Abstract

Triboelectric nanogenerators (TENGs) have emerged as a promising technology for harvesting mechanical energy via contact electrification (CE) at diverse interfaces, including solid–liquid, liquid–liquid, and gas–liquid phases. This review systematically explores fluid-based TENGs (Flu-TENGs), introducing a foundational and novel classification framework based on direct versus indirect charge transfer to the charge-collecting electrode (CCE). This framework addresses a critical gap by providing the first unified analysis of charge transfer mechanisms across all major fluid interfaces, establishing a clear design principle for future device engineering. We comprehensively compare the underlying mechanisms and performance outcomes, revealing that direct charge transfer consistently delivers superior energy conversion—with specific studies achieving up to 11-fold higher current and 8.8-fold higher voltage in solid–liquid TENGs (SL-TENGs), 60-fold current and 3-fold voltage gains in liquid–liquid TENGs (LL-TENGs), and 34-fold current and 10-fold voltage enhancements in gas–liquid TENGs (GL-TENGs). Indirect mechanisms, relying on electrostatic induction, provide stable Alternating Current (AC) output ideal for low-power, long-term applications such as environmental sensors and wearable bioelectronics, while direct mechanisms enable high-efficiency Direct Current (DC) output suitable for energy-intensive systems including soft actuators and biomedical micro-pumps. This review highlights a paradigm shift in Flu-TENG design, where the deliberate selection of charge transfer pathways based on this framework can optimize energy harvesting and device performance across a broad spectrum of next-generation sensing, actuation, and micro-power systems. By bridging fundamental charge dynamics with application-driven engineering, this work provides actionable insights for advancing sustainable energy solutions and expanding the practical impact of TENG technology.

1. Introduction

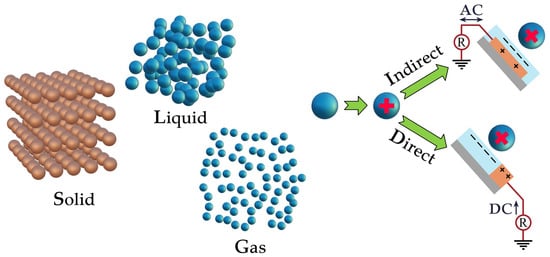

As global energy demands rise and environmental concerns intensify, the need for sustainable and renewable energy solutions has become more pressing than ever. To minimize the environmental issues caused by fossil fuel consumption, research on generating green energy from renewable sources has been ongoing, with significant progress beginning in the late 20th century. This effort has led to the development of energy generation technologies spanning various scales. Macro-scale energy alternatives have included wind [1], solar [2], hydroelectric [3], geothermal [4], biomass [5] and tidal power [6]. While small-scale energy generation alternatives have focused on piezoelectric generators [7], pyroelectric nanogenerators [8], hygro-electric generators [9], electromagnetic generators [10], and TENGs [11]. As small-scale energy generation becomes increasingly significant in addressing localized and portable energy needs, CE has emerged as a pivotal mechanism enabling efficient energy harvesting over diverse interfaces. This mechanism offers promising potential to enhance performance and expand the applicability of small-scale devices. The discovery of CE has inspired researchers to develop innovative energy conversion technologies and optimize the performance of TENGs. TENGs operate by efficiently harvesting energy through CE over a broad spectrum of interfaces, including solid–solid, liquid–solid, liquid–liquid, gas–solid, and gas–liquid interactions. These fundamental direct and indirect charge transfer mechanisms across various fluidic interfaces are schematically illustrated in Figure 1.

Figure 1.

Schematic Illustration of Direct and Indirect Charge Transfer Mechanisms in Flu-TENGs with CCE after CE at Solid, Liquid, and Gas Interfaces.

In 2012, Wang first introduced TENGs, establishing them as a pioneering small-scale energy harvesting technology [12]. This work marked the first introduction of solid–solid triboelectricity, broadening the understanding and applications of triboelectric phenomena. Despite the advantages of solid–solid TENGs, such as their simple structure, design, and ease of device fabrication, they face challenges including unavoidable wear issues due to contact between solid surfaces, leading to severe restrictions in durability and stability. Additionally, these TENGs often encounter performance degradation over time and limitations in consistent output due to mechanical fatigue and environmental factors. These limitations significantly hinder their further applications in long-term power supply systems and high-precision self-powered sensors, requiring innovative solutions to enhance their performance and reliability.

Distinct from conventional solid–solid TENGs, solid–liquid TENGs emerged in 2014 as a promising candidate to overcome their inherent limitations [13]. This new approach, exemplified by initial efforts to address the first challenge of solid-fluid (e.g., gas or liquid) TENGs, utilized interactions between fluids and solid materials via a sequential contact-electrification and electrostatic-induction process, demonstrating significant potential. It showed the ability to mitigate issues such as wear, durability, and stability, thereby broadening the applicability and reliability of TENGs for long-term energy solutions [11,13]. A L-L TENG was first proposed by Chen et al. in 2019, further expanding the scope of triboelectric generation by enabling efficient energy harvesting through interactions between two immiscible liquids [14]. This advancement exemplifies how liquid–liquid systems can overcome limitations associated with solid–solid configurations, broadening the potential applications of TENG technology. Beyond merely overcoming the limitations of solid–solid configurations, Fluid based TENGs pave the way for new possibilities in triboelectric generation through diverse interactions such as liquid–liquid, solid–gas, and gas–liquid systems. This broadens their potential applications and further establishes their role in innovative energy harvesting and sensing technologies.

Across solid–fluid and fluid–fluid modalities, the decisive factor governing output and stability is the efficacy of charge transfer at the interfaces. Both indirect (electrostatic induction) and direct pathways can dominate depending on interface chemistry, wettability, and flow/regime, and must be explicitly considered in design and comparison. Prior studies emphasize that systematically characterizing and reporting charge-transfer behavior enables fair benchmarking and standardization across TENG architectures [15,16].

In this review, we systematically categorize and compare the mechanisms of direct and indirect charge transfer in TENGs, focusing on their distinct pathways for energy generation and their impact on device performance. While individual studies have implicitly touched upon these concepts for specific devices, a comprehensive review that systematizes this direct vs. indirect dichotomy into a unified framework for all major fluid-based interfaces (Solid–Liquid, Liquid–Liquid, and Gas–Liquid) has been notably absent. Our work addresses this gap by establishing this classification as a fundamental design principle. Drawing from extensive studies involving over 40,000 related triboelectric studies of diverse interfaces, we highlight how charge accumulation on dielectric surfaces influences interactions with electrodes and energy conversion processes [17,18]. Indirect charge transfer occurs when a dielectric surface interacts with another material and becomes charged, with an electrode placed behind the surface enabling triboelectricity generation through electrostatic induction [19]. In this process, the accumulated charges create a potential difference, driving electron flow indirectly between the materials involved. Conversely, direct charge transfer occurs when a charged object moves across or comes into direct contact with a dielectric surface, enabling the accumulated charges to flow directly to an electrode without any intermediate barriers. It creates a straightforward path for charge transfer and enhances energy conduction. This review further explores and compares the electrical output performance and mechanisms between direct and indirect charge transfer, highlighting their influence on operational behavior across diverse applications and interface types. Understanding the distinct impacts of these mechanisms is crucial for optimizing TENG configurations. By leveraging the unique characteristics of both indirect and direct charge transfer, researchers can enhance energy conversion efficiency, broaden application potential, and improve device performance across various interactions and operating conditions.

2. Fundamentals of Contact Electrification and Charge Transfer

CE is a fundamental phenomenon that occurs when two materials—whether solids, liquids, or gases—come into contact and exchange electrical charges, resulting in a net electric potential difference upon separation [11]. This process has garnered significant attention due to its applications in energy harvesting, especially in TENGs [12]. The foundational understanding of CE across diverse interfaces requires a closer examination of mechanisms such as the electron cloud model and the electric double layer (EDL) theory. The electron cloud model, introduced by Erwin Schrödinger in 1926, shifted our comprehension of atomic structure by proposing that electrons exist in probability clouds around the nucleus rather than fixed orbits [20]. When materials come into contact, their electron clouds overlap, creating zones where charge transfer can occur. Research by Xu et al. highlighted that this overlap could produce asymmetric double potential wells due to different electro-negativities of the materials involved, thus influencing the transfer and trapping of electrons in 2018 [21]. Experimental validation of this model was further provided by Li et al. using photon emission spectroscopy, showcasing the transfer of interfacial electrons during CE events in 2021 [22].

Beyond electron transfer, ion transfer mechanisms are also crucial, particularly at interfaces involving fluids. The EDL theory explains the structuring of ions at interfaces, resulting in a compact Stern layer of tightly bound ions adjacent to the surface and a more diffuse layer of ions beyond it [23]. This arrangement influences the net charge distribution and contributes to current generation and electrostatic potential differences observed in CE. Recent advancements have led to a hybrid EDL model that integrates electron transfer and ion adsorption, offering a more comprehensive perspective on CE phenomena across various interfaces, especially liquid–solid boundaries [24]. This expanded model aids in the understanding of complex charge dynamics at interfaces where both ionic and electronic processes are significant.

