1. Introduction

Growing energy demand, dwindling fossil fuel resources, and the desire to reduce CO

2 emissions from combustion are driving the search for new sources of energy. Scientists are particularly interested in so-called renewable energy sources (RES). According to McKendry [

1] and Basu et al. [

2], the use of RES plays an important role in combating global warming by replacing fossil fuels, which is important for sustainable development [

3]. One of the energy sources considered as a CO

2-neutral fuel is biomass [

3,

4]. Currently, biomass accounts for about 70% of renewable energy, meaning that bioenergy accounts for 9% of the global energy supply, which amounts to 622 exajoules (EJ) (1EJ = 10

18J) [

5]. Globally, 83% of the energy consumed (422 EJ) comes from fossil fuels and 9.2% from biofuels, with the remainder coming from other sources, including hydropower, wind energy, and solar energy [

6]. Biomass is an increasingly important RES worldwide. Currently, it covers 14% and 38% of the primary energy demand of developed and developing countries, respectively [

7]. Biomass, through thermal combustion and gasification, is mainly used to produce heat and electricity. The end product of this production is biomass ash (BA) [

8]. Biomass can be used as a standalone fuel or co-combusted with hard coal [

9]. Also in the Polish energy sector, biomass is currently one of the primary sources of renewable energy. According to Poland’s Energy Policy, the share of renewable energy in all energy sources used by 2050 is planned to increase to 20% [

9].

The growing use of biomass for energy purposes results in the generation of increasing amounts of ash [

10]. BA generated from thermal processes, in accordance with the Regulation of the Minister of Climate of 2 January 2020, on the waste catalog in Poland [

11], as in European Union countries, is treated as waste and should be disposed of in landfills. However, this solution is expensive and, in the case of BA, leads to the loss of valuable resources [

10]. The use of BA in agriculture is an important issue related to nutrient cycling and the conservation of mineral fertilizers [

12]. In the context of the growing demand for mineral fertilizers, greater attention should be paid to mineral wastes as BA, with significant fertilization and liming potential. It is this high lime potential that makes BA an attractive alternative to commercial calcium fertilizers. The vast majority of cultivated crops are pH-sensitive, and low soil pH impacts yields [

13,

14]. Unfortunately, approximately 40% of the world’s agricultural soils [

15] and approximately 58% of Polish soils are affected by acidification [

16,

17]. This is particularly noticeable in areas with light and very light soils, low carbonate levels, and a predominance of precipitation over evaporation. Acidification processes are further exacerbated by the use of artificial fertilizers and other anthropogenic factors [

18,

19,

20]. Therefore, BA is becoming a material that, when used appropriately, can contribute to enriching soils with alkaline elements and thus mitigate the effects of soil acidification. Ashes from biomass combustion used in agricultural production are also a very good source of potassium [

21,

22]. According to Jian et al., BA’s are particularly beneficial for soils low in this element [

23]. Used in the cited authors’ research, ash enhanced the availability of essential nutrients such as K, Ca, Mg, P, and Mo in both the soil solution and crops. In addition, BA, according to Johansen et al. [

24], improves nutrient availability, pH stability, and nitrogen mineralization, leading to better crop growth. The potential for using ash is constantly increasing because BA is also recommended as a soil conditioner [

25] and as a raw material for fertilizer production [

26]. Such use would allow for closing the cycle of elements and their reintroduction into the environment, thus contributing to the integration of biomass-to-energy processes and sustainable energy production. Although the European Union’s soil protection strategy has emphasized the importance of promoting soil improvement through nutrient recycling [

27], and some Member States have already recognized the value of BA in the context of the circular economy, recycling this material at the European Union level, and the potential use of ash as fertilizer are still not adequately addressed within EU legislation. Appropriate regulations regarding BA from the energy sector are considered to be the most important thing as a driving force towards implementing proper management and valorization of ash as a raw material [

