Abstract

The shift towards renewable resources has positioned agar, a natural seaweed polysaccharide, as a pivotal and sustainable material for developing next-generation energy storage technologies. This review highlights the transformative role of agar-based composites as a game-changing and eco-friendly platform for supercapacitors, batteries, and fuel cells. Moving beyond the traditional synthetic polymers, agar introduces a novel paradigm by leveraging its natural gelation, superior film-forming ability, and inherent ionic conductivity to create advanced electrolytes, binders, and matrices. The novelty of this field lies in the strategic fabrication of synergistic composites with polymers, metal oxides, and carbon materials, engineered through innovative techniques like electrospinning, solvent casting, crosslinking, 3D printing, and freeze-drying. We critically examine how these innovative composites are breaking new ground in enhancing device efficacy, flexibility, and thermal stability. Ultimately, this analysis not only consolidates the current landscape but also charts future pathways, positioning agar-based materials as a pivotal and sustainable solution for powering the future.

1. Introduction

The rising interest in sustainable and eco-friendly materials has led to significant interest in polysaccharide-based biomaterials, which have unmatched advantages such as biodegradability, renewability, and versatility. Among these, agar, a natural polysaccharide extracted from red algae, has been identified as a promising candidate owing to its unique physicochemical properties such as gel-forming ability, biocompatibility, and thermal stability [1,2,3,4]. These characteristics make agar an excellent matrix for the creation of advanced functional materials, particularly for energy storage applications, where sustainability and performance need to go hand in hand. As the global energy landscape moves towards renewable sources of energy, the need for efficient, scalable, and environmentally benign energy storage systems has never been more critical. Novel Agar-based composites, with tunable properties and compatibility with several nanomaterials [5,6], carbon-based nanoparticles [7], polymers [3,8,9,10], ceramics [11,12], and certain inorganic clay constituents [13,14], are set to play a transformative role in this transition.

Materials scientists have advanced agar matrices significantly due to their superior integration capabilities for various conductive components, including metallic nanoparticles, graphene, and synthetic and natural polymers. Their broad applications across various fields are underpinned by their compatibility with energy technologies [15,16,17,18]. Agar-based composites are becoming increasingly popular in high-tech energy storage and conversion technologies [19,20,21,22]. The attachment of graphene carbon nanotubes with agar makes it more multifunctional [23,24]. These composites are being investigated as gel electrolytes for batteries, as they improve safety and enhance battery component durability [25,26,27]. These applications demonstrate the efficacy of the agar matrix in enabling functional improvements in energy devices along with possible future roles in sustainable energy technology development [28].

The exceptional performance of agar-based hybrid materials is evident in supercapacitors, fuel cells, and various batteries, as well as in gel electrolytes, due to their unique structural attributes and electrochemical properties. The porous structure of agar in supercapacitors facilitates degradation while forming a conductive matrix with carbon-based nanomaterials or metal oxides, resulting in an efficient ion storage material that enhances energy capacity and power density [29,30]. Agar composites used in fuel cells function as proton-conductive membranes due to their hydrophilic polymer structure, which retains water and facilitates efficient proton transfer while ensuring structural stability during prolonged electrochemical processes. Solid and gel-polymer electrolytes that incorporate agar leverage its adaptable gel structure for lithium–metal batteries, effectively limiting dendrite growth and accommodating expansion during charging cycles, which enhances battery safety and longevity [3,31,32,33]. The synergistic integration of agar with both natural and synthetic polymers, such as chitosan, gelatin, cellulose, PVA, etc., creates hybrid composites that harmonize eco-friendly attributes with enhanced mechanical and electrochemical functionality, positioning them as versatile, sustainable candidates for next-generation energy systems, from biodegradable batteries to self-healing supercapacitors [3].

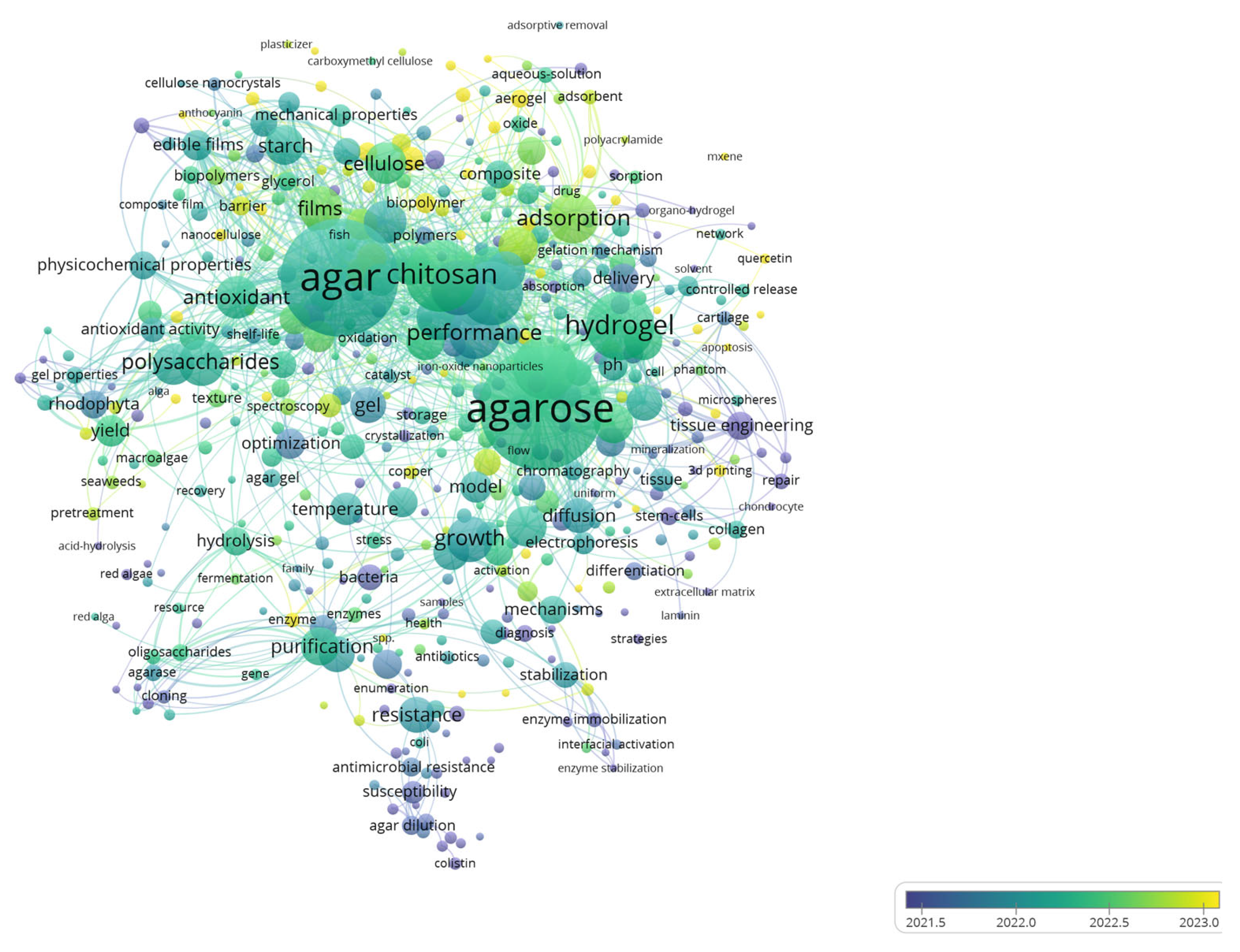

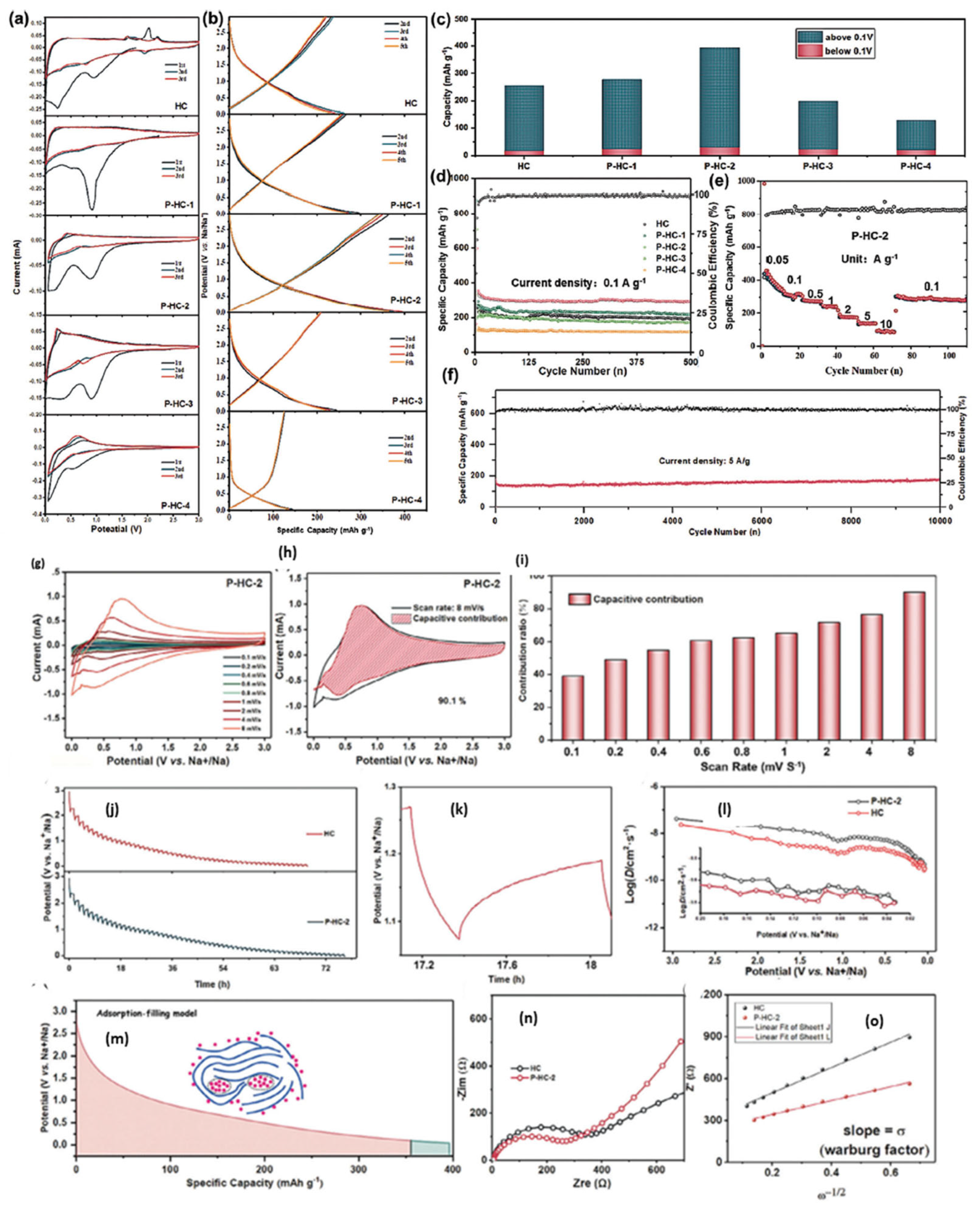

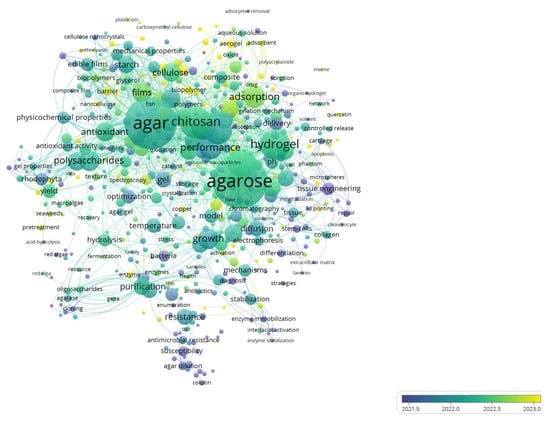

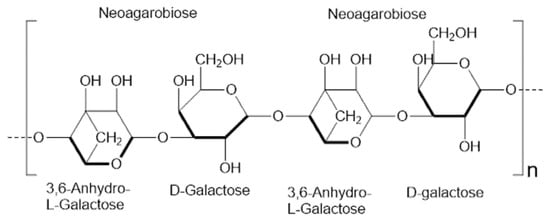

Research on agar-based composites is flourishing, evolving rapidly from traditional applications in microbial cultures and electrophoresis to advanced hydrogels/aerogels for sensitive drug delivery, tissue engineering, and environmental remediation (Figure 1). Since 2021, the literature has expanded sharply, with 2022–2024 showing the fastest growth and a pivot towards adsorption, 3D printing, and hybrid systems with chitosan, cellulose, collagen, and emerging MXene pairings. Current research trends prioritize tunable mechanical properties, stabilization, and controlled release, positioning agar composites as versatile, sustainable platforms for energy storage applications.

Figure 1.

Overlay visualization map depicting the co-occurrence of keywords from 1631 articles retrieved from the WOS databases as of 6 February 2025. The visualization is generated using VOSviewer version 1.6.20, developed by Universiteit Leiden, Netherlands.

This review explores the cutting-edge developments in agar-based composites, highlighting their transformative potential in energy storage technologies. By bridging natural polysaccharides with advanced nanomaterials, these innovative composites represent a pivotal step toward sustainable, high-performance energy solutions for a greener future. Additionally, a bibliometric analysis provides insights into research trends, key contributors, and emerging focus areas, offering a comprehensive perspective on the impact of agar-based materials in next-generation energy applications.

2. Fundamentals of Agar

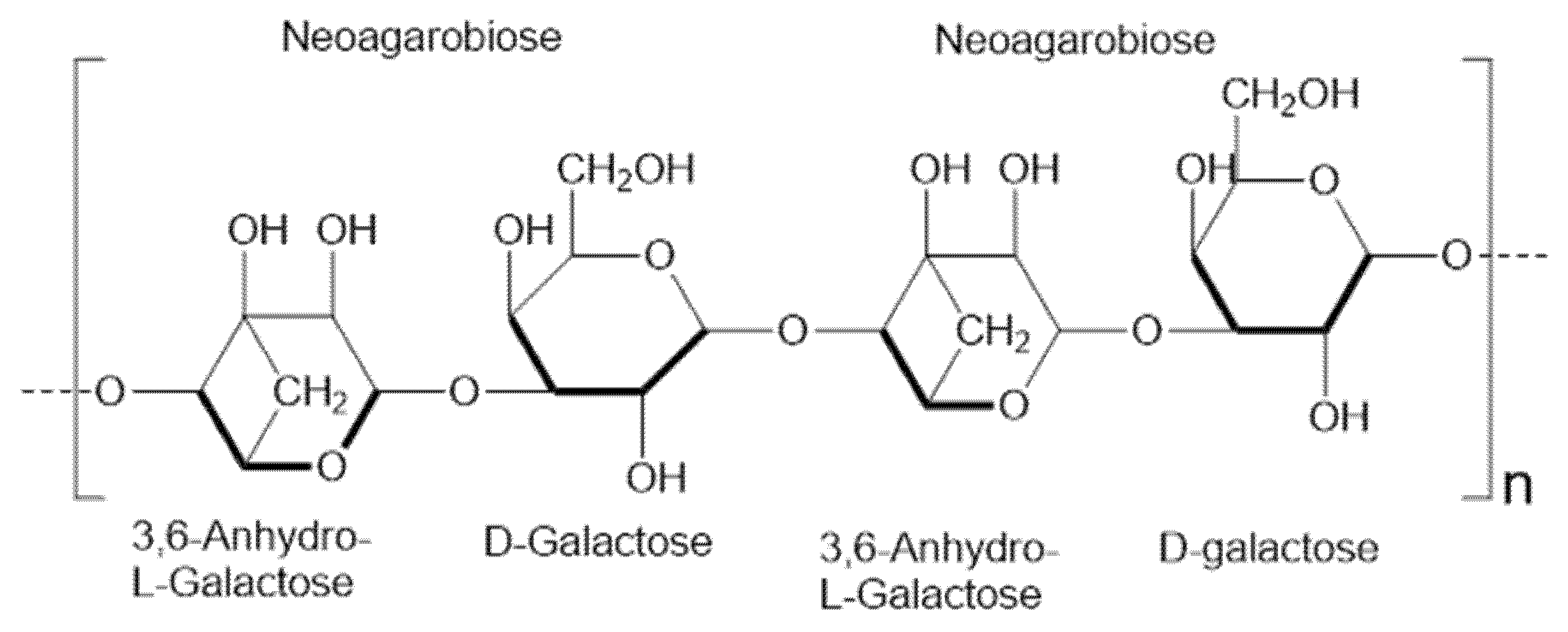

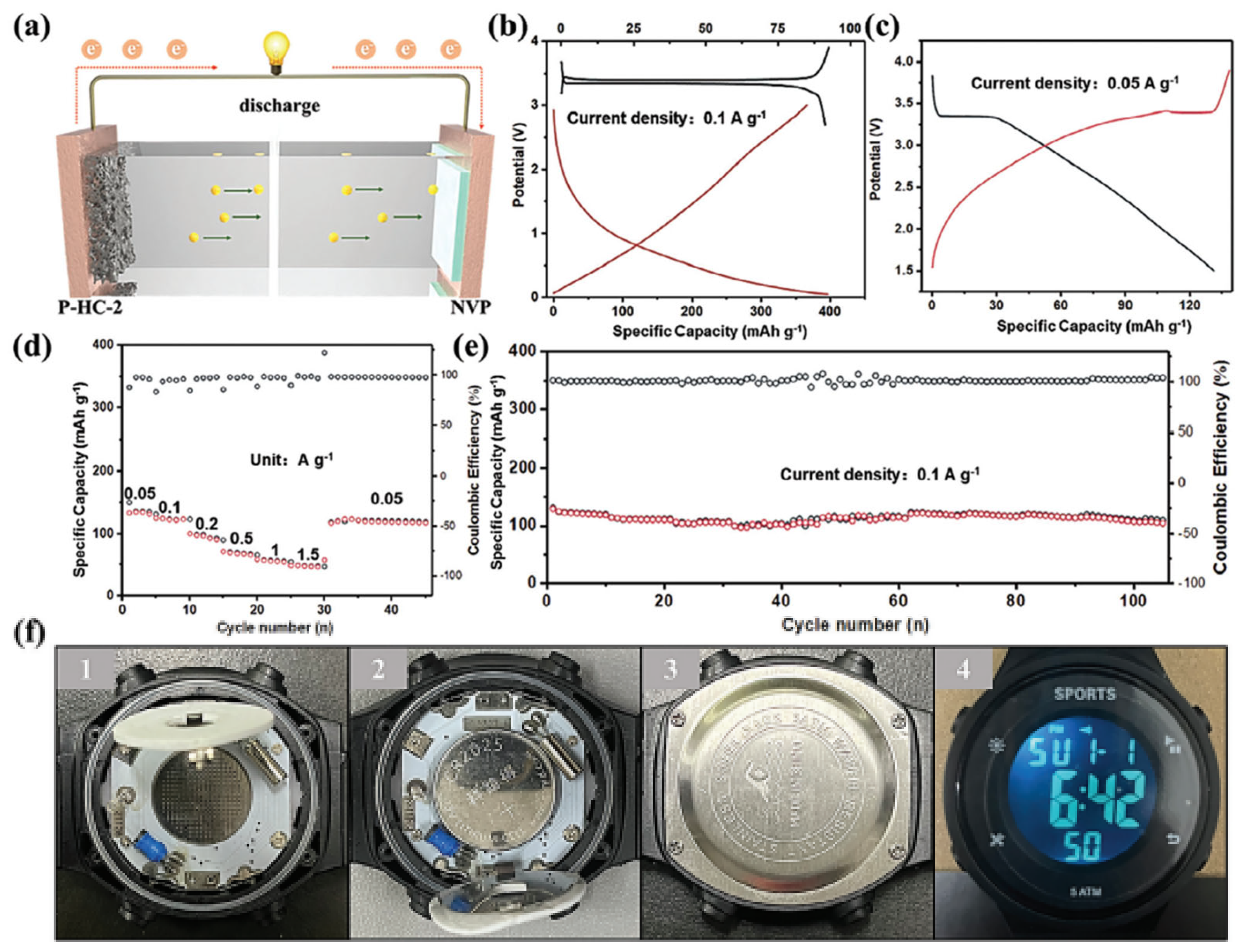

Agar, a heteropolysaccharide, was first extracted from red algae (Gracilaria spp.) in 1658. The primary structure consists of two essential components: agarose, which makes up 70% and serves as a thermoreversible gel polymer composed of alternating β-1,4-linked d-galactose and α-1,3-linked 3,6-anhydro-l-galactopyranose units, and agaropectin, which acts as the solvent-enhancing and ion-interaction-managing heterogeneous sulfated polymer. The integration of these two primary structural units establishes the foundation for the varied physical and chemical characteristics of agar materials, facilitating their use in microbiological applications and sophisticated biomaterials. This versatility is enhanced by their customizable gel strength and compatibility with biological components, as well as their chemical diversity [34,35,36] (see Figure 2). The process of cooling agarose allows the formation of a thermoreversible three-dimensional network through helical coiling, which is stabilized by hydrogen bonds and hydrophobic forces, and traps water to create porous gels with mechanical stability [37,38]. Controlling cooling rates and selecting agar concentration, or adding certain substances like glycerol or salts, helps researchers achieve desired pore sizes and network densities while modifying viscoelastic properties in agarose gels [39,40]. The unique properties of agar render it a valuable substance in the study of energy storage, particularly when utilized as a gel electrolyte material in batteries and supercapacitors [41,42].

Figure 2.

The repeating 3,6-anhydro-l-galactose and d-galactose units in agarose structure form agarobiose and neoagarobiose, which make up the principal component of agar.

