Distributed Hierarchical Control with Cost Optimization and Priority-Based Dispatch for Workplace EV Charging: A Field Study

Abstract

1. Introduction

- 1.

- Introduction and testing of a two-level control system, combining upper-level receding horizon optimization with lower-level priority-based dispatch, tailored for workplace EV charging under grid constraints.

- 2.

- Proof-of-concept implementation of a distributed hierarchical control architecture for workplace EV charging, demonstrating autonomous operation under real-world conditions.

- 3.

- Experimental performance validation of the system’s effectiveness in managing energy allocation, responding to dynamic price signals, maintaining grid compliance, and ensuring fair and adaptive charging through a lower-level priority-based dispatch algorithm.

- 4.

- Documentation of real-life challenges encountered during deployment, along with adaptation techniques and actionable recommendations for future implementations of distributed smart charging systems.

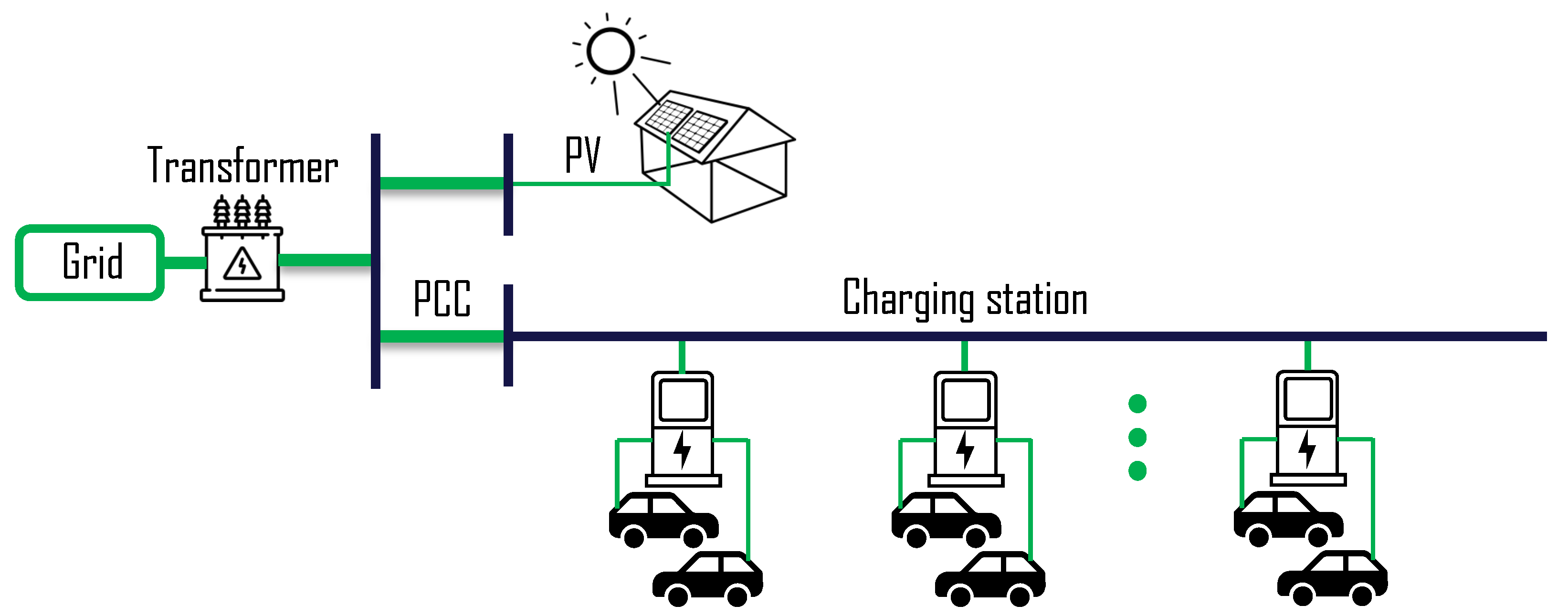

2. Application Framework

- 1.

- Grid connection limitations: Smart charging is essential to ensure that the total power drawn from the grid does not exceed predefined technical limits, thereby avoiding grid overloads and ensuring system stability.

- 2.

- Slow chargers: Price optimization and energy management systems are particularly effective in setups where charging time can be flexibly managed. Therefore, fast chargers, whose primary objective is to provide necessary energy as quickly as possible, are not in the scope of this setup.

- 3.

- Cluster of chargers or EV charging station: Aggregation of EV chargers into a cluster or charging station, connected to the same grid transformer, makes it possible to consider the charger loads as a single load unit in the control system.

- 4.

- Local PV generation: EV charging setups can benefit from the presence of local renewable energy sources (RES), particularly photovoltaic (PV) systems. Therefore, this work considers both the presence and absence of such generation in the control system design.