Charge transfer efficiency during CE depends on several influencing factors, such as ion concentration, material chemistry, and electronic structure of the interfaces. High ion concentrations in fluids, for instance, can impede electron mobility due to intensified ionic interactions, whereas the surface chemistry of solids plays a pivotal role in ion adsorption and subsequent charge transfer [18]. Modifications in electronic structure at the interfaces, influenced by charged species, can alter band offsets, further affecting charge dynamics. These band offsets, which refer to the energy differences between the conduction or valence bands of two materials at an interface, play a crucial role in determining the alignment of electronic states and influencing the movement and distribution of charges across the boundary. Li et al. (2019) [25] developed a method called edge approximation based equivalent capacitance (EDAEC) to analyze TENGs. This approach helps researchers better understand how electric fields and charges are distributed within TENGs, providing valuable insights for improving the understanding of electric field and charge distribution [25]. These insights underscore the complexity of CE across various material interfaces and highlight its potential for innovative applications in energy conversion and advanced material technologies. As ongoing research delves into CE across solid–solid, liquid–solid, liquid–liquid, and gas-based interfaces, new avenues for technological exploitation and energy solutions continue to emerge [19,26,27]. Building on these fundamental principles, the following section will explore their application in SL-TENGs, the most extensively studied category of Flu-TENGs.

3. Solid–Liquid Triboelectric Nanogenerators (SL-TENGs)

3.1. Working Principles of SL-TENGs

The operational mechanism of SL-TENGs centers on CE at the interface between a liquid and an insulating solid surface, facilitating efficient charge transfer and accumulation [11,12]. Charge transfer at these interfaces involves multiple pathways, primarily through the movement of electrons or ions between the materials and is influenced by the electronic structure of the solid surface, the ionic composition of the liquid, and the chemical properties of both materials [18,19]. Both electron transfer and ion adsorption contribute to the overall charge separation at the solid–liquid interface, with electron transfer frequently playing a dominant role [18,26]. This combined mechanism highlights the complexity of charge transfer processes and emphasizes the need to consider both ionic and electronic contributions for accurate modeling and optimization.

The design of the TENG system significantly influences charge transfer efficiency [11,12]. When the charged liquid makes direct contact with the CCE, direct charge transfer is initiated, leading to efficient triboelectric output with minimized losses [12,19]. In contrast, when the CCE is positioned behind an insulating layer, charge transfer occurs indirectly through electrostatic induction, offering enhanced device durability in specific applications despite a potential reduction in efficiency [11,19]. The charge transfer process in solid–liquid TENGs typically follows this sequence: (i) charges are induced on the triboelectric layer’s surface upon droplet contact according to electric double layer theory; (ii) as the droplets spread, charge transfer occurs; (iii) due to the hydrophobic nature of the triboelectric layer, droplets may subsequently rebound [12,26].

Optimizing charge transfer mechanisms at the solid–liquid interface is crucial for maximizing the performance and efficiency of TENGs [28,29]. Tailoring the surface chemistry of the solid, adjusting the ionic strength of the interacting liquid, and increasing the interfacial contact area are key strategies that directly impact charge transfer efficiency and device output [29,30]. Recent advancements in hybrid EDL models have provided a more nuanced understanding of how electron transfer and ion adsorption operate in tandem to drive CE [29,31]. This comprehensive perspective allows for more precise control over interfacial charge dynamics, leading to enhanced energy conversion efficiency [28,30]. Moreover, the introduction of the “pinning factor” concept offers a novel means of visualizing and quantifying the relationship between charge transfer and electronic structure changes, opening new pathways for innovative TENG designs tailored to specific applications [29,31]. These developments underscore the potential of solid–liquid TENGs in powering self-sustaining devices and enhancing energy harvesting technologies for a wide range of uses [30,32].

3.2. Indirect vs. Direct Charge Transfer Comparison

3.2.1. Droplet-Based SL-TENGs: Indirect vs. Direct Mechanisms

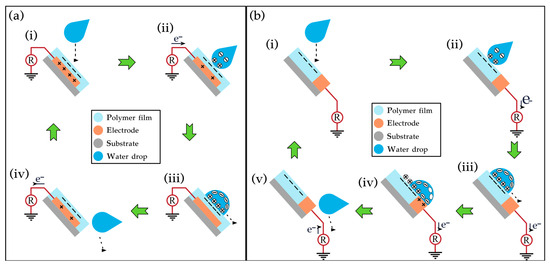

Figure 2 illustrates a comparative working mechanism of indirect and direct charge transfer processes in droplet-based liquid–solid TENGs. The mechanisms differ based on how charge transfer occurs—either indirectly through electrostatic induction or directly by contact with the CCE. The indirect mechanism involves water droplets interacting with a dielectric surface, creating an EDL through CE [18,19]. Upon contact with a polymer film surface, surface group ionization leads to negative charge accumulation on the polymer, while the droplet acquires a positive charge to maintain overall neutrality (Figure 2(a-i)). This interaction creates a potential difference as the positively charged droplet contacts the negatively charged polymer, forming an EDL. As the potential difference develops, electrons flow through an external circuit (Figure 2(a-ii)), generating an instantaneous current. The flow continues until the system reaches equilibrium (Figure 2(a-iii)). Once the droplet detaches from the polymer surface, a negative potential difference arises between the electrode and the ground, causing electron transfer to the ground to re-establish equilibrium (Figure 2(a-iv)). This process generates a potential difference, causing electron flow through an external circuit as droplets contact and detach from the polymer surface [26]. This repeated cycle generates a continuous AC, effectively converting mechanical energy from the droplet’s motion into electrical energy via electrostatic induction [12,18].

Figure 2.

Working mechanism comparison of indirect and direct charge transfer in droplet-based liquid–solid TENGs. (a) Mechanism of indirect charge transfer through electrostatic induction. (b) Mechanism of direct charge transfer through direct contact with the CCE [13]. Copyright 2014, Wiley-VCH.

Conversely, in the direct charge transfer mechanism (Figure 2b), water droplets establish contact with the CCE without an intermediate insulating layer [19,21]. This direct interaction facilitates rapid and efficient charge exchange, leveraging fundamental CE principles. Also, it enables immediate charge transfer between the droplet and the electrode. The absence of an insulating layer reduces potential energy losses and can lead to a more efficient triboelectric output. As the droplets contact the electrode, electron transfer occurs instantaneously, followed by a rebound effect. This simple yet direct process facilitates rapid charge exchange and efficient energy harvesting. However, the lack of an insulating layer may impact device durability in certain environments, making the choice of mechanism dependent on specific application needs and operational conditions. The direct charge transfer process starts with a water droplet approaching the membrane (Figure 2(b-i)) and contacting it (Figure 2(b-ii)) where, the droplets become positively charged, while the membrane acquires a negative charge due to the contact electrification effect. As the droplet expands on the membrane and moves toward the top electrode (Figure 2(b-iii)), the contact area increases and a potential develops between the charged droplet and the electrode. Upon contact, electrons from the droplet transfer directly to the top electrode (Figure 2(b-iv)), producing the output current through the external circuit. The efficiency of this step is influenced by the surface properties and characteristics of the droplet, such as hydrophilicity or hydrophobicity, which affect charge retention and transfer. As the droplet retracts and leaves the electrode (Figure 2(b-v)), the residual charges on the membrane and electrode are neutralized by electron flow to ground through the external circuit, restoring electrostatic equilibrium so the cycle repeats [11,26].

3.2.2. Streaming Flow-Based SL-TENGs: Indirect vs. Direct Mechanisms

In the indirect charge transfer mechanism (illustrated in Figure 3a), water flow interacts with a hydrophobic polymer-coated electrode, utilizing a polymer film to modulate surface charge affinity. The process initiates as water waves approach and make contact with the polymer layer (Figure 3(a-i)). This interaction triggers surface group ionization, leading to negative charge accumulation on the polymer film while the water gains a positive charge to maintain charge neutrality [18,19]. Factors such as flow rate, water composition, and temperature can significantly impact charge transfer efficiency. As the water flow continues along the polymer-coated surface (Figure 3(a-ii)), an EDL forms at the interface, creating a potential difference that drives electron flow through an external circuit, producing an electrical current. This current persists until a state of electrostatic equilibrium is achieved between the interacting charges (Figure 3(a-iii)). As the water wave recedes from the polymer surface (Figure 3(a-iv)), the re-establishment of a potential difference between the electrode and the ground prompts electron flow back to the ground, completing the charge transfer cycle and generating a continuous AC. The efficiency of this approach can be influenced by factors such as the choice of polymer materials, the thickness, composition, length, and affinity of the dielectric layer, as well as other related properties [12,33].

Figure 3.

Working mechanism comparison of indirect and direct charge transfer in Streaming flow-based liquid–solid SL-TENGs. (a) Mechanism of indirect charge transfer through electrostatic induction. (b) Mechanism of direct charge transfer through direct contact with the CCE [34]. Copyright 2014, American Chemical Society.

Conversely, the direct charge transfer mechanism (depicted in Figure 3b) involves direct interaction between water flow and the CCE without an intervening insulating layer. This method is initiated when water waves approach and come into contact with the CCE (Figure 3(b-i)), allowing immediate electron transfer based on CE principles [31,35]. The absence of an insulating layer minimizes resistive barriers, facilitating rapid electron transfer at the interface. As electrons migrate from the water to the CCE, opposite charges accumulate on the electrode surface, enhancing charge separation and conversion efficiency (Figure 3(b-ii)). As the fluid flows along the electrode, accumulated positive charges within the inner Helmholtz plane (IHP) of the EDL are attracted to the negatively charged electrode due to electrostatic forces, resulting in efficient electron transfer driven by the potential difference between the fluid and electrode surface. As the water flow spreads across the electrode (Figure 3(b-iii)), the contact area is maximized, allowing for continuous and efficient charge exchange that further boosts energy conversion [12,35]. Upon separation (Figure 3(b-iv)), residual charges create a potential difference, prompting electron flow through an external circuit to generate electrical energy.

