Physics-Informed Machine Learning for Intelligent Gas Turbine Digital Twins: A Review

Abstract

1. Introduction

2. Hybrid AI Methodologies for Gas Turbine Applications: Description, Advantages and Limitations

- ANN-augmented thermodynamic models;

- Physics-integrated operational architectures;

- Physics-constrained neural networks and Computational Fluid Dynamics surrogates;

- Generative and model discovery approaches.

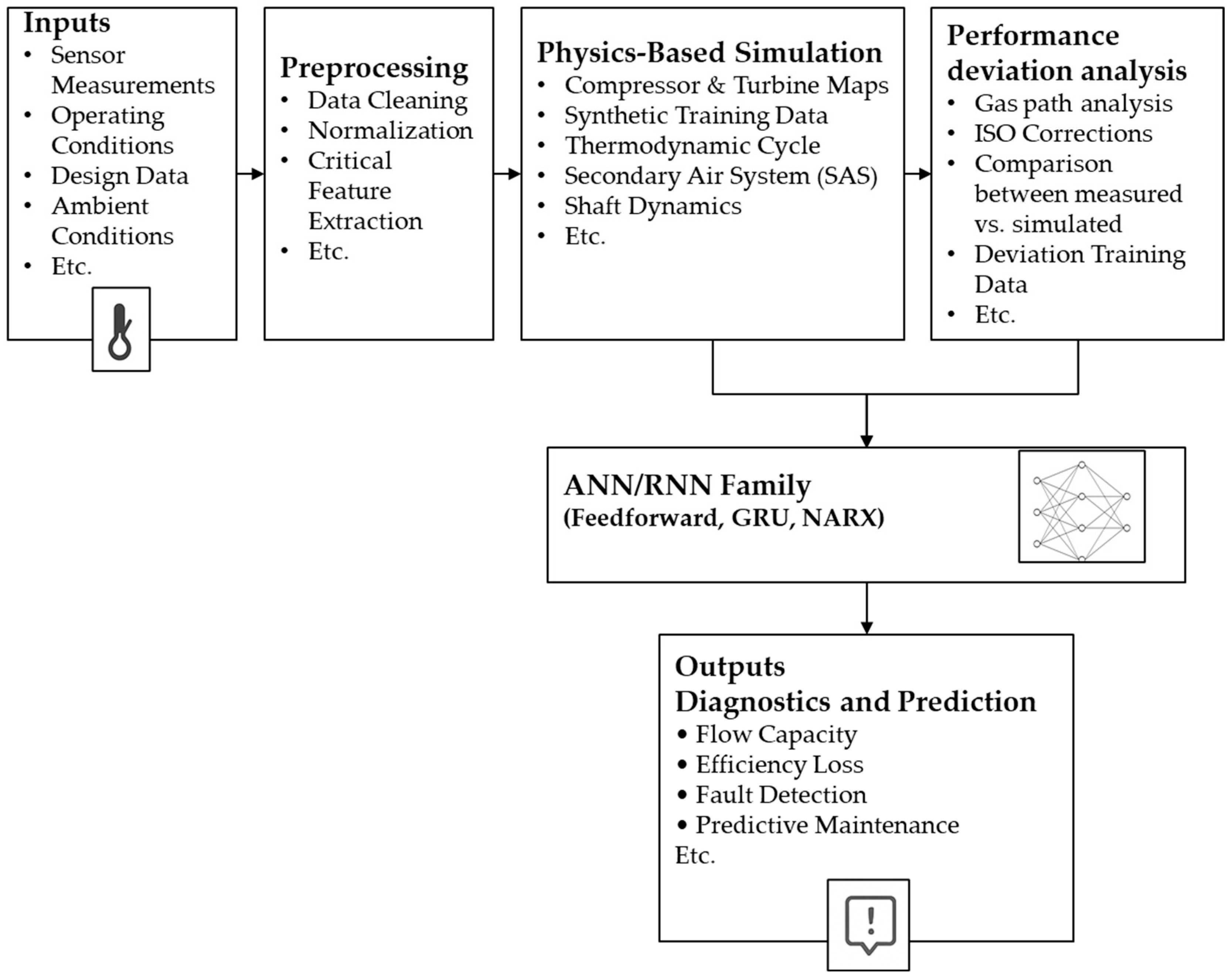

2.1. ANN-Augmented Thermodynamic Models

2.1.1. Advantages of ANN-Augmented Thermodynamic Models

2.1.2. Limitations of ANN-Augmented Thermodynamic Models

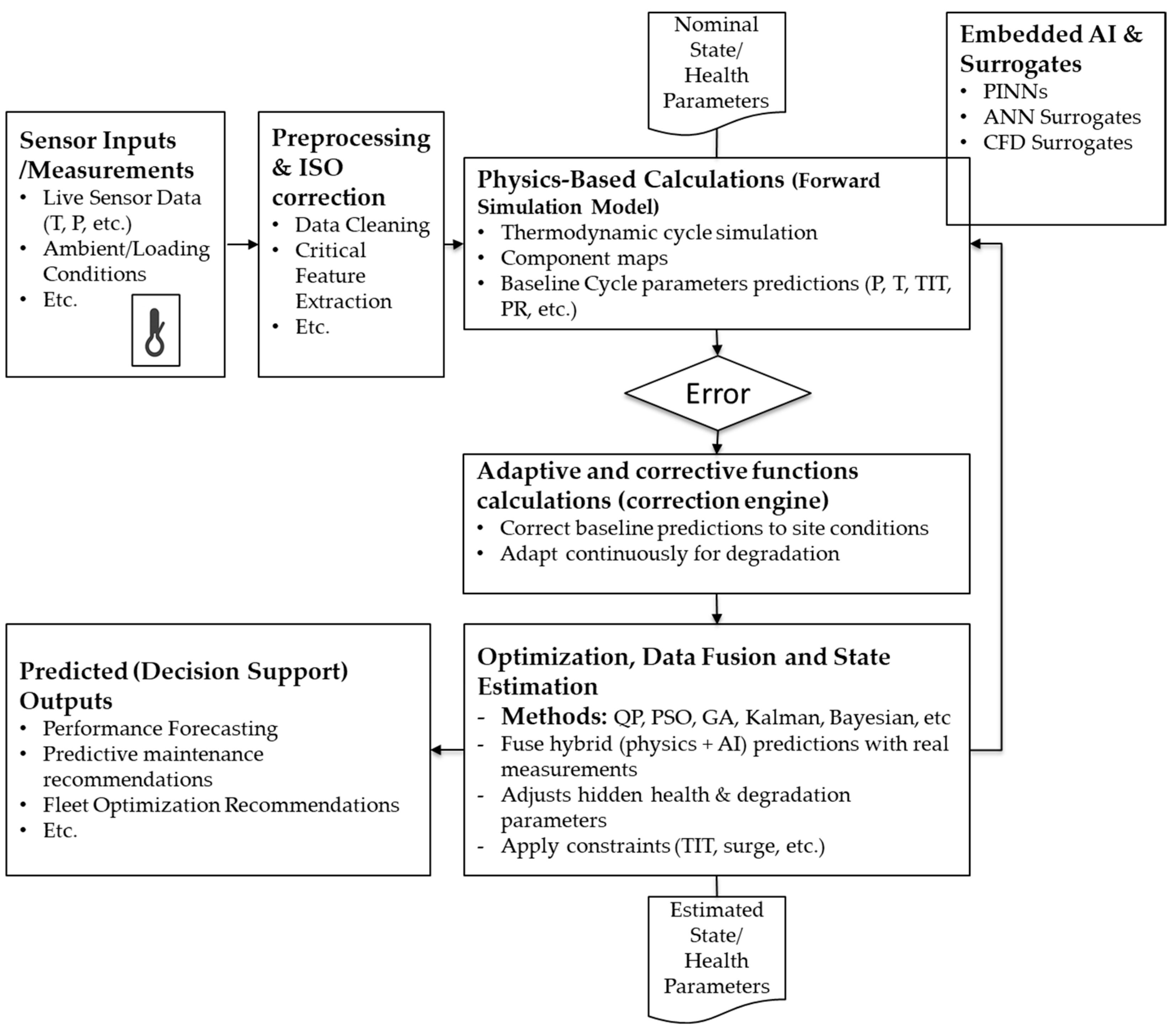

2.2. Physics-Integrated Operational Architectures

2.2.1. Advantages of Physics-Integrated Operational Architectures

- Real-time, system-wide representation of engine behavior using live sensor data integrated with physics-based thermodynamic cycle models such as NPSS [56];

