1. Introduction

As global attention shifts toward enhancing energy efficiency and supporting environmental sustainability, the transition to low-global-warming-potential (GWP) refrigerants has become a critical focus across various industries. The Kigali Amendment to the Montreal Protocol underscores the need for a gradual reduction in the use of high-GWP hydrofluorocarbons (HFCs), thereby placing increasing pressure on industry players and researchers alike to identify alternative refrigerants that deliver comparable thermal performance with a significantly lower environmental impact [

1]. Among these alternatives, dielectric fluids such as SF33 and HT55 have gained considerable interest as potential solutions for thermal management in sectors like high-power electronics and electric vehicles. Recent studies have highlighted the effectiveness of SF33, particularly in electric vehicle (EV) applications and high-performance computing (HPC) environments, where rapid heat dissipation is essential for preventing overheating and ensuring the stable operation of the systems [

2,

3].

One area that has seen notable advancements is two-phase immersion cooling, a thermal management approach that leverages the phase change of fluids from liquid to vapor to efficiently dissipate heat. This method is now widely adopted in sophisticated data centers and HPC systems, where increased heat loads require enhanced cooling capabilities. Dielectric fluids, including SF33 and HT55, are particularly valued in these environments for their ability to act as electrical insulators, thus enabling the immersion of electronics without risking short circuits [

4,

5]. As the demand for effective thermal management increases, these fluids contain potential to handle high heat-fluxes while remaining environmentally friendly has made them vital to the growth of next-generation cooling systems.

In the previous literature, SF33 has demonstrated significant potential, particularly for use in fast-charging electric vehicle battery systems, thanks to its low boiling point and high latent heat of vaporization. A study by Rémi and Juhasz [

3] highlighted that SF33 offers superior heat transfer performance compared to conventional fluids like Vertrel™ XF, making it a strong candidate for improving EV battery cooling efficiency. This improvement is critical for applications with high thermal loads, where failure to dissipate the heat quickly could lead to catastrophic outcomes such as battery failure or thermal runaway. Given its properties, SF33 has emerged as one of the most promising low-GWP refrigerants across a range of thermal management applications, from automotive systems to electronics cooling.

Despite the inherent properties of dielectric fluids, cooling performance is not solely reliant on the fluid itself but is also influenced by the characteristics of the heat exchange surfaces. Recent research, including studies by Khan et al. [

5] and Doran et al. [

4], has shown that modifications to the surface such as the addition of micro-fin arrays, pin fins, and nanostructured coatings a dramatically improve pool boiling performance. These surface enhancements increase the nucleation site density, which, in turn, improves both the heat transfer coefficient and the critical heat flux. Such modifications are crucial for improving the overall efficiency of two-phase immersion cooling, particularly in high-power electronics, where controlling heat is critical for maintaining system performance. Both SF33 and HT55 had been shown to respond positively to these surface modifications, demonstrating improvements in bubble nucleation and delayed critical heat flux onset [

4].

Additional research into the role of surface modifications in pool boiling heat transfer indicates that surfaces engineered with micro-structured or sintered features significantly enhance boiling behavior, particularly for highly wetting dielectric fluids like SF33 and HT55. In a review by Sajjad et al. [

6], the authors highlighted how surface engineering plays a pivotal role in boosting the heat transfer coefficient. While some surface alterations can negatively affect performance, others, such as micro-fin arrays and pin fins, show potential in improving both the critical heat flux and the heat transfer coefficient, making them essential for thermal management in data centers and HPC systems, where high heat dissipation is necessary to prevent thermal issues.

Although significant progress has been made in enhancing the thermal performance of dielectric fluids, there remains a lack of direct comparison between SF33 and HT55 under identical conditions, particularly at atmospheric pressure. Despite their potential applicability, comprehensive studies comparing their pool boiling behavior specifically in terms of heat transfer coefficient, nucleation site density, and critical heat flux remain scarce. Previous research on low-GWP refrigerants like R-1233zd(E), R-1234ze(E), and R-1336mzz(E) has highlighted the importance of understanding fluid dynamics and heat transfer in pool boiling systems [

7,

8]. These studies reinforce the need for further experimental research to directly compare low-GWP refrigerants, optimizing their use in immersion cooling applications.

The current study seeks to bridge this knowledge gap by comparing the pool boiling heat transfer properties of SF33 and HT55 under controlled conditions, evaluating their performance at respective saturation temperatures and atmospheric pressure. Key performance metrics such as heat transfer coefficient and critical heat flux will be assessed to provide critical insights into selecting and applying low-GWP refrigerants in advanced thermal management systems. The conclusion of this research work will contribute to the development of more sustainable, efficient cooling systems for high-power devices and offer valuable information on the role of surface engineering in enhancing dielectric fluid performance in immersion cooling applications.