10]. In addition to the above-mentioned components, this waste contains a high level of organic carbon, which, if used in agriculture, will promote carbon sequestration [

28]. However, the composition of ash varies greatly depending on the type of biomass from which it was derived. Unfortunately, waste resulting from biomass combustion often contains toxic trace metals, which can reduce crop yields and the quality of food or feed, and can also lead to soil contamination [

29,

30,

31]; therefore, the effects of BFA on crop growth and soil quality should be carefully evaluated. At the same time, some sources state that the use of biomass ash may contribute to reducing the bioavailability of elements such as Zn, Mn, Ni, and Cd in the soil solution [

23], This effect may be related to the presence of divalent calcium and magnesium ions in the BA, which increase the buffering properties of soils and thus increase the sorption capacity.

The cited literature data indicate many beneficial effects of BA on soil and plant yield. In addition to their rich chemical composition, BAs are also characterized by their alkaline nature, which may make them effective soil liming agents. However, the literature lacks comparative studies demonstrating how, or to what extent, BAs could replace calcium fertilizers. Therefore, the presented study aimed to investigate how the use of BA as a liming agent in corn cultivation would affect the yield and quality of the crop. The null hypothesis was that BA represents an interesting alternative to the commonly used agricultural lime as a soil liming agent and does not negatively impact plant yield or quality. The alternative hypothesis in the study was that ash would have a negative impact, resulting in reduced yield and deterioration in yield quality.

2. Materials and Methods

2.1. Description of the Experiment

A two-factor pot experiment was conducted in the greenhouse of the Faculty of Agriculture and Forestry, University of Warmia and Mazury in Olsztyn, Poland. The study assessed the effect of biomass fly ash (BFA) on plant yield and quality, as well as the potential use of BFA as a material to neutralize acidic soil pH. The effects of BFA were compared with those obtained after applying commercial agricultural lime (CAL) in doses equivalent in terms of neutralizing value (NV). The test plant used in the study was corn (Zea mays L.). In the presented study, the primary factor was the type of neutralizing materials used (BFA and CAL), while the secondary factor was the dose of neutralizing materials, which was intended to neutralize soil acidity equivalent to 0.5, 1.0, and 1.5 of the hydrolytic acidity value (Hh). The effects of the applied neutralizing materials were compared with those of the control object without the neutralizers.

The doses of neutralizing materials used in the experiment were calculated based on the neutralizing value (NV) [

32] of BFA and CAL.

The determined NV was 21.98% for BFA and 50.88% for CAL, meaning that 100 kg of BFA or CAL can replace 21.98 and 50.88 kg of CaO, respectively. Based on this neutralization value and the value of hydrolytic acidity of the soil, the following doses of neutralizers equal to 0.5, 1.0, and 1.5 Hh were used: for BFA: 16.20, 32.40, and 48.60 g pot−1, which correspond to: 5.40, 10.80, 16.20 Mg ha−1, and for CAL: 6.99, 13.98, and 20.97 g pot−1, which correspond to: 2.33, 4.66, 6.99 Mg ha−1.

The experiment was performed in 3 repetitions. NPK mineral fertilization was applied once at doses of 111 mg N in the form of urea 46% N (Police Chemical Plant S.A., Szczecin, Poland), 66 mg P in the form of potassium dihydrogen phosphate (EUROCHEM BGD Sp. z o.o., Tarnów, Poland), and 139 mg K kg−1 of soil in the form of potassium dihydrogen phosphate (EUROCHEM BGD Sp. z o.o., Tarnów, Poland) and potassium sulfate pure p.a. (PPH “POCh” SA, Gliwice, Poland). The assessed neutralizing materials and mineral fertilizers (NPK) were applied to the soil and mixed thoroughly during the setup of the experiment. BFA and CAL were used as a powder, while NPK fertilizers were used as a water solution. The experiment was carried out in plastic pots. The pots used in the experiment had the following dimensions: top diameter 22 cm, height 24 cm, base diameter 18 cm. The calculated volume of the pots is 7.564 dm−3. The pots were filled with 9 kg of soil. 12 corn seeds were sown in each pot. After emergence, the number of seedlings was thinned to 5 plants. The experiment was established on 21 May 2024, after emergence, which occurred 24 May 2025 r., the number of seedlings was thinned to 5 plants, which were cultivated for 60 days. The experiment was completed on 23 July 2024.