To further elaborate on the physical principles, especially under intermittent flow conditions like discrete waves or droplets, the generation of these electrical signals can be precisely described by an equivalent circuit model, such as the one detailed by Zheng et al. In this model, the system is represented by a primary dielectric capacitor (Cp) and two additional capacitors for the Electric Double Layers (C1, C2) at the interfaces [36]. Each time a new wave front makes contact, it acts as a switch, causing the pre-charged Cp to rapidly discharge through the low-impedance path. This instantaneous discharge, governed by the time constant τ = RC, results in a sharp, high-amplitude DC pulse rather than a steady continuous current. Thus, while the overall process involves continuous charge exchange with the flowing medium, the electrical output manifests as a series of distinct DC pulses corresponding to each contact event.

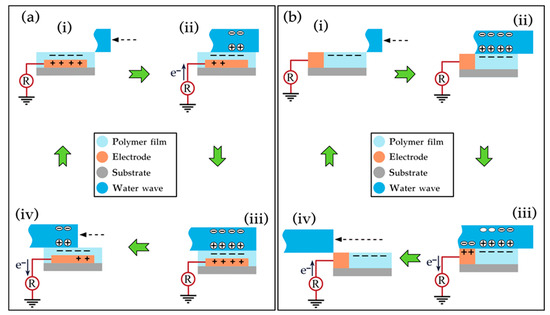

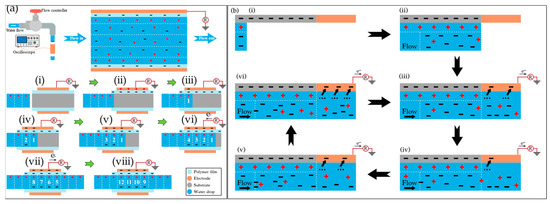

The fundamental principles of streaming flow-based-TENGs, rely on two main charge transfer processes: indirect and direct charge transfer mechanisms. These processes differ significantly in their interaction with the electrode and their effectiveness in energy conversion. Recent studies have offered detailed comparisons of these mechanisms under steady-state streaming flow conditions, emphasizing their distinctive advantages and potential limitations [33,35].These mechanisms are visually represented in Figure 4.

Figure 4.

Direct and indirect charge transfer mechanisms in SL-TENG. (a) Experimental setup with tap water flow and sequential operation steps [37]. Copyright 2022, Elsevier. (b) Charge transfer processes showing direct and indirect charge transfer mechanisms. Copyright 2020, Wiley-VCH.

This direct transfer mechanism ensures continuous charge exchange and maximizes energy harvesting by converting mechanical energy from streaming flow into electrical energy without significant energy losses. The interaction dynamics can be described through electrostatic forces; negative charges on the electrode attract positive charges in the stern layer while repelling negative ions in the fluid, establishing a balance between electrostatic attraction and repulsion. Additionally, transient free charges within the outer Helmholtz plane and diffuse layer—often referred to as transferable charges (TCs) can freely move with the flow, contributing to the charge transfer process. This movement of TCs enables rapid and direct charge transfer to the electrode, enhancing charge separation and energy conversion.

Research comparisons have demonstrated that the direct charge transfer mechanism generally outperforms the indirect approach in terms of energy conversion efficiency. This superior performance is largely attributed to the immediate and efficient nature of charge transfer in the direct mechanism, which eliminates energy losses associated with using an insulating polymer layer in indirect methods. However, while this approach provides enhanced output efficiency, it may face durability challenges due to the absence of a protective insulating layer. This exposure can lead to increased wear and possible degradation of the electrode surface over time. Potential strategies to improve durability could include applying protective coatings or optimizing material compositions to enhance resilience against wear.

3.3. Comparative Electrical Performance Analysis of SL-TENGs

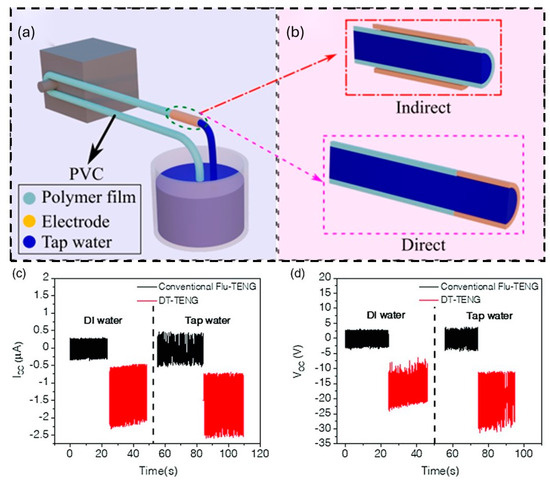

The LS-TENG designs presented in Figure 5 showcase two distinct charge transfer mechanisms: indirect charge transfer TENG (IT-TENG) and direct charge transfer TENG (DT-TENG). As illustrated in Figure 5a,b, the IT-TENG configuration incorporates a dielectric tube between the electrode and the liquid, preventing direct contact. In contrast, the DT-TENG design allows for direct contact between the electrode and the liquid, facilitating immediate charge transfer. Both configurations utilize a PVC tube as the primary structure, with deionized (DI) and tap water serving as the liquid medium for energy generation.

Figure 5.

Electrical output characteristics of SL-TENG comparing indirect and direct charge transfer mechanisms. (a,b) Schematic representation of the two mechanisms. (c,d) Direct charge transfer mode shows significantly higher short-circuit current (ISC) and open-circuit voltage (VOC) compared to the indirect mode, with results varying between DI water and tap water conditions [35]. Copyright 2020, Wiley-VCH.

The performance characteristics of these two TENG designs are quantitatively compared in Figure 5c,d, which display the short-circuit current (ISC) and open-circuit voltage (VOC) outputs, respectively. For DI water conditions, the IT-TENG produces an AC output with a current of approximately ±0.2 μA and a voltage of ±2.5 V, while the DT-TENG generates a DC output with significantly higher magnitudes: −2.2 μA for current and −22 V for voltage, representing an 11-fold increase in current and an 8.8-fold increase in voltage. When tap water is used, the IT-TENG maintains an AC output with a current of ±0.5 μA and a voltage of ±2 V, while the DT-TENG exhibits a DC output with a current of −2.5 μA and a voltage of −30 V, showing a 5-fold increase in current and a 15-fold increase in voltage. These distinct AC and DC output characteristics arise from their underlying charge transfer mechanisms, with the DT-TENG’s direct liquid-electrode contact enabling continuous charge flow in a single direction, leading to a stable DC output.

These performance differences can be attributed to the fundamental mechanisms of charge transfer in each approach. The direct contact between the liquid and electrode in DT-TENG reduces resistance to charge flow, contributing to increased current output [27]. The indirect method relies primarily on electrostatic induction, which generates a higher potential difference but limits the charge transfer rate, while the direct charge transfer mechanism enables immediate contact between the liquid and electrode, allowing for more efficient charge movement [13]. Additionally, the flow velocity plays a critical role in enhancing TENG performance by increasing fluid-surface interactions, leading to greater charge generation and transfer efficiency [38]. The direct transfer mechanism also exhibits a distinct advantage of producing a stable DC output after sharp initial peaks, which is ideal for applications requiring continuous and reliable power supply [39]. These characteristics highlight the superior practicality of the direct mechanism for energy harvesting systems [40]. Having established the distinct behaviors of direct and indirect charge transfer at the solid–liquid interface, we now turn our focus to systems where both interacting media are fluid: Liquid–Liquid TENGs.

4. Liquid–Liquid Triboelectric Nanogenerators (LL-TENGs)

4.1. Working Principles of LL-TENGs

LL-TENGs represent a promising frontier in energy harvesting technology, yet their underlying mechanisms remain less understood compared to their solid-state counterparts. The complex nature of liquid–liquid interfaces and the dynamic interactions between immiscible fluids pose significant challenges in elucidating and standardizing the mechanisms involved. Further research is needed to fully characterize and formalize these mechanisms due to the unique properties of liquid–liquid systems.

LL-TENGs harness the complex mechanisms of liquid–liquid contact electrification (L-L CE) at interfaces between two immiscible fluids with differing affinities. These mechanisms are influenced by the unique properties of the interacting liquids, including dissociable functional group interactions, preferential ion adsorption, and electron transfer [41,42]. The fundamental principles underlying LL-TENGs mechanisms include CE, electron transfer, dissociable functional group interactions, preferential ion adsorption, and the formation of an EDL [41,43]. These processes are further influenced by the hydrodynamic properties of the interacting liquids, including their flow and interfacial characteristics, which significantly impact charge separation and transfer efficiency [44,45].

To understand the charge transfer mechanisms in LL-TENGs, several theoretical models have been proposed. The EDL Model explains ion distribution and arrangement at the liquid–liquid interface, providing insight into charge separation and accumulation [41,45]. The Electrochemical Cell Model quantifies charge transfer at the liquid–liquid interface by employing a pinning factor to describe the linear correlation between charge transfer and electronic structure [41]. The Band Offset Model, adapted from semiconductor interfaces, utilizes energy differences in valence and conduction bands to describe interfacial charge transfer [43]. Additionally, the Electron Cloud Overlap Model, although primarily used for solid–solid interfaces, has been applied to elucidate electron transfer at liquid–liquid interfaces [41,43].

