Applications of the Digital Twin and the Related Technologies Within the Power Generation Sector: A Systematic Literature Review

Abstract

1. Introduction

- How can a balance be achieved between the trade-offs of transitioning to RES while maintaining existing power plants?

- How can the efficiency of both fossil-fuel-based power plants and RES be improved?

- How can faults be detected in both non-emissive and emissive power plants?

- How can energy systems, including power generation, microgrids, and associated equipment, be effectively managed?

- Quantitative Analysis—A systematic review of existing DT-driven research in the power generation sector, gathered from diverse sources, following the PRISMA protocol.

- Qualitative Assessment and Review—A comprehensive review of influential studies to identify trends and highlight the most common applications of DT technology in power generation.

- Categorization of DT Applications—An organized classification of DT applications in the power generation sector based on the reviewed literature.

2. Quantitative Review

2.1. Methodology

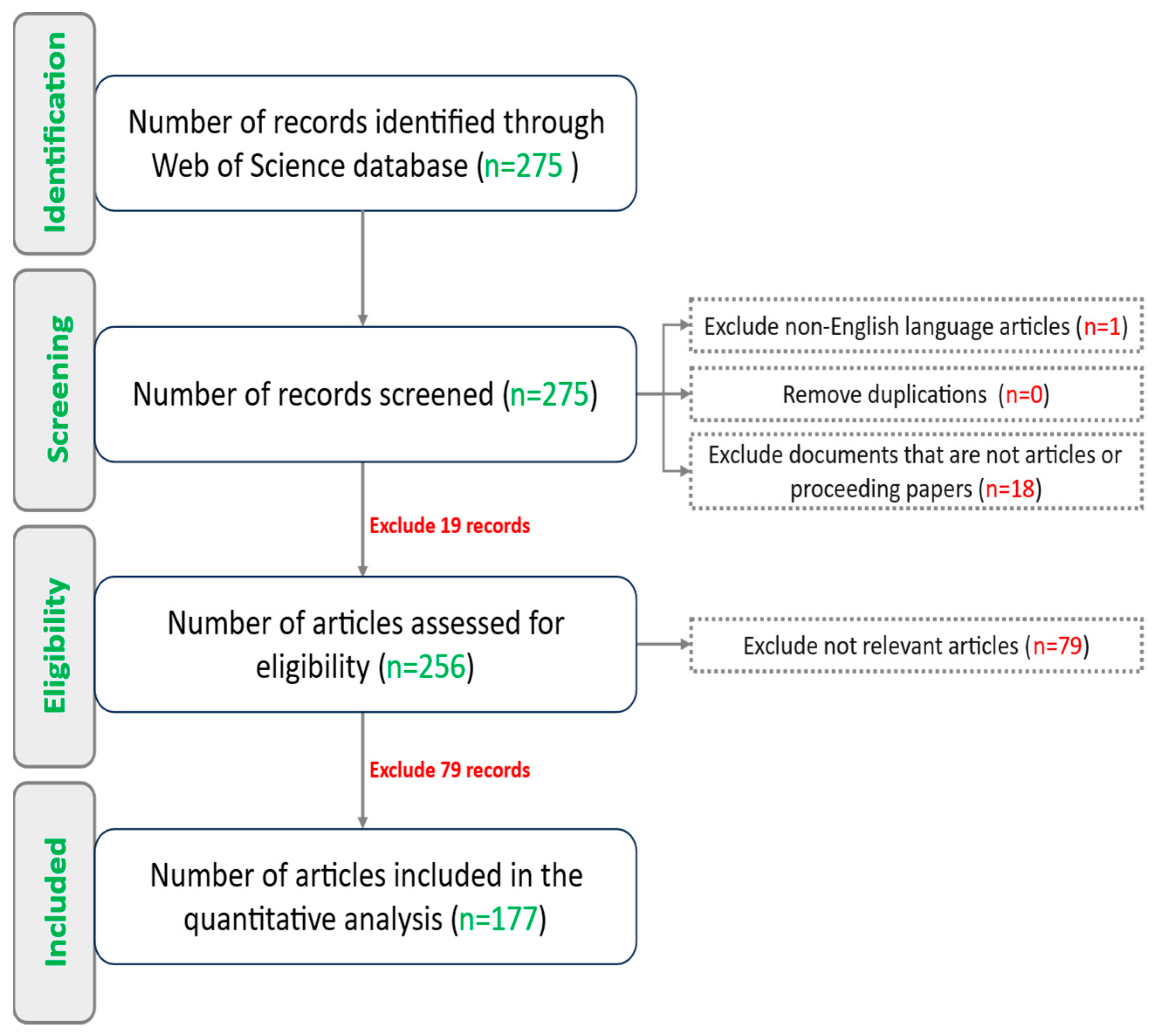

- Identification: To ensure a thorough review, multiple databases and search queries were evaluated to identify the most suitable source for this study. After comparing their scope and relevance, the Web of Science is selected as the primary database due to its broad inclusion of high-impact research from various fields, making it well-suited for an in-depth review. A comprehensive search was conducted in November 2024 using the Web of Science database. A tailored search query targeted titles, keywords, and abstracts related to DT and power generation technologies (Search query: “digital twin*” AND (“power plant” OR “power generation” OR “main shaft” OR “transformer*”)). Boolean operators and wildcard symbols enhanced precision. This search yielded 275 studies.

- Screening: Non-English articles (1) and non-article documents (18) were excluded, leaving 256 records.

- Eligibility: A detailed assessment excluded 79 irrelevant studies, reducing the dataset to 177 articles.

- Inclusion: The final dataset of 177 articles represents the most relevant research. Figure 1 summarizes this process using a PRISMA flowchart.

