Comprehensive Analysis of De-Icing Technologies for Wind Turbine Blades: Mechanisms, Modeling, and Performance Evaluation

Abstract

1. Introduction

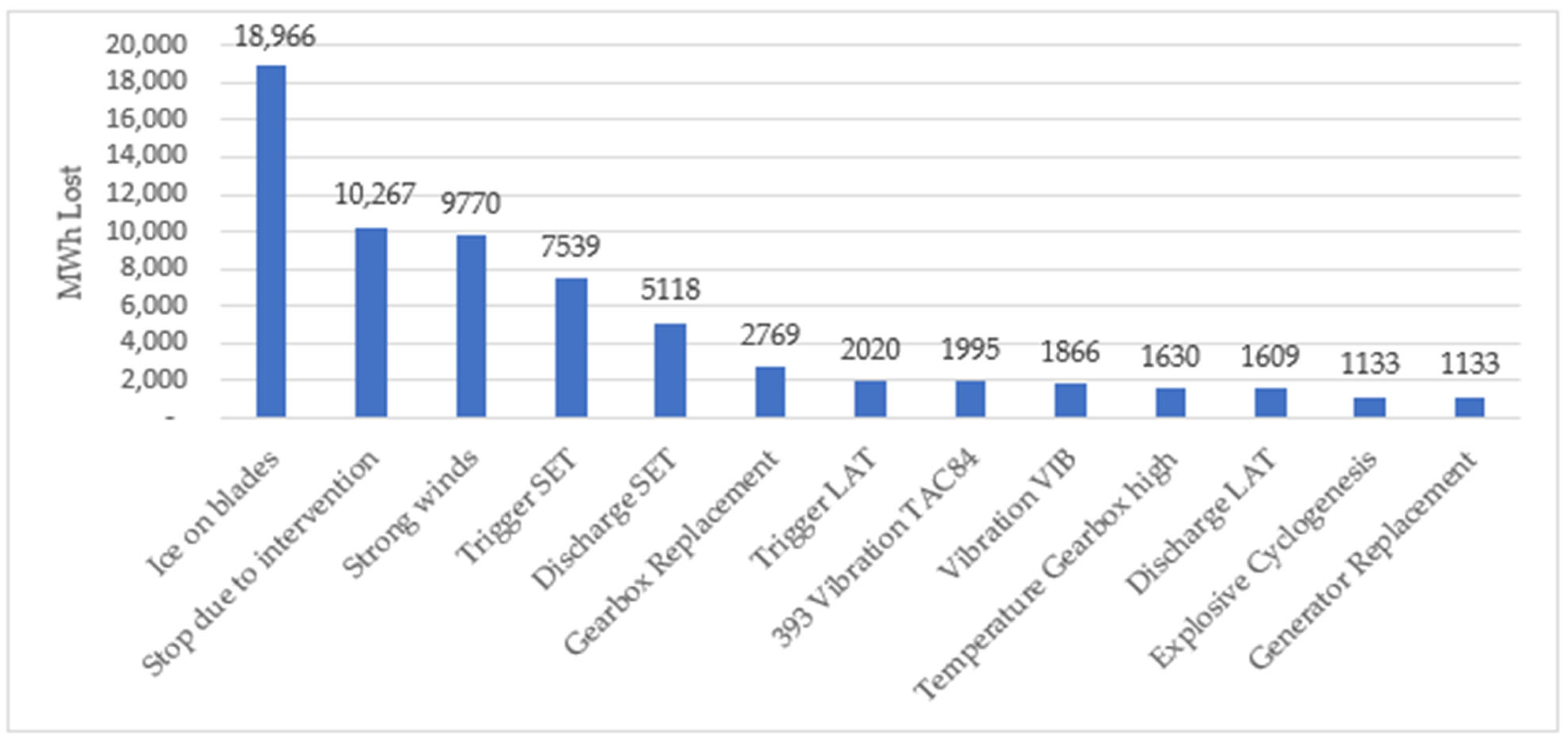

2. Mechanism and Contributing Factors of Wind Turbine Icing

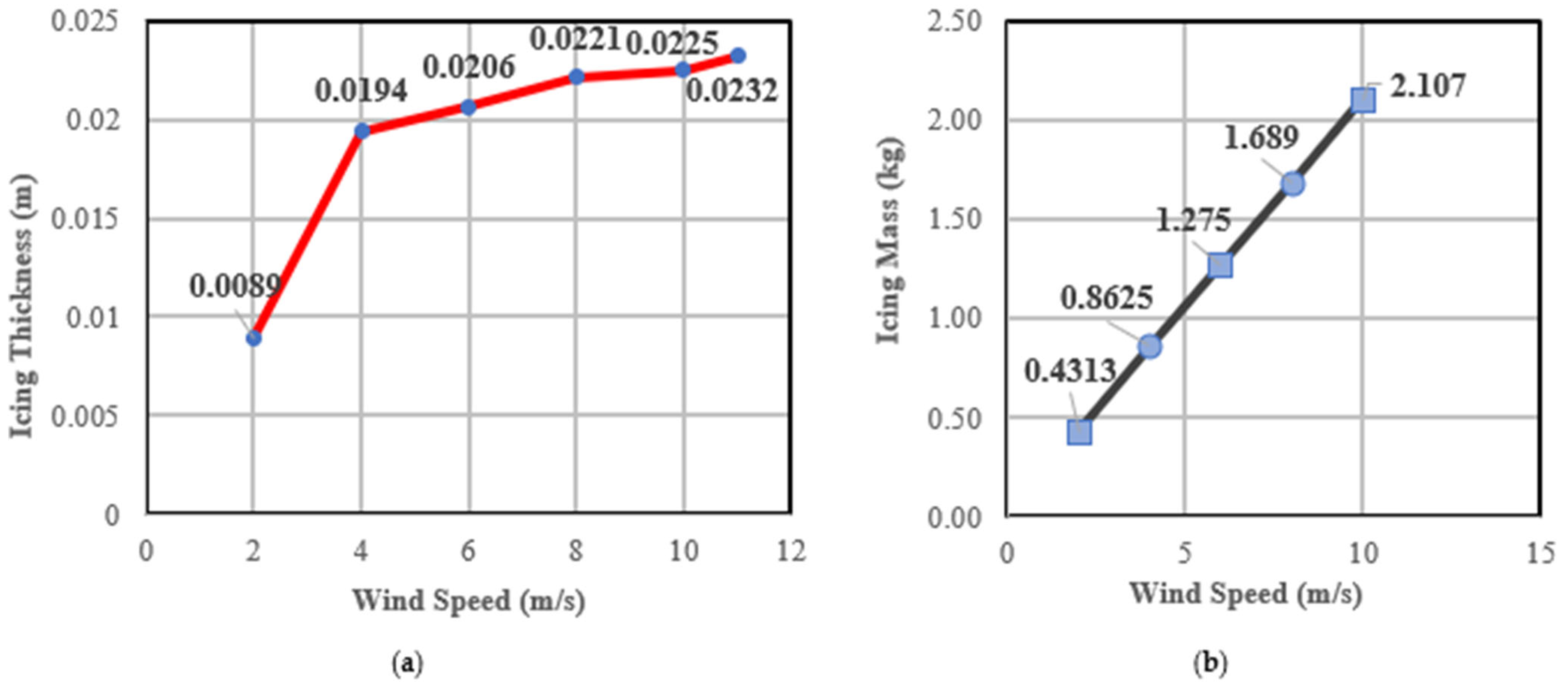

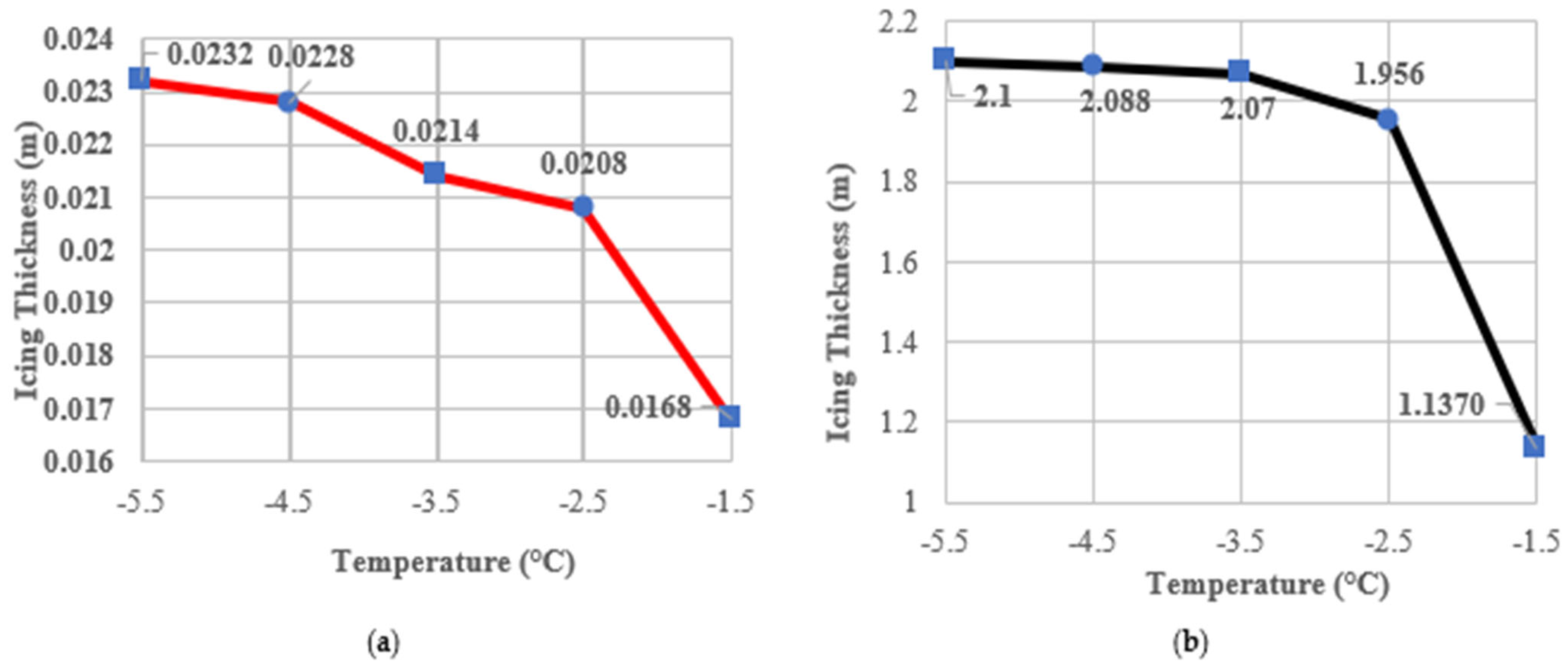

2.1. Influence of Windspeed on Turbine Blade Icing

2.2. Influence of Temperature on Turbine Icing

2.3. Effect of Rim and Glaze Ice

3. Impact of Icing on Power Generation

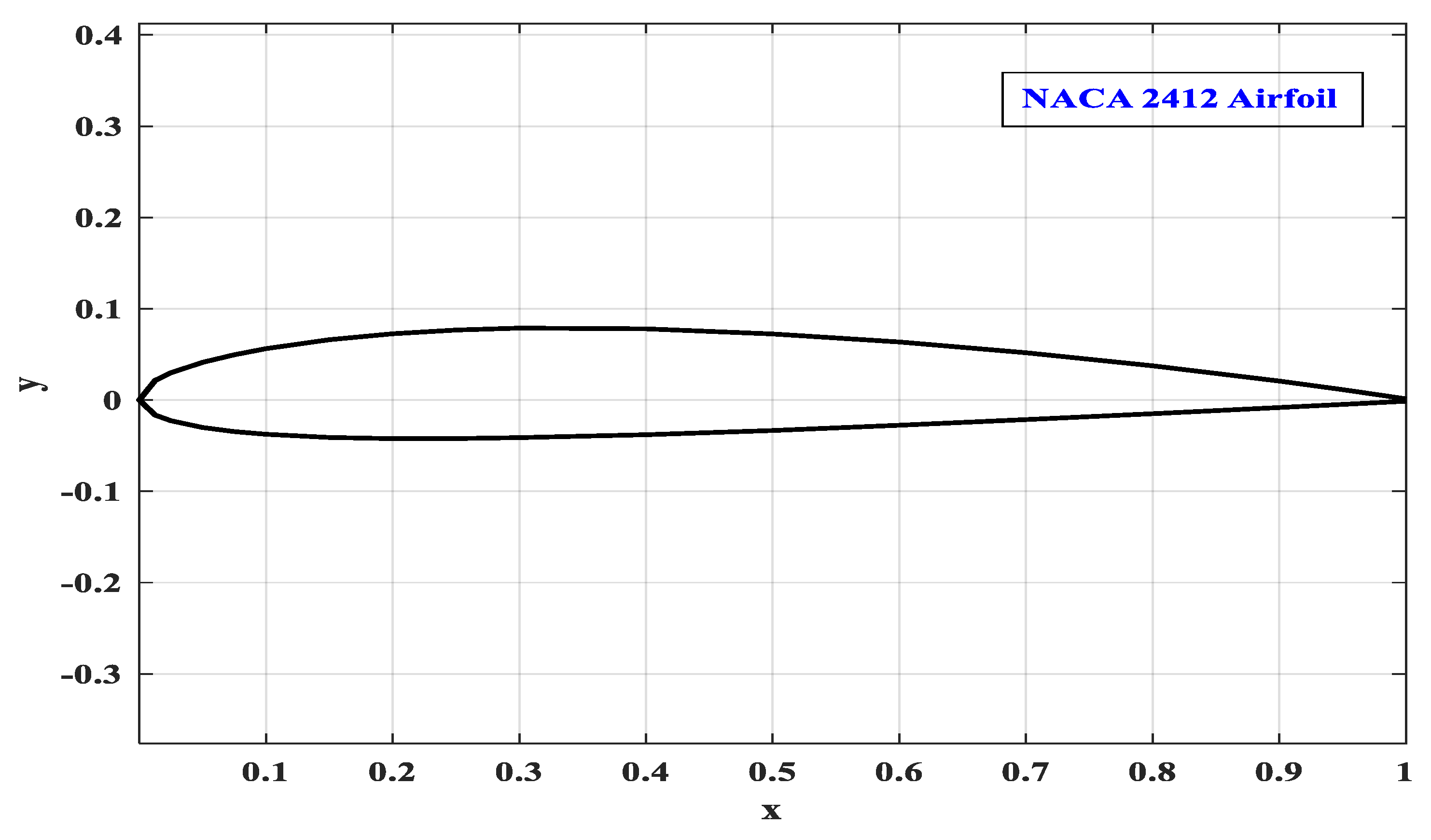

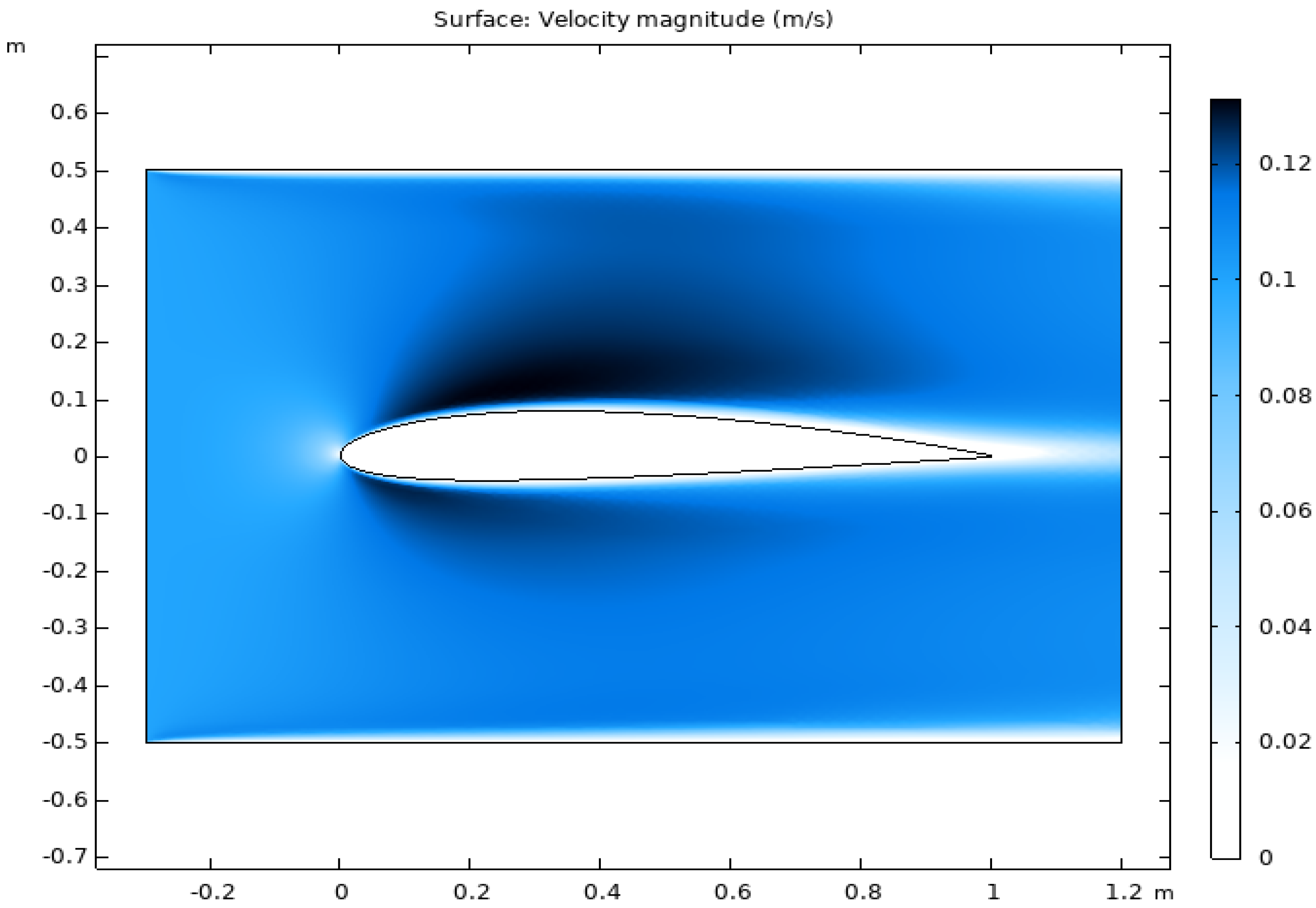

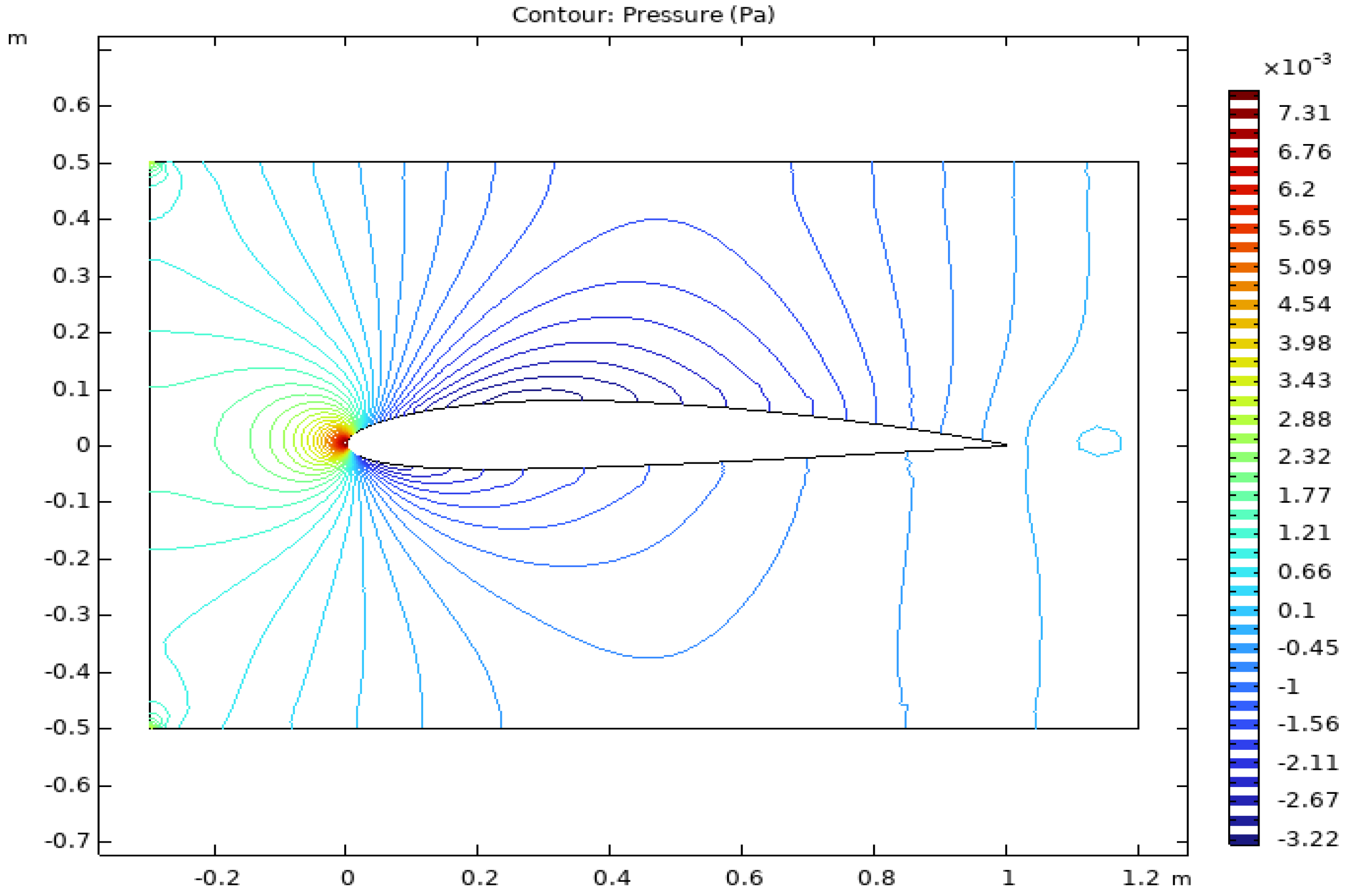

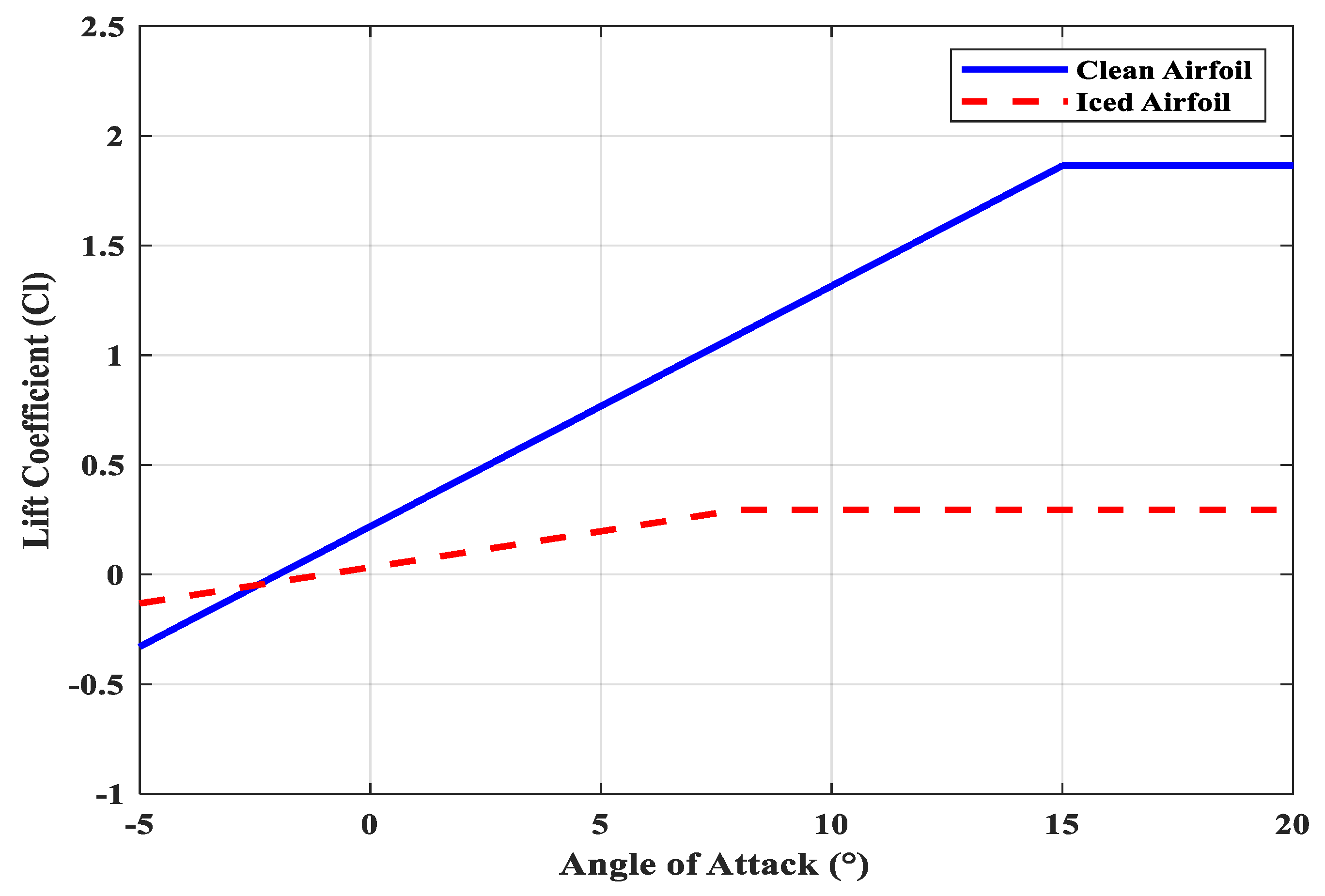