Agar demonstrates a built-in capability to form gels, which creates a dependable, biodegradable electrolyte medium that enhances ionic conductivity and structural strength. The electrochemical nature of agar allows its combination with carbon-based materials and metallic nanoparticles, which enhances electrochemical applications. Electrode performance improves through the addition of composites because they increase both surface area and electrical conductivity, which results in better energy storage efficiency and durability. Agar-based gel electrolytes integrated with composites offer an innovative solution to boost electrochemical storage technology because they use sustainable agar as both a resource and a functional material for modern energy applications [3,43]. Agar is distinguished as a remarkable sustainable energy storage material due to its unique degradation properties and hydrolytic stability, which complement its compatibility with polymers and metals. This enables the advancement of green energy technologies by effectively harnessing viscoelastic energy dissipation in conjunction with flexible gel networks.

Agar-based systems have built-in constraints that limit performance and scale-up. Their water-rich networks provide a narrow electrochemical stability window, so water splitting and gas formation can occur at modest voltages. Moisture changes cause drying, swelling, and syneresis, which shift ionic conductivity, dimensions, and self-discharge over time. The gels are relatively brittle and can creep or crack under repeated deformation, leading to contact loss at electrodes [44,45,46,47]. Thermal behavior is also restrictive: gelation occurs near room temperature, and softening or melting appears at higher temperatures, while cold conditions can embrittle the network [48]. Ionic conductivity and rate capability usually trail those of optimized liquid electrolytes unless plasticizers or high-salt formulations are used, and these fixes can weaken mechanical strength and accelerate aging. Interfaces with reactive metals (e.g., Zn) tend to require additives or protective interphases to curb dendrites and corrosion [49,50,51]. Robust performance depends on complex formulations, and seaweed-derived feedstocks introduce cost and batch-to-batch variability that complicate reproducibility and scaling.

3. Role of Agar in Energy Storage Applications

Agar is gaining popularity as a green source for use in energy storage devices because it is renewable, biodegradable, and not highly toxic. Agar is plentiful and environmentally friendly, unlike traditional petroleum-based polymers, and is thus in line with the objectives of green chemistry in the development of energy storage devices. Indeed, materials derived entirely or partially from algae are under consideration for batteries and supercapacitors to enhance sustainability [3,47]. The physicochemical properties of agar, e.g., its capacity to create hydrogels, to harbor ionic species, and to bind to surfaces, are reasons why agar is a good candidate for a range of electrochemical applications. Agar-based components have been added to batteries, supercapacitors, and fuel cells in recent studies, with agar being determined to be useful as a substitute for traditional binders or electrolytes that does not impair device functionality [47]. Due to its hydrophilicity and mechanical strength, agar is a flexible platform for developing functional composites in energy storage systems.

3.1. Film-Forming and Gelation Behavior

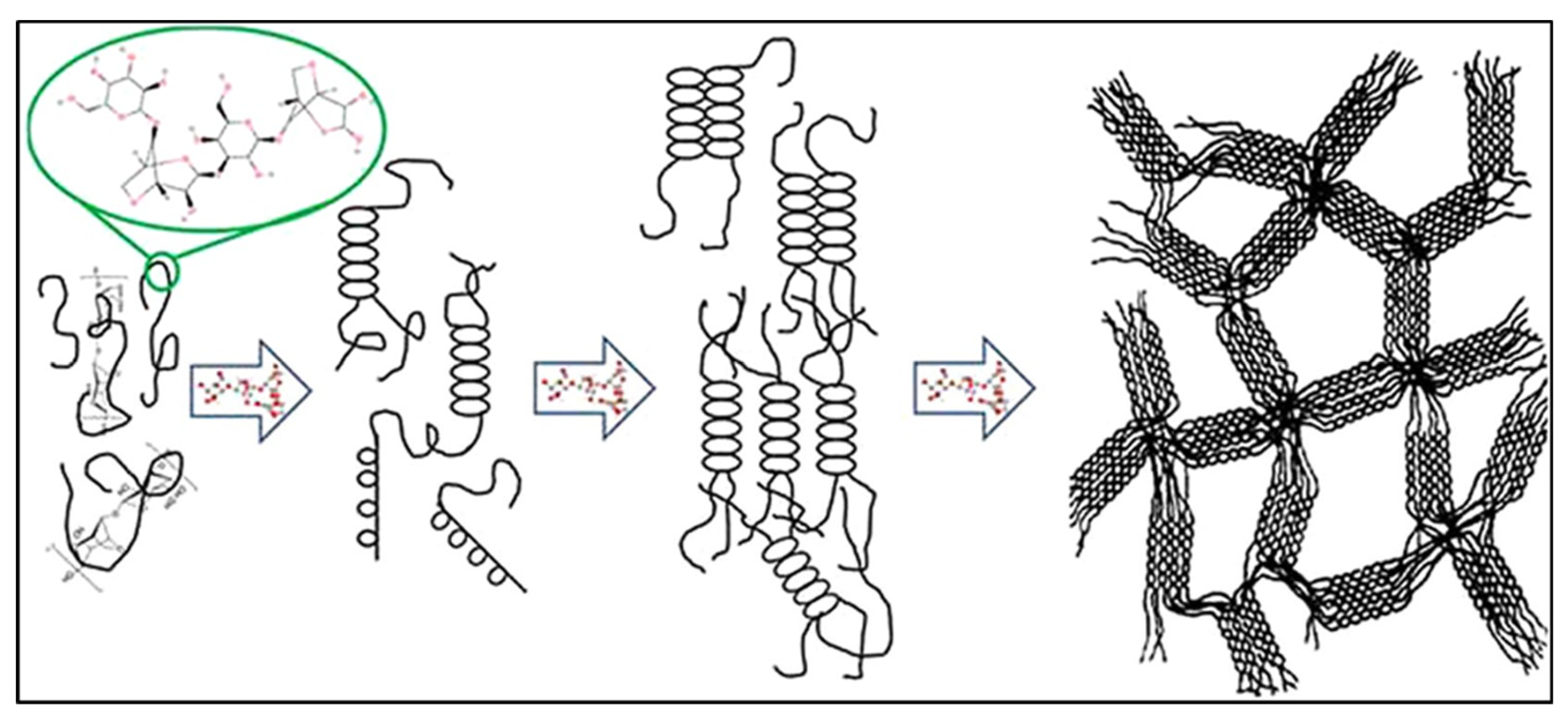

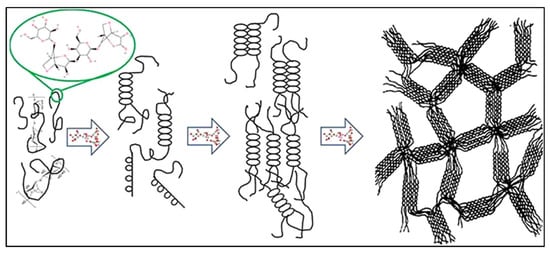

Agar has a distinct gelation property that is one of its most important characteristics. Agar is dissolved in hot water at 90 °C, then solidifies into a solid gel at temperatures below 40 °C following a thermoreversible sol–gel transition. The large hysteresis in this transition means that agar gels solidify at room temperature (approximately 35 °C) and do not melt until they are heated to approximately 85–90 °C [52,53]. During gelation, agarose chains are crosslinked physically through hydrogen-bonded double helices when chilled below the melting point. This produces a 3D network structure capable of containing large volumes of solvent. The powerful hydrogen bonding and high molecular weight of agarose give it excellent film-forming properties; agar solutions can be poured into a film or membrane, which will harden at room temperature without any extra crosslinkers (Figure 3) [54,55]. This property allows the production of thin agar-based films as solid electrolytes or separators in energy materials. In addition, agar can undergo reversibly gelation, enabling reprocessing and self-healing of materials. Kim et al. showed that an agarose composite hydrogel is moldable (into thin films, fibers, and 3D structures) and, upon being cut, the fragments could be recombined, restoring electrical activity in a short time [47]. This processing flexibility is advantageous for developing flexible and wearable energy storage devices. Structural integrity is also provided by the firm gel state of agar; e.g., an agar gel electrolyte can exist as a freestanding membrane, unlike liquid electrolytes that need a container. In general, the film-forming and gelation behavior of agar provide a basis for the development of robust, shape-conformable components within energy systems.

Figure 3.

The gelation mechanism of agarose involves the formation of helical structures and gelation through hydrogen bonds and electrostatic interactions among agarose chains [56].

3.2. Ionic Conductivity and Electrolyte Compatibility

Even though agar is an insulator, when it is loaded with electrolytes, its hydrogel network can be used as an ion-conducting medium. The high concentration of oxygen-containing groups (hydroxyls and ethers) on the polymer can bind with cations, and therefore agar is a good polymer host for ionic conduction [57]. Gels made from agar are usually impregnated with salts or acids to make them ionically conductive. For example, initial experiments demonstrated that a basic agar–KCl gel could serve as a salt bridge and polymer electrolyte, leading to other experiments on agar-based electrolytes [58]. Swollen agar hydrogels containing aqueous electrolytes have recorded ionic conductivities on the order of 10−3–10−1 S/cm, close to those of liquid electrolytes. In alkaline systems, a hydrogel of PVA–agar blend with 40–50% KOH gave room-temperature conductivities of approximately 0.2–0.24 S/cm (only two to three times lower than bulk 6 M KOH solution). This ionic conductivity is large enough to be of practical use and highlights the compatibility of agar with concentrated salt solutions. Agar gels have also been used with ammonium and lithium salts or even ionic liquids as proton- or ion-conducting membranes [59]. According to Moon et al., a NaCl–agarose gel polymer electrolyte of flexible supercapacitors allowed rapid ion movement through a 3D porous agarose scaffolding of aqueous electrolyte. Its oriented sub-micropores and bound water gave the gel agarose very efficient ionic conduction to the electrode surfaces, yielding a supercapacitor capacitance of up to about 80% of that with a liquid electrolyte. This proves that agar-based electrolytes can provide high electrochemical performance [46]. Furthermore, agar is particularly compatible with a variety of solvents: although it mainly swells in water, development of devices using organic solvents (glycerol, etc.) and ionic liquids have been investigated using agar [46].

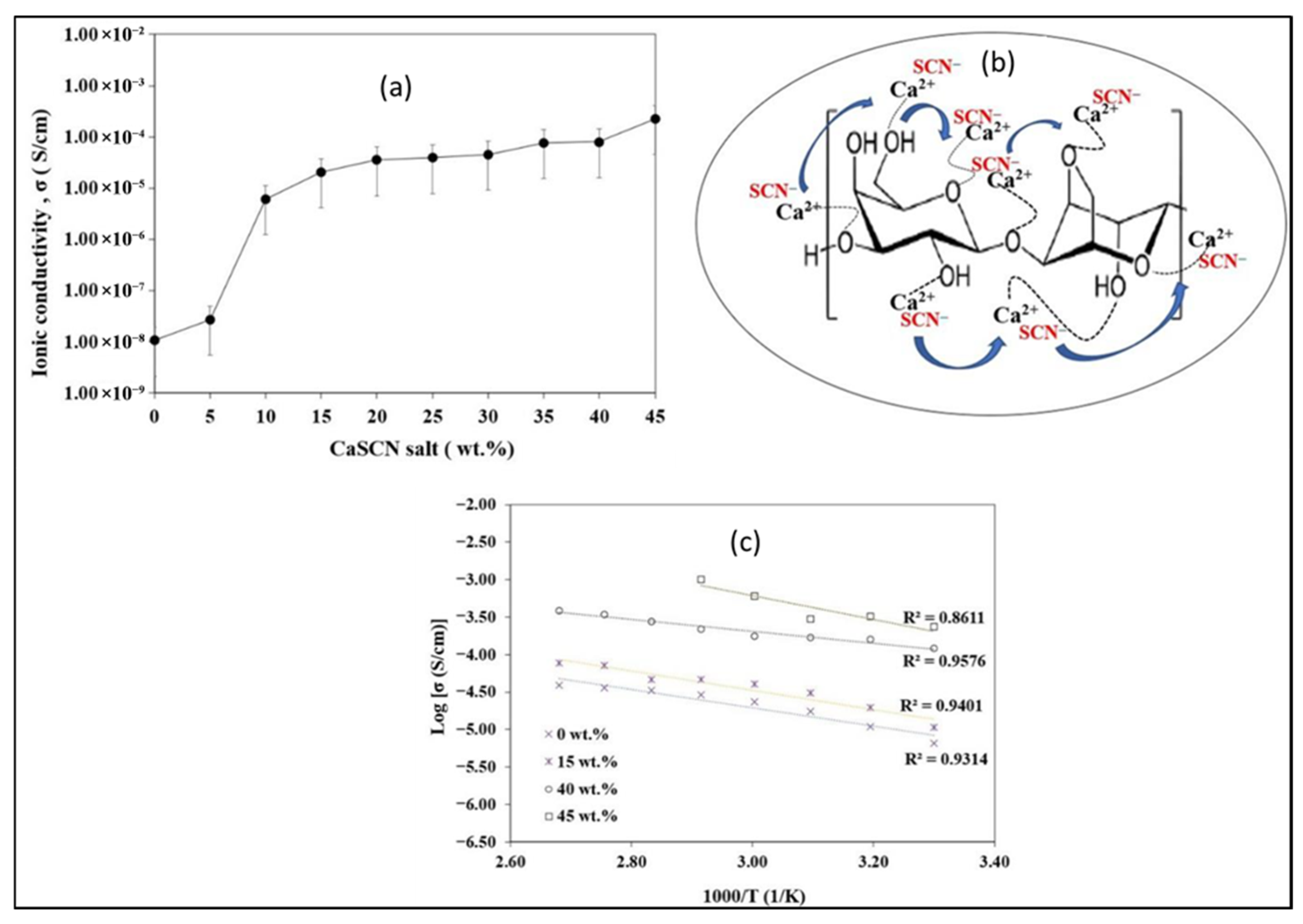

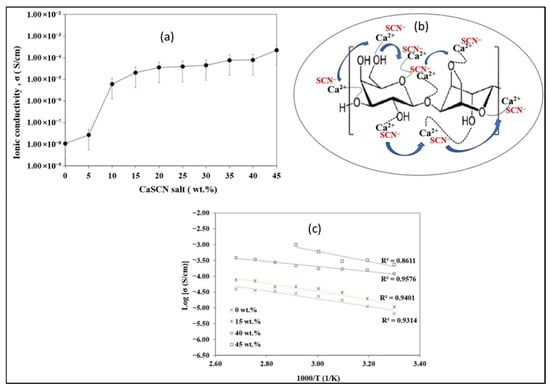

Mohd Rafi et al. reported that, at room temperature, the ionic conductivity of CaSCN-agarose biopolymer electrolytes (0–45 wt%) increases with salt content (Figure 4a). The salt-free matrix shows 1.07 × 10−8 S cm−1, within the typical range for neat polysaccharides (about 10−14 to 10−8 S cm−1), confirming agarose as a suitable host. Conductivity increases via a hopping mechanism in which Ca2+ diffuses through the agarose network and coordinates with oxygen lone pairs from hydroxyl/carboxyl groups to form polyionic interactions (Figure 4b). With added CaSCN, the density of mobile charge carriers (Ca2+/SCN−) grows, reaching 8.01 × 10−5 S cm−1 at 40 wt% and remaining high at 2.28 × 10−4 S cm−1 at 45 wt%. However, 45 wt% compromises mechanical/thermal integrity, failing above 353 K, so 40 wt% represents a practical optimum. Temperature-dependent data follow Arrhenius behavior, with linear log σ versus 1000/T plots (R2 ≈ 1) indicating thermally activated ion transport (Figure 4c) [60]. In conclusion, agar is a good hydrophilic network material with functional groups that can be utilized in ionic conduction when paired with suitable ion species and can be used as solid or gel polymer electrolytes in batteries, supercapacitors, and even fuel cells.

Figure 4.

(a) Ionic conductivity of various concentrations of CaSCN salt at ambient temperature; (b) hopping mechanism of Ca2+ in CaSCN–agarose biopolymer electrolytes; (c) temperature dependency curves of different concentrations of CaSCN–agarose biopolymer electrolytes (reproduced with permission) [60].

3.3. Mechanical and Thermal Stability

Agar materials have good mechanical strength and thermal stability for energy storage applications. Agar gels are mechanically strong relative to most other biopolymer gels—agarose gels (at a few % concentration) are strong gels (maximum gel strength > 800 g/cm2) and can resist stress-induced structural damage [61,62]. This mechanical stability is essential when agar is used as a binder or membrane, since it needs to resist swelling and changes in electrode volume as well as handling. It possesses a thick network of double-helical junction regions in the agar gel, which endows it with rigidity under deformation. The mechanical toughness of agarose has also led to its implementation in the scaffold of flexible electronics [47]. Agar gels are thermostable between their melting and gelation points across a broad temperature range. As observed, agar gel remains solid up to approximately 85 °C, which spans the operating temperatures of batteries and fuel cells (typically 60 °C). This thermal gel stability prevents premature liquefaction or flow of agar-based electrolytes or binders under moderate heating [63,64].

Although it is a polymer, the backbone of agar is also resistant to relatively high temperatures, even in dry form. Thermogravimetric analysis reveals that dry agar (in composite gels) decomposes significantly only at about 250 °C, once all the water has evaporated. This thermal strength is competitive with that of synthetic polymer binders (e.g., PVDF decomposition starts at about 300 °C) and suggests that agar can withstand the heat of cell assembly (e.g., drying, solvent removal) and operation [65]. Another stability feature is the capacity of agar to retain water. Because its gels already contain high levels of water, they retain moisture through extensive hydrogen bonding [66]. In a fuel cell scenario, this is advantageous—the agar hydrogel binder maintains the electrode wet, promoting ion conduction—whereas a conventional binder would dry out. Nevertheless, it is important to control water activity: excessive drying of an agar electrolyte may lead to shrinkage and loss of conductivity, whereas excessive heat may melt the gel [65,67].

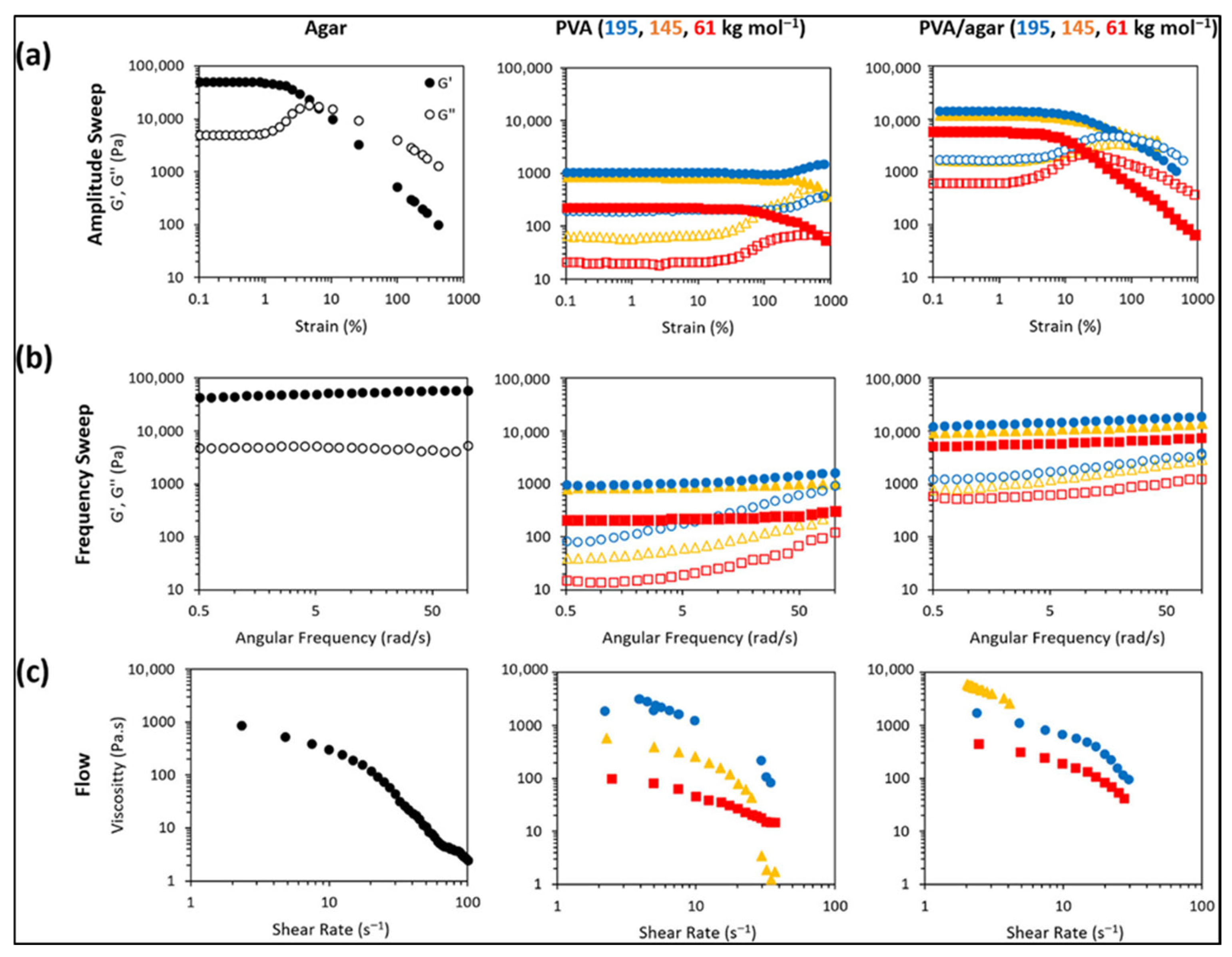

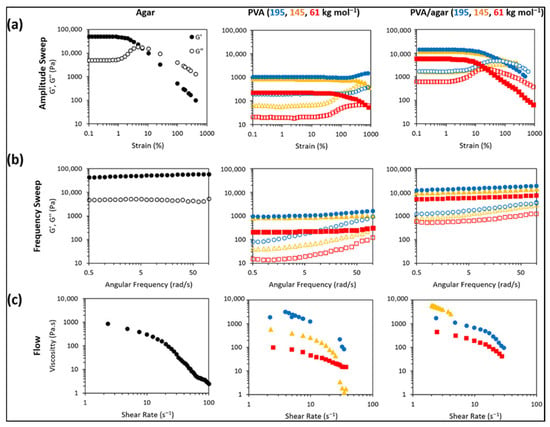

Zhang et al. reported the shear rheology of agar, PVA, and PVA–agar double networks (Figure 5a–c). In amplitude sweeps (Figure 5a), agar shows a high linear viscoelastic region modulus around 49 kPa but a low yield strain near 5%, indicating brittleness. PVA cryogels have lower modulus, higher yield strain, and the highest-molecular-weight sample shows clear strain hardening. Double networks combine strength and ductility, with moduli around 5.7, 11.7, and 14.1 kPa (for 61, 145, and 195 kg mol−1) and yield strains near 26% and 86% (61 and 195 kg mol−1). Frequency sweeps (Figure 5b) show weak frequency dependence, consistent with permanent-like networks in the tested window. Flow tests (Figure 5c) show shear-thinning for agar and PVA; double networks exhibit a nonmonotonic viscosity trend, and the 145 kg mol−1 PVA–agar sample reaches the instrument torque limit [68]. In general, agar has a combination of mechanical rigidity and thermal endurance that allows it to be used in composite electrodes and solid-state electrolyte membranes, and its safety profile (non-flammable, with no toxic degradation materials) is better than that of most traditional materials.

