Technical, Technological, Environmental and Energetical Aspects in Livestock Building Construction Using Structural Timber

Abstract

1. Introduction

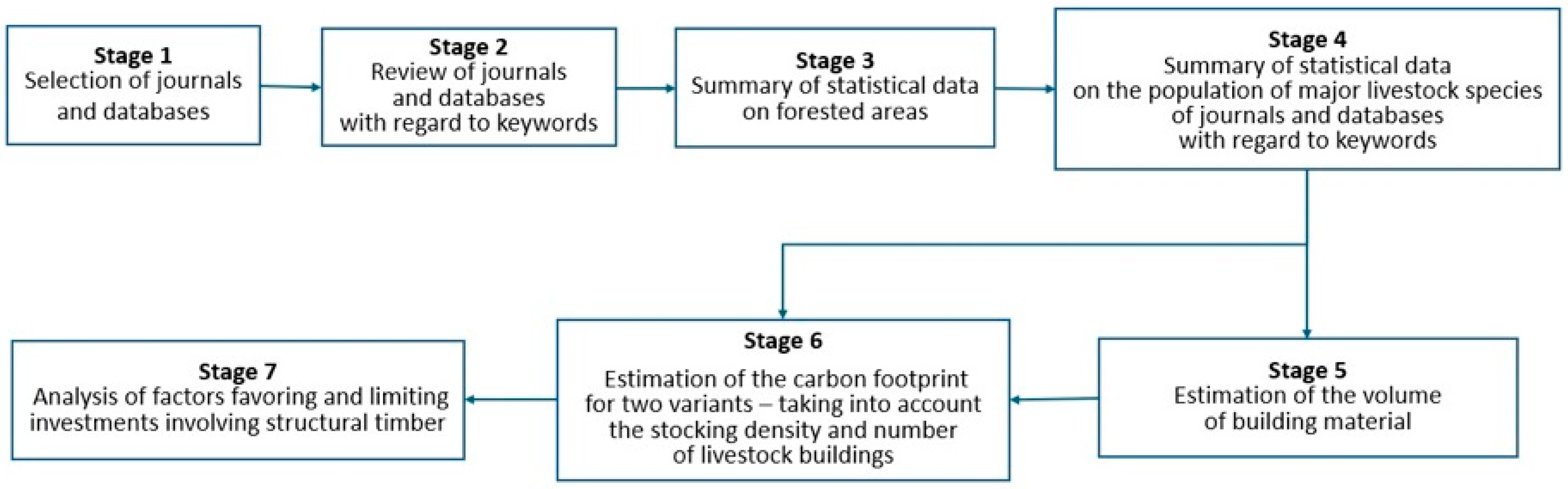

2. Materials and Methods

- EE—embodied energy;

- CFPcoeff—carbon foot print coefficient, (measured in kg CO2 equivalent) according to the IPCC;

- V—volume of material used in particular technological variant.

- 1 for biomaterials.

