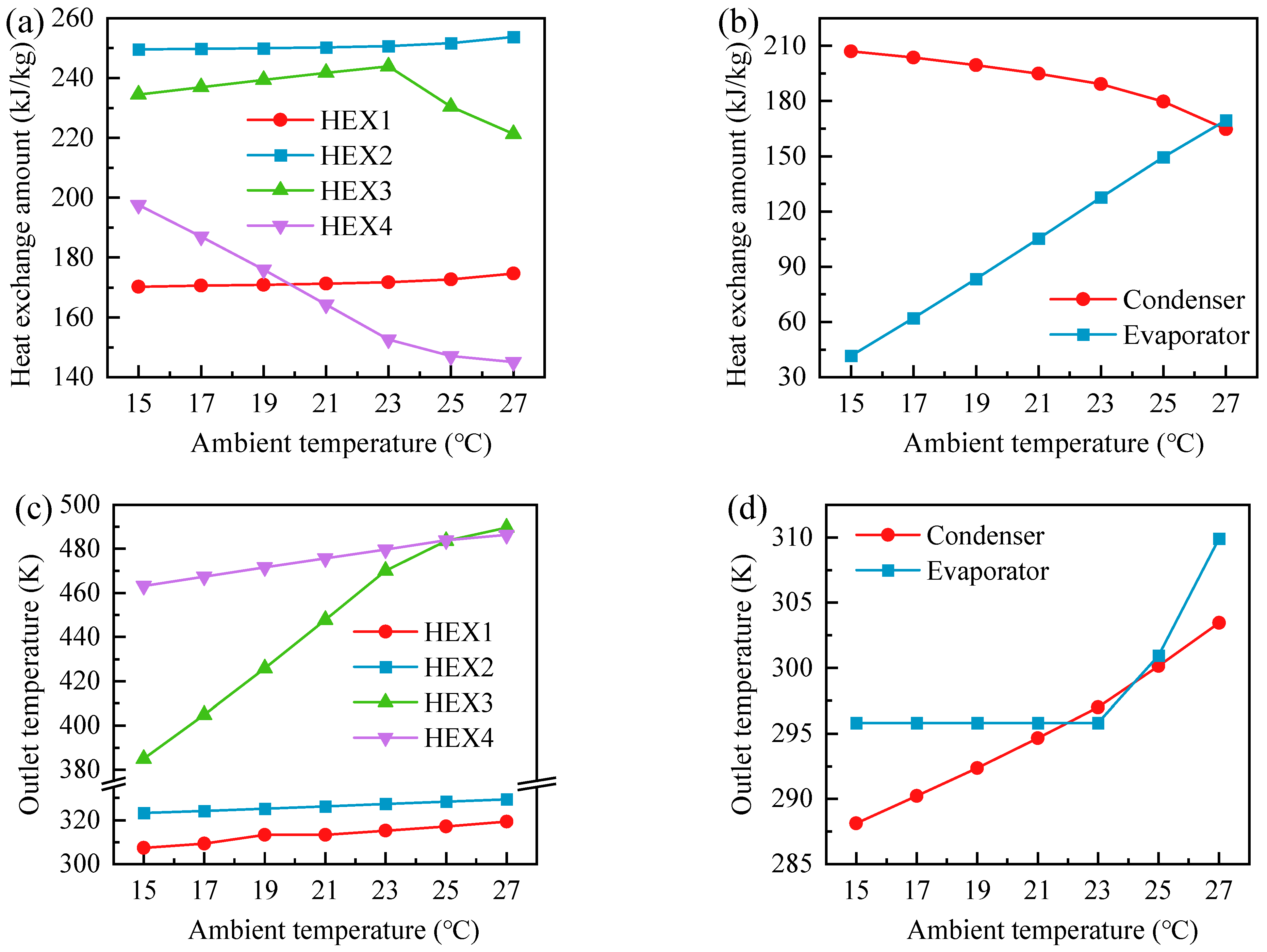

4.5.2. Effect on Heat Exchanger Performance

4.5.3. Effect on Overall System Performance

4.6. Comparison with Other Dynamic CCES Systems

5. Conclusions

- In the adiabatic high-pressure storage tank, CO2 undergoes distinct phase transitions between two-phase and pure-liquid states, leading to inflection points in the temporal evolution of pressure, temperature, and specific enthalpy. Parameter variations are faster in the liquid region and slower in the two-phase region.

