1. Introduction

Strawberries are one of the most widely consumed fruits in the world due to their adaptability to different climates and soils. While both greenhouse and open field systems are briefly discussed for contextual comparison, this study focuses exclusively on the sustainability assessment of open field strawberry production in the Batman region. In recent years, strawberry production has increased significantly in both open field and greenhouse systems worldwide, driven by growing market demand and advances in cultivation technologies [

1]. Energy consumption in strawberry cultivation is a critical factor affecting productivity, production cost, and environmental impact. Although greenhouse production enables higher yields and year-round cultivation, it is also one of the major contributors to greenhouse gas (GHG) emissions in the agricultural sector. Intensive farming systems, such as greenhouse cultivation, aim to achieve maximum output from limited land areas [

2]. In contrast, open field strawberry production operates under natural environmental conditions without control over factors such as sunlight, temperature, and air composition, which directly influence plant development [

3]. Consequently, open field systems are more exposed to climatic variability and may require seasonal transportation of products, increasing energy use and related emissions.

Yield and quality differences in strawberry production largely depend on cultivar characteristics and regional growing conditions [

4,

5]. These variations, which affect parameters such as fruit size, taste, and nutritional composition, are especially evident under controlled environments [

6,

7]. However, the present study focuses on open field production, where such variability interacts more strongly with climatic and soil factors rather than controlled greenhouse parameters.

In today’s world, energy policies focus on providing affordable, sufficient, and environmentally friendly energy to ensure sustainable development [

8]. Agriculture, supported in both developed and developing countries, is a key sector where efficient energy use is vital, particularly in Türkiye with its rich natural resources, favorable climate, and fertile lands [

9].

Türkiye ranks as the world’s third largest producer of strawberries with an output of 676,818 tons, following China (3.35 million ton) and the United States (1.26 million ton) in global rankings [

10]. According to official statistics, the strawberry planting area and production volume in Türkiye in 2023 were 21,983.5 ha and 676,818 ton, respectively. In Batman province, the planting area was recorded as 180 ha with a production volume of 6440 ton [

11]. This data indicates that the average yield per hectare obtained in Batman province is higher than the national average in Türkiye. This high-yield potential makes a detailed energy and sustainability analysis of strawberry production systems in the Batman region critical for regional and national agricultural policies.

Since energy consumption directly affects agricultural productivity and the national economy, optimizing its use has become an important research area. Agricultural energy use is generally classified as direct (electricity, fuel) and indirect (fertilizers, pesticides, labor), and studies show that both energy and exergy analyses are necessary. While energy analysis measures the quantity of energy consumed, exergy analysis evaluates its effectiveness and provides better insights for sustainable agricultural policies [

12,

13,

14]. Various mathematical models, including Data Envelopment Analysis (DEA) and Robust Data Envelopment Analysis (RDEA), have been used to optimize energy use in greenhouse and open field production, showing that fossil fuels and electricity dominate energy consumption. Additionally, machine learning methods have also been applied for input–output modeling in agricultural energy studies [

2,

15].

Nowadays, studies on sustainable agriculture are increasing in order to prevent environmental pollution and the depletion of natural resources. The concept of sustainable agriculture aims to preserve resources to meet the needs of both present and future generations. In this context, many researchers have focused on the integration of renewable energy sources into agricultural practices [

16,

17]. Furthermore, cumulative exergy consumption analysis has emerged as a new method for evaluating production processes, which represents the total exergy consumed from raw material to the final product within system boundaries. Reducing cumulative exergy consumption means utilizing fewer natural resources. Previous studies have analysed energy consumption in strawberry production, reporting significant variations between open field and greenhouse systems in terms of energy use, efficiency, and CO

2 emissions.

The literature consistently emphasizes the variability and productivity challenges of strawberry cultivation. For example, while total energy consumption for open field production is reported to be 35,092.4 MJ/ha, in intensive greenhouse systems this consumption increases significantly to 1,356,932.8 MJ/ha. This significant difference is paralleled by the environmental burden. In this context, total greenhouse gas emissions for open field production are 803.4 kg CO

2/ha, while for greenhouse production this amount increases sharply to 35,083.5 kg CO

2/ha [

2]. Beyond total consumption, studies on energy efficiency are of critical importance. A study conducted in the Kamyaran region of Iran reported that open field strawberry cultivation required a high specific energy requirement of 3.96 MJ/kg and showed a low energy ratio of 0.48, indicating that the energy output was less than the input. Furthermore, the same study pointed out a significant sustainability problem, with non-renewable resources accounting for a dominant proportion of the total energy inputs, 74.5% [

18]. These findings highlight the need for localized, thermodynamic assessments, such as those in the present study, to identify specific input inefficiencies and promote regional sustainability improvements. In another study, the total energy consumption for one ton of strawberry production in the open field was determined to be 6703.042 MJ, while this value decreases to 4200.881 MJ under greenhouse conditions. In addition, the greenhouse system caused a higher environmental burden with 506.07 kg CO

2 emission for one ton of strawberry production compared to the 243.06 kg CO

2 emission value in the open field [

19].

Most of these studies relied on the first law of thermodynamics (energy analysis), which only considers energy quantity and overlooks quality, limiting insight into conversion processes [

20]. This limitation is crucial as relying solely on energy quantity can result in incomplete sustainability profiles and potentially overestimate the true efficiency of resource utilization. Exergy analysis, based on the second law of thermodynamics, provides a more realistic assessment of agricultural systems by accounting for both the quantity and quality of energy flows. Unlike conventional energy analysis, it identifies the real efficiency losses occurring during transformation and utilization processes. Given that agricultural production involves multiple low and high-quality energy forms, such as fertilizers, diesel, and solar radiation, exergy analysis serves as a powerful tool to quantify resource degradation and sustainability performance more accurately. Previous studies on strawberry production have mainly focused on greenhouse conditions and energy-based assessments under the first law of thermodynamics. However, there remains a clear gap in understanding the exergetic behavior, renewability, and resource use efficiency of open field systems, particularly under semi-arid climatic conditions. This study addresses these gaps by integrating energy, exergy, and environmental performance metrics within a single analytical framework specific to the Batman region.