3. Results

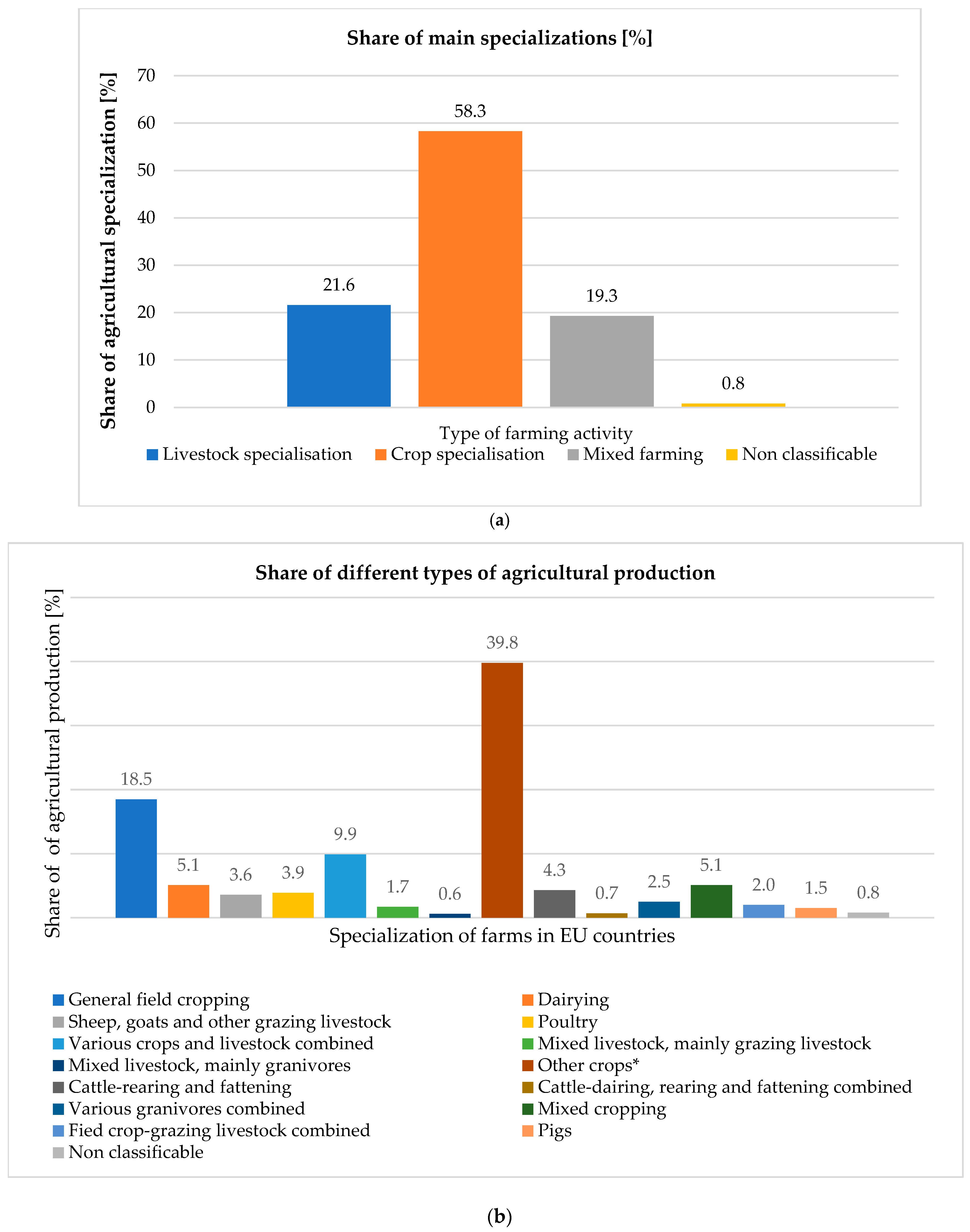

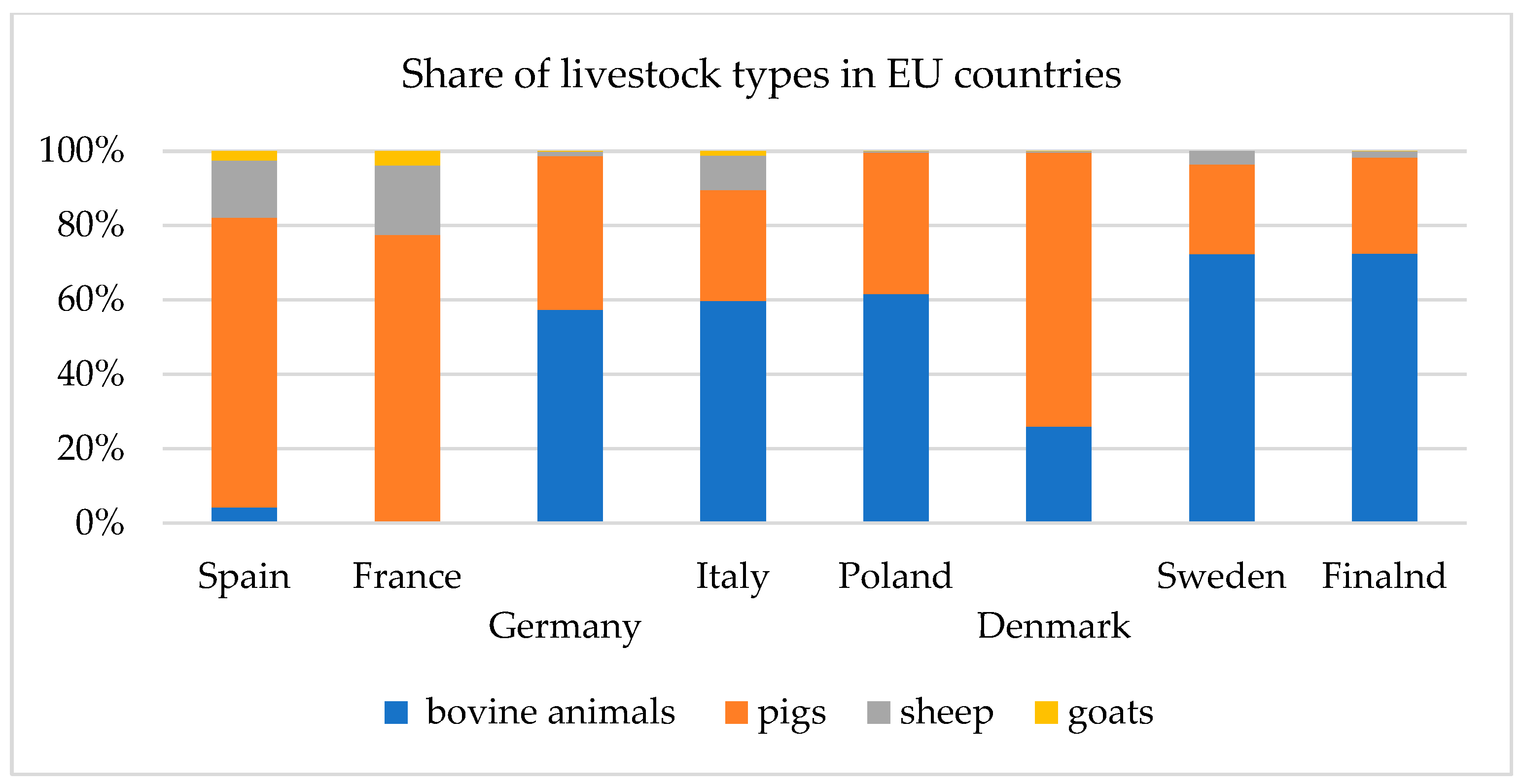

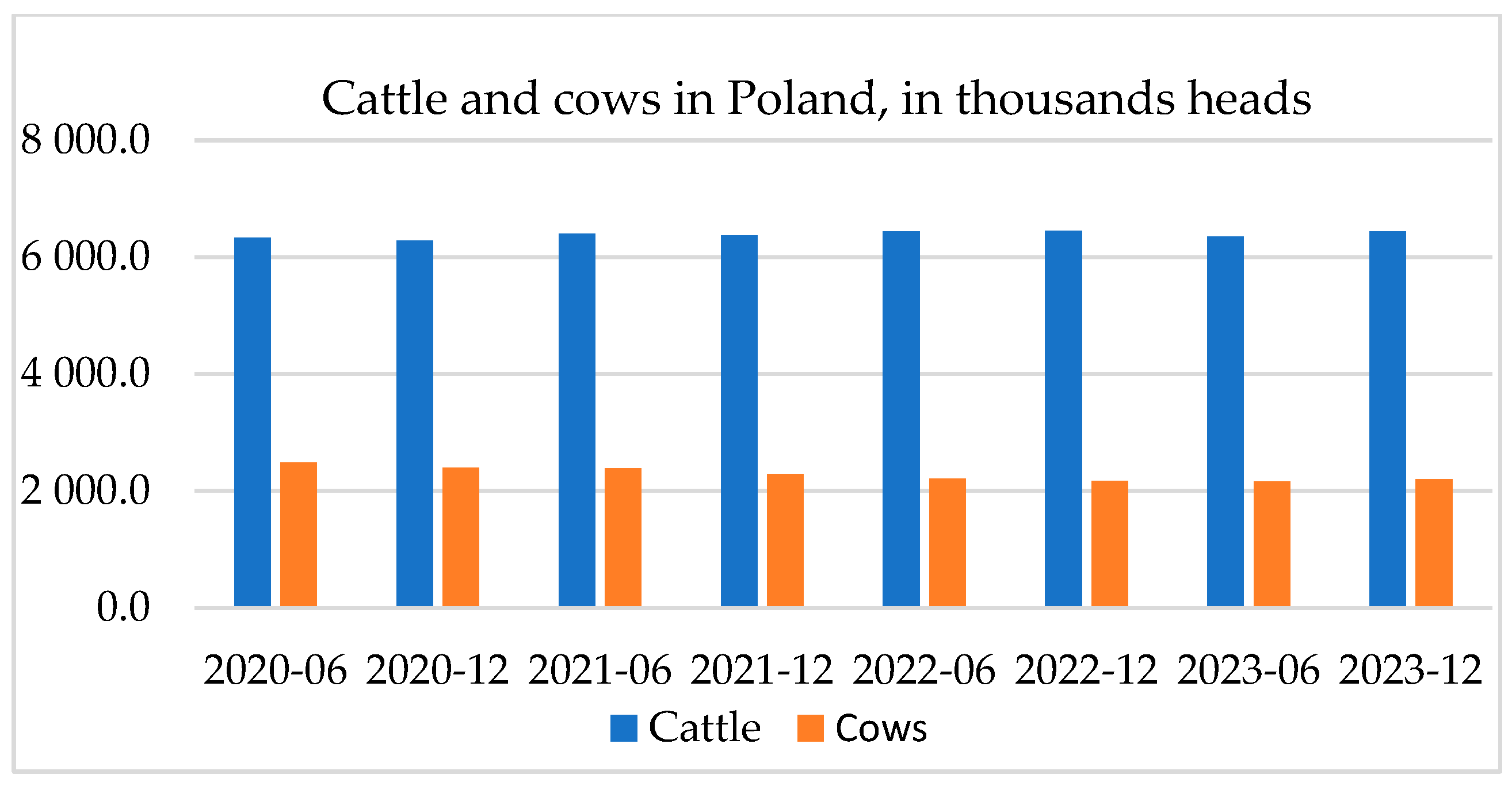

3.1. Intensification of Farming

- -

- Calves under 1 year of age—29.8%;

- -

- Young breeding and slaughter cattle aged 1–2 years—25.9%;

- -

- Cows—34.2%;

- -

- Other breeding and slaughter cattle aged 2 years and over—10%.

3.2. Afforestation

3.3. Carbon Footprint and Embodied Energy Analyses for Model Number of Buildings

- -

- Area for dairy cows: 8 m2 per LSU;

- -

- Area for pigs (fatteners): 1 m2 per LSU;

- -

- Area for goats: 1.5 m2 per head;

- -

- Thickness of boards for exterior walls: 0.025 m;

- -

- Buildings include a reinforced concrete foundation wall (plinth) 1 m high.

3.4. Factors Influencing Investments in Wood Constructions

| Economic Factors | |

|---|---|

| Characteristic features of the problem group | Advantages/Chances |

| |

| Market factors | |

|

|

| |

| |

| Environmental and Social Factors | |

|---|---|

| Characteristic features of the problem group | Advantages/Chances |

|

|

|

|

| |

|

|

|

|

| |

|

|

| |

| |

| |

| Characteristic Features of the Problem Group | Advantages/Chances |

|---|---|

| Technological and Technical Factors | |

|

|

4. Discussion

5. Conclusions

- Research on fire resistance, system certification, and updating regulations;

- Developing durable, cost-efficient protection systems against high humidity, ammonia, fermentation gases, and microorganisms;

- Promoting prefabricated components tailored for agricultural construction, alongside measures to increase the public awareness and acceptance of these technologies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Konieczna, A.; Mazur, K.; Koniuszy, A.; Gawlik, A.; Sikorski, I. Thermal Energy and Exhaust Emissions of a Gasifier Stove Feeding Pine and Hemp Pellets. Energies 2022, 15, 9458. [Google Scholar] [CrossRef]

- Wróbel, B.; Hryniewicz, M.; Kulkova, I.; Mazur, K.; Jakubowska, Z.; Borek, K.; Dobrzyński, J.; Konieczna, A.; Miecznikowski, A.; Piasecka-Jóźwiak, K.; et al. Fermentation Quality and Chemical Composition of Industrial Hemp (Cannabis sativa L.) Silage Inoculated with Bacterial Starter Cultures—A Pilot Study. Agronomy 2023, 13, 1371. [Google Scholar] [CrossRef]

- Roman, K.; Grzegorzewska, E.; Zatoń, P.; Konieczna, A.; Oleńska, S.; Borek, K.; Świętochowski, A. Dispersed Power Production in Terms of the Potential of Briquettes Made from Straw and Willow as Renewable Sources of Energy. Materials 2022, 15, 5235. [Google Scholar] [CrossRef] [PubMed]