- At elevated ambient temperatures, the two-stage compressors of the GL-CCES system cannot sustain the required pressure ratio, resulting in operational failure unless compensated by increased rotational speed. At lower ambient temperatures, the evaporator suffers from reduced heat transfer effectiveness despite its enhanced design configuration, causing significant efficiency losses.

- Under the design ambient temperature of 25 °C, the GL-CCES system achieves a maximum RTE of 70.52%, slightly lower than the steady-state design value, while the energy storage density is only 5.15 kWh/m3 (12.7% of the steady-state assumption). By comparison, the maximum energy storage density of 5.30 kWh/m3 occurs at 21 °C, but with a reduced RTE of 67.01%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CCES | Compressed CO2 Energy Storage | D | Characteristic length |

| CAES | Compressed Air Energy Storage | S | Flow area |

| GL-CCES | Gas–Liquid Compressed CO2 Energy Storage | μ | Dynamic viscosity |

| CCUS | Carbon Capture, Utilization, and Storage | CZ | Correction factor in the two-phase region |

| W | Power | v | Specific volume |

| ṁ | Mass flow rate | x | Dryness |

| h | Specific enthalpy | ΔP | Pressure drop |

| Heat transfer rate | J | Pressure drop coefficient | |

| η | Efficiency | ṁ0 | Laminar threshold of mass flow rate |

| T | Temperature | RTE | Round-trip efficiency |

| P | Pressure | EVR | Energy density |

| G | Corrected mass flow rate | Subscripts | |

| Relative corrected mass flow rate | in | Inlet | |

| n | Rotational speed | out | Outlet |

| N | Corrected speed | is | Isentropic process |

| Relative corrected speed | C | Compressor | |

| ε | Pressure ratio | T | Turbine/Expander |

| Relative pressure ratio | i | i-th stage | |

| Relative efficiency | valve | Valve | |

| u | Specific internal energy | CO2 | Carbon dioxide |

| ρ | Density | H2O | Water |

| V | Volume | d | Design |

| M | Mass | wall | Wall |

| UA | Overall thermal conductance | SV | Saturated vapor |

| Re | Reynolds number | SL | Saturated liquid |

| Pr | Prandtl number | in | Inlet |

| k | Thermal conductivity | HPST | High-pressure storage tank |

| K | Geometric factor |

References

- Yang, X.; Yu, J.; Guo, Z.; Jin, L.; He, Y.-L. Role of porous metal foam on the heat transfer enhancement for a thermal energy storage tube. Appl. Energy 2019, 239, 142–156. [Google Scholar] [CrossRef]

- Leal, V.M.; Ribeiro, J.S.; Coelho, E.L.D.; Freitas, M.B.J.G. Recycling of spent lithium-ion batteries as a sustainable solution to obtain raw materials for different applications. J. Energy Chem. 2023, 79, 118–134. [Google Scholar] [CrossRef]

- Zhao, P.; Xu, W.; Zhang, S.; Gou, F.; Wang, J.; Dai, Y. Components design and performance analysis of a novel compressed carbon dioxide energy storage system: A pathway towards realizability. Energy Convers. Manag. 2021, 229, 113679. [Google Scholar] [CrossRef]

- Zhao, P.; Dai, Y.; Wang, J. Design and thermodynamic analysis of a hybrid energy storage system based on A-CAES (adiabatic compressed air energy storage) and FESS (flywheel energy storage system) for wind power application. Energy 2014, 70, 674–684. [Google Scholar] [CrossRef]

