1. Introduction

In the context of the increasingly severe global climate change, greenhouse gas emissions-induced global warming has become a major environmental challenge threatening human survival and development [

1]. The Sixth Assessment Report by the Intergovernmental Panel on Climate Change (IPCC) points out [

2], since the Industrial Revolution, the global average temperature has risen by approximately 1.1 °C. If strong emission reduction measures are not adopted, the temperature increase might exceed 2 °C by the end of this century, leading to frequent extreme weather events, sea level rise, ecosystem collapse, and other severe consequences. The thermal power sector, as one of the main sources of energy consumption and carbon emissions, its accuracy and reliability of carbon emission data are crucial for the effective operation of the carbon market, the formulation of emission reduction policies, and the progress of global climate governance [

3]. According to data from the International Energy Agency (IEA) [

4]. In 2022, carbon emissions from the global power sector accounted for more than 40% of total emissions, of which the thermal power industry contributed about 70% of the power sector’s carbon emissions [

5]. Therefore, precise monitoring and accounting of thermal power carbon emissions have become a core link in global emission reduction actions.

Existing studies on thermal power carbon emission data quality control have mainly focused on single-region system introductions or partial technical comparisons. For example, some studies only elaborate on the EU’s MRR/AVR regulatory framework but lack in-depth cross-regional analysis of management mechanisms [

6]; others compare the U.S. and China’s monitoring technologies but ignore the linkage between regulatory systems and market applications [

7]. Few studies have systematically constructed a “regulatory-technical-management” three-dimensional comparison framework covering China, the EU, and the U.S., nor have they targeted China’s 2024 legalization of CEMS data to conduct forward-looking risk analysis.

The quality control system for carbon emissions from thermal power in the European Union has undergone several years of development. In 2003, the “Directive 2003/87/EC” was issued [

8], which first incorporated greenhouse gas emissions into systematic legal management, marking the start of the “basic establishment phase” [

9]. During this period, between 2004 and 2007, the “Greenhouse Gas Emission Accounting and Reporting Guide (MRG)” was revised, clarifying the initial monitoring principles [

10]. In 2012, the EU introduced the “Monitoring Reporting Regulation (MRR, EU 601/2012) [

11]” and the “Verification Regulation (AVR, EU 600/2012) [

12]”, establishing a closed-loop monitoring reporting verification (MRV) system, transitioning into the “system maturity phase”. In 2015, the full quality control mechanism of QAL1-QAL3+AST was implemented across thermal power units above 20 MW [

13]. From 2018 onwards, it has been the “optimization and upgrade phase”, where the EU continuously updates standards such as EN 15267-3 [

14], enhancing the adaptability of CEMS to complex conditions. The annual uncertainty consistency of thermal power carbon emission data has reached 92%.

The development of the data quality control system for carbon emissions from thermal power in the United States is marked by key policy and technical milestones. The 1990 amendment to the Clean Air Act introduced the “Acid Rain Program [

15],” requiring controlled power facilities to carry out CO

2 monitoring. In 1993, a pilot verification of flue gas flow CEMS was organized, confirming the accuracy of ultrasonic flow meters, and initiated the “pilot exploration phase.” From 2000 to 2010, it entered the “standardization phase,” where the U.S. Environmental Protection Agency (EPA) issued 40 CFR Part 75 in 2000 [

16], establishing the CEMS regulatory framework, and introduced 40 CFR Part 98 in 2009 [

17], mandating annual greenhouse gas reporting. In 2008, the ASTM established the D7036 standard to regulate laboratory qualifications. In 2011, the EPA updated 40 CFR Part 75, requiring tests to be conducted by ASTM D7036 certified laboratories. In 2018, the U.S. National Institute of Standards and Technology (NIST) established both model-level and industrial-level flue gas flow testing platforms [

18]. In 2020, the U.S. Electric Power Research Institute (EPRI) developed an automatic positioning Pitot tube to further reduce manual operation errors [

19].

The establishment of a data quality control system for carbon emissions from thermal power generation in China started relatively late, but it exhibits significant phased characteristics. In 2013, the National Development and Reform Commission issued the “Guidelines for Greenhouse Gas Accounting in the Power Generation Industry (Trial)”, establishing the dominance of the emission factor method (error ±8–12%) [

20]. From 2017 to 2020, it entered the “CEMS pilot phase”, with the release of the “Technical Specifications for Continuous Monitoring of CO

2 in Flue Gas from Thermal Power Generation” in 2017, marking the inclusion of CEMS in the management system. By 2020, domestically produced CEMS based on non-dispersive infrared technology was applied on a small scale within key power generation groups. The period from 2021 to 2024 is the “system construction phase”, with the national carbon market launching in 2021, covering 2162 power generation companies [

21]. In the same year, 22 of the first batch of thermal power units began a carbon monitoring pilot, which expanded to 114 units in 2023. In 2024, the “Work Plan for Improving the Carbon Emission Statistics and Accounting System” was released, formally establishing the legal status of CEMS data as the basis for carbon trading compliance.

In this context, it is of great theoretical and practical significance to systematically review the quality control systems for thermal power carbon emissions in the European Union, the United States, and China, analyze the characteristics of the three in terms of regulatory standards, quality indicators, and control mechanisms, and summarize the international experiences that can be applied to China, use a three-dimensional framework of “regulatory effectiveness-technology adaptability management operability” to compare the data quality control system of direct carbon emission from thermal power generation in China, the EU and the U.S. The primary dimensions and secondary indicators are selected. The data is cross-verified with multi-source materials to eliminate bias, and typical cases are used to reflect actual effects. To ensure the regulatory documents included in the study are representative and relevant, this research adopts the following screening method: prioritize documents with legal binding force, with non-mandatory guidelines only retained if they reflect core implementation details. Furthermore, they must simultaneously meet the criteria of “covering thermal power CO2 emissions monitoring/reporting/verification” and “containing technical indicators or management rules”, retaining historical documents that form the basis of the current framework. Comparative analysis combines horizontal comparison and longitudinal evolution tracking, and it also links system design with actual effects to illuminate its merits and demerits. This will not only help improve the quality control system for thermal power carbon emission data in China, enhance the credibility of the data, and support the healthy operation of the national carbon market, but also provide a “Chinese solution” for global climate governance and promote mutual recognition and cooperation in international carbon emission data.

This study’s novelty lies in three aspects: First, it constructs a cross-regional comparative framework integrating “regulatory effectiveness technical adaptability management operability”, which fills the gap in existing studies that focus on partial dimensions. Second, it targets China’s 2024 legalization of CEMS data, and for the first time analyzes the potential risks of data application in carbon trading from the perspectives of regional differences and technical bottlenecks. Third, it proposes an integrated quality control system suitable for China’s national conditions, which provides a “Chinese solution” for global climate governance while supporting the healthy operation of China’s carbon market.

2. Thermal Power Carbon Emission Data Quality Control in EU

The EU started early in terms of quality control of carbon emissions from thermal power generation. After many years of development, a comprehensive and rigorous system has been established, covering various aspects including regulatory standards, hierarchical management, end-to-end control, and neutrality guarantees. This provides an important reference model for global quality control of carbon emissions from thermal power generation.

2.1. Regulatory Standard System: A Multi-Level, Systematic Legal Framework

The European Union has established a three-tier systematic management model of “Directive-Norm-Standard”, providing a solid legal foundation and technical support for the quality control of thermal power carbon emission data. This ensures that every aspect from top-level design to specific implementation has laws to follow and regulations to adhere to (

Table 1).

The “Directive 2003/87/EC” issued in 2003 [

22] is a fundamental legal document for the EU’s greenhouse gas management. It clarifies the overall principles of comprehensive management of greenhouse gases, including explanations of monitoring methods and general requirements for quality control, laying the foundation for subsequent related regulations and standards. The introduction of this directive marks the beginning of the EU’s inclusion of greenhouse gas emissions into a systematic and law-based management track.

Based on Directive 2003/87, the EU continuously improved relevant regulations. In 2012, the EU introduced the Monitoring and Reporting Regulation (MRR, EU 601/2012) [

11] and the Accreditation and Verification Regulation (AVR, EU 600/2012) [

12], forming a Monitoring, Reporting, and Verification (MRV) system. These two regulations replaced some of the previous directives and guidelines, further refining the requirements for monitoring, reporting, and verification of carbon emissions from thermal power generation, ensuring that each link of quality control has a clear legal basis. Among them, MRR mainly stipulates the specific processes, methods, and requirements for monitoring and reporting, while AVR focuses on the standards and procedures for certification and verification. The two complement each other, forming a complete closed-loop management system.

Table 1.

The main legal provisions and standards involved in EU data quality control are as follows.

Table 1.