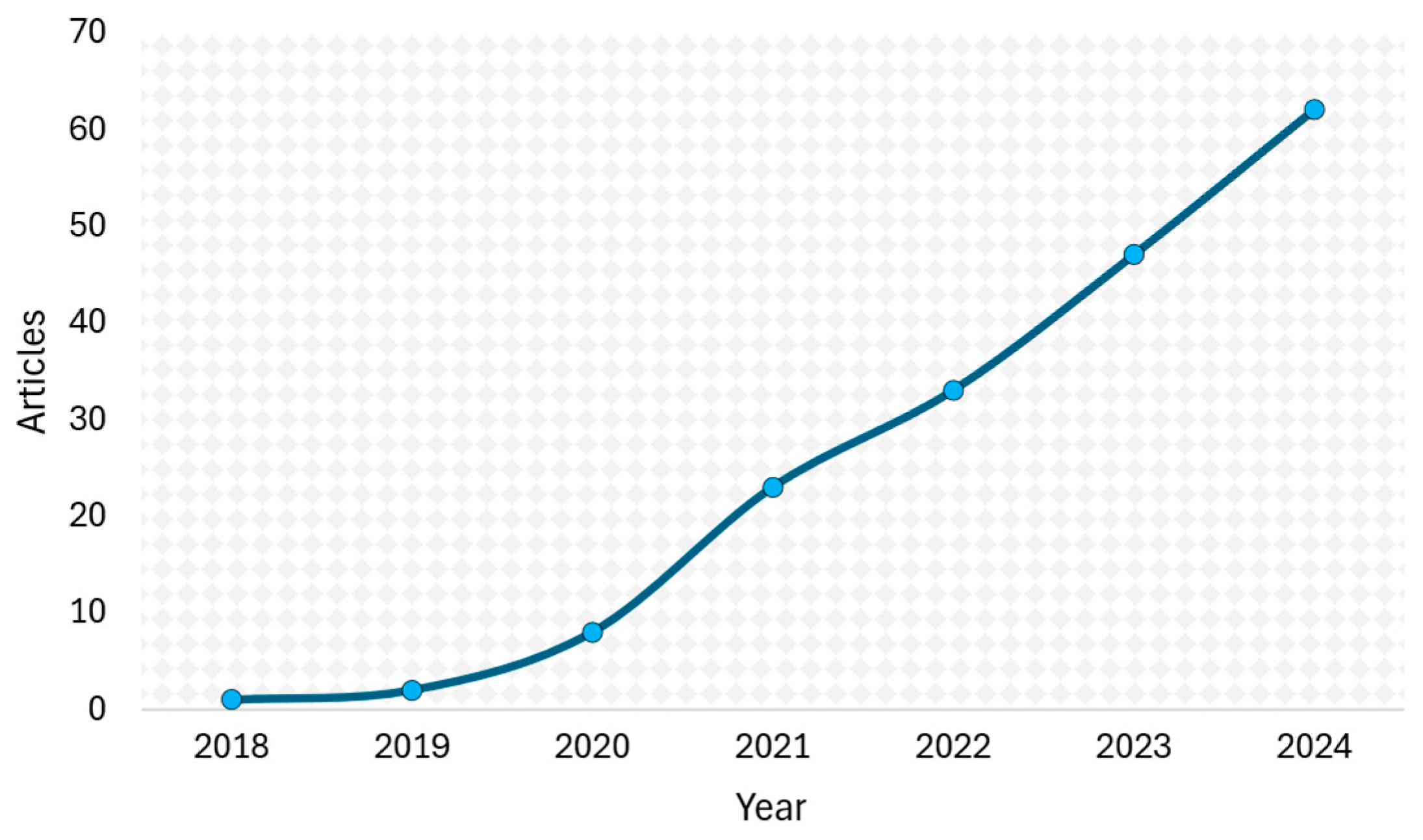

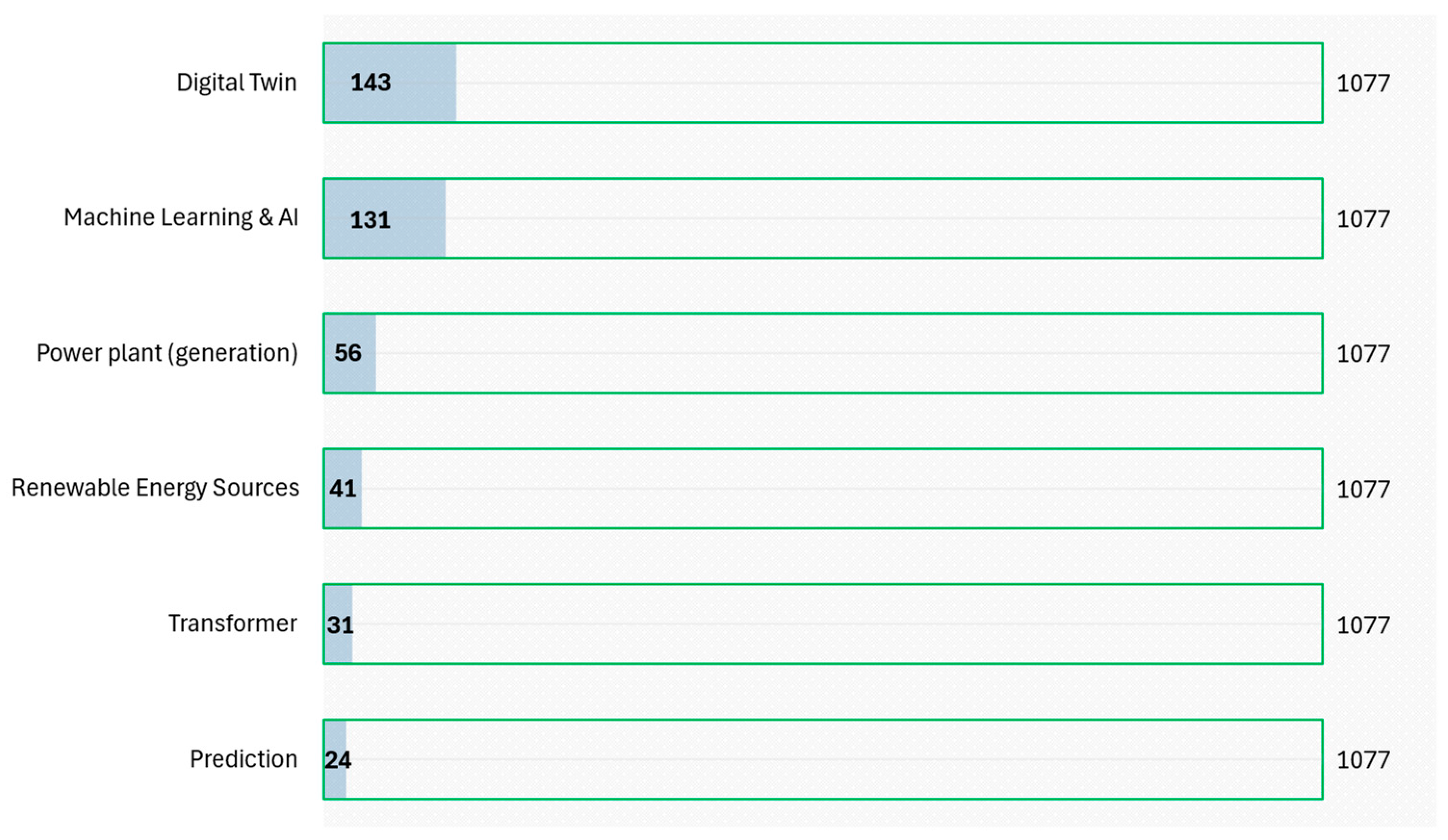

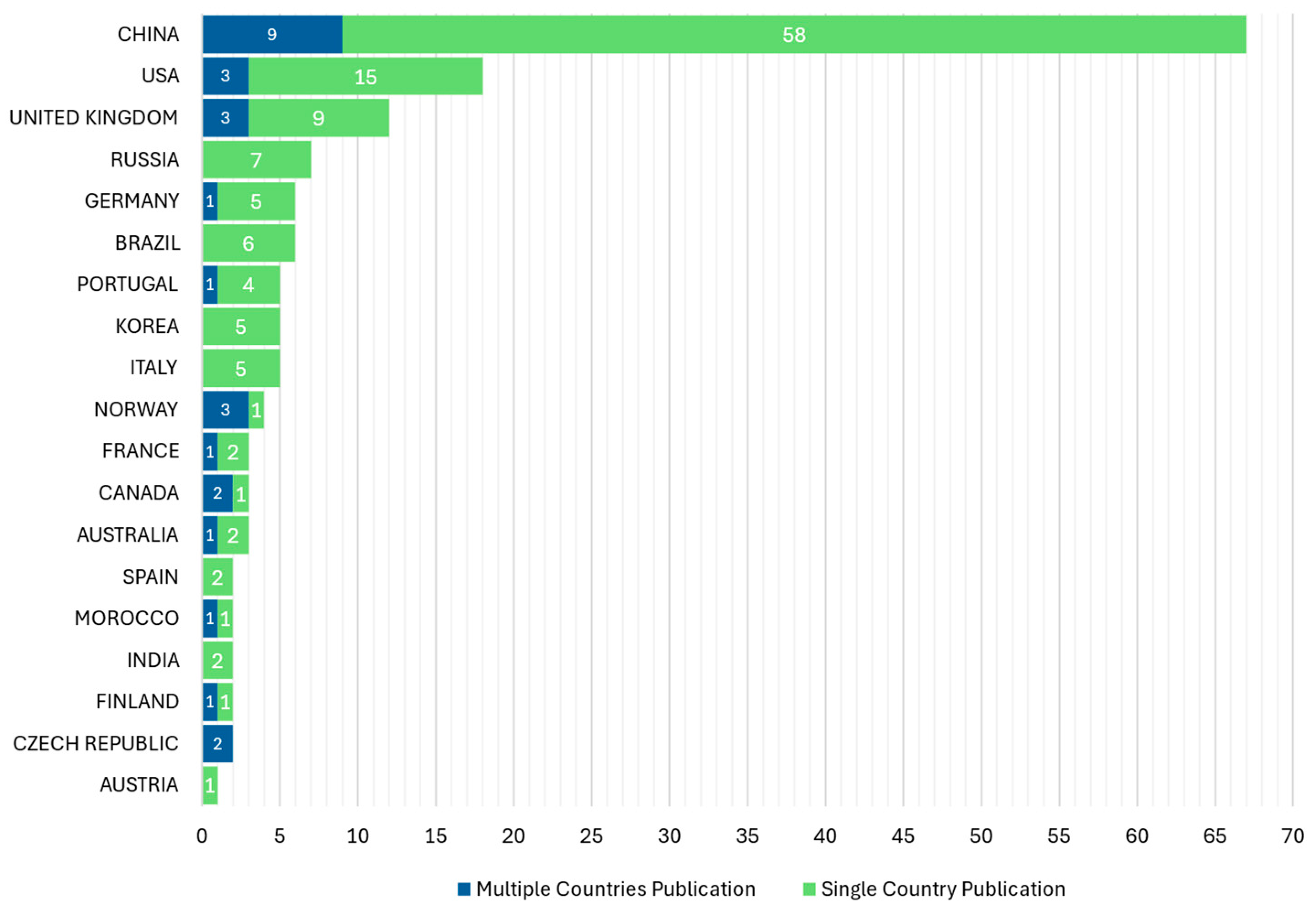

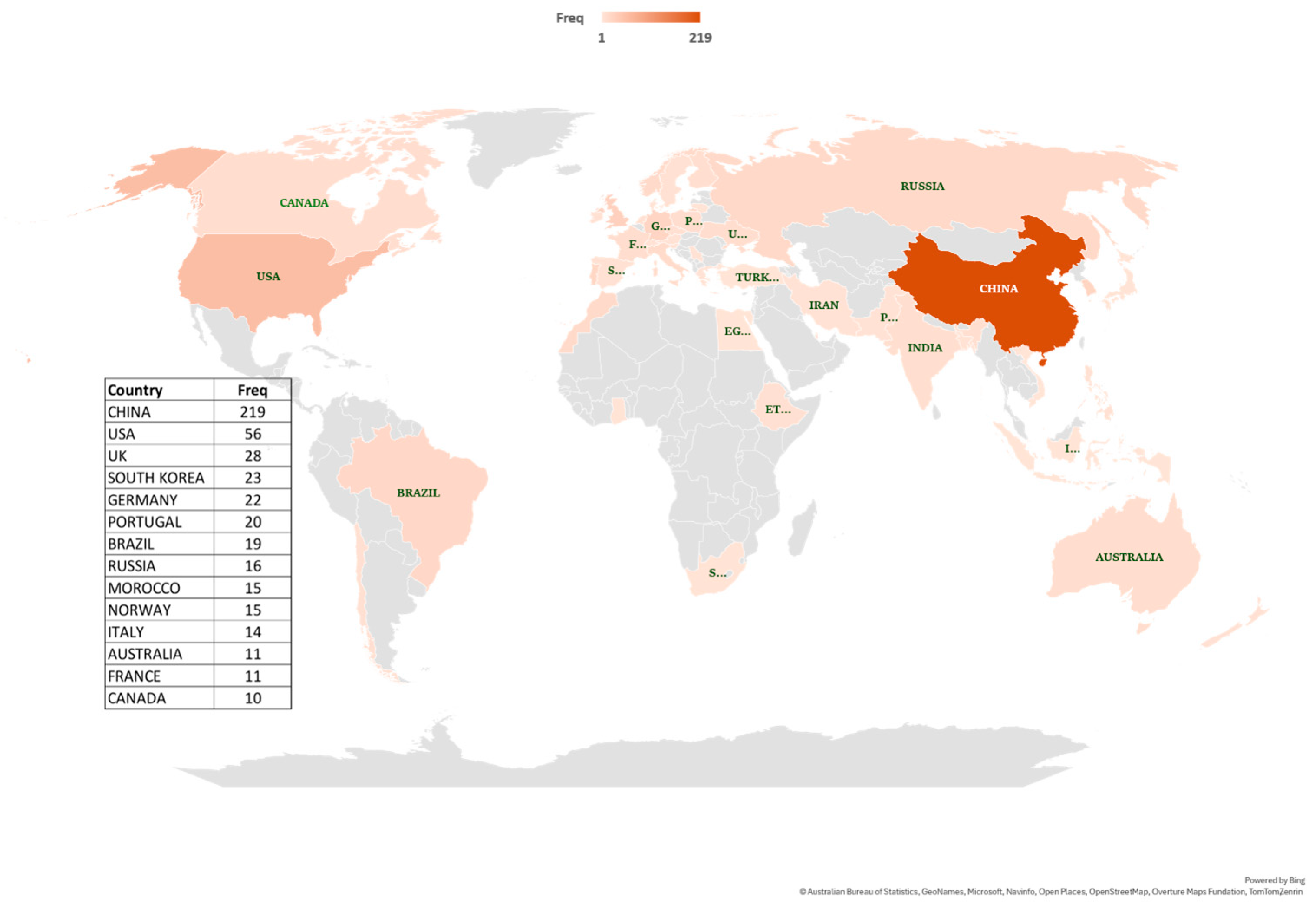

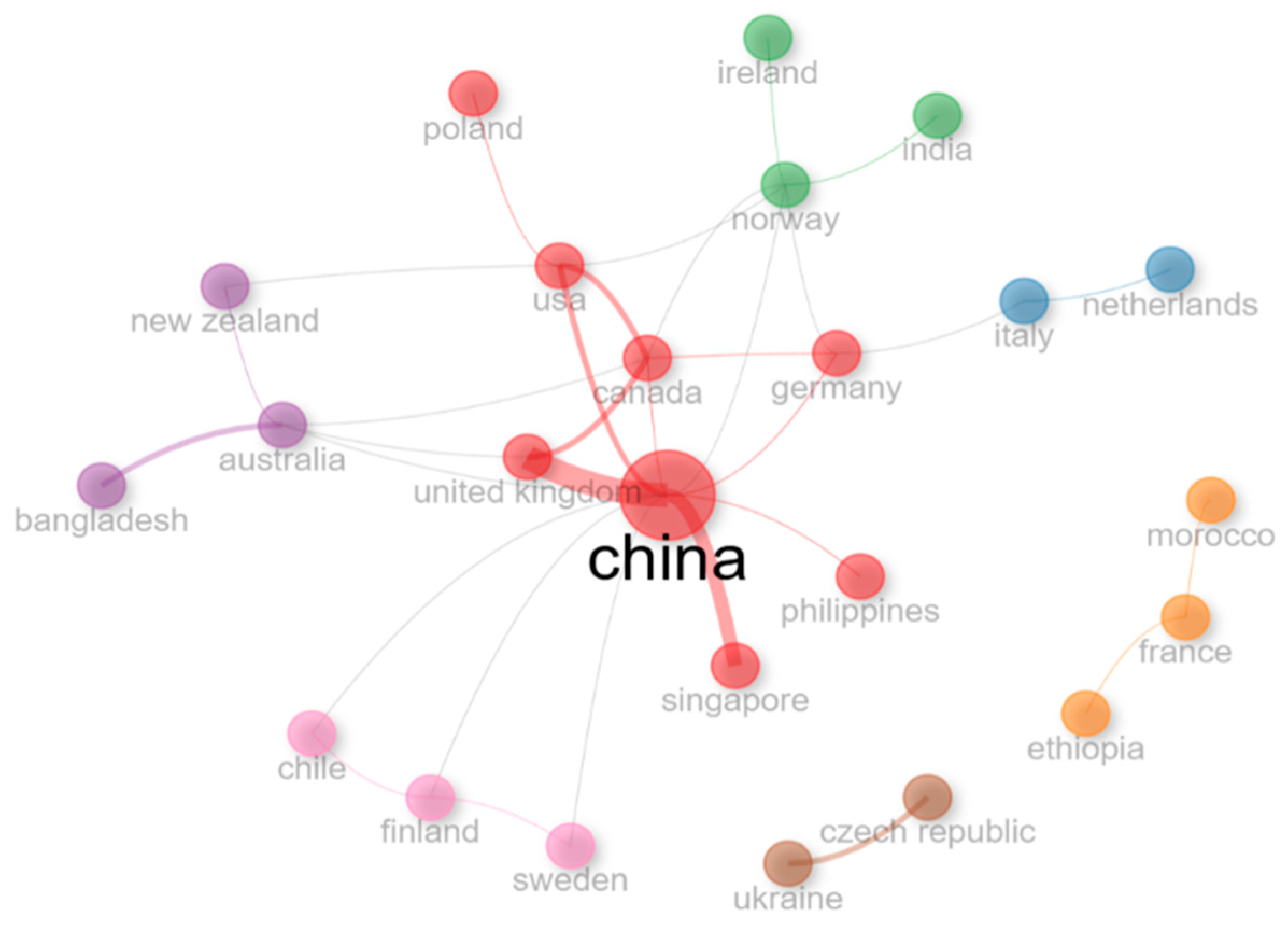

2.2. Results of Quantitative Analysis

2.3. Selection of the Most Appropriate Documents

2.3.1. Similarity Index

2.3.2. SJR Score

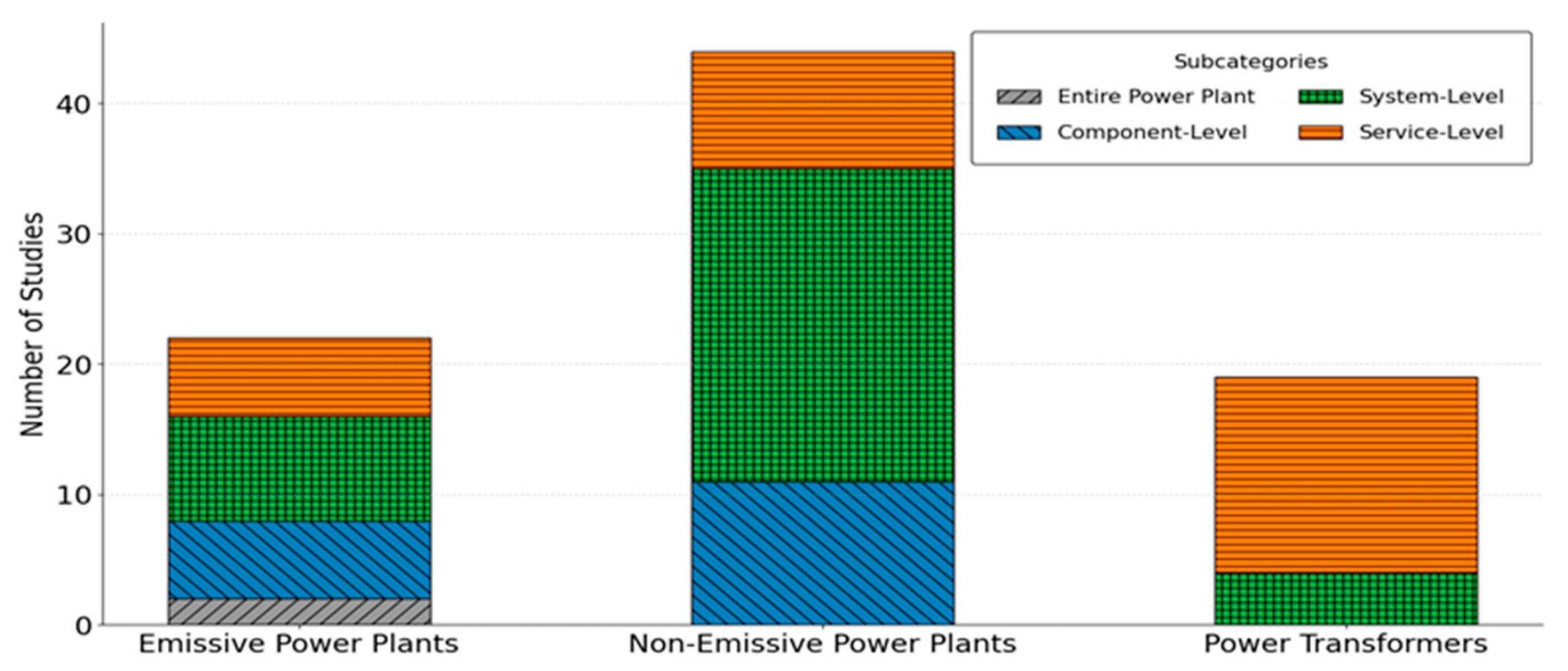

2.4. Discussion on Quantitative Analysis

- Component-Level: This subcategory includes studies that focus on the individual components of the power plant, such as turbines, rotors, blades, and cooling systems. These papers typically analyze the performance and behavior of specific parts of the system, including their material properties and operational characteristics.

- System-Level: The system-level subcategory involves papers that examine the interaction and optimization of multiple components within the power generation system. These studies often explore how different subsystems (e.g., turbines, generators, and transformers) work together to achieve optimal performance, such as reducing losses or increasing output power. Papers in this category typically focus on system-wide control, efficiency improvements, and integrated operations, sometimes including modeling and simulation of various system configurations.

- Service-Level: This subcategory focuses on the value-added services provided by DTs for the operational management of power plants. Services such as condition monitoring (CM), predictive maintenance (PM), fault detection, and other maintenance management functions directly impact the overall performance of power plants, leading to improved asset longevity and reduced potential failures.