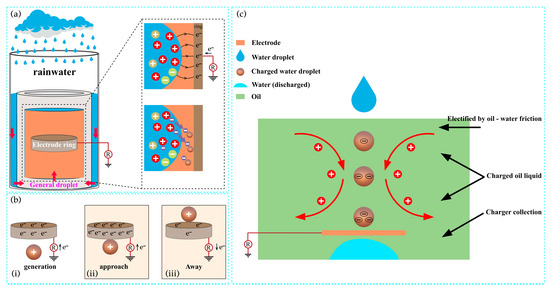

Indirect charge transfer in LL-TENGs relies on electrostatic induction, where relative motion between immiscible fluids creates a charge imbalance without direct electrode contact [42,44]. This indirect mechanism is conceptually illustrated in Figure 6a,c. This mechanism is particularly effective in systems such as oleic acid-water, where functional group dissociation dominates [41,43]. Optimizing parameters like pH can enhance charge generation via electrostatic induction. Turbulent flows and emulsified systems promote indirect charge transfer by maximizing relative motion and enhancing electrostatic induction across the liquid interface [44,45]. This mechanism can be leveraged in designs that emphasize capillary flow or dynamic interfaces, suitable for applications in environmental monitoring and energy harvesting from fluid motion [42,44].

Figure 6.

Indirect and Direct Charge Transfer Mechanisms in Liquid–Liquid TENGs. (a,c) Indirect mechanism using electrostatic induction between two liquid phases [46]. Copyright 2022, Wiley-VCH. (b) Direct mechanism with immediate electron transfer through direct contact with the CCE [47]. Copyright 2021, Elsevier.

Direct charge transfer, on the other hand, involves immediate interaction between one fluid phase and a CCE, facilitating rapid electron transfer at the interface [43,45], this direct mechanism is depicted in Figure 6b. This mechanism is exemplified in systems like HFE-water, where fluorine’s high electronegativity ensures efficient electron transfer [41,45]. Direct charge transfer can be optimized in microfluidic designs with embedded electrodes, enabling continuous and rapid electron exchange [43,44]. This approach is particularly effective in scenarios requiring high energy conversion efficiency and minimal charge loss, making it suitable for applications in wearable electronics and small-scale power generation [42,43,45].

4.2. Comparative Electrical Performance Analysis of LL-TENGs

The comparison between direct and indirect charge transfer mechanisms reveals significant differences in current output, charge transfer efficiency, saturation time, and overall output characteristics. The underlying schematic and charge distribution simulation for the indirect mechanism are shown in Figure 7a,b. In the indirect charge transfer mechanism, the output current is limited to approximately 4.5–6.5 pA due to its reliance on ion adsorption and electrostatic induction at the interface. The periodic peaks in the output signal indicate repetitive charge transfer cycles, but the amplitude remains low, limiting energy transfer efficiency. The total transferred charge in the indirect method is measured to be approximately −5.3 pC, a consequence of charge transfer being constrained by resistance within the fluid and incomplete contact at the interface. Furthermore, the AC nature of the output in the indirect method necessitates additional AC-to-DC conversion for practical applications, leading to energy losses during the process.

Figure 7.

LL-TENG electric output performance comparison. (a,b) Schematic and charge distribution simulation for LL-TENG with indirect charge transfer [46]. Copyright 2022, Wiley-VCH. (c,d) Output current and voltage waveforms for LL-TENG with direct charge transfer [42]. Copyright 2022, Nature Communications.

In contrast, the direct charge transfer mechanism exhibits a significantly improved performance due to the free movement of charges at the interface between the fluid and the electrode. Experimental results as depicted by the current and voltage waveforms in Figure 7c,d show that the direct mechanism achieves an initial peak current of up to ±60 pA, which is more than 10 times higher than that of the indirect method. The transferred charge also demonstrates superior results, reaching a maximum of 2.1 pC, with continuous accumulation observed. While the direct method initially exhibits high-amplitude fluctuations, the output stabilizes over time as it reaches a saturation state. This stabilization occurs approximately 30% faster compared to the indirect method, reflecting a quicker equilibrium between charge transfer and interface saturation. The enhanced performance in the direct mechanism can be attributed to reduced resistance and shorter charge transfer pathways, which allow for greater charge mobility. Importantly, the DC nature of the output eliminates the need for AC-to-DC conversion, enabling direct and efficient power delivery.

In summary, the direct charge transfer mechanism outperforms the indirect mechanism, delivering 10 times higher current output, approximately 2 times greater charge transfer, and achieving saturation in a significantly shorter time. These performance improvements arise from the more efficient electron transfer process at the liquid-electrode interface, which minimizes energy loss. As a result, the direct charge transfer mechanism is particularly suitable for energy harvesting systems requiring high output power and stable, continuous energy delivery without additional conversion processes. Moving from liquid–liquid interactions, the next section explores the dynamic and high-energy interface between gas and liquid phases, a promising frontier for TENG technology.

5. Gas–Liquid TENGs

5.1. Working Principles of Gas–Liquid TENGs

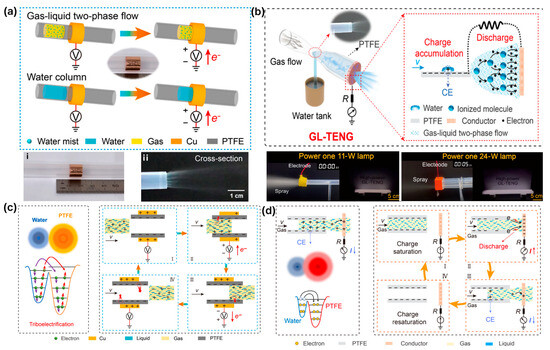

Gas–liquid triboelectric nanogenerators (GL-TENGs) represent an innovative approach to energy harvesting, utilizing the dynamic interaction between high-speed gas–liquid two-phase flows and dielectric surfaces. These devices exploit the principles of CE and electrostatic induction to convert mechanical energy into electrical output. The core mechanism involves the atomization of liquid into fine droplets by high-speed airflow, creating a turbulent two-phase flow that continuously interacts with a dielectric surface, typically polytetrafluoroethylene (PTFE) [48,49,50,51].

These devices exploit the principles of CE and electrostatic induction to convert mechanical energy into electrical output [52,53]. The core mechanism involves the atomization of liquid into fine droplets by high-speed airflow, creating a turbulent two-phase flow that continuously interacts with a dielectric surface, typically PTFE [51,54]. This interaction leads to charge transfer and accumulation, which is then harnessed to generate electrical energy [53,55].

In the indirect charge transfer mechanism, triboelectrification occurs at the solid–liquid interface, inducing electrostatic induction on a single ring-shaped electrode [50]. The EDL refers to the accumulation of oppositely charged ions at the solid–liquid interface, creating a potential difference that induces charges on nearby electrodes through electrostatic induction. This phenomenon is critical in indirect charge transfer mechanisms for enhancing current generation. As the gas–liquid flow contacts the PTFE surface, electrons transfer from the liquid to the PTFE, creating a charge imbalance [51,55]. This imbalance induces opposite charges on the electrode through the shielding effect of the EDL [55]. When the gas–liquid flow moves through and separates from the PTFE, a current is generated between the electrode and the ground [50,51]. The high-speed, nonlinear motion of the gas–liquid flow significantly enhances the solid–liquid CE area and separation velocity, resulting in higher charge transfer efficiency compared to static liquid systems [51]. This repeated cycle of contact, electrostatic induction, and separation enables consistent AC power generation with high electrical output and stable performance. The indirect charge transfer mechanism, operating via electrostatic principles without requiring direct electrode contact, further enhances durability [17,52].

The indirect charge transfer mechanism operates as follows: Initially, the gas–liquid two-phase flow approaches the surface (Figure 8(c-I)). As the flow contacts the surface, electrons transfer from the liquid to the surface, creating a charge imbalance (Figure 8(c-II)). This results in negative charges accumulating on the surface while the gas–liquid flow becomes positively charged (Figure 8(c-III)). The charge imbalance induces opposite charges on the electrodes through the EDL effect. As the flow moves through and separates from the surface (Figure 8(c-IV)), a current is generated between the electrode and the ground. This process repeats continuously, creating consistent AC power generation.

Figure 8.

Comparison of indirect and direct charge transfer mechanisms in GL-TENGs: (a,c) Indirect mechanism with electrostatic induction via gas–liquid flow in a PTFE tube [50]. Copyright 2024, Elsevier. (b,d) Direct mechanism enabling charge transfer through direct contact with electrodes [51]. Copyright 2022, Science Advances.