- Chaychizadeh, F.; Dehghandorost, H.; Aliabadi, A.; Taklifi, A. Stochastic dynamic simulation of a novel hybrid thermal-compressed carbon dioxide energy storage system (T-CCES) integrated with a wind farm. Energy Convers. Manag. 2018, 166, 500–511. [Google Scholar] [CrossRef]

- Li, P.; Hu, Q.; Li, G.; Wang, B.; Bai, Y.; Han, X.; Han, Z. Research on thermo-economic characteristics of a combined cooling, heating and power system based on advanced adiabatic compressed air energy storage. J. Energy Storage 2022, 47, 103590. [Google Scholar] [CrossRef]

- Zhang, M.; Shi, L.; Hu, P.; Pei, G.; Shu, G. Carnot battery system integrated with low-grade waste heat recovery: Toward high energy storage efficiency. J. Energy Storage 2023, 57, 106234. [Google Scholar] [CrossRef]

- Baghalnezhad, M.; Salehi, G.; Mirabdolah Lavasani, A.; Vahabi, M.; Nimafar, M. Decision study and optimization of an innovative three-state multigeneration process using solar energy and compressed air energy storage: A data-driven scenario. Appl. Therm. Eng. 2024, 256, 124069. [Google Scholar] [CrossRef]

- Rahimimotlagh, Z.; Ahmadi, A. Energy, exergy, exergoeconomic and exergoenvironmental analysis and optimization of combined solar, SRC cycles with compressed air energy storage (CAES) and methane production system. Energy Convers. Manag. 2024, 317, 118855. [Google Scholar] [CrossRef]

- Guizzi, G.L.; Manno, M.; Tolomei, L.M.; Vitali, R.M. Thermodynamic analysis of a liquid air energy storage system. Energy 2015, 93, 1639–1647. [Google Scholar] [CrossRef]

- He, T.; Cao, Y.; Si, F. Thermodynamic analysis and optimization of a compressed carbon dioxide energy storage system coupled with a combined heating and power unit. Energy Convers. Manag. 2023, 277, 116618. [Google Scholar] [CrossRef]

- Wu, C.; Wan, Y.; Liu, Y.; Xu, X.; Liu, C. Thermodynamic simulation and economic analysis of a novel liquid carbon dioxide energy storage system. J. Energy Storage 2022, 55, 105544. [Google Scholar] [CrossRef]

- Li, H.; Ding, R.; Su, W.; Lin, X.; Guan, S.; Ye, Q.; Zheng, Z.; Wang, J. A comprehensive performance comparison between compressed air energy storage and compressed carbon dioxide energy storage. Energy Convers. Manag. 2024, 319, 118972. [Google Scholar] [CrossRef]

- Zhang, Y.; Yao, E.; Wang, T. Comparative analysis of compressed carbon dioxide energy storage system and compressed air energy storage system under low-temperature conditions based on conventional and advanced exergy methods. J. Energy Storage 2021, 35, 102274. [Google Scholar] [CrossRef]

- Hu, D.; Zhao, M.; Zhang, C.; Zhu, Y.; Xu, Y.; Shen, G.; Chen, H. Performance analysis of coal-fired power plant with carbon capture integrated with a supercritical compressed carbon dioxide energy storage system. Energy 2025, 336, 138342. [Google Scholar] [CrossRef]

- Zhang, T.; Qin, S.; Wei, G.; Xie, M.; Peng, Y.; Tang, Z.; Sun, Q.; Du, Q.; Feng, D.; Gao, J.; et al. Thermodynamic analysis of a novel trans-critical compressed carbon dioxide energy storage system based on 13X zeolite temperature swing adsorption. Energy 2023, 282, 128399. [Google Scholar] [CrossRef]

- Chen, K.-Q.; Pu, W.-H.; Zhang, Q.; Xing, X.-L.; Xiong, C.; Guo, M.-D. Thermodynamic and Economic Assessment on the Supercritical Compressed Carbon Dioxide Energy Storage System coupled with Solar Thermal Storage. J. Energy Storage 2021, 41, 102959. [Google Scholar] [CrossRef]