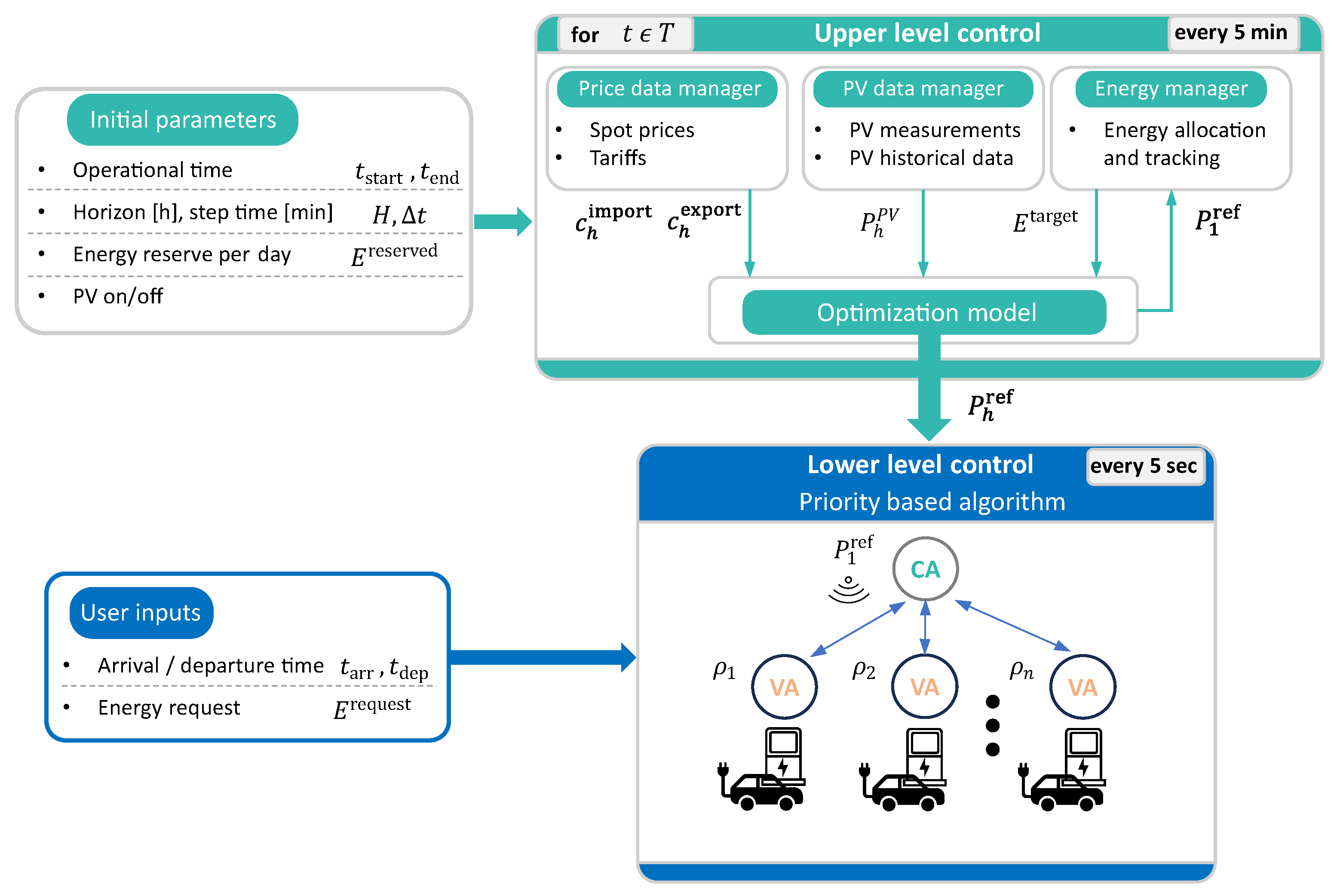

3. Control Architecture Overview

3.1. Upper-Level Control

- Optimization model: The core component of upper-level control, which solves the optimization problem by minimizing electricity purchase cost under different constraints (power limitations, energy compliance, time constraints, etc.) and sets the power reference for the charging station.

- Price data manager: Retrieves, processes, and supplies electricity price information to the optimization model, including day-ahead spot prices, distribution system operator (DSO) tariffs, transmission system operator (TSO) tariffs, and taxes.

- PV data manager: Collects historical PV data and PV measurements and then prepares the PV data for the optimization model. It combines persistence-based forecasting with real-time measurement logic to capture both the current situation and the broader seasonal patterns. An extended explanation of the adapted PV data methodology can be found in [27].

- Energy manager: Determines the target amount of energy to be consumed during the current model run. It tracks how much energy has already been allocated via previous power reference decisions and ensures that the total energy consumption is aligned within the predefined daily energy reserve. This module utilizes knowledge of the operational time window and the total energy reserve to guide allocation decisions dynamically.

| Algorithm 1 : Receding horizon optimization with PV and energy tracking |

|

- 1.

- Price loading: Retrieve the latest electricity prices and tariffs for the next horizon.

- 2.

- PV loading: Collect current PV measurements and last day PV data, and generate a forecast.

- 3.

- Energy allocation: Estimate the energy target required for the current run and track energy usage based on previous power reference allocations. The target is recalculated at each step by taking the remaining daily energy and proportionally scaling it to the number of visible operational steps () in the current optimization horizon relative to the total operational steps left for the day (). This approach prevents both overloading energy use early in the day and leaving too little for later, ensuring a balanced and consistent distribution throughout the entire operational period.