2.2. Characteristics of the Tested Plant

The Garantio FAO 190-210 corn variety (KWS Polska Sp. z o.o., Poznań, Poland) was used as the test crop. This variety is a versatile grain and silage variety. In the COBORU 2020–2021 registration trials, the Garantio variety achieved 106% grain yield, meaning it yielded 0.73 Mg ha

−1 higher than the reference average. According to the breeder, this variety can cope well with short-term drought conditions and mosaic soils [

33].

2.3. Characteristics of the Initial Soil Used in the Pot Experiment

For the presented research, the soil collected from the arable-humus level (0–25 cm) of a field owned by the Bałdy Educational and Research Station of the University of Warmia and Mazury, located in Tomaszkowo, near Olsztyn, Poland, was used. The soil was described as loamy sand (72% of sand 0.05–2.00 mm, 27% of silt 0.002–0.05 mm, and 1.0% of clay < 0.002 mm) [

34], and characterized by an acidic reaction, low electrical conductivity, and a rather poor sorption complex

Table 1.

2.4. Characteristics of Biomass Fly Ash (BFA) and Commercial Agricultural Lime (CAL) Used in the Pot Experiment

The biomass fly ash (BFA) used in the experiment was obtained as a waste product of the biomass combustion process from the bioheating plant of the Thermal Energy Company (ENERGA Kogeneracja Sp. z o.o., Elbląg, Poland). The biofuel used in the heating process was a biopellet (

Figure 1), the dominant part of which was straw from commonly cultivated plants (wheat, rye, rapeseed).