The main legal provisions and standards involved in EU data quality control are as follows.

| Title 1 | Title 2 | Title 3 |

|---|

| Directive 2003/87 | Directive 2003/87/EC of the European Parliament and of the Council | fundamentals of law |

| EU 601/2012 | Monitoring and reporting regulation (MRR) | Monitoring report guidance document |

| EU 600/2012 | Accreditation and verification regulation (AVR) | Monitoring report guidance document |

| EN 14181 | Stationary source emissions-Quality assurance of automated measuring systems | Overall quality assurance standards |

| EN 15267-3 [23] | Air quality-Certification of automated measuring systems-Part 3: Performance criteria and test procedures for automated measuring systems for monitoring emissions from stationary sources | Quality Assurance Program |

| EN ISO 14956 | Air quality-Evaluation of the suitability of a measurement procedure by comparison with a required measurement uncertainty | Quality assurance performance indicators |

| EN 15259 | Stationary source emissions-Requirements for the measurement sections and sites and for the measurement objective, plan and report CEMS | Installation of CEMS and selection of sampling points |

| ISO 12039 | Stationary source emissions-Determination of carbon monoxide, carbon dioxide and oxygen-Performance characteristics and calibration of automated measuring systems | Reference method for CO2 standards |

| EN ISO/IEC 17025 | General requirements for the competence of testing and calibration laboratories | Certification process for laboratories and experimental instruments |

In addition to directives and regulations, the EU has a series of supporting standards that provide detailed provisions from the overall standards of quality assurance, specific procedures to performance indicators, ensuring the standardization and normalization of quality control work. For example, EN 14181 “Quality Assurance for Automatic Measurement Systems for Stationary Source Emissions” [

24] is one of the most important and demanding standards ever developed by the European Committee for Standardization, laying the foundation for the EU’s CEMS quality assurance system; EN 15267-3 “Air Quality-Automatic Measurement System Accreditation-Part 3: Performance Criteria and Test Procedures for Monitoring Automatic Measurement Systems for Stationary Source Emissions” specifies the performance criteria and test procedures for monitoring automatic measurement systems for stationary source emissions [

23]. EN ISO 14956 “Air Quality-Assessment of the Suitability of Measurement Procedures by Comparison with Required Measurement Uncertain” [

25] provides a basis for assessing the suitability of measurement procedures.

The regulatory standard system of the EU has the characteristic of dynamic adjustment. With the advancement of monitoring technology and new situations arising in practical applications, the European Commission timely adjusts, enriches, and improves regulations and standards. For example, the “Greenhouse Gas Emission Accounting and Reporting Guidelines” (MRG) have undergone revisions from MRG2004 to MRG2007 [

26]. The MRR and AVR introduced in 2012 are further developments based on previous regulations, making the quality assurance system more adapted to actual needs. This dynamic adjustment mechanism ensures that EU regulatory standards can always keep up with the pace of development, providing continuous and effective guarantees for the quality control of carbon emissions data from thermal power plants.

2.2. Graded Management of Data Quality: Differential Control Based on Emission Volumes

The EU uses uncertainty as the core indicator to reflect the quality of carbon emission data from thermal power generation, and implements graded management based on the annual CO

2 emission volume of power plants [

27]. This approach ensures data quality while taking into account the monitoring costs of enterprises, demonstrating strong practicality and operability.

Uncertainty integrates the concepts of precision and accuracy, reflecting both the authenticity and repeatability of data. It is one of the commonly used parameters internationally to indicate data quality [

28]. Using uncertainty as a core indicator allows for a more comprehensive and scientific evaluation of the quality of thermal power carbon emission data.

The data quality levels are divided into 4 levels; the lower the emission amount, the lower the level, and the higher the allowed maximum uncertainty. The specific grading is shown in

Table 2:

The rationale for this tiered management approach is that, for power plants with smaller emission volumes, appropriately relaxing data quality requirements can reduce their monitoring costs and avoid overburdening the enterprises. On the other hand, for power plants with larger emission volumes, stringent data quality requirements help ensure the accuracy of overall carbon emission data, as their emissions have a greater impact on regional and even global carbon emission totals. Through this differentiated management method, the EU effectively controls data quality while also taking into account the actual situation of enterprises of different scales, enhancing the enthusiasm of enterprises to participate in carbon emission monitoring and management.

EU Tier 1–4 uncertainty limits are calculated based on the “GUM (Guide to the Expression of Uncertainty in Measurement)” framework, integrating random errors and systematic errors of CEMS [

29], with specific steps and formulas specified in EN ISO 14956 (“Air Quality-Evaluation of the Suitability of a Measurement Procedure by Comparison with a Required Measurement Uncertainty”) and MRR (EU 601/2012) Annex V.

The combined standard uncertainty

uc (expanded to k = 2 for 95% confidence level, resulting in the final uncertainty

U = 2

uc is calculated as follows:

whereas

u1 is uncertainty from flue gas flow measurement,

u2 is uncertainty from CO

2 concentration measurement,

u3 is uncertainty from auxiliary parameters.

For an 800 MW coal-fired unit (Tier 4, required uncertainty ≤ ±2.5%):

Measure

u1 = 1.2% (X-type dual-channel ultrasonic flowmeter, calibrated per EN ISO 12039 [

30]),

u2 = 0.8% (NDIR CO

2 analyzer, verified via QAL2 against SRM [

31]),

u3 = 0.3% (temperature/pressure sensors, daily zero calibration [

32]).

uc is calculated as follows:

Final uncertainty U = 2uc = 2.94%, exceeds Tier 4 requirements. After optimizing flowmeter sensor layout (per CFD simulation, reducing u1 to 0.9%), recalculate uc = 1.22%, U = 2.44%, meeting Tier 4 standards.

2.3. Full Process Quality Control: Comprehensive Management from Installation to Operation

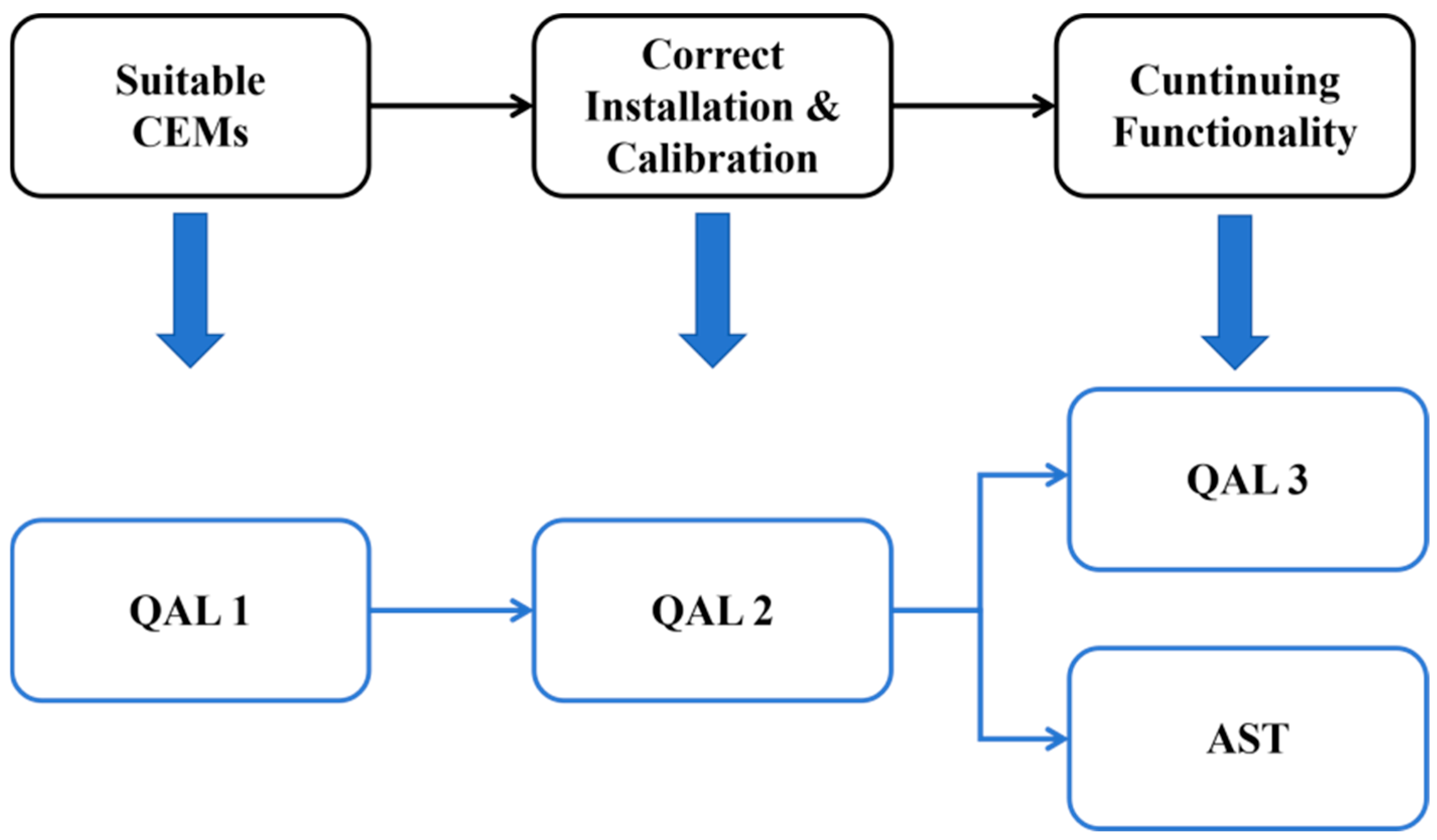

The quality control of thermal power carbon emission data in the European Union includes three Quality Assurance Levels (QAL) and one Annual Surveillance Test (AST), realizing comprehensive and continuous control from instrument installation to daily operation, ensuring that data quality is always within the prescribed uncertainty range (

Table 3 and

Figure 1).