- 4.

- Optimization model execution: Solve the problem of cost minimization under constraints, generate a power reference for the next horizon length, and pass it to the lower-level control logic and to the energy manager module.

3.2. Lower-Level Control

- Its own priority share relative to the cluster;

- Its position in the priority order;

- The current operational state of other chargers.

- Idle: No EV connected or waiting to start.

- Queue: EV is waiting for available capacity.

- Initiation (Wait for Space, Take Minimum, Stabilize): Coordinated start-up sequence to smoothly integrate a new charging session without disrupting others.

- Steady Operation: Either Single VA Steady (only one EV charging) or Multi VA Steady (multiple EVs charging), where power sharing is continuously adjusted by a PI control loop asThis formulation implements a PI controller with a dynamic proportional gain and an integral gain equal to 1 (). This formulation ensures that high-priority sessions respond more strongly to positive errors and reduce less during negative errors, while low-priority sessions adjust in the opposite manner.

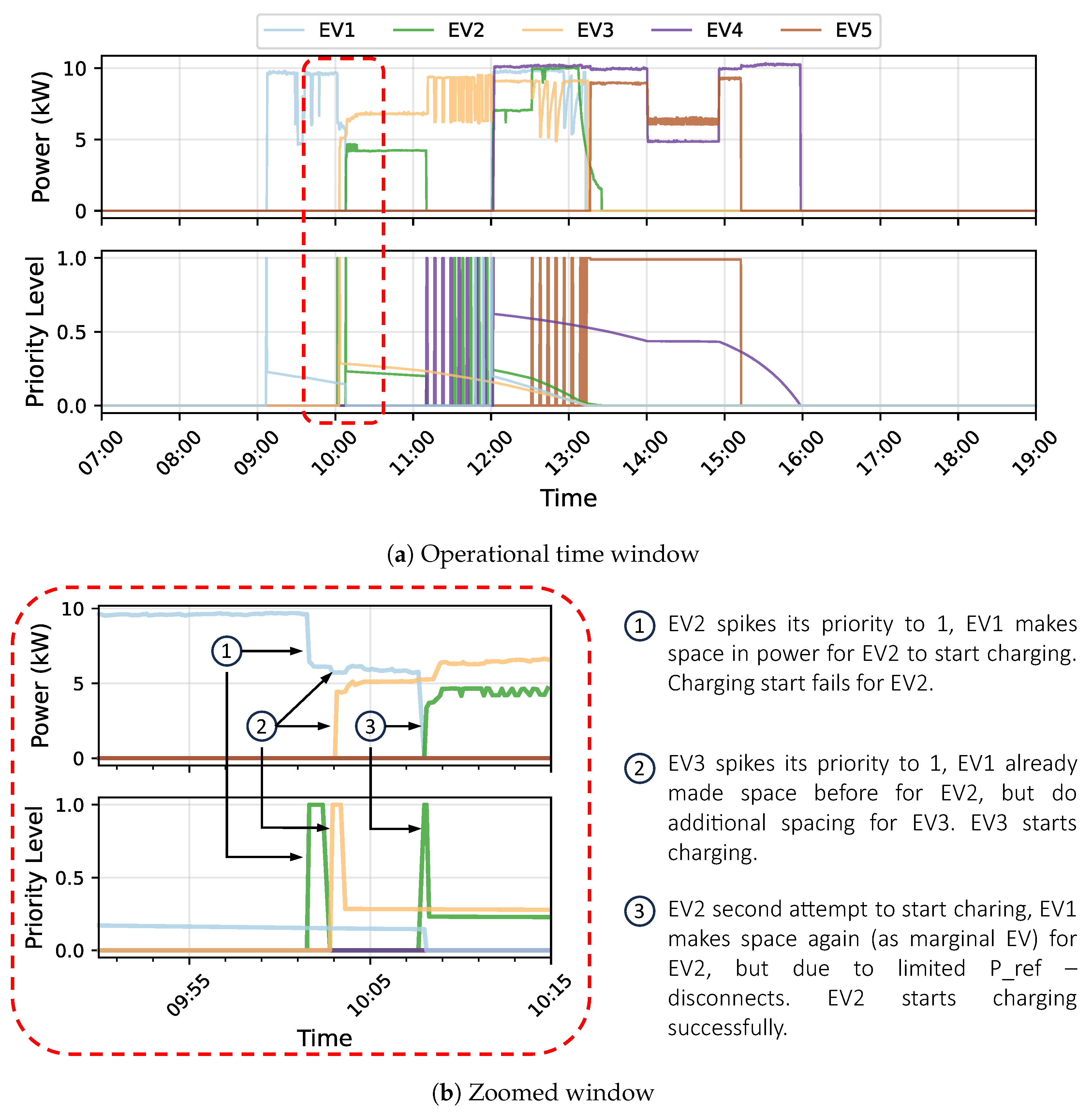

- Making Space: All chargers freeze their power output, except for the charger serving the lowest-priority session (marginal EV), which reduces its power to create capacity for a higher-priority EV to start charging. A minimum power boundary is enforced. If the reduced allocation falls below this limit, the low-priority EV transitions back to the queue state until conditions allow re-entry.