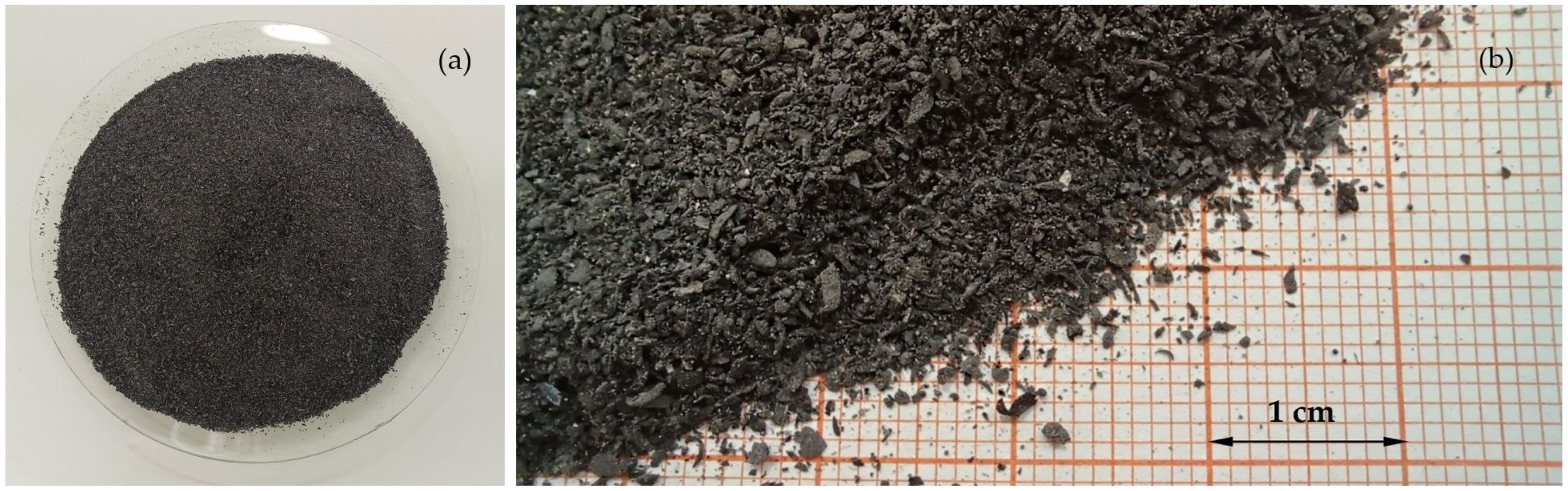

BFA (

Figure 2) was in a black-gray powdery form with a specific gravity of 0.35 kg dm

−3, and very high total carbon (TC) content (300.2 g kg

−1). The literature indicates that the average carbon content in fly ash from biomass combustion varies. According to Shibaoka, this level ranges from 2.3 to 25.3 wt% [

35], while according to Eberhardt and Pan, the carbon contents of fly ash from the processing of biomass typically range from 10% to 60% [

36]. Polish research indicates that the content of unburned carbon in biomass ash, depending on the place of ash formation, ranges from 47% for fly ash to 1.62% for bottom ash with slag [

37]. Previous research conducted by Rolka et al. on the agricultural use of ash from burning wood chips showed that the content of unburned carbon reached 20.8% [

38]. Kilpimaa et al., on the other hand, indicate that the unburned coal content in the ashes analyzed by the authors ranged from 1.3 to as much as 89.4%, depending on the type of boiler used and the combustion temperature [

39]. The properties of ash and agricultural lime are presented in

Table 2.

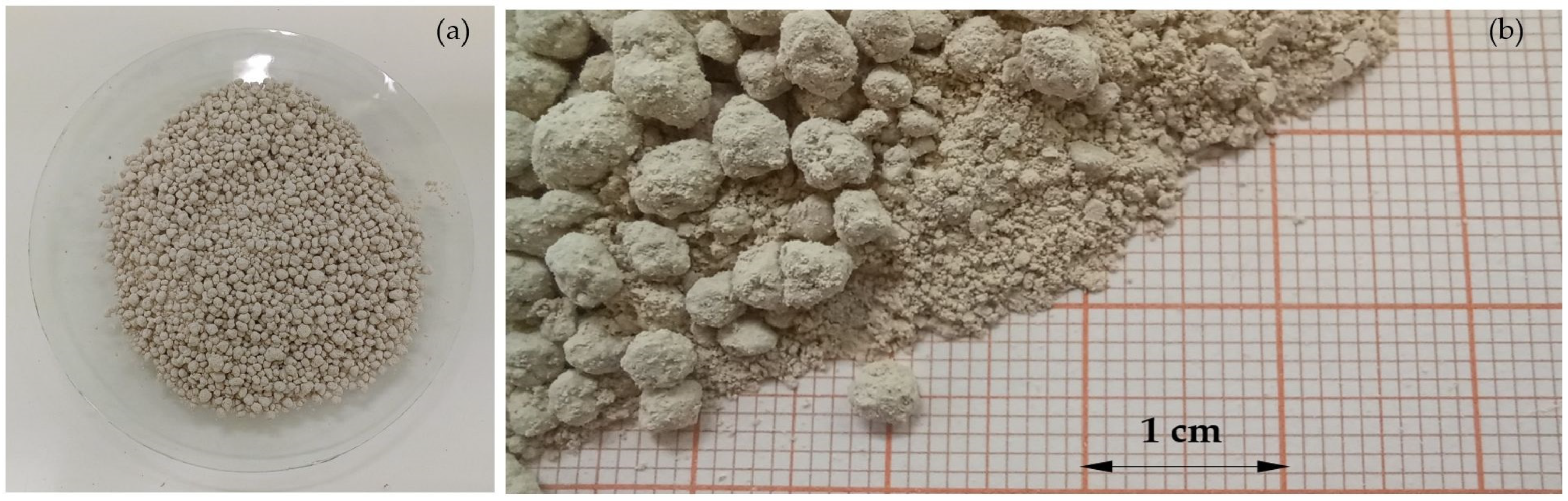

The CAL used in the experiment was purchased at Wap-Pol Trade, Service and Transport Company (WAP-POL, Radoszewice, Poland). The highly reactive, granulated calcium fertilizer (