3. Qualitative Review

3.1. DT Technology: Definitions

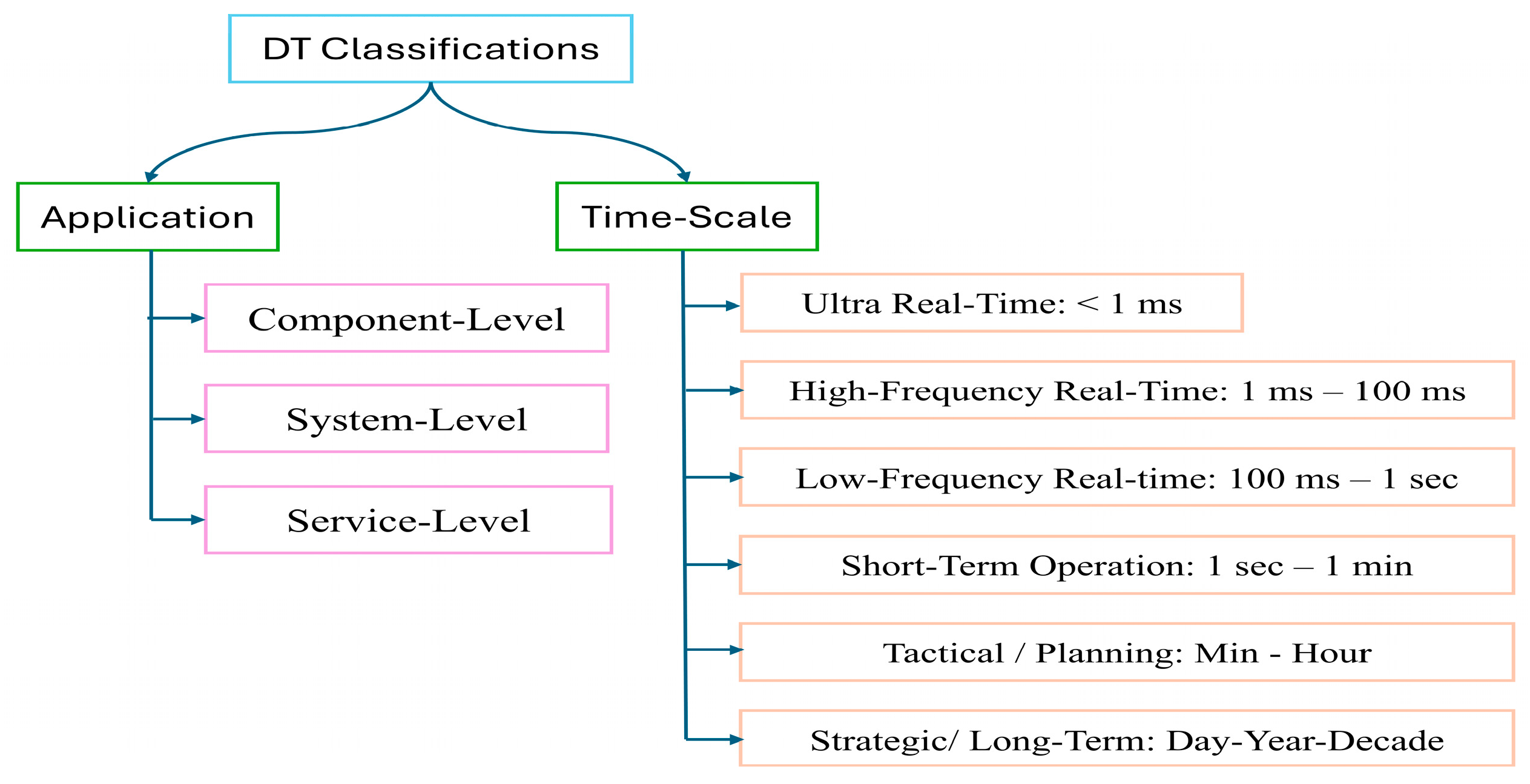

3.2. DT Technology: Time-Scale Classifications

- High-Frequency Real-Time (1–100 ms): The vibration signal analysis for OLTC (Online Tap-Changer) operation is conducted using a high sampling rate of 10,240 Hz.

- Low-Frequency Real-Time (100 ms−1 s): Vibration signals generated by OLTC operations are recorded over approximately 0.2 s.

- Short-Term Operational (1 s−1 min): The study applies dynamic model updating and optimization-based estimation after each OLTC operation.

- Strategic/Long-Term (Days–Years–Decades): It also tracks degradation trends such as spring looseness and delays in diverter switching due to wear.

3.3. Digital Twin Applications in Emissive Power Plants

3.3.1. Component-Level Digital Twins

3.3.2. System-Level Digital Twins

3.3.3. Service-Level Digital Twins: Reliability and Maintenance

3.4. Non-Emissive Power Plants

3.4.1. Component-Level Applications

3.4.2. System-Level Applications

3.4.3. Service-Level Digital Twins: Reliability and Maintenance

3.5. Power Transformer

3.5.1. System-Level Applications

3.5.2. Service-Level Digital Twins: Reliability and Maintenance

4. Conclusions and Challenges

4.1. Emissive Power Plants

4.2. Non-Emissive Power Plants

4.3. Power Transformer

4.4. Future Direction

- Advanced fault detection using AI-driven DT models that improve real-time PM and reduce downtime across both emissive and non-emissive plants.

- Optimization of RES integration through DTs, especially for wind, solar, and energy storage systems, to improve grid stability and minimize curtailment.

- Integration of DTs with microgrids to enable dynamic optimization, ensuring resilience and autonomous operation during grid failures.

- Collaborative DT research for cyber-physical systems to enhance the interoperability and robustness of DERs, smart grids, and VPPs.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, W.; Chen, P. The political economy of air pollution: Local development, sustainability, and political incentives in China. Energy Res. Soc. Sci. 2020, 69, 101707. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Karimipouya, A.; Ghezelbashan, A.; Shahmoradi, S. Frequency Control in the Presence of Dynamic Model of Induction Motor Based on Virtual Inertia. In Proceedings of the 2023 3rd International Conference on Electrical Machines and Drives (ICEMD), Tehran, Iran, 20–21 December 2023; pp. 1–9. [Google Scholar]

- Shivakumar, V.; Veena, M.B. Cybersecurity and IEC 62351 for SCADA Systems of Power Grid. SSRG Int. J. Electr. Electron. Eng. 2024, 11, 36–52. [Google Scholar] [CrossRef]

- He, W.; Baig, M.J.; Iqbal, M.T. An Internet of Things—Supervisory Control and Data Acquisition (IoT-SCADA) Architecture for Photovoltaic System Monitoring, Control, and Inspection in Real Time. Electronics 2025, 14, 42. [Google Scholar] [CrossRef]

- Mischos, S.; Dalagdi, E.; Vrakas, D. Intelligent energy management systems: A review. Artif. Intell. Rev. 2023, 56, 11635–11674. [Google Scholar] [CrossRef]

- Strezoski, L. Distributed energy resource management systems—DERMS: State of the art and how to move forward. WIREs Energy Environ. 2023, 12, e460. [Google Scholar] [CrossRef]

- Yang, C.; Sun, Y.; Zou, Y.; Zheng, F.; Liu, S.; Zhao, B.; Wu, M.; Cui, H. Optimal Power Flow in Distribution Network: A Review on Problem Formulation and Optimization Methods. Energies 2023, 16, 5974. [Google Scholar] [CrossRef]

- Safari, A.; Daneshvar, M.; Anvari-Moghaddam, A. Energy Intelligence: A Systematic Review of Artificial Intelligence for Energy Management. Appl. Sci. 2024, 14, 11112. [Google Scholar] [CrossRef]

- Gore, R.; Kande, M. Analysis of Wide Area Monitoring System architectures. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; pp. 1269–1274. [Google Scholar]

- Bazmohammadi, N.; Madary, A.; Vasquez, J.C.; Mohammadi, H.B.; Khan, B.; Wu, Y.; Guerrero, J.M. Microgrid Digital Twins: Concepts, Applications, and Future Trends. IEEE Access 2022, 10, 2284–2302. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence Through Virtual Factory Replication; Digital Twin: San Jose, Costa Rica, 2014. [Google Scholar]

- National Aeronautics and Space Administration. Modeling, Simulation, Information Technology & Processing Roadmap; NASA: Washington, DC, USA, 2010.

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. Int. J. Aerosp. Eng. 2011, 2011, 154798. [Google Scholar] [CrossRef]

- Yin, Z.H.; Wang, L. Application and Development Prospect of Digital Twin Technology in Aerospace. IFAC-PapersOnLine 2020, 53, 732–737. [Google Scholar] [CrossRef]

- Pan, H.; Dou, Z.; Cai, Y.; Li, W.; Lei, X.; Han, D. Digital Twin and Its Application in Power System. In Proceedings of the 2020 5th International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 12–14 September 2020; pp. 21–26. [Google Scholar]

- Danilczyk, W.; Sun, Y.; He, H. ANGEL: An Intelligent Digital Twin Framework for Microgrid Security. In Proceedings of the 2019 North American Power Symposium (NAPS), Wichita, KS, USA, 13–15 October 2019; pp. 1–6. [Google Scholar]

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital twin in energy industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- Pritchard, A. Statistical bibliography or bibliometrics. J. Doc. 1969, 25, 348–349. [Google Scholar]

- Huang, L.; Liu, F.; Zhang, Y. Overlapping Community Discovery for Identifying Key Research Themes. IEEE Trans. Eng. Manag. 2020, 68, 1321–1333. [Google Scholar] [CrossRef]

- Manesh, M.F.; Pellegrini, M.M.; Marzi, G.; Dabic, M. Knowledge management in the fourth industrial revolution: Mapping the literature and scoping future avenues. IEEE Trans. Eng. Manag. 2020, 68, 289–300. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Group, P. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Imani, M.H.; Bompard, E.; Colella, P.; Huang, T. Data analytics in the electricity market: A systematic literature review. Energy Syst. 2023, 16, 1–35. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Bird, S.; Klein, E.; Loper, E. Natural Language Processing with Python: Analyzing Text with the Natural Language Toolkit; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2009; ISBN 0596555717. [Google Scholar]

- vom Scheidt, F.; Medinová, H.; Ludwig, N.; Richter, B.; Staudt, P.; Weinhardt, C. Data analytics in the electricity sector–a quantitative and qualitative literature review. Energy AI 2020, 1, 100009. [Google Scholar] [CrossRef]

- Scimago Journal & Country Rank. Available online: https://www.scimagojr.com/journalrank.php (accessed on 6 November 2024).