- Session Ended: A session is terminated either because the energy request is met or by user intervention.

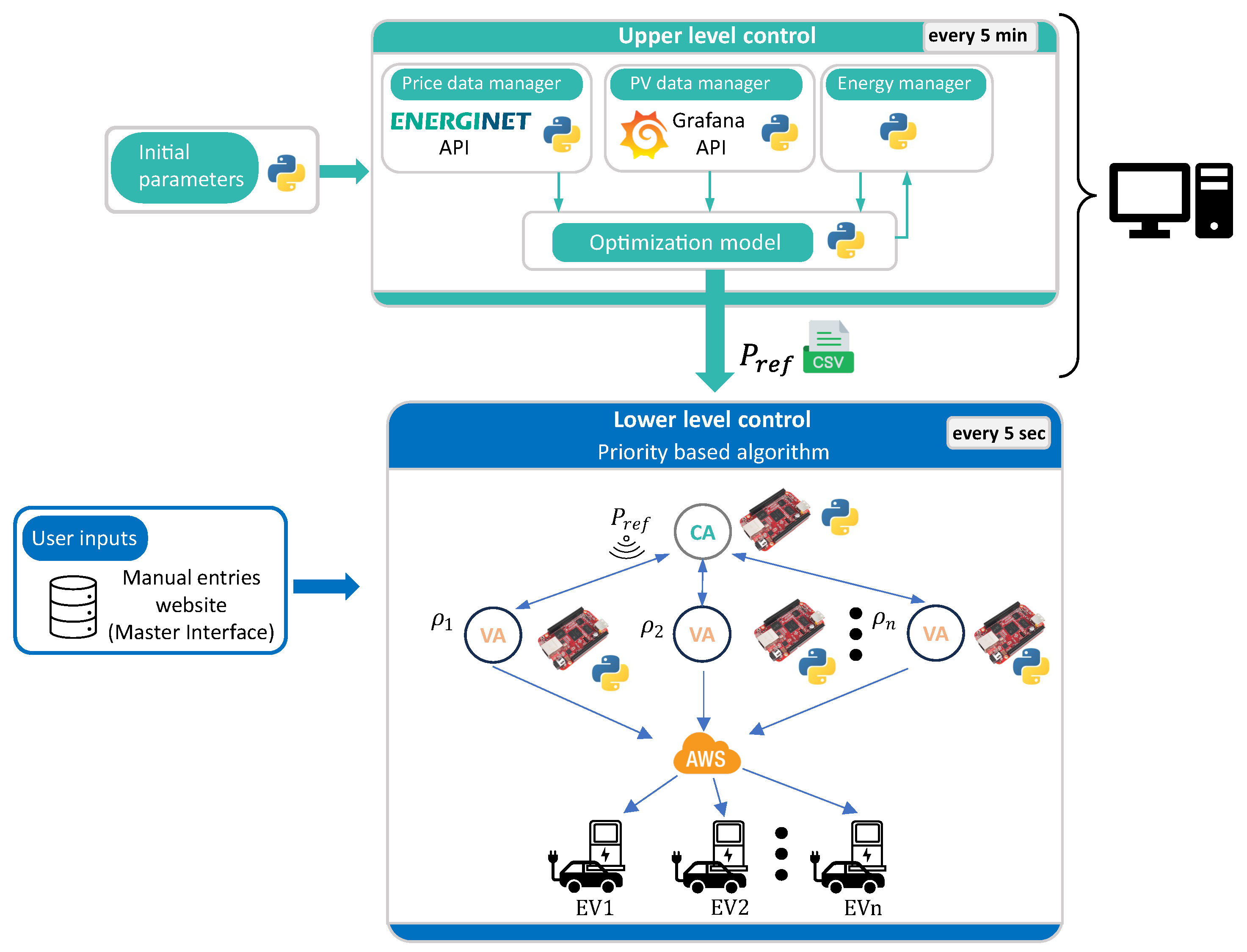

4. Physical Implementation of the Control Architecture

4.1. Hardware

4.2. Software

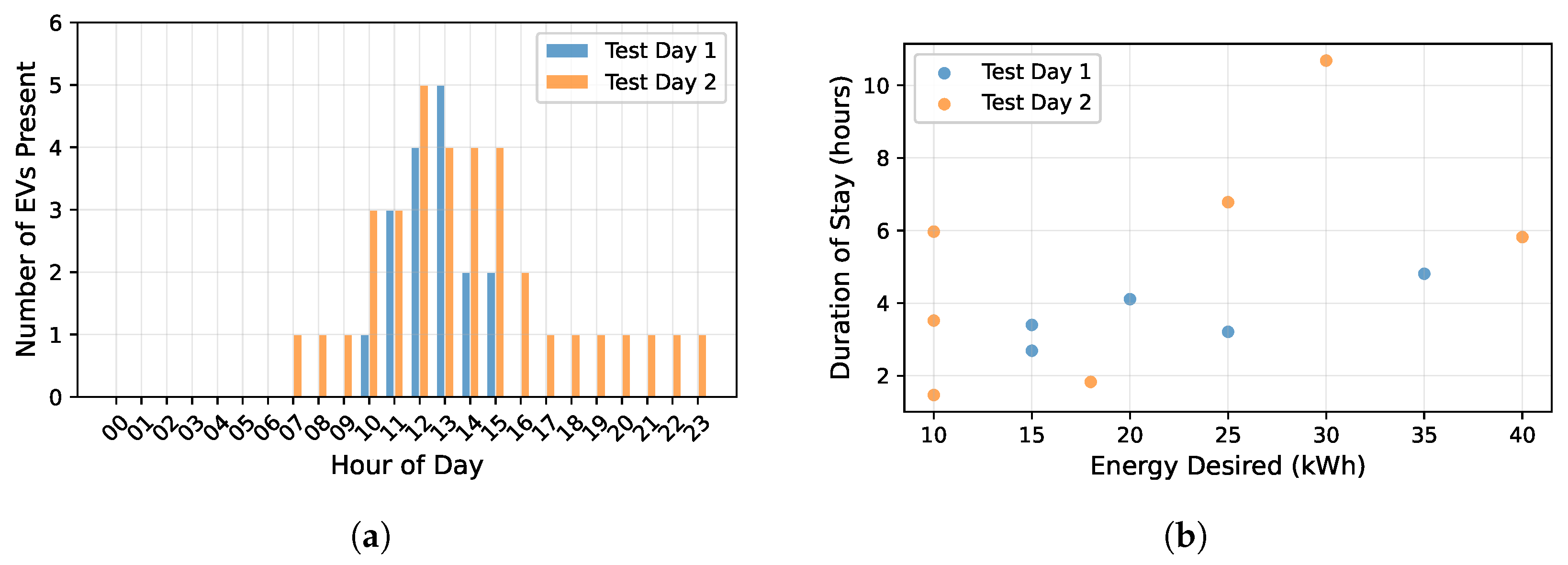

5. Field Tests Description

5.1. Parameters

5.2. EVs

6. Results

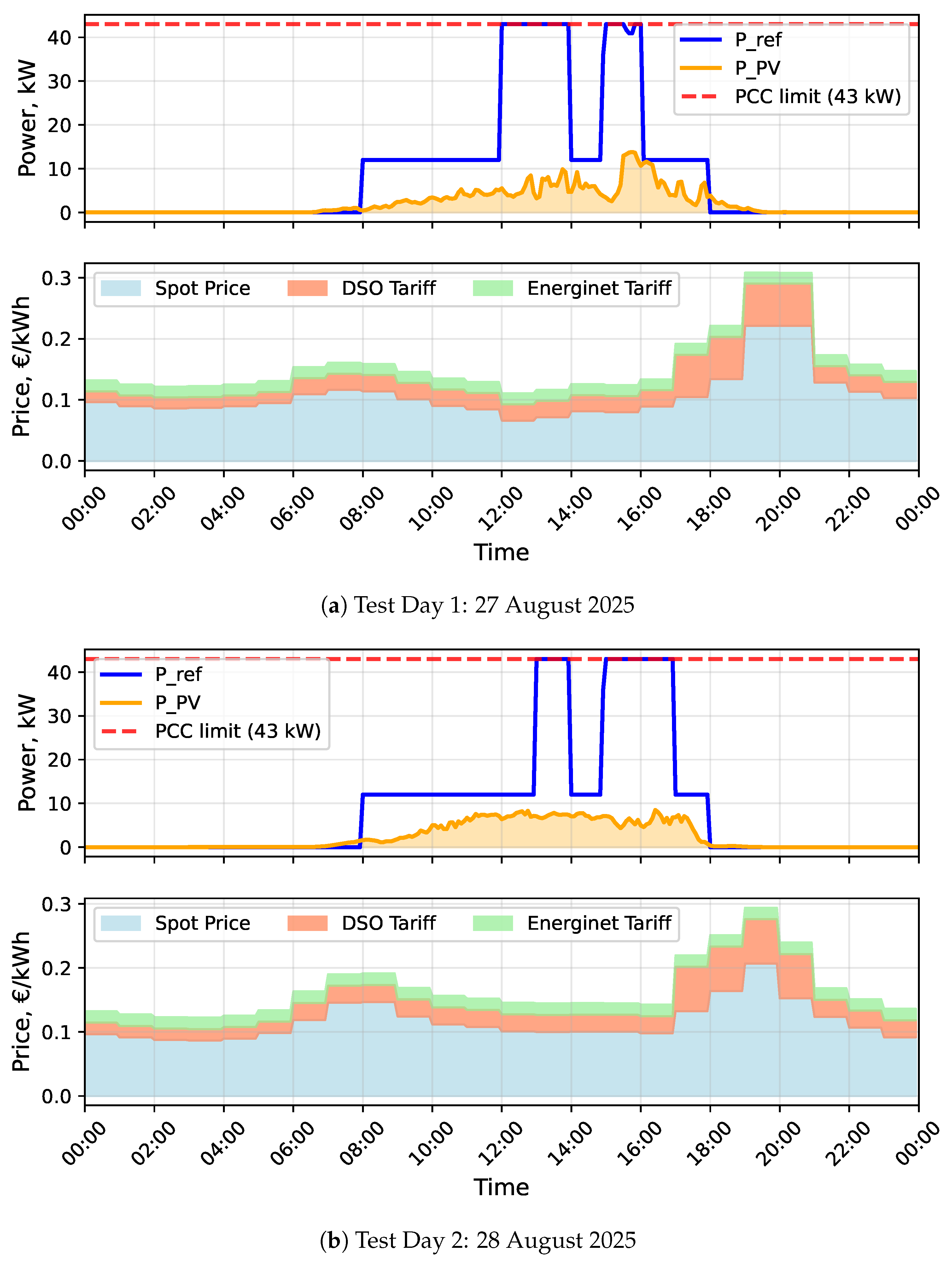

6.1. Upper-Level Control Performance

6.2. Alignment of Lower-Level EV Charging with Upper-Level Control Power Reference

6.3. Lower-Level Priority-Based EVs Charging

6.4. Summary of EV Charging Sessions and Delivery Rates

7. Real-Life Implementation Experiences: Challenges and Adaptations

7.1. Charger Communication Error and Hardware Faults

7.2. Failed Initiations of Charging Sessions

7.3. EV-Side Communications and Sleep Modes

7.4. Misalignment Between Upper- and Lower-Level Controls

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AWS | Amazon Web Services |

| CA | Cloud Aggregator |

| CPO | Charge Point Operator |

| DSO | Distribution System Operator |

| DTU | Technical University of Denmark |

| EV | Electric Vehicle |

| MILP | Mixed-Integer Linear Programming |

| PCC | Point of Chargers Connection |

| PC | Personal Computer |

| PV | Photovoltaic |

| RES | Renewable Energy Sources |

| TSO | Transmission System Operator |

| VA | Virtual Aggregator |

| V2G | Vehicle-to-Grid |

Nomenclature

| Sets and indices | |

| T | Set of decision times (actual time indices) |