3. Uncertainty Analysis and Data Reduction

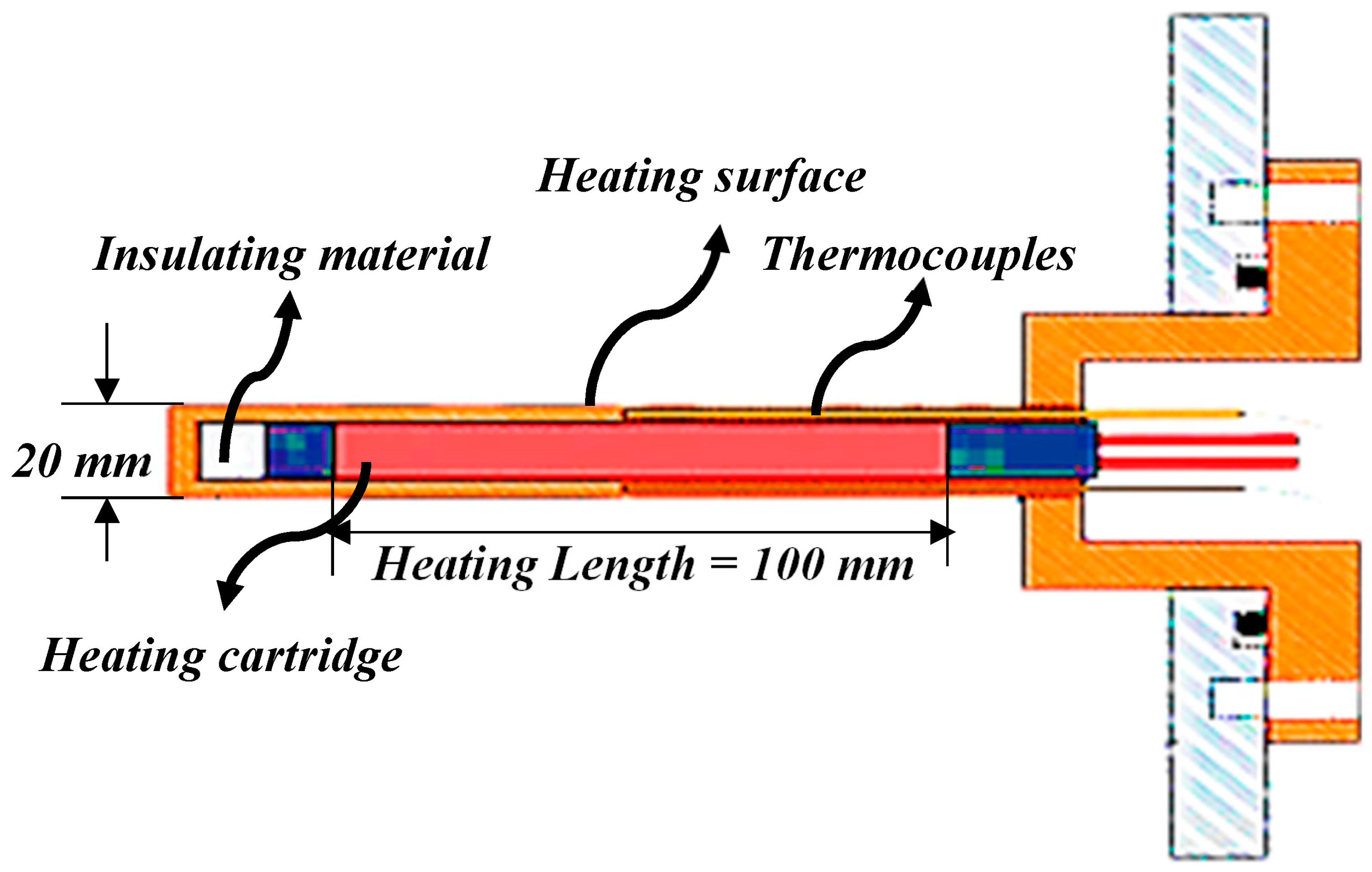

The following equation evaluates heat transfer coefficients “

h” of SF33 and HT55 on a plane tube surface:

where

Ttube is surface temperature of the tube, and

Tsat is the saturation temperature of the working fluids,

Qp is the heat supplied by the heater,

is the heat flux,

Do is the outer diameter of the tube, and

L is the effective heating length. The wall temperature (

Tw) of the tube surface is estimated by the Fourier law:

where the average temperature,

Tavg, is determined by four thermocouples placed around the tube circumference. The distance from the location of four thermocouples is denoted by

Di, and

k represents the thermal conductivity of the tube material.

The uncertainty in the measurement is determined by the instrument’s calibration. The experimental uncertainties are estimated using the uncertainty analysis method as described in the literature [

11]. A resistance temperature detector (RTD, Pt-100) with an accuracy of ±0.05 °C was used to calibrate the thermocouples. The voltage and current of the heater cartridge that was inserted into the test section assembly were verified using a digital DC GWINSTEK (GPR-16H50DA) power supply with an uncertainty of 2–5 W. The uncertainty associated with the absolute pressure transducers was ±5 kPa. For parameters like wall superheat

and heat flux

the uncertainties were 1.25–2.85% and 1–3.33%, respectively. Finally, the uncertainty for heat transfer coefficients

was estimated to be around 6.8–11.35%.