- Konieczna, A.; Koniuszy, A. Greenhouse gas and ammonia emissions in modelled cereal crop production under Polish agricultural conditions: An example spring barley. J. Water Land. Dev. 2024, 61, 39–47. [Google Scholar] [CrossRef]

- Angili, P.; Grzesik, K. Unlocking the circular economy potential: Techno-economic analysis of rapeseed meal valorization through pyrolysis. J. Water Land Dev. 2025, 65, 122–132. [Google Scholar] [CrossRef]

- RESILENT, Project. Available online: https://cordis.europa.eu/project/id/818187/results (accessed on 3 July 2025).

- Wardal, W.J.; Mazur, K.; Barwicki, J.; Tseyko, M. Fundamental Barriers to Green Energy Production in Selected EU Countries. Energies 2024, 17, 3664. [Google Scholar] [CrossRef]

- Lithourgidis, A.A.; Firfiris, V.K.; Kalamaras, S.D.; Tzenos, C.A.; Brozos, C.N.; Kotsopoulos, T.A. Energy Conservation in a Livestock Building Combined with a Renewable Energy Heating System towards CO2 Emission Reduction: The Case Study of a Sheep Barn in North Greece. Energies 2023, 16, 1087. [Google Scholar] [CrossRef]

- Benni, S.; Garcia, C.A.P.; Bovo, M.; Barbaresi, A.; Tinti, F.; Loris, A.; Acosta-Pazmiño, I.P.; Bakalis, P.; Tassinari, P.; Torreggiani, D. A Smart Heating System Based on Integrated Renewable Energy Sources for Swine Nursery Buildings. Energies 2025, 18, 1393. [Google Scholar] [CrossRef]

- Hołaj-Krzak, J.T.; Konieczna, A.; Borek, K.; Gryszkiewicz-Zalega, D.; Sitko, E.; Urbaniak, M.; Dybek, B.; Anders, D.; Szymenderski, J.; Koniuszy, A.; et al. Goat Manure Potential as a Substrate for Biomethane Production—An Experiment for Photofermentation. Energies 2024, 17, 3967. [Google Scholar] [CrossRef]

- Konieczna, A.; Borek, K.; Hołaj-Krzak, J.T.; Dybek, B.; Anders, D.; Szymenderski, J.; Klimek, K.; Kapłan, M.; Jarosz, Z.; Syrotyuk, S.; et al. The Potential of Utilizing Cattle (Cow) Manure for Biomethane Production—An Experiment for Photofermentation. Energies 2024, 17, 6119. [Google Scholar] [CrossRef]

- Wear, D.N.; Prestemon, J.P.; Foster, M.O. US Forest Products in the Global Economy. J. For. 2016, 114, 483–493. [Google Scholar] [CrossRef]

- González-Retamal, M.; Forcael, E.; Saelzer-Fuica, G.; Vargas-Mosqueda, M. From Trees to Skyscrapers: Holistic Review of the Advances and Limitations of Multi-Storey Timber Buildings. Buildings 2022, 12, 1263. [Google Scholar] [CrossRef]