Figure 5.

Rheological evaluation of agar, PVA, and PVA/agar double-network (DN) hydrogels, including (a) amplitude sweeps, (b) frequency sweeps, and (c) flow rheology (reproduced with permission) [68].

3.4. Role as Matrix or Binder in Composite Electrodes

Agar may also be used as a matrix or binder in composite electrodes (including batteries, supercapacitors, fuel cells, etc.) to bind together active materials, conductive additives, and current collectors. The role is similar to PVDF in Li-ion batteries or Nafion in certain fuel cells, but agar has specific advantages in terms of sustainability and performance. Research has demonstrated that agar-based binders have the potential to maintain electrode cohesion and interparticle contact intact throughout cycling. As an example, Tang et al. used a chemically modified agar (oxidized to expose carboxyl groups) as a water-soluble binder for lithium–sulfur battery cathodes [69]. The agar binder maintained close contact between sulfur and carbon black and the aluminum current collector, and its polar functional groups immobilized lithium polysulfides, inhibiting the shuttle effect. This led to a Li-S electrode with an initial discharge capacity of approximately 700 mAh g−1, and high capacity retention of 90.7% after 100 cycles, which is much higher than that of the traditional PVDF-bound electrode [69]. This demonstrates the stability of the agar binder for electrode structure and chemistry during repeat charging/discharging. Similarly, agar binders have been promising in Zn-based batteries. An alkaline Zn-air battery anode with an agar binder outperformed a binder-free electrode in mechanical integrity and cycle life, as agar inhibited active-material shedding in the very alkaline KOH environment [65]. A crosslinked agar hydrogel binder was used to replace the Nafion ionomer in the catalyst layer in fuel cells. The electrode bound with ACH had a higher peak power density compared to the one bound with Nafion, due to agar’s hydrophilic, water-retaining character, which facilitates mass and charge transport [65]. It is worth noting that the water-processability of agar enables electrode fabrication with benign solvents (replacing NMP with water), which makes the process easier to manufacture and less harmful to the environment. When incorporated and dried on the electrode, agar is not involved in side reactions (electrochemically inert) and is therefore stable during cell operation [69]. Its excellent adhesive and film-forming qualities make it possible to tolerate even high-volume-change materials (such as Si anodes or conversion-type cathodes) better, since the binder can gel and reharden to accommodate strain. Overall, agar represents a useful binder matrix that not only holds the composite electrode together but also has added advantages of entrapping deleterious species (e.g., polysulfides) and enhancing ionic percolation within the electrode.

3.5. Synergistic Effects with Conducting Constituents

The applications of agar in energy storage are mostly in composite form, wherein the agar acts synergistically with conductive carbons and metal oxides to form functional hybrids. Agarose is a gel-forming polymer and thus is able to evenly disperse filler materials to enhance the structural homogeneity of the composite. In the case of carbon materials, agar establishes a complementary relationship: the agar network offers mechanical strength and ionic transport, and carbon (e.g., activated carbon, carbon nanotubes, graphene) offers conductivity [3,65]. Agarose-based soft electrodes have recently been developed in which high-surface-area carbon is incorporated into an agarose hydrogel matrix. Kim et al. prepared an agarose–spherical activated carbon (agar/SAC) gel, which could be cast in different shapes (films, fibers, and 3D structures) and had similar electrical properties [47]. Agar forms a reversible gel, allowing the molding and even recycling of these electrodes, and the carbon content gave them conductivities in the 10−4–100 S/cm range. These composites benefit from hydrogel–carbon interactions: agarose chains can cover and separate carbon nanoparticles to avoid agglomeration and expose the large surface area of nano-carbons to store charge. Additionally, the wetting of carbon surfaces by electrolytes can be enhanced by the moisture in agar. It has also been demonstrated that carbon–agarose gels can be made conductive by the addition of conducting polymers (e.g., polyaniline, PEDOT), and that conductivity and pseudocapacitance can be increased further, suggesting the versatility of agarose as a host matrix [47,70].

Agar in combination with metal oxides has the potential to enhance the performance and stability of electrodes in a variety of ways. One particular example is the use of an ultrathin film of agar (sometimes called an agar microskin) on MnO2 cathode particles to make Zn-ion batteries. This wetted agar layer was observed to have a positive effect on electrode wettability (to help diffusion of Zn2+ ions) and also serve as a physical barrier that reduced dissolution of manganese in the electrolyte [71]. The agar-covered MnO2 cathode had a significantly higher discharge capacity (~240 mAh g−1 at 0.5 A g−1) than the bare cathode (160 mAh g−1) and it maintained 85.6% of its capacity after 500 cycles, whereas the non-protected one maintained only 51%. This dramatic change can be attributed to the properties of agar in preserving the structural integrity of the a-MnO2 framework during the cycling process by avoiding excessive contact with the electrolyte and compensating for the change in volume [71]. As a rule, in the case of agar as a binder or a matrix to hold metal-oxide-based electrodes (e.g., Fe3O4, TiO2, MnO2, etc.), the agar allows strain accommodation and prevents the pulverization of particles because of its cushioning effect as a gel. It also provides functional groups to interact with the surface, and this may help in increasing electron transfer at the particle–binder interface. In dye solar cells and supercapacitors, for example, agar-based gels doped with metal oxides (TiO2, Co3O4) had higher ionic conductivity and superior dispersion of the oxide than the oxide in a dry polymer [57,72,73]. As a result, agar is effective as a small additive (coating) or a bulk material (bulk matrix) with inorganic materials to benefit from the film-forming, ion-conducting, and flexible characteristics of agar combined with electrical or faradaic characteristics of conducting additives. This synergy enables the design of next-generation composite electrodes that are high performance and derived from sustainable materials.

Despite these advantages, research on agar used as an electrochemical material remains, compared to other polymers, at a very immature level. Therefore, there are several aspects of future work to pursue in order to achieve the maximum value of agar. For example, chemical modification of agar/agarose has been demonstrated to be a viable means of controlling the solubility and behavior of the compound—oxidized agar has been shown to improve polysulfide binding in Li-S batteries, and crosslinked agar has been shown to improve stability in fuel cells. These modifications may improve the ease of use of agar in non-aqueous media and/or its ionic conductivity. In addition, a more fundamental characterization of ion transport in agar networks and predictive modeling would be desirable for the design of agar electrolytes with predetermined pore structures or ionic liquids that have broad electrochemical stability ranges. In addition to this, more practical aspects of the matter should also be considered—for example, how an agar-based component breaks down after cell disassembly, and whether this can simply be repurposed to rerecycle batteries in an environmentally friendly way.

4. Agar vs. Other Biopolymers in Energy Storage Applications

Compared with other bio-based polymers used in energy storage, agarose offers a uniquely advantageous balance of ionic transport, mechanical integrity, processing simplicity, and interfacial compatibility that makes it particularly promising for supercapacitors and batteries. First, agar forms robust, water-gelled networks at low polymer loadings, so its quasi-solid electrolytes can approach liquid-like ionic conductivities while tightly retaining solvent, reducing leakage and self-discharge [74,75]. Cellulose matrices, by contrast, typically need derivatization (e.g., CMC) or plasticizers to reach comparable conductivities, trading off mechanical strength or adding processing steps; nanocellulose separators are mechanically excellent but require a separate gel/electrolyte infusion to conduct ions efficiently [76,77]. Chitosan can form proton-conductive films, yet it relies on acidic dissolution and often becomes brittle without plasticizers, limiting durability under repeated bending [78]. Alginate gels readily via Ca2+ crosslinking, but those ionic bridges are environmentally sensitive (ion exchange, pH, humidity), and carboxylate coordination can immobilize multivalent charge carriers, depressing net ion mobility [79,80,81]. Second, agar’s hydrogen-bonded double-helix network produces self-standing, flexible films with tunable porosity and thickness by simple aqueous casting, enabling leak-free, bend-tolerant gel electrolytes and separators [82,83]; chitosan and cellulose often require harsher solvents or complex regeneration routes, while alginate’s performance can drift as crosslinkers redistribute. Third, agar’s abundant hydroxyl and ether groups provide a neutral yet sticky surface chemistry that binds well to both organic (conducting polymers such as PANI/PPy) and inorganic additives (carbon blacks, graphene, CNTs, metal oxides), promoting uniform dispersion and strong electrode–binder adhesion; chitosan’s cationic amines can interact too strongly with anionic species, complicating electrochemistry, and alginate’s carboxylates can sequester active cations, whereas cellulose’s relatively inert backbone may require extra functionalization to achieve comparable interfaces [84,85,86]. Next, agar gels exhibit broad thermal and electrochemical stability: they resist drying-induced cracking, reduce solvent evaporation, and help extend the usable voltage of aqueous devices by maintaining a sealed microenvironment; cellulose and chitosan films are heat-stable as solids but can undergo phase or chemical changes in alkaline or highly oxidative regimes, and alginate networks soften as crosslink ions are displaced. In practical architectures, agar has proven effective as a gel electrolyte for flexible supercapacitors (stable capacitance under bending/twisting), as a green binder for high-expansion anodes (improved adhesion and cycling vs. conventional binders), and as a dendrite-suppressing host for aqueous metal-ion batteries (smooth plating/stripping and wide operating temperatures) [17,31,86,87]. Taken together, high ionic flux at low polymer fraction, simple and benign processing, resilient mechanics, and additive-agnostic interfacial chemistry are traits that consistently position agar ahead of cellulose, chitosan, and alginate for next-generation, flexible, and sustainable energy storage devices.

5. Agar-Based Composites

Agar-based composites represent a paradigm shift from native agar, transcending its inherent limitations by integrating diverse functional particles to achieve multidimensional enhancements. Unlike native agar, which exhibits modest thermal stability, mechanical fragility, and limited electrical conductivity, composites reinforced with metallic nanoparticles (e.g., Fe, Ag, Cu) or carbon derivatives (graphene, carbon nanotubes) demonstrate remarkable thermal resilience, withstanding high-temperature environments in battery systems or catalytic processes [3,14]. The incorporation of fillers like graphene oxide (GO) or reduced graphene oxide (rGO) introduces exceptional mechanical strength, transforming brittle agar into flexible, fracture-resistant films ideal for bendable supercapacitors [88,89,90]. Electrically insulating native agar gains conductive pathways through additives such as silver nanowires or polyaniline, enabling efficient charge transport in electrodes. Additionally, hybridizing agar with polymers (e.g., chitosan, PVA, etc.) or silica nanoparticles enhances hydrophobicity and structural integrity without compromising its biodegradability. These composites also retain agar’s eco-friendly essence while addressing critical challenges like swelling in aqueous electrolytes or cycle instability in energy devices [91,92,93]. By synergizing agar’s natural versatility with advanced nanomaterials, these composites redefine performance benchmarks, offering tailored solutions for thermal management, mechanical durability, electrochemical activity, and environmental sustainability in energy storage technologies.

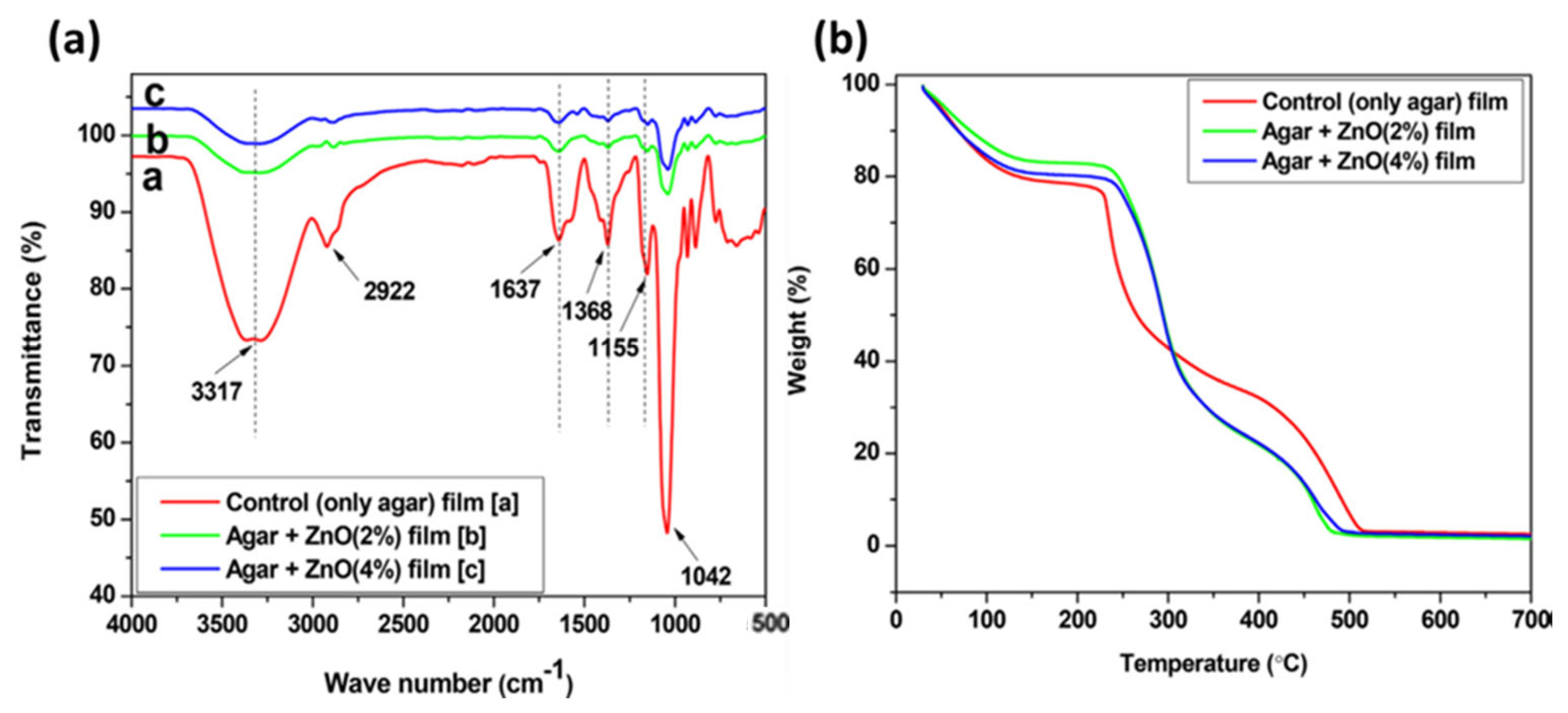

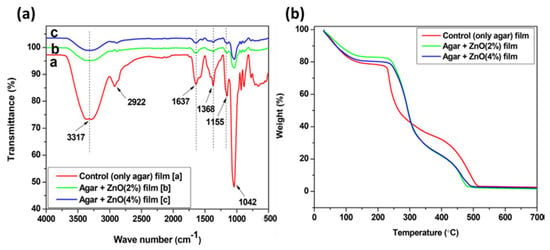

The addition of various additives to agar-based polymeric matrices yields positive outcomes, as demonstrated through systematic physicochemical and thermal characterization techniques. Kumar et al. [94] demonstrated that native agar behaves very differently from its composites, as shown through FTIR spectroscopy and thermogravimetry studies (see Figure 6a,b). The native agar film exhibited peaks corresponding to -NH2, -OH, -CH3, and C=O groups. However, these peak intensities were reduced in the agar–ZnOPs composite films, suggesting a transformation of native agar into a different form within the composite, without major structural changes. Thermogravimetric analysis further highlighted the distinct behavior between native agar and its composites (see Figure 6b). The composite films showed higher thermal stability, with a shift in maximum weight loss from 225 °C in the composites, indicating enhanced stability due to the incorporation of ZnONPs. This enhanced thermal stability is consistent with moisture removal, degradation of glycerol, and removal of organic groups.

Figure 6.

(a) FTIR spectra of agar, and agar/ZnO composite films; (b) TGA profile of agar, and agar/ZnO composite films (reproduced with permission) [94].

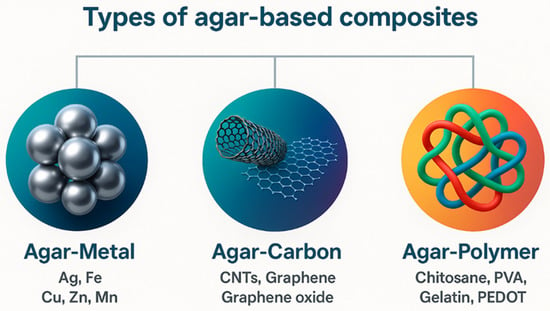

5.1. Types of Agar-Based Composites

Agar-based composites are formed through the dynamic binding forces between the polysaccharide matrix of agar and various reinforcing materials, including metallic nanoparticles, carbon derivatives, and polymers (see Figure 7) [3]. The agar network, characterized by numerous hydroxyl groups, facilitates the formation of hydrogen bonds and contributes to the uniform stabilization of reinforcing components within the structure. The combination of these composites yields enhanced properties, wherein metallic nanomaterials augment electrical conductivity and antimicrobial functionality, while carbon-based additives enhance mechanical properties and thermal stability [95,96]. Additionally, polymers like chitosan [97,98] or synthetic elastomers [99,100] contribute flexibility and stimuli-responsive characteristics. The structural combination of agar preserves its biodegradability while incorporating the additional features of secondary materials into unified hybrid units. Such hybrid materials are utilized in antibacterial wound dressings for medical applications, stretchable conductive sensors, and sustainable, degradable packaging. The molecular structure of these materials enables them to combine with other elements for improved macroscopic properties in environmental and biomedical research.

Figure 7.

Various types of agar-based composites.

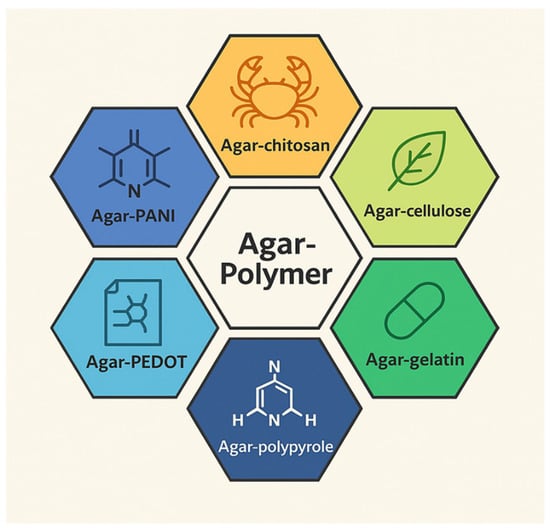

5.1.1. Agar–Polymer Composites

Innovative applications are made possible by agar’s wide compatibility with polymers, including PVA [101], butylene adipate [102], chitosan [97], gelatin [103], starch [104], and polyethylene glycol [105,106,107,108]. Agar’s idiosyncratic nature enables researchers to craft cutting-edge composites that revolutionize sustainable synthetic methods, biodegradable films, electroactive scaffolds, and environmentally friendly applications. Various agar–polymer hybrids are shown in Figure 8.

Figure 8.

Various types of agar–polymer hybrids.

Agar serves as a strong structural matrix for numerous conducting polymers, e.g., PANI, PEDOT, PPy, etc., for improved electromechanical behavior. The intrinsic biodegradability of agar and the adjustable conductivity of conductive polymers are the main advantages that distinguish these hybrids [27,109,110,111,112,113]. When combined, they offer a highly flexible and environmentally benign framework for creating cutting-edge energy storage materials that are suited to particular performance requirements. These composites, which combine the sustainability of agar with the capabilities of conductive polymers, open the door to creative, high-performing energy storage solutions that are both technologically and environmentally sophisticated [70,114].

