1. Introduction

Hydropower stands as the leading renewable energy source in global electricity generation, since it supplies 16–17% of worldwide power output and generates over half of all renewable electricity [

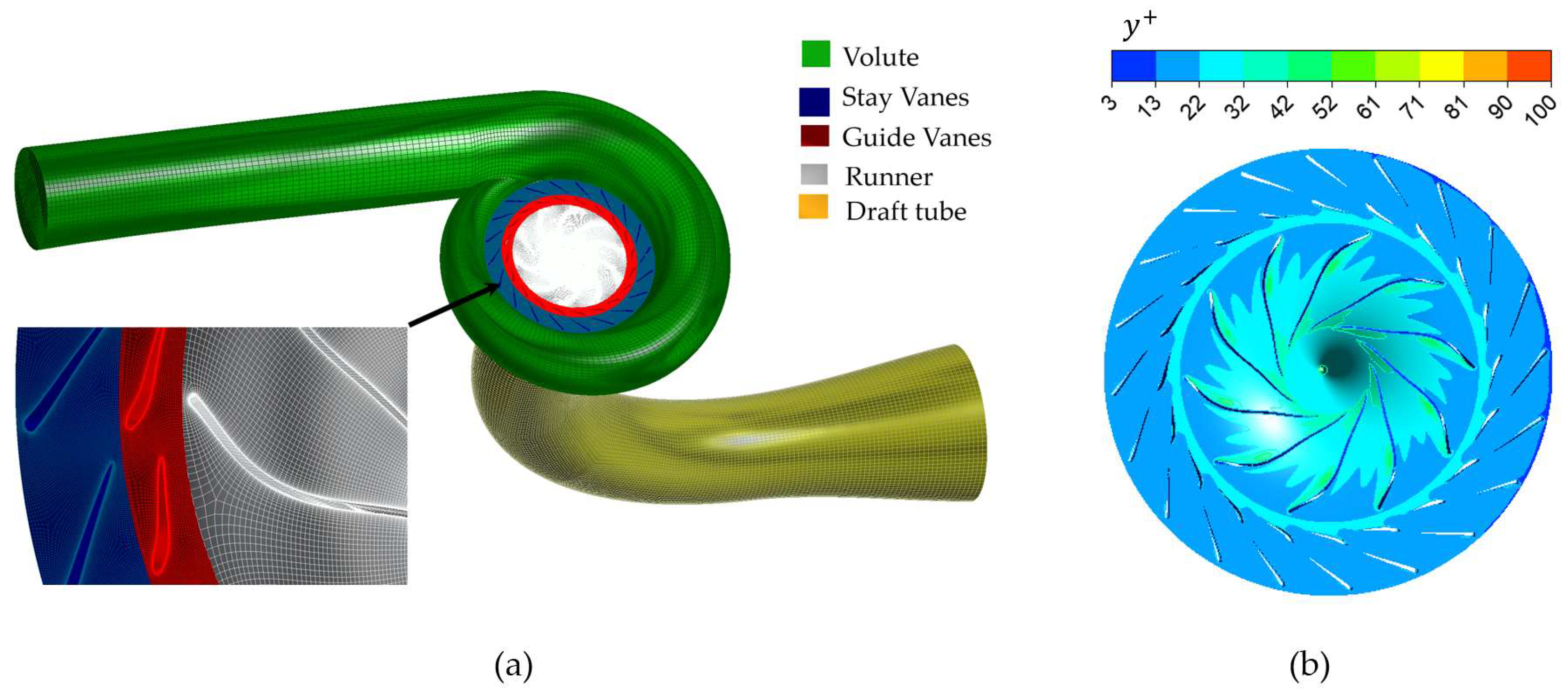

1,

2]. The energy storage capabilities combined with affordable and adaptable power generation characteristics of hydropower systems make it essential for power grids which increasingly depend on intermittent renewable sources like wind and solar power. The Francis turbine dominates hydropower technology applications because it works effectively across different head and discharge ranges. Energy system evolution demands that existing older hydropower facilities must perform flexible operations beyond their original design parameters and run in off-design and transient conditions.

The digitalisation of ageing hydropower facilities is essential to meet these new operational requirements. The traditional turbine design optimisation process requires extensive designer expertise and time-consuming results through repeated CFD simulations [

3]. The conventional direct design approach that changes blade geometry offers restricted control over the internal flow field patterns. The process of making small geometric changes leads to substantial unpredictable alterations in flow patterns both upstream and downstream which slows down the process while increasing computational expenses and requiring extensive trial-and-error testing.

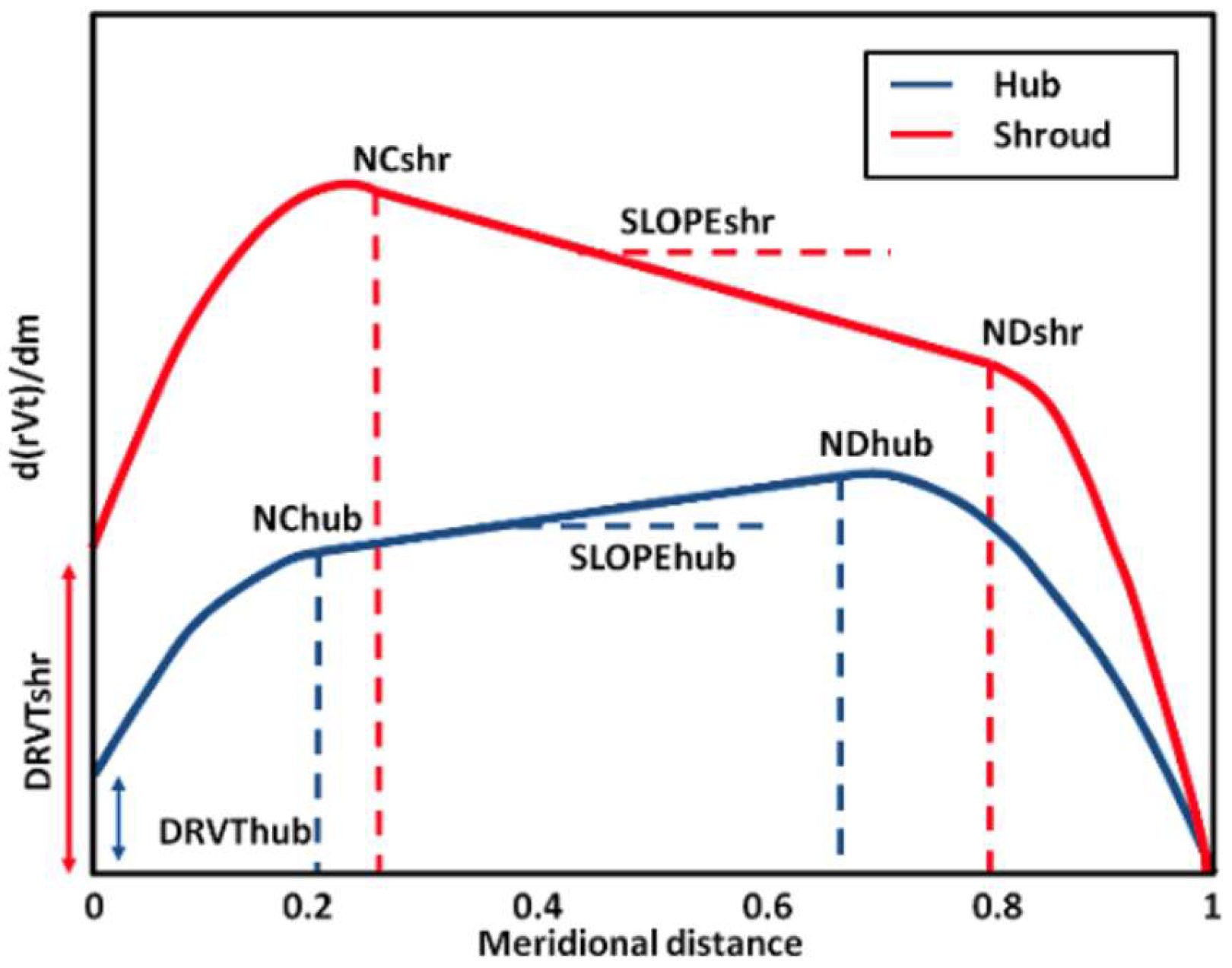

The inverse design method (IDM) presents a transformative alternative. The IDM technique modifies blade loading distribution as its primary design variables instead of modifying the blade geometry directly [

4,

5]. Through this approach designers achieve better control of the flow field during design and need fewer iterations for optimisation. The IDM provides superior three-dimensional flow management and improved secondary flow control along with the potential to create hydrodynamically optimised blades at reduced computational expense.

