Thermal Performance of Double-Glass Evacuated Tube Solar Collectors: Flow Rate Variation Under International Standard Testing Conditions

Abstract

1. Introduction

Previous Studies

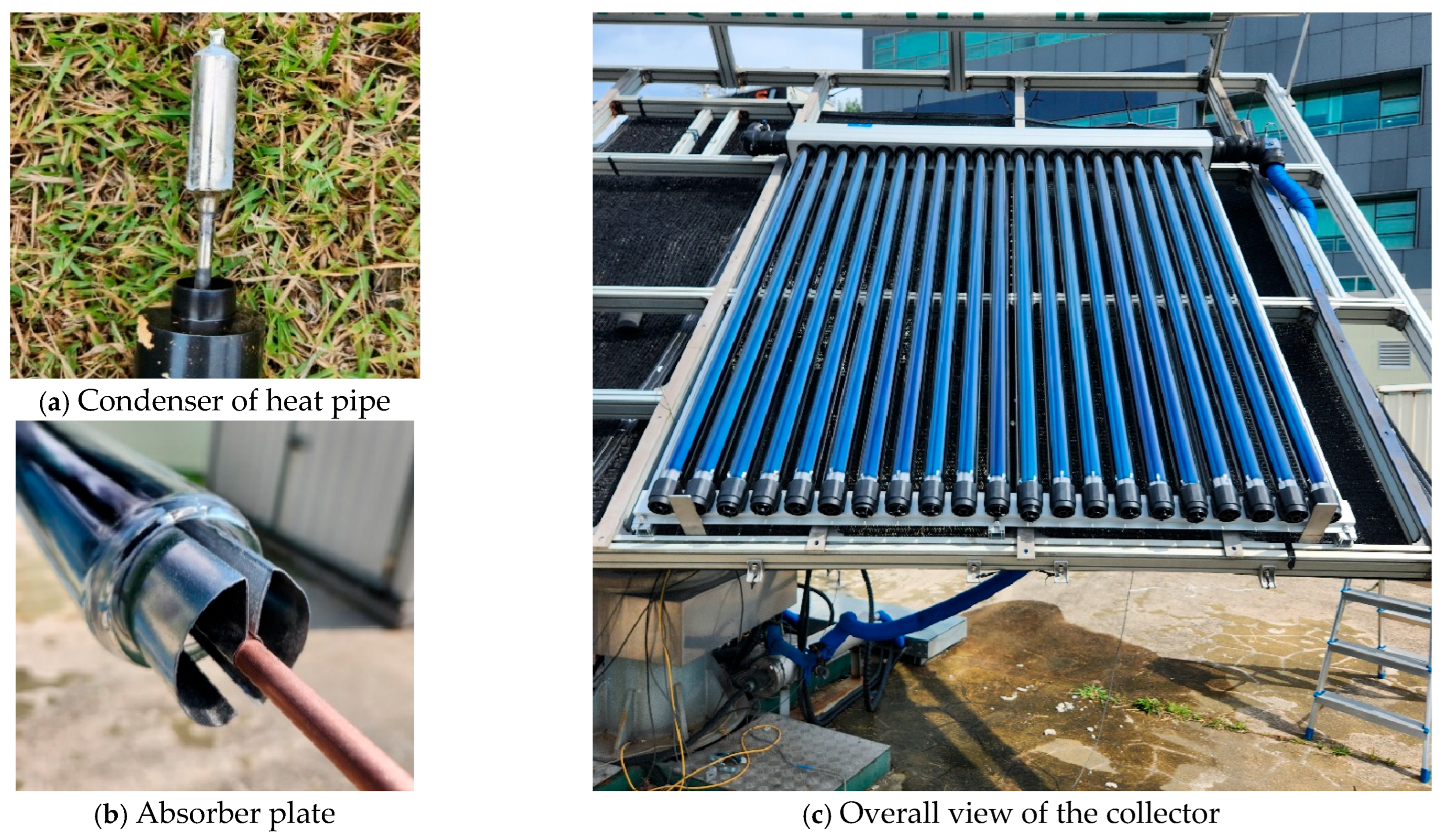