The direct charge transfer mechanism, on the other hand, involves a more immediate transfer of charges from the gas–liquid phase to the electrode [52,54]. In this configuration, the continuous interaction between the two-phase flow and the PTFE surface leads to direct electron transfer from water molecules to the PTFE via CE [51,55]. This results in significant negative charge accumulation on the PTFE and positive charging of the gas–liquid phase. As the charge on the PTFE surface reaches saturation, the electric field at the gas–liquid interface exceeds its breakdown threshold. The dielectric breakdown initiates and facilitates the rapid transfer of charges to a porous conductive electrode. The high-speed flow ensures rapid charge saturation, while the porous structure of the electrode maximizes charge capture efficiency [51,54]. This cyclic mechanism, combining enhanced CE through the gas–liquid interface and efficient discharge at reduced breakdown voltages, ensures high energy conversion rates and stable long-term performance of the GL-TENG [17,51,52]. These innovations highlight GL-TENGs’ unique contributions compared to existing TENGs by offering enhanced material compatibility and increased output under diverse environmental conditions.

The direct charge transfer mechanism in gas–liquid two-phase flow proceeds through several sequential stages: Initially, as the gas–liquid two-phase flow approaches the PTFE surface and CCE, direct contact between water molecules and PTFE occurs, enabling electron transfer through CE and resulting in significant negative charge accumulation on the PTFE surface (Figure 8(d-I)). When the PTFE reaches charge saturation, the electric field at the gas–liquid interface exceeds its breakdown threshold, triggering rapid charge transfer to the porous conductive electrode (Figure 8(d-II)). Following discharge, charge redistribution occurs while maintaining high-speed flow (Figure 8(d-III)), and finally, the system returns to its initial state, beginning a new charge accumulation cycle (Figure 8(d-IV)), with this continuous process sustained by the high-speed flow that ensures efficient charge saturation and discharge cycles.

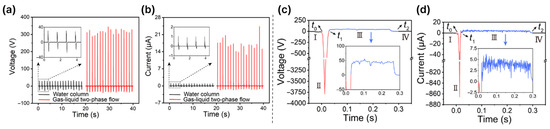

5.2. Comparative Electrical Performance Analysis of GL-TENGs

The comparison of voltage and current outputs between indirect and direct charge transfer mechanisms in gas–liquid two-phase flow TENGs (GL-TENGs) reveals a significant performance enhancement in the direct method. For voltage output, the indirect charge transfer mechanism (Figure 9a) peaks at approximately 300–350 V, while the direct charge transfer method (Figure 9c) achieves a substantially higher voltage of around −3750 V, representing an increase of over 10 times. Similarly, for current output, the indirect mechanism (Figure 9b) yields a maximum of about 21–25 μA, whereas the direct method (Figure 9d) reaches approximately −860 μA, marking an increase of over 34 times. These results highlight the ability of the direct charge transfer mechanism to achieve significantly higher output performance compared to its indirect counterpart.

Figure 9.

Comparison of electrical performance between indirect and direct charge transfer mechanisms in GL-TENGs. (a,b) Peak voltage and current output of RSE-TENG based on gas-liquid two-phase flow (in red), which is much higher than the control group based on water column (in black) [50]. Copyright 2024, Elsevier. (c) Voltage, and (d) Generated current, from the GL-TENG. Copyright 2022, [51] Science Advances.

This dramatic improvement underscores the advantages of direct charge transfer, where ionized molecules come into immediate contact with the conductor, enabling more effective charge accumulation and discharge. Notably, the flow velocity of the gas–liquid two-phase mixture plays a critical role in enhancing the performance of TENGs, as demonstrated in previous studies [34,56,57,58,59]. As the flow rate increases, the frequency and intensity of fluid-surface interactions grow, leading to greater charge generation and transfer efficiency. This effect is particularly pronounced in GL-TENGs, where the high-speed flow of the gas–liquid interface enables rapid charge saturation and efficient discharge, contributing to the observed 10-fold voltage and 34-fold current enhancements in the direct charge transfer mechanism.

The direct charge transfer mechanism not only achieves significantly higher electrical outputs but also enables the generation of DC, in contrast to the AC produced by the indirect charge transfer mechanism. This distinction is critical, as the direct method exhibits output currents several orders of magnitude higher than those of the indirect method, further enhancing its practical utility. The sharp initial peaks followed by stable DC output observed in the direct mechanism are particularly advantageous for applications requiring continuous and reliable power supply. To better understand and optimize the complex charge transfer dynamics discussed across the SL, LL, and GL interfaces, computational modeling and simulation provide invaluable insights, as will be discussed next.

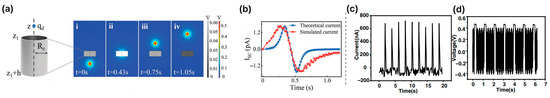

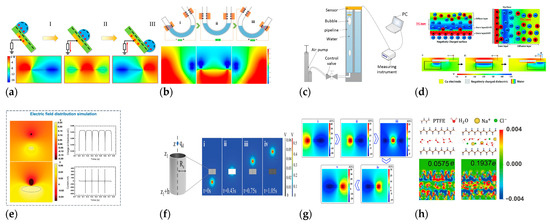

6. Simulation and Analysis

To accurately model charge transfer behaviors, many fundamental simulation approaches are typically employed. Figure 10 provides visual examples of various simulation approaches and results related to indirect and direct charge transfer mechanisms in fluid-based TENGs, especially for Gas–Liquid TENGs. Among these methods, Charge Distribution is the most frequently simulated, as it directly relates to the charge transfer behavior at different interfaces. Computational tools such as COMSOL Multiphysics AC/DC module are widely used to evaluate the electric potential and charge accumulation in these systems, providing valuable insights into optimizing charge transfer efficiency.

Figure 10.

Comparison of indirect and direct charge transfer mechanisms in GL-TENGs: (a) Charge and potential changes in liquid and gas flow sensors [60]. Copyright 2021, ACS Nano. (b) The U-tube TENG’s structure, material surface, charge movement, and potential distribution during operation [61]. Copyright 2023, Micromachines. (c) The schematic setup for detecting two-phase CBM flow using a sensor in a water-filled pipeline with air bubbles [62]. Copyright 2020, Nanotechnology. (d) Working mechanism of the DT-TENG [35]. Copyright 2020, Advanced Energy and Sustainability Research. (e) Simulations of fluid dynamics and electric field distribution for FB-TENGs [58]. Copyright 2024, Advanced Materials. (f) Simulation of the electric field during droplet’s movement in the L–L TENG [46]. Copyright 2022, Advanced Functional Materials. (g) Simulations of electric field distribution for LLi-TENGs [46]. Copyright 2020, Nano Energy. (h) Simulation of solid–liquid charge transfer based on density functional theory (DFT) [51]. Copyright 2022, Science advances.

6.1. SL TENG Simulation Result Analysis

Charge transfer in SL TENG interactions has been extensively studied, focusing on both direct and indirect mechanisms. In indirect charge transfer, triboelectric effects dominate, where contact and separation between a liquid and a solid surface induce charge accumulation. A study by [60] simulated the working mechanism of Triboelectric Motion Sensors (TMSs) by analyzing charge and potential distributions in Liquid-TMS and Gas-TMS, highlighting their charge transfer mechanisms and motion sensing capabilities. The results demonstrate that the Liquid-TMS generates an output voltage of 0.18 V, confirming its effectiveness in converting mechanical motion into electrical signals. Additionally, simulations in [61] modeled the electrical potential distribution in a U-tube TENGs using COMSOL Multiphysics, confirming its ability to generate alternating potential and current for efficient energy harvesting from oscillating liquid motion. Another study [62] simulated the flow field to evaluate the maximum contact area between liquid and solid by analyzing the velocity distribution of water at motor driving frequencies of 3.5 Hz and 1.5 Hz. The results show that the water reaches its maximum height when the vertical velocity of the rightmost liquid is zero, with maximum liquid levels of 29 mm and 52 mm, respectively.

In contrast, direct charge transfer in SL TENG systems involves direct electron exchange between a conducting liquid and a solid electrode. A study by [35] focused on the charge behavior of a TFC-layer in a direct charge transfer system. The simulation revealed stable charge accumulation with a voltage output of 14.84 V and a current of 1.28 μA. Another study by Jiang investigated the tribo-polarity effect and CE at water/polymer interfaces using density functional theory (DFT) and charge transfer measurements, analyzing the impact of water layer thickness, atomic arrangement, and polymer composition [58]. The results reveal that electron transfer occurs only at the outermost atomic layer, with interface structure significantly influencing triboelectric performance, yielding an output voltage of 0.5 V and a current of 0.4–1 µA. While indirect charge transfer remains widely used due to its relevance in triboelectric applications, direct charge transfer shows potential for achieving higher and more stable energy output.

6.2. LL-TENG Simulation Result Analysis

The distinction between direct and indirect charge transfer mechanisms is also evident in Liquid–Liquid interactions. Direct charge transfer occurs when charge carriers freely migrate between two liquid phases, enhancing charge redistribution. A study by aimed to analyze the electric field distribution in FB-TENGs, showing that fluid interface separation directly influences charge transfer and output current, with fluid morphology and external properties playing key roles in performance [58]. Another study simulated water droplet movement through an electrode ring using finite element analysis, confirming charge induction and short-circuit current predictions. COMSOL results validate the electric field distribution, showing that liquid type, contact distance, and salt concentration affect charge transfer efficiency, with optimized parameters achieving 1.87 V and 7 pA output in rainwater-based LL-TENGs. These findings highlight that direct charge transfer in LL-TENGs is efficient and provides stable charge flow, making it well suited for energy-harvesting applications.