- Mensah, P.; Pimenta, A.S.; de Melo, R.R.; Amponsah, J.; Tuo, G.; Chakurah, I.; Ampadu, S.D.; Buckman, I.; Nikoi, M.; Minkah, E.; et al. The Global Supply Chain of Wood Products: A Literature Review. Forests 2025, 16, 1036. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Razman, M.R.; Ramli, Z.; Zakaria, S.Z.S.; Khan, T.; Stepinac, M.; et al. Creep Properties and Analysis of Cross Arms’ Materials and Structures in Latticed Transmission Towers: Current Progress and Future Perspectives. Materials 2023, 16, 1747. [Google Scholar] [CrossRef]

- Padalu, P.K.V.R.; Surana, M.; Rajput, A.S. Seismic Behaviour of Timber-Reinforced Masonry Housing Typologies in the Himalayan Region: A State-of-the-Art Survey. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025, 49, 4375–4461. [Google Scholar]

- Stepinac, M.; Gašparović, M. A review of emerging technologies for an assessment of safety and seismic vulnerability and damage detection of existing masonry structures. Appl. Sci. 2020, 10, 5060. [Google Scholar] [CrossRef]

- Ilgın, H.E.; Aslantamer, Ö.N. High-Rise Timber Offices: Main Architectural and Structural Design Parameters. Buildings 2024, 14, 1951. [Google Scholar] [CrossRef]

- Lakshmanan, R. Benefits of Glulam Timber Roof Structure for Airport Passenger Terminal Building. J. Inst. Eng. India Ser. A 2022, 103, 689–694. [Google Scholar] [CrossRef]

- Wenzel, A.; Guindos, P.; Carpio, M. Using Timber in Mid-Rise and Tall Buildings to Construct Our Cities: A Science Mapping Study. Sustainability 2025, 17, 1928. [Google Scholar] [CrossRef]

- Cabral, M.R.; Blanchet, P. A State of the Art of the Overall Energy Efficiency of Wood Buildings—An Overview and Future Possibilities. Materials 2021, 14, 1848. [Google Scholar] [CrossRef]

- Gonzalez-Torres, M.; Pérez-Lombard, L.; Coronel, J.F.; Maestre, I.R.; Yan, D. A review on buildings energy information: Trends, end-uses, fuels and drivers. Energy Rep. 2022, 8, 626–637. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, J.; Chui, Y.H. Deflection criteria for controlling timber floor vibrations: A 200-year evolution. Eng. Struct. 2025, 326, 119370. [Google Scholar] [CrossRef]

- Materials 2050. Available online: https://2050-materials.com/blog/climate-resilient-materials-for-the-built-environment-a-data-centred-prime/ (accessed on 1 July 2025).

- Perez Garcia, C.A.; Bovo, M.; Torreggiani, D.; Tassinari, P.; Benni, S. Indoor Temperature Forecasting in Livestock Buildings: A Data-Driven Approach. Agriculture 2024, 14, 316. [Google Scholar] [CrossRef]

- Alapieti, T.; Mikkola, R.; Pasanen, P.; Salonen, H. The influence of wooden interior materials on indoor environment: A review. Eur.J. Wood Wood Prod. 2020, 78, 617–634. [Google Scholar] [CrossRef]

- Mamić, D.; Domljan, D. Positive Aspects of Using Solid Wood in Interiors on Human Wellbeing: A Review. Drv. Ind. 2023, 74, 3. [Google Scholar] [CrossRef]

- Seo, H.-J.; Oh, B.-W.; Seo, I.-H. Environmental Monitoring and Thermal Data Analysis Related to Mortality Rates in a Commercial Pig House. Agriculture 2025, 15, 635. [Google Scholar] [CrossRef]

- Laurindo, G.M.; Ferraz, G.A.e.S.; Damasceno, F.A.; Nascimento, J.A.C.d.; Santos, G.H.R.d.; Ferraz, P.F.P. Thermal Environment and Behavior Analysis of Confined Cows in a Compost Barn. Animals 2022, 12, 2214. [Google Scholar] [CrossRef]

- Mazur, K.E.; Wardal, W.J.; Barwicki, J.; Tseyko, M. Thermal Insulation of Agricultural Buildings Using Different Biomass Materials. Energies 2025, 18, 636. [Google Scholar] [CrossRef]

- EN 1995-1-2:2008; Eurocode 5: Design of Timber Structures—Part 1-2: General—Structural Fire Design. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- EN 13501-2:2016; Fire Classification of Construction Products and Building Elements. Part 2: Classification Using Data From Fire Resistance and/or Smoke Control Tests, Excluding Ventilation Services. European Union: Brussels, Belgium, 2025.

- Regulation of the Minister of Development and Technology of May 9, 2024, Amending the Regulation on Technical Conditions to be Met by Buildings and Their Location. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20240000726/O/D20240726.pdf (accessed on 22 July 2025).

- Directive (EU) 2015/1535 of the European Parliament and of the Council of 9 September 2015 Laying Down a Procedure for the Provision of Information in the Field of Technical Regulations and of Rules on Information Society Services. Available online: https://eur-lex.europa.eu/eli/dir/2015/1535/oj (accessed on 22 July 2025).

- Grand View Research. Wood Based Panel Market Size, Share & Trends Analysis Report by Product (Plywood, MDF, HDF, Particleboard, OSB, Softboard, Hardboard), by Application (Furniture, Construction, Packaging), by Region, and Segment Forecasts, 2025–2030; Grand View Research: San Francisco, CA, USA, 2024; Available online: https://www.grandviewresearch.com/industry-analysis/wood-based-panel-market (accessed on 10 June 2025).

- Bartkowiak, A. Energy-saving and low-emission livestock buildings in the concept of a smart farming. J. Water Land Dev. 2021, 51, 272–278. [Google Scholar] [CrossRef]

- Mazur, K.E.; Barwicki, J.; Tseiko, V. Comparison of Mechanized and Automated Technologies in the Scope of Cumulative Energy in Sustainable Milk Production. Sustainability 2024, 16, 906. [Google Scholar] [CrossRef]

- Bhoj, S.; Tarafdar, A.; Singh, M.; Gaur, G.K. Smart and Automatic Milking Systems: Benefits and Prospects. In Smart and Sustainable Food Technologies; Sehgal, S., Singh, B., Sharma, V., Eds.; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Martin, T.; Gasselin, P.; Hostiou, N.; Feron, G.; Laurens, L.; Purseigle, F.; Ollivier, G. Robots and transformations of work in farm: A systematic review of the literature and a research agenda. Agron. Sustain. Dev. 2022, 42, 66. [Google Scholar] [CrossRef]

- Project: Improving-Energy-Efficiency-and-Indoor-Climate-of-Livestock-Buildings-Through-Passive-and-Active-Adaptation-Measures. Available online: https://www.slu.se/en/research/research-catalogue/projekt/f/improving-energy-efficiency-and-indoor-climate-of-livestock-buildings-through-passive-and-active-adaptation-measures/?utm_source=chatgpt.com (accessed on 1 July 2025).