2.2.2. Limitations of Physics-Integrated Operational Architectures

- Integration complexity, including sensor synchronization, model calibration, and the need for robust data pipelines when interfacing with existing Condition Monitoring Systems (CMS) and plant control networks [56];

2.3. Physics-Constrained Neural Networks and CFD Surrogates

2.3.1. Advantages of Physics-Constrained Neural Networks and CFD Surrogates

2.3.2. Limitations of Physics-Constrained Neural Networks and CFD Surrogates

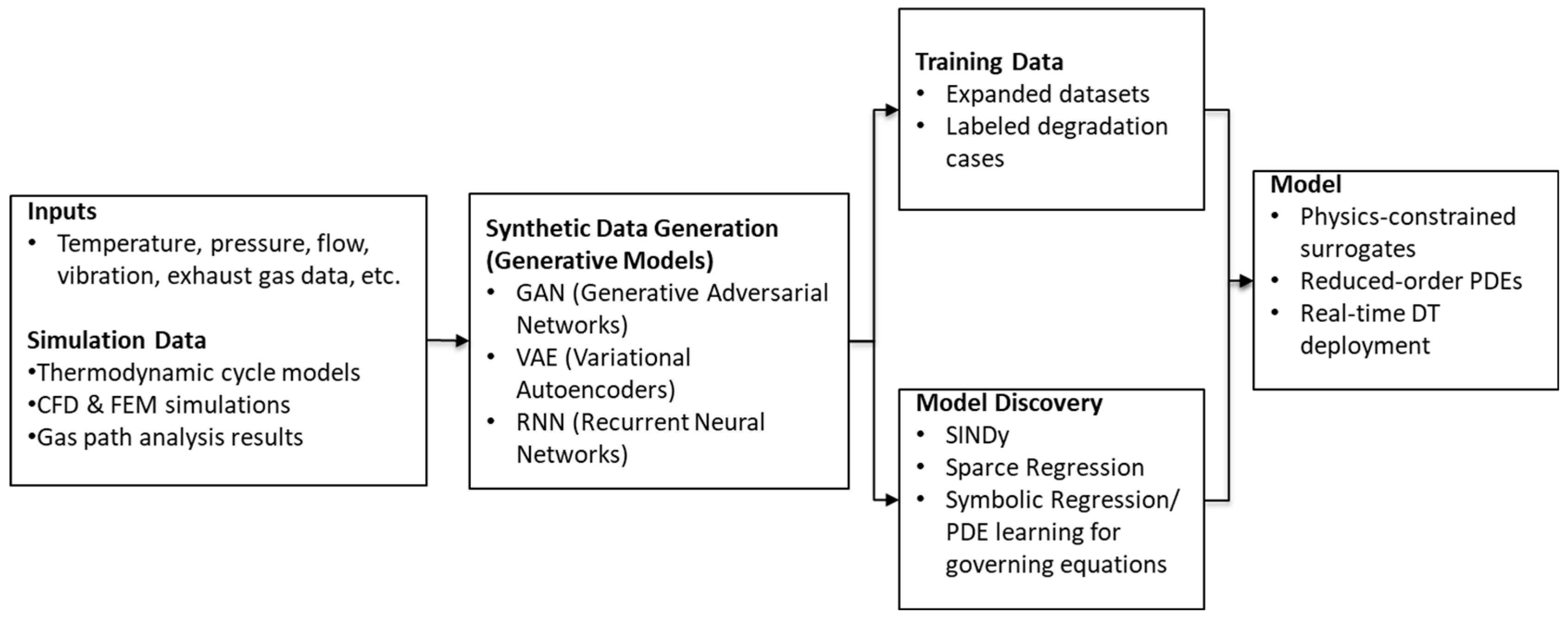

2.4. Generative and Model Discovery Approaches

2.4.1. Generative Models

2.4.2. Model Discovery

2.4.3. Emerging Architectures

2.4.4. Advantages of Generative and Model Discovery Approaches

2.4.5. Limitations of Generative and Model Discovery Approaches

- Equation discovery methods such as SINDy are sensitive to noise and feature selection [69];