Indirect charge transfer in LL-TENGs, however, often relies on electrostatic induction or the presence of insulating barriers, which significantly restrict charge mobility. A study by calculated the potential distribution of three typical states under open-circuit conditions for a ferrofluid-based TMS, verifying its working mechanism [63]. The results confirm that as the droplet moves over the electrode, the potential shifts from negative to positive, inducing electron flow from the ground, and reverses when the droplet moves away, validating the charge redistribution mechanism for TMS signal generation. The results showed that indirect charge transfer mechanisms produced lower current outputs, approximately 1.5 nA. The findings indicated that indirect charge transfer was not highly inefficient compared to direct charge transfer. The comparison between these mechanisms underscores that while indirect charge transfer plays a role in charge redistribution, direct charge transfer remains considerably more effective for Liquid–Liquid energy conversion.

6.3. GL TENG Simulation Result Analysis

Although less frequently studied, GL-TENGs present unique opportunities, particularly for atmospheric electricity applications. Direct charge transfer occurs when ionized gas species interact with a liquid surface, facilitating charge accumulation. A study by simulated charge dynamics in a continuous-flow GL-TENGs, confirming stable output for capacitor charging and low-power devices while highlighting the effects of CE and gas–liquid flow on energy transfer [51]. Their system achieved a high voltage output of 60 V and a current of 6 μA. The study also simulated the pressure distribution of gas–liquid two-phase flow in the tube under different gas flow velocities. The results showed that higher gas velocity leads to a greater amount of gas–liquid two-phase mixture flow and increased flow velocity within the tube.

Currently, there is a lack of published literature addressing simulation studies on GL-TENGs indirect charge transfer, and no evidence suggests that such simulations have been performed. Nevertheless, future investigations are expected to offer comprehensive and conclusive analysis of the techniques that have been employed or are intended for application in this system.

7. Application and Future

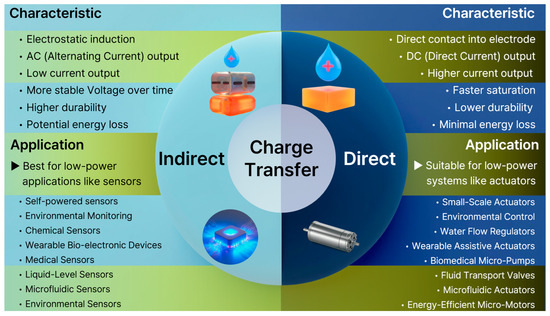

Figure 11 presents a comprehensive comparative analysis of the characteristics and applications of indirect and direct charge transfer mechanisms in TENGs. TENGs operate via two primary mechanisms for charge transfer: indirect and direct. Indirect charge transfer relies on electrostatic induction, where an insulating layer mediates the interaction between a dielectric material and an electrode. This mechanism often produces an AC output, with lower current and voltage magnitudes but enhanced durability and stability over time. In contrast, direct charge transfer occurs through immediate contact between the fluid medium and the electrode, resulting in a DC output. This method achieves significantly higher current and voltage levels due to the absence of intermediate barriers, facilitating efficient energy transfer. However, the direct mechanism has limitations in durability because of increased wear on the electrode’s surface. These characteristics define their suitability for different applications: indirect charge transfer is best for low-power, stable systems, while direct charge transfer supports high-power applications with rapid energy delivery.

Figure 11.

Comparative Analysis of Indirect and Direct Charge Transfer Mechanisms: Characteristics and Applications.

The indirect charge transfer mechanism excels in powering low-energy systems where stability and long-term durability are critical. Self-powered sensors are one of its primary applications, including humidity, temperature, and pressure monitoring devices [64,65,66]. In environmental monitoring, indirect TENGs can track chemical pollutants, soil pH, and water quality [67,68,69,70]. Wearable bio-electronic devices, such as those for monitoring heart rate and respiratory movements, are also ideal due to their low power requirements and consistent AC output [71,72]. Medical sensors for real-time diagnostics and lab-on-chip systems further benefit from this mechanism, leveraging its precision and stable energy output [68]. Additionally, liquid-level sensors and microfluidic devices in healthcare and research settings use indirect charge transfer to ensure reliable operation over extended periods [73]. These applications highlight the value of indirect mechanisms in areas where energy efficiency and device longevity are paramount.

Direct charge transfer, with its high current and voltage capabilities, is well suited for low-power actuators requiring efficient energy conversion. Small-scale actuators, such as water flow regulators for irrigation systems and greenhouse environmental controllers, rely on this mechanism for real-time precision control [74]. In wearable assistive devices, direct TENGs enable soft robotics and exoskeleton systems to deliver real-time motion assistance [75,76,77,78]. Biomedical applications, including micro-pumps for drug delivery, take advantage of the high efficiency and portability of direct charge transfer [79]. Furthermore, fluid transport valves and microfluidic actuators in compact systems provide precise control for portable water purification and sample manipulation [80,81]. Energy-efficient micro-motors, often used in robotics or small electronic devices, benefit from the DC output of direct charge transfer mechanisms. These applications demonstrate the versatility of direct charge transfer in powering compact, high-performance systems where rapid energy transfer is critical.

The future potential of indirect and direct charge transfer mechanisms lies in their ability to address evolving technological demands in precision sensing and actuation systems. For indirect charge transfer, advancements could lead to ultra-low-power sensors embedded in smart cities for real-time environmental monitoring, such as air quality and noise pollution tracking [68,74]. Wearable healthcare devices may evolve into fully self-powered systems capable of long-term monitoring of vital signs, integrating indirect TENGs with IoT platforms for continuous data transmission [82]. In agriculture, these mechanisms could enable precise soil nutrient and moisture analysis sensors, empowering data-driven farming practices [68,83]. For direct charge transfer, future applications could focus on compact, high-efficiency actuators for autonomous robotics in industries such as logistics and manufacturing. Soft robotic actuators for medical rehabilitation and assistive devices could achieve greater portability and responsiveness, making them viable for personalized care solutions [84]. Additionally, direct TENGs may power miniaturized hydraulic systems for aerospace and underwater robotics, addressing challenges in harsh and constrained environments [85]. These advancements in both mechanisms have the potential to revolutionize low-power sensor and actuator technologies across diverse fields.

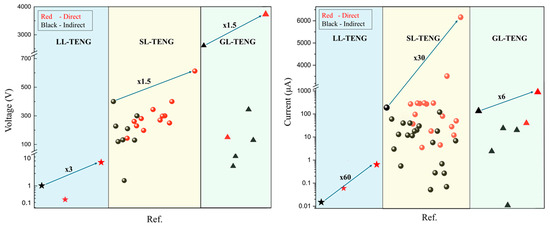

8. Conclusions and Perspective

Figure 12 provides a comparative overview of voltage and current outputs between indirect and direct charge transfer mechanisms across various TENG configurations. This review makes a foundational contribution to the field of fluid-based TENGs by proposing the first systematic framework that defines and standardizes the mechanisms of direct versus indirect charge transfer. Unlike previous works that primarily categorized devices by interface type (e.g., SL, LL, or GL), our framework provides a unified classification based on a rigorous analysis of physical principles, device architectures, and quantitative energy conversion results. This work establishes the direct vs. indirect dichotomy as a fundamental, cross-cutting design principle, reframing the field’s understanding of triboelectric performance limits. Furthermore, it delivers practical guidance for optimizing material selection, interface structure, and application-specific system architectures to realize high-efficiency, robust, and scalable energy harvesting devices.

Figure 12.

Comparison of Voltage and Current Outputs between Indirect and Direct Charge Transfer Mechanisms in LL, SL, and GL TENGs.

The superiority of the direct charge transfer mechanism is evident across SL, LL, and GL interfaces, although the experimental context for each comparison varies. For comparison, the reported electrical output of various devices using the indirect and direct Charge Transfer are summarized in Table 1 and Table 2 across all the interfaces. From the tables the superiority of the devices using direct charge transfer is clearly visible. For SL-TENGs, a controlled study was conducted using identical materials and structures (a PVC tube and DI water), where only the charge transfer mechanism was altered. This direct comparison yielded an 11-fold higher current and an 8.8-fold higher voltage than the indirect method, clearly demonstrating the intrinsic superiority of the direct mechanism when all other variables are controlled. In contrast, the performance comparison for LL-TENGs was made between different material systems, showcasing the high potential of the direct mechanism; a direct-contact TENG using PEG/DEX achieved a 60-fold greater current than an indirect-contact TENG using ferrofluid/lubricant oil (720 nA vs. 12 nA). Similarly, in the GL-TENG domain, a comparison was made between systems sharing a similar operational principle—high-speed gas–liquid two-phase flow interacting with a PTFE surface. Under these conditions, the direct charge transfer approach yielded over a 34-fold increase in current (867 µA vs. 24 µA) and a 10-fold increase in voltage (3789 V vs. 344 V) compared to the indirect method, proving its effectiveness in high-energy-density applications. It is important to note that these performance multiples are derived from different studies and serve as illustrative examples; due to variations in experimental conditions, materials, and device configurations across reports, these values should not be seen as absolute benchmarks.

Table 1.

Comparative Electrical Performance Analysis between Direct and Indirect Charge Transfer Mechanisms of SL-TENGs.

Table 2.

Comparative Electrical Performance Analysis between Direct and Indirect Charge Transfer Mechanisms of GL-TENGS and LL-TENGS.