2.3.1. QAL1: Suitability Assessment Before Installation

The purpose of QAL1 assessment [

33] is to ensure that the installed instrument can transmit data normally, stably, continuously and accurately after installation. Suitability assessment includes laboratory tests and at least 3 months of field tests.

Laboratory tests are mainly to check whether the instrument meets the relevant performance requirements under controlled conditions, such as the reaction index of the instrument (response time, standard deviation of repeatability at zero and span points), environmental impact index (temperature, sample gas pressure, voltage change, vibration, interference cross-sensitivity) and so on. Through laboratory tests, instruments that meet the basic performance requirements can be preliminarily screened, which lays a foundation for the subsequent field tests.

The on-site applicability test is to ensure that the instrument can maintain stability, continuous operation, and good technical performance under actual harsh conditions, such as linearity, zero drift, span drift, and reproducibility under field conditions. The environment of the field test is consistent with the actual operating environment, which can more realistically reflect the actual performance of the instrument, ensuring that the instrument can adapt to complex field conditions after installation.

The laboratory and on-site dual-phase testing of QAL1 directly reduces the fundamental uncertainty of carbon market data from the source. For example, in the QAL1 phase of a 600 MW coal-fired power unit in Germany, through 3 months of on-site testing, it was found that: the CO

2 concentration measurement deviation of CEMS without adaptive screening reached 12% under high temperature conditions in the flue gas (>180 °C), which is far beyond the ±2.5% required by the EU Tier 4 (>500,000 t); After QAL1 screening and replacing with high-temperature resistant sensors, the deviation was reduced to 1.8%, ensuring that the initial uncertainty of the subsequent carbon market compliance data of this unit meets regulatory requirements. According to the 2023 MRV system evaluation report of the European Commission, the CEMS that have undergone QAL1 can reduce the uncertainty of carbon market basic data by 40–60%, avoiding quota accounting biases caused by insufficient instrument adaptability (reducing the annual quota dispute volume of a single unit by about 20,000 t CO

2 on average) [

34].

2.3.2. QAL2: Calibration and Verification After Installation and Data Deviation

QAL2 assessment is required after the installation of the CEMS or when the monitoring data deviates outside the accuracy range of monitoring [

35]. This evaluation, conducted by national accredited laboratories, serves two purposes: one is to determine whether the instrument function continues to be normal, and the other is to calibrate and verify the instrument, timely adjusting the instrument to reduce systematic errors.

In the QAL2 evaluation, the monitoring data will be compared with a series of measurement results using approved standard reference methods (SRM), and the instrument will be calibrated according to the comparison results to ensure the accuracy of the instrument’s measurement. The standard reference method has high accuracy and authority. By comparing with the standard reference method, problems existing in the instrument measurement process can be effectively discovered and targeted adjustment and calibration can be performed.

QAL2 calibration, through comparison with the Standard Reference Method (SRM), directly corrects systematic errors, providing a key guarantee for the accuracy of carbon market data. Taking a 400 MW gas unit in France as an example, its CEMS exhibited data drift after 18 months of operation, with CO

2 concentration measurements underestimating the actual values by 7% (if used directly in the carbon market, the annual emissions would be under-reported by approximately 8500 t CO

2, leading to a shortfall in quota payments by the company of about 850,000 Euros); after undergoing QAL2 assessment by a laboratory certified to the EU EN ISO 14956 standard and calibration using SRM (gas chromatography), the error was reduced to 2.2%, meeting the requirements of Tier 3 (50,000–500,000 t) ±5.0%. EU ETS data shows that between 2020 and 2023, units calibrated through QAL2 had their carbon emission accounting errors reduced by 65% compared to uncalibrated units, and the rate of carbon market compliance disputes decreased from 12% to 3.5% [

36].

2.3.3. QAL3: Continuous Monitoring During Operation

During the normal operation of CEMS, it is necessary to conduct QAL3 monitoring to ensure the continuous stability of data quality [

37]. QAL3 typically uses quality control charts to evaluate the results of periodic zero and span checks of CEMS. By analyzing the data trend in the quality control charts, it predicts the possibility of the instrument going out of control, allowing for timely adjustments or operational maintenance of the CEMS.

This continuous monitoring can cause problems during the operation of the instrument, take measures to correct them, and ensure the accuracy and reliability of the data. Quality control charts are an intuitive and effective data analysis tool that can help operators promptly detect abnormal changes in the data, providing a basis for the maintenance and adjustment of the instrument.

Real-time quality control chart monitoring of QAL3 can dynamically suppress data fluctuations and maintain the long-term stability of carbon market data. In the QAL3 phase of a 200 MW coal-fired power unit in Poland, through daily zero/span checks and quality control chart analysis, it was found that after a sudden drop in boiler load (from 80% to 30%), the CEMS flow measurement drift reached 6% (if not intervened in time, the monthly emission calculation deviation would reach 4200 t CO2); based on the quality control chart warning, the operation and maintenance team completed equipment debugging within 24 h, and the drift was controlled within 1.5%. Statistics from the European Environment Agency show that the monthly fluctuation range of carbon emission data of units implementing QAL3 has been reduced from ±8% to ±3%, providing reliability support for the “monthly data retrospection” of carbon market quota settlement, avoiding annual performance deviations caused by short-term data anomalies.

2.3.4. AST: Annual Surveillance Test

An AST is carried out once a year by an accredited laboratory in accordance with EN 14181 [

38]. The AST is a test of the variability and validity of the calibration function of the instrument, which demonstrates through testing that the instrumentation equipment is complete and effective, and that the calibration function has not changed.

The AST is a comprehensive inspection of the annual operation of the CEMS, and is an important link to ensure the long-term stable operation of the instrument. Through annual surveillance tests, the performance status of the instrument can be fully evaluated, potential problems can be discovered in time, providing a basis for the maintenance and updating of the instrument.

The annual comprehensive verification of AST prevents the accumulation of long-term uncertainties caused by the degradation of equipment performance, ensuring the cross-year comparability of carbon market data. Data from an 800 MW coal-fired power unit in Spain over three consecutive years of AST show that before the implementation of AST, the annual measurement error of its CEMS increased by an average of 2.1% (with the error reaching 7.8% in the third year, exceeding the Tier 4 requirements). After introducing AST, problems such as sensor aging and pipeline leaks were promptly discovered through the EN 15267-3 standard testing every year, and the error was controlled within the range of 2.3–2.5%. Tracking data from the EU MRR regulation (EU 601/2012) indicate that after the mandatory implementation of AST, the annual uncertainty consistency of carbon emission data from EU thermal power companies increased to 92% (a 38% improvement compared to before), directly reducing the accounting risk of cross-year quota carryover in the carbon market.

2.4. Neutrality Guarantee Mechanism: Institutional Support for CEMS Construction and Operation

In order to ensure the neutrality and objectivity of the construction and operation of CEMS systems, the European Union has adopted a series of measures, strictly controlling for aspects such as institutional independence, process standardization, and personnel capabilities.

At the EU level, it is stipulated that the third-party institutions responsible for carbon emission data verification must be independent of thermal power enterprises, to avoid affecting the impartiality of the verification results due to conflicts of interest [

39]. As an independent third party, the third-party verification institution can verify the carbon emission data of thermal power enterprises with an objective and impartial attitude, ensuring the authenticity and accuracy of the data.

A standard process, including application, construction, implementation, and maintenance, has been established to ensure the standardization and transparency of the construction and operation maintenance process of the CEMS system. The establishment of a standard process can reduce interference from human factors, improve work efficiency, and guarantee the quality of construction and operation maintenance of the CEMS system.

Regularly check the performance of the auditors to ensure that their capabilities maintain a certain level and achieve stable improvement. Through performance checks, auditors can be motivated to continuously improve their business abilities and professional competence, ensuring the quality of the audit work.

Establish technical personnel certification bodies at the member state level, and regularly evaluate technical personnel to ensure they possess the corresponding professional capabilities and operational skills. Technical personnel are the specific implementable of the construction and operation maintenance of the CEMS system, and their professional capabilities and operational skills directly affect the operation quality of the CEMS system and the accuracy of the data. Through the certification of technical personnel, the quality of technical personnel can be ensured, providing talent guarantee for the stable operation of the CEMS system.