4. Results and Discussion

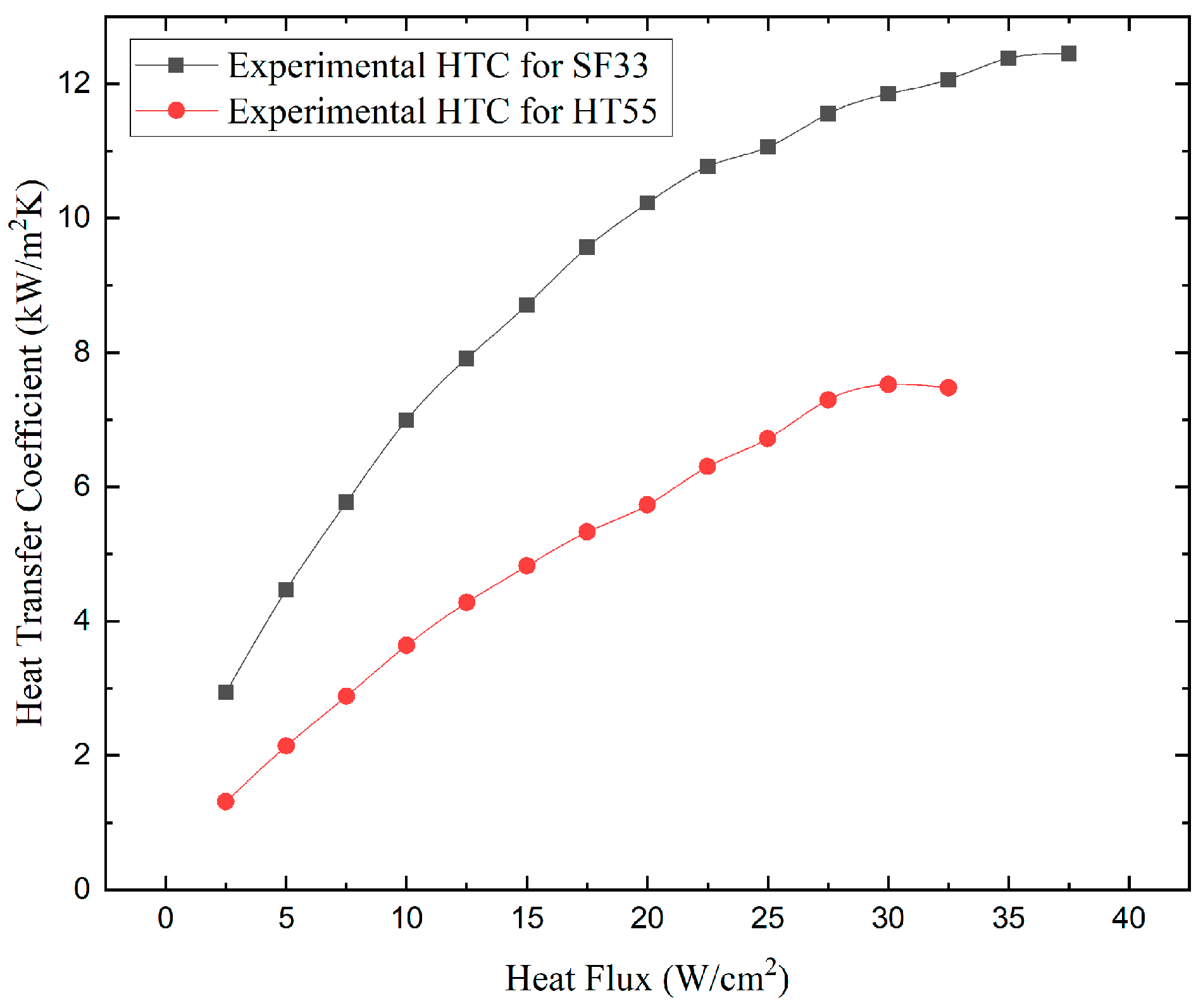

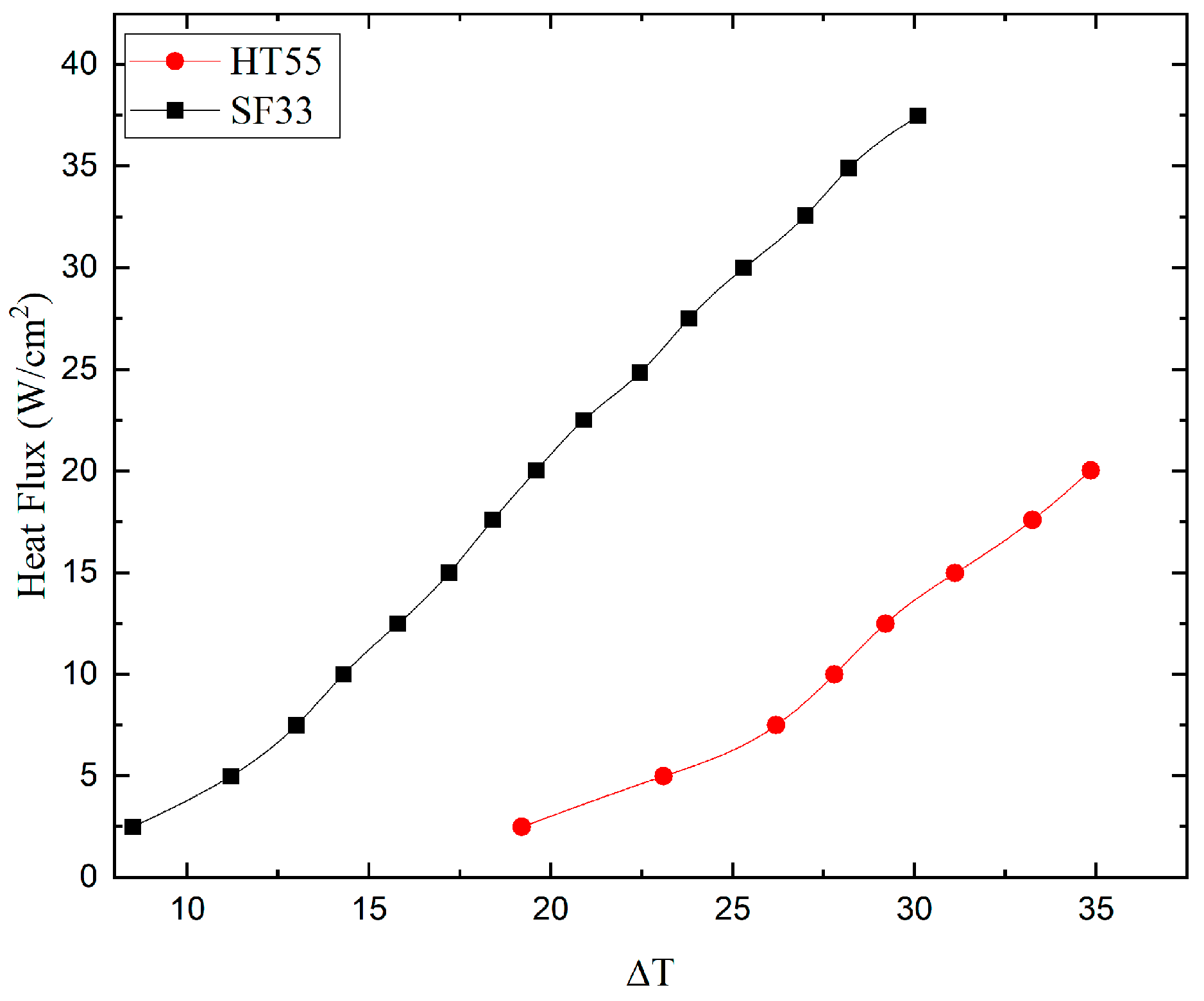

Figure 3 shows the heat transfer coefficient vs. wall superheat for the present two working fluids. The SF33 demonstrates a consistent increase in heat transfer coefficient as the heat flux increases, reaching approximately 12 W/m

2·K at the maximal heat flux levels. In contrast, HT55 exhibits a significantly lower heat transfer coefficient than that of SF33, with a maximum of approximately 6 kW/m

2·K at comparable heat flux values. This analysis illustrates that SF33 has a higher heat transfer performance than HT55 at all heat flux levels as it is evident from