- Zheng, L.; Li, Y.; Mao, Y.; Xue, X.; Xu, G.; Lin, X. Thermodynamic and economic analyses of a novel liquid carbon dioxide energy storage system incorporated with a coal-fired power plant. Energy 2025, 325, 136212. [Google Scholar] [CrossRef]

- Li, H.; Su, W.; Dai, H.; Lin, X.; Ding, R.; Wang, J.; Guan, S.; Zheng, Z.; Ye, Q. Thermo-economic analysis on the gas-liquid compressed carbon dioxide energy storage under different sliding pressure ranges of low-pressure gas storage. J. Energy Storage 2025, 134, 118167. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, Z. Thermo-economic performance of a compressed CO2 energy storage system with a flexible gas holder. J. Energy Storage 2023, 60, 106675. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Yin, S.; Su, C.; Liu, Z. Design and performance analysis of a novel compressed air-liquid CO2 energy storage. Energy Convers. Manag. 2024, 301, 118068. [Google Scholar] [CrossRef]

- Li, F.; Xing, L.; Su, W.; Lin, X.; Liang, Y.; Shi, W. An idea to construct integrated energy systems of data center by combining CO2 heat pump and compressed CO2 energy storage. J. Energy Storage 2024, 75, 109581. [Google Scholar] [CrossRef]

- Qiao, L.; Pu, W.; Wu, B.; Liu, R.; Song, N. Performance study of a supercritical carbon dioxide energy storage system with non-uniform graded compression heat recovery. Energy 2024, 313, 133876. [Google Scholar] [CrossRef]

- Yari, M.; Khodaei, E.; Nami, H. Techno-economic assessment of a low-carbon solar-assisted compressed air energy storage system integrated with calcium looping carbon capture. Appl. Therm. Eng. 2025, 279, 127869. [Google Scholar] [CrossRef]

- Ma, H.; Liu, Z. Techno-economic assessment on a multi-stage compressed carbon dioxide energy storage system with liquid storage. Energy Rep. 2022, 8, 11740–11750. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, T.; Yang, K. An integrated energy storage system consisting of Compressed Carbon dioxide energy storage and Organic Rankine Cycle: Exergoeconomic evaluation and multi-objective optimization. Energy 2022, 247, 123566. [Google Scholar] [CrossRef]

- Hou, K.; Guo, J.; Liu, X.; Lv, K.; He, M. Dynamic characteristics and performance analysis of typical liquid carbon dioxide energy storage systems. Energy 2025, 336, 138463. [Google Scholar] [CrossRef]

- Hao, Y.; Xu, X.; Wang, F.; Wang, Y.; Du, J.; Wu, C.; Li, Q. Dynamic characteristics of gas-liquid type compressed CO2 energy storage system with focus on high-pressure liquid energy release process. Energy 2025, 316, 134502. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Y.; Yang, K. Dynamic characteristics of a two-stage compression and two-stage expansion Compressed Carbon dioxide energy storage system under sliding pressure operation. Energy Convers. Manag. 2022, 254, 115218. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, X.; Tian, Z.; Kan, A.; Gao, W.; Yang, K. A step towards dynamic: An investigation on a carbon dioxide binary mixtures based compressed gas energy storage system using energy and exergy analysis. Energy 2023, 282, 128415. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, J.; Yu, X.; Sun, E.; Xie, J.; Liu, G. Optimization of dynamic compressed CO2 energy storage system: The role of supercritical fluid properties. Energy 2025, 328, 136417. [Google Scholar] [CrossRef]

- Wang, D.; Han, X.; Si, L.; Zhou, Y. A coordinated control strategy and dynamic characteristics of coal-fired units coupled with the S-CO2 energy storage cycle. Appl. Energy 2024, 372, 123812. [Google Scholar] [CrossRef]