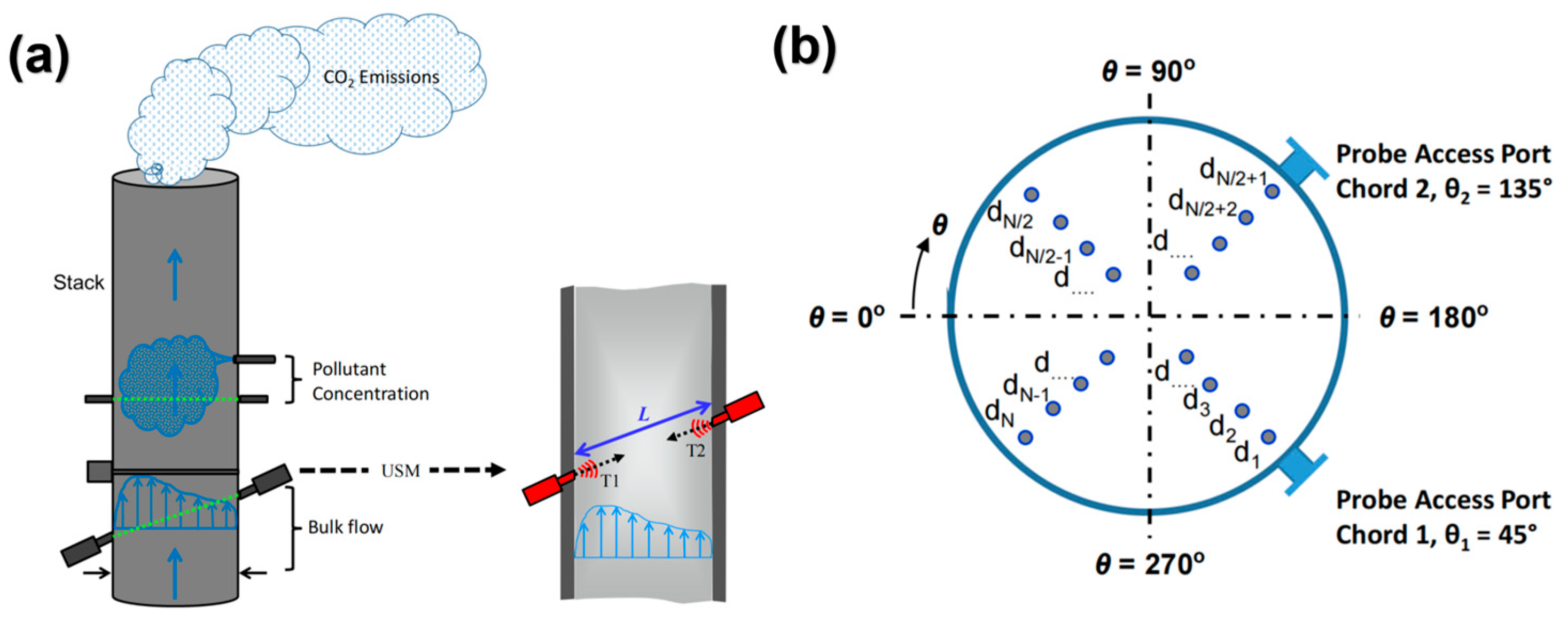

2.5. Technical Principles of EU Monitoring Systems

The EU’s thermal power carbon emission monitoring system is centered around the CEMS of “Non-dispersive Infrared (NDIR) concentration measurement + ultrasonic flow measurement”, strictly adhering to EN 14181 (Quality Assurance for Automated Measurement Systems) and EN ISO 12039 (Standard for Flue Gas Component Measurement), ensuring that data accuracy highly aligns with regulatory requirements. Its technology selection logic revolves around “full-adaptability”, addressing the complex characteristics of high temperature, high humidity, and high dust in thermal power flue gases. Through hardware design optimization and software algorithm compensation, it achieves stable measurement migration from laboratory to on-site, providing reliable technical support for the MRV system.

In the measurement of CO2 concentration, the NDIR technology has become mainstream due to its high specificity and low maintenance cost. This technology utilizes the characteristic absorption feature of CO2 for infrared radiation at a wavelength of 4.26 μm, calculating the concentration through a closed-loop process of “emission—absorption-detection”: the analyzer’s built-in infrared light source emits a stable light beam to the sample pool, where the CO2 molecules in the flue gas absorb part of the light energy. The detector then receives the remaining light intensity and converts it into an electrical signal, ultimately deducing the CO2 concentration based on the Lambert-Beer law. The 2024 revision of EN 15267-3 further upgrades technical requirements, mandating a dual-beam design (reducing annual drift to ±1%) and wide temperature range compensation (error ≤ ±0.5% in environments between −10~50 °C), effectively addressing the issue of traditional single-beam NDIR being easily affected by environmental temperature interference.

The flue gas flow measurement mainly relies on X-type dual-channel ultrasonic flowmeters (with a market share of 65%). The core principle is the “time-difference method”: the flowmeter symmetrically arranges two pairs of ultrasonic transducers in the flue, alternately transmitting signals in the downstream and upstream directions. The flow of flue gas shortens the transmission time of the downstream signal and lengthens that of the upstream signal. By calculating the difference between the two times, combined with the speed of sound, the distance between transducers, and the angle between the acoustic path and the flow direction, the flue gas flow rate is calculated. European standard EN 15259 explicitly requires that before installation, the distribution of the flow field inside the flue must be simulated using Computational Fluid Dynamics (CFD) software (Ansys Fluent Workbench 18.0) to optimize the installation angle and position of the transducers. For example, to address the swirling flow problem at bends in the flue, adjusting the acoustic path angle reduces the measurement error from 8% to ≤2.5%, ensuring that the flow data of large emission units (Tier 4) meet the uncertainty requirement of ±2.5%.

3. Data Quality Control of Carbon Emissions from Fire Power Generation in the U.S.

The data quality control system for thermal power carbon emissions in the United States is supported by comprehensive regulations, centered on clear quality indicators, and guaranteed by strict audit mechanisms, forming a scientific and rigorous management model. It has accumulated rich experiences in technology application, institutional design, and practical effects, which holds significant reference value for the construction of related systems in other countries worldwide.

3.1. Regulatory System Support: Multi-Level, Full-Coverage Legal Protection

In the U.S., the quality control of carbon emissions from thermal power generation is based on the “Clean Air Act”. Subsequent federal regulations have been introduced for the detailed standardization of monitoring and reporting of carbon emissions from thermal power generation, forming a multi-level and comprehensive legal guarantee system. This provides a solid legal foundation for the precise monitoring and effective management of carbon emissions from thermal power generation.

In 1970, the United States Congress passed the Clean Air Act [

40], to address the increasingly serious problem of air pollution. In 1990, the act was significantly revised and innovatively introduced the “Acid Rain Program” [

41,

42,

43], which regulates the emissions of SO

2 and NO

x from fossil fuel power generation units. It requires relevant thermal power plants to install CEMS or use other alternative monitoring methods with equivalent measurement effects. At the same time, it specifically requires power facilities included in the control to simultaneously implement CO

2 emission monitoring, laying a legal foundation for the quality control of carbon emissions data from thermal power generation.

On the basis of the Clean Air Act, EPA formulated a series of federal regulations [

44,

45,

46,

47], such as 40 CFR Part 75 and 40 CFR Part 98.

The 40 CFR Part 75 “Continuous Emission Monitoring” [

11] systematically establishes a regulatory framework for CO

2 emissions from thermal power plants, granting them the autonomy to choose between continuous emission monitoring methods or accounting methods. At the same time, it provides detailed regulations from perspectives such as equipment configuration requirements, operational maintenance standards, and data quality assurance measures. It also specifies the Relative Accuracy Test Audit (RATA) as the mechanism to evaluate and verify the accuracy of monitoring data.

40 CFR Part 98 “Mandatory Greenhouse Gas Reporting” [

12] requires large direct emission facilities, fossil fuel and greenhouse gas supply enterprises, etc., to report annual greenhouse gas data, covering most units in the thermal power industry. The regulation stipulates the monitoring methods for different types of thermal power units, such as those included in the “Acid Rain Program” still follow the requirements of 40 CFR Part 75 to monitor and report CO

2 emissions. For general stationary combustion facilities with annual emissions exceeding 25,000t CO

2 e, different monitoring methods are specified according to the type of fuel, etc. The specific monitoring methods and features are shown in

Table 4 below.

These regulations complement each other, forming a comprehensive control over the entire process of carbon emission data from monitoring, reporting to auditing in thermal power generation, ensuring the accuracy and reliability of the data. This makes the management of carbon emissions in American thermal power generation lawful and standardized, providing institutional support for effective carbon emission control.

3.2. Quality Control Indicators and Requirements: Clear and Actionable Criteria

The United States mainly represents the accuracy of carbon emission monitoring data from thermal power generation in terms of calibration error and has set clear requirements for different monitoring links, with strong operability. These standards provide clear guidance for the monitoring work of thermal power enterprises and also provide a specific basis for the audit of regulatory authorities.

40 CFR Part 98 stipulates that when calculated with reference values, the calibration error of each measurement point shall not exceed 5% of the reference value; when calculated with both reference values and full-scale values, each measurement point shall not exceed 2% of the full-scale value or the sum of calibration errors of three measurement points at each calibration level shall not exceed 6%.