Figure 3a) contains 55% CaO, with a granule size of 3–6 mm representing at least 90% by weight, according to ISO 3310-1:2016 [

40] (

Figure 3b).

The content of the marked forms of heavy metals in the compared neutralizing materials did not exceed the permissible standards specified in EU [

40] and national regulations [

41].

2.5. Chemical Analyses

One of the parameters indicating plant nutritional status is chlorophyll content, which can be calculated based on extinction measurements of extracts obtained from plant leaves or based on absorption of visible radiation in the 400–500 nm (blue light) and 600–700 nm (red light) ranges by leaf tissue. The presented study utilized a chlorophyllmeter, which allows for the measurement of leaf greenness using a non-destructive method, unlike the previously mentioned methods, which require maceration of leaves with an organic solvent to extract chlorophyll pigments. Leaf greenness index (SPAD) was measured with Chlorophyll meter SPAD–502Plus (Konica–Minolta, Osaka, Japan) [

42]. Leaf greenness was expressed in SPAD (Leaf-Plant Analysis Development) units developed by Konica-Minolta. Numerous studies in the scientific literature confirm a strong correlation between SPAD readings and chlorophyll content in acetone extracts, subsequently measured spectrophotometrically [

43,

44,

45,

46]. The measurements were made three times during the experiment: 20, 40, and 60 days after plant emergence (DAE), i.e., on 13 June, 3 July, and 23 July. The individual development stages of maize plants were determined based on a standardized system for describing the phenological stages of plant development (BBCH—Biologische Bundesanstalt, Bundessortenamt und Chemische Industrie), i.e., the key growth stages that plants go through from sowing to maturity [

47]. The first measurement of the leaves’ greenness was made at the BBCH 15 stage (five unfolded leaves) on the third leaf, the second on the fifth leaf at the BBCH 17 stage (seven unfolded leaves), and the third on the seventh leaf at the BBCH 61 stage (beginning of pollination). Measurements were taken five times on each of the five plants, and the resulting readings were presented as averages.

During harvesting, the plant’s height and the mass of the above-ground part of the plants (green forage) from each pot were measured. Harvested plants were cut into 2 cm pieces and dried with a FED 720 dryer (Binder, Tuttlingen, Germany) [

48]. Drying was carried out at 60 °C until constant weight, and then the dry matter content was determined. The dried material was ground using a cutting mill SM 200 (Retsch; Haan, Germany) [

49]. The ground plant samples were stored in polypropylene containers for further chemical analysis. Initial soil particle size distribution measured with particle size analyzer Mastersizer 3000 equipped with a Hydro EV module (Malvern Instruments, Worcestershire, UK) [

50]. Soil reaction (pHH2O) measured according to the potentiometric method in a demineralized water, in the ratio of 1:2.5 (

w/

v), using a pH 538 laboratory pH meter and SenTix61 electrode (WTW, Wrocław, Poland) [

51]. Soil EC was measured with the Hanna HI8733 conductivity meter (Hanna Instruments, Leighton Buzzard, UK) in a mixture of soil/deionized water in the 1:2 ratio (

w/

v) [

51]. NV of BFA and CAL were measured with the titrimetric method according to ISO 20978 [

32]. Soil sum of base cations (SBC) and hydrolytic acidity (Hh) were measured with Kappen’s method described by Ostrowska et al. 1991 [