4. Analysis of NACA 2412 Airfoil: Aerodynamic Impact of Ice Accretion

4.1. Impact of Atmospheric Conditions on Ice Adhesion

4.2. Modeling the Impact of Ice Accretion on Lift and Stall Performance

5. Sensing Mechanisms for Detecting Ice Formation on Wind Turbine Blade Surface

5.1. Indirect Methods: Deduce Icing Conditions from Variations

5.2. Direct Methods

- Capacitive sensors: Identify changes in permittivity resulting from ice buildup. Although they are precise, they demand robust installation to endure extreme conditions.

- Optical and infrared sensors: Assess changes in light reflection caused by ice accumulation. These systems are quick and sensitive but can be affected by dirt or fog.

- Ultrasonic sensors: detect ice through variations in sound wave propagation. They are effective for thicker ice layers but are vulnerable to noise interference.

- Microwave sensors: utilize frequency shifts caused by variations in dielectric properties to confirm the presence of ice. They deliver high precision and rapid responses.

- Flexible dielectric impedance sensors: provide real-time, wireless ice thickness monitoring with minimal aerodynamic disruption [5].

6. De-Icing Techniques

- Thermal De-Icing

- 2.

- Electro-Impulse and Ultrasonic De-Icing

- 3.

- Ultrasonic de-icing

- 4.

- Mechanical and Pneumatic Systems

- 5.