For the flue gas flow rate and CO2 concentration measured by CEMS, the median relative accuracy is approximately 2%, and it must not exceed 10%, with a reduction in RATA inspection frequency if it does not exceed 7.5%. Based on actual monitoring data, the accuracy of CEMS measurements for flue gas flow rate and CO2 concentration in U.S. thermal power units is relatively high and has remained stable in recent years. Specifically: for the flue gas flow rate, the median relative accuracy is about 2%, the maximum value is about 7.5%, 75% of the units are below 4%, and 25% of the units are close to 1%; for CO2 concentration, the median relative accuracy is approximately 2%, the maximum value is approximately 6.5%, 75% of the units are below 3.5%, and 25% of the units are close to 1%. These clear indicators provide a defined standard for the monitoring work of thermal power companies and a basis for regulatory audits, ensuring the quality of monitoring data and making the data from different companies and units comparable and reliable.

3.3. Inspection Agencies and Review Mechanisms: Strict and Standardized Quality Control

To ensure the quality of carbon emission monitoring data from thermal power generation, the United States has established strict mechanisms for the management of testing institutions and data review. From the qualification recognition of testing institutions to the data review process, detailed regulations have been implemented to guarantee the authenticity and accuracy of the monitoring data.

The American Society for Testing and Materials (ASTM) has formulated the “Standard Specification for the Competence of Air Emission Testing Laboratories” (ASTM D7036), which stipulates the quality management system and personnel qualifications of testing institutions [

48,

49]. This standard requires air emission testing institutions to prepare a quality management manual, equip technical management, quality supervision, and certified testing personnel, and formulate a detailed test plan before the project is implemented. The plan includes the objectives and overview of the test project, unit information, test list, sampling locations, test methods, test schedule, involved process data, quality control and audit plans, report formats and data units, power plant entry permits and safety measures, division of personnel responsibilities, and a tentative test schedule, etc., and implement an annual internal audit system to ensure that all testing activities comply with the standard specifications.

The Stack Testing Accreditation Committee (STAC) is responsible for conducting the certification of air emission testing institutions, further ensuring the competence and level of these institutions. In 2011, when the U.S. Environmental Protection Agency updated 40 CFR Part 75, they introduced a minimum capability threshold for testing institutions. It was specified that starting from March 2012, thermal power facilities included in the “Acid Rain Program” must choose air emission testing institutions that have been certified through ASTM D7036, and the testing personnel must possess professional qualifications and practical experience [

50].

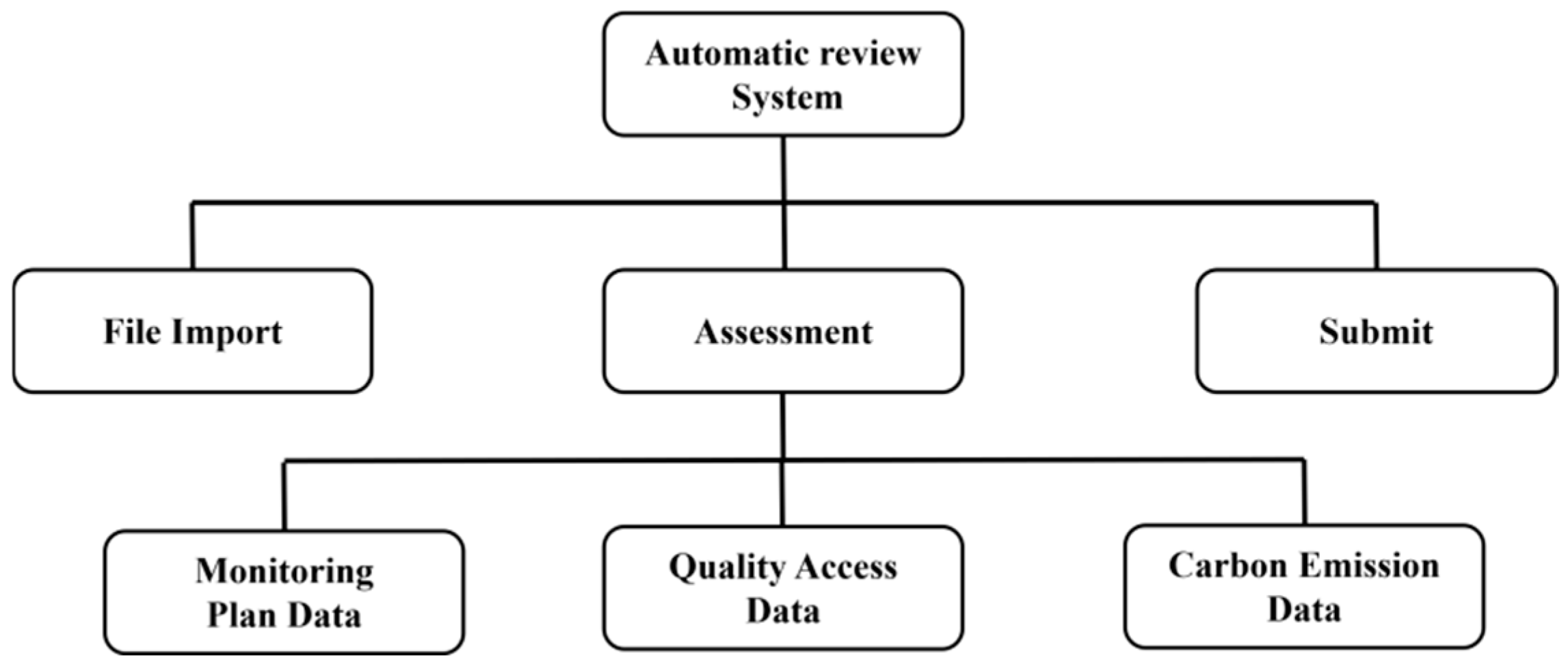

In terms of data audit, the U.S. adopts a combination of on-site audit and annual report audit.

The on-site audit uses TTFA (Targeting Tool for Field Audits) software (1.6.0.3) for preparatory work, which includes linear inspection tests, relative accuracy detection, whether to use over-range standard gas, calibration error test results, analyzer range, flow rate load ratio, data capture rate, missing data time period, and whether to continue using CEMS equipment after QA test failures, among other audit contents. According to the monitoring plan data and historical emission data (generally, at least 3 quarters of data need to be reviewed), the power plants that need on-site audits are selected. The content of the on-site audit includes historical data analysis, on-site instrument inspection, on-site maintenance log inspection, QA test investigation, and discussions with relevant personnel from the pollution source enterprise, which can comprehensively evaluate the quality of the power plant’s monitoring data (

Figure 2).

The annual report review is conducted by combining the automatic review system and manual check. The power plants are required to self-certify and submit their carbon emissions annual reports, and the automatic review system performs an automated check of the annual reports and provides real-time feedback of potential data errors to the power plants; after the reports are submitted to the database, the staff evaluates the reports based on the potential errors marked by electronic checks, and manually check to evaluate the marked reasons, and ensure the accuracy, completeness, and consistency of the data, and the specific process is shown in

Figure 3 below.

3.4. Technical Research and Development and Innovation: Continuously Improve the Monitoring Capacity

The U.S. places high importance on the research and development of carbon emission monitoring technology for thermal power. National research institutions play a crucial leading and supporting role in this area. Through continuous technological research and innovation, they continuously improve the accuracy and reliability of carbon emission monitoring for thermal power.

The NIST has long been dedicated to the research of greenhouse gas emission measurement methods and standards, establishing high-accuracy flue gas flow test platforms, including model-level and industrial-level platforms, for verifying the accuracy of various flue gas flow measurement technologies and improving them [

51]. In the model-level platform, the NIST regulates flue gas flow with low uncertainty flow control devices to verify the measurement accuracy of various types of flue gas flow measurement technologies and improve them. The simulation conditions of the industrial-level platform are closer to the actual production process. The NIST installs the flue gas flow meters that have been verified on the model-level platform in the industrial-level platform to further verify their measurement accuracy.

The NIST also proposed improvements for CEMS flue gas flow monitoring, such as recommending the use of multi-channel ultrasonic flowmeters to cope with the skew and vortex flow of flue gas in chimneys, thus enhancing measurement accuracy. The NIST’s experimental research shows that the measurement error of single-channel ultrasonic flowmeters is about 17%, while the measurement error of X-type dual-channel ultrasonic flowmeters is only 1% [

52]. Currently, some U.S. thermal power plants have adopted dual-channel ultrasonic flowmeters for flue gas flow monitoring. In spatial measurements, the NIST recommends using instruments such as three-dimensional laser scanners to determine the acoustic path length, angle, and stack diameter of the ultrasonic flowmeter, and to optimize the frequency and channel angle of the ultrasonic transducer to improve the accuracy of flue gas flow measurement. At the same time, in the process of formulating the ultrasonic transducer arrangement scheme, computational fluid dynamics software is used to simulate the distribution of flue gas flow field within the flue, enhancing the measurement effect of the ultrasonic flowmeter.