The IDM concept has undergone substantial growth since its first deployment. The IDM method appeared as a design tool for hydrofoils before its development for hydraulic pumps in the 1980s and 1990s and remained limited to two-dimensional incompressible potential flow modelling. Borges [

6] achieved notable progress in IDM development through his work on radial and mixed-flow machine design which produced superior performance compared to traditional approaches. Zangeneh et al. [

7,

8] developed IDM through their work on three-dimensional compressible potential flow models that produced precise blade geometries for radial and mixed-flow turbomachinery.

IDM proved successful for minimising flow instabilities while minimising secondary losses in diverse types of machines throughout time. Zangeneh et al. [

8,

9] showed that IDM eliminated secondary flows in pumps and compressors. Goto et al. [

10] applied IDM to redesign diffuser vanes that eliminated flow separation. Demeulenaere et al. [

11] and Dang et al. [

12] achieved design improvements by integrating prescribed pressure distributions into inverse design processes which expanded the method’s applicability for turbine and compressor blades. IDM researchers later extended the design approach to handle three-dimensional viscous flows [

13,

14], which eliminated the difference between theoretical design assumptions and actual turbomachinery operational performance.

The IDM approach has proven its effectiveness as a design methodology throughout various turbomachinery applications including inducers [

15,

16], pumps [

17], diffusers [

10,

18], and compressors [

8,

19,

20]. IDM has proven effective in enhancing critical performance metrics like hydraulic efficiency and shock control and flow stability by incorporating viscosity and blade thickness effects in later models [

21].

The IDM method continues to depend on steady idealised flow models and faces difficulties in directly managing fully three-dimensional turbulent and unsteady flow phenomena that matter for actual operating conditions. The open-source IDM framework developed by Leguizamón and Avellan [

3] for Francis turbines marks an important step toward enhancing IDM usability and adaptability in hydraulic turbine design. Ohiemi and McNabola [

22], recently applied the IDM in combination with computational fluid dynamics (CFD) techniques and optimisation methods to create a digital model of a large scale 110 MW hydropower plant using Francis turbines and a limited set of historic design parameters and operation data available.

The continuous progress of CFD has produced increasingly precise simulations of turbomachinery flows that cost less computationally. The potential of IDM integration with CFD is still largely untapped when it comes to optimising ageing hydropower turbines. This study further confirms IDM as a solution to optimise hydropower turbines through MOGA optimisation methods that show promising potential for this limitation. The complex performance objectives in turbine design, which include maximising efficiency while reducing cavitation and structural loads, make MOGA an optimal choice for addressing these challenges.

Modern hydropower machinery benefits from IDM as a powerful framework for optimisation in pump turbines and Francis turbines. Design optimisation of pump turbine equipment has received extensive research to enhance operational efficiency while expanding stable operation boundaries and reducing flow instabilities and cavitation effects. The low-head pump turbine received IDM optimisation by Kerschberger and Gehrer [

23] which resulted in improved runner performance with higher instability onset heads and increased efficiency and extended cavitation-free operation.

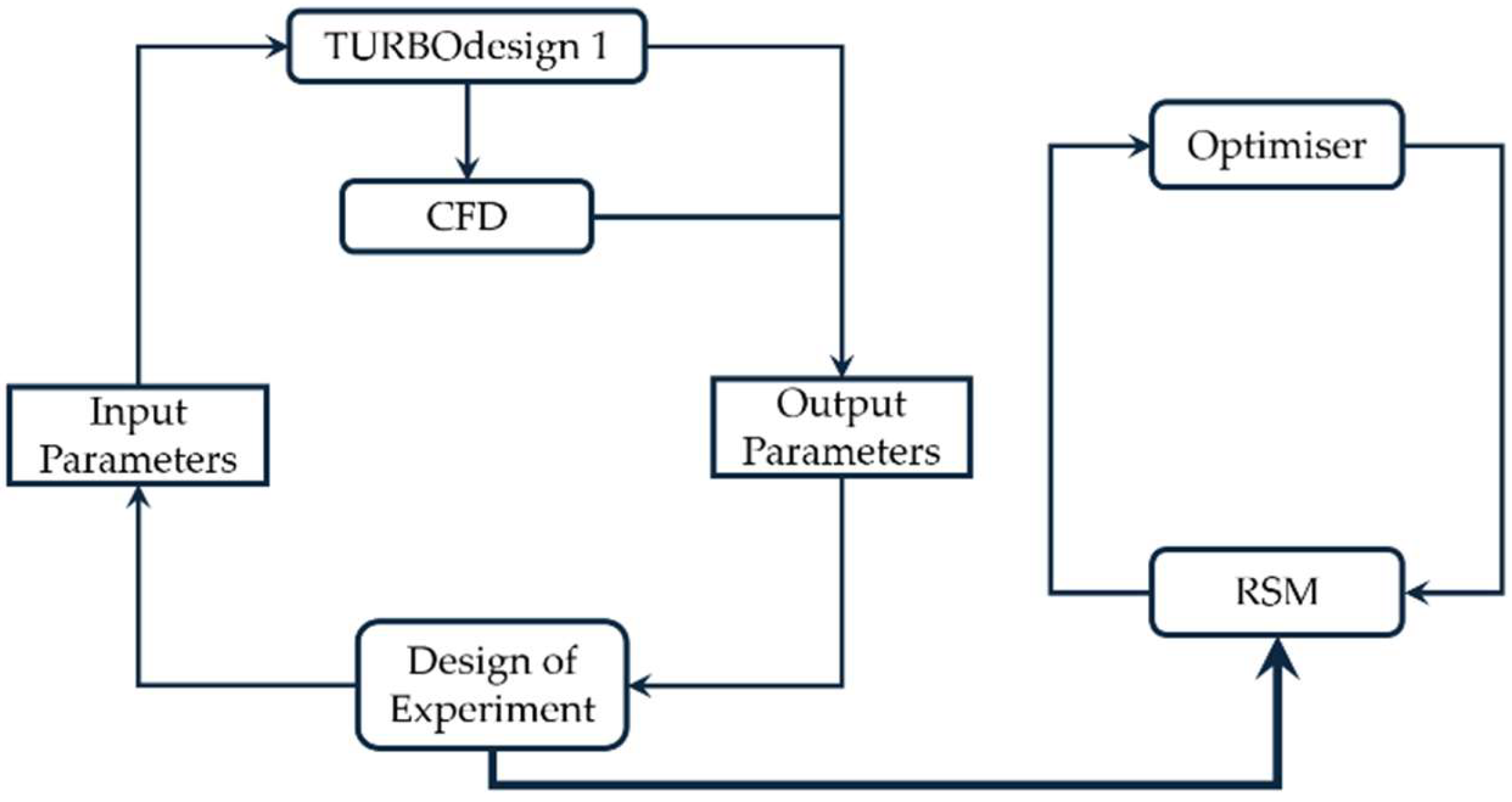

Yang and Xiao [

24] introduced a multi-objective optimisation framework combining IDM, CFD, design of experiments (DoE), response surface methodology (RSM), and multi-objective genetic algorithms (MOGA). The optimisation of blade loading distributions and stacking angles through their research led to major efficiency improvements and minimised crossflow occurrences in pump-turbine operations.

Yin et al. [

25] analysed methods to eliminate the S-shaped curve which triggers hydraulic instability at low load conditions. The study showed that making the meridional passage wider helped decrease the negative slope of the performance curve to improve stability but did not investigate pump mode implications.

Wang et al. [

26] and Xuhe et al. [

27] used blade loading distributions with fore-loaded designs to enhance turbine-mode performance without significant pump-mode efficiency reduction.

Zhu et al. [

28] introduced extensive negative blade lean angles and optimised meridional channels to enhance cavitation resistance while improving part-load operations in both turbine and pump modes [

29].

Liu et al. [

30] implemented MOGA with IDM, RSM, and CFD to optimise blade lean angles and loading distributions for ultra-high-head turbines. They achieved a 0.7% efficiency increase while improving the cavitation performance of their system.

Wang et al. [

31] presented a trade-off optimisation method that optimises both secondary flow reduction and profile loss minimisation without changing the meridional channel configuration. The authors supported the use of moderate aft-loaded hub distributions to minimise secondary flows and recommended strong fore-loaded hub distributions to decrease profile losses.