- Liu, H.; Wang, Z.; Du, X.; Qi, F.; Wang, C.; Shi, Z. Decarbonizing Agricultural Buildings: A Life-Cycle Carbon Emissions Assessment of Dairy Barns. Agriculture 2025, 15, 1645. [Google Scholar] [CrossRef]

- Shmuelly-Kagami, T.; Matsumura, S. Progress of Timber Multi-Storey Apartment Building in Europe and Japan. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2–5 June 2008; Curran Associates Inc.: Red Hook, NY, USA, 2008; Volume 1–4, pp. 21–28, ISBN 978-1-61567-088-8. Available online: https://www.proceedings.com/content/005/005408webtoc.pdf?utm_source=chatgpt.com (accessed on 7 October 2025).

- Myllyntaus, T.; Mattila, T. Decline or increase? The standing timber stock in Finland 1800–1997, Special Section: European Environmental History and Ecological Economics. Ecol. Econ. 2002, 41, 271–288. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- EUROSTAT. Farm Specialisations. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agri-environmental_indicator_-_specialisation&oldid=597612 (accessed on 11 June 2025).

- EUROSTAT. Available online: https://ec.europa.eu/eurostat/databrowser/view/ef_lsk_bovine/default/bar?lang=en&category=agr.ef.ef_livestock (accessed on 11 June 2025).

- EUROSTAT. Decline in EU Livestock Population in 2023. 2023. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/w/ddn-20240521-2 (accessed on 11 June 2025).

- EUROSTAT. 2023. Available online: https://ec.europa.eu/eurostat/databrowser/view/ef_lsk_sheep/default/table?lang=en&category=agr.ef.ef_livestock (accessed on 20 June 2025).

- EUROSTAT. Available online: https://ec.europa.eu/eurostat/databrowser/view/ef_lsk_pigs/default/table?lang=en&category=agr.ef.ef_livestock (accessed on 20 June 2025).

- EUROSTAT. Available online: https://ec.europa.eu/eurostat/databrowser/view/ef_lsk_goats/default/table?lang=en&category=agr.ef.ef_livestock (accessed on 20 June 2025).

- GUS. 2023. Available online: https://stat.gov.pl/download/gfx/portalinformacyjny/pl/defaultaktualnosci/5508/5/25/1/poglowie_bydla_wedlug_stanu_w_grudniu_2023_r.pdf (accessed on 20 June 2025).

- EUROSTAT. Forests, Forestry and Logging. 2022. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Forests,_forestry_and_logging (accessed on 20 June 2025).

- EUROSTAT. Area of Wooded Land (EFA Questionnaire). Available online: https://ec.europa.eu/eurostat/databrowser/view/for_area_efa/default/table?lang=en&category=for.for_sfm (accessed on 20 June 2025).

- Eslami, H.; Yaghma, A.; Jayasinghe, B.; Wald, D. Comparative life cycle assessment of light frame timber and reinforced concrete masonry structural systems for single-family houses in Luxembourg. Heliyon 2024, 10, e26083. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Jones, S.; Maples, I.; Gong, Y.; Ganguly, I. Comparative Life Cycle Assessment of Mass Timber and Concrete Residential Buildings: A Case Study in China. Sustainability 2022, 14, 144. [Google Scholar] [CrossRef]

- Andersen, C.E.; Rasmussen, F.N.; Habert, G.; Birgisdóttir, H. Embodied GHG Emissions of Wooden Buildings—Challenges of Biogenic Carbon Accounting in Current LCA Methods. Front. Built Environ. 2021, 7, 729096. [Google Scholar] [CrossRef]

- Alam, A.; Goto, Y.; Hagy, S.; Tuomasjukka, D.; Hughes, M. Sustainability Assessment of a Wooden Multi-Storey Building with an Equivalent Reinforced Concrete Alternative Using ToSIA: Finnish Perspective. J. Sustain. Res. 2022, 4, e220014. [Google Scholar] [CrossRef]

- Rinne, R.; Ilgın, H.E.; Karjalainen, M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. [Google Scholar] [CrossRef]

- Schenk, D.; Amiri, A. Life cycle energy analysis of residential wooden buildings versus concrete and steel buildings: A review. Front. Built Environ 2022, 8, 975071. [Google Scholar] [CrossRef]

- Programme of Prime Minister Sanna Marin’s Government 10 December 2019, Inclusive and Competent Finland—A Socially, Economically and Ecologically Sustainable Society. Available online: http://urn.fi/URN:ISBN:978-952-287-811-3 (accessed on 3 July 2025).

- National Objectives for Public Wood Construction in Finland, Ministry of the Environment. 2020. Available online: https://ym.fi/documents/1410903/38439968/Julkisen-puurakentamisen-kansalliset-tavoitteet-45F5028E_8436_408A_8CD7_510C6C1AD000-161609.pdf/1fc95a52-5c50-4c9b-1f5d-325395658d72/Julkisen-puurakentamisen-kansalliset-tavoitteet-45F5028E_8436_408A_8CD7_510C6C1AD000-161609.pdf?t=1603259868530 (accessed on 5 July 2025).

- The National Forest and Wood Programme PNFB 2016–2026, Ministere de l’Agriculture et de l’Alimentation. 2016. Available online: https://agriculture.gouv.fr/le-programme-national-de-la-foret-et-du-bois-2016-2026 (accessed on 15 July 2025).

- Ministry of Climate and Environment. Wooden Construction—Research Report. 2020. Available online: https://www.gov.pl/web/climate/wooden-buildings (accessed on 15 July 2025).

- National Wood Construction Strategy Committee. Ds 2004: 1. Mer trä i Byggandet. Underlag för en Nationell Strategi Att Främja Användning av trä i Byggandet. Regeringskansliet: Näringsdepartementet [Support Material Related to the National Strategy Supporting the Increased Use of Wood in Construction. Department of Commerce]. Available online: http://www.regeringen.se/contentassets/622a4cddc02a4026a3bc3c4f5d5b94aa/mer-tra-i-byggandet---underlag-for-en-nationell-strategi-for-att-framja-tra-i-byggandet-ds-20041 (accessed on 18 July 2025).

- Bowyer, J.; Fernholz, K.; Kacprzak, A. Circularity concepts in wood construction. In ECE/TIM/DP/95 Forestry and Timber Section; United Nations (UNECE) and the Food and Agriculture Organization of the United Nations (FAO): Geneva, Switzerland, 2023; Available online: https://unece.org/sites/default/files/2023-05/ECE_TIM_DP95E_web.pdf (accessed on 18 July 2025).