In addition, the NIST is also committed to improving the accuracy of flue gas flow measurement reference methods [

53,

54]. RATA takes the discrete measurement of the Pitot tube as the reference method, and evaluates the measurement accuracy of CEMS based on the reference method’s measurement values and relative errors. NIST believes that there are two problems with RATA that affect the accuracy evaluation of CEMS measurements (

Figure 4). On one hand, during the implementation process, a large number of RATA reference methods use S-type Pitot tubes, which are difficult to cope with complex flue gas flow field conditions and cannot ensure low uncertainty in their measurement results; on the other hand, manual operation in the RATA implementation process may introduce bias. In order to make the RATA reference method measurement results have low uncertainty and thus reduce the measurement uncertainty of CEMS, NIST has carried out extensive research on the Pitot tube flue gas flow measurement technology using a flue gas flow test platform, and developed a new three-dimensional Pitot tube to adapt to the complex flow field distribution such as swirling flow in chimneys. At the same time, the measurement and calibration process of the new Pitot tube has been improved to reduce the time and cost of measurement and calibration, and enhance the practicality of the new three-dimensional Pitot tube (

Figure 5).

The Electric Power Research Institute (EPRI) conducted a survey on the application of continuous monitoring systems for CO

2 emissions from thermal power plants in the U.S., calculated the measurement uncertainty, analyzed the key factors affecting measurement uncertainty, and proposed suggestions to reduce the uncertainty in continuous flue gas flow monitoring [

55,

56]. By comparing the CEMS measurements with the RATA reference method, EPRI calculated the measurement uncertainty of a 350 MW coal-fired power unit’s CEMS. The study showed that under high and low load conditions, the uncertainty of the CEMS flue gas flow measurements using a pressure differential flow meter were 3.8% and 5.9%, respectively.

EPRI offers optimization suggestions for the operation and maintenance management of ultrasonic flowmeters: ① The use of multi-channel ultrasonic flowmeters, such as the X-type, can significantly improve measurement accuracy. ② In terms of routine maintenance, it is recommended to perform an automated calibration verification daily, covering zero-point calibration and full-scale upper limit testing; conduct a disturbance check daily, including blowing and dusting of the ultrasonic transducers; quarterly, a systematic maintenance should be carried out, requiring on-site inspection of the blowing nozzles and updating of the air filtering device. For differential pressure flow measurement systems, EPRI recommends implementing automated calibration checks daily and simultaneously conducting air-tightness tests and Pitot tube back-blow cleaning; annually, a comprehensive calibration of the entire system should be performed, covering performance verification of core components such as pressure sensors and differential pressure transmitters.

For the installation and arrangement of flow meters, EPRI recommends the use of computational fluid dynamics software to assist in formulating flow meter installation plans. Through simulation modeling, the visualization of flue gas flow can be achieved, and the process of flue gas flow changes within the chimney can be demonstrated, thereby helping staff identify adverse flow features such as backflow and swirling flow. Additionally, during the process of installing flow meters, the impact of unfavorable factors such as flow stratification and non-axial flow can typically be alleviated by measures like installing adjusting vanes. Utilizing computational fluid dynamics modeling can economically and effectively simulate the effects of the above measures, thereby assisting installation decision-making. Regarding the measurement of installation dimensions, EPRI suggests using a laser rangefinder to measure the diameter of the chimney at the installation site of the flow meter, and calculating the average diameter of the chimney through multiple measurements; also, in order to fully reflect the thermal expansion effect of the chimney during unit operation, it is necessary to carry out chimney diameter measurement work under the conventional load conditions of the unit.

EPRI also proposes implementation suggestions for flue gas flow measurement reference methods. For measuring instruments, it is recommended to use an automatically positioning Pitot tube to discretely measure the flue gas flow field inside the chimney. The automatic positioning Pitot tube can eliminate uncertainties caused by manual operations, reducing the uncertainty of flue gas flow measurements by 2 percentage points. The Pitot tube used for testing must be calibrated in a wind tunnel, and parameters such as the speed, temperature, and turbulence of the airflow in the wind tunnel must be consistent with the on-site flue gas conditions in the chimney. To better measure subtle pressure differences, it is necessary to equip a certified, high-accuracy micro-manometer. Moreover, EPRI points out that when using reference method measurement values to correct CEMS in advance, the relative error between CEMS measurements and the reference method must be controlled within ±1%. Regarding the arrangement of measurement points, it is recommended to48 measurement points in two diameter directions of the chimney when using reference methods to measure flue gas velocity, to achieve accurate measurement of the flue gas flow field. At the same time, it is suggested to use a laser detector to measure the inner diameter of the chimney to improve the accuracy of the chimney’s inner diameter measurement.

The research and development of these technologies provide strong technical support for improving the quality of carbon emission data from thermal power in the United States, continuously promoting the advancement of monitoring technology and the accuracy of monitoring, ensuring that the United States maintains a leading position in the field of thermal power carbon emission monitoring.

3.5. CEMS Technical Route Selection

3.5.1. CEMS Flue Gas CO2 Concentration Monitoring Technology

In 1975, the U.S. Environmental Protection Agency revised 40 CFR Part 60, beginning a large-scale promotion for thermal power companies to install CEMS to measure flue gas pollutant concentrations. At the same time, in order to assist in calculating pollutant emissions, it was required to apply CEMS to measure the concentration of O2 and CO2 in flue gases. After long-term development and application, the accuracy and reliability of current CEMS CO2 concentration measurements have reached a high level. According to statistics from the professional environmental consulting firm RMB Consulting & Research, the vast majority of flue gas CO2 concentration meters equipped in U.S. thermal power CEMS use non-dispersive infrared technology, with more than 90% using the dilution method.

3.5.2. CEMS Flue Gas Flow Monitoring Technology

Compared to flue gas CO2 concentration, the continuous monitoring of flue gas flow rate started later. With the implementation of the “Acid Rain Program”, CEMS flue gas flow rate monitoring has been widely applied in the U.S. thermal power sector since 1993. Due to the relative lack of experience in the application of continuous flue gas flow rate monitoring, and the significant impact of CEMS flue gas flow rate measurements on SO2 emission monitoring results, the accuracy of CEMS flue gas flow rate measurement technology has received high attention. Before the implementation of the “Acid Rain Program”, the U.S. Environmental Protection Agency organized some thermal power units to conduct pilot verifications of various types of flue gas flow rate measurement methods, finding that ultrasonic flow meters have higher accuracy and reliability.

Currently, ultrasonic flow meters and differential pressure flow meters are both used in flue gas flow measurement of thermal power CEMS in the United States, among which ultrasonic flow meters are the most widely used and are the mainstream means of flue gas flow measurement in American thermal power CEMS. According to EPRI’s research, the use of ultrasonic flow meters accounts for about 65% of the total use of flue gas flow meters in American thermal power CEMS, while differential pressure flow meters account for about 30%. The manufacturer with the largest market share of ultrasonic flow meters is Teledyne, which produces 85% of the ultrasonic flow meters installed in the US; the manufacturer with the largest market share of differential pressure flow meters is EMRC.

Application of CEMS in carbon measurement for thermal power generation.

In terms of emission scale, the CO

2 emissions monitored by CEMS account for a high proportion of the total CO

2 emissions from US thermal power units. For thermal power units under the control of 40 CFR Part 98, in the early stages of the regulation implementation, the CO

2 emissions measured by CEMS accounted for 91.6% of the total emissions. Subsequently, a large number of coal-fired units in the US were converted to gas-fired units or were decommissioned, leading to a significant reduction in the proportion of electricity generated by coal-fired units. As a result, the proportion of CO

2 emissions covered by CEMS also significantly decreased. In 2017, the proportion of CO

2 emissions measured by CEMS dropped to 70.2% of the total emissions [

57].

In terms of unit types, the units that use CEMS to monitor CO2 emissions are mainly coal-fired power generation units, while gas-fired power generation units mainly use the accounting method. Due to the continuous decline in the number and scale of coal-fired power generation units in the United States in recent years, the number and proportion of units applying CEMS to monitor CO2 have also decreased accordingly. According to statistics from the U.S. Environmental Protection Agency, by the end of 2023, among the thermal power units regulated under 40 CFR Part 75, those using CEMS to monitor CO2 emissions account for 15% of the total units, and the CO2 emissions obtained account for 58% of the total emissions from these units.

3.6. Effectiveness and Challenges of Quality Control in U.S. Thermal Power Carbon Emission Data

3.6.1. Main Results

The effective implementation of the data quality control system for carbon emissions from thermal power in the United States has achieved significant results. In terms of data quality, through strict regulatory standards, advanced monitoring technology, and a comprehensive audit mechanism, the accuracy and reliability of monitoring data on carbon emissions from thermal power in the United States have been effectively guaranteed, providing a solid data foundation for the operation of the carbon market and the formulation of emission reduction policies.

In terms of carbon emission reduction, accurate carbon emission data helps companies formulate scientifically sound reduction strategies. It also provides a basis for government departments to evaluate the effects of emission reduction policies and adjust their targets, promoting a continuous decline in carbon emissions in the U.S. thermal power sector. Relevant data shows that the carbon emission of the U.S. power sector decreased by 11.3% in 2015 compared to 2011, which is inextricably linked to the effective implementation of the thermal power carbon emission data quality control system.

In terms of market operation, high-quality carbon emission data ensures the fairness and stability of the carbon market. The successful operation of regional carbon markets such as the Regional Greenhouse Gas Initiative and the California Total Compensation and Trading System depends on the support of accurate and reliable carbon emission data. These markets incentivize companies to increase their investment in emissions reduction through carbon pricing mechanisms, promoting the development of clean energy and optimizing the energy structure.