Kang et al. examined the application of ϰ-carrageenan–agar (ϰC-Agar) composite materials as biodegradable elements in triboelectric nanogenerators (TENGs). The research demonstrates that a composite material with an optimal concentration exhibits a 57.5% enhancement in electron-donating properties, attributed to improved charge trapping enabled by Ca2+ cations and sulfate ester groups. The material exhibited enhanced biocompatibility, as indicated by positive MTT assay results and diminished inflammation in subdermal assessments, due to its hydrophilic properties. A thin, flexible TENG was developed, demonstrating significant output and highlighting the potential of ϰC-Agar composites for self-powered transient electronics [115]. Lin et al. synthesized quaternary polysaccharide gels utilizing konjac glucomannan (KGM), xanthan gum, κ-carrageenan, and agar, achieving optimal springiness and thermal stability at their ideal composition. The gels demonstrated pseudoplastic properties and enhanced solid-like behavior at higher temperatures, rendering them suitable for practical applications [116]. Qiao et al. investigated ternary systems comprising agar, KGM, and κ-carrageenan, revealing that κ-carrageenan concentrations below 25% increased both the sol–gel transition temperature and gel hardness. Ternary composites demonstrated superior performance compared to binary agar/KGM composites in terms of stable mechanical properties and hydrophilicity across varying relative humidity levels, indicating their potential for diverse applications with improved material characteristics [117]. Shakya et al. demonstrated that the addition of TEMPO-oxidized bacterial cellulose to agar matrices enhanced the hemostatic and mechanical properties of the resulting agar and oxidized bacterial cellulose composite cryogels. The cryogels exhibited a rapid blood-clotting capability of 90 s in vitro, comparable to the performance of commercial products Axiostat and Surgispon [118]. In another study, the development of environmentally friendly nanocomposite fibers through dry-jet wet spinning involved all-biomass agar and cellulose nanocrystals. The developed fibers improved mechanical stability while demonstrating rapid methylene blue (MB) adsorption, which implies their potential to reduce water pollution from plastic wastes. The study illustrates how sustainable materials present a solution to environmental issues that appear when fiber-based commodities become waste products [119]. Manna et al. synthesized Fe(III)-crosslinked cellulose–agar beads via sol–gel methods for phosphate removal in water. The optimal conditions facilitated the beads’ adsorption of 94% of phosphate, achieving a maximum adsorption capacity of 73.13 mg/g at pH 5. The adsorbents demonstrated stable performance, retaining 42% of their initial removal capacity over six adsorption–desorption cycles utilizing sodium chloride as the desorption agent. This study shows that hydrogel beads are effective in water purification systems [120].

Namasivayam et al. synthesized biocomposites using starch, gum acacia, agar, chitosan, and PVA via environmentally friendly methods. The chitosan–starch–gum acacia biocomposite demonstrated significant herbicidal effects, resulting in necrotic lesions that expanded from 6 h to a maximum size of 30.0 mm. These biocomposites released herbicidal metabolites in controlled patterns under in vitro and in soil conditions, preserving soil health and promoting plant growth without toxic effects, thereby demonstrating their agricultural potential [91]. Safarimehr et al. developed a triple-layer intelligent film composed of chitosan, gelatin, and agar, incorporating 4% w/v roselle anthocyanin extract for monitoring the freshness of red snapper fish. The film demonstrated pH-sensitive color changes from dark red to pale red with greenish hues, indicating spoilage when volatile basic nitrogen levels in fish surpassed safety thresholds over a 7-day storage period at 4 °C [121]. Safarimehr et al. synthesized Fe3O4 microspheres coated with chitosan and agarose, subsequently immobilizing palladium nanoparticles to generate Fe3O4 MPs@CS–agar/Pd NPs, which exhibited efficacy in Suzuki–Miyaura reactions. The nanocatalyst demonstrated durability due to its nanostructured characteristics, allowing up to eight consecutive applications without a decline in activity [122]. Table 1 shows various types of agar–polymer hybrids and their applications in energy storage devices.

Table 1.

Different types of agar–polymer composites, their methods of synthesis, properties, and applications in energy storage devices.

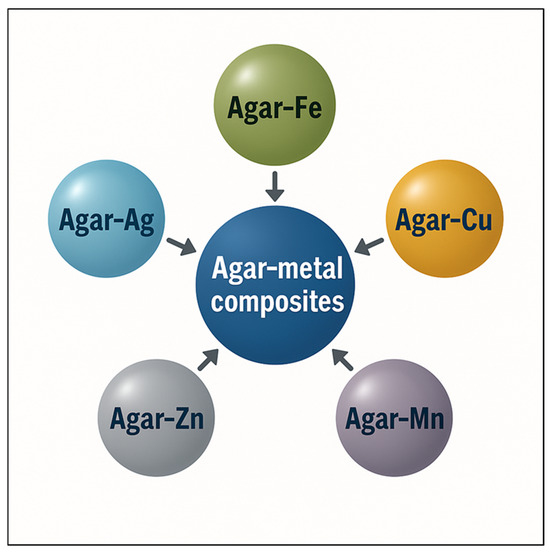

5.1.2. Agar–Metal Composites

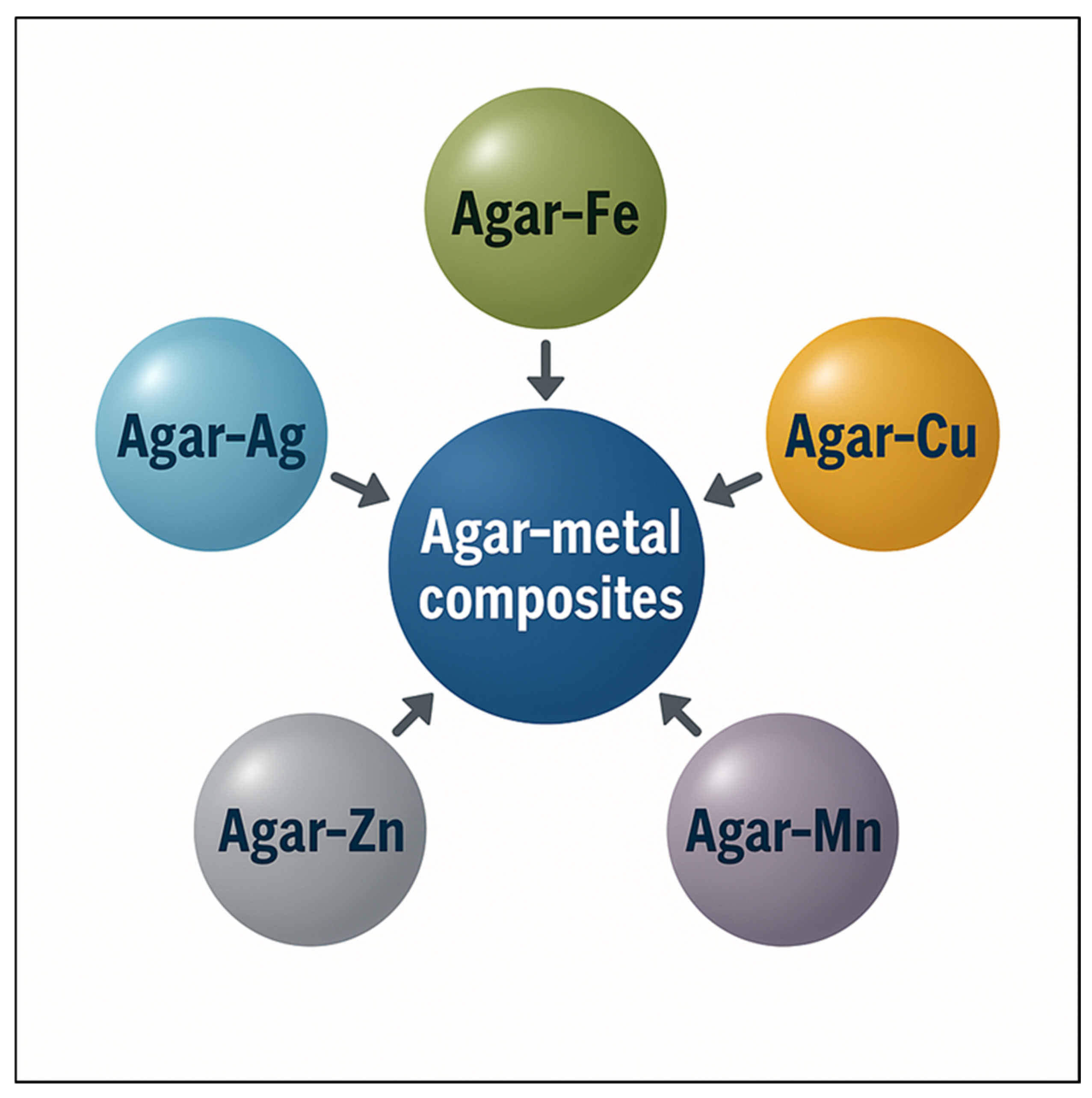

Due to nano-metals’ unique functional properties and agar’s biocompatibility, composites of metals and agar have many innovative applications. Silver’s significant antimicrobial effects are used in wound dressings and antibacterial coatings [129,130,131,132], and zeolite–agar hybrids break down contaminants and absorb heavy metals in environmental cleanup due to iron’s magnetic characteristics [131,133,134]. Agar–magnetic composites have versatile applications in biomedical, environmental, and electrical fields [13,14]. The customizable porosity and environmentally friendly degradability of these composites make them suitable for healthcare and packaging applications. Eco-friendly agar and multi-purpose metals create sustainable materials with significant technological potential for biomedical, environmental, and industrial uses. Figure 9 shows various agar–metal functional hybrid composites.

Figure 9.

Different types of agar–metal composites.

Magesh et al. developed ZnO nanoparticles using agar biopolymer, which influenced their morphology and optical properties. The study demonstrated that agar/ZnO nanocomposites exhibit antibacterial activity against Gram-positive and Gram-negative bacteria and show dose-dependent cytotoxicity in normal and cancer cell lines [135]. Roy et al. developed a pectin/agar-based composite film enhanced with zinc sulfide nanoparticles, which improved the film’s mechanical strength and UV protection. The film maintained its transparency and original properties, showing strong antibacterial activity against E. coli and L. monocytogenes, suggesting potential for active packaging applications [136]. Hu et al. developed a biosafe composite hydrogel (MSG-Zn2+) by crosslinking sodium alginate and agar with Ti3C2Tx MXene and zinc ions for wound-dressing applications. This hydrogel combines the photothermal properties of MXene and the antimicrobial activity of zinc, offering effective photothermal and chemical antibacterial therapies. It demonstrated broad-spectrum antibacterial effects against both Gram-positive Staphylococcus aureus and Gram-negative Escherichia coli, with excellent biocompatibility and enhanced cell migration, indicating its potential as an economical and efficient wound dressing [137].

Agar–silver composites not only revolutionize biomedical and environmental research but also hold promising potential in enhancing energy storage technologies. Rhim et al. prepared composite films using silver nanoparticles (AgNPs) and agar, where the AgNPs were synthesized through an environmentally friendly reduction method involving trisodium citrate and heating. These films showed enhanced water-vapor barrier properties and increased surface hydrophobicity with higher AgNP concentrations while maintaining mechanical strength. Films with more than 1 wt% AgNPs demonstrated strong antimicrobial activity against both Gram-positive (Listeria monocytogenes) and Gram-negative (Escherichia coli O157:H7) bacteria [138]. Ghosh et al. developed highly stable Ag/agar films that demonstrated strong and sustainable antimicrobial effects against E. coli, S. aureus, and particularly C. albicans, with retained mechanical strength even after multiple use cycles [139]. Mostafa et al. developed an agar–carboxymethylcellulose–AgNP nanocomposite, which demonstrated a high adsorption capacity for MB dye. The adsorption process conformed to the Langmuir isotherm and pseudo-second-order kinetics, indicating its potential as a reusable biosorbent, although its efficacy decreased after multiple cycles [140].

Agar–iron-based composites, particularly those incorporating magnetic particles, are transforming diverse research fields with their versatile applications. For instance, Shah et al. synthesized highly intercalated magnetic composites using montmorillonite clay, agar, and magnetic iron oxide nanoparticles through a thermo-physicomechanical method. These composites demonstrated increased hydrophobicity and improved thermal stability, showing significant antibacterial activity against Escherichia coli and notable antioxidant properties, along with conductor-like electrical behavior [14]. Gautam et al. prepared agar-based aqueous suspensions with lignin magnetic nanocomposites using a pH-driven co-precipitation method. The study demonstrated that adding low concentrations of lignin-coated Fe3O4 nanoparticles to the suspension enhances thermal conductivity by up to 10% at 45 °C. Additionally, varying magnetic fields at room temperature initially increased the thermal conductivity, with a peak at 0.02 T, before decreasing at higher fields due to nanoparticle aggregation [141].

Gupta et al. demonstrated that using agar in a sol–gel synthesis technique enhances the structural and electrochemical properties of LiNi0.8Co0.1Mn0.1O2/C cathodes for lithium-ion batteries. The agar-assisted method produced bi-pyramidal particles with a high specific discharge capacity of 182 mAh/g and improved capacity retention of 78% after 50 cycles. This approach resulted in lower charge-transfer resistance and better ion diffusion, significantly boosting cell efficiency compared to traditional methods [142]. Lu et al. developed olivine-structured LiMn0.5Fe0.5PO4 cathode materials for energy storage applications. The optimal synthesis at 700 °C yielded cathodes with superior electrochemical performance, characterized by lower charge-transfer resistance and high capacity retention of 95% after 40 cycles at a C/3 rate. This method demonstrated that agar effectively facilitates the synthesis of phase-pure LiMn0.5Fe0.5PO4, enhancing the structural and functional properties of the cathode material [143]. Table 2 indicates various agar-metal composites, synthesis and energy storage devices applications.

Table 2.

Various agar–metal composites, their methods of synthesis, properties, and applications in energy storage devices.

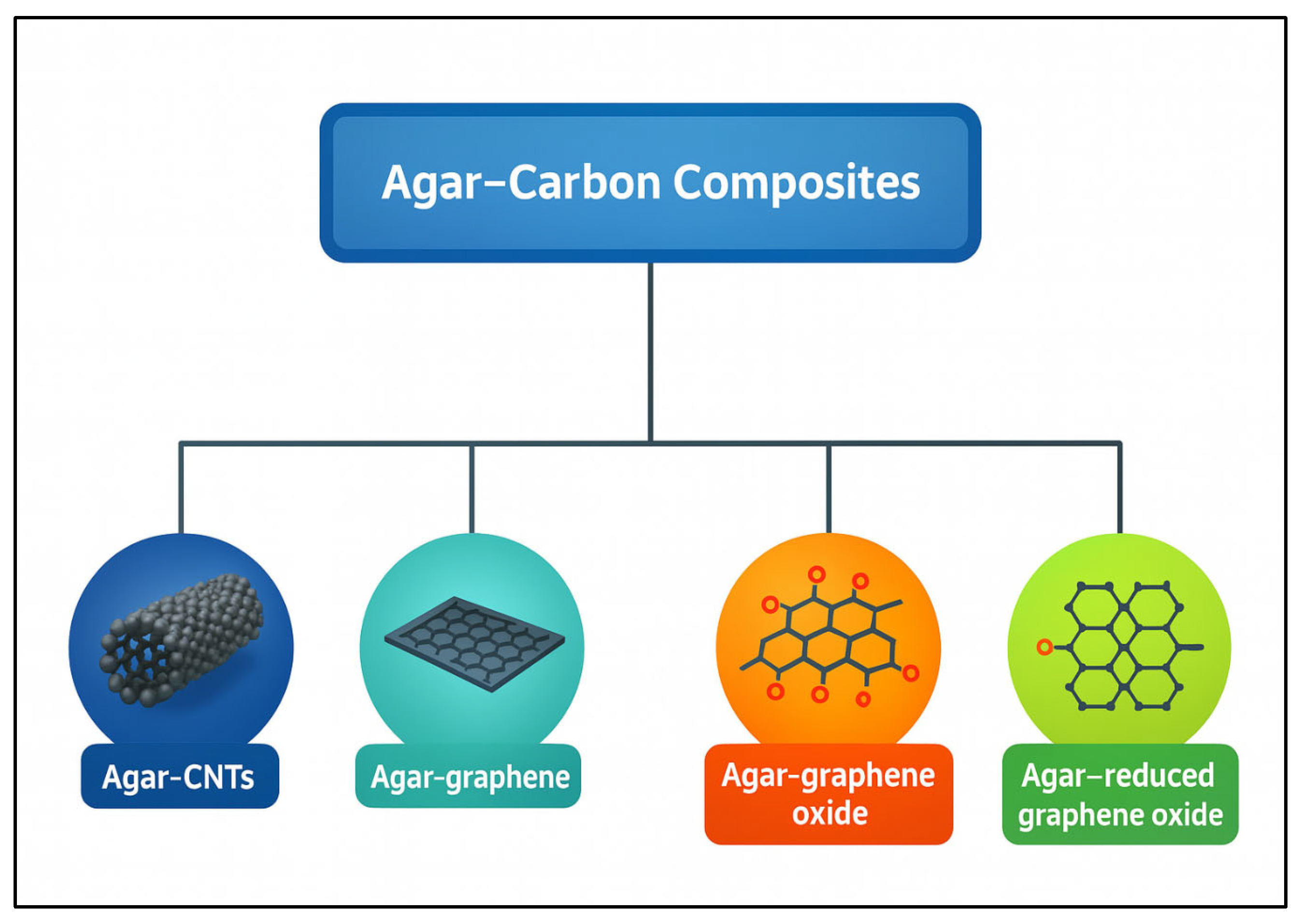

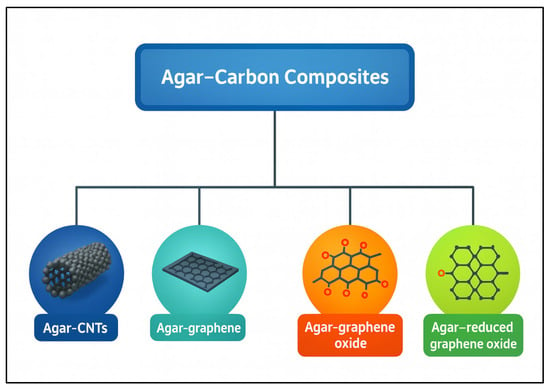

5.1.3. Agar–Carbon Composites

Agar–carbon composites (see Figure 10) represent a significant advancement in the development of functional materials applicable to energy storage devices. These composites leverage the unique properties of agar and carbon-based materials, such as graphene, graphene oxide, and carbon nanotubes, by incorporating them into the agar matrix [152,153,154,155,156,157]. Agar provides two critical functions: it serves as a biocompatible scaffold that facilitates the distribution of carbon materials and enhances both electrical conductivity and structural strength. The electrochemical performance of composites is significantly enhanced due to graphene’s superior electrical conductivity and high surface area, rendering them suitable for applications in supercapacitors and batteries. The incorporation of carbon nanotubes in electrode design enhances structural integrity and electrical connectivity [158,159,160,161,162]. The synergy between agar and carbon materials enhances energy storage capability and cyclic reliability in devices, while also promoting flexible and environmentally sustainable designs for advanced energy systems as summarized in Table 3. Next-generation energy storage technologies necessitate innovations that ensure high efficiency and environmental sustainability.

Figure 10.

Various types of agar–carbon composites.