51]. Based on the obtained values of SBC and Hh, cation exchange capacity (CEC) (1) and base saturation (BS) (2) were calculated according to the following formulas:

The Total nitrogen (N) of soil, neutralizing materials, and plants was measured with the Kjeldahl method after prior mineralization of samples in pure concentrated sulphuric acid (H

2SO

4) (Chempur, Piekary Śląskie, Poland) in the presence of hydrogen peroxide (H

2O

2) (Stanlab, Lublin, Poland) as an oxidant. For wet digestion of the mentioned samples, we used a Speed Digester K-439 equipped with a scrubber K-415 (BÜCHI Labortechnik AG, Flawil, Switzerland). Nitrogen distillation was performed with a K-355 apparatus (BÜCHI Labortechnik AG, Flawil, Switzerland), and then titrated with TitroLine 7000 (Xylem Analytics, Weilheim, Germany) [

52].

Total carbon (TC) content was determined with a Shimadzu TOC-L analyzer coupled with a module for solid samples SSM-5000A (Shimadzu Corporation, Kyoto, Japan). Chemically pure D-(+)-Glucose (Sigma-Aldrich Co., St. Louis, MO, USA) was used as a standard of carbon content (40% TC).

The C/N ratio was calculated based on TC content and N content.

Total forms of macroelements were determined in the same solutions in which total N was determined. The vanadium-molybdenum method was used for the colorimetric determination of total form of phosphorus (P) with UV-1900i Plus UV-Vis Spectrophotometer (Shimadzu Corporation, Kyoto, Japan) [

51]. The potassium (K), calcium (Ca), and sodium (Na) were determined using flame atomic emission spectrometry (FAES) with a spectrophotometer SpectrAA-240FS (Varian Inc., Mulgrave, VIC, Australia). The magnesium (Mg) was determined with flame atomic absorption spectrometry (FAAS) using the same spectrometer.

Total forms of heavy metals (HMs), such as cadmium (Cd), cobalt (Co), chromium (Cr), copper (Cu), iron (Fe), manganium (Mn), nickel (Ni), lead (Pb), and zinc (Zn), were determined in the samples mineralized according to the US-EPA3051 protocol [

53]. Microwave mineralization was performed using MARS 5 microwave oven (CEM Corporation, Matthews, NC, USA) in a mixture of acids: 65% HNO

3 (Chempur, Piekary Śląskie, Poland) and 38% HCl (Chempur, Piekary Śląskie, Poland) mixed in a 4:1 (

v/

v) ratio. The metals in soil samples were determined using flame atomic absorption spectrometry (FAAS) with an absorption spectrophotometer, SpectrAA-240FS (Varian Inc., Mulgrave, VIC, Australia), with reference standards (Merck, Darmstadt, Germany).

2.6. Statistical Analyses

A two-way ANOVA was processed using Statistica

® v. 13.3 PL Software (TIBCO, Palo Alto, CA, USA) [

54]. The correlation coefficients were established using a simple linear correlation model, with Microsoft Excel

® for Microsoft 365 MSO v. 2206 (Microsoft, Redmond, WA, USA) [

55]. The simple Pearson coefficient (

r) was used to determine the relationship between the tested features. The significance of the (

r) value was determined based on statistical tables [

56].

4. Discussion

The results of the presented study showed that, despite the lack of differences in plant height (

Table 5) and reduced dry matter content (

Table 6) compared to the treatments fertilized with agricultural lime and the control treatment, the addition of BFA significantly contributed to increasing both corn green forage and dry matter yield (