| t | Decision time index, |

| H | Planning horizon (set of foreseen steps); is horizon length [steps] |

| h | Index of step in the planning horizon, |

| Parameters | |

| Step duration [min] | |

| H | Horizon length [hours] |

| Operational time window | |

| Daily energy reserve [kWh] | |

| Maximum power at PCC [kW] | |

| Minimum cluster power [kW] | |

| Rated power of EVSE (charger) [kW] | |

| PV on/off | Binary flag for PV data availability () |

| Decision and state variables | |

| Cluster power reference for horizon H at time t [kW] | |

| First-step cluster power reference [kW] | |

| PV power forecast for horizon H at time t [kW] | |

| Net grid power (import > 0, export < 0) [kW] | |

| Grid import power [kW] | |

| Grid export power [kW] | |

| Import electricity price [€/kWh] | |

| Export electricity price [€/kWh] | |

| Cumulative energy allocated up to time t [kWh] | |

| Remaining daily energy at time t [kWh] | |

| Energy target for current optimization run [kWh] | |

| Number of operational steps visible in horizon [–] | |

| Number of operational steps remaining in day [–] | |

| Slack variable for objective function | |

| Lower-level control variables | |

| Measured total power at PCC [kW] | |

| PCC power error for PI controller [kW] | |

| Power reference for EVi [kW] | |

| User-requested energy for a session [kWh] | |

| Energy delivered so far to EV [kWh] | |

| Declared departure time | |