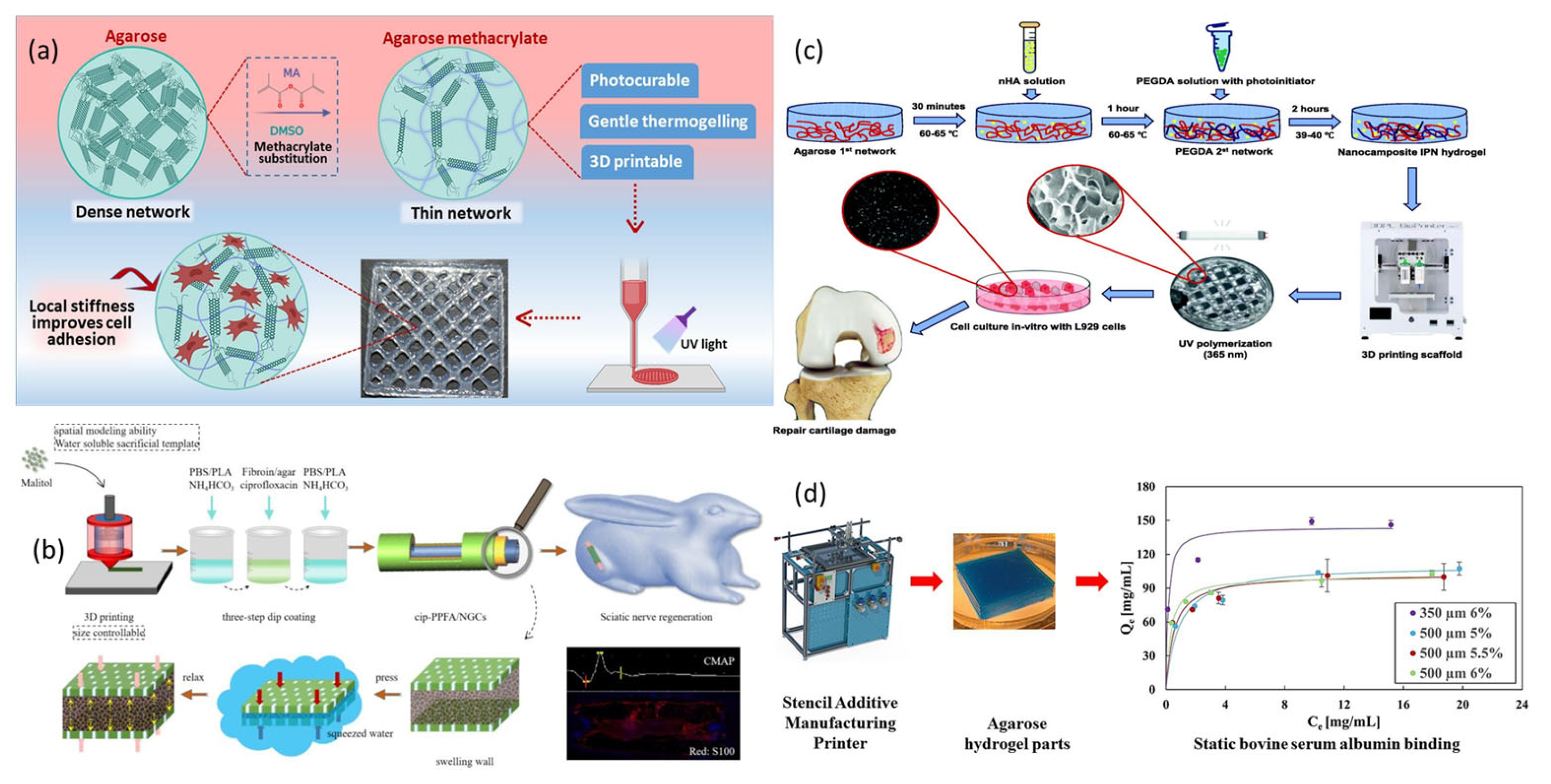

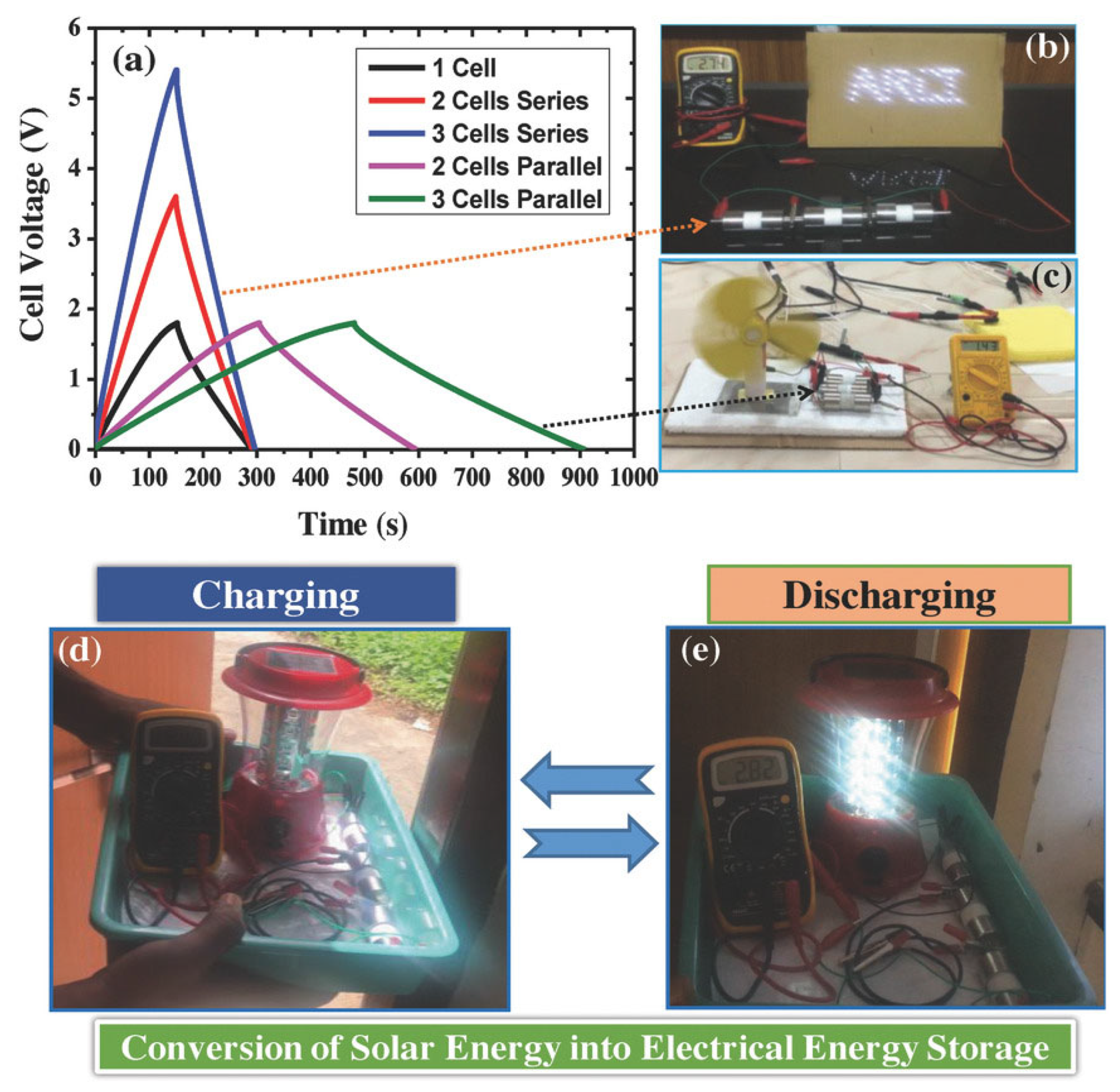

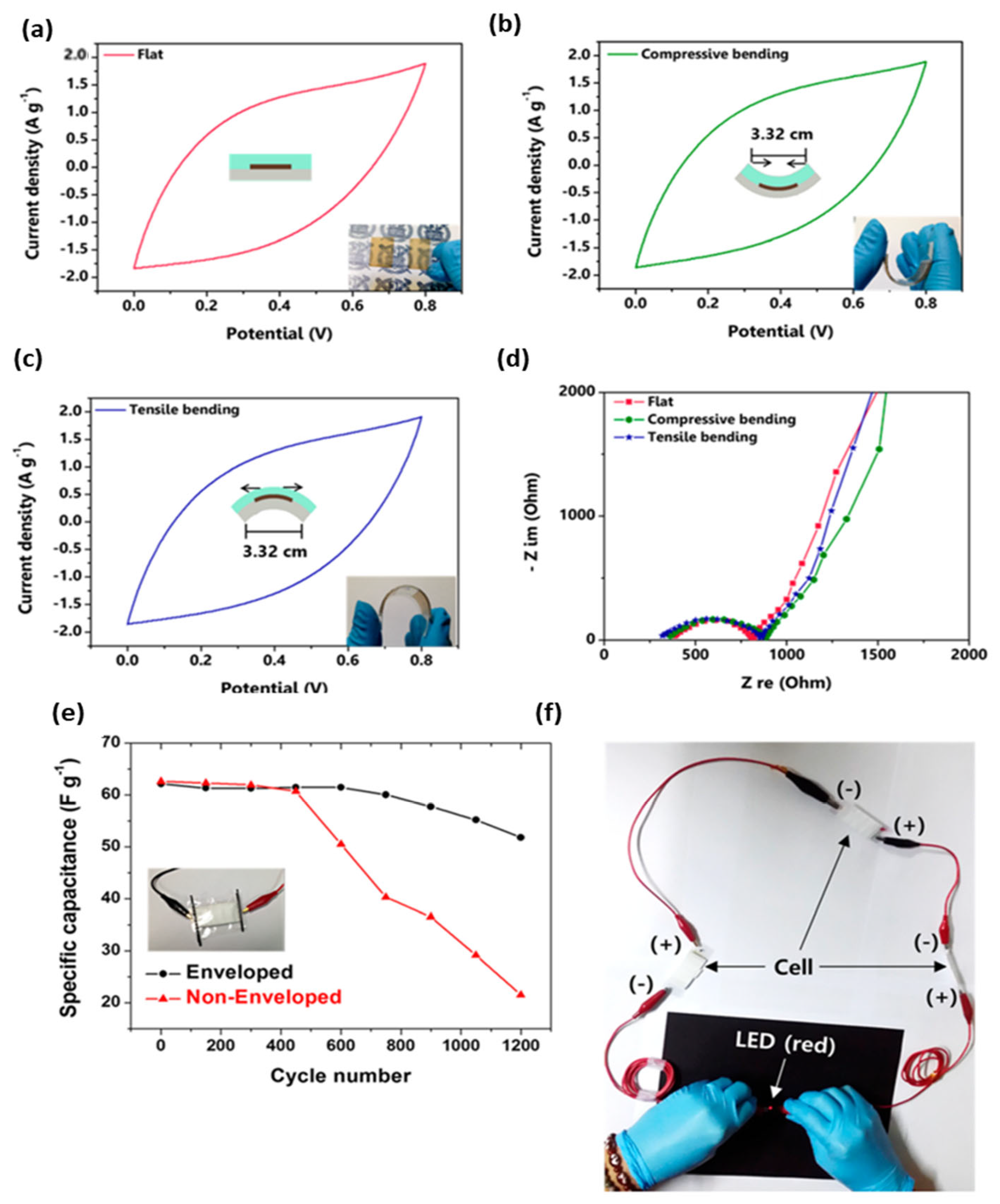

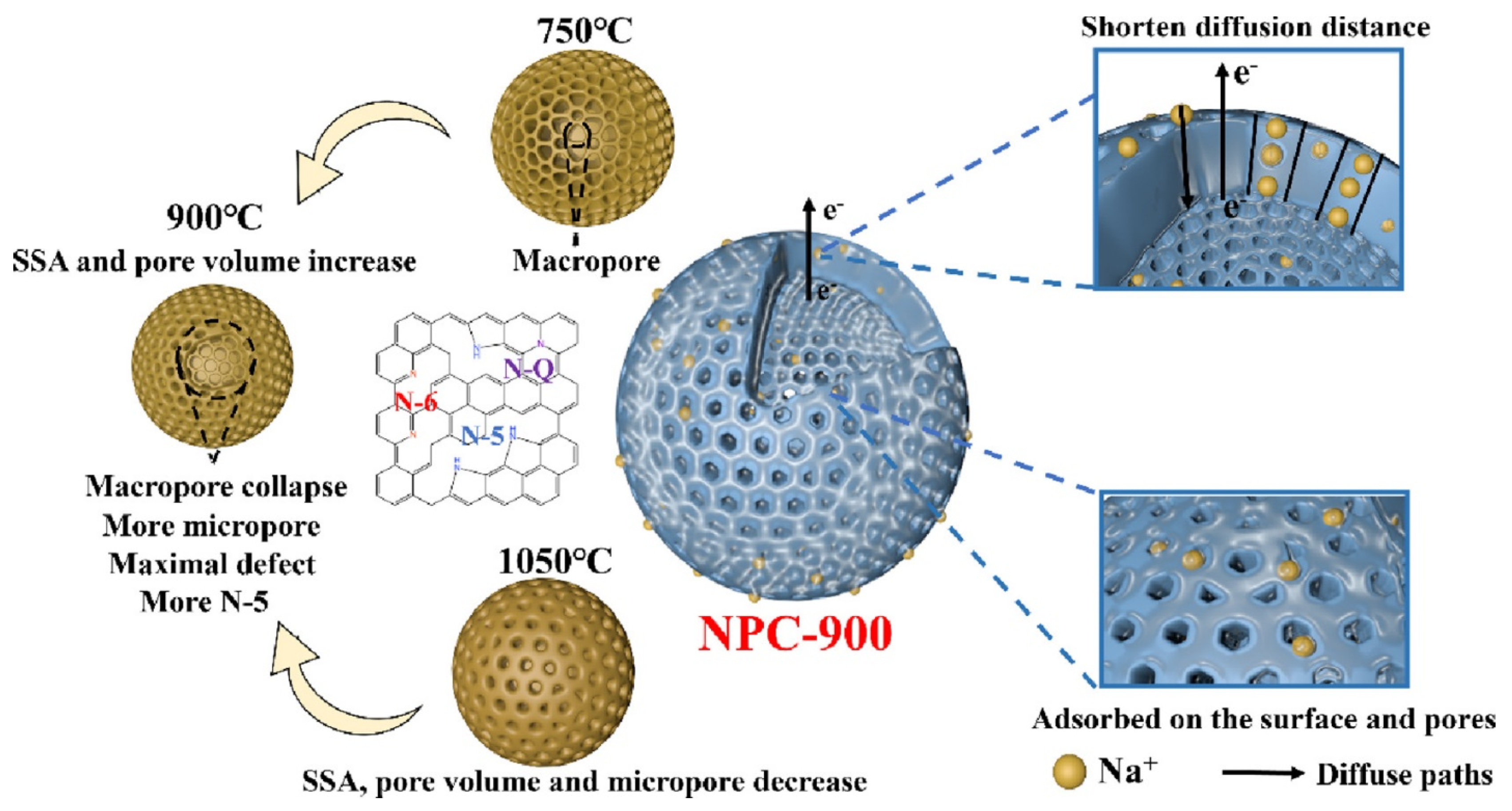

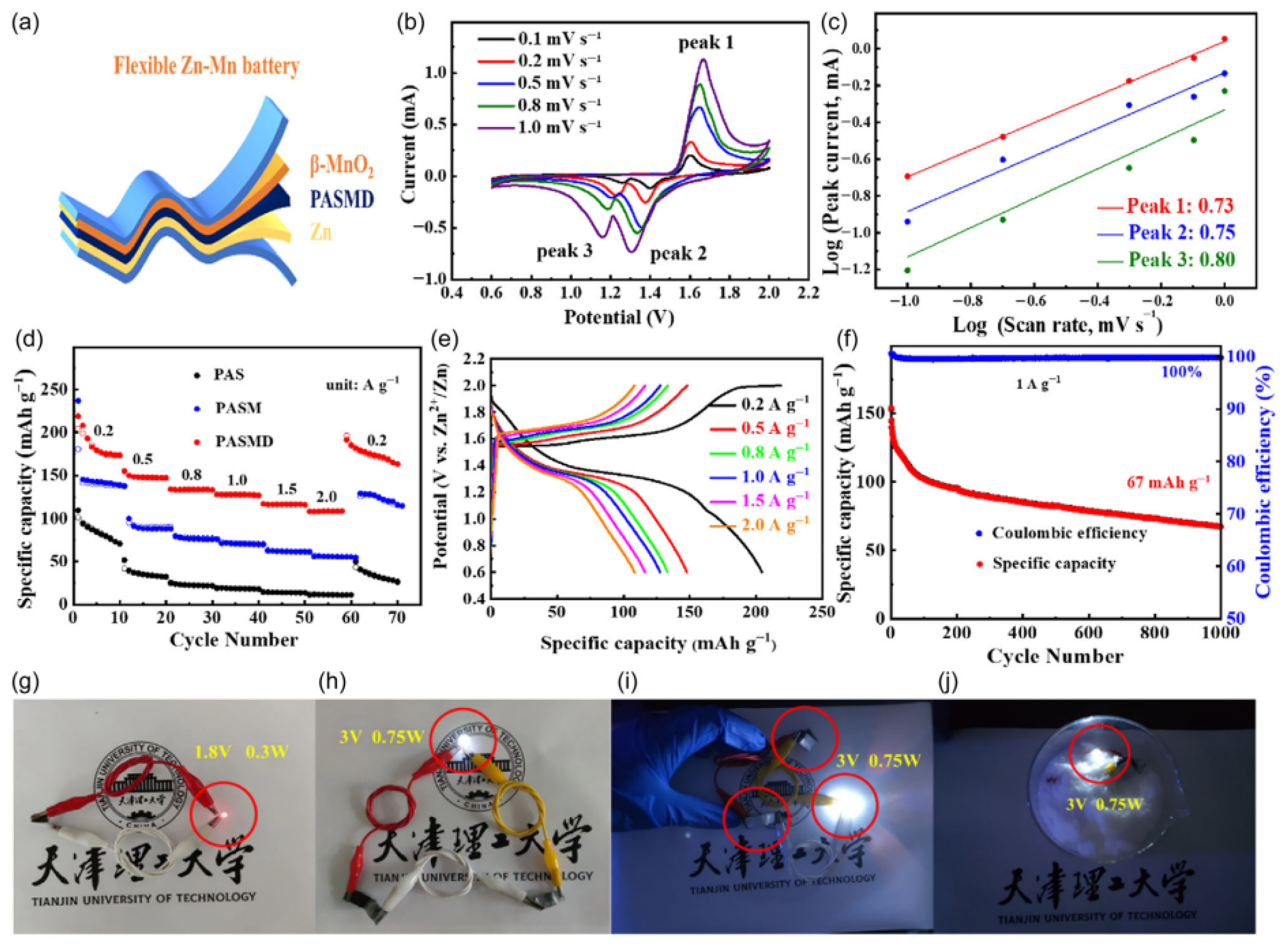

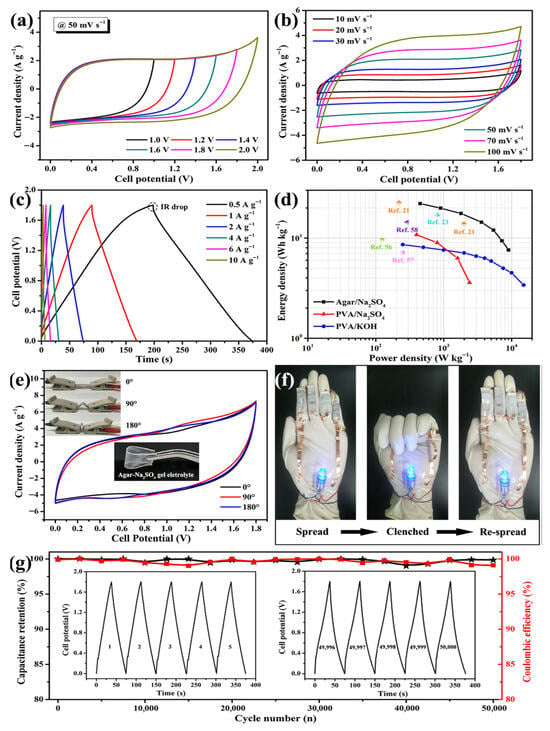

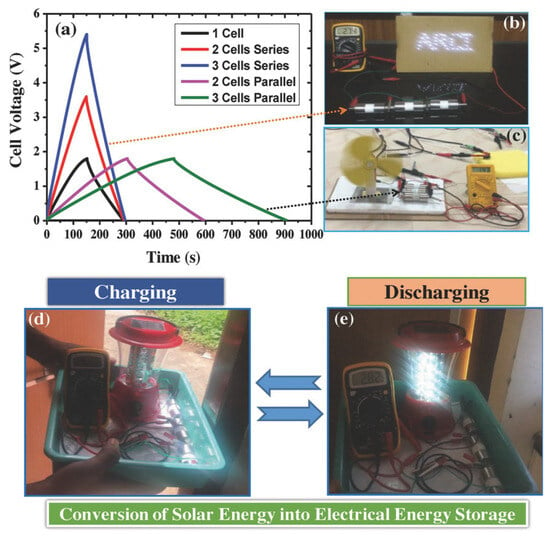

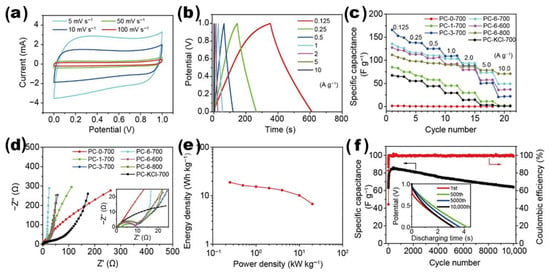

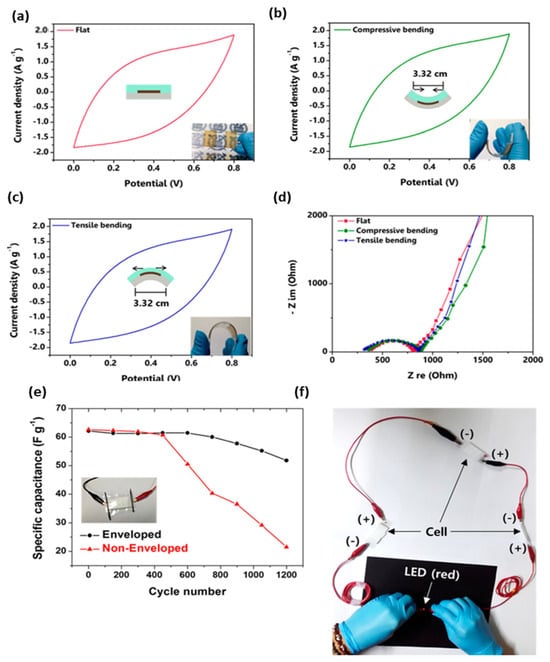

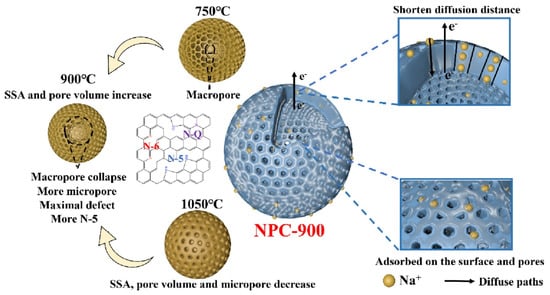

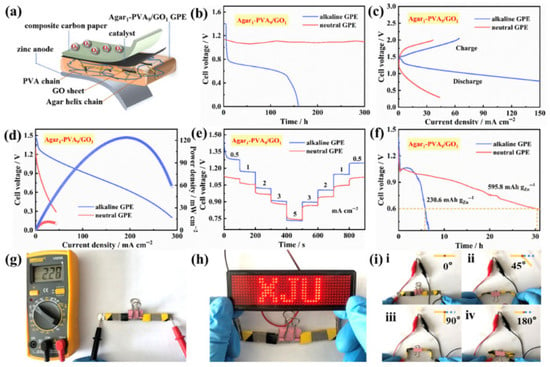

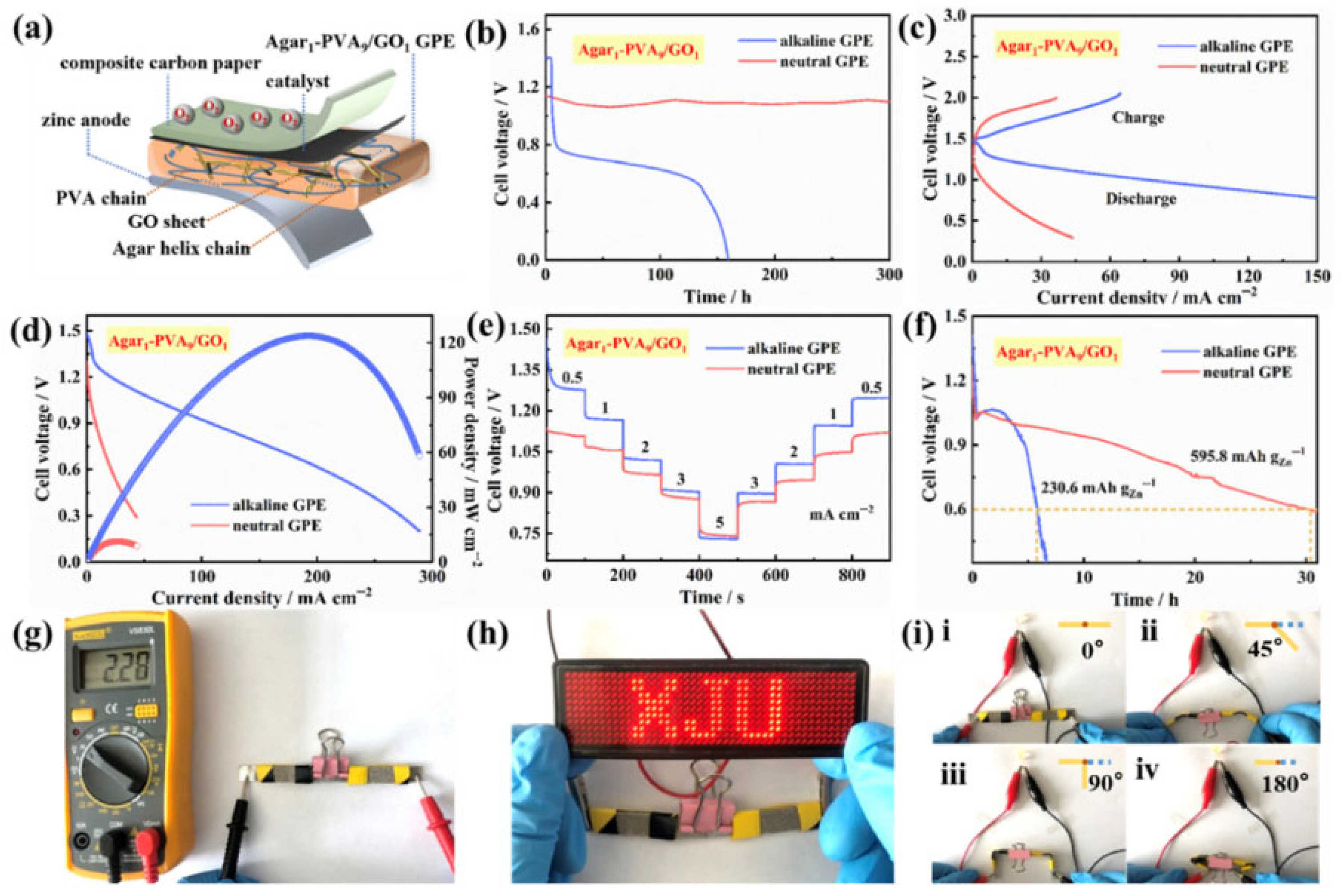

Yang et al. presented a double-network hydrogel electrolyte that functions as a component of a flexible zinc–air battery (FZAB), demonstrating significant ionic conductivity alongside robust mechanical stability. The hydrogel electrolyte comprises two networks: a rigid agar network and a secondary polyvinyl alcohol (PVA) network, achieving a power density of 123.7 mW/cm2, a stretchability of 246%, and a maximum tensile strength of 388 kPa. The electrolyte system enables FZABs to function effectively under various bending conditions, demonstrating significant potential for flexible energy storage applications [163]. Ji et al. developed biomass agar-derived N-doped porous carbon (NPC) at varying carbonization temperatures, optimizing the NPC-900 variant for sodium-ion batteries (SIBs). NPC-900 demonstrated a superior reversible capacity and excellent rate capability, achieving a high practical energy density of 267 Wh/kg when paired with a Na3V2(PO4)3 cathode, highlighting its potential for efficient sodium storage [164]. Chen et al. developed a three-dimensional agar/GO composite aerogel with a high MB adsorption capacity of 578 mg/g, showcasing endothermic and spontaneous adsorption kinetics. The aerogel maintained over 91% of its adsorption capacity after three recycling rounds, using a dilute NaOH solution for regeneration [10].

In another study, a novel triple-network hydrogel combining PVA, agar, and graphene nanoplatelets was developed through a one-pot, green solution-mixing method. This hydrogel exhibited high strength, toughness, and rapid self-healing within 10 min, making it suitable for various biomedical applications [165]. Belay et al. enhanced the mechanical properties and water resistance of agar by incorporating GO and reduced RGO, which increased the tensile strength by 118.4% and 69.4%, respectively, at 2% loading. The composite films showed improved hydrophobicity and resistance to swelling, although the tensile strength decreased at higher reinforcement concentrations due to pore formation [7]. De Araujo et al. developed nano-biocomposite hydrogel samples using GO and agar, which were effective in adsorbing cationic dyes Nile Blue A (NB) and MB from water, achieving maximum adsorption capacities of 284.69 mg/g for NB and 141.48 mg/g for MB. The hydrogels maintained consistent adsorption capacity through five cycles, demonstrating significant regenerative potential [166]. De Araujo et al. synthesized a hydrogel biocomposite using GO and agar biopolymer (agar–GO) for fixed-bed adsorption in textile wastewater treatment, showing high adsorption capacities for dyes like Nile Blue A, MB, Malachite Green, and Basic Fuchsin. The biocomposite demonstrated eco-friendly attributes, effectively treating over 6 L of wastewater and displaying significant regenerative capacity, suitable for industrial applications [167]. In a recent study, a one-step gelation process produced an agar–GO hydrogel that demonstrated effective water treatment capabilities for the removal of chloroquine diphosphate and safranin O. Batch adsorption experiments showed significant binding properties for both contaminants. The Sips model (R2 > 0.98) effectively represented the safranin O data, while the Freundlich model was appropriate for the chloroquine data. The presence of multiple contaminants in solution reduced the adsorption capacity of both pollutants by approximately 10 mg g−1 per molecule, yielding capacities of 41 mg g−1 for safranin O and 31 mg g−1 for chloroquine. The fixed-bed column assessment demonstrated effective removal of chloroquine at 63 mg g−1, while safranin O achieved 100 mg g−1, exhibiting excellent regeneration capabilities. The agar–GO biocomposite demonstrated its efficacy as an environmentally sustainable, reusable system for the effective dual elimination of pollutants in water purification applications [168]. Felipe Melo Lima Gomes et al. developed an agar–GO hydrogel to adsorb Cd(II) and Methyl Violet from water, demonstrating high adsorption capacities and effective fitting with the Sips model for isotherm data. The hydrogel showed excellent regeneration potential, maintaining strong adsorption performance through multiple adsorption–desorption cycles [169].