Table 6). Green forage yield was significantly higher after the application of BFA doses balancing the hydrolytic acidity of the soil within the range of 1.0 and 1.5 Hh than in the control treatment and the treatment fertilized with BFA at a dose equivalent to 0.5 Hh, ultimately contributing to an increase in dry matter yield. This result demonstrates the yield-enhancing potential of BFA. The BFA, as a waste generated during biomass combustion, in terms of the resulting corn yield, is a good alternative to CAL, which, in the presented case, had a lower yield-enhancing effect. This raises the question of why BFA might affect plant growth differently than CAL. The research presented in this paper showed that using equivalent doses of BFA and CAL in terms of liming effect, significantly higher corn green forage yields were achieved in treatments fertilized with BFA than with CAL. It is important to note that BFA, in addition to its neutralizing properties, which result primarily from the content of divalent cations, i.e., calcium and magnesium, contains a number of other components (macro- and micronutrients) (

Table 2). These additional components determined the greater yield-enhancing effect of BFA than CAL. CAL, in turn, containing small amounts of additional components, was primarily responsible for regulating soil pH and, of course, the content of available calcium. It is safe to say that BFA is a good amendment that can be used to improve soil properties. An increase in yield after using BFA as a soil improver was also observed in studies conducted by other authors [

57,

58,

59,

60,

61]. Among others, Ajala et al. showed that under the influence of ash, there was a significant increase in such indicators as plant height, leaf length, leaf area, and stem diameter, which resulted in an increase in plant weight and, consequently, in an increase in total biomass [

57]. These beneficial changes are primarily due to the lime effect obtained after the use of ashes [

62]. According to Baloch et al., biomass ash improves soil structure and water capacity, and also increases the availability of nutrients and the buffering capacity of soils, which has a beneficial effect on the physicochemical and biological properties of soils [

63]. The introduction of biomass ash to the soil, resulting in increased soil fertility, is of significant importance not only in corn cultivation but also in the cultivation of other plants. Füzesi et al. [

64] demonstrated a positive effect of biomass ash on the yield of perennial ryegrass (

Lolium perenne L.) and white mustard (

Sinapis alba L.). Gill et al., in their research, after using biomass ash as a soil improver, observed higher yields of rapeseed (

Brassica napus L.), field pea (

Pisum sativum L.), and barley (

Hordeum vulgare L.) [

65]. Romdhane et al. concluded that the increase in corn yield after using biomass ash may be related to reduced transpiration, making biomass ash one of the possible cost-effective options for counteracting drought periods in corn cultivation [

59]. The research presented in this paper seems to confirm this thesis, taking into account the reduced dry matter content of corn as a result of the biomass ash.

Biomass ash affects not only plant growth and yield but can also cause changes in plant chlorophyll content, which is expressed as leaf greenness. The SPAD index, which is often measured at critical stages of corn growth, can be used as a method for determining the yield of plants intended for silage production [

46]. The results presented in this study showed significant variability in chlorophyll content in corn plant leaves, depending not only on the material used to neutralize the acidic soil reaction but also on the vegetation stage. Young plants were characterized by a higher SPAD index than plants assessed at 40 and 60 days of vegetation. The study currently presented showed that the SPAD index measured on the 20 days after emergence (DAE) significantly decreased for both of the neutralizing materials used at the highest dose, equal to 1.5 Hh. During the next measurement (40th DAE), leaf greenness increased for each neutralizer to a similar extent; however, the last SPAD measurement showed no changes in leaf greenness for any of the neutralizing materials compared to the control. Ajala et al. [

57] showed that both in solo corn cultivation and in the intercropping system with lima beans, regardless of the amount of beans, they always achieved an increase in the chlorophyll content in leaves under the influence of the BA used. In turn, in the research conducted by Rolka et al. [

66], also conducted on corn, the authors stated that the SPAD value steadily decreased under ash elevated doses. Similar fertilization was used in both experiments, suggesting that this discrepancy may be due to the use of BA with a different composition than the ash used in the above study. Cited earlier, Ajala et al. [

57] connected the phenomenon of an increase in the leaf greenness under the use of BA with higher photosynthesis rates, which contributed to potentially higher yields. The leaf greenness index is influenced not only by soil properties and the specific doses of additives used, as shown in the present study, but also by the species of the tested plant, as demonstrated by Żołnowski et al. [

67]. These studies demonstrated significantly higher leaf greenness in sunflower and rapeseed than in corn, and combined with the currently presented research, it can be concluded that this parameter also changes significantly depending on the plant’s vegetation phase, which is also confirmed by the results obtained by Romdhane et al. [

59] regarding the dynamics of SPAD values, especially at the end of the growing season of corn.