| Current time when priority is evaluated | |

| Priority index [–] | |

| Proportional gain in lower-level control [–] | |

| Integral gain in lower-level control () [–] | |

References

- IEA. Global EV Outlook 2025—Analysis. Available online: https://iea.blob.core.windows.net/assets/7ea38b60-3033-42a6-9589-71134f4229f4/GlobalEVOutlook2025.pdf (accessed on 15 September 2025).

- Vishnu, G.; Kaliyaperumal, D.; Jayaprakash, R.; Karthick, A.; Kumar Chinnaiyan, V.; Ghosh, A. Review of Challenges and Opportunities in the Integration of Electric Vehicles to the Grid. World Electr. Veh. J. 2023, 14, 259. [Google Scholar] [CrossRef]

- Unterluggauer, T.; Hipolito, F.; Rich, J.; Marinelli, M.; Andersen, P.B. Impact of cost-based smart electric vehicle charging on urban low voltage power distribution networks. Sustain. Energy Grids Netw. 2023, 35, 101085. [Google Scholar] [CrossRef]

- Jones, C.B.; Lave, M.; Vining, W.; Garcia, B.M. Uncontrolled Electric Vehicle Charging Impacts on Distribution Electric Power Systems with Primarily Residential, Commercial or Industrial Loads. Energies 2021, 14, 1688. [Google Scholar] [CrossRef]

- Striani, S.; Sevdari, K.; Calearo, L.; Andersen, P.B.; Marinelli, M. Barriers and Solutions for EVs Integration in the Distribution Grid. In Proceedings of the 2021 56th International Universities Power Engineering Conference: Powering Net Zero Emissions, UPEC 2021—Proceedings, Middlesbrough, UK, 31 August–3 September 2021. [Google Scholar] [CrossRef]