- Yang, D.L.; Tang, G.H.; Sheng, Q.; Li, X.L.; Fan, Y.H.; He, Y.L.; Luo, K.H. Effects of multiple insufficient charging and discharging on compressed carbon dioxide energy storage. Energy 2023, 278, 127901. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, B.; Chen, W.; Zhang, X.; Li, D.; Li, J.; Li, H.; Xue, X. Investigation and optimization of the thermal performance of compressed supercritical CO2 energy storage system based on dynamic modeling and transient simulation. Renew. Energy 2025, 238, 121966. [Google Scholar] [CrossRef]

- Liu, Z.; Yan, X.; Wang, S.; Wei, X.; Zhang, Y.; Ding, J.; Su, C. Performance of compressed CO2 energy storage systems with different liquefaction and storage scenarios. Fuel 2024, 359, 130527. [Google Scholar] [CrossRef]

- Zhao, P.; Xu, W.; Gou, F.; Fan, G.; Wang, J. Performance analysis of a self-condensation compressed carbon dioxide energy storage system with vortex tube. J. Energy Storage 2021, 41, 102995. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z.; Xin, X.; Yang, X. Proposal and assessment of a novel carbon dioxide energy storage system with electrical thermal storage and ejector condensing cycle: Energy and exergy analysis. Appl. Energy 2020, 269, 115067. [Google Scholar] [CrossRef]

- Yan, X.; Ding, J.; Zhang, Y.; Zhang, Y.; Liu, Z. Thermodynamic evaluation on a new CO2 energy storage system assisted by adsorption bed. J. Energy Storage 2023, 61, 106775. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, K.; Hong, H.; Zhong, X.; Xu, J. Thermodynamic analysis of a novel energy storage system with carbon dioxide as working fluid. Renew. Energy 2016, 99, 682–697. [Google Scholar] [CrossRef]

- Guo, H.; Xu, Y.; Zhang, Y.; Liang, Q.; Tang, H.; Zhang, X.; Zuo, Z.; Chen, H. Off-design performance and an optimal operation strategy for the multistage compression process in adiabatic compressed air energy storage systems. Appl. Therm. Eng. 2019, 149, 262–274. [Google Scholar] [CrossRef]

- Yu, W.; Wang, S.; Liu, C.; Li, Q.; Xu, X. Study on the thermal stability of a new siloxane working fluid modified by octamethyltrisiloxane and its application potential in organic Rankine cycle. Energy 2025, 320, 135017. [Google Scholar] [CrossRef]

- Cavallini, A.; Zecchin, R. A Dimensionless Correlation for Heat Transfer in Forced Convection Condensation; Begell House Inc.: Danbury, CT, USA, 1974. [Google Scholar]

- Yang, K.; Zhang, Y.; Li, X.; Xu, J. Theoretical evaluation on the impact of heat exchanger in Advanced Adiabatic Compressed Air Energy Storage system. Energy Convers. Manag. 2014, 86, 1031–1044. [Google Scholar] [CrossRef]

- Deng, T.; Li, X.; Wang, Q.; Ma, T. Dynamic modelling and transient characteristics of supercritical CO2 recompression Brayton cycle. Energy 2019, 180, 292–302. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Ambient temperature/K | 298.15 | Ambient pressure/MPa | 0.1 |

| Compressor isentropic efficiency | 0.85 | Expander isentropic efficiency | 0.88 |

| Charging duration/h | 8 | Discharging duration/h | 8 |

| Terminal ΔT of HX1–HX4/K | 5 | Terminal ΔT of condenser & evaporator/K | 3 |

| Charging pressure of CO2/MPa | 7.8 | Discharging pressure of CO2/MPa | 6.1 |

| Parameter | First Stage | Second Stage | ||||

|---|---|---|---|---|---|---|

| This Work | Ref. [35] | Error/% | This Work | Ref. [35] | Error/% | |

| Compressor 1/2 outlet T/K | 495.506 | 495.5 | 0.001 | 528.242 | 528.24 | 0.001 |

| Compressor 1/2 outlet P/MPa | 0.883 | 0.88 | 0.361 | 7.800 | 7.8 | 0 |

| Expander 1/2 outlet T/K | 331.202 | 332.03 | −0.249 | 339.241 | 340.04 | −0.235 |