This research is novel because it is the first to examine the open field strawberry production system in Batman Province, Türkiye, within an integrated framework that encompasses cumulative energy consumption (CEnC), cumulative exergy consumption (CExC), cumulative carbon dioxide emissions (CCO2E), the degree of perfection (CDP), and the renewability indicator (RI). While previous studies have typically relied on conventional energy analyses based solely on the first law of thermodynamics, this study introduces a comprehensive second law-based approach that evaluates not only the quantity but also the quality and usability of the consumed energy resources. This integrated assessment provides deeper insights into the true sustainability performance of agricultural production systems by linking energy efficiency, exergy efficiency, and environmental impact within a single analytical framework. Through this approach, the study identifies hidden inefficiencies and thermodynamic losses that conventional energy analysis cannot capture, thereby offering more accurate and actionable guidance for improving resource utilization, reducing fossil fuel dependence, and enhancing overall system renewability.

2. Methodology

This study focuses on open field strawberry production in Batman province, located in southeastern Türkiye, which is characterized by a continental climate with hot, dry summers and cold winters. Beyond its climatic features, Batman was selected as the study area because strawberry cultivation has become an increasingly important source of income and rural employment in the region over the past decade. The province provides a representative case for semi-arid agricultural conditions where water and energy efficiency play a decisive role in sustainable production. The average annual temperature in Batman is approximately 16 °C, and the mean annual precipitation is around 488.8 mm, concentrated mainly between October and May [

21]. These climatic and socio-economic factors make the region a suitable case study for evaluating the sustainability performance of open field strawberry production systems. To evaluate the sustainability of open field strawberry production in Batman, analyses of CEnC, CExC, and CCO

2E were conducted. Furthermore, CDP and RI for the agricultural production process were calculated based on these analyses. The functional unit for this study was defined as “1 ton of strawberry production,” and all calculations were based on this unit. The agricultural inputs and their quantities used for producing 1 ton of strawberries in Batman were sourced from [

22] and are shown in

Table 1. The agricultural input quantities used in this study (chemical fertilizers, farmyard manure, diesel, electricity, water for irrigation) were empirically determined. The data was collected via a detailed survey applied to 189 strawberry producers in the Sason district of Batman province. These empirical data points specifically reflect the producers’ actual input usage trends observed over the recent growing seasons. This approach ensures the analysis provides a realistic profile of regional agricultural practices rather than purely theoretical assumptions. These inputs include chemical fertilizers (nitrogen, phosphorus, potassium), agrochemicals (insecticides, fungicides), farmyard manure, diesel fuel, electricity, and irrigation water. The system boundaries for the analysis encompass all agricultural activities from land preparation to harvesting.

To determine the energy, exergy, and carbon dioxide emission values, coefficients reported in the literature were used (

Table 2). These coefficients were selected from comprehensive studies that represent the entire life cycle of each input, from production to field application. During the selection process, priority was given to studies that are methodologically consistent, have clearly defined system boundaries, and are based on agricultural systems with climatic, operational, and management conditions similar to those in Türkiye. The use of coefficients obtained from different literature sources may lead to minor variations due to differences in data collection years, technological advancements, or definitions of system boundaries. However, since all coefficients were standardized based on the same functional units (e.g., per kilogram or per megajoule), such variations are not expected to significantly affect the overall interpretation of the sustainability indicators, including energy, exergy, and environmental performance. Nevertheless, this approach enhances the methodological scope and comparability of the results by considering the diversity of existing studies in the literature.