- Tirunagari, S.; Gu, M.; Meegahapola, L. Reaping the Benefits of Smart Electric Vehicle Charging and Vehicle-to-Grid Technologies: Regulatory, Policy and Technical Aspects. IEEE Access 2022, 10, 114657–114672. [Google Scholar] [CrossRef]

- Ahmad, A.; Khalid, M.; Ullah, Z.; Ahmad, N.; Aljaidi, M.; Malik, F.A.; Manzoor, U. Electric Vehicle Charging Modes, Technologies and Applications of Smart Charging. Energies 2022, 15, 9471. [Google Scholar] [CrossRef]

- Mogire, E.; Kilbourn, P.; Luke, R. Smart Charging for E-Mobility in Urban Areas: A Bibliometric Review. Energies 2025, 18, 4655. [Google Scholar] [CrossRef]

- Diaz-Londono, C.; Maffezzoni, P.; Daniel, L.; Gruosso, G. Flexibility of Electric Vehicle Chargers in Residential, Workplace, and Public Locations Based on Real-World Data. In Proceedings of the EUROCON 2023—20th International Conference on Smart Technologies, Torino, Italy, 6–8 July 2023; pp. 354–359. [Google Scholar] [CrossRef]

- Han, X.; Heussen, K.; Gehrke, O.; Bindner, H.W.; Kroposki, B. Taxonomy for Evaluation of Distributed Control Strategies for Distributed Energy Resources. IEEE Trans. Smart Grid 2018, 9, 5185–5195. [Google Scholar] [CrossRef]

- Dahiwale, P.V.; Rather, Z.H.; Mitra, I. A Comprehensive Review of Smart Charging Strategies for Electric Vehicles and Way Forward. IEEE Trans. Intell. Transp. Syst. 2024, 25, 10462–10482. [Google Scholar] [CrossRef]

- Richardson, P.; Flynn, D.; Keane, A. Local versus centralized charging strategies for electric vehicles in low voltage distribution systems. IEEE Trans. Smart Grid 2012, 3, 1020–1028. [Google Scholar] [CrossRef]

- García-Villalobos, J.; Zamora, I.; San Martín, J.I.; Asensio, F.J.; Aperribay, V. Plug-in electric vehicles in electric distribution networks: A review of smart charging approaches. Renew. Sustain. Energy Rev. 2014, 38, 717–731. [Google Scholar] [CrossRef]

- Nimalsiri, N.I.; Mediwaththe, C.P.; Ratnam, E.L.; Shaw, M.; Smith, D.B.; Halgamuge, S.K. A Survey of Algorithms for Distributed Charging Control of Electric Vehicles in Smart Grid. IEEE Trans. Intell. Transp. Syst. 2020, 21, 4497–4515. [Google Scholar] [CrossRef]

- Kisacikoglu, M.C.; Erden, F.; Erdogan, N. Distributed Control of PEV Charging Based on Energy Demand Forecast. IEEE Trans. Ind. Inform. 2018, 14, 332–341. [Google Scholar] [CrossRef]

- Ardakanian, O.; Keshav, S.; Rosenberg, C. Real-time distributed control for smart electric vehicle chargers: From a static to a dynamic study. IEEE Trans. Smart Grid 2014, 5, 2295–2305. [Google Scholar] [CrossRef]

- Abdullah Al Nahid, S.; Qi, J. A Hybrid EV Charging Approach Based on MILP and a Genetic Algorithm. Energies 2025, 18, 3656. [Google Scholar] [CrossRef]

- Amin, A.; Mahmood, A.; Khan, A.R.; Arshad, K.; Assaleh, K.; Zoha, A. A Two-Stage Multi-Agent EV Charging Coordination Scheme for Maximizing Grid Performance and Customer Satisfaction. Sensors 2023, 23, 2925. [Google Scholar] [CrossRef]

- He, C.; Zhang, Z. An efficient hierarchical electric vehicle charging control strategy. Int. J. Robust Nonlinear Control 2023, early view. [Google Scholar] [CrossRef]

- Wang, R.; Tian, X.; Wei, Z.; Sun, Q.; Wang, P. Fully distributed energy management strategy for DC bus charging stations with three charging modes. Sci. Rep. 2025, 15, 1009. [Google Scholar] [CrossRef] [PubMed]

- Alexeenko, P.; Bitar, E. Achieving reliable coordination of residential plug-in electric vehicle charging: A pilot study. Transp. Res. Part D: Transp. Environ. 2023, 118, 103658. [Google Scholar] [CrossRef]

- Black, D.; Yin, R.; Wang, B. Smart Charging of Electric Vehicles and Driver Engagement for Demand Management and Participation in Electricity Markets California Energy Commission; Technical Report; California Energy Commission: Sacramento, CA, USA, 2019. [Google Scholar]

- Tamis, M.; Hoed, R.v.d.; Thorsdottir, H. Smart charging in the Netherlands. In Proceedings of the European Battery, Hybrid & Fuel Cell Electric Vehicle Congress, Geneva, Switzerland, 14–16 March 2017. [Google Scholar]

- Striani, S.; Pedersen, K.L.; Engelhardt, J.; Marinelli, M. Experimental Investigation of a Distributed Architecture for EV Chargers Performing Frequency Control. World Electr. Veh. J. 2024, 15, 361. [Google Scholar] [CrossRef]