The optimisation framework developed by Hu et al. [

32] now supports pump turbines with splitter blades. The multi-objective optimisation strategy evaluated 17 design variables to show that boosting the splitter work ratio resulted in a 2.07% efficiency boost for turbine-mode operation. Hu et al. [

33] optimised the runner design to achieve maximum performance in both deep-part load conditions and cavitation resistance by determining the best combination of fore-loaded shroud and aft-loaded hub configurations.

Renewable energy adoption worldwide depends on hydropower systems to support power grid stability while achieving sustainability goals. Many ageing hydropower plants that operate in Europe and America date back more than several decades. Performance degradation, inefficient operation, and structural fatigue risks, together with cavitation issues, affect ageing plants under part-load or off-design conditions. The absence of comprehensive design documentation and detailed drawings in numerous plants creates major obstacles during refurbishment and performance optimisation efforts.

While IDM-CFD-MOGA methodologies have been successfully applied to turbomachinery optimisation in prior studies, their scope has predominantly focused on large-scale turbines or pump turbines and has often been limited to runner-only designs. For instance, Ohiemi and McNabola [

22] applied IDM in combination with CFD and multi-objective genetic algorithms to optimise the runner of a 110 MW Francis turbine, using a limited set of historic design and operational data. Similarly, Yang and Xiao [

24], Liu et al. [

30], and Hu et al. [

32,

33] showed the effectiveness of IDM-CFD-MOGA for pump turbine systems, achieving improvements in hydraulic efficiency, cavitation performance, and secondary flow reduction. However, these studies did not extend the optimisation framework to guide vanes, nor did they target small-legacy hydropower plants where design documentation is often incomplete or absent.

In contrast, the present study advances the application of IDM-CFD-MOGA by optimising both the runner and guide vane configurations of a small-legacy Francis turbine (Bérchules case study) using limited historical information. This approach enables the reconstruction of hydraulically efficient blade geometries in a digital environment, effectively creating a digital twin of the turbine without the need for original blueprints or intrusive measurements. By extending optimisation to guide vanes and applying it to a small-legacy plant, this work shows a novel methodology for the refurbishment and performance enhancement of ageing hydropower facilities, addressing limitations of previous studies and providing a practical framework for modernising legacy turbines.

The Bérchules hydropower facility located in southern Spain illustrates this situation. The 70-year-old turbines are still undigitised, since their original designs while physical alterations since construction have caused their dimensions to drift from the original blueprints. The modernisation process meets two main difficulties because it needs to restore hydraulic components from limited historical information and achieve enhanced performance for current energy market flexibility requirements.

IDM enables hydraulically efficient blade geometries to be systematically reconstructed through performance target-based generation instead of fixed shape definitions. CFD integration with this method delivers complete understanding of internal flow patterns and MOGA searches for optimal trade-offs between efficiency and cavitation resistance and flow uniformity.

This integrated framework enables digital twin development of existing turbines without needing original drawings or intrusive physical measurement data. Designers can use this method to duplicate old turbines in a digital environment before performing assessments and modern performance improvements. The method delivers exceptional value for hydropower refurbishment because CFD models with accurate precision become essential for developing solutions to plant issues.

The following structure explains the remaining sections of this paper.

Section 2 describes the numerical modelling procedure, followed by CFD validation protocols.

Section 3 describes the IDM and MOGA-based optimisation strategy. The paper demonstrates sensitivity analysis, followed by optimisation results and performance validation using the Bérchules Francis turbine case study in

Section 4. The final part discusses conclusions while proposing future research paths for IDM-based approaches to hydropower turbine refurbishment and optimisation.

4. Result and Discussion

4.1. Sensitivity Analysis

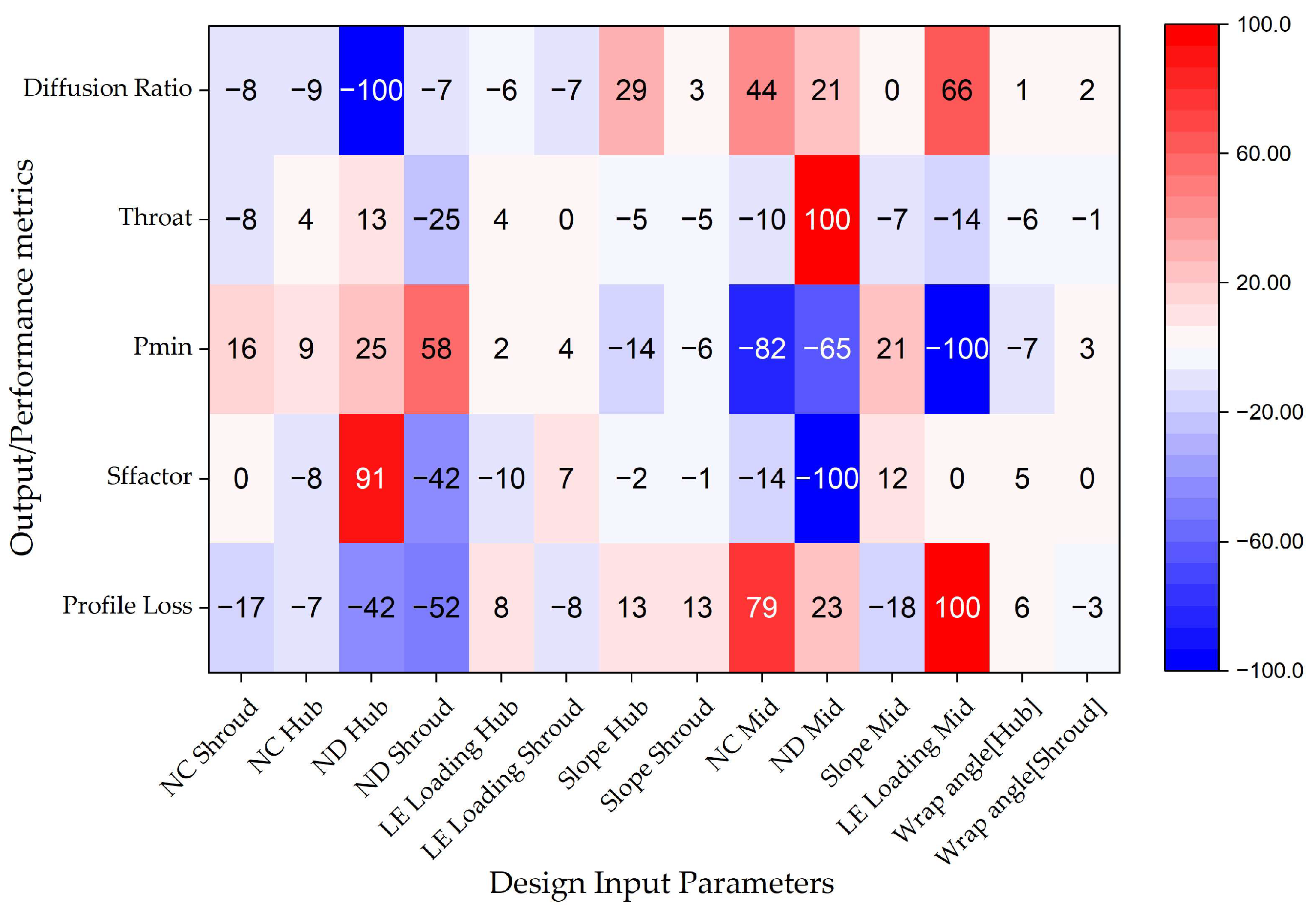

A minimum–maximum sensitivity analysis was conducted to identify the most significant design input parameters with respect to key fluid performance metrics. This method pinpoints the parameters that either greatly improve or hinder performance outcomes and directs optimisation efforts effectively, as illustrated in

Figure 6. Among the design variables considered, LE Loading Mid had the most substantial influence across different metrics.

It notably boosted profile loss, showing that adjusting this aspect enhances flow attachment and energy recuperation significantly. Conversely, the LE Loading Mid adversely affected the minimum pressure, showing a high tendency for cavitation when aggressive loading is applied. Furthermore, the diffusion ratio is extremely sensitive to the LE Loading Mid. These extremes demonstrate the crucial role of mid-span loading in determining both performance and operational risk.