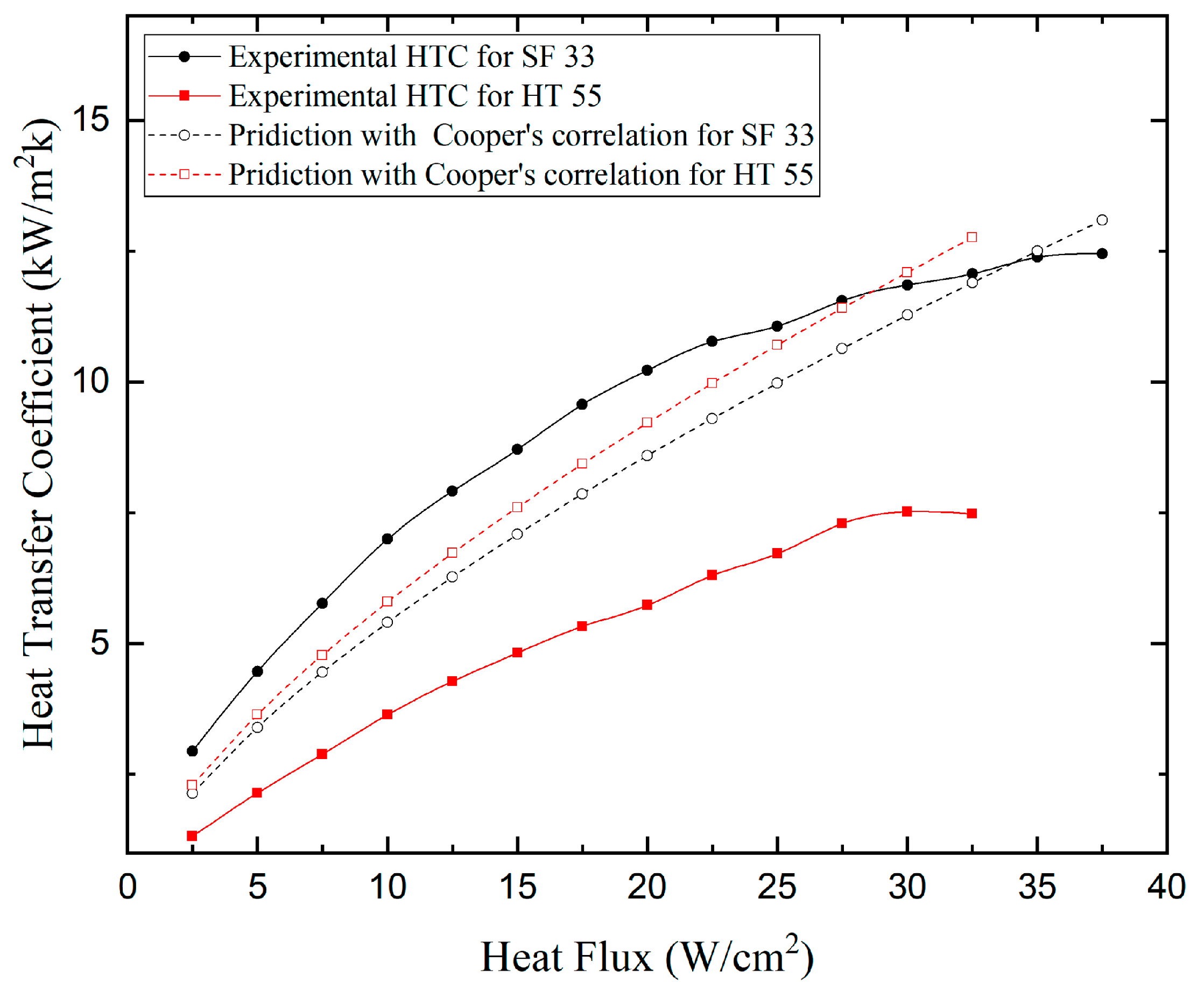

Figure 4. The higher heat transfer coefficient observed with SF33 is mainly associated with the difference in latent heat. The latent heat for SF33 is nearly 84% higher than that of HT55. As the heat flow increases, the disparity in performance between the two fluids becomes more pronounced. In high heat flux applications, such as power electronics, SF33 maintains efficacy and exhibits enhanced performance, whereas HT55 exhibits symptoms of saturation and inefficiency at elevated heat fluxes. The enhanced heat transfer coefficient demonstrated by SF33 at elevated heat fluxes indicates its greater capacity to manage increased thermal loads. HT55, however, seems to reach its performance threshold more rapidly, suggesting some limitations in high-demand scenarios.

In order to validate the experiments the results are compared against three very frequently used heat transfer predicting correlations (i.e., Cooper [

12], Ribatski and Jabardo [

13], and Jung [

14]) as recommended in [

8].

Figure 5,

Figure 6 and

Figure 7, depict the compression of experimental heat transfer coefficients with predictions across the full heat-flux range. For SF33, Cooper follows the experimental trend and is reasonably close at low–mid heat fluxes, but it remains below the data through most of the range and only converges near the highest

(30–35 W/cm

2). For HT55, Cooper consistently overpredicts the heat transfer coefficient with almost parallel slope relative to the measurements. Overall, Cooper’s correlation is acceptable for trend comparison with SF33 but is biased high for HT55.