3. Results

4. Discussion and Future Trends

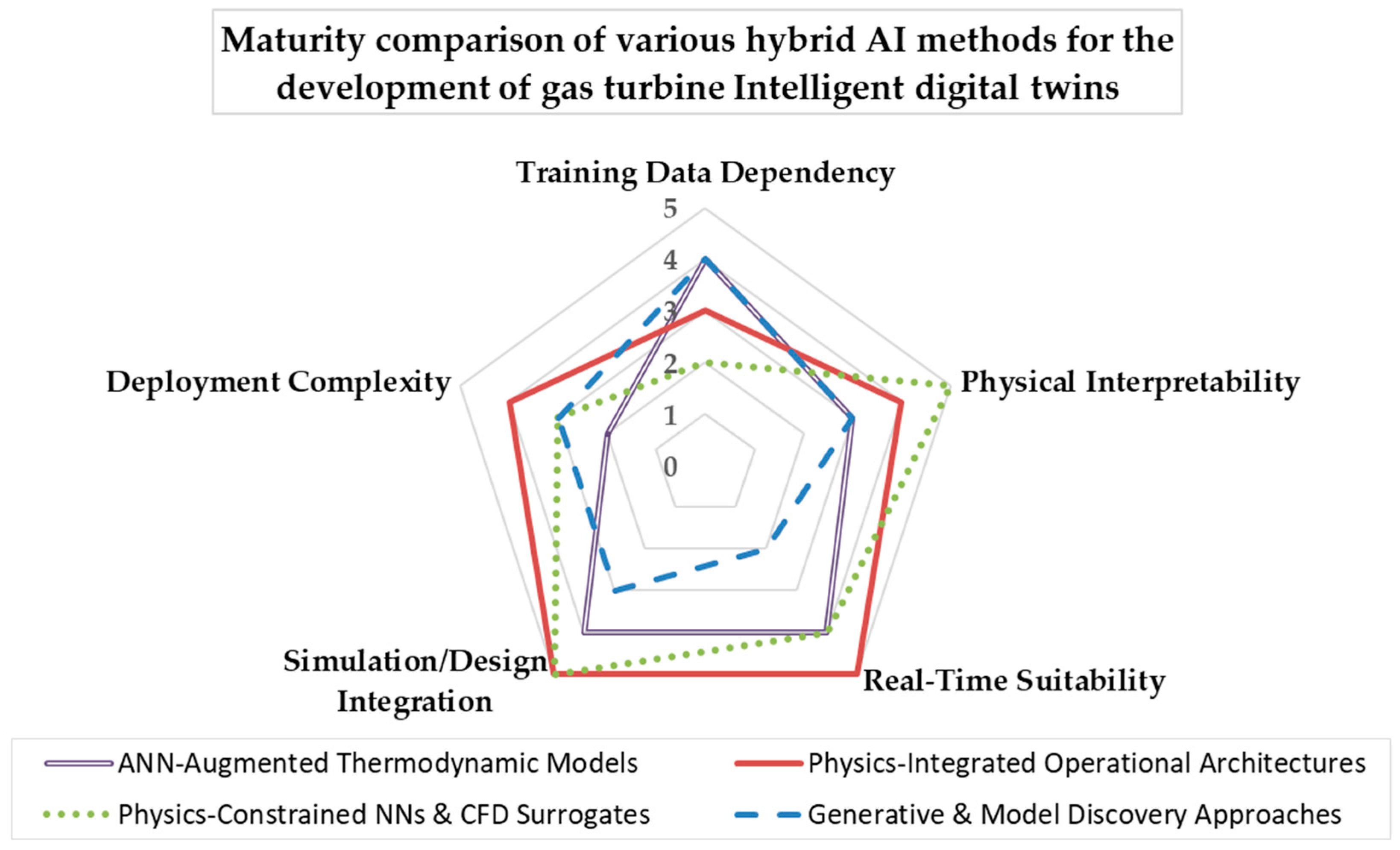

4.1. Comparative Maturity of Hybrid AI Methods

4.2. Challenges and Opportunities

4.2.1. Operational Integration of Hybrid AI Intelligent Digital Twins

4.2.2. Cybersecurity and Integration Challenges in Hybrid Digital Twins

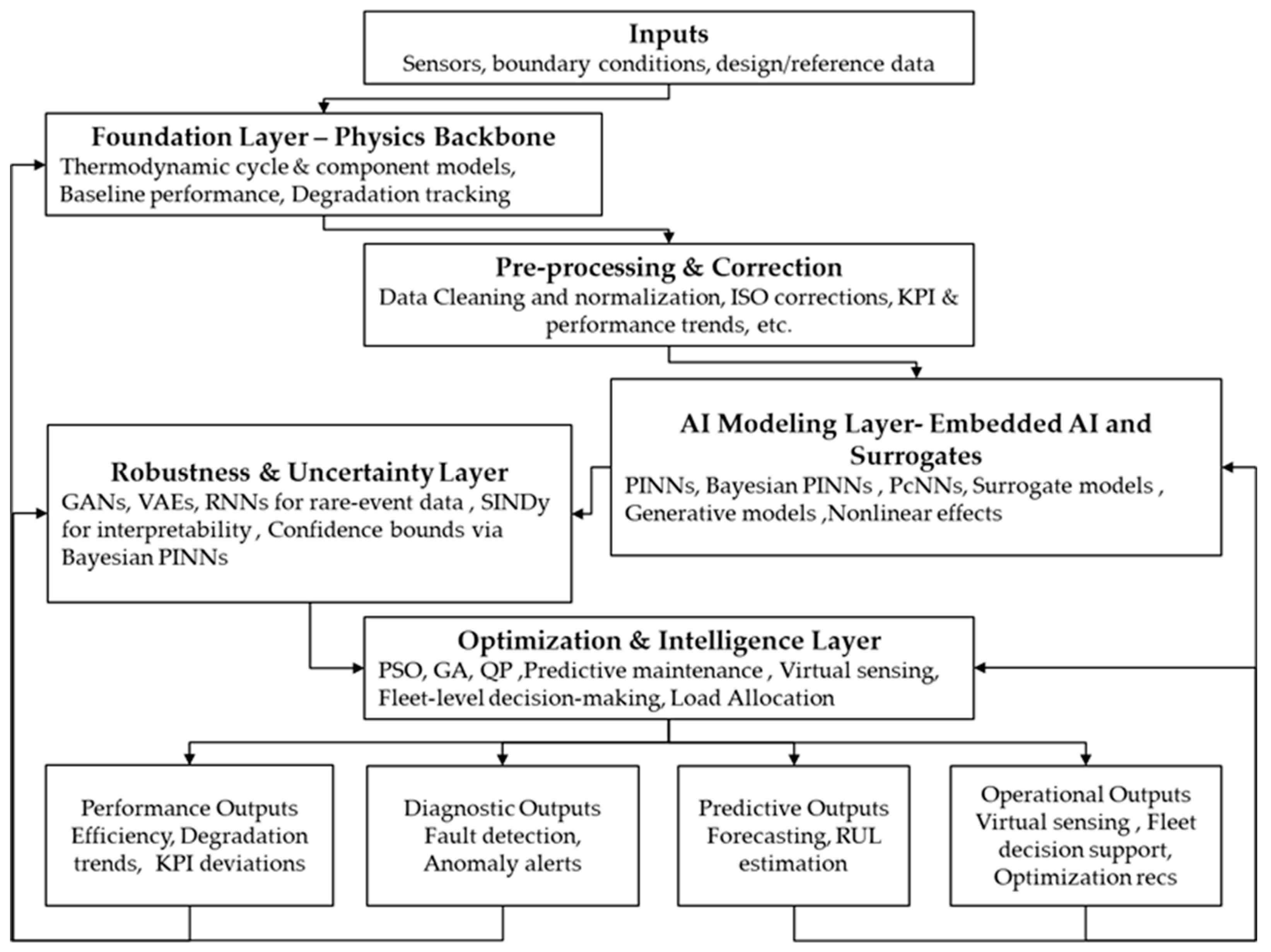

4.3. Future Research Directions and Proposed Hybrid AI Framework

4.3.1. Physics Backbone (Foundation Layer)

4.3.2. AI Modeling Layer

4.3.3. Robustness and Uncertainty Layer

4.3.4. Optimization and Intelligence Layer

5. Limitations

6. Conclusions

- Establishing open and reproducible benchmark datasets for gas turbine applications;

- Advancing uncertainty quantification methods such as Bayesian deep learning with physics-informed constraints;

- Developing validation workflows that integrate thermodynamic and CFD simulations;

- Building deployment frameworks that align with SCADA and condition monitoring infrastructures;

- Adopting cybersecurity and compliance standards for digital twin integration;

- Designing operator-facing dashboards that combine predictions with actionable confidence levels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| ATOM | Autonomous Turbine Operation and Maintenance |

| CFD | Computational Fluid Dynamics |

| CHP | Combined Heat and Power |

| CMS | Condition Monitoring System |

| EPRI | Electric Power Research Institute |

| FNO | Fourier Neural Operator |

| GA | Genetic Algorithm |

| GAN | Generative Adversarial Network |

| GE | General Electric |

| GNN | Graph Neural Network |