NC Mid also showed a sensitivity to profile loss while affecting minimum pressure and throat area negatively at the time. This suggests that a reduction in camber at the midspan can enhance velocity gradients to lessen losses but might also disrupt pressure fields and decrease the passage area, potentially resulting in flow separation and pressure drops. The SF factor analysis revealed that ND Hub and ND Mid had an impact on sensitivity levels within the spectrum of variables studied concerning axial momentum recovery in the turbine system.

Increasing the ND at the hub was found to enhance axial momentum recovery efficiency. On the other hand, excessive diffusion in ND Mid had a negative impact, likely leading to flow deceleration or boundary layer detachment within the mid-span zone. These findings underscored how optimising blade count is spatially dependent and can significantly affect uniformity across the turbine system.

Elevated loading, at mid span was shown to have an impact on pressure margins and cavitation risk in comparison to other parameters, such as ND Shroud and ND Hub. These improved minimum pressure by helping in stabilising flow and reducing pressure troughs through blade count adjustments at end walls.

In the examination of the throat region of the blade design study, ND Mid showed an impact, hinting that adding more blades at the midsection widens the flow path and lowers the risk of choking. Conversely, NC Mid resulted in a reduction, implying that heightened camber contraction around the midsection might overly constrict the throat and potentially cause choking or separation issues.

The diffusion ratio was significantly affected by the LE Loading Mid in a manner which highlighted its ability to effectively control velocity gradients and diffusion behaviour. On the hand, ND Hub showed a negative impact, suggesting that high diffusion near the hub can worsen local adverse pressure gradients and decrease pressure recovery.

Other factors such as Slope Hub, Slope Shroud, Wrap angle at the Hub, and Wrap angle at the Shroud seem to have minimum impact on the performance values. This suggests that these aspects play a role towards minor performance adjustments rather than being key factors driving major performance changes.

In conclusion, this min–max sensitivity analysis shows that LE Loading Mid, ND Mid, and NC Mid are the most significant design parameters, each employing maximum effects—either negative or positive —for multiple metrics. These outcomes show that the blade design at the mid-span accounts for the greatest leverage for performance improvement but is also susceptible to the highest risk of cavitation or flow instability if not optimally standardised. The ND Hub and ND Shroud are critical for harmonising pressure fields and mitigating secondary flows. Optimisation efforts should therefore deliberately rank these dominant variables to accomplish elevated efficiency without compromising hydraulic stability.

4.2. Optimisation Results

This section demonstrates the results of the two-stage optimisation work on hydraulic turbomachine systems compared to the baseline design obtained from the inverse design. The research focuses on boosting performance through blade runner geometry optimisation (Stage 1) and guide vane geometry optimisation (Stage 2). The main goals included minimising Profile Loss and Secondary Flow Factor (SF factor) while maximising the Minimum Pressure (Pmin) to decrease cavitation risk. TURBOdesign Suite was used to performed design optimisation evaluations to generate Pareto fronts for each stage. A total of 900 design variants were generated for each optimisation stage, which resulted in the 3D plots signifying the relationships and trade-offs between the optimisation objectives.

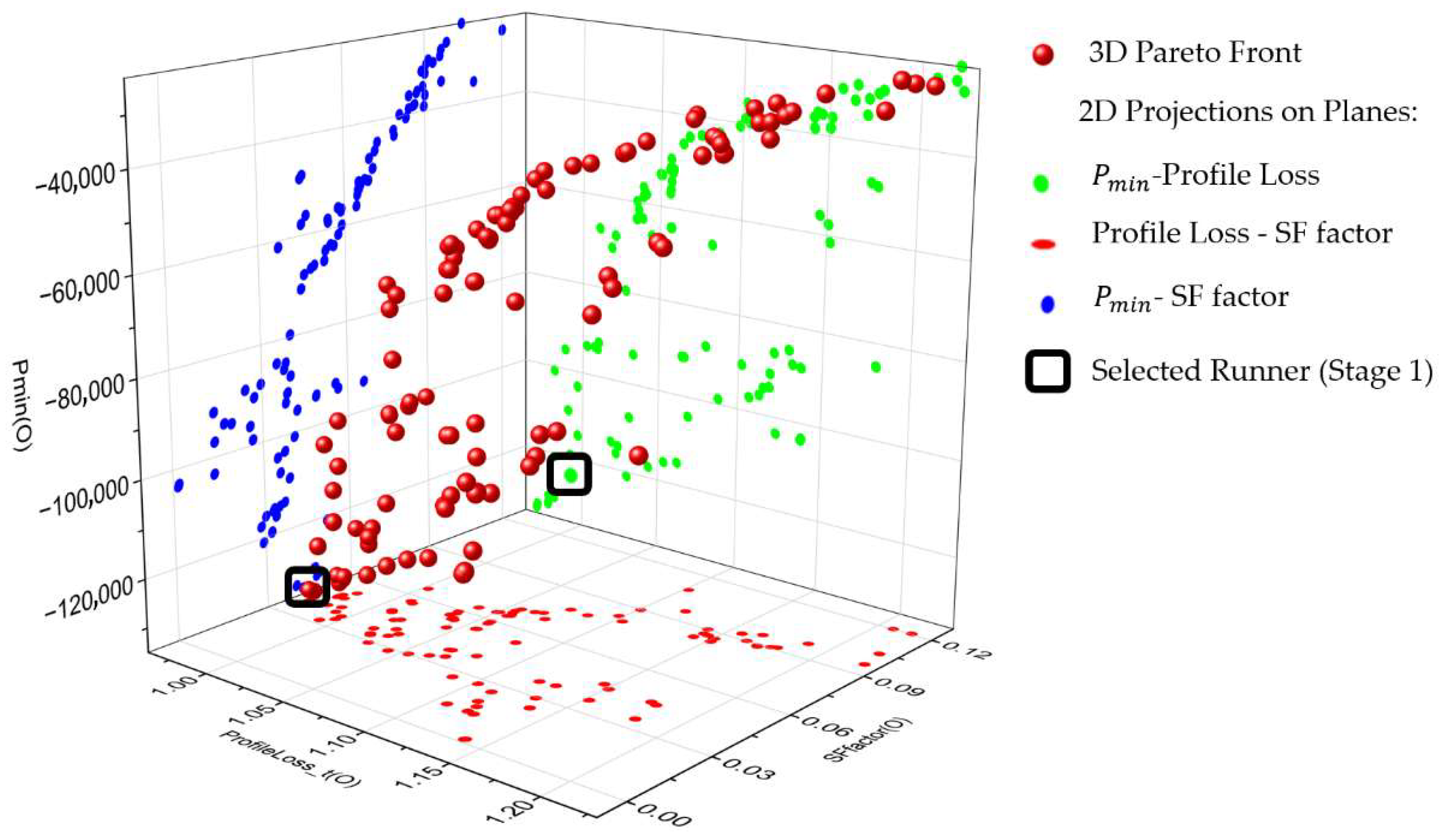

4.2.1. Stage 1 Optimisation-Runner Blades

The first-stage optimisation results in

Figure 7 show the Pareto front when only runner blade geometry was varied. The design space consists of three dimensions, including Profile Loss, SF factor, and Minimum Pressure (

Pmin). The plot demonstrates obvious trade-offs between the optimisation objectives. The combination of low Profile Loss and low SF factor values directly correlates with higher values because these configurations minimise both viscous and secondary flow losses, which results in better pressure recovery and reduced cavitation onset. Profile Loss increases rapidly when the SF factor also rises, which leads to a significant decrease in

Pmin values, which shows increased cavitation risk. The Pareto-optimal set shows that lowering viscous losses plays a major role in achieving higher pressure at the blade surface, which is essential for safe operation under different flow conditions.

The destabilising effects of secondary flows, which produce swirling motions and crossflows, result in significant pressure distribution disturbances that produce suboptimal designs with low

Pmin values. The design selected in

Figure 7 stands for a compromise between all the objectives, as shown in

Table 6.

The Profile Loss decreased by ~22.7%, and SF factor dropped by ~16.8% compared to the baseline runner, signifying improved aerodynamic performance and reduced secondary flow effects. The pressure minimum value Pmin shows a substantial improvement from −877,325.5 Pa to −132,703.4 Pa, which shows a significant reduction in cavitation risk. The 3D Pareto front shows that the area with low Profile Loss and SF factor values produces the least negative pressures, thus confirming the effectiveness of the runner blade redesign. The optimisation of runner blades at this stage proves essential for reducing internal energy losses while maximising the pressure field.