Tang et al. developed an environmentally friendly method to synthesize agar–rGO (ArGO), achieving controlled topological features and physical properties by varying water content. The resulting ArGO materials, ranging from water-stable dehydrated films to highly swellable hydrogels, exhibited enhanced mechanical strength and chemical stability, promising for applications in water purification and tissue engineering [170]. Belay et al. developed agar/rGO composites with enhanced tensile strength and thermal properties, showing a 55% increase in strength with just 2% rGO loading. These composites not only serve as biodegradable packaging materials but also have potential uses in supercapacitors and electric-field-induced wound healing [22]. Bagheri et al. optimized the electro-Fenton process using an agar-functionalized GO-immobilized copper ferrite aerogel to degrade MB in wastewater. They achieved 99.9% degradation under optimal conditions of 20 mg catalyst, 2 mL H2O2, 40 °C, and pH 6, demonstrating the process’s effectiveness through pseudo-second-order kinetics [171].

Table 3.

Different types of agar-carbon composite their methods of synthesis and properties and applications in energy storage devices.

Table 3.

Different types of agar-carbon composite their methods of synthesis and properties and applications in energy storage devices.

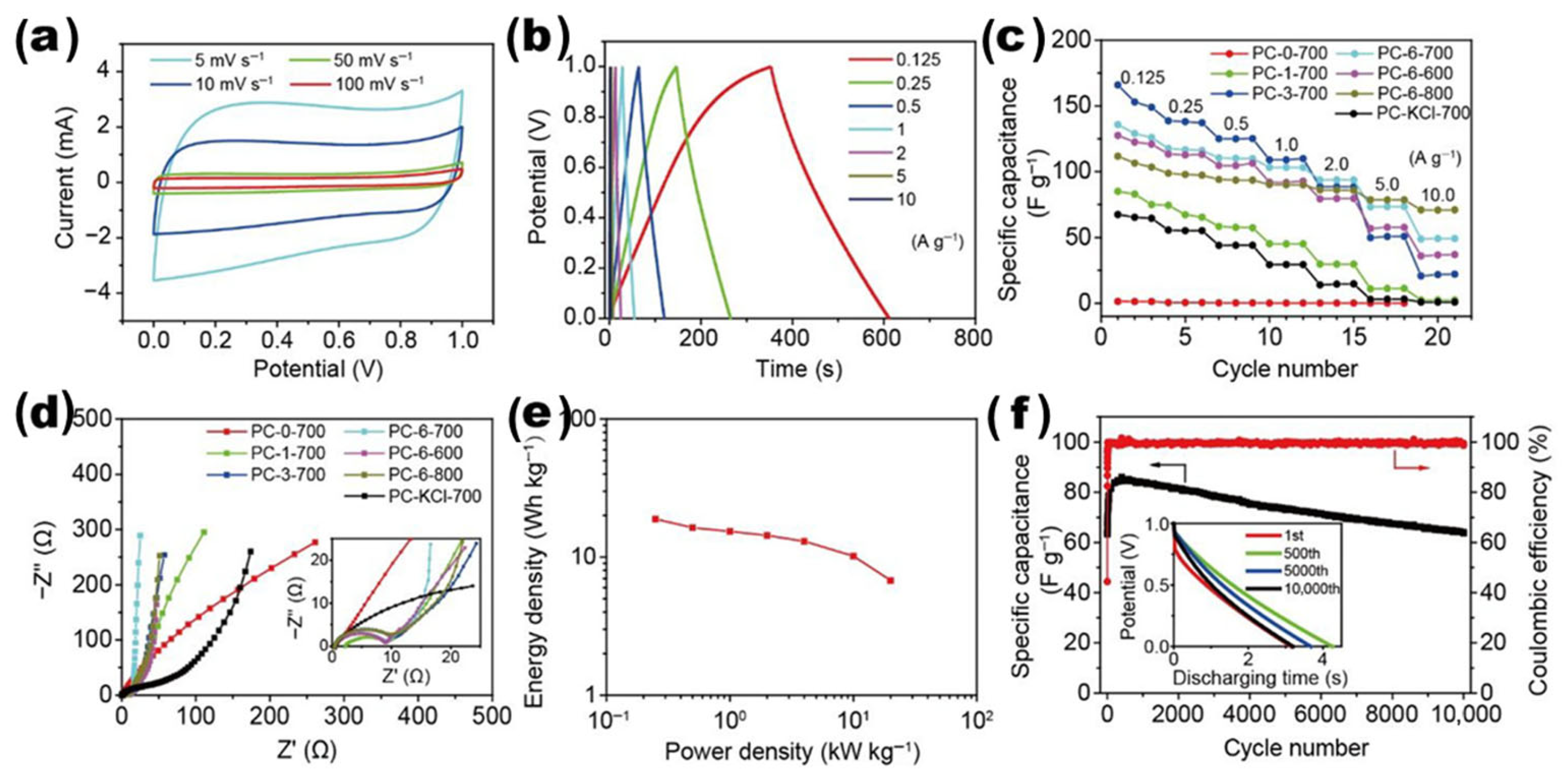

| Composite | Carbon Type | Synthesis | Properties | Application in Energy Storage | Ref. |

|---|---|---|---|---|---|

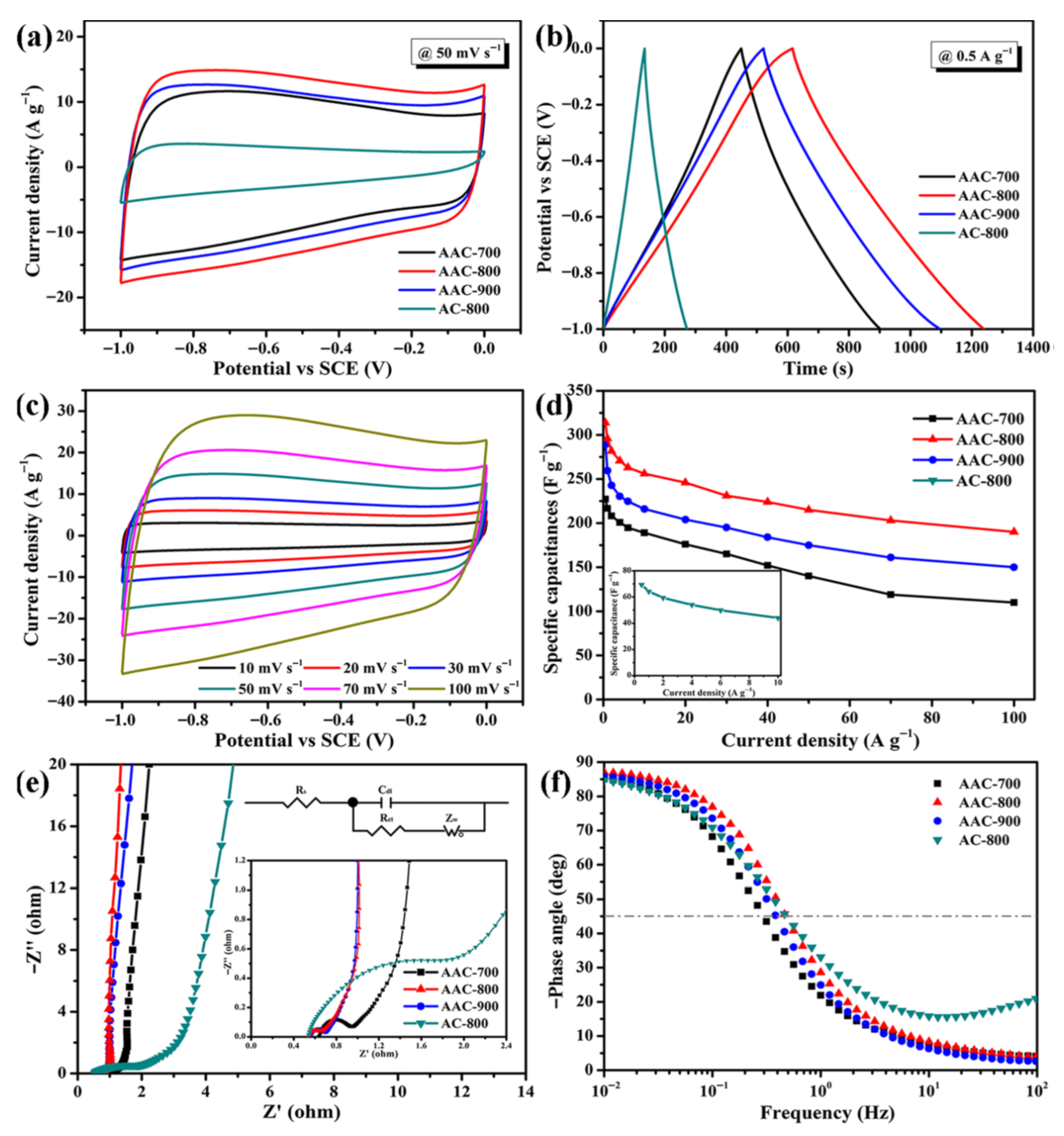

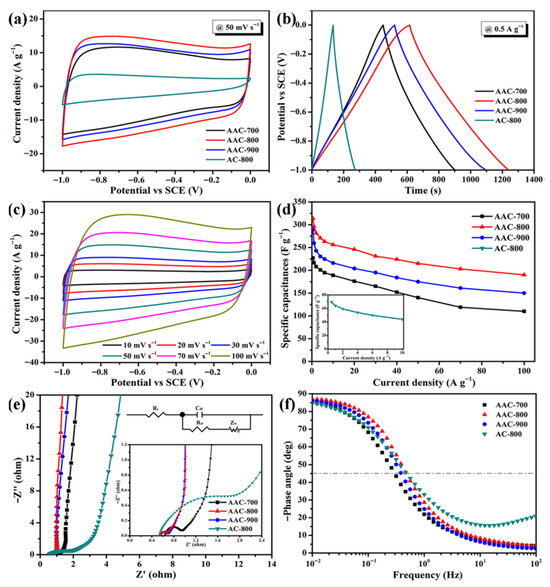

| Agar-N-doped porous carbon | N-doped porous carbon | Sol–gel process followed by freeze-drying and activation with KHCO3 | Ultra-high SSA of 3184 m2/g; hierarchical porous structure; specific capacitance of 443.0 F/g at 0.5 A/g in 6 M KOH; excellent rate capability (255 F/g at 50 A/g) | Used in supercapacitors; achieved energy density of 35.5 Wh/kg with a capacitance retention of 99.7% after 20,000 cycles | [172] |

| Nitrogen-doped porous carbon (NPC-750), coupled with LiFePO4 cathode | N-doped porous carbon | One-pot pyrolysis of agar at 750 °C | High surface area (2914 m2/g); N content (2.84%); excellent capacity and cycle life; fast charging | Anode material for lithium-ion batteries | [173] |

| Water-soluble graphene (WSG)-incorporated agar gel-electrolyte | Graphene | - | Ionic conductivity: 8.62 × 10−2 S cm−1; OCV: 1.7–1.6 V; high discharge capacity (1010.60 mAh g−1); high energy density (1406.09 mWh g−1) | Electrolyte for magnesium–air batteries | [174] |

| Agar/graphene conductive organoge | Graphene | - | Excellent adhesion to various substrates; rapid self-healing via hydrogen bonding; wearable | Wearable electronic devices for motion and physiological activity detection | [175] |

| Agarose/GO | GO | - | Ionic conductivity 73.8 mS cm−1; specific capacitance (791.67 mF cm−2) | Solid-state supercapacitor | [176] |

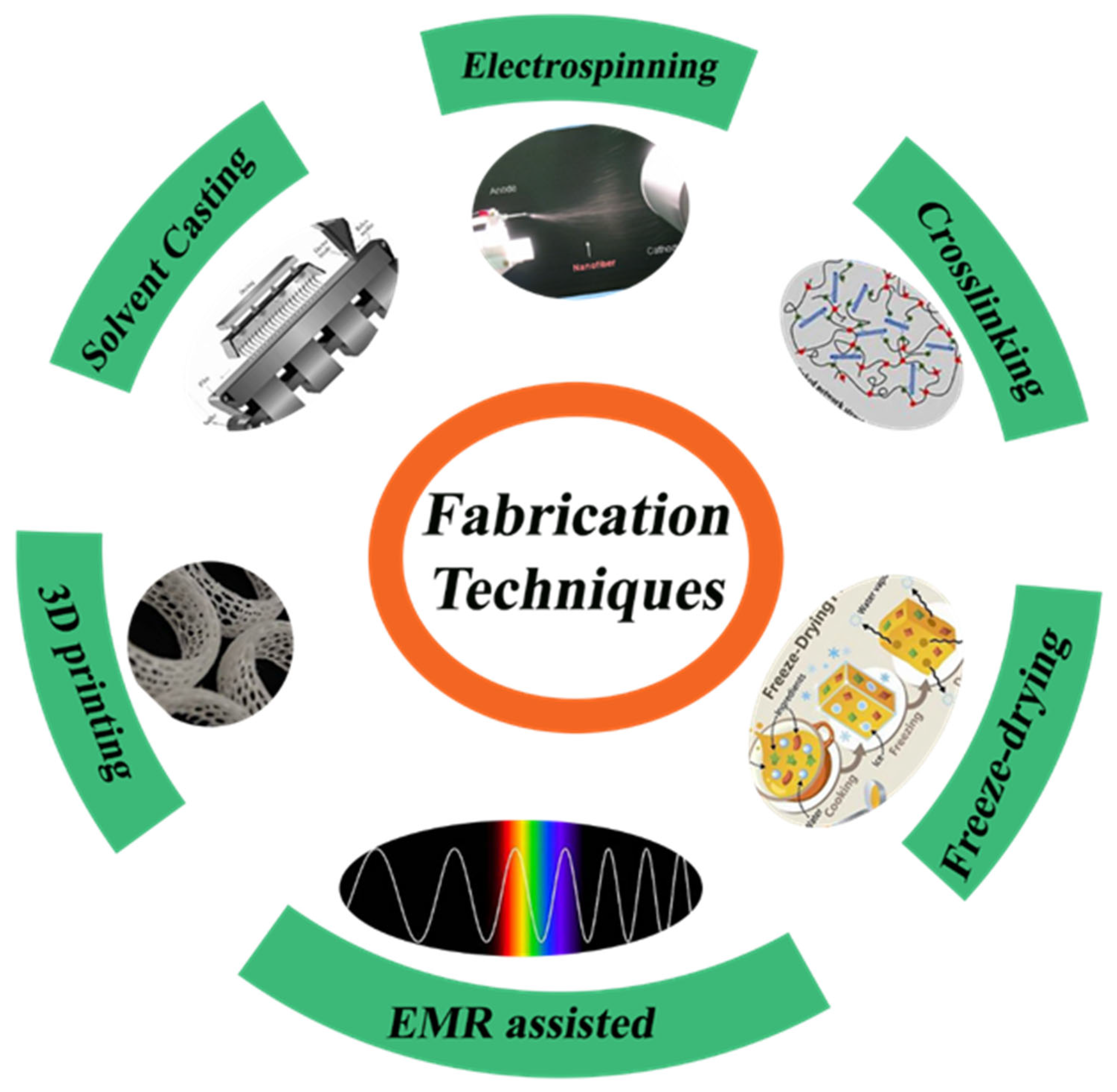

6. Fabrication Routes

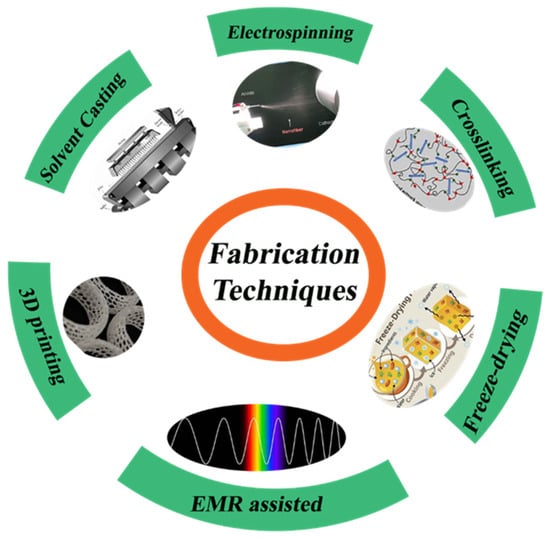

Diverse methodologies enhance the inherent qualities of agar, rendering it more advantageous for environmental technology and medicinal science. The properties of agar-based composites in energy storage depend strongly on the chosen fabrication route. Electrospinning can produce agar/PVA nanofiber mats with extremely high porosity and surface area, enhancing ion diffusion and double-layer capacitance. However, pure agar gels are not directly spinnable (hence PVA blends are required), which complicates uniform fiber formation and scale-up [101]. Solvent casting is simpler: cast agar gels or films (used as electrolytes or binders) are mechanically robust and can exhibit broad voltage-stability windows. For example, a solvent-cast agar/Na2SO4 gel showed an expanded electrochemical window (1.8 V) and excellent flexibility [177]. Likewise, a cast agar–PAM electrolyte had high Zn2+ conductivity and enabled stable Zn plating/stripping from −25 °C to 50 °C. Casting is readily scalable (e.g., roll-to-roll film formation) but tends to yield dense gels, which may limit ionic mobility. Three-dimensional (3D) printing (e.g., direct ink writing) allows customized architectures [178], but agar’s low viscosity and wide gelling range make precise printing difficult [179] (additives like alginate are usually needed). In summary, electrospun agar mats maximize surface area (raising capacitance) but require complex processing [101], whereas cast agar gels offer flexibility and wide voltage windows [50]. Three-dimensional-printed agar structures provide design flexibility but currently face rheological and throughput limitations [178,179]. These fabrication choices directly affect device conductivity, capacitance, and structural integrity. Figure 11 represents various techniques for the fabrication of agar-based composites.