| GPA | Gas Path Analysis |

| LNN | Lagrangian Neural Network |

| ML | Machine Learning |

| NPSS | Numerical Propulsion System Simulation |

| NSFnet | Navier–Stokes Flow Network |

| PcNN | Physics-Constrained Neural Network |

| PDE | Partial Differential Equation |

| PINN | Physics-Informed Neural Network |

| PIML | Physics-Informed Machine Learning |

| PSO | Particle Swarm Optimization |

| PySINDy | Python implementation of Sparse Identification of Nonlinear Dynamics |

| QP | Quadratic Programming |

| RNN | Recurrent Neural Network |

| RUL | Remaining Useful Life |

| SCADA | Supervisory Control and Data Acquisition |

| SFC | Specific Fuel Consumption |

| SINDy | Sparse Identification of Nonlinear Dynamics |

| TIT | Turbine Inlet Temperature |

| VAE | Variational Autoencoder |

References

- Farhat, H.; Salvini, C. Novel gas turbine challenges to support the clean energy transition. Energies 2022, 15, 5474. [Google Scholar] [CrossRef]

- Farhat, H. Models for Gas-Turbine Performance Deterioration Predictions for Optimum Operation Management. Ph.D. Thesis, Università degli Studi Roma Tre, Rome, Italy, 2024. [Google Scholar]

- Genrup, M. Theory for Turbomachinery Degradation and Monitoring Tools. Licentiate Thesis, Lund University, Lund, Sweden, 2003. [Google Scholar]

- Liu, Y.; Jiang, X.; Ge, X.; Wei, M. A Physics-Informed Machine Learning Approach for Performance Degradation Monitoring of Gas Turbines. In Proceedings of the 4th Asia Pacific Conference of Prognostics and Health Management (PHM-Asia Pacific), Tokyo, Japan, 11–14 September 2023. [Google Scholar]