The content of individual macroelements in the tested green forage indicates the quality of the feed obtained from it [

68]. According to Symanowicz [

69], BA is a rich source of macronutrients and, when added to the soil, can introduce significant amounts of C (160 kg), N (6 kg), P (20 kg), K (98 kg), Ca (302 kg), Mg (39 kg), and S (18 kg). The current study showed that the content of macronutrients in corn green forage after the application of BA increased with increasing doses of this neutralizing material. The exceptions were Ca, whose content decreased with increasing ash doses, and N, whose content decreased after the application of BFA and did not increase with increasing doses. The results differ from those of Rolka et al. [

66] conducted on corn, where the use of BA increased the content of components such as N, Ca, K, Mg, and Na, while the content of P decreased. Here, the situation regarding the content of Ca and P was completely different.

Results similar to those presented were obtained in the study by Meller and Bilenda [

60]. Their study showed significantly higher uptake of most nutrients (P, K, Mg, Ca, Na) by corn, but in this case, the Ca content also increased. Iderawumi [

58] believes that the increased content of macronutrients in the aboveground parts of plants is due to the increased solubility of P and K, which results from the liming properties of BA. Szostek et al. [

70] believe that this phenomenon is also caused by the greater availability of soluble forms of these elements in the soil after the application of BA.

Among the basic cations, the most important role in shaping the quality of feed is attributed to potassium and sodium, which are the basic cations of body fluids and are of great importance for the proper functioning of animal organisms, because they influence the water-electrolyte and acid-base balance [

71]. Hence, the ratios of potassium to other elements such as Ca, Mg, and Na are estimated. According to Czuba and Mazur [

72], another important indicator of plant quality, in addition to the content of individual macronutrients, is their mutual ratio. This characterizes the proportions of these components in plant products. The values of the most important ratios in the green forage according to literature data should be as follows: K:(Ca + Mg) = 1.6–2.2; K:Mg = 6; K:Ca = 2; K:Na = 5–10; Ca:Mg = 2–3; K:Ca = 2; and Ca:P = 1.5–2 (molar ratio) [

73,

74,

75,

76,

77]. Therefore, when applying fertilization, farmers should consider not only the yield but also the quality of the feed, determined by the content of macronutrients and their proper mutual relationships. In the presented study, the observed changes in ionic ratios induced by BFA and CAL fertilization mainly concerned the K:(Ca + Mg) ratio (

Table 9) and K:Mg ratio (

Table 10), for which the use of BFA determined a wider value. This fact resulted mainly from the higher potassium content in BFA compared to CAL (

Table 2). As can be seen, the use of BFA at doses equivalent to CAL contributed not only to increased yield in treatments fertilized with BFA compared to those fertilized with CAL (

Table 6) but also improved their ionic balance through better supply of plants with potassium and sodium. In the current study, the K:(Ca + Mg) ratio was consistent with the recommended values [

72]. However, the K:Mg ratio was narrow and the K:Ca ratio was wide, resulting from low magnesium and high calcium supply, respectively. In this case, additional magnesium fertilization should be considered. The current study also revealed a relatively narrow Ca:P ratio compared to the recommended values [

72]. To improve it, additional fertilization with phosphate fertilizers should be considered. Supplemental doses of mineral fertilizers should be applied individually, as the literature indicates that the chemical composition of BA varies greatly and depends on many factors, including the type of biomass, the species of plants used, the type of organic waste, the type of boiler, the combustion temperature, etc. [

78,

79].