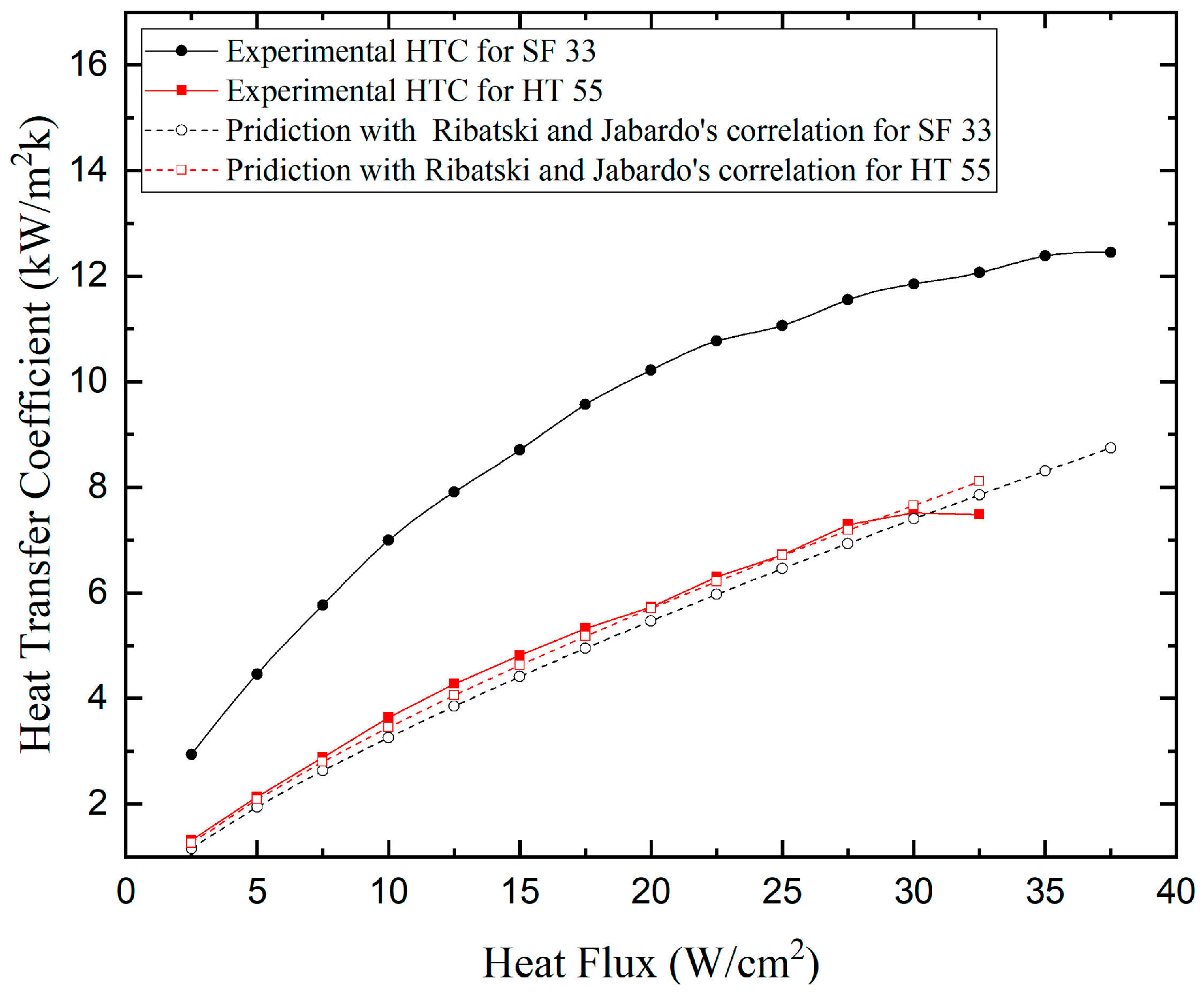

Ribatski & Jabardo’s correlation tracks HT55 the best predictions follow the experimental slope closely and stay within roughly an experimental increment over most of the range, with only a modest high-end deviation. For SF33, it underpredicts across the entire range by a nearly constant offset (the predicted curve lies below the data with a slightly lower slope). Thus, Ribatski & Jabardo is the most suitable baseline for HT55 in this study, but it is conservative for SF33.

Jung’s predictions for SF33 are systematically low (increasing underprediction with heat flux), indicating that Jung’s formulation, derived for halogenated refrigerants on smooth tubes, does not capture SF33’s higher performance. For HT55, the opposite occurs: predictions overshoot the data and the bias grows with

, suggesting that Jung’s pressure/density scaling is not appropriate for this high-molecular-weight dielectric.

Among the tested models, Ribatski & Jabardo best represents HT55, while none of them can well correlate SF33 with small error across all heat fluxes. The Cooper’s correlation comes closest in shape but remains low until the highest . These results motivate either a tuned coefficient set for these correlations tailored specific to SF33 and HT55 or a compact corrective factor based on reduced pressure and a viscosity/surface tension ratio to reconcile both fluids on the same plain-tube geometry.

The boiling point of SF33 is 33.4 °C, which is considerably lower than HT55’s boiling point of 55 °C. The reduced boiling point enables faster boiling and enhanced heat transfer at lower temperatures, providing SF33 with a performance edge in applications necessitating swift heat dissipation. Furthermore, SF33’s reduced molecular weight (164 g/mol) in contrast to HT55 (466 g/mol) facilitates its vaporization, enhancing its heat transfer efficacy. The reduced density of SF33 (1360 kg/m3) and its lower surface tension (12.7 mN/m) relative to density (1650 kg/m3) of HT55 and surface tension (14 mN/m) further improve its boiling properties. Reduced density and surface tension facilitate more frequent bubble nucleation and expedited evacuation, hence enhancing the overall efficiency of the boiling process. Conversely, HT55’s elevated density and surface tension necessitate increased energy for bubble formation and detachment, leading to a diminished heat transfer coefficient. The performance patterns of SF33 indicate a markedly elevated critical heat flux in comparison to HT55.

A fluid with an elevated critical heat flux can accommodate greater heat loads without encountering dryout, a condition where a vapor coating develops on the heating surface, significantly impairing heat transfer. The SF33’s enhanced heat transfer coefficient at elevated heat fluxes indicates a greater critical heat flux, rendering it more appropriate for rigorous applications. HT55, conversely, seems to reach its critical heat flux threshold at reduced heat flux levels, limiting its applicability in intense heat dissipation scenarios. It is observed that the SF33 outperforms HT55 across all heat flux levels and temperature differentials due to its superior thermophysical features, including a larger latent heat of vaporization, a lower boiling point, and enhanced density and surface tension. SF33’s capacity to attain elevated heat transfer coefficient values and endure increased thermal loads without encountering critical heat flux renders it the ideal selection for high-performance cooling applications, including immersion cooling in data centers and power electronics. Although HT55 may suffice for less rigorous applications, its diminished heat transfer coefficient and critical heat flux restrict its efficacy in settings necessitating prolonged high heat flux removal.