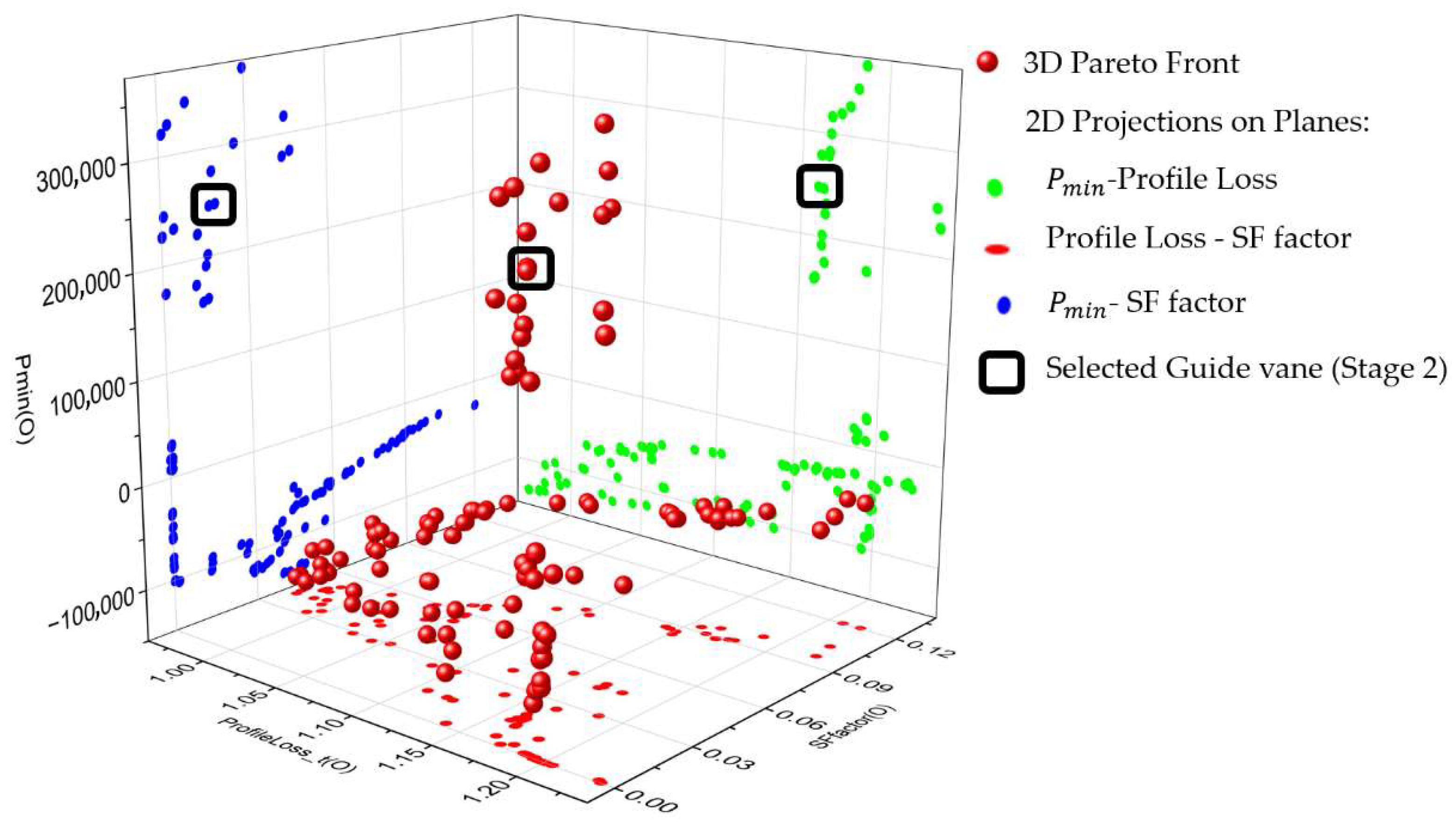

4.2.2. Stage 2 Optimisation: Guide Vane

The second-stage optimisation integrated guide vane geometry as contemporary design variables while keeping the results of the optimised runner from Stage 1. The Pareto front presented in

Figure 8 displays a wider range of performance response, primarily through its

Pmin values. The guide vane design plays a crucial role in pre-conditioning the flow entering the runner, because this stage shows a new high-performance region with Profile Loss in the middle range, while the SF factor is lower and the

Pmin values exceed those of the baseline design. The guide vane design stands out as the essential factor that determines how flow enters the runner.

The proper design of guide vanes enables effective alignment of inlet velocity vectors while reducing separation and vortex formation and creating smooth flow profiles, which reduces local pressure drops and enhances cavitation resistance. The chosen design in

Figure 8 represents the optimal balance of all objectives as listed in

Table 7.

The Profile Loss of the guide vane decreased by 9.3% in the optimised version compared to its baseline, while the SF factor showed a 20% improvement. The most significant gain comes from Pmin, which rose from 87.6 kPa to 247.5 kPa, standing for a 183% boost in cavitation resistance. The optimisation process shows that properly shaped guide vanes realign the incoming velocity vector and decrease flow separation to produce enhanced stability before the flow reaches the runner.

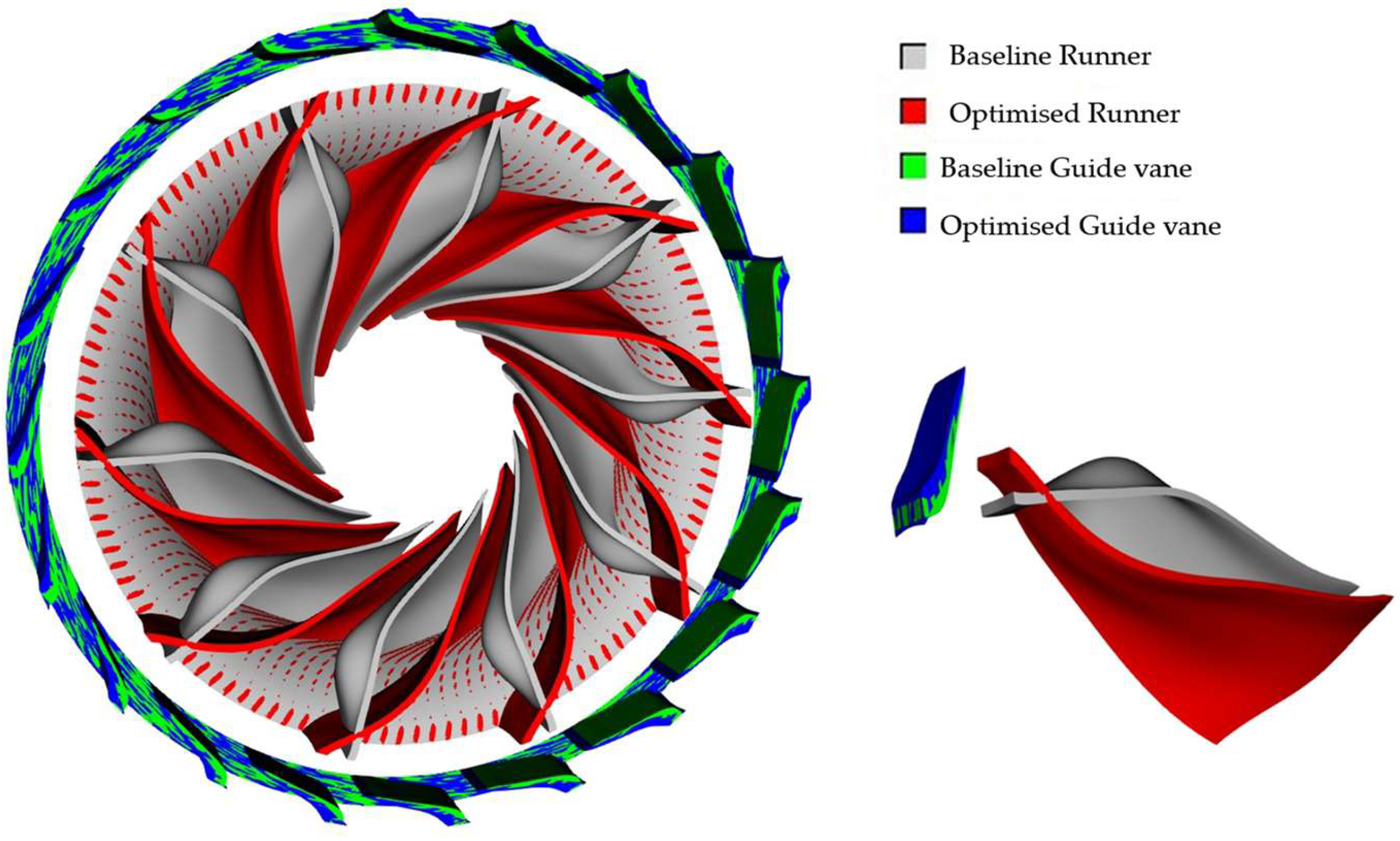

4.2.3. Synergistic Effects and Design Implications

The collective findings between both stages demonstrate the beneficial synergies that arise from designing guide vanes and runner blades as a single system. The guide vanes set up the flow conditions that directly affect the runner inlet, while the runner blades determine the energy extraction and pressure recovery capabilities. The 3D representation in

Figure 9 displays the baseline and optimised configurations of the guide vane and runner blades.