These findings establish the direct vs. indirect framework not just as a classification, but as a prescriptive design tool for the future researchers. Based on the desired application, a specific charge transfer pathway can now be intentionally selected to balance key engineering trade-offs. For instance, direct charge transfer, with its rapid, high-power DC output, is ideally suited for future systems like small-scale actuators and biomedical micro-pumps. Conversely, the enhanced durability and stable AC output of indirect charge transfer mechanisms position them as the optimal choice for long-term, low-power applications like environmental and wearable sensors. A key challenge for future research will be to address the durability limitations of the direct mechanism, likely through the optimization of interface materials or the development of novel hybrid systems. By empowering researchers to make these intentional design choices, this framework unlocks the full potential of fluid-based energy harvesting and paves the way for the next generation of self-powered systems for a sustainable future.

Author Contributions

Conceptualization, J.H.A.; methodology, J.H.A. and Q.T.N.; software, J.H.A.; validation, J.H.A., T.B.T.N. and M.F.R.; formal analysis, J.H.A.; investigation, Y.H.L.; resources, J.H.A.; data curation, M.F.R.; writing—original draft preparation, J.H.A.; writing—review and editing, K.K.A.; visualization, V.H.N.; supervision, K.K.A.; project administration, K.K.A.; funding acquisition, K.K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This result was supported by the “Regional Innovation System & Education (RISE)” through the Ulsan RISE Center, funded by the Ministry of Education (MOE) and the Ulsan Metropolitan Government (2025-RISE-07-001).

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dincer, F. The analysis on wind energy electricity generation status, potential and policies in the world. Renew. Sustain. Energy Rev. 2011, 15, 5135–5142. [Google Scholar] [CrossRef]

- Zhang, P.; Li, W.; Li, S.; Wang, Y.; Xiao, W. Reliability assessment of photovoltaic power systems: Review of current status and future perspectives. Appl. Energy 2013, 104, 822–833. [Google Scholar] [CrossRef]

- Yüksel, I. Hydropower for sustainable water and energy development. Renew. Sustain. Energy Rev. 2010, 14, 462–469. [Google Scholar] [CrossRef]

- Fridleifsson, I.B.; Bertani, R.; Huenges, E.; Lund, J.W.; Ragnarsson, A.; Rybach, L. The possible role and contribution of geothermal energy to the mitigation of climate change. In Proceedings of the IPCC Scoping Meeting on Renewable Energy Sources, Luebeck, Germany, 21–25 January 2008. [Google Scholar]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- O’Rourke, F.; Boyle, F.; Reynolds, A. Tidal energy update 2009. Appl. Energy 2010, 87, 398–409. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D.J. Piezoelectric Energy Harvesting; John Wiley & Sons: Chichester, UK, 2011. [Google Scholar]

- Yang, Y.; Guo, W.; Pradel, K.C.; Zhu, G.; Zhou, Y.; Zhang, Y.; Hu, Y.; Lin, L.; Wang, Z.L. Pyroelectric nanogenerators for harvesting thermoelectric energy. Nano Lett. 2012, 12, 2833–2838. [Google Scholar] [CrossRef]

- Zhao, F.; Liang, Y.; Cheng, H.; Jiang, L.; Qu, L. Highly efficient moisture-enabled electricity generation from graphene oxide frameworks. Energy Environ. Sci. 2016, 9, 912–916. [Google Scholar] [CrossRef]

- Beeby, S.P.; Torah, R.N.; Tudor, M.J.; Glynne-Jones, P.; O’Donnell, T.; Saha, C.R.; Roy, S. A micro electromagnetic generator for vibration energy harvesting. J. Micromech. Microeng. 2007, 17, 1257. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology for self-powered systems and as active mechanical and chemical sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Lin, Z.-H.; Cheng, G.; Lee, S.; Pradel, K.C.; Wang, Z.L. Harvesting water drop energy by a sequential contact-electrification and electrostatic-induction process. Adv. Mater. 2014, 26, 4690–4696. [Google Scholar] [CrossRef]

- Nie, J.; Wang, Z.; Ren, Z.; Li, S.; Chen, X.; Wang, Z.L. Power generation from the interaction of a liquid droplet and a liquid membrane. Nat. Commun. 2019, 10, 2264. [Google Scholar] [CrossRef]

- Guo, X.; He, J.; Zheng, Y.; Wu, J.; Pan, C.; Zi, Y.; Cui, H.; Li, X. High-performance triboelectric nanogenerator based on theoretical analysis and ferroelectric nanocomposites and its high-voltage applications. Nano Res. Energy 2023, 2, e9120074. [Google Scholar] [CrossRef]

- Sheng, F.; Zhang, Y.; Wang, J.; Wang, X.; Wang, F.; Wang, Z.L. Wearable energy harvesting-storage hybrid textiles as on-body self-charging power systems. Nano Res. Energy 2023, 2, e9120079. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerator (TENG)—Sparking an energy and sensor revolution. Adv. Energy Mater. 2020, 10, 2000137. [Google Scholar] [CrossRef]

- Lin, S.; Xu, L.; Wang, A.C.; Wang, Z.L. Quantifying electron-transfer in liquid-solid contact electrification and the formation of electric double-layer. Nat. Commun. 2020, 11, 399. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wang, A.C. On the origin of contact-electrification. Mater. Today 2019, 30, 34–51. [Google Scholar] [CrossRef]

- Schrödinger, E. An undulatory theory of the mechanics of atoms and molecules. Phys. Rev. 1926, 28, 1049. [Google Scholar] [CrossRef]

- Xu, C.; Zi, Y.; Wang, A.C.; Zou, H.; Dai, Y.; He, X.; Wang, P.; Wang, Y.-c.; Feng, P.; Li, D.; et al. On the electron-transfer mechanism in the contact-electrification effect. Adv. Mater. 2018, 30, 1706790. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Y.; Zi, Y.; Zhang, G.; Wang, Z.L. Excluding contact electrification in surface potential measurement using kelvin probe force microscopy. ACS Nano 2016, 10, 2528–2535. [Google Scholar] [CrossRef]

- Bard, A.J.; Faulkner, L.R. Electrochemical Methods: Fundamentals and Applications, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Li, Y.; Lau, T.H.; Guan, D.; Zi, Y. A universal method for quantitative analysis of triboelectric nanogenerators. J. Mater. Chem. A 2019, 7, 19485–19494. [Google Scholar] [CrossRef]

- Li, A.; Zi, Y.; Guo, H.; Wang, Z.L.; Fernández, F.M. Triboelectric nanogenerators for sensitive nano-coulomb molecular mass spectrometry. Nat. Nanotechnol. 2017, 12, 481–487. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Paria, S.; Si, S.K.; Karan, S.K.; Das, A.K.; Maitra, A.; Bera, R.; Halder, L.; Bera, A.; De, A.; Khatua, B.B. A strategy to develop highly efficient TENGs through the dielectric constant, internal resistance optimization, and surface modification. J. Mater. Chem. A 2019, 7, 3979–3991. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Wang, Z.; He, W.; Tang, Q.; Xi, Y.; Wang, X.; Guo, H.; Hu, C. Quantifying contact status and the air-breakdown model of charge-excitation triboelectric nanogenerators to maximize charge density. Nat. Commun. 2020, 11, 1599. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Li, Z.; Shen, F.; Zhang, Q.; Gong, Y.; Guo, H.; Peng, Y.; Wang, Z.L. Progress on techniques for improving output performance of triboelectric nanogenerators. Energy Environ. Sci. 2024, 17, 3546–3592. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, Y.; Li, Y.; Chen, X.; Shen, H. A review: Contact electrification on special interfaces. Front. Mater. 2022, 9, 909746. [Google Scholar] [CrossRef]

- Li, C.; Bai, Y.; Shao, J.; Meng, H.; Li, Z. Strategies to improve the output performance of triboelectric nanogenerators. Small Methods 2024, 8, 2301682. [Google Scholar] [CrossRef]

- Ahn, J.H.; Hwang, J.Y.; Kim, C.G.; Nam, G.H.; Ahn, K.K. Unsteady streaming flow based TENG using hydrophobic film tube with different charge affinity. Nano Energy 2020, 67, 104269. [Google Scholar] [CrossRef]

- Zhu, G.; Su, Y.; Bai, P.; Chen, J.; Jing, Q.; Yang, W.; Wang, Z.L. Harvesting water wave energy by asymmetric screening of electrostatic charges on a nanostructured hydrophobic thin-film surface. ACS Nano 2014, 8, 6031–6037. [Google Scholar] [CrossRef]

- Nam, G.H.; Ahn, J.H.; Lee, G.H.; Vo, C.P.; Ahn, K.K. A new pathway for liquid–solid Triboelectric Nanogenerator using streaming flow by a novel direct charge transfer. Adv. Energy Sustain. Res. 2020, 1, 2000031. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, T.; Wu, J.; Xu, T.; Wang, X.; Han, X.; Cui, H.; Xu, X.; Pan, C.; Li, X. Energy conversion analysis of multilayered triboelectric nanogenerators for synergistic rain and solar energy harvesting. Adv. Mater. 2022, 34, 2202238. [Google Scholar] [CrossRef]

- Munirathinam, K.; Kim, D.-S.; Shanmugasundaram, A.; Park, J.; Jeong, Y.J.; Lee, D.-W. Flowing water-based tubular triboelectric nanogenerators for sustainable green energy harvesting. Nano Energy 2022, 102, 107675. [Google Scholar] [CrossRef]