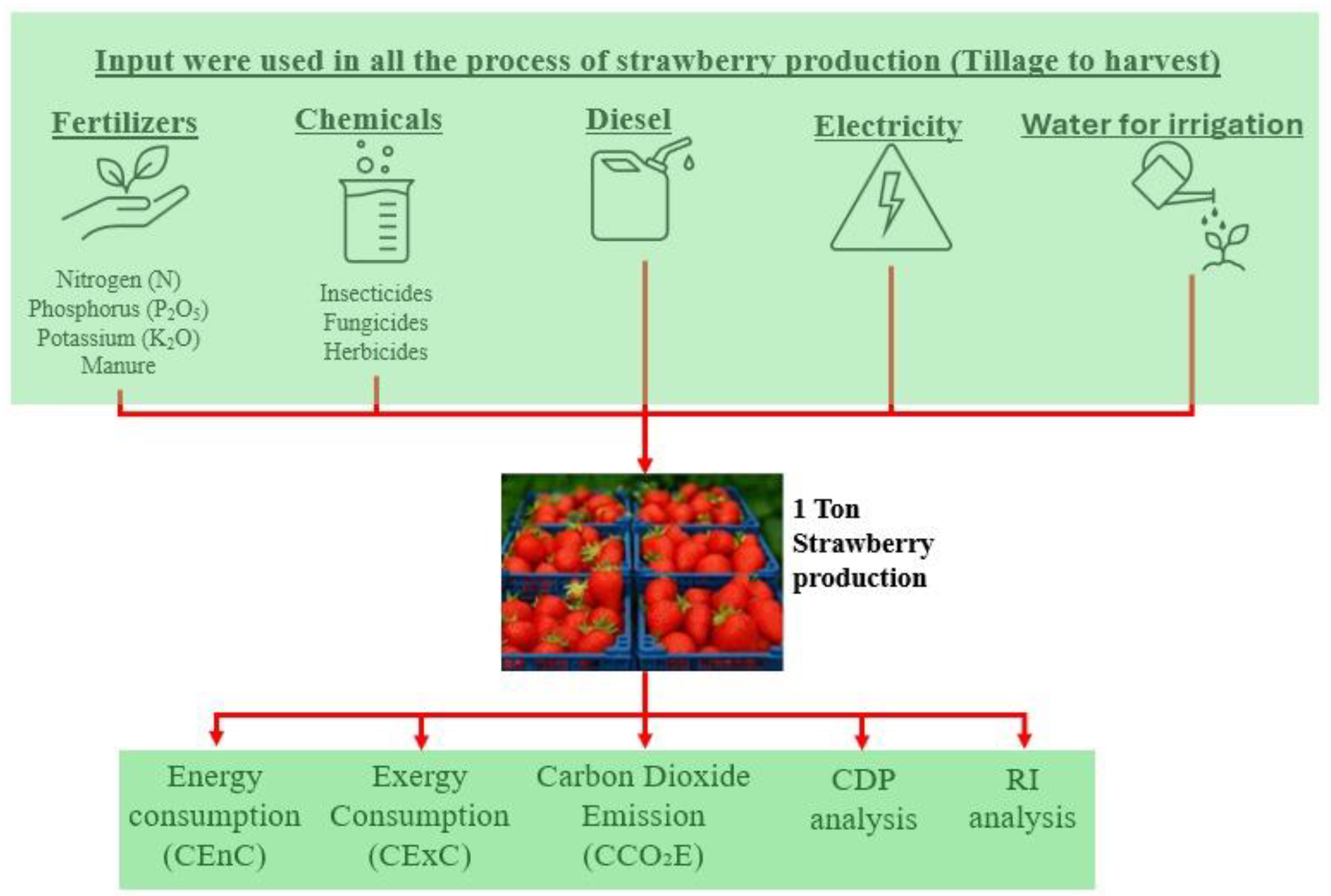

The analytical framework of this research, as illustrated in

Figure 1, is limited to the agricultural activities required to obtain 1 ton of strawberry crop. Accordingly, post-harvest stages such as logistics, processing, or storage were excluded from the assessment. The initial phase of the methodology involved identifying the primary resources used in the production process, followed by calculating the corresponding energy, exergy, and carbon dioxide equivalent values for each input based on the literature. From these calculations, key sustainability metrics CEnC, CExC, and CCO

2E were established. Additionally, sustainability metrics were determined by calculating CDP and RI values for the agricultural production process. This approach aims to provide a comprehensive assessment of the ecological footprint and resource use efficiency of strawberry cultivation.

The equations required for the energy and exergy-based analysis of the strawberry production process are given below [

24,

33,

34,

35].

Mass balance calculations were performed as expressed in Equation (1):

Here,

min (kg) refers to the mass entering the system, and

mout (kg) represents the mass leaving the system. Energy balance calculations were determined using Equation (2):

In this expression,

h (kJ/kg) represents enthalpy,

W (kJ) denotes work, and

Q (kJ) refers to heat energy. Exergy balance was evaluated according to Equation (3):

Here,

b (kJ/kg) indicates the exergy flow,

To (K) denotes the ambient temperature,

Tk (K) is the source temperature,

Qk (kJ) represents the heat energy, and

Xloss (kJ) represents the exergy loss. Entropy balance was calculated using Equation (4):

where

S refers to entropy. The flow exergy (

b) for strawberry production is computed using Equation (5):

Here,

bch is used to calculate chemical exergy, and

bph is used to calculate physical exergy. Chemical exergy is calculated using Equation (6):

The exergetic performance of a production technique is assessed using a critical indicator known as CDP. This value is calculated by dividing the chemical exergy of the final product by the total (cumulative) exergy of all natural resources consumed during the production process. Therefore, a high CDP value indicates a more efficient production method [

24].

The formula given in Equation (7) is used to calculate the CDP indicator:

Here, (mb)

product is the exergy value of the produced product. Based on the CExC concept, two new metrics have been derived: net exergy consumption (CNEx) and restoration work (

Wr), as defined in [

34]:

where Ex

p refers to chemical exergy of products.

Wr can calculate by:

The key components used in calculating the sustainability level of a production system from a renewability perspective include CNEx

p and CNEx

waste. The term CNEx

p defines the cumulative exergy derived from non-renewable resources consumed in the production process, while CNEx

waste represents the exergy expended in processing and disposing of the resulting waste. RI expresses the ratio of the useful work produced by the system to the restoration work required to remedy the environmental degradation it causes and is found using Equation (10) [

34]:

The Renewable Index (RI) can be classified into four categories [

34]. A value of 1 indicates a fully renewable process, whereas values between 0 and 1 represent processes that are partially renewable. When RI equals 0, the work required for production and restoration is balanced. Negative values of RI correspond to non-renewable processes. In this study, the system boundaries are limited to the strawberry production process, and other agricultural operations such as transportation, storage, and post-harvest handling are not considered.

3. Results and Discussion

Modern agricultural systems are complex energy conversion processes that rely on both direct (e.g., diesel fuel, electricity) and indirect (e.g., fertilizers, chemicals) energy inputs. This study aims to characterize the operational model of a specific agricultural system and identify its primary energy dependencies by analysing its cumulative energy consumption profile (MJ/ton of product). Based on the methodology and system boundaries previously defined, the values for CEnC, CExC, CCO2E, CDP, and RI were calculated for the open field production of 1 ton of strawberries in Batman, Türkiye.