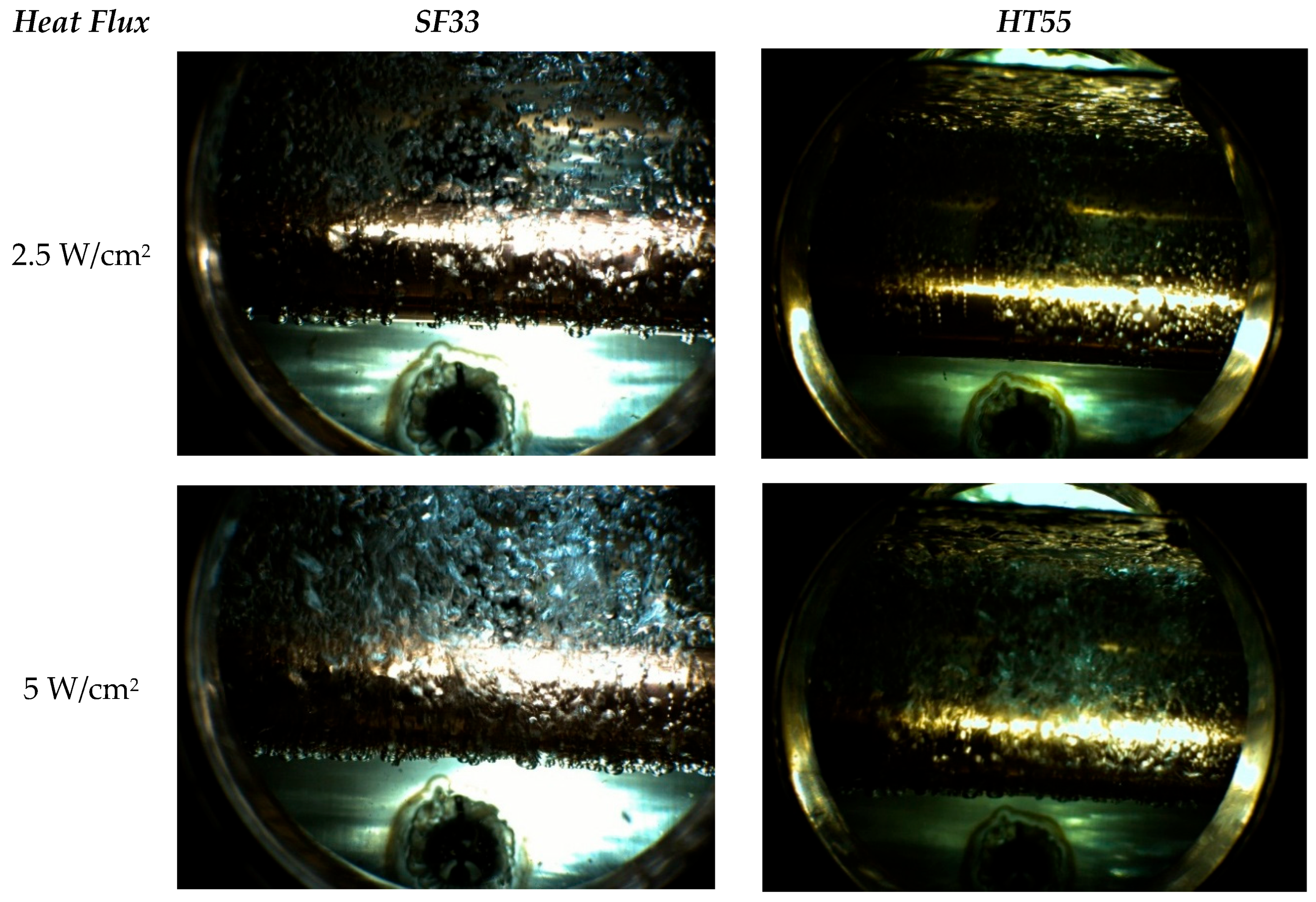

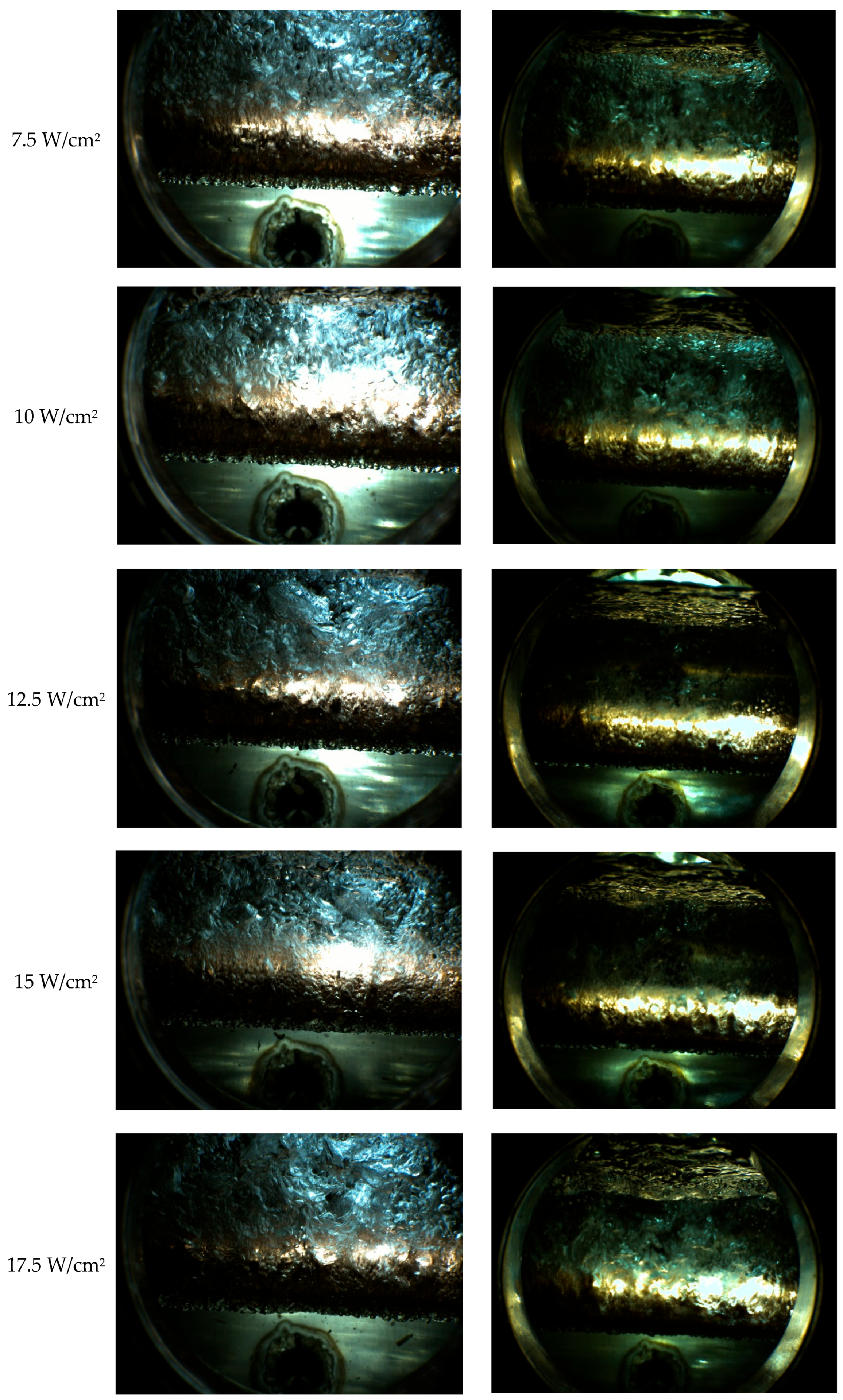

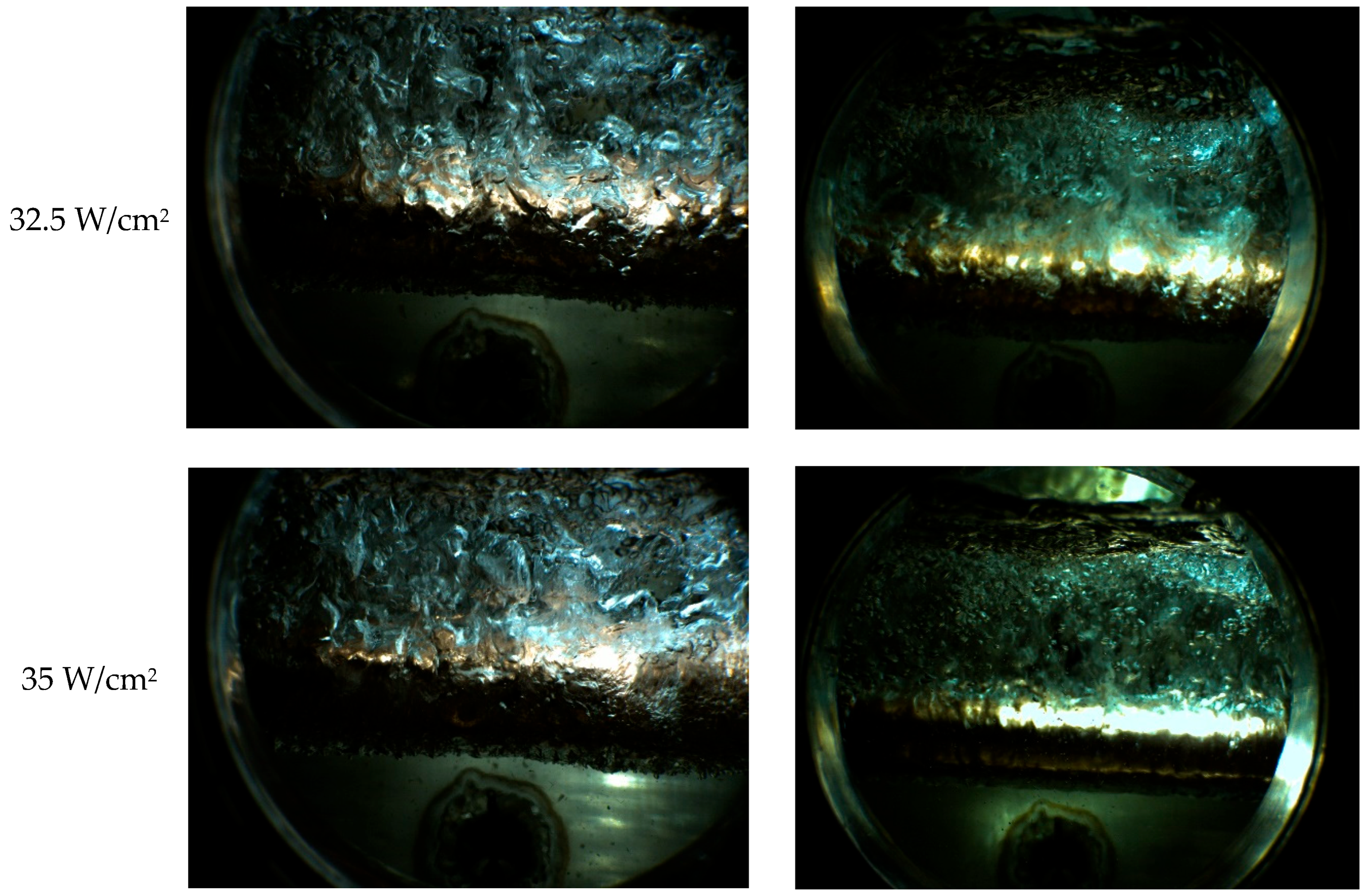

The boiling characteristics of SF33 and HT55 are visually compared here in

Figure 8 as the heat flux increases. The heat transfer performance of both fluids is significantly influenced by the dynamics of bubble nucleation, growth, and departure, which are vividly captured in the images.