- Hybrid and Intelligent Systems

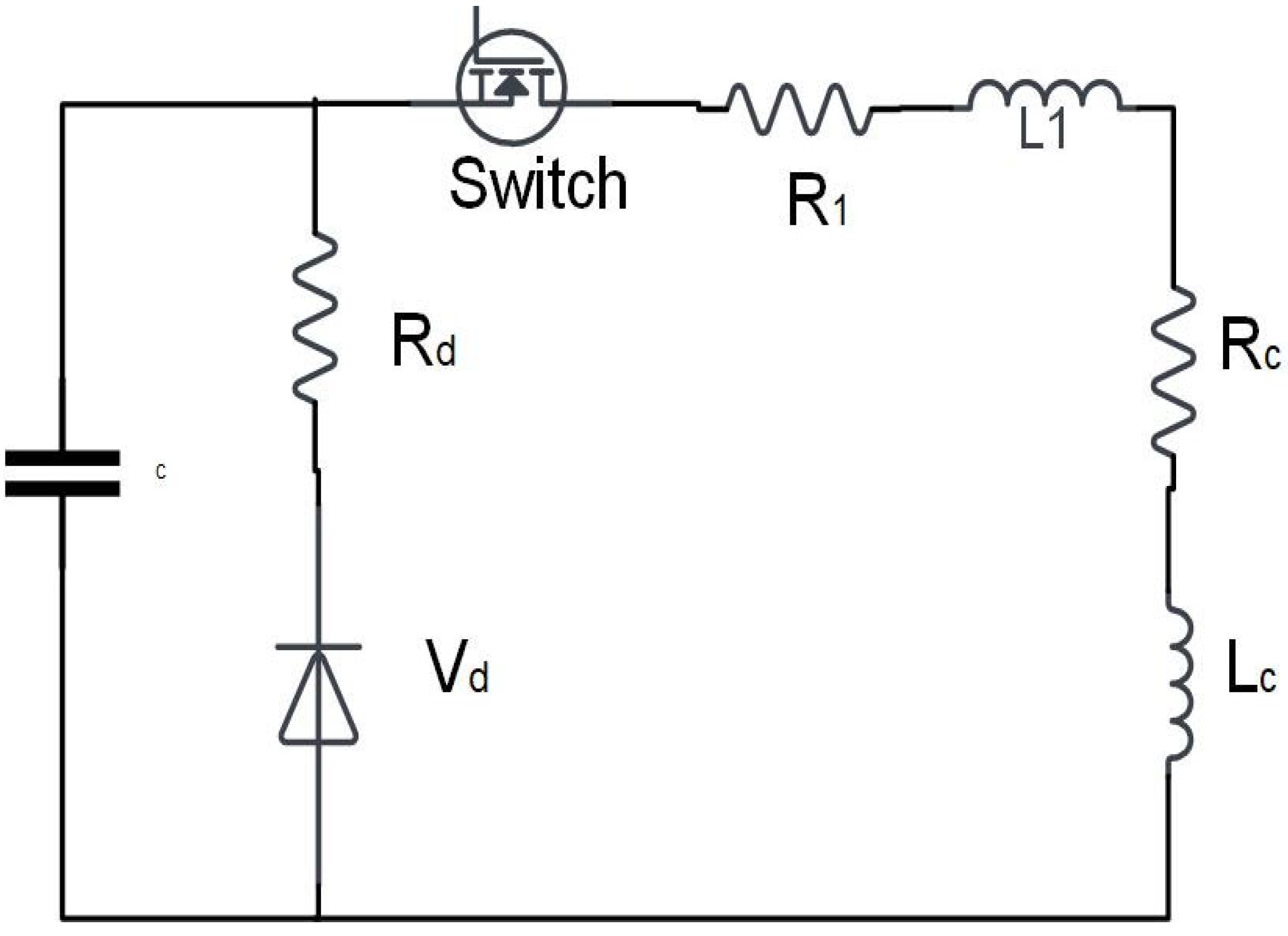

7. Multiphysics Simulation of Electro Impulse Ice Mitigation Technique

7.1. Principle of Electro-Impulse De-Icing

7.2. Simulation Set Up

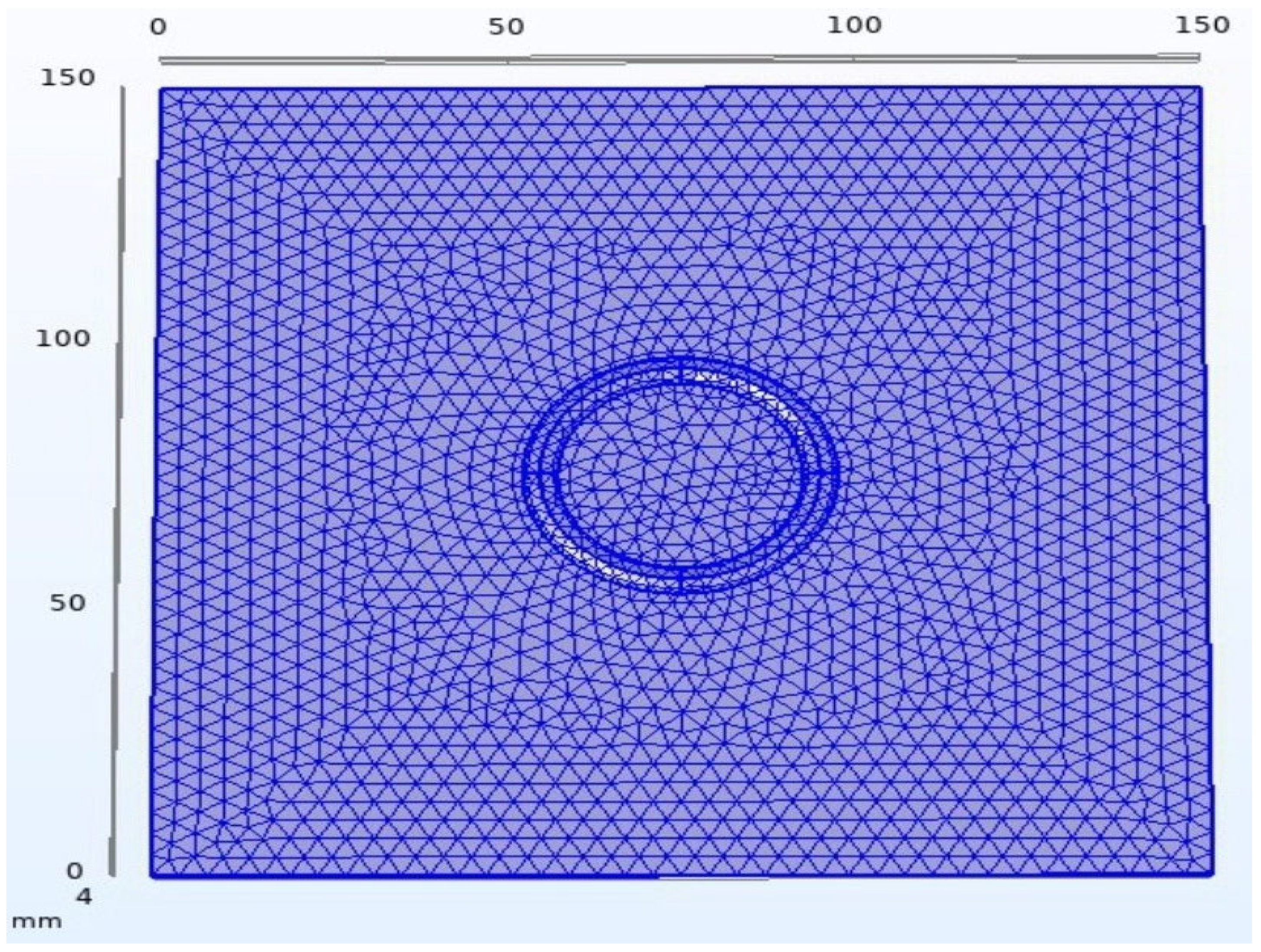

8. Time-Dependent Electromagnetic-Thermomechanical Coupling Analysis in EIDI Systems

- Magnetic Fields (mf)—to solve transient magnetic flux density and induced Lorentz forces.

- Solid Mechanics (solid)—to analyze resulting structural deformation and stress.