3.1. Cumulative Energy Consumption (CEnC) Analysis

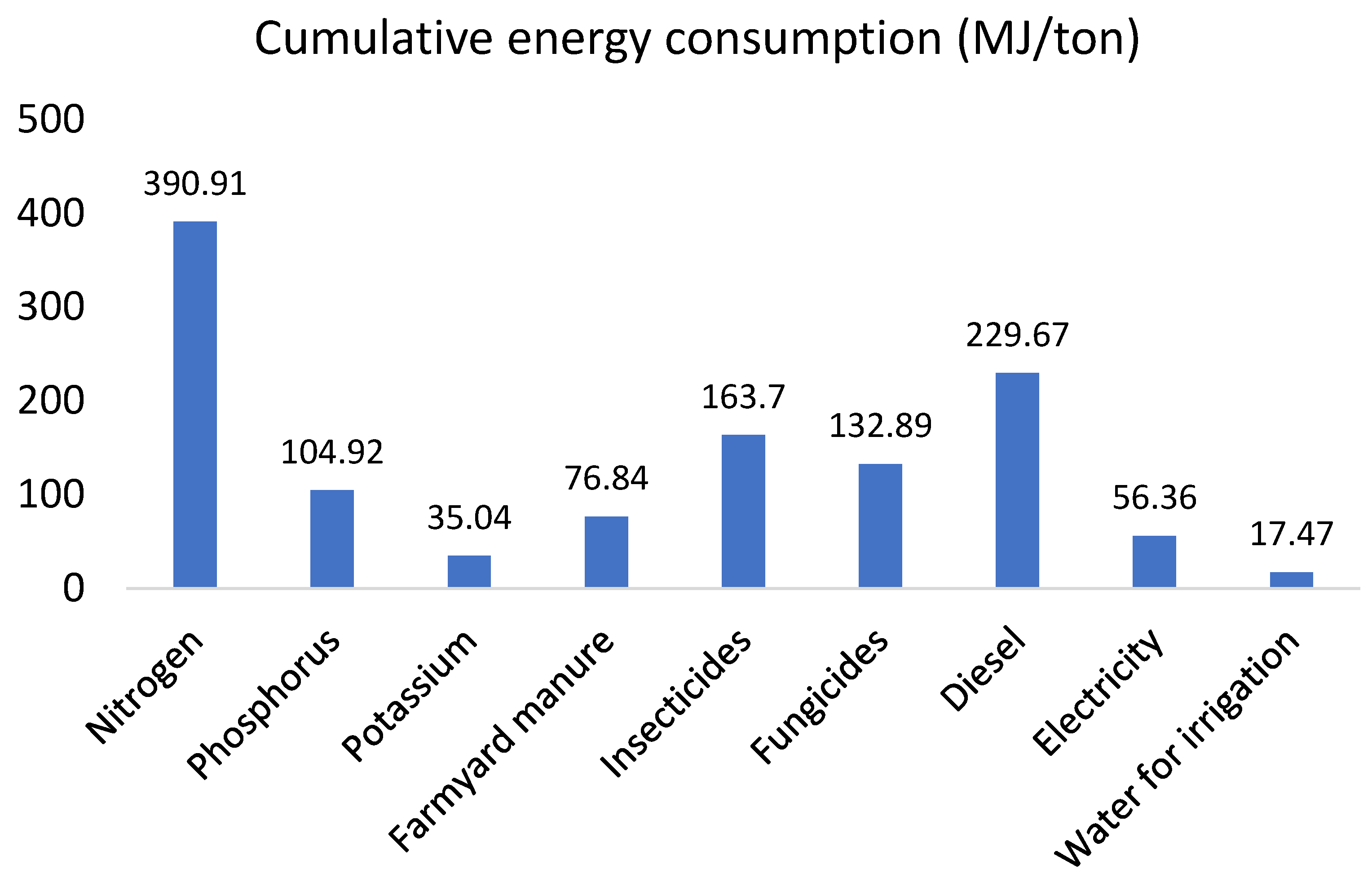

As shown in

Figure 2, the total CEnC value for the inputs used in the strawberry production process in Batman, Türkiye, was 1207.8 MJ/ton. According to the data, the highest energy consumption stemmed from the use of nitrogen fertilizer, at 390.91 MJ/ton. This highlights that chemical fertilizers, in particular, are energy-intensive inputs in modern agriculture and play a critical role in terms of environmental impact.

The second largest energy consumption was attributed to diesel fuel, at 229.67 MJ/ton. This finding indicates that agricultural mechanization (e.g., tractors, irrigation pumps) significantly increases the energy load of the production process. Insecticides (163.70 MJ/ton) and fungicides (132.89 MJ/ton) also accounted for considerable energy consumption, demonstrating that chemical pest control methods constitute a significant portion of the energy budget in strawberry cultivation. In contrast, phosphorus fertilizer (104.92 MJ/ton), farmyard manure (76.84 MJ/ton), and electricity (56.36 MJ/ton) were moderate energy inputs, while potassium fertilizer (35.04 MJ/ton) and irrigation water (17.47 MJ/ton) had relatively low energy consumption.