Figure 11.

Various techniques for the synthesis of agar-based composites.

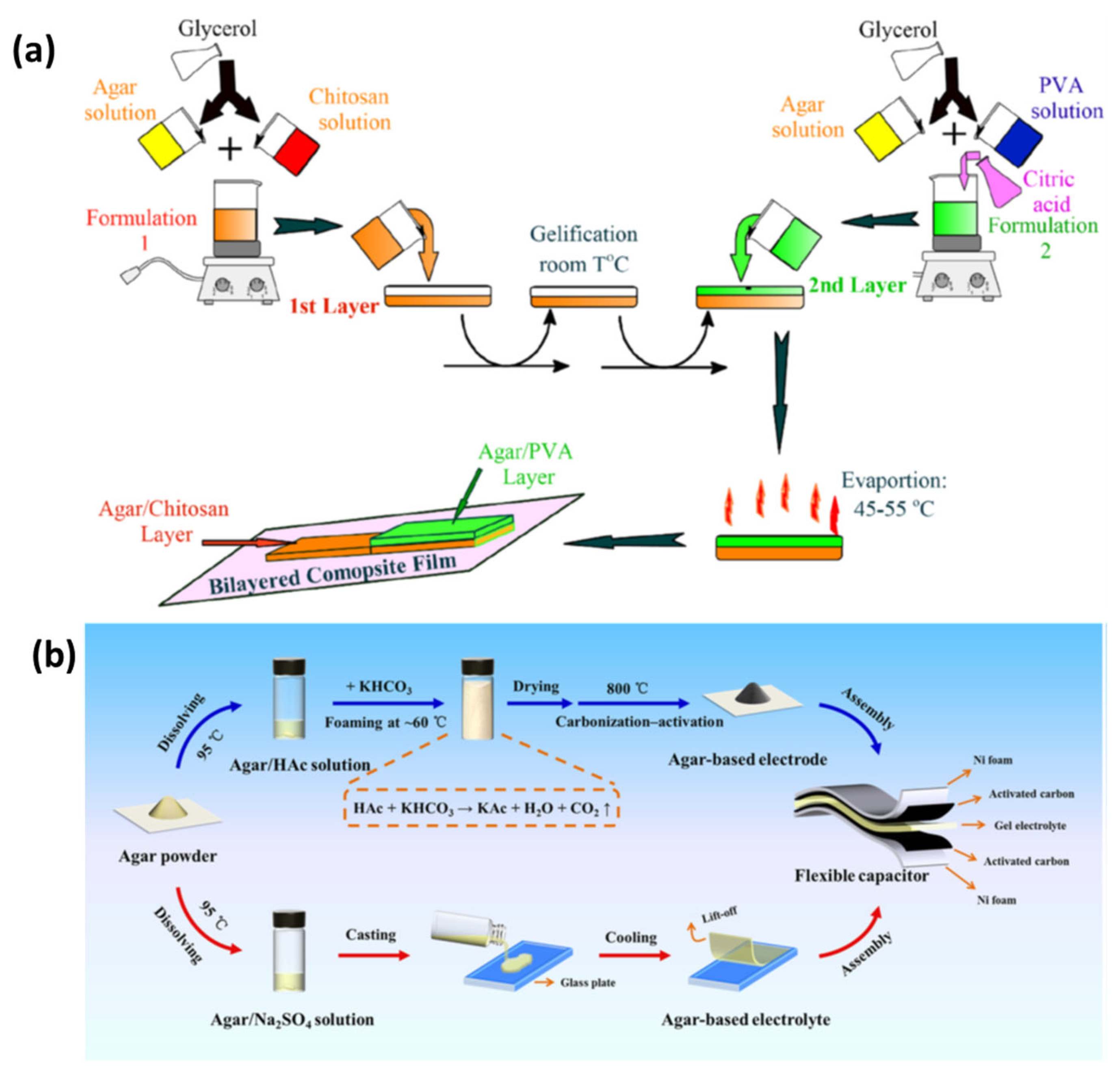

6.1. Solvent Casting

The solvent casting strategy is a cost-effective approach for producing thin films and membranes. This process involves dissolving polymers in suitable solutions, followed by pouring or spreading the mixture into molds or onto flat surfaces, leading to the formation of dried solid polymer products. The fundamental manufacturing technique allows for the utilization of diverse polymers and additives, facilitating the production of smooth and uniform film surfaces. However, this method presents several drawbacks, as it necessitates careful management of volatile organic compounds that pose environmental and health risks. Additionally, it introduces challenges in maintaining solvent-free films, producing defect-free thicker materials, and requires precise drying processes for industrial-scale implementation [180,181,182].

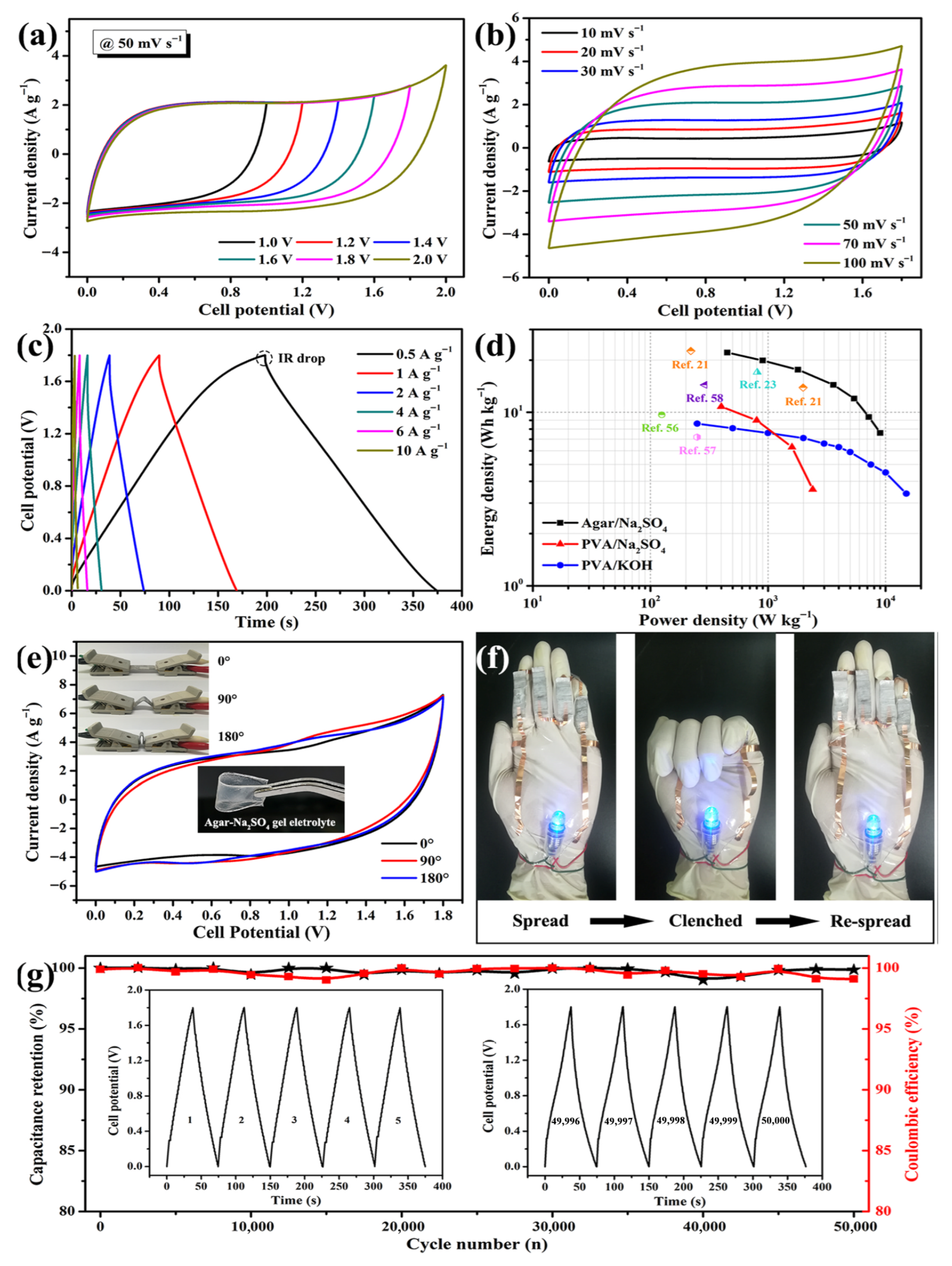

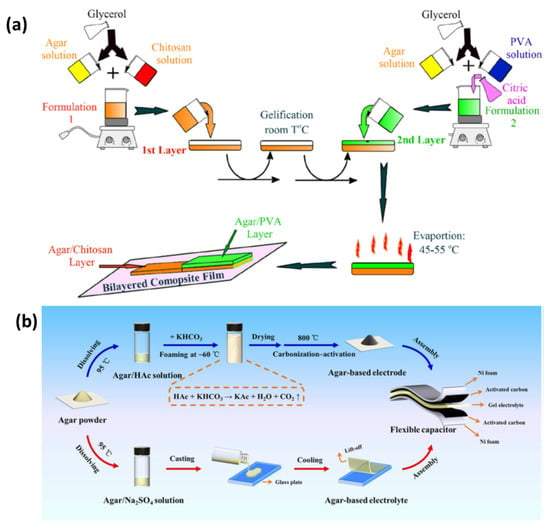

Rhim et al. synthesized their films using solvent-casting methods, incorporating agar with silver nanoparticles (AgNPs), with agar serving as both the structural component and a protective nano-scale coating for the nanoparticles. The nanoparticles were produced using an environmentally friendly method employing trisodium citrate and heat to reduce AgNO3. Research efforts involved incorporating varying amounts of AgNPs into the agar solution during the preparation process. The presence of AgNPs within the films resulted in the generation of plasmonic colors. The films exhibited enhanced water-vapor-barrier properties and surface water resistance, while preserving structural integrity as AgNPs concentration increased [138]. Han et al. synthesized Agar/CMC films incorporating HAP nanoparticles by dissolving the components and subsequently employing a solvent-casting method. HAP nanoparticles were mixed into a uniform agar–CMC solution, resulting in the formation of films in molds through the solvent-casting process. The films retained their healing properties under suitable drying conditions, facilitating applications in bone repair [183]. Jayram et al. extracted nanosized Acalypha indica (Ai) components from ethanol to develop wound treatments via solvent-casting methods. The solvent-casting technique facilitated the effective combination of herbal extract with guar gum and chitosan, while also incorporating PVA into the formulation. The study produced a medically effective and physically stable wound-dressing film, PBTFAi, utilizing a solution-casting technique [184]. The advancements in wound healing are attributed to the two-layered dressing developed by Rathore et al., which integrates agar with Janus nanofiber materials. The hypodermic support layer was developed through solvent casting utilizing silver nitrate and agar to provide extended bacterial protection. The electrospun polycaprolactone and agar incorporating gallic acid functioned as the secondary layer, imparting antioxidant properties to the system. The dressing effectively facilitated fluid absorption while allowing water vapor to escape through its porous structure, as indicated by test results. The wound-care dressing demonstrated significant inhibition of bacterial growth, safe removal of oxidizing agents, and environmentally friendly degradation. Application of this dressing resulted in accelerated wound healing and skin-tissue restoration in animal trials. Evidence of its wide applicability suggests its effectiveness in treating diverse wound types [185]. Using a layer-by-layer solvent-casting approach, Diop et al. prepared double-layered films as shown in Figure 12a. First, an agar and chitosan blend solution was formed by dissolving agar powder with glycerol as a plasticizer in distilled water under stirring while heating. The blend was then spread on a Teflon plate and allowed to gel at room temperature. An additional layer composed of agar, PVA, and citric acid was also produced and cast over the first layer. After standing at room temperature, both layers were allowed to dry in an air-circulating oven. The physical properties of the films were affected by the temperature of the drying process and were stored in a desiccator until testing. Apparently, this method successfully produced bilayer composite films with tunable properties [186]. Guo et al. used solvent-casting technique to prepare an agar composite containing activated carbon, suitable for energy storage applications (Figure 12b). The process involved creating foamy carbon (activated at 700–900 °C) while agar–sodium-sulfate solution cast on glass produced a solid gel electrolyte, together yielding efficient energy-storage-ready materials [177].

Figure 12.

(a) Preparation process of agar/chitosan and agar/PVA double-layered composite films: enhanced physical properties in the layer-by-layer solvent-casting approach with optimized drying conditions (reproduced with permission) [186]; (b) exploring agar-based porous electrodes and electrolytes for ultra-high energy density in flexible symmetric supercapacitors (reproduced with permission) [177].

6.2. Electrospinning Technique

Electrospinning creates fine polymer fibers through a powerful yet straightforward production method. The process employs a high-voltage electric field to form fibers from a liquid polymer or melted material. Upon entering the spinneret, the electrical charge disrupts the surface tension of the polymer liquid, producing a fluid jet that elongates toward the collector. As the solvent evaporates, solid polymer strands deposit on the collector surface as a fabric-like material [187,188,189]. The method provides precise control over fiber dimensions and structural properties to achieve optimal surface performance.

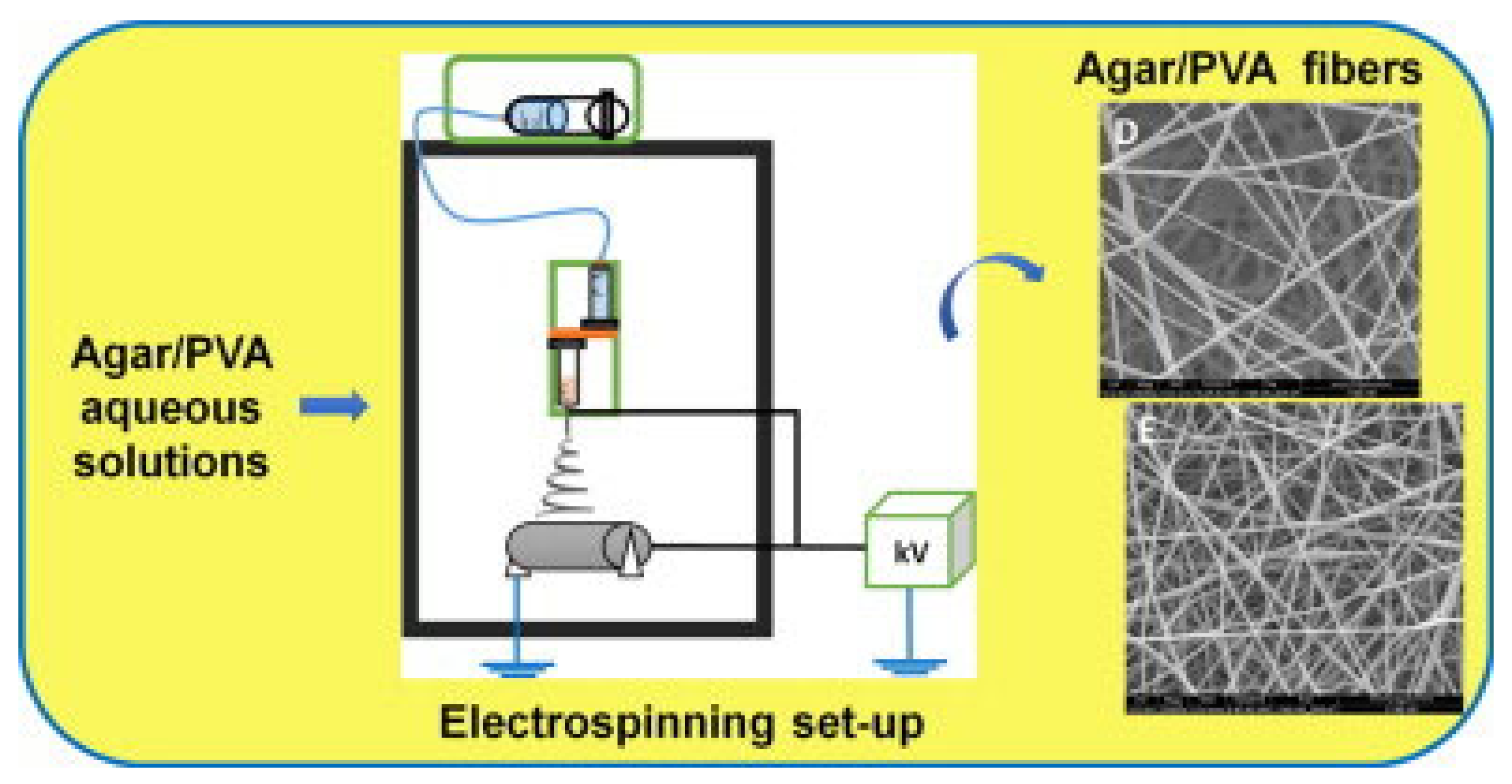

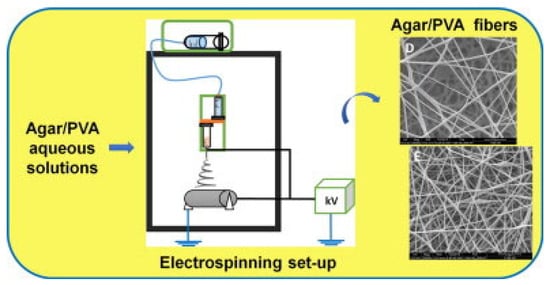

Sousa et al. created agar-based nanofibers through water-based electrospinning (Figure 13). They operated a tubeless spinneret inside an electrospinning chamber maintained at 50 °C to prevent agar from gelling. An initial 1% agar solution showed poor spinning results, which improved after adding PVA. Agar/PVA blends ranging from 100/0 to 0/100 were tested under various electrospinning conditions. Mixing 30% agar with 70% PVA and 20% agar with 80% PVA produced the best agar/PVA nanofiber outcomes, indicating prospective applications for agar nanofibers in medical fields [101]. Duman et al. used a series of processing steps to clean oil-contaminated water and created advanced PVA-based membranes with superhydrophobic properties. Electrospinning was used to spin fibers into membranes, which were then treated with methyltrichlorosilane in petroleum ether to increase water resistance and hardened using glutaraldehyde. The PVA and agar water-treatment membranes exhibited exceptional efficacy in eliminating organic solvents and oily contaminants from water in a cost-effective and sustainable manner [190]. Rathore et al. developed a two-layer medicated skin patch utilizing agar-based nanofiber technology for transdermal medicinal applications. To produce optimal nanofibers, precise parameters were utilized: the material was delivered at a rate of 10 μL/min over a distance of 7 cm from the nozzle to the collector, while a voltage of 15 kV was applied and the collector rotated at 700 rpm. The second layer, composed of a PVA matrix with cephalexin hydrate and agar–PCL fibers, was designed to retain and gradually release the medication. Both membrane layers had exceptional physical properties, featuring a tensile strength of 7 MPa, an eightfold increase in swelling, and a moisture-permeability rate of 2174 g/m2/day. These mats demonstrated antibacterial efficacy and compatibility with blood and cellular systems, indicating their significant potential as drug-delivery methods in medical technology [191].

Figure 13.

The combination of agar-based nanofibers with a PVA co-blending polymer enhances their spinnability during electrospinning, forming continuous fiber mats when using 30/70 or 20/80 ratio blends of agar/PVA (reproduced with permission) [101].

6.3. Chemical and Physical Crosslinking

Chemical crosslinking agents form new covalent bonds between agar polymer chains, thereby enhancing mechanical strength, heat tolerance, and the structural properties of composites. The hydroxyl groups in the polysaccharide backbone of agar interact with crosslinking agents, including glutaraldehyde, epichlorohydrin, or genipin, to form robust three-dimensional networks. This procedure offers the advantage of enhancing mechanical strength and thermal stability of the composite, allowing for more durable and reliable hybrid materials for a wide range of sustainable applications [192,193].