The runner blade optimisation converted an original design that caused severe cavitation into a design that does not cavitate at all, while the guide vane optimisation increased Pmin to positive pressures, which created safe operating conditions. These results confirm that optimising components in isolation is insufficient. The coordinated two-stage optimisation produces superior performance rather than separate optimisation of individual components. The two-stage optimisation approach achieved improved hydraulic performance along with enhanced cavitation resistance through iterative design changes in runner blades and guide vanes. The Pareto front development proves the intricate relationship between different performance parameters, including losses, flow characteristics, and pressure dynamics. Through this method, designers can explore a wide and clearly defined optimisation space that reveals solutions that meet operational needs, including maximum efficiency, stability, and cavitation robustness.

4.3. CFD Validation of the Combined Optimised Design

Following the two-stage optimisation of the hydraulic turbine’s runner blades and guide vanes, a complete 3D CFD simulation of the baseline design and stages 1 and 2 optimisations under rated operating conditions was conducted to confirm hydraulic performance. The CFD analysis confirmed the optimisation results while studying the intercomponent interactions to measure efficiency improvements and head and power increases compared to the baseline design. Validation was performed through comparison with obtained site operating conditions, as shown in

Table 8.

The operating conditions of 0.8 m3/s and 1500 rpm with 136.5 m head and 942 kW power output were applied to the three configurations for uniform evaluation and ensure consistency and comparability across all performance metrics.

4.3.1. CFD Performance Validation Using Site Operating Data

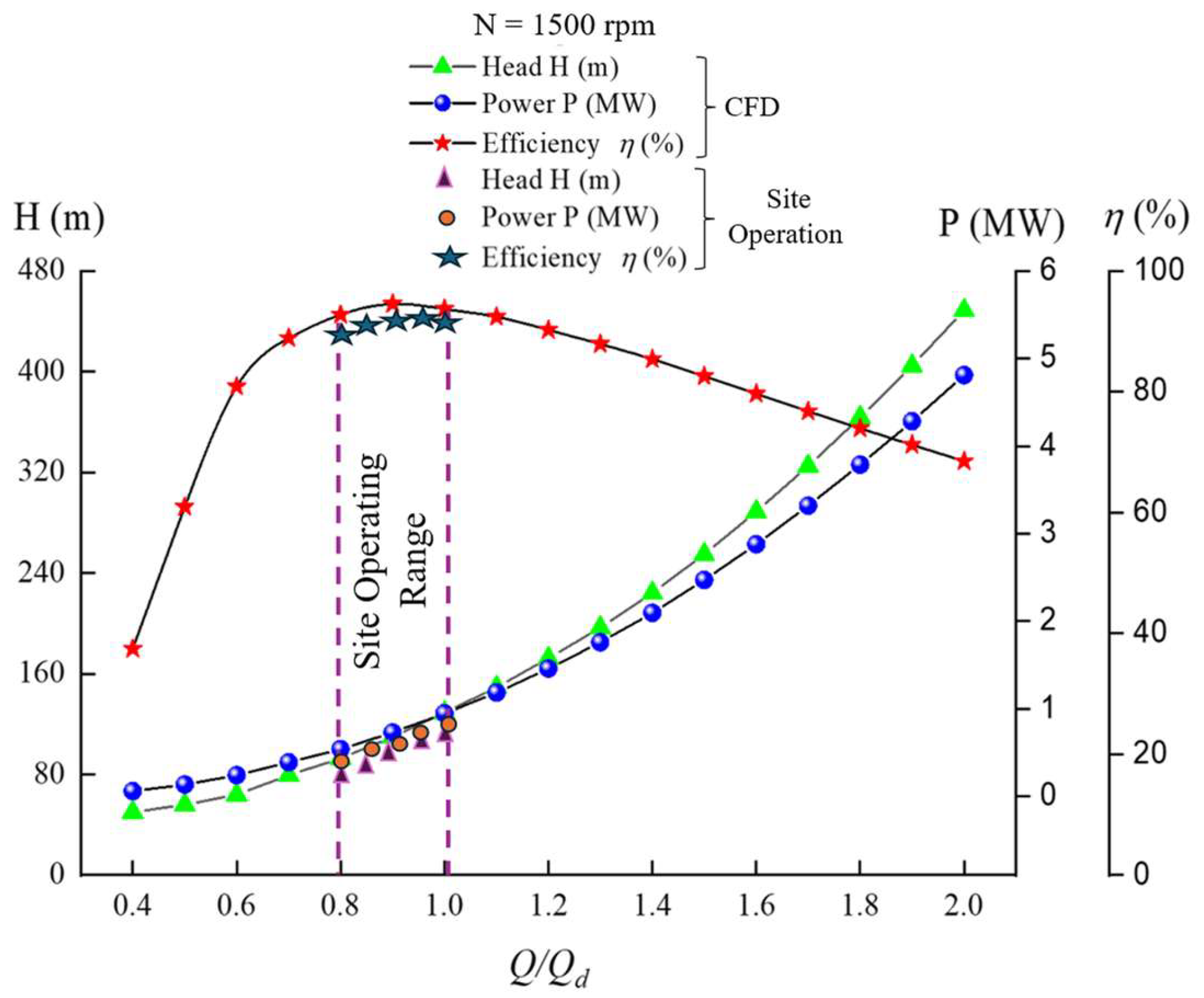

The performance of the final optimised design obtained through the two-stage optimisation of the runner and guide vane was confirmed against actual site operating data obtained from Bérchules hydropower plant in Spain. As shown in

Figure 10, the variation in head (

H), power output (

P), and hydraulic efficiency (

η), with respect to the flow ratio (

Q/Qd), was used to benchmark the CFD predictions.

The site measurements served as a trustworthy benchmark to evaluate the accuracy of the CFD model. The CFD results matched measured data precisely throughout the entire operating range, particularly during the site’s normal operating conditions. The simulation results matched the site data for both head and power output trends and precisely located the maximum efficiency point. The minor discrepancies at off-design flow rates fall within normal engineering limits because of operational variations and small measurement errors. The strong correlation between the CFD model and actual measurements proves the model’s robustness while confirming the practical application of the optimised Stage II runner through its simulation results.

When comparing CFD-derived efficiencies with nameplate or experimentally measured values, it is important to recognise inherent differences between the two approaches. CFD simulations typically report higher efficiencies because they capture only the hydraulic behaviour of the turbine under idealised flow conditions. They do not account for mechanical losses (e.g., bearings, seals), electrical losses in the generator, or more factors such as surface roughness, wear, and cavitation, which are always present in real machines.

By contrast, nameplate ratings and experimental measurements reflect the actual operational performance of the entire turbine–generator system, incorporating all the above loss mechanisms. As such, direct comparisons between CFD predictions and field efficiencies will inevitably show a discrepancy.

The purpose of CFD-based optimisation, therefore, is not to reproduce absolute nameplate efficiency but to show relative improvements within the same numerical framework. Efficiency gains reported in CFD highlight the effectiveness of geometric or operational modifications to the hydraulic components, while acknowledging that real-world operating values will be lower.

This distinction underscores the value of CFD as a design and optimisation tool rather than a direct predictor of field efficiency, providing engineers with insights into performance improvements that can later be validated through experimental or operational testing.

The predictive precision of the developed method via CFD was quantitatively computed against site performance data. Standard error metrics, namely Mean Percentage Error (MPE), Mean Absolute Error (MAE), and Root Mean Square Error (RMSE) were used for this analysis (see

Table 9).