- Kitek Kuzman, M.; Sandberg, D. Comparison of timber-house technologies and initiatives supporting use of timber in Slovenia and in Sweden—The state of the art. iForest 2017, 10, 930–938. [Google Scholar] [CrossRef]

- Petruch, M.; Walcher, D. Timber for future? Attitudes towards timber construction by young millennials in Austria—Marketing implications from a representative study. J. Clean. Prod. 2021, 294, 126324. [Google Scholar] [CrossRef]

- Mahapatra, K.; Gustavsson, L.; Hemström, K. Multi-storey wood-frame buildings in Germany, Sweden and the UK. Constr. Innov. Inf. Process Manag. 2012, 12, 62–85. [Google Scholar] [CrossRef]

- Leszczyszyn, E.; Heräjärvi, H.; Verkasalo, E.; Garcia-Jaca, J.; Araya-Letelier, G.; Lanvin, J.-D.; Bidzińska, G.; Augustyniak-Wysocka, D.; Kies, U.; Calvillo, A.; et al. The Future of Wood Construction: Opportunities and Barriers Based on Surveys in Europe and Chile. Sustainability 2022, 14, 4358. [Google Scholar] [CrossRef]

- Johansson, M. Structural properties of sawn timber and engineered wood products. In Design of Timber Structures. Structural Aspects of Timber Construction; Swedish Wood: Stockholm, Sweden, 2022; pp. 1–256. Available online: https://www.swedishwood.com/siteassets/5-publikationer/pdfer/sw-design-of-timber-structures-vol1-2022.pdf (accessed on 7 October 2025).

- Nord, T. Prefabrication Strategies in the Timber Housing Industry: A Comparison of Swedish and Austrian Markets; Technical Report; Luleå University of Technology: Luleå, Sweden, 2008; p. 51. [Google Scholar]

- Vihemäki, H.; Toppinen, A.; Toivonen, R. Intermediaries to accelerate the diffusion of wooden multi-storey construction in Finland. Environ. Innov. Soc. Transit. 2020, 36, 433–448. [Google Scholar] [CrossRef]

- Alsayegh, G.; Mukhopadhyaya, P.; Wang, J.; Zalok, E.; van Reenen, D. Preliminary Characterization of Physical Properties of Cross-Laminated-Timber (CLT) Panels for Hygrothermal Modelling. ASTM Int. Adv. Civ. Eng. Matls. 2013, 2, 472–484. [Google Scholar] [CrossRef]

- Jussila, J.; Nagy, E.; Lahtinen, K.; Hurmekoski, E.; Hayrinen, L.; Mark-Herbert, C.; Roos, A.; Toivonen, R.; Toppinen, A. Wooden multi-storey construction market development—Systematic literature review within a global scope with insights on the Nordic region. Silva Fenn. 2022, 56, 10609. [Google Scholar] [CrossRef]

- Manninen, H. Long-term Outlook for Engineered Wood Products in Europe. 2014. Available online: https://www.semanticscholar.org/paper/Long-term-outlook-for-engineered-wood-products-in-Manninen/078edf2d7bc9a807dca32fb22181d6b6dbe978d0 (accessed on 1 August 2025).

- Shang, G.; Pheng, L.S.; Fai, B.P.K. Receptiveness of mass-engineered timber (MET) residential buildings among young stakeholders. Smart Sustain. Built Environ. 2025, 14, 696–714. [Google Scholar] [CrossRef]

- Gold, S.; Rubik, F. Consumer attitudes towards timber as a construction material and towards timber frame houses—Selected findings of a representative survey among the German population. J. Clean. Prod. 2009, 17, 303–309. [Google Scholar] [CrossRef]

- Toivonen, R.; Lilja, A.; Vihemäki, H.; Toppinen, A. Future export markets of industrial wood construction—A qualitative backcasting study. For. Policy Econ. 2021, 128, 102480. [Google Scholar] [CrossRef]

- Mastrucci, A.; Guo, F.; Zhong, X.; Maczek, F.; van Ruijven, B. Circular strategies for building sector decarbonization in China: A scenario analysis. J. Ind. Ecol. 2024, 28, 1089–1102. [Google Scholar] [CrossRef]

- Shirmohammadli, Y.; Pizzi, A.; Raftery, G.M.; Hashemi, A. One-component polyurethane adhesives in timber engineering applications: A review. Int. J. Adhes. Adhes. 2023, 123, 103358. [Google Scholar] [CrossRef]

- CBE JU, European Commission. Project: SUSBOARD. Biobased Adhesives for Sustainable Wood-Based Boards. Available online: https://www.cbe.europa.eu/projects/susboard (accessed on 25 August 2025).

- Larivière-Lajoie, R.; Blanchet, P.; Amor, B. Evaluating the importance of the embodied impacts of wall assemblies in the context of a low environmental impact energy mix. Build. Environ. 2022, 207, 108534. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Project: STARGATE, Resilient Farming By Adaptive Microclimate Management. Available online: https://www.stargate-h2020.eu/ (accessed on 25 August 2025).

- Simonson, C.J.; Salonvaara, M.; Ojanen, T. Improving Indoor Climate and Comfort with Wooden Structures; Technical Research Centre of Finland, VTT Publications: Espoo, Finland, 2001; Available online: https://cris.vtt.fi/en/publications/improving-indoor-climate-and-comfort-with-wooden-structures (accessed on 25 August 2025).

- Nyrud, A.Q.; Bringslimark, T. Is interior wood use psychologically beneficial? A review of psychological responses toward wood. Wood Fiber Sci. 2010, 42, 202–218. Available online: https://wfs.swst.org/index.php/wfs/article/view/1365/1365 (accessed on 25 August 2025).

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Communications from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Renovation Wave for Europe–Greening out Buildings, Creating Jobs, Improving Lives. European Commission: Brussels, Belgium, 2020. Available online: https://ec.europa.eu/energy/sites/ener/files/eu_renovation_wave_strategy.pdf (accessed on 1 July 2025).