- Lim, J.T.; Habibullah, A.; Ng, E.Y.K. Towards a digital twin for gas turbines: Thermodynamic modeling, critical parameter estimation, and performance optimization using PINN and PSO. Energies 2025, 18, 3721. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Xiong, J.; Fink, O.; Zhou, J.; Ma, Y. Controlled physics-informed data generation for deep learning-based remaining useful life prediction under unseen operation conditions. Mech. Syst. Signal Process. 2023, 197, 110359. [Google Scholar] [CrossRef]

- Maschler, B.; Braun, D.; Jazdi, N.; Weyrich, M. Transfer Learning as an Enabler of the Intelligent Digital Twin. Procedia CIRP 2021, 100, 127–132. [Google Scholar] [CrossRef]

- Fast, M.; Palmè, T. Application of artificial neural networks to the condition monitoring and diagnosis of a combined heat and power plant. Energy 2010, 35, 1114–1120. [Google Scholar] [CrossRef]

- Sepe, M.; Graziano, A.; Badora, M.; Di Stazio, A.; Bellani, L.; Compare, M.; Zio, E. A physics-informed machine learning framework for predictive maintenance applied to turbomachinery assets. J. Glob. Power Propuls. Soc. 2021, 3, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Fentaye, A.D.; Gilani, S.I.; Baheta, A.T. Gas turbine gas path diagnostics: A review. MATEC Web Conf. 2016, 95, 00005. [Google Scholar] [CrossRef]

- Ogaji, S.O.; Singh, R. Advanced Gas-Path Fault Diagnostics for Stationary Gas Turbines. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2003. [Google Scholar]

- Cerri, G.; Sandra, B.; Salvini, C. Models for simulation and diagnosis of energy plant components. In Proceedings of the ASME Power 2006, Atlanta, GA, USA, 2–6 May 2006. Paper No. PWR2006. [Google Scholar]

- Cerri, G.; Borghetti, S.; Salvini, C. Inverse Methodologies for Actual Status Recognition of Gas Turbine Components. In Proceedings of the ASME Power Conference, Orlando, FL, USA, 19–23 June 2005. Paper No. PWR2005-50033. [Google Scholar]

- Panov, V. Model-based control and diagnostic techniques for operational improvements of gas turbine engines. In Proceedings of the 10th European Conference on Turbomachinery—Fluid Dynamics & Thermodynamics (ETC10), Lappeenranta, Finland, 15–19 April 2013. Paper No. ETC2013-123. [Google Scholar]

- Cuomo, S.; Di Cola, V.S.; Giampaolo, F.; Rozza, G.; Raissi, M.; Piccialli, F. Scientific machine learning through physics-informed neural networks: Where we are and what’s next. J. Sci. Comput. 2022, 92, 88. [Google Scholar] [CrossRef]

- Asgari, H.; Chen, X.; Menhaj, M.B. Artificial neural network-based system identification for a single-shaft gas turbine. ASME J. Eng. Gas Turbines Power 2013, 135, 092601. [Google Scholar] [CrossRef]

- Arias Chao, M.; Kulkarni, C.; Goebel, K.; Fink, O. Fusing physics-based and deep learning models for prognostics. Reliab. Eng. Syst. Saf. 2022, 217, 107961. [Google Scholar] [CrossRef]

- Enríquez-Zárate, J.; Trujillo, L.; Larac, S.; Castelli, M.; Z-Flores, E.; Munoz, L.; Popovic, L. Automatic modeling of a gas turbine using genetic programming: An experimental study. Appl. Soft Comput. 2017, 52, 123–135. [Google Scholar] [CrossRef]

- Sophiya, A.A.; Maleki, S.; Bruni, G.; Krishnababu, S.K. Physics-informed neural networks for industrial gas turbines: Recent trends, advancements and challenges. arXiv 2025, arXiv:2506.19503. [Google Scholar] [CrossRef]

- Farhat, H.; Salvini, C. The Development of a Novel Hybrid Gas Turbine Digital Twin to Predict Performance Deterioration. In Proceedings of the International Workshop on Simulation for Energy, Sustainable Development and Environment (SESDE), Naples, Italy, 18–20 September 2023; pp. 1–10. [Google Scholar]

- Cerri, G.; Monacchia, S.; Seyedan, B. Optimum load allocation in cogeneration gas–steam combined plants. In Proceedings of the ASME Turbo Expo 1999: Power for Land, Sea, and Air, Indianapolis, IN, USA, 7–10 June 1999. Paper No. GT1999-0006. [Google Scholar]

- de Silva, B.; Callaham, J.; Kutz, J.N.; Brunton, S.L. PySINDy: A Python package for the sparse identification of nonlinear dynamical systems. J. Open Source Softw. 2020, 5, 2104. [Google Scholar] [CrossRef]

- Jin, X.; Cai, S.; Li, Z.; Karniadakis, G.E. NSFnets (Navier–Stokes flow nets). arXiv 2020, arXiv:2003.06496. [Google Scholar]

- Al Sayed, N.; Hamdouni, A.; Liberge, E.; Razafindralandy, D. The symmetry group of the non-isothermal Navier–Stokes equations and turbulence modelling. Symmetry 2010, 2, 848–867. [Google Scholar] [CrossRef]

- Rishikesh, A.; Ahmed, R.; Gaitonde, D.V. DiscretizationNet: A machine-learning-based solver for Navier–Stokes equations using finite volume discretization. Comput. Methods Appl. Mech. Eng. 2023, 413, 116123. [Google Scholar]

- Li, Z.; Kovachki, N.; Azizzadenesheli, K.; Liu, B.; Stuart, A.; Bhattacharya, K.; Anandkumar, A. Fourier neural operator for parametric partial differential equations. arXiv 2021, arXiv:2010.08895. [Google Scholar] [CrossRef]