Based on the analysis, the energy consumption profile of strawberry production in Batman is predominantly reliant on fertilizer and fuel use. The dominance of nitrogen fertilizer is directly linked to its high inherent embodied energy content and the relatively high application rates necessary for maintaining optimum yield in the intensive open field systems prevalent in the Batman region. The significant share of diesel fuel, on the other hand, reflects the extensive use of mechanized power for land preparation, tillage, and particularly water pumping for irrigation in the empirical sample group, which is typical for the larger, more commercial farms surveyed. These findings suggest that immediate energy efficiency gains should focus on two practical strategies: (1) optimizing fertilizer use through precise application methods or the adoption of integrated soil nutrient management, and (2) transitioning to solar-powered or high-efficiency electric motors for irrigation pumping to reduce reliance on diesel fuel.

The energy and exergy inputs required to produce agricultural products such as strawberries vary depending on the type of product, the cultivation conditions and regional differences. In a study conducted in Iran, Yildizhan calculated the cumulative energy consumption for producing one ton of strawberries to be 4200.881 MJ in greenhouses and 6703.042 MJ in open fields [

19]. Banaeian et al. reported that the majority of energy consumption in greenhouse strawberry production came from diesel fuel, accounting for a 78% share at 805,380 MJ/ha. They noted that intensive energy consumption in greenhouses is due to electricity, whereas in open fields, as in this study, it is due to chemical fertilizer use [

28]. Similarly, Khoshnevisan et al. stated that greenhouse-grown strawberries consumed more energy [

2]. These findings show that energy input under greenhouse conditions is considerably higher than in open fields, indicating significant differences that must be considered for energy efficiency. Degerli et al. calculated that wheat production in Türkiye consumed 13,047 MJ/ha of energy, compared to 15,598 MJ/ha in Germany [

36]. In both Türkiye and Germany, the primary sources of energy consumption were diesel and fertilizer use, consistent with this study. These findings reveal the impact of inputs on production efficiency and provide important data on the energy efficiency of different products and production systems.

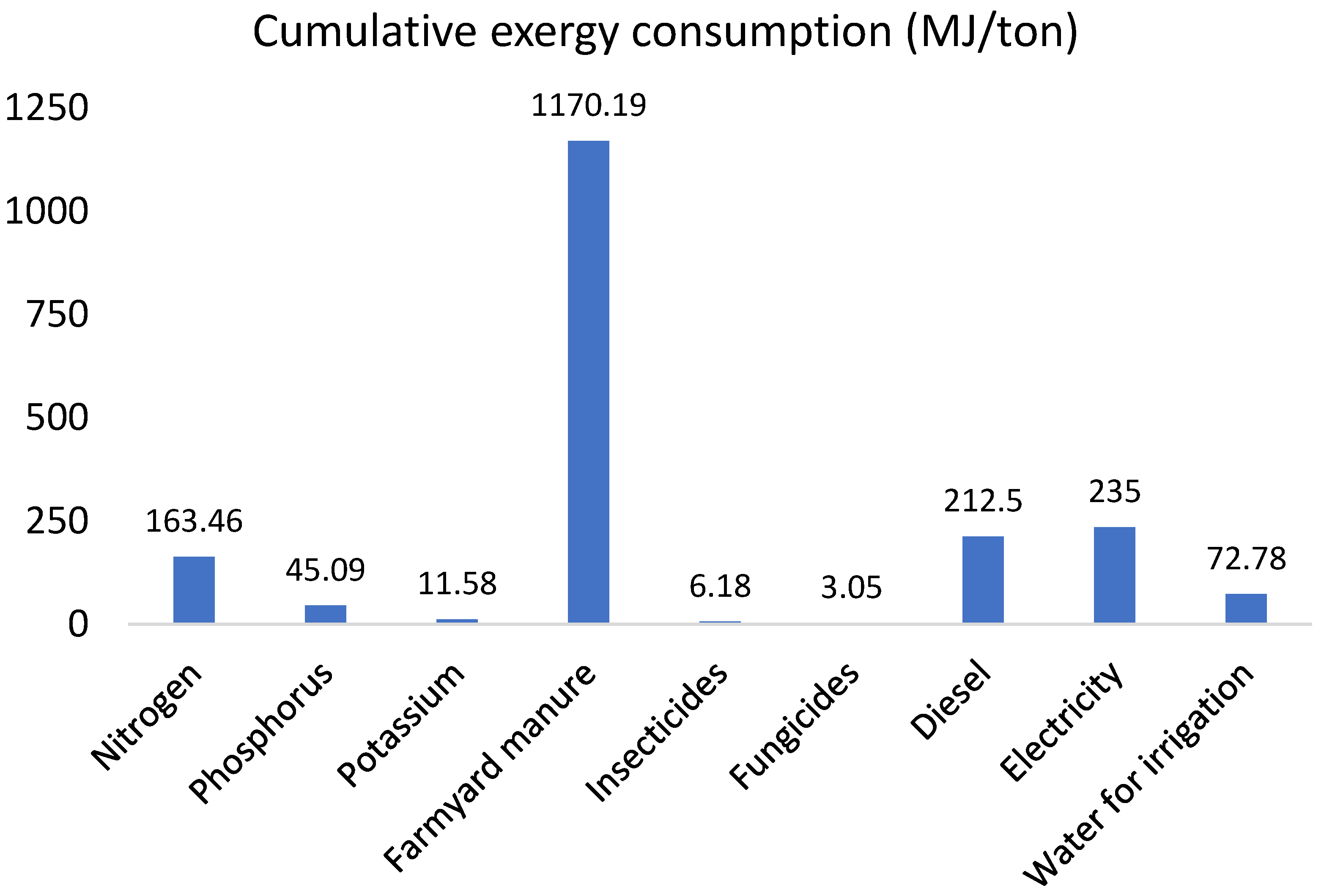

3.2. Cumulative Exergy Consumption (CExC) Analysis

Compared to energy analysis, the exergy approach provides more comprehensive information about the true thermodynamic efficiency of a system, as it considers not only the quantity but also the availability and quality differences in the inputs. As seen in