Bubble Nucleation and Growth: SF33 exhibits a higher bubble departure frequency and more vigorous bubble nucleation across all heat flux levels. This is a result of the reduced surface tension of SF33 (12.7 mN/m), which facilitates the formation of nucleation sites. Bubbles seem to be more numerous, thinner, and detach from the surface rapidly. The bubbles in HT55 are larger but fewer, and they nucleate more slowly and grow larger before detaching from the heated surface, due to its higher surface tension (17 mN/m). In comparison to SF33, this heat transmission mechanism is less efficient due to the slower nucleation rate.

Bubble Coalescence and Vapor Layer: SF33 facilitates efficient heat transmission throughout the boiling process by maintaining smaller, more frequent bubbles that do not coalesce into large vapor masses as the heat flux increases. This characteristic is crucial for the preservation of a higher critical heat flux, as SF33 prevents the formation of an insulating vapor layer on the surface, even at higher heat fluxes. On the other hand, bubble coalescence is observed in HT55 at increased heat fluxes. The boiling process becomes less efficient as the bubbles become larger and more irregular. Eventually, these coalescing bubbles could create a vapor layer on the surface, which could result in a rapid approach to the critical heat flux and the potential for drying.

Film Boiling and Critical Heat Flux Onset: The experimental data is corroborated by the visual analysis, which suggests that SF33 can withstand significantly higher heat flux levels and attain a significantly higher heat transfer coefficient before reaching its critical heat flux. SF33 does not experience substantial film boiling until it reaches significantly higher heat flux levels, and it exhibits well-distributed bubbles. However, the irregular bubble dynamics and the initial formation of vapor regions on the surface provide evidence that HT55 begins to exhibit symptoms of approaching critical heat flux at lower heat fluxes. This is in accordance with the fact that HT55 has a reduced critical heat flux and is unable to withstand sustained high thermal loads without experiencing a substantial performance degradation.

In essence, SF33 has superior boiling efficiency, bubble dynamics, and heat transfer than HT55, making it a better immersion cooling dielectric fluid. Increased heat flow hinders vapor layer formation and bubble coalescence, facilitates rapid bubble departure, and enhances the nucleation rate. HT55 is unsuitable for high-performance applications as it remains stable at lower heat fluxes but begins to deteriorate at elevated levels. In scenarios characterized by significant heat transfer and minimal ΔT, SF33 provides considerable benefits owing to its enhanced versatility and energy efficiency in advanced immersion cooling systems. HT55 is inadequate for high-performance applications. These applications require excellent heat dissipation for system stability and efficiency. SF33 is best for high-performance cooling applications due to its higher critical heat flux and heat transfer coefficient, while HT55 is inappropriate for high-load applications due to its lower heat dissipation.

5. Conclusions

This study conducted a comprehensive comparison of the pool boiling heat transfer performance of SF33 and HT55. The findings indicate that SF33 outperforms in high-performance cooling applications. Quantitative data analysis and visual observations of boiling behavior indicate that SF33 surpasses HT55 regarding heat transfer coefficient and critical heat flux. SF33 demonstrates a superior capability to maintain a higher heat transfer coefficient at increasing heat flux levels, along with an enhanced critical heat flux, positioning it as a suitable option for applications necessitating efficient heat dissipation, including data centers, high-performance computing (HPC), and power electronics. The thermophysical properties of SF33, including a higher latent heat of vaporization, a lower boiling point, and reduced surface tension, improve its performance by promoting more frequent and efficient bubble nucleation and departure. SF33 exhibits resistance to the formation of insulating vapor layers due to these properties. This indicates its capability to manage elevated thermal loads without a decline in performance or premature attainment of critical heat flux. HT55 demonstrated larger, slower nucleation bubbles and initial indications of vapor coalescence, which constrained its performance at increased heat fluxes. Consequently, applications involving low or moderate heat flux, which emphasize thermal stability and chemical inertness rather than extreme performance, are more appropriate for HT55.

Visual observations further support the enhanced performance of SF33. Under conditions of high heat flux, SF33 exhibited more consistent and efficient phase-change dynamics, preventing the formation of large vapor bubbles and reducing the risk of dryout, which can significantly impair heat transfer efficiency. HT55 reached its operational limits sooner, resulting in the formation and coalescence of larger, slower bubbles at reduced heat fluxes, which suggests an earlier onset of critical heat flux. The implications of this study for the development and optimization of next-generation cooling systems are substantial. SF33 provides an effective solution for immersion cooling applications, emphasizing the importance of optimizing heat transfer performance and ensuring system stability. The ability to adapt to various heat fluxes and temperature differentials enhances its applicability across diverse thermal management systems.

A number of studies indicate that surfaces with micro fins significantly improve heat transfer coefficients and generate smaller diameter bubbles with a higher departure frequency for dielectric fluids like FC-72 and HFE-7100 [

15,

16,

17,

18,

19]. The results have demonstrated that increasing the number of fins can improve the heat transfer coefficient. Micro-fin surfaces enhance heat transfer at low heat fluxes, with surface shape identified as a crucial determinant. In these articles identified that by reducing fin spacing or increasing fin length may improve the heat transfer coefficient, with the most notable enhancement being five times greater than that of a flat surface. Subsequent research may investigate the efficacy of SF33 and HT55 with various surface modifications or improved boiling surfaces, potentially broadening their applicability. Furthermore, conducting tests under diverse pressures and environmental conditions will yield a comprehensive understanding of the performance of these fluids in practical applications. Considering the growing significance of low-GWP refrigerants in eco-friendly cooling applications, SF33 signifies a noteworthy advancement in sustainable, high-performance thermal management technologies. HT55 is effective in less demanding applications; however, it is unlikely to satisfy the stringent performance standards necessary for high heat flux environments.

In summary, SF33 has demonstrated its efficacy as the optimal dielectric fluid for contemporary thermal management issues. The superior heat transfer coefficient, critical heat flux, and overall boiling performance render it the optimal selection for industries dependent on efficient and reliable cooling solutions. This study’s results can guide the design and optimization of advanced cooling systems, enabling engineers to make informed choices regarding working fluids for high-performance environments. The increasing demand for efficient and environmentally sustainable cooling solutions highlights SF33 as a robust, adaptable, and energy-efficient alternative for future thermal management.