- Kharazmi, E.; Zhang, Z.; Karniadakis, G.E. Variational physics-informed neural networks for solving partial differential equations. arXiv 2019, arXiv:1912.00873. [Google Scholar] [CrossRef]

- Schaeffer, H. Learning partial differential equations via data discovery and sparse optimization. Proc. R. Soc. A 2017, 473, 20160446. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Sirignano, J.; Spiliopoulos, K. DGM: A deep learning algorithm for solving partial differential equations. arXiv 2018, arXiv:1806.07366. [Google Scholar] [CrossRef]

- Cranmer, M.; Greydanus, S.; Battaglia, P.; Spergel, D.; Ho, S. Lagrangian neural networks. arXiv 2020, arXiv:2003.04630. [Google Scholar] [CrossRef]

- Sanchez-Gonzalez, A.; Pfaff, T.; Ying, R.; Leskovec, J.; Battaglia, P. Learning to simulate complex physics with graph networks. arXiv 2020, arXiv:2002.09405. [Google Scholar]

- Sanchez-Gonzalez, A.; Heess, N.; Springenberg, J.T.; Merel, J.; Riedmiller, M.; Hadsell, R.; Battaglia, P.W. Graph networks as learnable physics engines for inference and control. arXiv 2018, arXiv:1806.01242. [Google Scholar] [CrossRef]

- Gao, H.; Zahr, M.J.; Wang, J.-X. Physics-Informed Graph Neural Galerkin Networks: A Unified Framework for Solving PDE-Governed Forward and Inverse Problems. Comput. Methods Appl. Mech. Eng. 2022, 390, 114502. [Google Scholar] [CrossRef]

- Jiang, C.; Li, Y.; He, Y.; Jiang, Y.; He, S. Physics-Informed Graph Convolutional Neural Networks for Simulating Natural Convection. Comput. Methods Appl. Mech. Eng. 2022, 398, 115280. [Google Scholar]

- Li, Q.; Li, X.; Chen, X.; Yao, W. A novel graph modeling method for GNN-based hypersonic aircraft flow field reconstruction. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2394177. [Google Scholar] [CrossRef]

- Zobeiry, N.; Humfeld, K.D. A physics-informed machine learning approach for solving heat transfer equation in advanced manufacturing and engineering applications. Eng. Appl. Artif. Intell. 2021, 101, 104232. [Google Scholar] [CrossRef]

- Wang, J.-X.; Wu, Z.; Zhong, M.-L.; Ya, S. Data-driven modeling of a forced convection system for super-real-time transient thermal performance prediction. Int. Commun. Heat Mass Transf. 2021, 126, 105387. [Google Scholar] [CrossRef]

- Marinai, L.; Probert, D.; Singh, R. Prospects for aero gas-turbine diagnostics: A review. Appl. Energy 2004, 79, 109–126. [Google Scholar] [CrossRef]

- Talaat, M.; Gobran, M.H.; Wasfi, M. A hybrid model of an artificial neural network with thermodynamic model for system diagnosis of electrical power plant gas turbine. Eng. Appl. Artif. Intell. 2018, 68, 222–235. [Google Scholar] [CrossRef]

- Alblawi, A. Fault diagnosis of an industrial gas turbine based on the thermodynamic model coupled with a multi feed-forward artificial neural networks. Energy Rep. 2020, 6, 123–135. [Google Scholar]

- Joly, R.B.; Ogaji, S.O.T.; Singh, R.; Probert, S.D. Gas-turbine diagnostics using artificial neural networks for a high bypass ratio military turbofan engine. Appl. Energy 2003, 76, 523–535. [Google Scholar] [CrossRef]

- Aulich, M.; Goinis, G.; Voß, C. Data-Driven AI Model for Turbomachinery Compressor Aerodynamics Enabling Rapid Approximation of 3D Flow Solutions. Aerospace 2024, 11, 723. [Google Scholar] [CrossRef]

- Cerri, G.; Chennaoui, L.; Giovannelli, A.; Salvini, C. Gas path analysis and gas turbine re-mapping. In Proceedings of the ASME Turbo Expo 2011: Power for Land, Sea, and Air, Vancouver, BC, Canada, 6–10 June 2011. Paper No. GT2011-46424. [Google Scholar]

- Capata, R. An artificial neural network-based diagnostic methodology for gas turbine path analysis—Part II: Case study. Energy Ecol. Environ. 2016, 1, 351–359. [Google Scholar] [CrossRef]

- Wang, K.; Tan, R.; Peng, Q.; Wang, F.; Shao, P.; Gao, Z. A holistic method of complex product development based on a neural network-aided technological evolution system. Adv. Eng. Inform. 2021, 48, 101265. [Google Scholar] [CrossRef]

- Ghorbanian, K.; Gholamrezaei, M. An artificial neural network approach to compressor performance prediction. Appl. Energy 2009, 86, 1210–1221. [Google Scholar] [CrossRef]

- Yang, S.; Kim, H.; Hong, Y.; Yee, K.; Maulik, R.; Kang, N. Data-driven physics-informed neural networks: A digital twin perspective. arXiv 2024, arXiv:2401.08667. [Google Scholar] [CrossRef]

- Hashmi, M.B.; Mansouri, M.; Fentaye, A.D.; Ahsan, S.; Kyprianidis, K. An Artificial Neural Network-Based Fault Diagnostics Approach for Hydrogen-Fueled Micro Gas Turbines. Energies 2024, 17, 719. [Google Scholar] [CrossRef]

- Zhang, R.; Li, X.; Yao, W.; Zheng, X.; Wang, N.; Sun, J. Implicitly Physics-Informed Multi-Fidelity Physical Field Data Fusion Method Based on Taylor Modal Decomposition. Adv. Eng. Inform. 2024, 62 Pt 4, 102738. [Google Scholar] [CrossRef]

- Ogaji, S.; Sampath, S.; Singh, R.; Probert, D. Novel approach for improving power-plant availability using advanced engine diagnostics. Appl. Energy 2002, 72, 67–83. [Google Scholar] [CrossRef]