Figure 3, the total CExC value of the production process was calculated as 1919.82 MJ/ton, with the highest exergy consumption stemming from the use of farmyard manure at 1170.19 MJ/ton. This reveals that input with moderate energy consumption is, in fact, a dominant input from an exergy perspective. This is due to the high biochemical energy potential inherent in organic fertilizers. Following farmyard manure, the next most significant inputs for exergy consumption were electricity (235.00 MJ/ton) and diesel fuel (212.50 MJ/ton). These two direct energy sources account for approximately 23% of the total exergy consumption, highlighting the system’s dependence on fossil fuels and grid electricity. Nitrogen (163.46 MJ/ton) and phosphorus (45.09 MJ/ton) are also notable exergy inputs in the production process. However, potassium fertilizer (11.58 MJ/ton), insecticides (6.18 MJ/ton), and fungicides (3.05 MJ/ton) remain at lower levels. Irrigation water (72.78 MJ/ton) represented a moderate level of exergy consumption. The distribution of exergy consumption in strawberry production in Batman differs from the energy consumption analysis. While the energy analysis highlighted nitrogen fertilizer and diesel fuel, the exergy analysis revealed that farmyard manure, electricity, and diesel fuel constitute the most significant portion of the inputs.

The high share of farm manure in total consumption, at 61% in the CExC analysis, necessitates more careful use of this resource in agricultural processes. This striking dominance is primarily due to manure’s relatively high exergy coefficient, which reflects its nature as a valuable, high-quality chemical exergy resource. Consequently, the high CExC value in this study reflects the inherent quality of the resource rather than an inefficient physical process during its application. Researchers must acknowledge this result as a methodological limitation: the CExC metric highly prioritizes the conservation of chemical resources, sometimes overshadowing the environmental burden of fossil fuel usage. The practical implication is the necessity for farmers to employ best practices for manure storage and application (e.g., composting and deeper incorporation into the soil) to maximize nutrient retention and minimize the loss of its inherent chemical exergy content through uncontrolled decomposition.

In a study by Yildizhan, the highest exergy consumption in open field strawberry production was from manure (5430 MJ/ton) [

19]. Similarly, this study found that the highest exergy consumption was from farmyard manure (1170.19 MJ/ton). In comparable studies on different products, exergy consumption was reported as 10,762.6 MJ/ton for olives, 9051.4 MJ/ton for soybeans, and 8819.1 MJ/ton for sunflowers [

37], while for bread wheat production, it was calculated as 6.7 MJ/kg in Türkiye and 2.7 MJ/kg in Germany [

36]. These similar studies show that exergy consumption is heavily influenced by farmyard manure, suggesting it should be used more carefully and efficiently. These results indicate that to improve the exergetic efficiency of strawberry production, the primary focus should be on farmyard manure management, followed by improving the efficiency of electricity and diesel use in irrigation and field operations.