| Expander 1/2 outlet P/MPa | 0.781 | 0.78 | 0.131 | 0.100 | 0.1 | 0 |

| HX1/HX2 outlet T/K | 317.150 | 317.15 | 0 | 328.150 | 327.15 | 0.306 |

| Condenser/Evaporator outlet T/K | 301.150 | 301.16 | −0.003 | 300.840 | 300.84 | 0 |

| HX3/HX4 outlet T /K | 483.339 | 484.34 | −0.207 | 483.868 | 484.87 | −0.207 |

| Parameter | Simulated | Ref. [35] | Error (%) |

|---|---|---|---|

| Energy density (kWh/m3) | 40.52 | 40.61 | 0.22 |

| Mass flow rate (kg/s) | 37.96 | 37.86 | 0.26 |

| Round-trip efficiency (%) | 71.37 | 71.54 | 0.20 |

| Parameter | First Stage | Second Stage | ||||

|---|---|---|---|---|---|---|

| Dynamic Simulation Value | Design Value | Error/% | Dynamic Simulation Value | Design Value | Error/% | |

| Compressor 1/2 outlet T/K | 495.610 | 495.506 | 0.021% | 528.467 | 528.242 | 0.043% |

| Compressor 1/2 outlet P/MPa | 0.884 | 0.883 | 0.144% | 7.805 | 7.800 | 0.064% |

| Expander 1/2 outlet T/K | 331.613 | 331.202 | 0.124% | 339.251 | 339.241 | 0.003% |

| Expander 1/2 outlet P/MPa | 0.782 | 0.781 | 0.063% | 0.100 | 0.100 | 0 |

| HX1/HX2 outlet T/K | 317.146 | 317.150 | −0.001% | 328.375 | 328.150 | 0.069% |

| Condenser/Evaporator outlet T/K | 300.154 | 301.150 | −0.331% | 300.950 | 300.840 | 0.037% |

| HX3/HX4 outlet T/K | 483.610 | 483.339 | 0.056% | 483.877 | 483.868 | 0.002% |

| This Paper | Hao et al. [28] | Jiang et al. [34] | |

|---|---|---|---|

| System type | GL-CCES | GL-CCES | SC-CCES |

| EVR (kWh/m3) | 5.15 | 0.08 | 431.2 |

| RTE (%) | 70.52 | 61.69 | 60.26 |

| Discharge duration (h) | 7.88 | 1.00 | 1.95 |

| Power (MW) | 9.984 | \ | \ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Chen, G.; Wang, S.; Deng, T.; Huang, Z.; Li, Z.; Wu, C.; Luo, K. Dynamic Behaviors and Ambient Temperature Effects of a Gas–Liquid Type Compressed CO2 Energy Storage System. Energies 2025, 18, 5923. https://doi.org/10.3390/en18225923

Zhao X, Chen G, Wang S, Deng T, Huang Z, Li Z, Wu C, Luo K. Dynamic Behaviors and Ambient Temperature Effects of a Gas–Liquid Type Compressed CO2 Energy Storage System. Energies. 2025; 18(22):5923. https://doi.org/10.3390/en18225923

Chicago/Turabian StyleZhao, Xianbo, Guohao Chen, Shan Wang, Tianyu Deng, Zihao Huang, Zhiming Li, Chuang Wu, and Kui Luo. 2025. "Dynamic Behaviors and Ambient Temperature Effects of a Gas–Liquid Type Compressed CO2 Energy Storage System" Energies 18, no. 22: 5923. https://doi.org/10.3390/en18225923

APA StyleZhao, X., Chen, G., Wang, S., Deng, T., Huang, Z., Li, Z., Wu, C., & Luo, K. (2025). Dynamic Behaviors and Ambient Temperature Effects of a Gas–Liquid Type Compressed CO2 Energy Storage System. Energies, 18(22), 5923. https://doi.org/10.3390/en18225923