- González, M.; Salgado, O.; Croes, J.; Pluymers, B.; Desmet, W. A Digital Twin for Operational Evaluation of Vertical Transportation Systems. IEEE Access 2020, 8, 114389–114400. [Google Scholar] [CrossRef]

- Venkatesh, K.P.; Brito, G.; Kamel Boulos, M.N. Health Digital Twins in Life Science and Health Care Innovation. Annu. Rev. Pharmacol. Toxicol. 2024, 64, 159–170. [Google Scholar] [CrossRef]

- Madusanka, N.S.; Fan, Y.; Yang, S.; Xiang, X. Digital Twin in the Maritime Domain: A Review and Emerging Trends. J. Mar. Sci. Eng. 2023, 11, 1021. [Google Scholar] [CrossRef]

- Shahmoradi, S.; Mazza, A.; Pons, E. Digital Twin Applications in the Energy Sector. In Proceedings of the 2024 AEIT International Annual Conference (AEIT), Trento, Italy, 25–27 September 2024; pp. 1–6. [Google Scholar]

- Zhang, C.; Zhou, G.; Li, H.; Cao, Y. Manufacturing Blockchain of Things for the Configuration of a Data- and Knowledge-Driven Digital Twin Manufacturing Cell. IEEE Internet Things J. 2020, 7, 11884–11894. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Yang, B.; Zhu, L.; Liu, F. Big data driven Hierarchical Digital Twin Predictive Remanufacturing paradigm: Architecture, control mechanism, application scenario and benefits. J. Clean. Prod. 2020, 248, 119299. [Google Scholar] [CrossRef]

- Lei, Z.; Zhou, H.; Hu, W.; Liu, G.-P.; Guan, S.; Feng, X. Toward a Web-Based Digital Twin Thermal Power Plant. IEEE Trans. Ind. Inform. 2022, 18, 1716–1725. [Google Scholar] [CrossRef]

- Yu, J.; Petersen, N.; Liu, P.; Li, Z.; Wirsum, M. Hybrid modelling and simulation of thermal systems of in-service power plants for digital twin development. Energy 2022, 260, 125088. [Google Scholar] [CrossRef]

- Li, L.; Ma, H.; Wei, M.; Zhang, X.; Chen, Q.; Xin, Y. Thermal Power Plant Turbine Rotor Digital Twin Automation Construction and Monitoring System. Math. Probl. Eng. 2022, 2022, 8527281. [Google Scholar] [CrossRef]

- Junior, C.A.A.d.A.; Villanueva, J.M.M.; de Almeida, R.J.S.; de Medeiros, I.E.A. Digital Twins of the Water Cooling System in a Power Plant Based on Fuzzy Logic. Sensors 2021, 21, 6737. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Cai, Y.; Jiang, H. Recurrent Neural Network-Based Hybrid Modeling Method for Digital Twin of Boiler System in Coal-Fired Power Plant. Appl. Sci. 2023, 13, 4905. [Google Scholar] [CrossRef]

- Wang, Y.; Qi, Y.; Li, J.; Huan, L.; Li, Y.; Xie, B.; Wang, Y. The Wind and Photovoltaic Power Forecasting Method Based on Digital Twins. Appl. Sci. 2023, 13, 8374. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Li, T.; Gui, Y.; Sun, Q.; Gao, D.W. Digital Twin Empowered PV Power Prediction. J. Mod. Power Syst. Clean Energy 2024, 12, 1472–1483. [Google Scholar] [CrossRef]

- Hong, Y.-Y.; Pula, R.A. Diagnosis of PV faults using digital twin and convolutional mixer with LoRa notification system. Energy Reports 2023, 9, 1963–1976. [Google Scholar] [CrossRef]

- Kaitouni, S.I.; Abdelmoula, I.A.; Es-sakali, N.; Mghazli, M.O.; Er-retby, H.; Zoubir, Z.; El Mansouri, F.; Ahachad, M.; Brigui, J. Implementing a Digital Twin-based fault detection and diagnosis approach for optimal operation and maintenance of urban distributed solar photovoltaics. Renew. Energy Focus 2024, 48, 100530. [Google Scholar] [CrossRef]

- Guo, Z.; Ye, Z.; Ni, P.; Cao, C.; Wei, X.; Zhao, J.; He, X. Intelligent Digital Twin Modelling for Hybrid PV-SOFC Power Generation System. Energies 2023, 16, 2806. [Google Scholar] [CrossRef]

- Sultanov, M.M.; Arakelyan, E.K.; Boldyrev, I.A.; Lunenko, V.S.; Menshikov, P.D. Digital twins application in control systems for distributed generation of heat and electric energy. Arch. Thermodyn. 2021, 42, 89–101. [Google Scholar] [CrossRef]

- Kanchiralla, F.M.; Jalo, N.; Thollander, P.; Andersson, M.; Johnsson, S. Energy use categorization with performance indicators for the food industry and a conceptual energy planning framework. Appl. Energy 2021, 304, 117788. [Google Scholar] [CrossRef]

- de Carvalho Michalski, M.A.; de Andrade Melani, A.H.; da Silva, R.F.; de Souza, G.F. A Fault Detection Framework Based on Data-Driven Digital Shadows. ASCE-ASME J. Risk Uncert. Eng. Syst. Part B Mech. Eng. 2024, 10, 011103. [Google Scholar] [CrossRef]

- Park, H.-A.; Byeon, G.; Son, W.; Kim, J.; Kim, S. Data-Driven Modeling of HVAC Systems for Operation of Virtual Power Plants Using a Digital Twin. Energies 2023, 16, 7032. [Google Scholar] [CrossRef]

- El Houda, Z.A.; Brik, B. Next-power: Next-generation framework for secure and sustainable energy trading in the metaverse. Ad Hoc Netw. 2023, 149, 103243. [Google Scholar] [CrossRef]

- Jing, Y.; Wang, X.; Yu, Z.; Wang, C.; Liu, Z.; Li, Y. Diagnostic Research for the Failure of Electrical Transformer Winding Based on Digital Twin Technology. IEEJ Trans. Electr. Electron. Eng. 2022, 17, 1629–1636. [Google Scholar] [CrossRef]

- Feng, J.; Zhao, N.; Wang, B. Digital Twin-Driven Hot Spot Capture for Power Transformer Interturn Short-Circuit Fault Diagnosis Based on Microthermal Field. IEEE Trans. Instrum. Meas. 2024, 73, 3532613. [Google Scholar] [CrossRef]

- Yao, H.; Zhang, X.; Guo, Q.; Miao, Y.; Guan, S. Fault diagnosis method for oil-immersed transformers integrated digital twin model. Sci. Rep. 2024, 14, 20355. [Google Scholar] [CrossRef]

- Abo-Khalil, A.G. Digital twin real-time hybrid simulation platform for power system stability. Case Stud. Therm. Eng. 2023, 49, 103237. [Google Scholar] [CrossRef]

- Padmawansa, N.; Gunawardane, K.; Madanian, S.; Than Oo, A.M. Battery Energy Storage Capacity Estimation for Microgrids Using Digital Twin Concept. Energies 2023, 16, 4540. [Google Scholar] [CrossRef]

- ABB. Digital Twin. Available online: https://search.abb.com/library/Download.aspx?Action=Launch&DocumentID=9AKK107046A8849&DocumentPartId=&LanguageCode=en (accessed on 12 March 2025).

- GE. What is Digital Twin? Available online: https://www.gevernova.com/software/blog/what-digital-twin (accessed on 12 March 2025).

- Siemens. Digital Twin. Available online: https://www.plm.automation.siemens.com/global/en/our-story/glossary/digital-twin/24465 (accessed on 12 March 2025).

- Microsoft. Microsoft Azure Digital Twin. Available online: https://azure.microsoft.com/en-us/services/digital-twins/ (accessed on 12 March 2025).

- Thaler, B.; Posch, S.; Wimmer, A.; Pirker, G. Hybrid model predictive control of renewable microgrids and seasonal hydrogen storage. Int. J. Hydrogen Energy 2023, 48, 38125–38142. [Google Scholar] [CrossRef]

- Chen, C.; Liu, M.; Li, M.; Wang, Y.; Wang, C.; Yan, J. Digital twin modeling and operation optimization of the steam turbine system of thermal power plants. Energy 2024, 290, 129969. [Google Scholar] [CrossRef]

- Baker, M.; Rosic, B. The Hybrid Pathway to Flexible Power Turbines, Part I: Novel Autoencoder Methods for the Automated Optimization of Thermal Probes and Fast Sparse Data Reconstruction, Enabling Real-Time Thermal Analysis. J. Eng. Gas Turbines Power 2024, 146, 031020. [Google Scholar] [CrossRef]

- Baker, M.; Rosic, B. The Hybrid Pathway to Flexible Power Turbines, Part II: Fast Data Transfer Methods Between Varying Fidelity Simulations, to Enable Efficient Conjugate Thermal Field Prediction. J. Eng. Gas Turbines Power 2024, 146, 031021. [Google Scholar] [CrossRef]

- Ghita, M.; Siham, B.; Hicham, M.; Amine, M. HT-TPP: A Hybrid Twin Architecture for Thermal Power Plant Collaborative Condition Monitoring. Energies 2022, 15, 5383. [Google Scholar] [CrossRef]

- Zhao, Y.; Cai, Y.; Jiang, H. Digital twin-based subspace model predictive control for thermal power plant. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2023, 237, 1171–1186. [Google Scholar] [CrossRef]

- Yu, J.; Liu, P.; Li, Z. Data reconciliation-based simulation of thermal power plants for performance estimation and digital twin development. Comput. Chem. Eng. 2022, 168, 108063. [Google Scholar] [CrossRef]

- Zhou, D.; Gao, H.; Wang, W.; Cao, J.; Yang, W.; Zeng, R.; He, Y. Application of Three-Flow Fusion Technology Based on Modelica in Thermal Power Digital Twin. IEEE J. Radio Freq. Identif. 2022, 6, 715–723. [Google Scholar] [CrossRef]

- Deon, B.; Cotta, K.P.; Silva, R.F.V.; Batista, C.B.; Justino, G.T.; Freitas, G.C.; Cordeiro, A.M.; Barbosa, A.S.; Loucao, F.L., Jr.; Simioni, T.; et al. Digital twin and machine learning for decision support in thermal power plant with combustion engines. Knowl.-Based Syst. 2022, 253, 109578. [Google Scholar] [CrossRef]

- Spinti, J.P.; Smith, P.J.; Smith, S.T. Atikokan Digital Twin: Machine learning in a biomass energy system. Appl. Energy 2022, 310, 118436. [Google Scholar] [CrossRef]

- Spinti, J.P.; Smith, P.J.; Smith, S.T.; Diaz-Ibarra, O.H. Atikokan Digital Twin, Part B: Bayesian decision theory for process optimization in a biomass energy system. Appl. Energy 2023, 334, 120625. [Google Scholar] [CrossRef]