The slight discrepancies observed in the site data and CFD depicts a close prediction of the turbine head, since the RMSE, MAE, and MPE are 5.53, 5.06, and 5.00%, respectively.

Furthermore, the error metrics of RMSE (0.022), MAE (0.015), and MPE (2.48%) were recorded in the power output prediction. These low margins clearly represent excellent predictive agreement in the power output. In terms of efficiency, RMSE (2.97), MAE (2.80), and MPE (3.05%) were recorded. The values obtained via CFD are marginally higher than the site data, but these discrepancies are within an acceptable range for the validation of hydraulic turbine performance.

The analysis confirms the reliability and consistency of the proposed method for predicting actual turbine characteristics. The RMSE, MAE, and MPE are moderate across all performance metrics and are within the acceptable limits recorded in the literature [

22,

34].

As observed in the work of Ohiemi and McNabola [

22], the CFD model analytically provides marginally higher estimations of performance. Nevertheless, the clear alliance of the performance tendencies and the comparatively insignificant percentage errors establish that the combination of the IDM with CFD and MOGA is a valid and accurate predictive framework for reproducing digital models of legacy hydro turbines with limited blueprints, regardless of the size of plant in question.

Whilst global SCADA data were employed for system-level validation in this study, we acknowledge that such comparisons are insufficient to fully capture local flow physics. Ideally, local validation data such as pressure tap measurements, LDV velocity profiles, or cavitation observations would provide stronger corroboration of CFD predictions of secondary flows, profile losses, and minimum pressure. However, implementing these methods in the present case was not practicable. The hydropower facility investigated is an operational legacy plant, where intrusive instrumentation would necessitate modifications to the turbine casing, runner, or guide vane system, leading to operational downtime. Such approaches are more readily undertaken in laboratory-scale rigs or experimental turbines, where measurement access can be incorporated by design. We therefore relied on global SCADA data for validation, which offered reliable system-level insights across operating conditions. Future studies, particularly those undertaken during major refurbishments or on dedicated test rigs, may incorporate local validation techniques to further strengthen the link between CFD predictions and measured flow behaviour.

4.3.2. Velocity Field and Streamlines

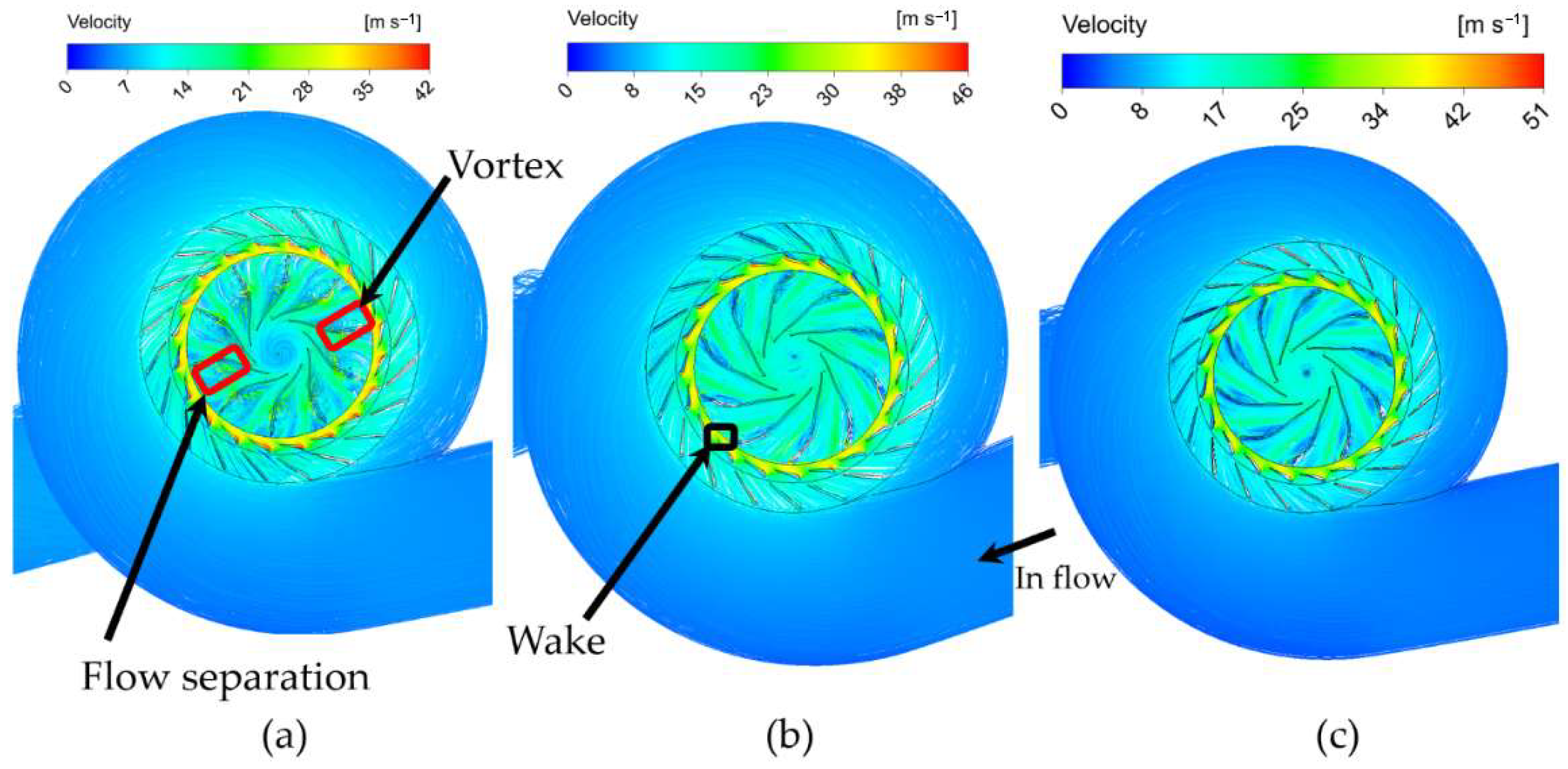

Velocity contour plots and streamline analyses in

Figure 11 and

Figure 12 showed that the baseline turbine experienced significant flow misalignment and separation zones at both guide vane exits and runner inlets (See

Figure 11a and

Figure 12b). These phenomena generated secondary vortices and localised turbulence that contributed to energy loss and pressure drops.

The optimised geometry maintained uniform inlet flow conditions at the runner with streamlines that accelerated smoothly and showed minimal cross-passage deviation as seen in

Figure 12b,c. The suppression of vortex formation became evident, especially near blade tips and roots, which led to a significant decrease in secondary flow intensity. The SF factor reduction from 0.0483 (baseline) to 0.0187 (Stage 2) matches the observed improvement. The baseline turbine showed high viscous losses together with flow detachment on the suction side of the runner blades and in the guide vane wake region. The optimised design displayed reduced wall shear stress and total pressure loss contours, which proved the improvement of the isentropic flow path especially in areas where boundary layer separation and recirculation occurred. The Profile Loss decreased to 0.96 in Stage 1 and remained at 1.16 in Stage 2 due to runner and guide vane optimisation, which simultaneously reduced flow resistance and improved passage diffusion rates.

4.4. Internal Flow Field Analysis

This section solely relies on CFD validation to present visual data that validates previous results. It provides an extensive examination of pressure and velocity contour plots that demonstrates the progression from the baseline through Stage 1 runner blade optimisation to Stage 2 combined runner and guide vane optimisation.

4.4.1. Pressure Distribution at Blade Spanwise Sections

The internal flow behaviour changes resulting from two-stage optimisation can be better understood by analysing spanwise pressure contour plots at three representative blade heights (Span = 0.1, 0.5, and 0.9) for every design configuration. The plots are presented in

Figure 13. Static pressure distribution visualisations in

Figure 13 display meridional slices between guide vane and runner passages, offering insight into blade loading areas and cavitation-prone points across the span.

Figure 13a presents the pressure distribution across individual blades for the baseline design. The pressure contour demonstrates extensive low-pressure areas that exist mainly on the suction side of the runner blade at spans 0.5 and 0.9. These regions display the indicators of high loading, along with potential cavitation risks. The pressure distribution at Span 0.1 remains less intense compared to other regions, but the passage experiences uneven pressure gradients. The Stage 1-optimised runner blade geometry produces a more balanced pressure field, as shown in

Figure 12b.