3.6.2. Challenges Ahead

Despite certain effectiveness in improving the quality control of carbon emissions from thermal power in the United States, there are still some challenges. On one hand, there are differences in the implementation of regulations and the application of monitoring technology between different regions, resulting in uneven quality of monitoring data in some areas, affecting the uniformity and comparability of carbon emission data nationwide. For instance, the audit frequency in Texas is 20% lower than that in California, which may lead to differences in the quality of monitoring data between the two places.

On the other hand, with the continuous development of monitoring technology, existing regulatory standards and audit mechanisms need to be continuously updated and improved to adapt to the application of new technologies. For example, the emergence of new monitoring technologies such as laser spectroscopy monitoring technology has put forward new requirements for existing calibration methods, data processing procedures, etc., and it is necessary to revise relevant regulatory standards in a timely manner to ensure that new technologies can be effectively applied.

In addition, monitoring costs are also an indispensable challenge. Advanced monitoring equipment, strict auditing mechanisms, and technical research and development all require substantial financial investments. For some small thermal power companies, this may pose significant economic pressures, affecting their enthusiasm to participate in carbon emission monitoring and management.

3.6.3. Limitations of Data Comparability and Transaction Fairness

Due to Inconsistent Regional Implementation The “federal framework + regional autonomous implementation” model in the United States ensures technical flexibility, but the differences in regulatory intensity and enforcement standards between regions pose long-term challenges to the comparability of national carbon emission data and the fairness of carbon transactions.

Damaged Data Comparability: The Disparity in Cross-Regional Data Deviates and Exaggerates Taking the comparison between Texas and California as an example, the two states have significant differences in the frequency of CEMS audits and RATA (Relative Accuracy Test) requirements: California requires coal-fired units to conduct one on-site audit every 12 months, with an RATA passing rate of ≥90%, and mandates the use of ASTM D7036 certified laboratories [

58]; Texas only requires one on-site audit every 18 months, with an RATA passing rate of ≥80%, and the laboratory qualification can be determined by state agencies themselves [

59]. According to EPA data from 2023, the CEMS data deviation for coal-fired units of the same size (600 MW) in the two states can reach up to 5.8%—the CO

2 concentration measurement error for units in California remains stable at 1.8–2.2% due to high-frequency audits and strict RATA, while the error fluctuation for units in Texas is 2.5–4.5% due to longer audit intervals. Such deviations result in a lack of a unified benchmark for cross-regional corporate emission data: For instance, a power group operating across states might report an annual emission amount of 2.8 million tons for its California plants and 2.96 million tons for its Texas plants of the same type. Although the actual emissions are similar, the data discrepancy raises investors’ doubts about the valuation of the company’s carbon assets, reducing the credibility of national carbon market data.

Imbalance of Fairness in Carbon Trading: Divergence in Compliance Costs and “Regulatory Arbitrage” Regional implementation differences in compliance costs lead to uneven compliance costs for enterprises, and even induce “regulatory arbitrage” behaviors. In terms of compliance costs, the annual average CEMS operation and audit costs for thermal power companies in California is approximately $220,000 (including 2 on-site audits per year, high-frequency RATA), while the annual average cost for companies in Texas is about $150,000 (1 on-site audit per year, relaxed RATA), with a cost gap of 31.8%. This disparity has prompted some high-emission units to relocate to regions with more relaxed regulations: between 2020 and 2023, 12 coal-fired units in the United States moved from California and states covered by the Regional Greenhouse Gas Initiative (RGGI) in the Northeast to states like Texas and Oklahoma with looser regulations. The total emissions of these relocated units reached 12 million tons per year. Such “regulatory arbitrage” not only weakens the overall emission reduction effect but also leads to higher compliance costs and competitive disadvantages for enterprises left in strictly regulated areas (such as native power plants in California), undermining the fairness principle of “polluter pays” in carbon trading.

Difficulties in Long-term Policy Synergy: Data Docking and Target Assessment Obstacles Inconsistent regional data standards pose risks for federal carbon reduction target assessments and the integration of cross-regional carbon markets. The U.S. Inflation Reduction Act (IRA) proposed a goal to reduce emissions in the power sector by 40% by 2030 [

60]. However, due to the lack of a unified regional data calibration mechanism, the federal EPA needs to invest an additional 30% of manpower to correct data when compiling data from various states (such as converting Texas data according to California standards), causing a delay in target assessments by 3–6 months [

61]. Moreover, differences in regional data also hinder the interconnection of cross-regional carbon markets: The RGGI region and the California carbon market once attempted to establish a quota mutual recognition mechanism, but due to a 4.2% deviation in CEMS data between the two states, the mutual recognition negotiations were forced to be shelved, affecting the progress of building a national unified carbon market [

62].

3.7. Technical Principles of US Monitoring Systems

The U.S. thermal power carbon emission monitoring system adopts a differentiated technical approach of “focusing on coal-fired unit CEMS, supplemented by gas-fired unit accounting methods”. This design both fits the characteristic of coal-fired flue gas requiring real-time monitoring due to its complexity and takes into account the need for simplified cost management for gas-fired units with stable emissions. The technical standards are all built around 40 CFR Part 75 (Continuous Emission Monitoring) and ASTM series standards, forming a “precision-first, cost-adaptive” technical logic. Among them, CEMS focuses on real-time and traceability of data, while the accounting method emphasizes verifiability of parameters. Together, they support the compliance data needs of the U.S. carbon market.

CO

2 concentration measurement mainly involves dilution sampling NDIR (accounting for 90% of the market share) [

63]: the system extracts flue gas through a sampling pump, removes dust through a filter, and dilutes it with clean air at a ratio of 1:10–1:20, reducing the saturation interference of high CO

2 concentrations on the detector, while also minimizing the impact of water condensation in the flue gas. The final measurement error is controlled at ≤±2%, with a median relative accuracy stable at approximately 2%. Flow measurement is divided into two categories: the mainstream Teledyne X-type ultrasonic flowmeter adopts a 4-channel design, covering different flow field areas of the flue cross-section. It reduces the influence of swirling and stratified flows by averaging multiple sets of data, with an RATA pass rate requirement of ≥90% and an error of ≤±7.5%. Thermal mass flowmeters (TMF), which account for 15% of the market, calculate flow rate by measuring the heat transfer rate of flue gas to the heating element, especially suitable for low-load (<30% rated load) conditions, with an error controllable at ≤±3%, compensating for the lack of precision of ultrasonic flowmeters under low flow rates.

Gas-fired units generally adopt the Tier 3 accounting method stipulated by 40 CFR Part 98, all parameters are ensured for accuracy through standardized measurement. Fuel consumption is measured using a turbine flowmeter, which utilizes fluid momentum to drive the turbine rotation and calculates consumption through the linear relationship between rotational speed and flow, with an error of ≤±0.5%; the fuel emission factor is sampled on-site according to the ASTM D6378 standard, analyzing the carbon content in the fuel (such as the carbon proportion of components like methane and ethane in natural gas), with an error of ≤±1%; the calorific value is tested using the ASTM D240 bomb calorimeter, calculating it inversely from the heat released by complete combustion of the fuel, with an error of ≤±0.5%. The total uncertainty of this method is ≤±5%, and its annual average cost is only 1/3 of that of CEMS (approximately 30,000–50,000 USD/unit), significantly reducing the monitoring burden of gas-fired units [

64].

4. Data Quality Control for Carbon Emissions from Thermal Power in China

The construction of a data quality control system for carbon emissions from thermal power in China began at the beginning of the 21st century, evolving from “pilot exploration” to “systematic construction”. With the advancement of the “dual carbon” goals, our country has formed a unique system based on regulatory standards, supported by technological innovation, and linked by market mechanisms. The core of this system is to achieve precise control of data quality through a dual-track system of “concurrent accounting and monitoring”.

4.1. The Development and Evolution of the Regulatory Standard System

The regulatory construction of carbon emission data quality control in China’s thermal power generation presents distinct phased characteristics. The issuance and improvement of regulatory documents at each stage have promoted the transition of thermal power carbon emission monitoring from extensive management to refined control (

Table 5) [

65].

In 2013, the National Development and Reform Commission issued the “Guidelines for the Accounting and Reporting of Greenhouse Gas Emissions in the Power Generation Industry (Trial)” [

66], which standardized the basic methods for carbon emission accounting in thermal power enterprises for the first time and established the dominant position of the emission factor method. The guidelines specified the accounting and reporting requirements for carbon dioxide emissions from fossil fuel combustion, carbon dioxide emissions from desulfurization processes, and carbon dioxide emissions from purchased electricity, providing a unified technical framework for carbon emission accounting in China’s thermal power industry.