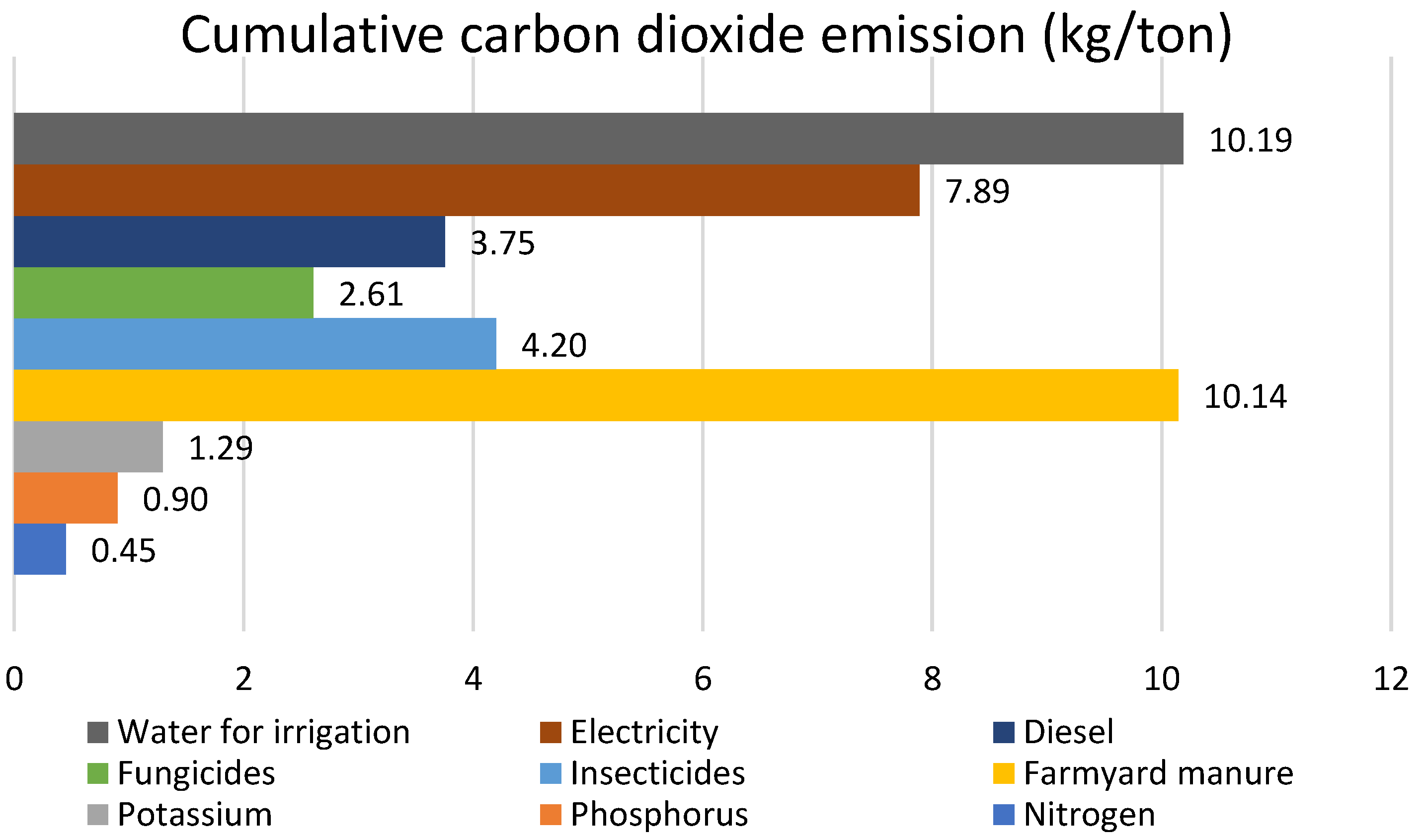

3.3. Cumulative Carbon Dioxide Emission (CCO2E) Analysis

According to the analysis, the production of 1 ton of strawberries results in the release of a total of 41.43 kg of CO

2 equivalent greenhouse gas emissions into the atmosphere.

Figure 4 shows the CCO

2E values generated by the inputs used in strawberry production in Batman. The data show how significantly the environmental impacts of different inputs can vary within an agricultural production process. The two main inputs with the highest emission values, which are very close to each other, are irrigation water (10.19 kg/ton) and farmyard manure (10.14 kg/ton). These two inputs alone account for approximately 49% of the total carbon footprint. This shows that irrigation activities are directly linked to energy consumption and thus play a critical role in production’s carbon footprint. Similarly, farmyard manure (10.14 kg/ton) is one of the highest carbon-emitting inputs. This is consistent with its high exergy potential and underscores the need to consider emissions from the biological decomposition process. These two main sources are followed by electricity consumption at 7.89 kg/ton. Electricity accounts for about 19% of the total emissions, making it a significant contributor. Given that irrigation and electricity needs are met by renewable energy sources, it would be possible to significantly reduce carbon emissions. The other inputs remained at relatively lower levels.

When comparing carbon emissions from open field and greenhouse studies for strawberry production, it has been observed that greenhouse production has higher carbon emissions than open field. Khoshnevisan et al. reported that total greenhouse gas emissions for open field and greenhouse production were 803.4 kg CO

2/ha and 35,083.5 kg CO

2/ha, respectively [

2]. Yildizhan calculated that producing one ton of strawberries resulted in 506.07 kg of CO

2 emissions in greenhouses and 243.06 kg of CO

2 in open fields [

19]. Hesampour et al. (2022) stated in their study that approximately half of the carbon emissions in the date production process are caused by fertilization [

38]. The analysis revealed that the largest contributors to the total CCO

2E were irrigation water (10.19 kg/ton) and farmyard manure (10.14 kg/ton). The significant impact of irrigation water on the carbon footprint is not due to the water itself, but rather the energy required for pumping it from its source to the fields, exacerbated by the hot and dry climate of the Batman region, which necessitates intensive irrigation. The high emission associated with farmyard manure mainly arises from the potent greenhouse gases released during the manure storage, management, and uncontrolled decomposition phases. These findings indicate that reducing the environmental burden requires targeted interventions such as implementing drip irrigation systems to reduce pumping energy and adopting controlled manure management practices (e.g., anaerobic digestion or optimized composting) to mitigate greenhouse gas emissions.

3.4. CDP and RI Analysis

The chemical composition value (b) for the strawberry analysed in this study was calculated as 2.58 MJ/kg by Özilgen and Sorgüven [

31]. For the open field strawberry production process in Batman, CDP was determined to be 1.34, and RI was 0.26. These key sustainability values allow for a detailed and systematic comparison of the system’s resource use efficiency and renewability profile against other agricultural production systems in the literature. The calculated CDP value of 1.34 indicates a moderate level of exergetic efficiency for the strawberry production process under investigation. This value is significantly higher than the CDP reported for strawberry cultivation in Iran, which was 0.29 for open field and 0.18 for greenhouse systems [

19]. These differences can be primarily attributed to differences in climatic conditions, energy inputs, and agricultural practices. In addition, the current study and the study conducted in Iran have shown that reducing and optimizing the use of manure and electricity consumption will increase the CDP value. The higher CDP value is calculated in Southeastern Türkiye (Batman) due to the warmer and sunnier climate, more efficient photosynthetic activity, and lower electricity and diesel consumption compared to the Iranian strawberry production process. Furthermore, differences in the calculation limits and yield levels adopted also contribute to this discrepancy. Compared to other crops, CDP values for wet and dry wheat production are reported as 2.9 and 6.48, respectively [

39], and 3.78 for rapeseed [

40]. CDP values for various vegetable oils are 0.92 for soybean oil, 0.98 for olive oil, and 2.36 for sunflower oil [

37]. The moderate CDP value obtained in this study indicates that open field strawberry production in Batman is more efficient than other strawberry production systems reported in the literature, but less efficient than high-energy crops such as wheat or rapeseed, which utilize higher biomass output per unit of input energy. The high CDP value for wheat and the low CDP for other crops is largely due to the high chemical composition and exergy value of wheat. The RI value of 0.26 reflects the system’s “partially renewable” status, clearly indicating a strong reliance on non-renewable energy sources. This value is lower than for high-biomass crops such as rapeseed (0.72) [

40], date palm (0.62) [

37], and both wet (0.65) and dry (0.84) wheat production [

39]. The low RI value is explained by the high share of fossil fuel-based energy inputs in the cultivation process, specifically for irrigation, machinery operation, and transportation, alongside the relatively low contribution of renewable or biological energy flows inherent in strawberry cultivation. In contrast, crops like wheat and rapeseed are often cultivated under larger, mechanized systems that may involve a higher utilization of renewable bioenergy residues or benefit from different input balances. The comparison of the results obtained in this study with the data of other agricultural products in the literature is presented in

Table 3.