8.1. Simulation Parameter Selection

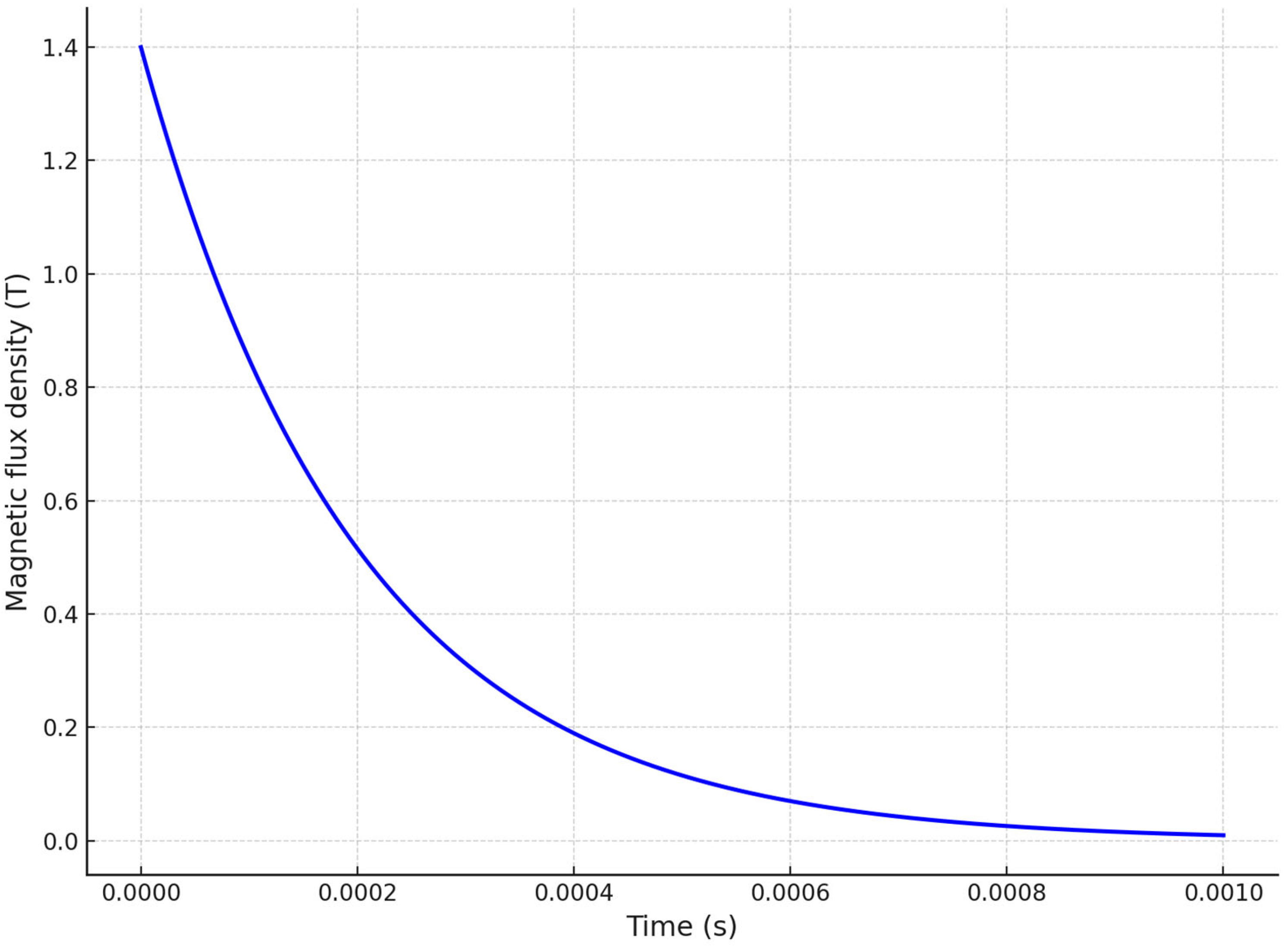

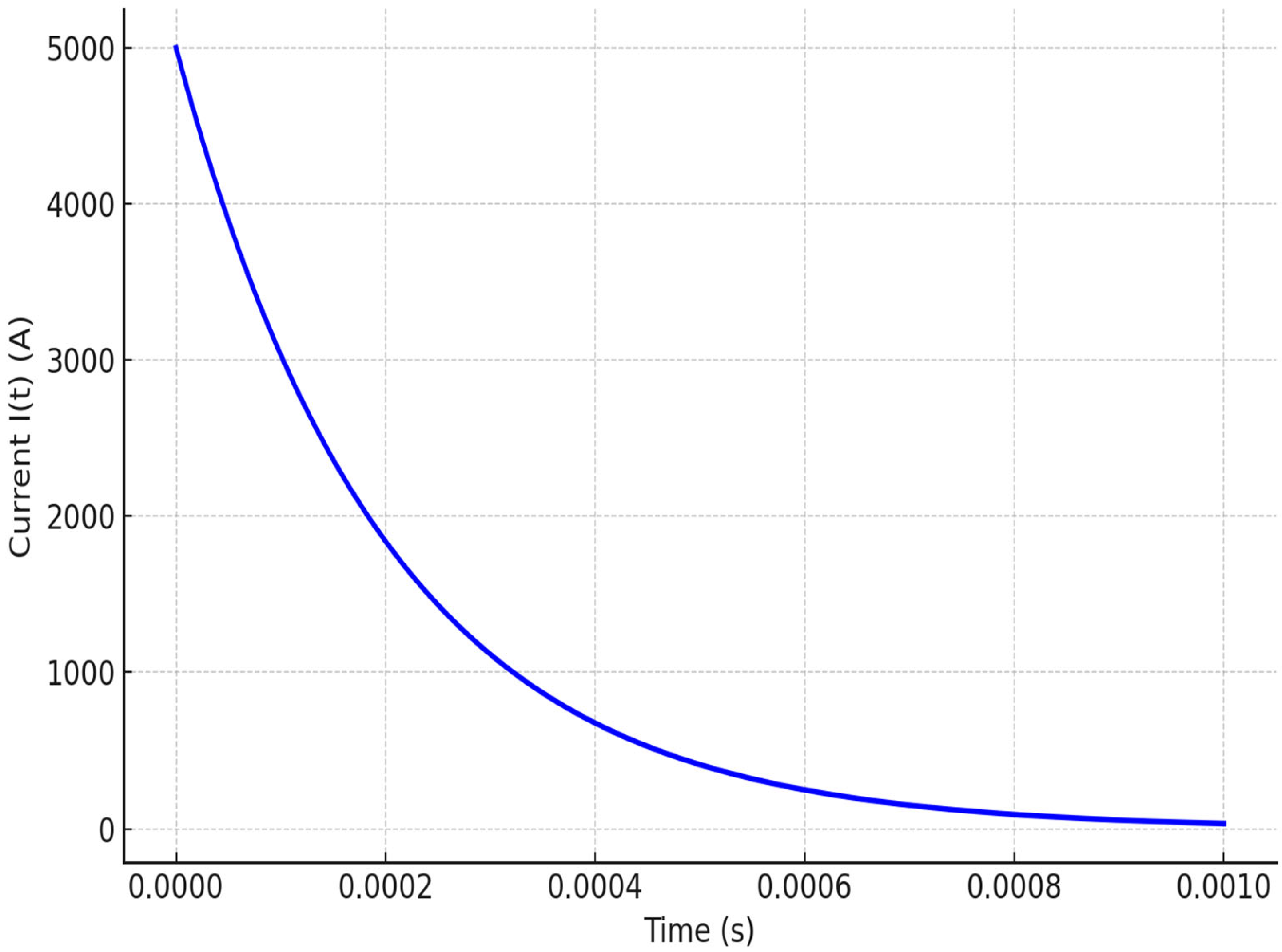

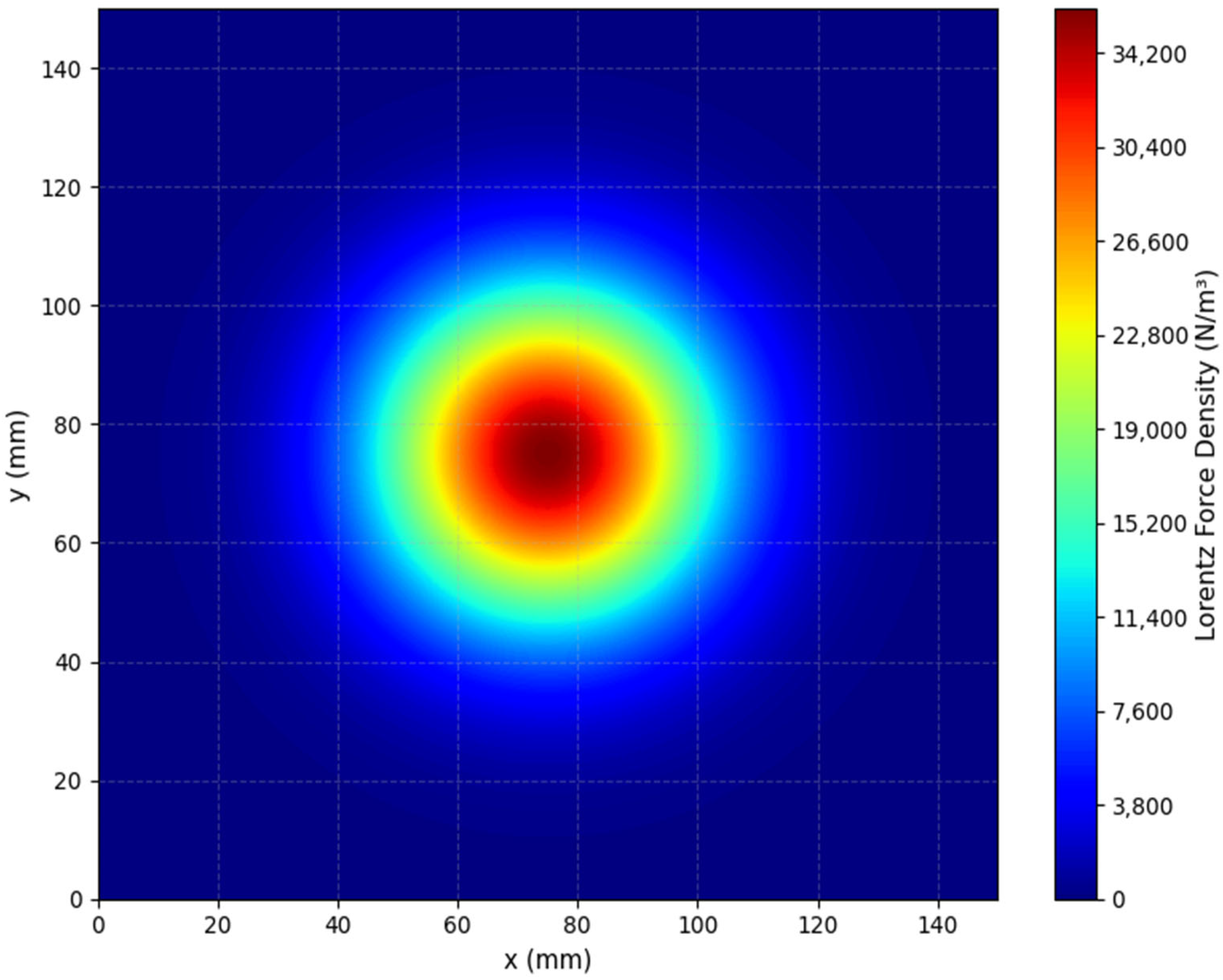

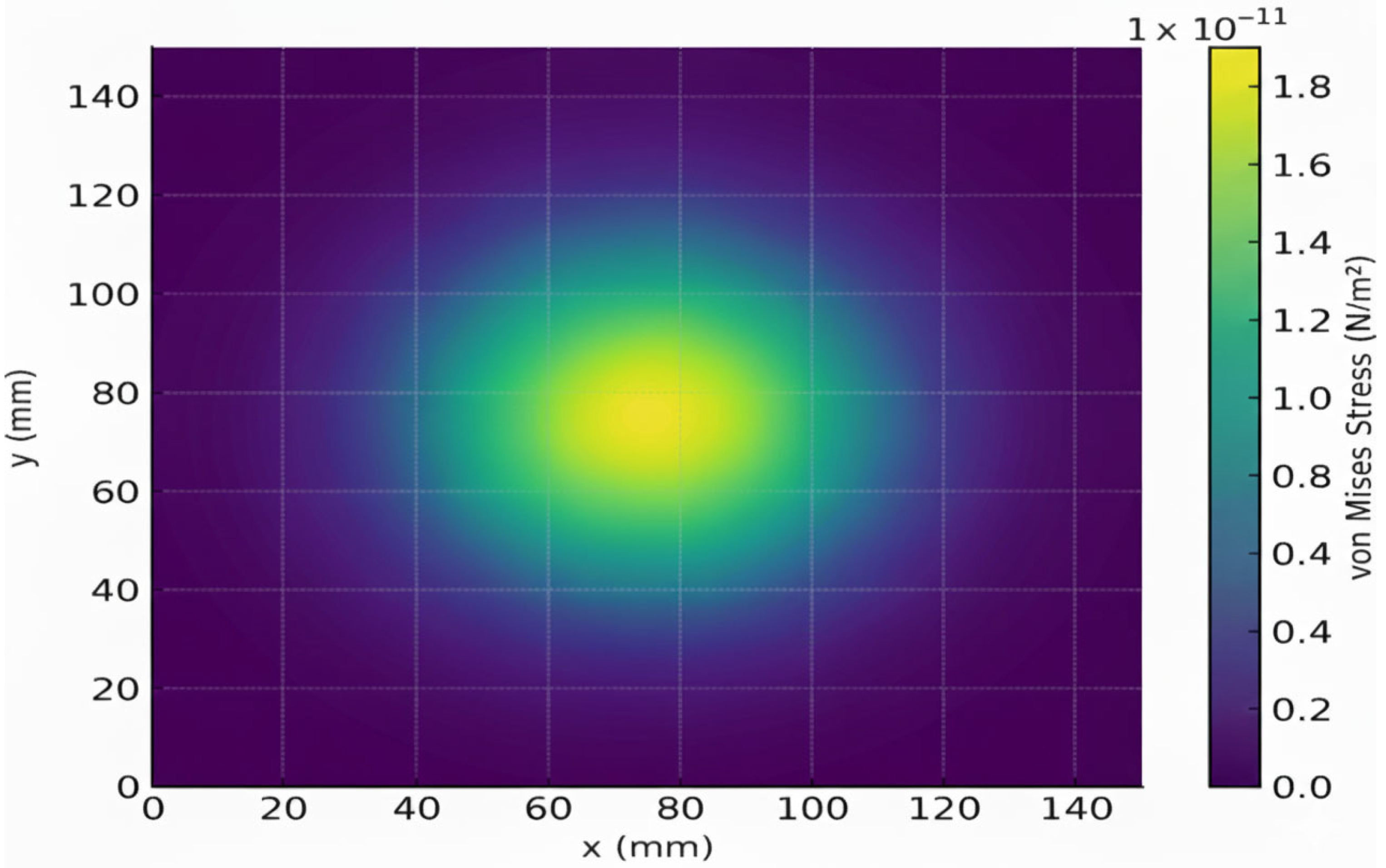

8.2. Simulation Output

8.2.1. Magnetic Flux Density Norm (B-Field) vs. Time

8.2.2. Input Current Pulse vs. Time

8.2.3. Lorentz Force Density Distribution

9. Electromagnetic–Thermomechanical Coupling

10. Simulation Findings and Discussion

- Increasing peak current I0 would proportionally scale Lorentz forces.

- Modifying coil geometry can tailor force distribution to match critical ice adhesion regions.

- Plate material selection will strongly influence vibration efficiency.

10.1. Energy Consumption Analysis of EIDI System

- Daily and Seasonal Operation

- 2.

- Energy Scaling with Blade Length

- 3.

- Energy Consumption under Zone-Based Distribution

- Root (0–10 m): 1 coil every 2 m → ~5 coils → 125 kWh/season

- Mid-span (10–35 m): 1 coil per meter → ~25 coils → 625 kWh/season

- Tip (35–50 m): 1 coil every 2.5 m → ~6 coils → 150 kWh/season

- Total: ~36 coils → 900 kWh/season

10.2. Comparative Energy Consumption Analysis of EIDI, Thermal, and Ultrasonic De-Icing Systems

10.3. Performance and Energy Assessment of EIDI in Comparison to Thermal and Ultrasonic De-Icing Methods

10.4. Trade-Offs and Practical Considerations

- Operational Trade-Offs: Anti-Icing, De-Icing, and Hybrid Approaches

- 2.

- Energy Consumption Trade-Offs

- 3.

- Fatigue and Structural Durability

- 4.

- Geometric Simplifications in Modeling

- 5.

- Material Trade-Offs: Aluminum vs. Composites

11. Limitations and Future Directions

12. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- WindEurope. Wind Energy in Europe: Scenarios for 2030; WindEurope: Brussels, Belgium, 2017. [Google Scholar]