- Ersan, M.; Irmak, E. Development and Integration of a Digital Twin Model for a Real Hydroelectric Power Plant. Sensors 2024, 24, 4174. [Google Scholar] [CrossRef]

- Fahim, M.; Sharma, V.; Cao, T.-V.; Canberk, B.; Duong, T.Q. Machine Learning-Based Digital Twin for Predictive Modeling in Wind Turbines. IEEE Access 2022, 10, 14184–14194. [Google Scholar] [CrossRef]

- Belik, M.; Rubanenko, O. Implementation of Digital Twin for Increasing Efficiency of Renewable Energy Sources. Energies 2023, 16, 4787. [Google Scholar] [CrossRef]

- Vieira, J.; de Almeida, N.M.; Martins, J.P.; Patricio, H.; Morgado, J.G. Analysing the Value of Digital Twinning Opportunities in Infrastructure Asset Management. Infrastructures 2024, 9, 158. [Google Scholar] [CrossRef]

- Dong, X.; Huang, J.; Luo, N.; Hu, W.; Lei, Z. Design and Implementation of Digital Twin Diesel Generator Systems. Energies 2023, 16, 6422. [Google Scholar] [CrossRef]

- Lichte, D.; Torres, F.S.; Engler, E. Framework for Operational Resilience Management of Critical Infrastructures and Organizations. Infrastructures 2022, 7, 70. [Google Scholar] [CrossRef]

- Wang, P.; Ma, Y.; Zhao, H. Online assessment of multi-parameter stability region and stability margin of wind power plants. Int. J. Electr. Power Energy Syst. 2024, 155, 109413. [Google Scholar] [CrossRef]

- Benato, A.; De Vanna, F.; Stoppato, A. Levelling the Photovoltaic Power Profile with the Integrated Energy Storage System. Energies 2022, 15, 9521. [Google Scholar] [CrossRef]

- Hanzala, M.; Memon, Z.; Hussain, M.I.; Azeem, F.; Shahzad, N.; Kim, J.-T. Fuzzy-Logic-Based Cascaded Decentralized Control and Power Quantification of Residential Buildings for Effective Energy Load Management. Buildings 2024, 14, 2896. [Google Scholar] [CrossRef]

- Xiao, L.; Han, D.; Yang, C.; Cai, J.; Liang, W.; Li, K.-C. TS-DP: An Efficient Data Processing Algorithm for Distribution Digital Twin Grid for Industry 5.0. IEEE Trans. Consum. Electron. 2024, 70, 1983–1994. [Google Scholar] [CrossRef]

- Natgunanathan, I.; Mak-Hau, V.; Rajasegarar, S.; Anwar, A. Deakin microgrid digital twin and analysis of AI models for power generation prediction. Energy Convers. Manag. 2023, 18, 100370. [Google Scholar] [CrossRef]

- Jiang, H.; Tjandra, R.; Soh, C.B.; Cao, S.; Soh, D.C.L.; Tan, K.T.; Tseng, K.J.; Krishnan, S.B. Digital Twin of Microgrid for Predictive Power Control to Buildings. Sustainability 2024, 16, 482. [Google Scholar] [CrossRef]

- Espin-Sarzosa, D.; Palma-Behnke, R.; Valencia-Arroyave, F. Towards Digital Twins of Small Productive Processes in Microgrids. Energies 2023, 16, 4324. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, C.; Gao, M.; Xu, Y.; Fu, M.; Zhuo, R. Improved thermal hydraulic network modelling and error analysis in disc-type transformer windings. IET Gener. Transm. Distrib. 2024, 18, 202–213. [Google Scholar] [CrossRef]

- Wu, T.; Yang, F.; Farooq, U.; Li, X.; Jiang, J. An online learning method for constructing self-update digital twin model of power transformer temperature prediction. Appl. Therm. Eng. 2024, 237, 121728. [Google Scholar] [CrossRef]

- Wang, L.; Dong, X.; Jing, L.; Li, T.; Zhao, H.; Zhang, B. Research on digital twin modeling method of transformer temperature field based on POD. Energy Rep. 2023, 9, 299–307. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, Y.; Liu, G.; Hu, W.; Wang, W.; Wang, B. Fast calculation of temperature distribution in oil-immersed transformer windings based on U-net neural network. AIP Adv. 2023, 13, 035132. [Google Scholar] [CrossRef]

- Ma, A.; Gao, D.; Qin, T.; Wang, W. Identification method for inter-turn faults in transformers based on digital twin concept. Front. Energy Res. 2024, 12, 1376306. [Google Scholar] [CrossRef]

- Zhang, L.; Sheng, G.; Zhou, N.; Ni, Z.; Jiang, X. Incipient interturn fault detection for ONAN power transformers using electrothermal characteristic fusion analysis. IET Gener. Transm. Distrib. 2024, 18, 1871–1884. [Google Scholar] [CrossRef]

- Jing, Y.; Liu, Z.; Liu, Y.; Yu, Z.; Li, Y. Research on Digital Technology of Mechanical Structure Fault Diagnosis of Power Transformer Based on Comprehensive Feature Extraction and SABO-PNN. IEEE Trans. Appl. Supercond. 2024, 34, 5501204. [Google Scholar] [CrossRef]

- Liu, J.; Yao, C.; Yu, L.; Dong, S.; Liu, Y. Using MLP to locate transformer winding fault based on digital twin. Front. Energy Res. 2023, 11, 1175808. [Google Scholar] [CrossRef]

- Li, Z.; Liu, K.; Lin, M.; Xin, D.; Tang, H.; Wu, G. A zero-sample state evaluation model for valve-side bushing of UHV converter transformer oriented to digital twin under attribute analysis. IET Gener. Transm. Distrib. 2023, 17, 1123–1134. [Google Scholar] [CrossRef]

- Etxegarai, A.; Valverde, V.; Eguia, P.; Perea, E. Analysis of Loss of Life of Dry-Type WTSU Transformers in Offshore Wind Farms. Int. J. Renew. Energy Res. 2020, 10, 448–455. [Google Scholar] [CrossRef]

- Szulborski, M.; Lapczynski, S.; Kolimas, L.; Kozarek, L.; Cichecki, H.; Sul, P.; Owsinski, M.; Berowski, P.; Baczynski, D.; Wesolowski, M. Examination of Electrodynamic Forces in High Voltage Disconnector Related to the Short-Circuit Current Using the Digital Twin Technology. IEEE Access 2024, 12, 75701–75717. [Google Scholar] [CrossRef]

- Soderang, E.; Hautala, S.; Mikulski, M.; Storm, X.; Niemi, S. Development of a digital twin for real-time simulation of a combustion engine-based power plant with battery storage and grid coupling. Energy Convers. Manag. 2022, 266, 115793. [Google Scholar] [CrossRef]

- Sifat, M.M.H.; Choudhury, S.M.; Das, S.K.; Pota, H.; Yang, F. Novel abstractions and experimental validation for digital twin microgrid design: Lab scale studies and large scale proposals. Appl. Energy 2025, 377, 124621. [Google Scholar] [CrossRef]

- He, X.; Zhang, M. Blockchain-Based energy trading in Renewable-Based community based Self-Sufficient Utility: Analysis of Technical, Economic, and regulatory aspects. Sustain. Energy Technol. Assess. 2024, 64, 103679. [Google Scholar] [CrossRef]

- Chaves, T.R.; Martins, M.A.I.; Martins, K.A.; de Macedo, A.F.; de Francisci, S. Application Study in the Field of Solutions for the Monitoring Distribution Transformers of the Overhead Power Grid. Energies 2021, 14, 6072. [Google Scholar] [CrossRef]

- Lekidis, A.; Georgakis, A.; Dalamagkas, C.; Papageorgiou, E.I. Predictive Maintenance Framework for Fault Detection in Remote Terminal Units. Forecasting 2024, 6, 239–265. [Google Scholar] [CrossRef]

- Xu, B.; Wang, J.; Wang, X.; Liang, Z.; Cui, L.; Liu, X.; Ku, A.Y. A case study of digital-twin-modelling analysis on power-plant-performance optimizations. Clean Energy 2019, 3, 227–234. [Google Scholar] [CrossRef]

- Sharew, S.S.; Di Pretoro, A.; Yimam, A.; Negny, S.; Montastruc, L. Exploiting exergy and exergoeconomic analysis as decisional tool for cogeneration plant optimal operating mode: A sugar factory case study. Energy Rep. 2024, 12, 143–157. [Google Scholar] [CrossRef]

- Keprate, A.; Bagalkot, N.; Siddiqui, M.S.; Sen, S. Reliability analysis of 15MW horizontal axis wind turbine rotor blades using fluid-structure interaction simulation and adaptive kriging model. Ocean Eng. 2023, 288, 116138. [Google Scholar] [CrossRef]

- Dibaj, A.; Gao, Z.; Nejad, A.R. Fault detection of offshore wind turbine drivetrains in different environmental conditions through optimal selection of vibration measurements. Renew. Energy 2023, 203, 161–176. [Google Scholar] [CrossRef]

- Martire, M.; Kaya, A.F.; Morselli, N.; Puglia, M.; Allesina, G.; Pedrazzi, S. Analysis and optimization of a hybrid system for the production and use of green hydrogen as fuel for a commercial boiler. Int. J. Hydrogen Energy 2024, 56, 769–779. [Google Scholar] [CrossRef]

- Polo, J.; Martin-Chivelet, N.; Sanz-Saiz, C. BIPV Modeling with Artificial Neural Networks: Towards a BIPV Digital Twin. Energies 2022, 15, 4173. [Google Scholar] [CrossRef]

- Zohdi, T.I. A digital-twin and machine-learning framework for the design of multiobjective agrophotovoltaic solar farms. Comput. Mech. 2021, 68, 357–370. [Google Scholar] [CrossRef]

- Adu-Kankam, K.O.; Camarinha-Matos, L.M. Modeling Collaborative Behaviors in Energy Ecosystems. Computers 2023, 12, 39. [Google Scholar] [CrossRef]

- Feng, C.; Liu, C.; Jiang, D. Root cause localization for wind turbines using physics guided multivariate graphical modeling and fault propagation analysis. Knowl. Based Syst. 2024, 295, 111838. [Google Scholar] [CrossRef]