In 2017, the “Technical Specifications for Continuous Monitoring of Carbon Dioxide Emissions from Thermal Power Plant Flue Gas” (DL/T 2376-2017) was issued, marking the beginning of the incorporation of the continuous emission monitoring method (CEMS) into the management system. This standard made comprehensive regulations on the installation, performance, operation, and maintenance of the thermal power carbon emission continuous monitoring system, providing a technical basis for the application of CEMS in the thermal power industry. In 2021, this specification was further upgraded [

67]. In the same year, HJ 75-2017 “Technical Specifications for Continuous Monitoring of Flue Gas Emissions (SO

2, NOx, Particulate Matter) from Fixed Pollution Sources” and HJ 76-2017 “Technical Requirements and Test Methods for Continuous Monitoring System of Flue Gas Emissions (SO

2, NOx, Particulate Matter) from Fixed Pollution Sources” were released [

68], Although they mainly target conventional pollutants, some technical requirements also provide references for the continuous monitoring of CO

2 emissions from thermal power plants.

In 2021, the Ministry of Ecology and Environment issued the “Carbon Monitoring and Evaluation Pilot Work Plan” [

69], launching the first phase of pilot work. 22 thermal power units from 3 power generation groups participated in the pilot to explore the online monitoring technology and methods of CO

2 emissions from thermal power. The pilot work focused on the installation and debugging of CEMS, data collection and transmission, quality control, and other aspects, accumulating experience for subsequent large-scale promotion.

In September 2023, the Ministry of Ecology and Environment released the “Work Plan for Deepening Carbon Monitoring and Evaluation Pilot Program”, launching the second phase of pilot work [

70], One hundred and fourteen thermal power units from five power generation groups participated. The plan proposed encouraging the study and comparison of flue gas flow measurement technologies based on different principles, aiming to enhance the accuracy of CO

2 emission testing. The expansion of pilot scope and the increase in technical requirements have promoted the innovation and application of carbon emission monitoring technology in thermal power.

In 2024, the “Work Plan for Improving the Carbon Emission Statistical Accounting System” was released [

71], further refining the regulatory requirements and establishing the legal status of CEMS data. It clarified that the data can be used as the basis for fulfilling carbon trading obligations, forming a three-tier system of “law-administrative regulations-industry standards”:

Legal Aspect: The “Environmental Protection Law of the People’s Republic of China” provides the basic legal basis for carbon emissions monitoring, requiring enterprises to truthfully declare their pollutant emissions and be responsible for the authenticity and accuracy of monitoring data.

The administrative regulation: “Carbon Emission Rights Trading Management Measures (Trial)” [

72] stipulates the requirements for submitting monitoring data, clarifying that key emission units should carry out carbon emission monitoring and accounting in accordance with relevant technical specifications, and regularly submit monitoring reports.

Industry standards: DL/T 2376-2021 [

67] Technical specification for continuous emission monitoring of CO

2 in flue gas from thermal power plants and GB/T 40789-2021 “Determination of performance characteristics of online automatic measurement systems for carbon monoxide content, carbon dioxide content, and oxygen content” [

73] and other standards specify the technical parameters, performance requirements, calibration methods, and other technical details of CEMS.

4.2. Monitoring the Transformation Path of Technology Roadmap

The monitoring of carbon emissions from thermal power generation in China has undergone a technical transformation from “pure accounting” to “combination of calculation methods”. Before 2013, more than 90% of thermal power plants in the country adopted the emission factor method based on fuel consumption. Although this method is easy to operate, it has a large error (±8–12%) [

74], mainly due to fluctuations in fuel quality and manual statistical deviations.

After 2017, the CEMS technology was rapidly promoted, and its measurement principle is based on the non-dispersive infrared absorption method [

75]. During the application of CEMS technology, Chinese thermal power companies have actively developed new flue gas flow measurement technologies, such as flue gas flow measurement technology based on induced draft fan flow measurement, and multi-channel ultrasonic flow partition measurement technology. Pilot studies show that these technologies have high measurement accuracy and can adapt to complex flue gas conditions. For example, the multi-channel ultrasonic flowmeter measures the flue gas flow velocity through multiple channels, effectively overcoming the influence of uneven flow field in the flue on the measurement results, with the measurement error controlled within ±1.5%.

4.3. The Entire Process Management of Data Quality Control

To ensure the quality of carbon emission monitoring data from thermal power generation, China has established a three-level quality control mechanism of “enterprise self-inspection-third-party audit-government supervision” to manage the entire process of monitoring data.

4.3.1. Enterprise Self-Inspection

As the main body responsible for carbon emission monitoring, enterprises need to perform zero-point/span calibration daily to ensure that the CEMS is in normal operation. The calibration process strictly follows the requirements of DL/T 2376-2021, using standard gas to calibrate the CO2 concentration monitor and a standard flow meter to calibrate the flue gas velocity monitor. At the same time, enterprises need to record calibration data and equipment operating status, forming a calibration report, with a data validity rate of ≥90%.

In addition, enterprises need to regularly maintain and service the CEMS, including cleaning sensors, checking pipeline seals, replacing vulnerable parts, etc., to ensure the long-term stable operation of the equipment. Monthly statistical analysis of monitoring data is conducted, compared with fuel consumption, power generation data, etc., to verify the rationality of the monitoring data.

4.3.2. Third-Party Review

Third-party institutions conduct quarterly comparative monitoring, using reference methods (such as GB/T 37186-2018 “Determination of Carbon Dioxide in Waste Gas from Fixed Pollution Sources Non-dispersive Infrared Absorption Method”) [

76] to verify the data from CEMS monitoring. Comparative monitoring includes parameters such as CO

2 concentration, flue gas flow rate, and flue gas temperature, with a relative accuracy required to be ≤5%.

During the audit process, third-party institutions need to review the company’s monitoring plan, calibration records, maintenance logs, etc., and conduct on-site inspections of the installation position and operational status of CEMS to ensure that the company’s monitoring work complies with relevant standards and specifications. After the audit is completed, an audit report is issued, pointing out existing problems and proposing rectification suggestions.

4.3.3. Government Regulation

The ecological and environmental department conducts annual flight inspections, focusing on verifying anomalous data. Flight inspections adopt a random sampling method without prior notice to enterprises, and on-site checks of the operational status of CEMS, calibration records, and data transmission are performed to validate the authenticity and accuracy of monitoring data. Simultaneously, the ecological and environmental department has also established a “carbon data anomaly identification model” using big data technology. After the application of this model nationwide in 2023, the efficiency of anomaly data identification increased by 72%, and the processing time was reduced from 72 h to 24 h, effectively curbing data fraudulent behaviors.

4.4. The Linkage Mechanism of Carbon Market and Monitoring Data

The national carbon market uses CEMS data as the core basis for compliance, forming a “monitoring-accounting-trading” closed loop, which has promoted thermal power companies to strengthen carbon emission management and improve the quality of monitoring data.

Companies upload their CEMS data to the national carbon trading platform every month, which includes parameters such as hourly CO2 emissions, flue gas concentration, and flue gas flow rate. Third-party institutions review the uploaded data, checking its completeness, accuracy, consistency, etc., with an approval rate required to be ≥95%. Approved data serves as the basis for calculating the company’s carbon emissions and is used to determine the company’s annual actual emissions.

At the annual performance time, the difference between the actual emissions of enterprises and the quota is settled at the market price. If the actual emissions exceed the quota, enterprises need to purchase the corresponding quota to fulfill their obligations; if the actual emissions are lower than the quota, enterprises can sell the remaining quota in the carbon market. Data from 2023 shows that the compliance accuracy rate of enterprises using CEMS reached 98.6%, which is 12.3 percentage points higher than that of enterprises using the emission factor method, indicating that the application of CEMS data has improved the efficiency and fairness of the carbon market’s compliance.

4.5. Existing Problems and Improvement Directions

4.5.1. Risk of Regional Data Inconsistency Affecting Market Fairness

The unbalanced installation of CEMS between eastern and western regions may lead to “differentiated compliance costs” in carbon trading. As of 2024, the CEMS installation rate in western provinces is only 58% (vs. ~90% in eastern provinces), and 30% of small thermal power units in remote areas still rely on the emission factor method (uncertainty ±8–12%). When CEMS data (with lower uncertainty) becomes the mandatory trading basis, enterprises in western regions using the emission factor method may face higher “quota gap risks”—for example, a 300 MW coal-fired unit in a western province using the emission factor method may overestimate emissions by ~10% (equivalent to 15,000 t CO

2/year) compared to CEMS, leading to additional quota purchase costs of ~1.5 million yuan/year (based on 2023 national carbon market average price of 100 yuan/t [

77]). This regional disparity may further widen the development gap between eastern and western thermal power enterprises and even trigger unfair competition in the national carbon market.

4.5.2. Technical Risks of CEMS Adaptability Under Complex Conditions

Under harsh operating environments (high dust, high humidity, low load), the measurement stability of CEMS may fail to meet trading requirements, leading to “data invalidation risks”. Pilot data shows that in high-dust environments (flue dust concentration > 50 mg/m

3), the measurement error of domestic CEMS increases by 3–5% (e.g., a 600 MW unit in northern China had CEMS CO

2 concentration error rise from 2% to 6.8% during winter heating periods). In addition, 40% of domestic CEMS equipment lacks adaptive algorithms for low-load conditions (<30% load), resulting in data capture rates dropping to <85% (below the 90% validity requirement). Once such low-quality data is used for carbon trading settlement, it may trigger disputes between enterprises and regulatory authorities [