- National Energy Board. Canada’s Energy Future: Energy Supply and Demand Projections to 2035. An Energy Market Assessment 2011; National Energy Board: Calgary, AB, Canada, 2011. [Google Scholar]

- Bevrani, H.; Afzal, F.; Virk, M.S. Review of Icing Effects on Wind Turbine in Cold Regions. E3S Web Conf. 2018, 72, 01007. [Google Scholar]

- Castellani, F.; Astolfi, D. Editorial on Special Issue ‘Wind Turbine Power Optimization Technology’. Energies 2020, 13, 1796. [Google Scholar] [CrossRef]

- Madi, E.; Pope, K.; Huang, W.; Iqbal, T. A review of integrating ice detection and mitigation for wind turbine blades. Renew. Sustain. Energy Rev. 2019, 103, 269–281. [Google Scholar] [CrossRef]

- Gao, L.; Hu, H. Wind turbine icing characteristics and icing-induced power losses to utility-scale wind turbines. Proc. Natl. Acad. Sci. USA 2021, 118, e2111461118. [Google Scholar] [CrossRef]

- Davis, N.; Hahmann, A.N.; Clausen, N.-E.; Žagar, M. Forecast of Icing Events at a Wind Farm in Sweden. J. Appl. Meteorol. Climatol. 2014, 53, 262–281. [Google Scholar] [CrossRef]

- Pérez, J.M.P.; Márquez, F.P.G.; Hernández, D.R. Economic viability analysis for icing blades detection in wind turbines. J. Clean. Prod. 2016, 135, 1150–1160. [Google Scholar] [CrossRef]

- Hu, Q.; Hu, Z.; Li, B.; Fu, X.; Rao, L.; Duan, J. The Rapid Computational Model for Power Output of Ice-covered Wind Turbines Based on Airfoil Aerodynamic Parameters. In Proceedings of the 2023 IEEE Sustainable Power and Energy Conference (ISPEC), Chongqing, China, 28–30 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Lin, X.; Zheng, R.; Xu, L.; Wang, C.; Wu, T.; Yang, W.; Liao, Z.; Kang, P. Design of Steam Thermal Deicing Control System for Wind Turbine Blades Based on BP Neural Network Algorithm. In Proceedings of the 2023 International Conference on Power, Electrical Engineering, Electronics and Control (PEEEC), Athens, Greece, 25–27 September 2023; pp. 565–570. [Google Scholar] [CrossRef]