The moderate CDP and low RI values collectively highlight the critical need for optimizing resource utilization through renewable energy integration and efficiency improvements. To improve these sustainability indicators in the context of Batman province, several region-specific strategies can be implemented. First, integrating solar-powered irrigation systems would reduce diesel and grid electricity consumption, directly improving both CDP and RI values. Second, promoting the use of bio-based and composted fertilizers instead of mineral nitrogen fertilizers could significantly decrease fossil fuel dependency and enhance the system’s renewability. Third, improving irrigation efficiency through drip and sensor-based systems would reduce water and energy use simultaneously. Together, these measures would strengthen the sustainability performance of open field strawberry production in the Batman region by enhancing resource-use efficiency and reducing non-renewable energy reliance. Analysis of calculated indicators for open field strawberry production in Batman province (CEnC = 1207.8 MJ/ton, CExC = 1919.82 MJ/ton, CCO2E = 41.43 kg/ton, CDP = 1.34, RI = 0.26) revealed that seemingly energy-efficient inputs do not always provide advantages in terms of exergy and carbon performance. For example, farm manure, while contributing little in terms of energy consumption (76.84 MJ/ton), accounted for the highest share of exergy consumption (1170.19 MJ/ton) and also made a significant contribution to carbon emissions (10.14 kg/ton). This suggests that locally sourced organic inputs may offer advantages in terms of energy but disadvantages in terms of exergy and the environment. Similarly, although nitrogen fertilizer generates a high energy load (390.91 MJ/ton), its share of total exergy consumption (163.46 MJ/ton) and its emission contribution are relatively low. Furthermore, diesel fuel is a significant direct energy input (229.67 MJ/ton) in agricultural mechanization, possessing both a high exergy potential (212.50 MJ/ton) and carbon emissions (approximately 3.75 kg CO2/kg). However, reducing this input not only reduces fossil energy use but also has the potential to directly improve CDP and RI values. Electricity consumption is another noteworthy factor. Despite its relatively low energy input (56.36 MJ/ton), its high exergy coefficient (235.00 MJ/ton) increases the thermodynamic load of the system. Therefore, the renewable nature of the electricity source plays a critical role in increasing the RI value. In conclusion, these findings highlight the need for a clear balance between energy, exergy, and environmental performance indicators in open-field strawberry production in the Batman region. Even with energy efficiency, exergy losses and carbon emissions can increase in some cases. Therefore, energy, exergy, and carbon indicators must be optimized together to improve the system’s sustainability performance.

4. Conclusions

This study aimed to conduct a comprehensive evaluation of the energy consumption, exergetic performance, and environmental impacts of open field strawberry production in Batman, Türkiye. The analyses provided a detailed profile of resource use and sustainability for a functional unit of one ton of strawberry product. The necessary input quantities were empirically established through a detailed survey process involving 189 strawberry producers in the Sason district of Batman province. This dataset specifically reflects resource usage trends observed over the last few growing seasons, ensuring that the results are representative of local production practices.

The results indicated that the CEnC was 1207.8 MJ/ton, with the highest contributions from nitrogen fertilizer (390.91 MJ/ton) and diesel fuel (229.67 MJ/ton), highlighting the process’s dependence on chemical fertilizers and mechanization. The CExC was calculated to be 1919.82 MJ/ton, where farmyard manure (1170.19 MJ/ton) was identified as the most significant input, revealing the high thermodynamic cost associated with organic inputs. The CCO2E was 41.43 kg/ton, primarily driven by irrigation water (10.19 kg/ton) and farmyard manure (10.14 kg/ton), which together accounted for nearly half of the total emissions.

The key sustainability indicators, CDP and RI, were determined to be 1.34 and 0.26, respectively. The CDP value suggests a moderate exergetic efficiency, which is significantly higher than that reported for strawberry production in Iran (0.29 for open field). The RI value of 0.26 classifies the system as “partially renewable,” reflecting a substantial reliance on non-renewable energy sources compared to other staple crops.

From a practical perspective, the findings suggest that farmers can enhance sustainability by adopting solar-powered irrigation systems, improving irrigation efficiency through smart technologies, and substituting mineral fertilizers with bio-based or composted alternatives. Policymakers should focus on providing financial incentives for renewable energy integration and resource-efficient technologies in agriculture, while regional authorities may promote training programs aimed at optimizing energy and fertilizer management practices.

This study also has certain limitations. The dominance of manure in the exergy analysis may over represent its thermodynamic weight relative to its actual sustainability contribution. Moreover, the analysis is limited to the cultivation stage and does not include post-harvest, transportation, or processing phases, which may alter the overall energy and exergy profiles. Additionally, the results represent average conditions over recent years in the Sason district, without considering long-term climatic or market variability. In conclusion, to enhance the sustainability of strawberry production in the Batman region, future strategies should focus on optimizing fertilizer management, improving irrigation energy efficiency, and integrating renewable energy systems into agricultural operations, while addressing the methodological limitations identified in this study.