- Mumali, F. Artificial neural network-based decision support systems in manufacturing processes: A systematic literature review. Comput. Ind. Eng. 2022, 169, 107964. [Google Scholar] [CrossRef]

- Goyal, R.K.; Kaushal, S.; Sangaiah, A.K. The utility-based non-linear fuzzy AHP optimization model for network selection in heterogeneous wireless networks. Appl. Soft Comput. 2018, 67, 800–811. [Google Scholar] [CrossRef]

- Lim, J.; Perullo, C.A.; Milton, J.; Whitacre, R.; Jackson, C.; Griffin, C.; Noble, D.; Boche, L.; Seachman, S.; Angello, L.; et al. The EPRI turbine digital twin: A platform for operator-focused integrated diagnostics and performance forecasting. In Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference & Exposition, Virtual Conference, 7–11 June 2021. Paper No. GT2021-10627. [Google Scholar]

- GE Vernova. How CPV Used Digital Twin to Increase Power Output and Reduce Costs. GE Vernova—Customer Stories. 2023. Available online: https://www.gevernova.com/software/customer-stories/how-cpv-used-digital-twin-to-increase-power-output-reduce-costs (accessed on 31 July 2025).

- DecisionLab Ltd. ATOM Digital Twin of Siemens Gas Turbine Fleet Operations. AnyLogic—Case Studies. 2023. Available online: https://www.anylogic.com/resources/case-studies/atom-digital-twin-of-siemens-gas-turbine-fleet-operations/ (accessed on 31 July 2025).

- Bruni, G.; Maleki, S.; Krishnababu, S.K. Deep learning modeling of manufacturing and build variations on multistage axial compressors aerodynamics. Data-Cent. Eng. 2025, 6, e9. [Google Scholar] [CrossRef]

- Soltani, M.; Akbari, G.; Montazerin, N. Trade-off between reconstruction accuracy and physical validity in modeling turbomachinery particle image velocimetry data by physics-informed convolutional neural networks. Mech. Eng. J. 2024, 12, 345–356. [Google Scholar] [CrossRef]

- Wang, L.; Zhengchao, L. Data-driven product design evaluation method based on multi-stage artificial neural network. Appl. Soft Comput. 2021, 102, 107117. [Google Scholar] [CrossRef]

- Tahan, M.; Tsoutsanis, E.; Muhammad, M.; Abdul Karim, Z.A. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy 2017, 198, 122–145. [Google Scholar] [CrossRef]

- Kanelopoulos, K.; Stamatis, A.; Mathioudakis, K. Incorporating neural networks into gas turbine performance diagnostics. In Proceedings of the ASME Turbo Expo 1997: Power for Land, Sea, and Air, Orlando, FL, USA, 2–5 June 1997. Paper No. 97-GT-321. [Google Scholar]

- Anagnostopoulos, S.J.; Toscano, J.D.; Stergiopulos, N.; Karniadakis, G.E. Residual-based attention in physics-informed neural networks. arXiv 2022, arXiv:2205.01138. [Google Scholar] [CrossRef]

- Lu, L.; Jin, P.; Karniadakis, G.E. DeepONet: Learning nonlinear operators for differential equations. Nat. Mach. Intell. 2021, 3, 218–229. [Google Scholar] [CrossRef]

- Ghoreishi, S. Assessing the Role of Artificial Intelligence in Product Design Towards Circularity. Ph.D. Dissertation, Lappeenranta-Lahti University of Technology, Lappeenranta Finland, Lahti, Finland, 2019. [Google Scholar]

- Hadian, M.; Ebrahimi Saryazdi, S.M.; Mohammadzadeh, A.; Babaei, M. Application of Artificial Intelligence in Modeling, Control, and Fault Diagnosis. In Applications of Artificial Intelligence in Process Systems Engineering; Zamarripa, M., Espuña, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–28. [Google Scholar]

- Kwong, C.K.; Huimin, J.; Luo, X.G. AI-based methodology of integrating affective design, engineering, and marketing for defining design specifications of new products. Eng. Appl. Artif. Intell. 2016, 55, 178–190. [Google Scholar] [CrossRef]

- Brunton, S.L.; Proctor, J.L.; Kutz, J.N. Discovering governing equations from data: Sparse identification of nonlinear dynamical systems. Proc. Natl. Acad. Sci. USA 2016, 113, 3932–3937. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, Y.; Wang, J.; Zhang, H.; Lin, Z. Physics-Informed Diffusion Models for Unsupervised Anomaly Detection in Multivariate Time Series. arXiv 2025, arXiv:2508.11528. [Google Scholar] [CrossRef]

- Sharma, P.; Chung, W.T.; Akoush, B.; Ihme, M. A review of physics-informed machine learning in fluid mechanics. Energies 2023, 16, 2343. [Google Scholar] [CrossRef]

- Zaccaria, V.; Fentaye, A.D.; Kyprianidis, K.G. Bayesian information fusion for gas turbine diagnostics and prognostics. In Proceedings of the ASME Turbo Expo 2023: Turbomachinery Technical Conference & Exposition, Boston, MA, USA, 26–30 June 2023. Paper No. GT2023-103171. [Google Scholar]

- Suarez, A.; Narvaez, C.; Jimenez, J. Nonlinear surrogate model design for aerodynamic dataset generation based on artificial neural networks. Aerospace 2024, 11, 607. [Google Scholar] [CrossRef]

- Catalani, R.; Fesquet, J.; Bertrand, M.; Tost, D.; Morlier, J. Neural fields for rapid aircraft aerodynamics simulations. Sci. Rep. 2024, 14, 76983. [Google Scholar] [CrossRef]

- Roznowicz, D.; Stabile, G.; Demo, N.; Fransos, D.; Rozza, G. Large-scale graph-machine-learning surrogate models for 3D flowfield prediction in external aerodynamics. Adv. Model. Simul. Eng. Sci. 2024, 11, 32. [Google Scholar] [CrossRef]