- Wang, F.; Niu, L.; Wang, T.; Ye, L. Wind Turbine Blade Icing Monitoring, De-Icing and Wear Prediction Device Based on Machine Vision Recognition Algorithm. In Proceedings of the 2024 IEEE 2nd International Conference on Control, Electronics and Computer Technology (ICCECT), Jilin, China, 26–28 April 2024; pp. 687–694. [Google Scholar] [CrossRef]

- Luo, J.; Yang, H.; Chen, X.; Huang, L.; Li, B.; Hu, H. Design of a Flexible Icing Monitoring Sensor with Dielectric Shift”. In Proceedings of the 2024 14th International Conference on Power and Energy Systems (ICPES), Chengdu, China, 13–16 December 2024; pp. 193–197. [Google Scholar] [CrossRef]

- Huang, T.; Jiang, X.; Chen, Y.; Wang, M. Experimental Study on Electro-Impulse De-Icing of Wind Turbine Blades. In Proceedings of the 6th Asia Conf. Power and Electrical Engineering (ACPEE), Chongqing, China, 8–11 April 2021; pp. 205–210. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, X.; Cheng, X.; Jiang, G. A Physics-Based and Data-Driven Feature Extraction Model for Blades Icing Detection of Wind Turbines. IEEE Sens. J. 2023, 23, 3944–3955. [Google Scholar] [CrossRef]

- Chuang, Z.; Yi, H.; Chang, X.; Liu, H.; Zhang, H.; Xia, L. Comprehensive Analysis of the Impact of the Icing of Wind Turbine Blades on Power Loss in Cold Regions. J. Mar. Sci. Eng. 2023, 11, 1125. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Zhang, X.; Hu, Q.; Jiang, X. A Review of Wind Turbine Icing and Anti/De-Icing Technologies. Energies 2024, 7, 2805. [Google Scholar] [CrossRef]

- Apata, O.; Mavende, T. An Overview of Power Loss Estimation in Wind Turbines Due to Icing. In Wind Turbines-Design, Control and Applications; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Yu, D.; Si, G.; Kong, X.; Wen, J.; Chen, F.; Zhang, D.; Cao, T. Icing mechanism and prediction analysis of fan blades. Chin. J. Comput. Mech. 2021, 38, 27–336. (In Chinese) [Google Scholar]