- Jiang, D.; Xu, M.; Dong, M.; Guo, F.; Liu, X.; Chen, G.; Wang, Z.L. Water–solid triboelectric nanogenerators: An alternative means for harvesting hydropower. Renew. Sustain. Energy Rev. 2019, 115, 109366. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, L.; Zhou, L.; Yin, X.; Wei, X.; Zhang, C.; Hu, W.; Wang, J.; Wang, Z.L. Self-powered sensor for quantifying ocean surface water waves based on triboelectric nanogenerator. ACS Nano 2020, 14, 7092–7100. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Wang, Y.; Ma, Y.; Wang, C. Enhanced Energy Harvesting Performance of Triboelectric Nanogenerators via Dielectric Property Regulation. ACS Appl. Mater. Interfaces 2023, 15, 31795–31802. [Google Scholar] [CrossRef]

- Zhang, R.; Lin, H.; Shum, A.H.C. Liquid–liquid contact electrification for microfluidics–based triboelectric nanogenerator. In Proceedings of the 26th International Conference on Miniaturized Systems for Chemistry and Life Sciences (MicroTAS 2022), Hangzhou, China, 23–27 October 2022; Chemical and Biological Microsystems Society: San Diego, CA, USA, 2022; pp. 1171–1172. [Google Scholar]

- Lu, Y.; Jiang, L.; Yu, Y.; Wang, D.; Sun, W.; Liu, Y.; Yu, J.; Zhang, J.; Wang, K.; Hu, H.; et al. Liquid–liquid triboelectric nanogenerator based on the immiscible interface of an aqueous two–phase system. Nat. Commun. 2022, 13, 5316. [Google Scholar] [CrossRef] [PubMed]

- Bockris, J.O.M.; Devanathan, M.A.V.; Müller, K. On the Structure of Charged Interfaces. In Modern Aspects of Electrochemistry; Bockris, J.O.M., Conway, B.E., Eds.; Butterworths: London, UK, 1964; Volume 3, pp. 832–863. [Google Scholar]

- Dai, K.; Wang, Y.; Li, B.; Li, P.; Wang, X.; Gao, L. Advancements in Solid–Liquid Nanogenerators: A Comprehensive Review and Future Prospects. Molecules 2024, 29, 5716. [Google Scholar] [CrossRef]

- Reymond, F.; Girault, H.H. Liquid/Liquid Interfaces, Electrochemistry at. In Encyclopedia of Analytical Chemistry; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Zhang, R.; Wang, X.; Chen, S.; Lin, H.; Tian, Y.; Shum, A.H.C. Liquid–Liquid Triboelectric Nanogenerator for Harvesting Distributed Energy. Adv. Funct. Mater. 2022, 32, 2208393. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, C.; Zhang, C.; Zhang, N.; Wang, Z.; Wu, Z.; Nie, S.; Wang, Z.L. Studying of contact electrification and electron transfer at liquid–liquid interface. Nano Energy 2021, 87, 106186. [Google Scholar] [CrossRef]

- Manojkumar, K.; Muthuramalingam, M.; Sateesh, D.; Hajra, S.; Panda, S.; Kim, H.J.; Sundaramoorthy, A.; Vivekananthan, V. Advances in triboelectric energy harvesting at liquid–liquid interfaces. ACS Appl. Energy Mater. 2025, 8, 659–682. [Google Scholar] [CrossRef]

- Wang, D.; Liu, T.; Wang, X.; Xu, T.; He, W.; Zhang, Y.; Li, X. Ethylene chlorotrifluoroethylene/hydrogel-based liquid-solid triboelectric nanogenerator driven self-powered MXene-based sensor system for marine environmental monitoring. Nano Energy 2022, 100, 107519. [Google Scholar] [CrossRef]

- Dong, Y.; Shan, C.; Luo, J.; He, W.; Liu, W.; Hu, C. Ring-shaped single-electrode triboelectric nanogenerator (RSE-TENG) for energy harvesting and liquid flow rate monitoring of gas-liquid two-phase flow. Nano Energy 2024, 119, 109083. [Google Scholar] [CrossRef]

- Dong, Y.; Luo, J.; Shan, C.; He, W.; Liu, W.; Hu, C. Gas-liquid two-phase flow-based triboelectric nanogenerator with ultrahigh output power. Sci. Adv. 2022, 8, eadd0464. [Google Scholar] [CrossRef]

- Shan, C.; Luo, J.; Dong, Y.; He, W.; Liu, W.; Hu, C. Harvesting environment mechanical energy by direct current triboelectric nanogenerators. Nat. Commun. 2023, 14, 127. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef]

- Li, C.; Wu, Q.; Wang, W.; Wang, X.; Wang, Z.L. Gas-driven triboelectric nanogenerator for mechanical energy harvesting and displacement monitoring. Nano Energy 2024, 126, 109681. [Google Scholar] [CrossRef]

- Lin, Z.-H.; Zhu, G.; Zhou, Y.S.; Yang, Y.; Bai, P.; Chen, J.; Wang, Z.L. Water-solid surface contact electrification and its use for harvesting liquid-wave energy. Angew. Chem. Int. Ed. 2013, 52, 12545–12549. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Long, Y.; Guo, H.; Gao, Q.; Wang, Z.L. Solid-liquid triboelectric nanogenerator based on vortex-induced resonance. Nat. Commun. 2023, 14, 1036. [Google Scholar]

- Chen, B.D.; Yang, Y.; Chen, J.; Li, Y.L.; Zhang, L.; Wang, Z.L. Water wave energy harvesting and self-powered liquid-surface fluctuation sensing based on bionic-jellyfish triboelectric nanogenerator. Mater. Today 2018, 21, 88–97. [Google Scholar] [CrossRef]

- Jiang, F.; Zhan, L.; Lee, J.P.; Lee, P.S. Triboelectric nanogenerators based on fluid medium: From fundamental mechanisms toward multifunctional applications. Adv. Mater. 2024, 36, 2308197. [Google Scholar] [CrossRef]

- Xu, M.; Wang, S.; Zhang, S.L.; Ding, W.; Li, X.; Zheng, P.; Pan, X.; Wang, Z.L. A highly-sensitive wave sensor based on liquid-solid interfacing triboelectric nanogenerator for smart marine equipment. Nano Energy 2019, 57, 574–580. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, G.; Yang, W.; Jing, Q.; Bai, P.; Yang, Y.; Hou, T.-C.; Wang, Z.L. Self-Powered Triboelectric Micro Liquid/Gas Flow Sensor for Microfluidics. ACS Nano 2016, 10, 8104–8112. [Google Scholar] [CrossRef]

- Ling, Z.; Wu, H.; Zheng, H.; Jin, Y.; Zhang, Z.; Zhang, Y.; Zhang, C. Influence of Molecular Structure and Material Properties on the Output Performance of Liquid-Solid Triboelectric Nanogenerators. ACS Appl. Mater. Interfaces 2023, 15, 1825. [Google Scholar] [CrossRef]

- Fan, C.; Wu, C.; Wen, G. Development of gas-liquid two-phase flow pattern sensor of coalbed methane based on the principle of triboelectric nanogenerator. Nanotechnology 2020, 31, 195501. [Google Scholar] [CrossRef]

- Wang, P.; Pan, L.; Wang, J.; Xu, M.; Dai, G.; Zou, H.; Dong, K.; Wang, Z.L. Non-contact and liquid-liquid interfacing triboelectric nanogenerator for self-powered water/liquid level sensing. Nano Energy 2020, 72, 104703. [Google Scholar] [CrossRef]

- Jo, I.-S.; Yoon, H.J.; Lee, S.K.; Sim, J.Y.; Lee, J.H.; Kim, S.J.; Choi, H. Recent progress in self-powered sensors for structural and human monitoring systems using thermoelectric energy harvesters. J. Korean Soc. Adv. Compos. Struct. 2024, 15, 67–78. [Google Scholar] [CrossRef]

- Karlen, W.; Ansermino, J.M.; Dumont, G. Adaptive pulse segmentation and artifact detection in photoplethysmography for mobile applications. In Proceedings of the 2012 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Diego, CA, USA, 28 August–1 September 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 3131–3134. [Google Scholar]

- Schäfer, A.; Vagedes, J. Estimation of breathing rate from respiratory sinus arrhythmia: Comparison of various methods. Ann. Biomed. Eng. 2013, 41, 1440–1448. [Google Scholar] [CrossRef] [PubMed]

- Ardila, C.M. Advancing healthcare through laboratory on a chip technology: Transforming microorganism identification and diagnostics. World J. Clin. Cases 2025, 13, 161–165. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wang, D.; Li, S.; Zhang, Z.; Zhang, Q.; Li, H.; Wang, Z.L. Triboelectric nanogenerator based self-powered sensor for artificial intelligence. Nano Energy 2021, 84, 105887. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, M.; Ma, L.; Zheng, H.; Liu, S.; Wang, Z.L. Synergistic enhancement of coaxial nanofiber-based triboelectric nanogenerator through dielectric and dispersity modulation. Nano Energy 2020, 75, 104894. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, X.; Yin, J.; Xu, Y.; Fei, W.; Xue, M.; Wang, Q.; Chen, J.; Wang, Z.L. A portable triboelectric nanogenerator for real-time respiration monitoring. Nanoscale Adv. 2019, 1, 1459–1467. [Google Scholar] [CrossRef]