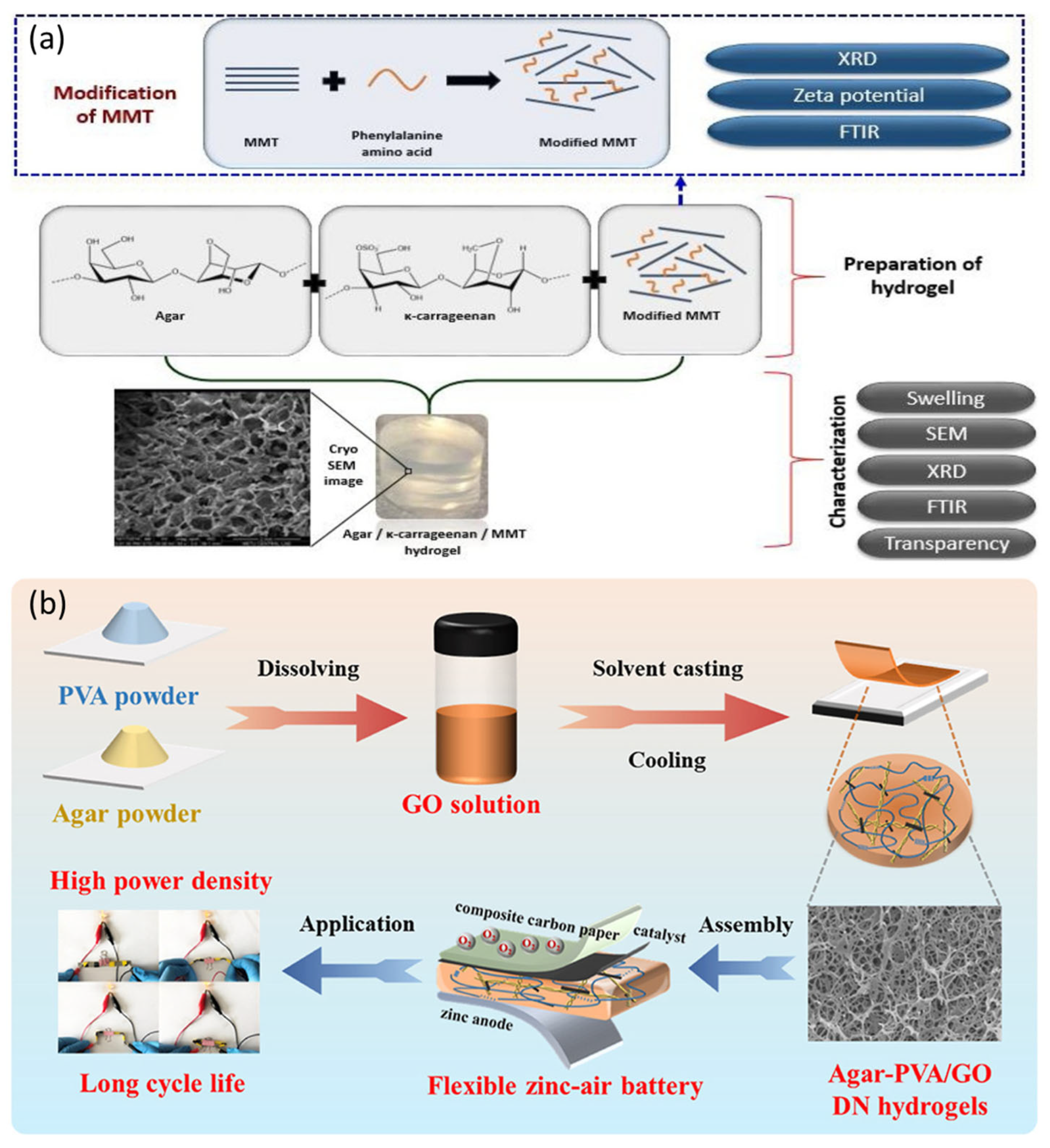

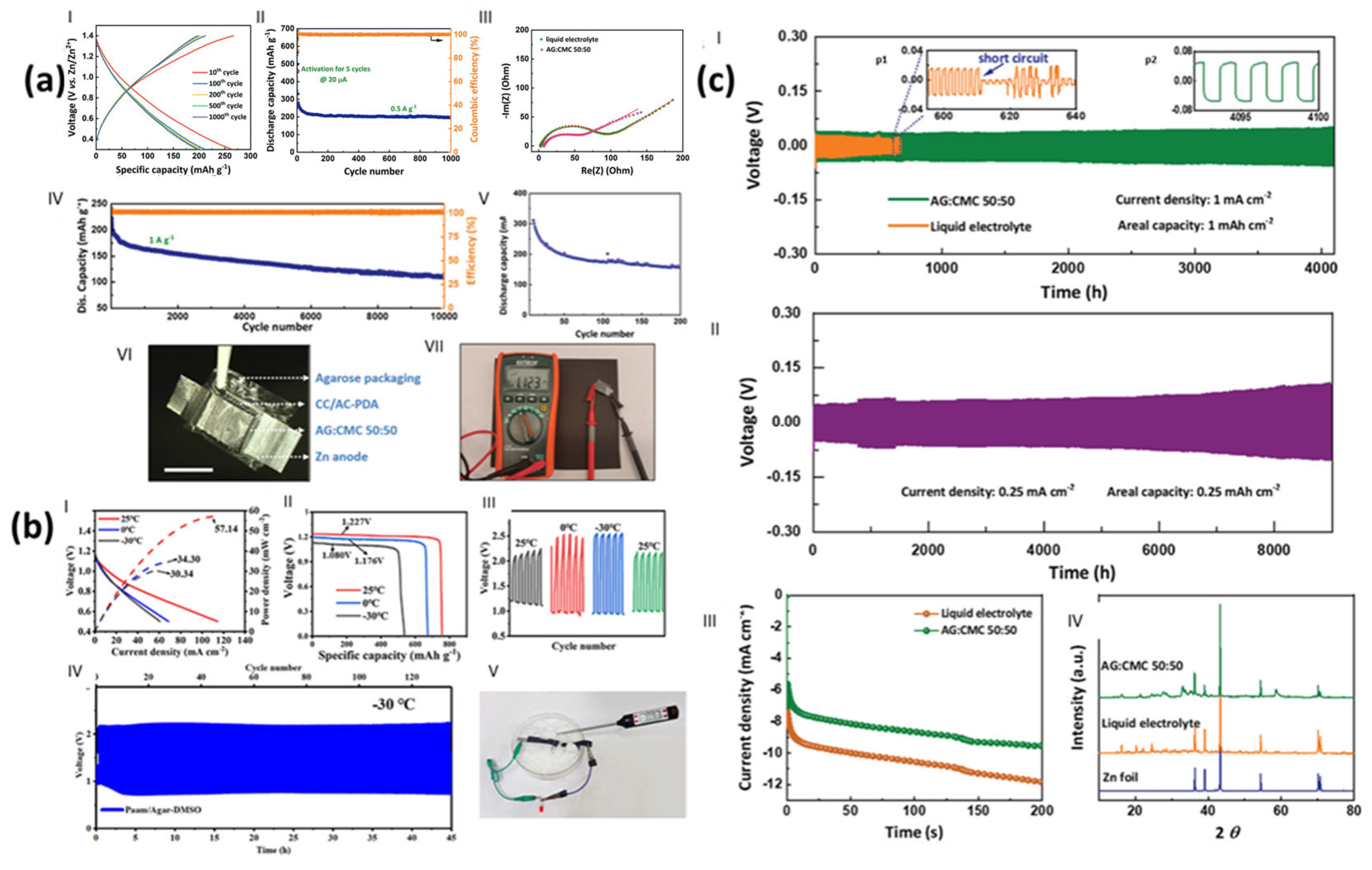

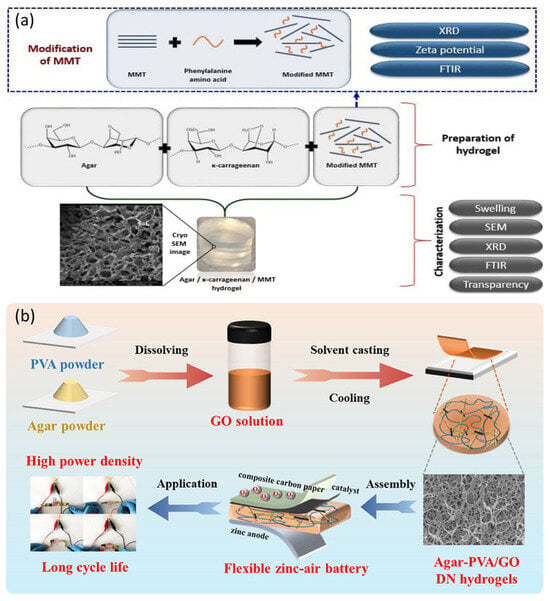

Belay et al. tested how agar performance could improve with succinic acid crosslinking combined with bacterial cellulose. Agar treated with succinic acid crosslinking and bacterial cellulose reinforcement together increased its tensile strength by 101%, compared with separate improvements of 70% and 56%, respectively. Once the agar was crosslinked, the material’s water absorption was greatly decreased. This technique makes agar appropriate for use in the production of food containers and medical devices by strengthening it while preserving its cell compatibility [194]. Wang et al. engineered a three-layer hydrogel combined with different linking approaches to make it more durable and stable. Agar molecular chains connected as a physical network through hydrogen bonding during freezing. They mixed acrylic acid (AAc) with a chemical crosslinker to produce a free-radical-polymerization-based chemically linked network. PVA addition created semi-crystalline zones that improved molecular chain organization. The strength of the polymer network increased when Fe3+ bonded to PAAc carboxyl groups, and the introduction of carbon nanotubes enhanced material performance. The experimental Agar/PAAc-Fe3+/PVA/CNTs hydrogel demonstrated superior mechanical characteristics, instantly returning to its original shape after repeated compression, highlighting its promise for demanding applications requiring strong and tough materials [195]. Gürkan Polat et al. produced new hydrogels by combining agar/κ-carrageenan with montmorillonite and crosslinking them through a free-radical process using triethylene glycol divinyl ether as the crosslinker (Figure 14a). Through careful adjustment of chemical composition and temperature while balancing agar and carrageenan, they created hydrogels that could expand to 2523% of their own volume. These special hydrogels absorb liquids through nonstandard methods, making them promising for medical use [196]. Yang et al. prepared a double-network hydrogel electrolyte for flexible Zn–air batteries by thermally gelling stiff agar (primary network) and subsequently adding poly(vinyl alcohol) crosslinked through repeated freezing–thawing to form microcrystalline contacts (secondary network) (Figure 14b). The resulting gel operates in both alkaline and neutral media, provides high ionic conductivity in alkaline KOH, retains water well in neutral salt, and allows shape-adaptive Zn–air cells that maintain output when bent, exemplifying its potential for safe, low-cost, high-performance wearable power sources [163].

Figure 14.

(a) Crosslinking new agar/κ-carrageenan/MMT hydrogels with TEGDE produced substances that absorbed water up to 2523% while exhibiting non-Fickian absorption patterns that varied with MMT content (reproduced with permission) [196]; (b) agar–PVA–GO crosslinked double-network gel composite electrolyte for extraordinary performance FZABs (reproduced with permission) [163].

Physical crosslinking processes in agar-based composites leverage the biopolymer’s intrinsic capacity to form reversible, non-covalent networks through hydrogen bonding, ionic interactions, or chain entanglements with natural or synthetic polymers. These processes enable tailored mechanical strength, stimuli-responsive behavior, and self-healing properties essential for cutting-edge energy storage and flexible electronic applications [197,198]. For instance, Mahamoud et al. developed biocompatible hydrogels made from PVA and agar incorporating tannic acid as a physical crosslinker to enhance mechanical strength for medical and water-treatment purposes. They subjected the hydrogels to repeated freezing–thawing cycles, observing that each cycle increased their mechanical strength. According to the results, the samples’ tensile strength rose from 1.56 MPa after one cycle to 3.77 MPa after five cycles while using less crosslinking agent. These hydrogels showed both lower swelling volume and improved water-retention capacity. By using tannic acid as a crosslinking agent and improving hydrogel performance through F/T cycles, the study demonstrated that PVA hydrogels become more suitable for wound-care and artificial-cartilage applications [199]. Through a single-step physical crosslinking technique, Li et al. produced a PASA hydrogel from PVA and agar with in situ-formed silk–AgNPs. AgNPs formed directly within the silk hydrogel because tyrosine in silk fibroin naturally reduces silver ions during synthesis. PVA crystallites and hydrogen-bonded agar networks strengthened the hydrogel structure. This method creates a strong bandage material that fights off bacteria that can help treat infected wounds [200]. Huang et al. developed a new type of physically crosslinked composite for advanced water-filtration systems. Agar physically bonded with sodium alginate bound by calcium ions forms the basis of this new aerogel system. When sodium alginate enters the agar system, it forms a stronger network that resists deformation and retains more material [201].

6.4. Freeze-Drying

Freeze-drying, or lyophilization, is as a vital method for preparing agar-based composite materials, especially when preservation of probiotic substances is required. Through freeze-drying, samples are solidified before the pressure is reduced, which turns ice directly into vapor and preserves the original biological structure and functionality of encapsulated substances. The process generates a spongy structure that supports many uses in the biotechnology and food industries for creating customized solutions [202,203,204].

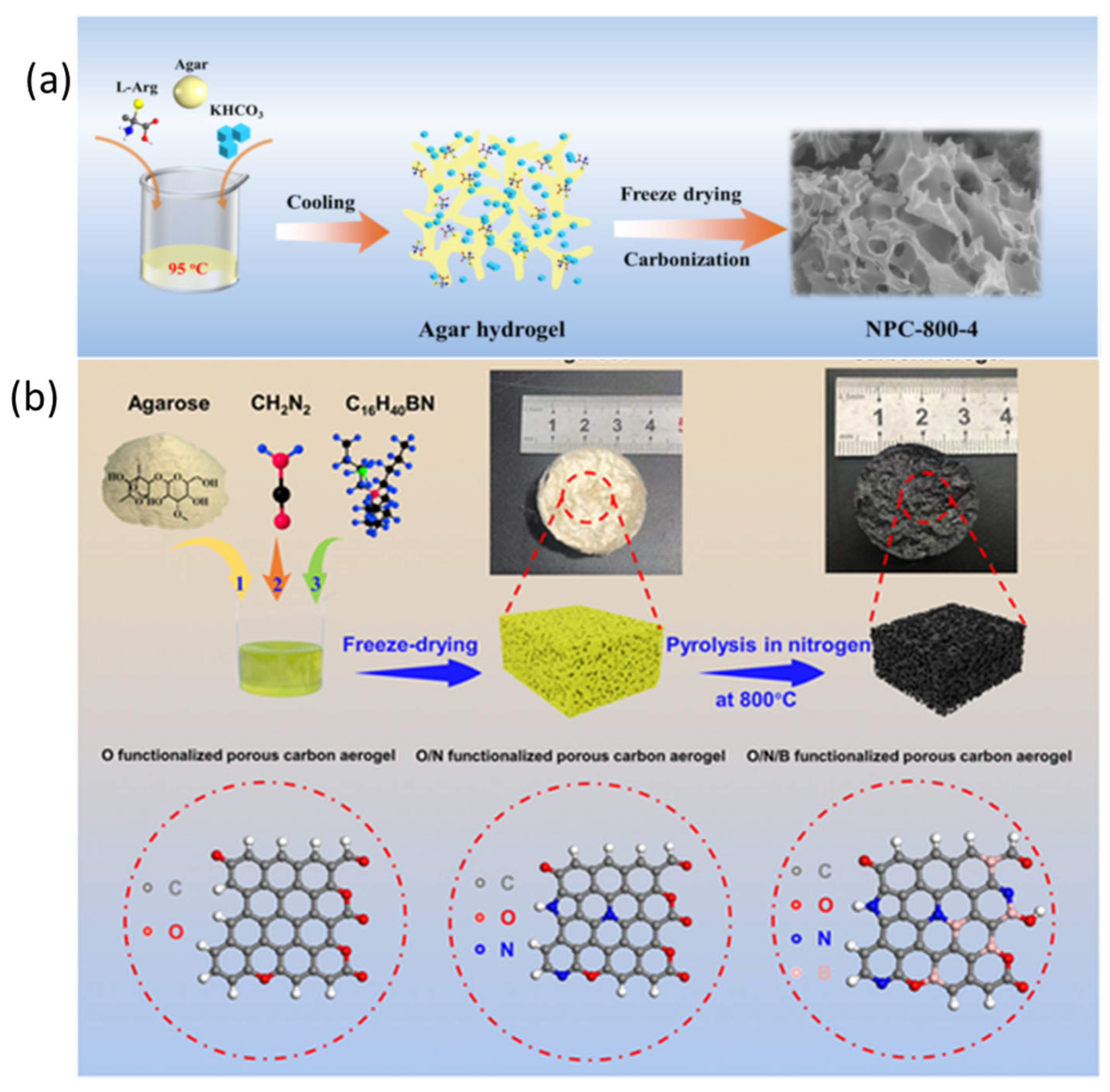

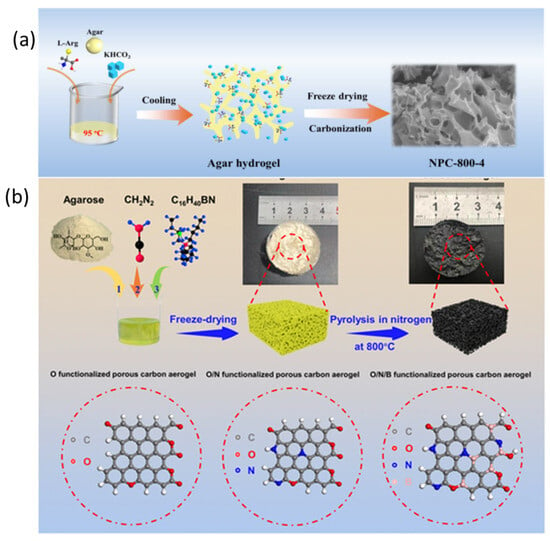

Ajisafe and Raichur et al. developed a 3D scaffold for cartilage repair when they freeze-dried agarose and snail mucus into AGSMu. Their scaffold combines agarose’s biodegradable nature with snail mucus’s healing properties. The process added mechanical stability to the scaffold and supported the growth of C28/I2 human chondrocyte cells. The AGSMu scaffolds demonstrate strong potential for repairing and regenerating joint cartilage tissue [205]. Liu et al. synthesized a porous carbon material exhibiting a surface area of 3184 m2/g via concurrent sol–gel and freeze-drying techniques, prior to activation (Figure 15a). Agar functioned as the carbon source, while L-arginine served as the nitrogen source, resulting in N-doped porous carbon that stored 443.0 F of electricity when evaluated at 0.5 A/g in 6 M KOH. They constructed a symmetrical supercapacitor utilizing their material and an agar–sodium-sulfate gel as electrodes, achieving an energy storage capacity of 35.5 Watt-hours per kilogram and 99.7% capacity retention over 20,000 cycles [172]. Xie et al. synthesized oxygen/nitrogen/boron codoped carbon aerogels through one-pot sol–gel polymerization of resorcinol/formaldehyde precursors with heteroatom sources, followed by freeze-drying and high-temperature carbonization (Figure 15b). The multi-element codoping strategically introduced lattice distortion, generating abundant neighboring active sites that provided high potassium-ion adsorption (1.62 eV) and very low diffusion barriers (0.12 eV) along N- or O-decorated rings. These structural benefits gave the prepared sample exceptional capacity, rate capability, and long-term retention, maintaining 83% of its capacitance after 10,000 cycles. A symmetric K-ion supercapacitor constructed from the material achieved 51.8 Wh kg−1 energy density at 443 W kg−1 power density, demonstrating the potential of heteroatom-codoped aerogels as building blocks of next-generation potassium-ion energy devices [206].

Figure 15.

(a) N-doped porous carbon synthesis: activation of agar-based gel for enhanced supercapacitor performance (reproduced with permission) [172]; (b) schematic representation of heteroatom-doped carbon aerogel synthesis: the agarose-derived hydrogels are freeze-dried and pyrolyzed at 800 °C in N2, and nitrogen and boron are doped using cyanamide and tetrabutylammonium borohydride to obtain the O-CA, ON-CA, and ONB-CA porous carbon structures (reproduced with permission) [206].

In another work, the freeze-drying process produced agar/PVA aerogels that effectively extract oil from water while being environmentally sustainable. These aerogels absorbed substantial volumes while attaining 99.3% separation purity for chloroform and water mixtures via their oil–water and solvent–water separation mechanism. Research indicates that these materials may aid in the removal of oil spills from aquatic systems [207]. Sang et al. fabricated agarose–chitosan scaffolds via freeze-drying, subsequently coating them with collagen at a concentration of 3 mg/mL, which exhibited superior mechanical properties for dermatological research applications [208]. Kumar et al. dissolved 3% agarose in water, added varying amounts of chitosan from acetic acid, and stirred continuously to create agarose scaffolds with embedded AgNPs coated in chitosan. The mixture changed from its initial state to a brownish-yellow color when the nanoparticles formed, and they used 1% glutaraldehyde to fix them in place. The AG-CHNp1 to AG-CHNp4 scaffolds were freeze-dried at −80 °C to produce natural pores by direct ice-crystal sublimation [209].

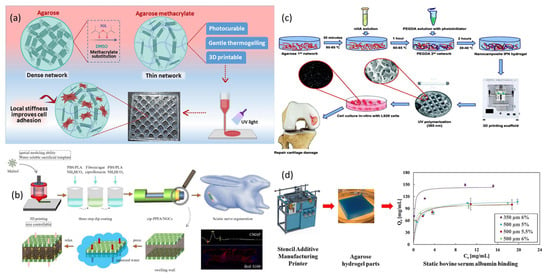

6.5. 3D Printing

The research capabilities in composite material creation were transformed by the precise delivery capabilities and robust design scaling mechanisms of 3D printing technology. The sequential building method facilitates the accurate placement of materials, thereby optimizing the mechanical, thermal, and electrical properties of the composite structure. FDM, along with other sophisticated manufacturing methods such as SLA and DIW, allows users to fabricate intricate, lightweight components that exceed the constraints of traditional manufacturing by integrating diverse matrices, including polymers and hydrogels, with reinforcements like nanoparticles and fibers [210,211]. The process has three main advantages: reduced waste production, expedited model creation, and tailored design possibilities for aerospace components, biomimetic implants, tissue scaffolds, battery electrodes, and electronic materials. Functional additives, including conducting polymers or ceramics, can be integrated to produce a wide range of smart devices, sensors, and sustainable infrastructure [212,213,214].