- Etemaddar, M.; Hansen, M.O.L.; Moan, T. Wind turbine aerodynamic response under atmospheric icing conditions. Wind Energy 2014, 17, 241–265. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Yue, S.; Zeng, W. A Review of Icing and Anti-Icing Technology for Transmission Lines. Energies 2023, 16, 601. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Yue, S.; Zhang, X.; Li, C.; Zeng, W. Growth characteristics and influence analysis of insulator strings in natural icing. Electr. Power Syst. Res. 2024, 228, 110097. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Zhou, W.; Hu, H. An experimental study on the aerodynamic performance degradation of a wind turbine blade model induced by ice accretion process. Renew. Energy 2019, 133, 663–675. [Google Scholar] [CrossRef]

- Petrenko, K.B.; Whitworth, R.W. Physics of Ice; Oxford University Press: Oxford, UK, 1999. [Google Scholar]

- Aliaga, C.; Aubé, J.; Habashi, W.G. FENSAP-ICE-Unsteady: Unified in-flight icing simulation methodology for aircraft, rotorcraft and jet engines. J. Aircr. 2010, 47, 925–938. [Google Scholar] [CrossRef]

- Myers, T. Extension to the Messinger model for aircraft icing. AIAA J. 2001, 39, 211–218. [Google Scholar] [CrossRef]

- Caccia, F.; Guardone, A. Numerical simulations of ice accretion on wind turbine blades: Are performance losses due to ice shape or surface roughness? Wind. Energy Sci. 2023, 8, 341–362. [Google Scholar] [CrossRef]

- Addy, H.E., Jr. Ice Accretions and Their Aerodynamic Effects on Wings and Airfoils; NASA Glenn Research Center Report NASA/TP-2000-210031; NASA Glenn Research Center: Cleveland, OH, USA, 2000. [Google Scholar]

- Ozcer, N.; Schnell, P.B.; Fleming, M.S. Aerodynamic performance degradation of iced NACA 2412 airfoil under varying ice thickness. Cold Reg. Sci. Technol. 2021, 188, 103425. [Google Scholar]

- Jiang, J.; Wang, Y. Studies on the Electro-Impulse De-Icing System of Aircraft. Aerospace 2019, 6, 67. [Google Scholar] [CrossRef]

- Zumwalt, G.W. Electro-Impulse De-Ice Testing Analysis and Design; NASA Contractor Report 1799; NASA Scientific and Technical Information Division: Washington, DC, USA, 1988. [Google Scholar]

- Guan, X.; Zhang, H.; Shi, Y.; Wang, Z. Numerical and experimental study on the fracture characteristics of electro-impulse de-icing for aircraft wings. Eng. Fract. Mech. 2025, 295, 110555. [Google Scholar]

- Velkoff, V.; Ketcham, A. Electro-Impulse De-Icing of Aircraft Structures; NASA Contractor Report CR-1799; NASA Lewis Research Center: Cleveland, OH, USA, 1968. [Google Scholar]

- Power, D. Electro-Impulse De-Icing System for Aircraft; NASA Contractor Report 195459; NASA Lewis Research Center: Cleveland, OH, USA, 1995. [Google Scholar]

- Goraj, Z. An overview of the deicing and antiicing technologies with prospects for the future. In Proceedings of the 25th International Congress of the Aeronautical Sciences (ICAS), Yokohama, Japan, 29 August–3 September 2004; p. 547. [Google Scholar]

- Palacios, J.; Smith, C.; Brown, D.C. Development of an electro-thermal anti-icing system for wind turbine blades. J. Sol. Energy Eng. 2011, 133, 011007. [Google Scholar]

- Quayson-Sackey, E.; Endalew, T.A.; Jonkman, J.M. Technological advancements for anti-icing and de-icing blade section control. Cold Reg. Sci. Technol. 2024, 226, 104070. [Google Scholar] [CrossRef]

- IEC 61400-1:2019; Wind Turbines—Design Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2019.

| Technique | Principle | Energy Use | Effectiveness | Integration Complexity |

|---|---|---|---|---|

| Electric Heating | Resistive heating | High | High | Moderate |

| Electro-Impulse (EIDI) | Magnetic shock pulse | Low | High | High |

| Ultrasonic Vibrations | Acoustic vibration | Low | Moderate | Moderate |

| Mechanical Actuators | Blade surface movement | Medium | Moderate | High |

| Pneumatic Boots | Surface inflation | Medium | Moderate | Moderate |

| Intelligent Hybrid Systems | Sensor-driven optimized | Variable | High | High |

| Material | Property | Value | Unit |

|---|---|---|---|

| Aluminum Plate | Electrical Conductivity | 3.5 × 107 | S/m |

| Density | 2700 | kg/m3 | |

| Young’s Modulus | 70 | GPa | |

| Poisson’s Ratio | 0.33 | - | |

| Copper Coil | Electrical Conductivity | 5.8 × 107 | S/m |

| Turns per Coil | 10 | - | |

| Coil Radius | 30 | mm |

| Parameter | Value | Unit | Description |

|---|---|---|---|

| 5000 | A | Peak current amplitude | |

| τ | s | Decay time constant | |

| Tp | s | Pulse duration (for reference) |

| Blade Length (m) | Linear Scaling (kWh/Season) | Zone-Based Scaling (kWh/Season) |

|---|---|---|

| 30 m | ~750 | ~540 |

| 50 m | ~1250 | ~900 |

| 80 m | ~2000 | ~1450 |

| Blade Length (m) | Pulse Rate (Pulses/Min) | Seasonal Energy (kWh) |

|---|---|---|

| 30 | 3 | 330 |

| 30 | 5 | 550 |

| 30 | 8 | 880 |

| 50 | 3 | 540 |

| 50 | 5 | 900 |

| 50 | 8 | 1440 |

| 80 | 3 | 870 |

| 80 | 5 | 1450 |

| 80 | 8 | 2320 |

| Blade Length (m) | Method | Seasonal Energy (kWh) |

|---|---|---|

| 30 | EIDI (5 pulses/min) | 550 |

| 30 | Thermal | ~8000 |

| 30 | Ultrasonic | ~3.5 |

| 50 | EIDI (5 pulses/min) | 900 |

| 50 | Thermal | ~13,000 |

| 50 | Ultrasonic | ~4.5 |

| 80 | EIDI (5 pulses/min) | 1450 |

| 80 | Thermal | ~19,500 |

| 80 | Ultrasonic | ~6.0 |

| Method | Energy Demand (kWh/Season, 50 m Blade) | Reliability (Ice Types) | Fatigue/Structural Impact | Integration Complexity | Key Trade-Offs |

|---|---|---|---|---|---|

| EIDI | ~900 (5 pulses/min) | High (rime + glaze) | Possible fatigue near joints under repeated impulses | Moderate (coils, capacitors, HV safety) | Efficient vs. thermal, less effective than anti-icing, structural fatigue requires study |

| Thermal | ~13,000 | High (all ice types) | Minimal fatigue, but long-term heating may degrade coatings | High (large heating mats, high power draw) | Reliable but very energy-intensive |

| Ultrasonic | ~4–5 | Moderate (rime ice only) | Low fatigue, but adhesives can degrade | High (actuator integration, bonding reliability) | Ultra-low energy but limited effectiveness for thick glaze ice |

| Hybrid | 6000–10,000 | Very High (sensor-triggered) | Low-Moderate (depends on subsystem) | Very High (complex control + integration) | Balances prevention + removal, but cost and system complexity are high |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Preonto, S.; Swarnaker, A.; Khan, A.A. Comprehensive Analysis of De-Icing Technologies for Wind Turbine Blades: Mechanisms, Modeling, and Performance Evaluation. Energies 2025, 18, 5486. https://doi.org/10.3390/en18205486

Preonto S, Swarnaker A, Khan AA. Comprehensive Analysis of De-Icing Technologies for Wind Turbine Blades: Mechanisms, Modeling, and Performance Evaluation. Energies. 2025; 18(20):5486. https://doi.org/10.3390/en18205486

Chicago/Turabian StylePreonto, Sayed, Aninda Swarnaker, and Ashraf Ali Khan. 2025. "Comprehensive Analysis of De-Icing Technologies for Wind Turbine Blades: Mechanisms, Modeling, and Performance Evaluation" Energies 18, no. 20: 5486. https://doi.org/10.3390/en18205486

APA StylePreonto, S., Swarnaker, A., & Khan, A. A. (2025). Comprehensive Analysis of De-Icing Technologies for Wind Turbine Blades: Mechanisms, Modeling, and Performance Evaluation. Energies, 18(20), 5486. https://doi.org/10.3390/en18205486