At Span 0.5, the pressure distribution demonstrates better loading patterns across the blade while showing reduced cavitation vulnerability. The runner blade maintains a steady pressure increase along its passage, which confirms the improved minimum pressure results. The pressure field reaches its most stable state when guide vane optimisation is implemented during Stage 2, as demonstrated in

Figure 13c. The spanwise pressure gradients decrease while the high-pressure zones linking from the vane leading edge to the runner trailing edge show uniform maintenance.

The greatest improvements were observed around the hub and mid-span regions, demonstrating excellent flow pre-conditioning from the optimised guide vane. The pressure distribution remains cohesive throughout all spans because combined guide vane and runner blade optimisation works to reduce pressure drops and increase blade loading.

4.4.2. Velocity Distribution at Blade Spanwise Sections

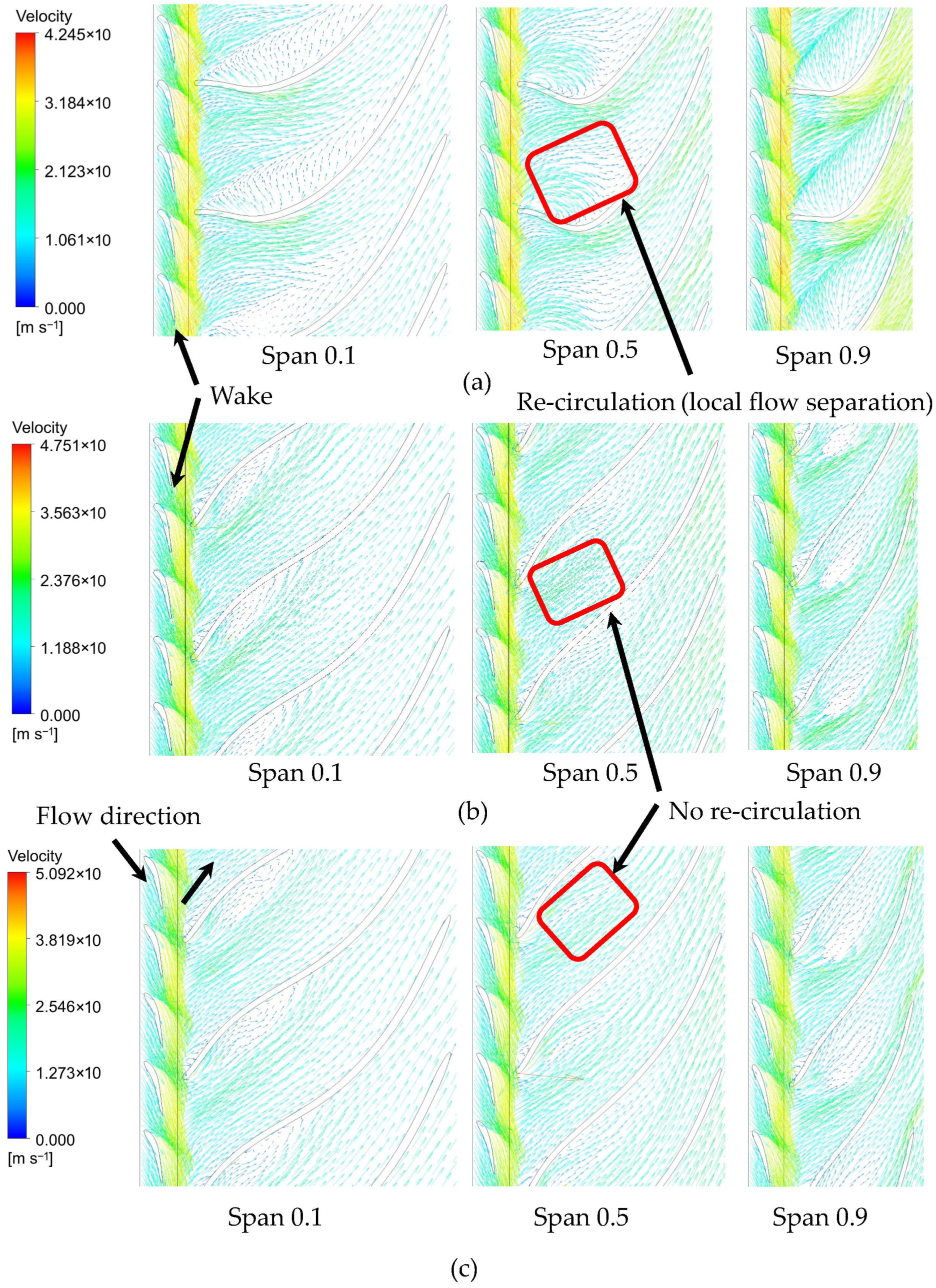

The evaluation of velocity vector plots alongside static pressure distributions was performed to critically examine the internal flow patterns and clearly visualise flow separation areas as well as misalignment regions in the turbine flow passage.

Figure 14 shows the velocity vector fields at three representative blade spans (Span = 0.1, 0.5, and 0.9) for the baseline design as well as Stage1 and Stage 2 optimisation. The velocity contours in

Figure 14a display both velocity magnitude and vector direction for visualising streamlines and flow attachment. It shows how the baseline design exhibits major misalignment and disordered behaviour mostly at the tip and mid-span. Flow separation occurs and the formation of strong cross-passage vortices reveals high levels of energy loss through secondary flows. The flow loses attachment to the pressure surface at Span 0.9, which results in increased profile loss and reduced efficiency. The runner optimisation at Stage 1 leads to vector alignment improvements throughout all span regions according to

Figure 14b. The elimination of swirling motions becomes evident when the flow tracks the blade surfaces more uniformly. The velocity magnitude shows a steady rise from one end of the passage to the other, especially at Span 0.5, where boundary layer separation is almost eliminated.

The Stage 2-optimised configuration displays flow behaviour that is nearly optimal according to

Figure 14c. The flow vectors show perfect alignment while maintaining uniform distribution without any visible separation zones or recirculation areas. The design transition demonstrates how the guide vane and runner blade operate together to control the incoming flow path while maximising axial velocity recovery. The design shows a highly efficient and hydraulically balanced design.

These improvements reflect a highly efficient and hydraulically balanced design. The guide vane optimisation clearly contributes to flow pre-conditioning, reducing turbulence and smoothing the flow field before it reaches the runner.

4.5. Discussion

4.5.1. Inverse Design Method and Baseline Design

The inverse design method (IDM) provides the foundation for this study. Starting from the targeted design point, IDM generates a baseline turbine design closely matching the existing site turbine. This ensures that initial geometries capture the primary hydraulic characteristics of the legacy turbine, providing a reliable starting point for optimisation and digital twin reconstruction. However, optimisation is necessary to achieve targeted performance, including efficiency, cavitation resistance, and flow uniformity under off-design conditions.

4.5.2. Limitations of Steady CFD

Optimisation was conducted using steady CFD simulations, which are computationally efficient and provide valuable insight into flow patterns and performance trade-offs. Nevertheless, steady CFD cannot capture transient phenomena such as load ramps, start-up/shutdown events, unsteady forces, or vortex shedding. Time-averaged turbulence models smooth out secondary flows and dynamic fluctuations, potentially underestimating cavitation risks or local instabilities. Additionally, steady simulations cannot accurately resolve dynamic forces critical for fatigue and structural integrity assessments.

Future work should explore unsteady CFD approaches (URANS or LES), rotor-stator interaction models, and transient cavitation simulations to more accurately represent operational realities. Integration with IDM–MOGA optimisation under unsteady conditions would enable robust turbine designs capable of performing efficiently across steady and transient operating scenarios.

4.5.3. Justification of MOGA Population Size and Generations

A population size of 30 individuals and 30 generations was selected for the MOGA to balance computational cost with effective design space exploration. Each candidate evaluation requires a full CFD simulation of the runner and guide vane, and increasing the population or number of generations would primarily increase computational time without significantly improving the Pareto front. The results indicated convergence toward the target performance, with Pareto-optimal solutions clustering around the desired objectives, suggesting diminishing returns for larger populations or generations.

4.5.4. Integration and Future Perspectives

By combining IDM, steady CFD, and MOGA, the framework provides an efficient pathway to optimise runner and guide vane designs for small-legacy Francis turbines. The IDM baseline ensures designs are hydraulically close to the site turbine, while MOGA refinement achieves the targeted performance. Future extensions could include adaptive or parallelised MOGA approaches integrated with unsteady CFD, improving robustness and reliability under off-design and transient operating conditions, and enabling broader application to legacy hydropower refurbishment.