- Alia Syahirah, Y.; Anwar, U.M.K.; Sh, L.; Ong, C.B.; Asniza, M.; Paridah, M.T. The properties of Cross Laminated Timber (CLT): A review. Int. J. Adhes. Adhes. 2025, 138, 103924. [Google Scholar] [CrossRef]

- Wieruszewski, M.; Wdowiak-Postulak, A.; Brol, J.; Krzosek, S.; Trociński, A.; Gocál, J.; Bahleda, F.; Prokop, J.; Nowak, T. Qualitative and Strength Analysis of Pine (Pinus sylvestris L.) Wood Mater—Study Pallet Elements. Drewno. Pr. Naukowe. Doniesienia. Komun. 2025, 68, 00042. [Google Scholar] [CrossRef]

- Lobos Calquin, D.; Mata, R.; Correa, C.; Nuñez, E.; Bustamante, G.; Caicedo, N.; Blanco Fernandez, D.; Díaz, M.; Pulgar-Rubilar, P.; Roa, L. Implementation of Building Information Modeling Technologies in Wood Construction: A Review of the State of the Art from a Multidisciplinary Approach. Buildings 2024, 14, 584. [Google Scholar] [CrossRef]

- De Araujo, V.; Aguiar, F.; Jardim, P.; Mascarenhas, F.; Marini, L.; Aquino, V.; Santos, H.; Panzera, T.; Lahr, F.; Christoforo, A. Is Cross-Laminated Timber (CLT) a Wood Panel, a Building, or a Construction System? A Systematic Review on Its Functions, Characteristics, Performances, and Applications. Forests 2023, 14, 264. [Google Scholar] [CrossRef]

- Hanna, D.; Tanner, T. Glulam connections assembled with screws in different installation angles. Maderas. Cienc. Y Tecnol. 2021, 23. Available online: https://www.scielo.cl/scielo.php?script=sci_arttext&pid=S0718-221X2021000100454 (accessed on 27 August 2025). [CrossRef]

- Rebeggiani, S.; Reddy, V.; Olofsson, L.; Fredriksson, M. Towards In-Line Measurements of Sawn Wood Surfaces. In Advances in Transdisciplinary Engineering; Andersson, J., Joshi, S., Malmsköld, L., Hanning, F., Eds.; IOS Press: Amsterdam, The Netherlands, 2024; Available online: https://ebooks.iospress.nl/doi/10.3233/ATDE240150 (accessed on 27 August 2025).

- Yehia, A. Zaher Ali, Flexural behavior of FRP strengthened concrete-wood composite beams. Ain Shams Eng. J. 2018, 9, 3419–3424. [Google Scholar]

- Van Niekerk, P.B.; Brischke, C.; Niklewski, J. Estimating the Service Life of Timber Structures Concerning Risk and Influence of Fungal Decay—A Review of Existing Theory and Modelling Approaches. Forests 2021, 12, 588. [Google Scholar] [CrossRef]

- Li, J.; Chen, H.; Wang, L.; Ou, Y.; Yin, T.; Zhang, J.; Qin, D.; Du, Y. The Application of Intelligent Construction Technology to Modern Wood Structures in China: A Critical Review. Buildings 2025, 15, 535. [Google Scholar] [CrossRef]

- Barkokebas, R.D.; Chen, X.; Yu, H.; Al-Hussein, M. Achieving housing energy-efficiency requirements: Methodologies and impacts on housing construction cost and energy performance. J. Build. Engin. 2019, 26, 100874. [Google Scholar] [CrossRef]

- Kitek, K.M.; Sandberg, D. A new Era for Multi-Storey Timber Buildings in Europe. In New Horizons for the Forest Products Industry, Proceedings of the 70th Forest Products Society International Convention, Portland, OR, USA, 26–29 June 2016; Forest Products Society: Ruston, LA, USA; Available online: https://www.diva-portal.org/smash/get/diva2:1004338/FULLTEXT01.pdf (accessed on 23 May 2025).

- Zhang, X.; Ai, M.; Song, X.; Gao, S.; Li, J. Insights into precise thermal conductivity evaluation of wood in construction applications: Temperature-coupled dielectric-based approach. Constr. Build. Mater. 2025, 479, 141408. [Google Scholar] [CrossRef]

- 11thWorld Sustainability Forum. Available online: https://sciforum.net/event/WSF-11?utm_source=mdpi_web&utm_medium=banner&utm_campaign=wsf11&utm_content=pubgrade&dclid=&gad_source=7 (accessed on 16 May 2025).

- OECD. Environmental Performance of Agriculture in OECD Countries: Key Trends and Insights; OECD Publishing: Paris, France, 2025. [Google Scholar] [CrossRef]

- Barwicki, J.; Roman, K.; Borek, K.; Mazur, K.; Wardal, W.J.; Kierończyk, M. Some experimental studies concerning mixing of loose and liquid agricultural materials. Inżynieria Mater. Mater. Eng. 2021, 42, 18–21. [Google Scholar] [CrossRef]

- Barwicki, J.; Borek, K. Remote sensing in farm machinery design—As fundamental improvement of development—Of precision agriculture phenomenon. Pol. Tech. Rev. 2019, 3, 26–30. [Google Scholar]

- Barwicki, J.; Mazur, K.; Borek, K. Some aspects of using automated electronic systems in the development of modern agriculture. Inżynieria Mater. 2020, 41, 13–18. [Google Scholar] [CrossRef]

- Mithraratne, N.; Vale, B. Life cycle analysis model for New Zealand houses. Build. Environ. 2004, 39, 483–492. [Google Scholar] [CrossRef]

- Galvin, R. Thermal upgrades of existing homes in Germany: The building code, subsidies, and economic efficiency. Energy Build. 2010, 42, 834–844. [Google Scholar] [CrossRef]

| Country | Forests (km2) | LSU (2020) | LSU∙km−2 of Forests |

|---|---|---|---|

| Finland | 250,051.0 | 821,030.0 | 0.3045 |

| Sweden | 310,244.0 | 1,394,440.0 | 0.2225 |

| France | 173,284.0 | 3,726,970.0 | 0.0465 |

| Spain | 189,746.0 | 10,457,500.0 | 0.0181 |

| Italy | 110,989.0 | 7,546,880.0 | 0.0147 |

| Poland | 96,302.0 | 7,552,460.0 | 0.0128 |

| Germany | 116,529.0 | 14,299,610.0 | 0.0082 |

| Denmark | 6464.0 | 3,874,700.0 | 0.0017 |

| Technical Parameter | Cowshed | Piggery | Goat Shed | Unit |

|---|---|---|---|---|

| Building dimensions (width × length) | 20 × 37.5 | 18 × 22 | 10 × 15 | m2 |

| Building area | 750.00 | 396.00 | 150.00 | m2 |

| Height of side walls | 3.00 | 3.00 | 3.50 | m |

| Ridge height | 7.45 | 7.90 | 5.73 | m |

| Surface of wooden walls | 299.00 | 200.00 | 125.00 | m2 |

| Gable roof slope | ~24.00 | ~24.00 | ~24.00 | ° |

| Roof area | 765.00 | 433.50 | 164.00 | m2 |

| The volume of timber for roof covering (including the roof structure, i.e., wall plates, rafters, collar beams, purlins) | 32.43 | 15.26 | 8.18 | m3 |