- Kolahi, M.; Esmailifar, S.M.; Sizkouhi, A.M.M.; Aghaei, M. Digital-PV: A digital twin-based platform for autonomous aerial monitoring of large-scale photovoltaic power plants. Energy Convers. Manag. 2024, 321, 118963. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, J.C.; Ren, Z.; Ni, Q.; Gu, F.; Feng, K.; Yu, K.; Ge, J.; Lei, Z.; Liu, Z. Digital twin-driven partial domain adaptation network for intelligent fault diagnosis of rolling bearing. Reliab. Eng. Syst. Saf. 2023, 234, 109186. [Google Scholar] [CrossRef]

- Gong, S.; Li, S.; Zhang, Y.; Zhou, L.; Xia, M. Digital twin-assisted intelligent fault diagnosis for bearings. Meas. Sci. Technol. 2024, 35, 106128. [Google Scholar] [CrossRef]

- Wan, A.; Chenyu, D.U.; Peng, C.; AL-Bukhaiti, K. Predictive modeling of combined cycle power plant performance using a digital twin-based neural ODE approach. J. Build. Eng. 2024, 96, 110390. [Google Scholar] [CrossRef]

- Song, M.; Moaveni, B.; Ebrahimian, H.; Hines, E.; Bajric, A. Joint parameter-input estimation for digital twinning of the Block Island wind turbine using output-only measurements. Mech. Syst. Signal Process. 2023, 198, 110425. [Google Scholar] [CrossRef]

- Yunqiao, L.; Yan, F. An innovative power prediction method for bifacial PV modules. Electr. Eng. 2023, 105, 2151–2159. [Google Scholar] [CrossRef]

- Vaicys, J.; Norkevicius, P.; Baronas, A.; Gudzius, S.; Jonaitis, A.; Peftitsis, D. Efficiency Evaluation of the Dual System Power Inverter for On-Grid Photovoltaic System. Energies 2022, 15, 161. [Google Scholar] [CrossRef]

- Gong, H.; Rooney, T.; Akeyo, O.M.; Branecky, B.; Ionel, D.M. Equivalent Electric and Heat-Pump Water Heater Models for Aggregated Community-Level Demand Response Virtual Power Plant Controls. IEEE Access 2021, 9, 141233–141244. [Google Scholar] [CrossRef]

- Hong, Y.-Y.; Pula, R.A. Diagnosis of photovoltaic faults using digital twin and PSO-optimized shifted window transformer. Appl. Soft Comput. 2024, 150, 111092. [Google Scholar] [CrossRef]

- Yu, W.; Liu, G.; Zhu, L.; Zhan, G. Enhancing interpretability in data-driven modeling of photovoltaic inverter systems through digital twin approach. Sol. Energy 2024, 276, 112679. [Google Scholar] [CrossRef]

- Vaccari, M.; Pannocchia, G.; Tognotti, L.; Paci, M. Rigorous simulation of geothermal power plants to evaluate environmental performance of alternative configurations. Renew. Energy 2023, 207, 471–483. [Google Scholar] [CrossRef]

- Powalla, D.; Hoerner, S.; Cleynen, O.; Muller, N.; Stamm, J.; Thevenin, D. A Computational Fluid Dynamics Model for a Water Vortex Power Plant as Platform for Etho- and Ecohydraulic Research. Energies 2021, 14, 639. [Google Scholar] [CrossRef]

- Kim, W.; Kim, S.; Jeong, J.; Kim, H.; Lee, H.; Youn, B.D. Digital twin approach for on-load tap changers using data-driven dynamic model updating and optimization-based operating condition estimation. Mech. Syst. Signal Process. 2022, 181, 109471. [Google Scholar] [CrossRef]

- Han, J.; Chen, Z.; Hu, P.; Li, H.; Li, G. Enhanced Detection of Electric Power Facilities Utilizing a Re-Parameterized Convolutional Network. Trait. Signal 2024, 41, 485–491. [Google Scholar] [CrossRef]

- Minchev, D.; Varbanets, R.; Shumylo, O.; Zalozh, V.; Aleksandrovska, N.; Bratchenko, P.; Truong, T.H. Digital Twin Test-Bench Performance for Marine Diesel Engine Applications. Pol. Marit. Res. 2023, 30, 81–91. [Google Scholar] [CrossRef]

- Xiong, J.; Ye, H.; Pei, W.; Kong, L.; Huo, Q.; Han, Y. A monitoring and diagnostics method based on FPGA-digital twin for power electronic transformer. Electr. Power Syst. Res. 2022, 210, 108111. [Google Scholar] [CrossRef]

- Vesely, L.; Fernandez, E.; Kapat, J.; Ghouse, J.H.; Bhattacharyya, D.; Ruscher, C.J.; Rolling, A.J. Fault Management Architecture Based on a Digital Twin Approach. J. Energy Resour. Technol. 2022, 144, 032106. [Google Scholar] [CrossRef]

- So, D.; Oh, J.; Leem, S.; Ha, H.; Moon, J. A Hybrid Ensemble Model for Solar Irradiance Forecasting: Advancing Digital Models for Smart Island Realization. Electronics 2023, 12, 2607. [Google Scholar] [CrossRef]

- Shahcheraghian, A.; Madani, H.; Ilinca, A. From White to Black-Box Models: A Review of Simulation Tools for Building Energy Management and Their Application in Consulting Practices. Energies 2024, 17, 376. [Google Scholar] [CrossRef]

- Saito, E.; Matsuno, N.; Tanaka, K.; Nishimoto, S.; Yamamoto, R.; Imano, S. Latest Technologies and Future Prospects for a New Steam Turbine. Mitsubishi Heavy Ind. Tech. Rev. 2015, 52, 39–46. [Google Scholar]

- Parlak, M.; Taplak, H. Rotor-Dynamic Analysis of a Small Steam Turbine Using Finite Element Method. Math. Model. Eng. Probl. 2020, 7, 68–72. [Google Scholar] [CrossRef][Green Version]

- Liu, T.; Pang, H.; He, S.; Zhao, B.; Zhang, Z.; Wang, J.; Liu, Z.; Huang, X.; Shi, Y.; Gao, M. Evaporative Cooling Applied in Thermal Power Plants: A Review of the State-of-the-Art and Typical Case Studies. Fluid Dyn. Mater. Process. 2023, 19, 2229–2266. [Google Scholar] [CrossRef]

- IEC 60045-1:2021; Steam Turbines—Part 1: Specifications. IEC: Geneva, Switzerland, 2021.

- Tsou, J.L.; Maulbetsch, J.; Shi, J. Power Plant Cooling System Overview for Researchers and Technology Developers; Electric Power Research Institute (EPRI): Palo Alto, CA, USA, 2013. [Google Scholar]

- Vilas Boas, F.M.; Borges-da-Silva, L.E.; Villa-Nova, H.F.; Bonaldi, E.L.; Oliveira, L.E.; Lambert-Torres, G.; Assuncao, F.D.; Costa, C.I.; Campos, M.M.; Sant’Ana, W.C.; et al. Condition Monitoring of Internal Combustion Engines in Thermal Power Plants Based on Control Charts and Adapted Nelson Rules. Energies 2021, 14, 4924. [Google Scholar] [CrossRef]

- ISO 13374:2015; Condition Monitoring and Diagnostics of Machines—Data processing, Communication and Presentation—Part 1: General guidelines. International Organization for Standardization: Geneva, Switzerland, 2015.

- Molęda, M.; Małysiak-Mrozek, B.; Ding, W.; Sunderam, V.; Mrozek, D. From Corrective to Predictive Maintenance—A Review of Maintenance Approaches for the Power Industry. Sensors 2023, 23, 5970. [Google Scholar] [CrossRef]

- IEEE Std 3006.3-2017; IEEE Recommended Practice for Determining the Impact of Preventative Maintenance on the Reliability of Industrial and Commercial Power Systems. IEEE: New York, NY, USA, 2018; pp. 1–34. [CrossRef]

- Redi, T. Systematic review of mitigation approaches in Ethiopia’s energy sector: Strategies for sustainable development and climate resilience [version 1; peer review: 1 approved with reservations]. F1000Research 2024, 13, 1377. [Google Scholar] [CrossRef]

- Prasad, M.B.; Ganesh, P.; Vinay Kumar, K.; Mohanarao, P.A.; Swathi, A.; Manoj, V. Renewable Energy Integration in Modern Power Systems: Challenges and Opportunities. E3S Web Conf. 2024, 591, 03002. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Firoozi, A.A.; Hejazi, F. Innovations in Wind Turbine Blade Engineering: Exploring Materials, Sustainability, and Market Dynamics. Sustainability 2024, 16, 8564. [Google Scholar] [CrossRef]

- Fathollahi, A.; Andresen, B. Power Quality Analysis and Improvement of Power-to-X Plants Using Digital Twins: A Practical Application in Denmark. IEEE Trans. Energy Convers. 2025, 40, 1909–1921. [Google Scholar] [CrossRef]

- Bai, R.; Sun, X.; Zhang, W.; Qiu, J.; Tao, Y.; Lai, S.; Zhao, J. Enhancing Integrated Gas and Electricity Networks Operation with Coupling Attention-Graph Convolutional Network Under Renewable Energy Variability. IEEE Trans. Netw. Sci. Eng. 2025, 12, 277–289. [Google Scholar] [CrossRef]

- Zakariazadeh, A.; Keane, A. Coordinated Planning of Wind Turbines, Batteries and Electrolyzers in Distribution Systems: A Stochastic Model. In Proceedings of the 2024 International Conference on Smart Energy Systems and Technologies (SEST), Torino, Italy, 10–12 September 2024; pp. 1–6. [Google Scholar]

- Xia, B.; Tang, Y.; He, Z.; Lin, W. Research on Digital Twin Modeling for Virtual Power Plant BT–Advances in Wireless Communications and Applications; Jain, L.C., Kountchev, R., Zhang, K., Kountcheva, R., Eds.; Springer Nature Singapore: Singapore, 2022; pp. 139–146. [Google Scholar]

- Sivaneasan, B.; Tan, K.T.; Zhang, W. Cognitive Digital Twin for Microgrid: A Real-World Study for Intelligent Energy Management and Optimization. IEEE Internet Comput. 2024, 29, 39–47. [Google Scholar] [CrossRef]