- Pedersen, K.L.; Striani, S.; Engelhardt, J.; Marinelli, M. Implementation of priority-based scheduling for electric vehicles through local distributed control. In Proceedings of the IEEE PES Innovative Smart Grid Technologies Europe, ISGT EUROPE 2024, Dubrovnik, Croatia, 14–17 October 2024. [Google Scholar] [CrossRef]

- Zunino, P.; Engelhardt, J.; Striani, S.; Pedersen, K.L.; Marinelli, M. Frequency Control in EV Clusters: Experimental Validation and Time Response Analysis of Centralized and Distributed Architectures. In Proceedings of the IEEE PES Innovative Smart Grid Technologies Europe, ISGT EUROPE 2024, Dubrovnik, Croatia, 14–17 October 2024. [Google Scholar] [CrossRef]

- Malkova, A.; Zepter, J.M.; Marinelli, M. Online optimization of a workplace electric vehicle charging station under grid constraints. IET Conf. Proc. 2023, 2023, 120–126. [Google Scholar] [CrossRef]

- Rawlings, J.; Mayne, D.Q. Model Predictive Control: Theory and Design; Nob Hill Publishing: San Francisco, CA, USA, 2009. [Google Scholar]

- Malkova, A.; Zepter, J.M.; Marinelli, M.; Korpås, M. Which control management strategies are best suited for EV charging stations? A comparison of price optimization and machine-learning approaches [Under review]. IEEE Trans. Transp. Electrif. 2025, in press. [Google Scholar]

- Energinet Day-Ahead Spot Prices. 2025. Available online: https://energidataservice.dk/tso-electricity/DayAheadPrices (accessed on 15 September 2025).

- Secchi, M.; Zepter, J.M.; Marinelli, M. Centralised Smart EV Charging in PV-Powered Parking Lots: A Techno-Economic Analysis. Smart Cities 2025, 8, 112. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Horizon (h) | 6 |

| Step time (min) | 5 |

| PV (on/off) | on |

| Operational time | 08:00–18:00 |

| Energy reserve (kWh) | 215 |

| Minimum power reference (kW) | 12 |

| Session ID | Arrival Time | Departure Time | Expected Departure Time | Duration [h] | Energy Desired [kWh] | Energy Charged [kWh] | Delivery Rate [%] |

|---|---|---|---|---|---|---|---|

| EV1 | 09:06 | 13:12 | 17:04 | 4.11 | 20 | 20 | 100.0 |

| EV2 | 10:01 | 13:25 | 15:58 | 3.40 | 15 | 15 | 100.0 |

| EV3 | 10:02 | 13:14 | 18:00 | 3.21 | 25 | 25 | 100.0 |

| EV4 | 11:09 | 15:58 | 17:10 | 4.81 | 35 | 35 | 100.0 |

| EV5 | 12:31 | 15:12 | 14:30 | 2.69 | 15 | 14.98 | 99.8 |

| Session ID | Arrival Time | Departure Time | Expected Departure Time | Duration [h] | Energy Desired [kWh] | Energy Charged [kWh] | Delivery Rate [%] |

|---|---|---|---|---|---|---|---|

| EV1 | 09:43 | 16:30 | 16:00 | 6.78 | 25 | 24.73 | 98.9 |

| EV2 | 15:19 | 01:59 | 18:00 | 10.68 | 30 | 22.40 | 74.7 |

| EV3 | 09:56 | 15:54 | 15:00 | 5.97 | 10 | 9.91 | 99.1 |

| EV4 | 11:53 | 13:43 | 16:00 | 1.83 | 18 | 0 | 0.0 |

| EV5 | 06:43 | 12:32 | 15:30 | 5.82 | 40 | 34.77 | 86.9 |

| EV6 | 13:50 | 15:18 | 15:30 | 1.47 | 10 | 10 | 100.0 |

| EV7 | 11:49 | 15:20 | 16:50 | 3.52 | 10 | 10 | 100.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malkova, A.; Striani, S.; Zepter, J.M.; Marinelli, M. Distributed Hierarchical Control with Cost Optimization and Priority-Based Dispatch for Workplace EV Charging: A Field Study. Energies 2025, 18, 5581. https://doi.org/10.3390/en18215581

Malkova A, Striani S, Zepter JM, Marinelli M. Distributed Hierarchical Control with Cost Optimization and Priority-Based Dispatch for Workplace EV Charging: A Field Study. Energies. 2025; 18(21):5581. https://doi.org/10.3390/en18215581

Chicago/Turabian StyleMalkova, Anna, Simone Striani, Jan Martin Zepter, and Mattia Marinelli. 2025. "Distributed Hierarchical Control with Cost Optimization and Priority-Based Dispatch for Workplace EV Charging: A Field Study" Energies 18, no. 21: 5581. https://doi.org/10.3390/en18215581

APA StyleMalkova, A., Striani, S., Zepter, J. M., & Marinelli, M. (2025). Distributed Hierarchical Control with Cost Optimization and Priority-Based Dispatch for Workplace EV Charging: A Field Study. Energies, 18(21), 5581. https://doi.org/10.3390/en18215581