| Total volume of structural timber (including columns, beams and reserves) | 46.83 | 21.66 | 18.27 | m3 |

| Foundation, for a thickness of 0.2 m | 23.00 | 16.00 | 10.00 | m3 |

| Building | Cattle | Pigs | Goats | Unit |

|---|---|---|---|---|

| Carbon footprint (wooden parts Ww) | 4683.0 | 2166.0 | 1827 | kg CO2e |

| Carbon footprint (concrete walls Cw foundation above ground part | 5750.0 | 4000.0 | 2500.0 | kg CO2 e |

| Total carbon footprint (Ww + Cw) | 10,433 | 6166 | 4327 | kg CO2e |

| Carbon footprint–building in traditional technology (T) | 17,450.0 | 9420.0 | 7070.0 | kg CO2e |

| Material | CFP Coefficient | Density | EE Coefficient | EE | EE | EE |

|---|---|---|---|---|---|---|

| [t CO2∙m−3] | [kg/m3] | [MJ/m3] | [MJ] | [MJ] | [MJ] | |

| Constructing wood | 0.1 | 500 | 1700 | 112,392 | 51,984 | 43,848 |

| Reinforced Concrete | 0.25 | 2400 | 2400 | 39,100 | 27,200 | 17,000 |

| Total embodied energy | 151,492 | 79,184 | 60,848 | |||

| Embodied energy in traditional technology (walls: reinforced concrete; layered roof: mineral wood, corrugated fiber cement sheet) | 246,783 | 131,644 | 73,674 | |||

| Country | Cattle [LSU] | Number of Cowsheds | Pigs [LSU] | Number of Piggeries | Goats [Units] | Number of Goat Sheds |

|---|---|---|---|---|---|---|

| Germany | 8,202,340 | 82,023 | 5,900,870 | 59,009 | 154,900 | 1549 |

| Spain | 450,100 | 4501 | 8,139,610 | 81,396 | 2,668,700 | 26,687 |

| Poland | 4,650,400 | 46,504 | 2,866,970 | 28,670 | 52,900 | 529 |

| Italy | 4,508,540 | 45,085 | 2,243,540 | 22,435 | 953,100 | 9531 |

| Denmark | 1,009,570 | 10,096 | 2,850,530 | 28,505 | 9000 | 90 |

| France | 12,510 | 125 | 2,873,740 | 28,737 | 1,412,200 | 14,122 |

| Sweden | 1,008,380 | 10,084 | 335,940 | 3359 | 0 | 0 |

| Finland | 594,400 | 5944 | 212,010 | 2120 | 6000 | 60 |

| Country | EE Traditional Variant | EE Wooden Variant | CO2e (t) Traditional Variant | CO2e (t) Wooden Variant |

|---|---|---|---|---|

| Germany | 28,129,371 | 17,350,285 | 1,007,578 | 872,851 |

| Spain | 13,793,356 | 8,707,966 | 520,835 | 456,673 |

| Poland | 15,288,333 | 9,352,533 | 547,418 | 474,292 |

| Italy | 14,775,201 | 9,218,813 | 537,197 | 465,282 |

| Denmark | 6,245,909 | 3,785,756 | 224,498 | 196,082 |

| France | 4,855,112 | 3,469,628 | 187,853 | 164,615 |

| Sweden | 2,926,303 | 1,795,078 | 104,715 | 90,554 |

| Finland | 1,539,026 | 1,021,247 | 62,589 | 54,082 |

| Traditional Variant EE [GJ] | Wooden Variant EE [GJ] | |||||

|---|---|---|---|---|---|---|

| Country | Cattle | Pigs | Goats | Cattle | Pigs | Goats |

| Germany | 13,140,270 | 10,669,786 | 4,319,315 | 8,168,457 | 6,630,462 | 2,551,366 |

| Spain | 3,283,166 | 8,363,320 | 2,146,870 | 1,904,199 | 6,539,012 | 264,755 |

| Poland | 8,304,651 | 4,561,091 | 2,422,591 | 5,095,430 | 3,565,495 | 691,608 |

| Italy | 5,989,298 | 5,060,328 | 3,725,575 | 3,674,342 | 3,959,259 | 1,585,212 |

| Denmark | 1,340,636 | 4,533,228 | 372,044 | 732,103 | 3,546,572 | 507,081 |

| France | 482,237 | 3,086,187 | 1,286,689 | 252,377 | 2,416,204 | 800,847 |

| Sweden | 1,004,153 | 1,338,053 | 584,097 | 525,555 | 1,047,050 | 222,473 |

| Finland | 629,995 | 765,371 | 143,660 | 329,512 | 598,153 | 93,582 |

| Source | Type of Buildings | Reduction Value Compared with Conventional Structures |

|---|---|---|

| Eslami, H. et al., 2024 [55] | Single-family house, light timber frames vs. masonry-concrete | 43.5% lower GWP for a wooden building compared to a concrete building |

| Chen, C.X. et al., 2022 [56] | Multi-story residential building, CLT vs. concrete | 25% reduction in GWP for a wooden building (cradle-to-gate). |

| Andersen, C.E. et al., 2021 [57] | Overview—studies of timber buildings | ~33–50% reduction (depending on scope and methodology). |

| Alam A, et al., 2022 [58] | Multi-story timber building vs. concrete | Wooden structures emit approximately 65% less GHG in the sourcing, manufacturing, and building phases than concrete structures |

| Rinne, R. et al., 2022 [59] | Multi-story apartment | 28% less than the hybrid building |

| Governance and Policy Factors | |

|---|---|

| Characteristic features of the problem group | Advantages/Chances |

| |

|

|

| |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barwicki, J.; Wardal, W.J.; Mazur, K.E.; Tseyko, M. Technical, Technological, Environmental and Energetical Aspects in Livestock Building Construction Using Structural Timber. Energies 2025, 18, 5411. https://doi.org/10.3390/en18205411

Barwicki J, Wardal WJ, Mazur KE, Tseyko M. Technical, Technological, Environmental and Energetical Aspects in Livestock Building Construction Using Structural Timber. Energies. 2025; 18(20):5411. https://doi.org/10.3390/en18205411

Chicago/Turabian StyleBarwicki, Jan, Witold Jan Wardal, Kamila Ewelina Mazur, and Mikhail Tseyko. 2025. "Technical, Technological, Environmental and Energetical Aspects in Livestock Building Construction Using Structural Timber" Energies 18, no. 20: 5411. https://doi.org/10.3390/en18205411

APA StyleBarwicki, J., Wardal, W. J., Mazur, K. E., & Tseyko, M. (2025). Technical, Technological, Environmental and Energetical Aspects in Livestock Building Construction Using Structural Timber. Energies, 18(20), 5411. https://doi.org/10.3390/en18205411