- Catalani, R.; Fesquet, J.; Bertrand, M.; Tost, D.; Morlier, J. Towards scalable surrogate models based on neural fields for large-scale aerodynamic simulations. arXiv 2025, arXiv:2505.14704. [Google Scholar]

- Gal, Y.; Ghahramani, Z. Dropout as a Bayesian Approximation: Representing Model Uncertainty in Deep Learning. In Proceedings of the 33rd International Conference on Machine Learning (ICML), New York, NY, USA, 19–24 June 2016; pp. 1050–1059. [Google Scholar]

- Lakshminarayanan, B.; Pritzel, A.; Blundell, C. Simple and Scalable Predictive Uncertainty Estimation Using Deep Ensembles. arXiv 2017, arXiv:1612.01474. [Google Scholar] [CrossRef]

- Abdar, M.; Pourpanah, F.; Hussain, S.; Rezazadegan, D.; Liu, L.; Ghavamzadeh, M.; Fieguth, P.; Cao, X.; Khosravi, A.; Acharya, U.R.; et al. A Review of Uncertainty Quantification in Deep Learning: Techniques, Applications, and Challenges. Inf. Fusion 2021, 76, 243–297. [Google Scholar] [CrossRef]

- Karpenko, M.; Ževžikov, P.; Stosiak, M.; Skačkauskas, P.; Borucka, A.; Delembovskyi, M. Vibration Research on Centrifugal Loop Dryer Machines Used in Plastic Recycling Processes. Machines 2024, 12, 29. [Google Scholar] [CrossRef]

- Case Western Reserve University Bearing Data Center. Bearing Vibration Dataset. Available online: https://engineering.case.edu/bearingdatacenter (accessed on 1 October 2025).

- NASA Prognostics Center of Excellence. Prognostics Data Repository. Available online: https://www.nasa.gov/intelligent-systems-division/discovery-and-systems-health/pcoe/pcoe-data-set-repository/ (accessed on 1 October 2025).

| Platform | Model Structure | Operational Role |

|---|---|---|

| EPRI Turbine Digital Twin [56] | NPSS thermodynamic modules with AI-based virtual sensors | Operator-facing diagnostics, anomaly detection, and performance forecasting |

| GE Vernova SmartSignal [57] | ANN-based predictive analytics integrated with thermodynamic baselines | Predictive maintenance, downtime reduction, and O&M optimization across large fleets |

| Siemens ATOM [58] | Agent-based framework combining physical models with AI optimization layers | Fleet-wide coordination, load sharing, and predictive maintenance planning |

| Criterion | Score 1–2 (Low) | Score 3 (Medium) | Score 4–5 (High) | Key References |

|---|---|---|---|---|

| Data Dependency | Strong reliance on large datasets; limited generalization; often restricted to synthetic | Moderate reliance; able to use a mix of simulation and sensor | Low reliance; physics constraints or transfer learning reduce data requirements | [29,42,53] |

| Physical Interpretability | Black-box predictions with little or no physical grounding | Partial transparency through hybrid coupling or explainable AI techniques | High interpretability with embedded governing equations or physics-preserving networks | [31,60,64] |

| Deployment Complexity | Simple deployment; minimal infrastructure needs | Moderate effort; requires calibration, pipelines, or custom tuning | High complexity; requires HPC, robust pipelines, and/or cybersecurity layers | [34,56] |

| Workflow Compatibility | Standalone; minimal integration with thermodynamic or CFD models | Partial integration with selected simulation modules | Full compatibility with SCADA, NPSS, CFD, and fleet-level digital twin workflows | [35,57,66] |

| Real-Time Capability | Limited to offline or retrospective analysis | Medium suitability; fast inference but not yet fully validated online | Demonstrated real-time diagnostics, control, and predictive maintenance | [9,16,56] |

| Category | Advantages | Limitations | Typical Use Cases |

|---|---|---|---|

| ANN-Augmented Thermodynamic Models | Improves diagnostic sensitivity; compensates for degradation drift; fast inference for online use | Limited extrapolation outside training domain; dependent on baseline model fidelity | Moderate data needs (sensor + baseline cycle data); low–moderate compute (training offline, lightweight online inference) |

| Physics-integrated operational architectures | Maintains physical consistency; integrates sensor data with fleet/asset models; scalable to plant operations | Calibration effort; higher deployment complexity; potential cybersecurity concerns | Large operational datasets (SCADA, historian logs); moderate–high compute (integration, pipelines, dashboards) |

| Physics-constrained neural networks and CFD surrogates | High interpretability; preserves conservation laws; enables rapid flow-field predictions | Training complexity; surrogate validation required; performance tied to CFD reference quality | High-fidelity CFD or experimental datasets; high compute for training; reduced cost at inference |

| Generative and model discovery approaches | Identifies governing equations directly from data; adaptable to unseen conditions; supports synthetic data generation | Data hungry; interpretability varies; early-stage maturity for industrial adoption | Large, diverse datasets (including synthetic/augmented); high compute for training (GANs, VAEs, SINDy), variable at inference |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farhat, H.; Altarawneh, A. Physics-Informed Machine Learning for Intelligent Gas Turbine Digital Twins: A Review. Energies 2025, 18, 5523. https://doi.org/10.3390/en18205523

Farhat H, Altarawneh A. Physics-Informed Machine Learning for Intelligent Gas Turbine Digital Twins: A Review. Energies. 2025; 18(20):5523. https://doi.org/10.3390/en18205523

Chicago/Turabian StyleFarhat, Hiyam, and Amani Altarawneh. 2025. "Physics-Informed Machine Learning for Intelligent Gas Turbine Digital Twins: A Review" Energies 18, no. 20: 5523. https://doi.org/10.3390/en18205523

APA StyleFarhat, H., & Altarawneh, A. (2025). Physics-Informed Machine Learning for Intelligent Gas Turbine Digital Twins: A Review. Energies, 18(20), 5523. https://doi.org/10.3390/en18205523