- Naghibi, A.F.; Akbari, E.; Shahmoradi, S.; Pirouzi, S.; Shahbazi, A. Stochastic economic sizing and placement of renewable integrated energy system with combined hydrogen and power technology in the active distribution network. Sci. Rep. 2024, 14, 28354. [Google Scholar] [CrossRef] [PubMed]

- Jokar, M.R.; Shahmoradi, S.; Mohammed, A.H.; Foong, L.K.; Le, B.N.; Pirouzi, S. Stationary and mobile storages-based renewable off-grid system planning considering storage degradation cost based on information-gap decision theory optimization. J. Energy Storage 2023, 58, 106389. [Google Scholar] [CrossRef]

- Naghibi, A.F.; Akbari, E.; Shahmoradi, S.; Veisi, M.; Pirouzi, S. Flexibility regulation-based economic energy scheduling in multi-microgrids with renewable/non-renewable resource and stationary storage systems considering sustainable computing by hybrid metaheuristic algorithm. Sustain. Comput. Inform. Syst. 2025, 48, 101196. [Google Scholar] [CrossRef]

- Naghibi, A.F.; Akbari, E.; Veisi, M.; Shahmoradi, S.; Pirouzi, S. non-renewable/renewable units. Sci. Rep. 2025, 15, 24856. [Google Scholar] [CrossRef]

- Wandel, S.; Bartschat, A.; Glodowski, J.; Bader, N.; Poll, G. Wear Development in Oscillating Rolling Element Bearings. Lubricants 2023, 11, 117. [Google Scholar] [CrossRef]

- Msane, M.R.; Thango, B.A.; Ogudo, K.A. Condition Monitoring of Electrical Transformers Using the Internet of Things: A Systematic Literature Review. Appl. Sci. 2024, 14, 9690. [Google Scholar] [CrossRef]

- IEEE Std C57.106-2015; IEEE Guide for Acceptance and Maintenance of Insulating Mineral Oil in Electrical Equipment; (Revision IEEE Std C57.106-2006). IEEE: New York, NY, USA, 2016; pp. 1–38. [CrossRef]

- Zare Ghaleh Seyyedi, A.; Armand, M.J.; Shahmoradi, S.; Mahmoudi Rashid, S.; Akbari, E.; Al-Hassanawy, A.J.K. Iterative optimization of a bi-level formulation to identify severe contingencies in power transmission systems. Int. J. Electr. Power Energy Syst. 2023, 145, 108670. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

| Description | Results |

|---|---|

| Timespan | 2018:2025 |

| All documents | 177 |

| Sources (Journals, Books, etc.) | 119 |

| Journal articles | 126 |

| Conference papers | 51 |

| Document Average Age | 2.29 |

| Average citations per document | 6.2 |

| Author’s Keywords | 754 |

| Authors | 760 |

| Single-authored documents | 6 |

| Co-Authors per Documents | 4.96 |

| N. | Ref. | Definitions |

|---|---|---|

| ACADEMIA | ||

| 1 | [34] | An exact cyber copy of a physical system that can represent all the functionalities |

| 2 | [35] | Accurate simulation of the entire process of real physical systems based on high-precision models |

| 3 | [36] | Accurately simulate and portray the behavior of physical entities in the real world. |

| 4 | [37] | Creates models of physical systems with the ability to continuously adapt to changes in the environment or operation, using data from the sensors in real-time. |

| 5 | [38] | An effective way for interconnection between information space and the physical world, which can realize the deep integration of information technology and traditional industry. |

| 6 | [39] | Integrate historical load data, weather data, renewable energy data, and other parameters to establish prediction models in the field of renewable energy power load forecasting. |

| 7 | [40] | A virtual system in a virtual space that utilizes physical models and operational historical data to accurately represent and map the physical entity or process. |

| 8 | [41] | DT is a virtual/digital model that is designed to reflect accurately the behavior and characteristics of a physical object. |

| 9 | [42] | Enables simulation, monitoring, and adaptation to operational changes, predicting the future states of the physical model. |

| 10 | [43] | Offers a new view to deal with the current problems encountered during smart energy development. |

| 11 | [44] | Mapping of the physical asset models in a digital platform, where a virtual digital replica model is created. |

| 12 | [45] | Ties the virtual representation to the physical asset and updates the virtual twin. |

| 13 | [46] | A dynamic and self-evolving virtual model or simulation of a real-life object representing the exact state of its physical twin at any given point of time via exchanging real-time data as well as preserving historical data. |

| 14 | [47] | Digital twin technology refers to a technology that combines physical equipment (e.g., power generators, ESS, and PV) and life-cycle elements of equipment operations (e.g., design, operation, and preventive maintenance) with AI, IoT, and big data technologies to represent them in a digital space. |

| 15 | [48] | A digital twin is a virtual representation of a physical object or system, and it can be used to simulate and optimize energy generation and usage. |

| 16 | [49] | Its greatest advantage lies in the ability to obtain real-time change data of the physical transformer through sensors, based on this data to update, simulate, analyze, predict, and thus guide the physical transformer operation. |

| 17 | [50] | Serving as a synchronized replica of the real equipment in the digital space, with the development of modeling, sensing, data analysis, and data mining algorithms. |

| 18 | [51] | The core concept is to construct a holographic virtual twin model in the digital realm, utilizing advanced technologies such as intelligent sensing and data transmission. |

| 19 | [52] | This tool uses real data collected automatically through an acquisition system to mirror physical behaviors in a virtual environment. |

| 20 | [53] | Continuously updated and is visualized in a variety of ways to predict current and future conditions in both design and operational environments to enhance decision-making. |

| INDUSTRY | ||

| 21 | [54] | ABB: An evolving digital profile of the historical and current behavior of a physical object or process that helps optimize business performance. |

| 22 | [55] | GE: Digital Twin is most commonly defined as a software representation of a physical asset, system, or process designed to detect, prevent, predict, and optimize through real-time analytics to deliver business value. |

| 23 | [56] | Siemens: The DT is the precise virtual model of a product or a production plant. |

| 24 | [57] | Microsoft Azure: IoT platform provides the capabilities to fuse together both physical and digital worlds, allowing you to transform your business and create breakthrough customer experiences. |

| N. | Ref. | Ultra Real-Time (<1 ms) | High-Frequency Real-Time (1–100 ms) | Low-Frequency Real-Time (100 ms−1 s) | Short-Term Operational (1 s−1 min) | Tactical/Planning (Minutes–Hours) | Strategic/ Long-Term (Days–Years) |

|---|---|---|---|---|---|---|---|

| 1 | [34,58] |  |  |  |  |  |  |

| 2 | [35,36,37,42,44,59,60,61,62,63,64,65,66,67,68,69,70,71,72] |  |  |  |  |  |  |

| 3 | [38,39,43,46,50,51,53,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92] |  |  |  |  |  |  |

| 4 | [52,93,94,95,96] |  |  |  |  |  |  |

| 5 | [97,98,99,100,101,102,103,104,105,106,107,108,109] |  |  |  |  |  |  |

| 6 | [110,111] |  |  |  |  |  |  |

| 7 | [41,112,113,114,115] |  |  |  |  |  |  |

| 8 | [47,116] |  |  |  |  |  |  |

| 9 | [40,48] |  |  |  |  |  |  |

| 10 | [117,118] |  |  |  |  |  |  |

| 11 | [119,120] |  |  |  |  |  |  |

| 12 | [49] |  |  |  |  |  |  |

| 13 | [121] |  |  |  |  |  |  |

| 14 | [122] |  |  |  |  |  |  |

| Main Category | Subcategory | Specific Focus Areas/Papers | N. | References |

|---|---|---|---|---|

| Emissive Power Plants | Entire Power Plant | Evaluation of overall operational efficiency. | 2 | [34,35] |

| Component-Level | Turbine Evaluation, Rotor Performance, and Cooling System | 6 | [36,37,59,60,61,123] | |

| System-Level | Optimization and Fault Detection | 8 | [38,73,74,93,97,98,110,121] | |

| Service-Level | CM and PM | 6 | [62,63,64,65,66,99] | |

| Non-Emissive Power Plants | Component-Level | Analysis of operational performance and efficiency focusing on: Blade, Drivetrain, Stability Assessment, Biomass, HEPP, Electrolyzers, and Geothermal PP | 11 | [43,46,67,68,69,75,100,101,102,117,118] |

| System-Level | Power prediction, output optimization, Operational efficiency, power prediction, energy management | 24 | [39,40,44,47,48,53,58,70,71,76,77,78,79,80,81,94,95,103,104,105,112,113,114,124] | |

| Service-Level | CM, PM, and Fault Detection | 9 | [41,42,106,107,108,109,111,115,116] | |

| Power Transformer | System-Level | Thermal performance and prediction. | 4 | [82,83,84,85] |

| Service-Level | CM, PM, and Fault Detection | 15 | [49,50,51,52,72,86,87,88,89,90,91,92,96,119,122] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahmoradi, S.; Hosseini Imani, M.; Mazza, A.; Pons, E. Applications of the Digital Twin and the Related Technologies Within the Power Generation Sector: A Systematic Literature Review. Energies 2025, 18, 5627. https://doi.org/10.3390/en18215627

Shahmoradi S, Hosseini Imani M, Mazza A, Pons E. Applications of the Digital Twin and the Related Technologies Within the Power Generation Sector: A Systematic Literature Review. Energies. 2025; 18(21):5627. https://doi.org/10.3390/en18215627

Chicago/Turabian StyleShahmoradi, Saeid, Mahmood Hosseini Imani, Andrea Mazza, and Enrico Pons. 2025. "Applications of the Digital Twin and the Related Technologies Within the Power Generation Sector: A Systematic Literature Review" Energies 18, no. 21: 5627. https://doi.org/10.3390/en18215627

APA StyleShahmoradi, S., Hosseini Imani, M., Mazza, A., & Pons, E. (2025). Applications of the Digital Twin and the Related Technologies Within the Power Generation Sector: A Systematic Literature Review. Energies, 18(21), 5627. https://doi.org/10.3390/en18215627