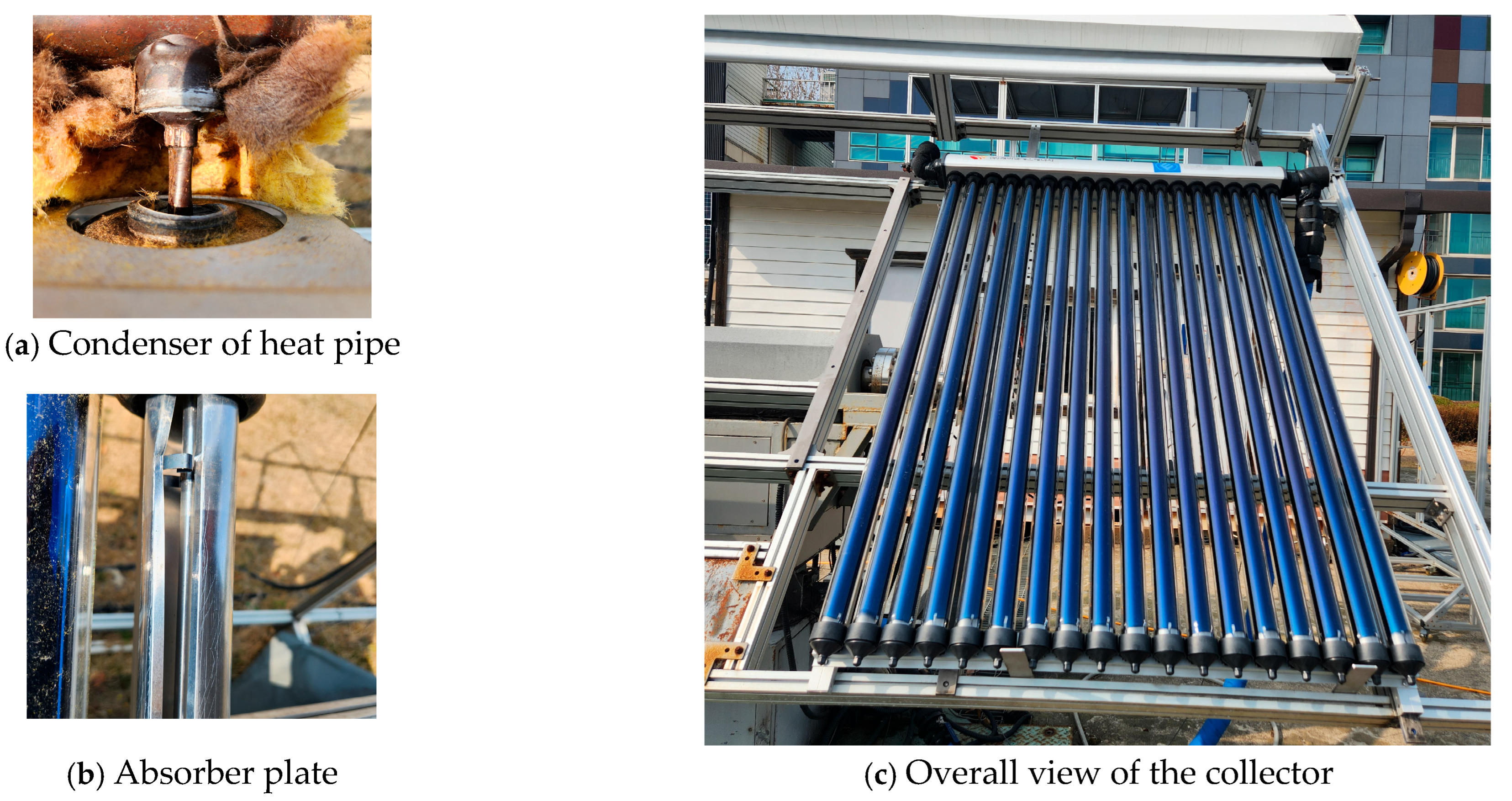

2. Specimen

3. Methodology

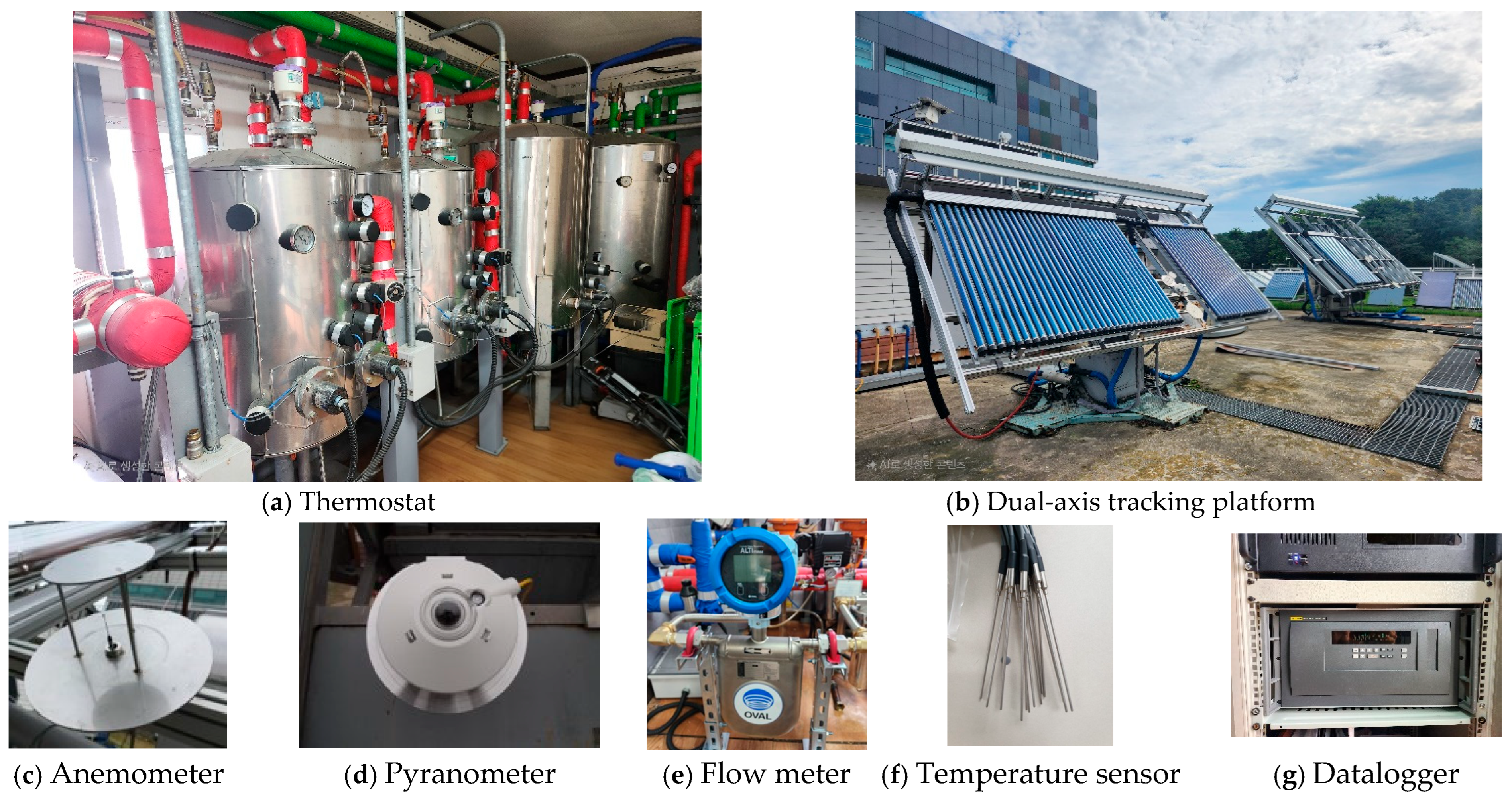

3.1. Experimental Setup

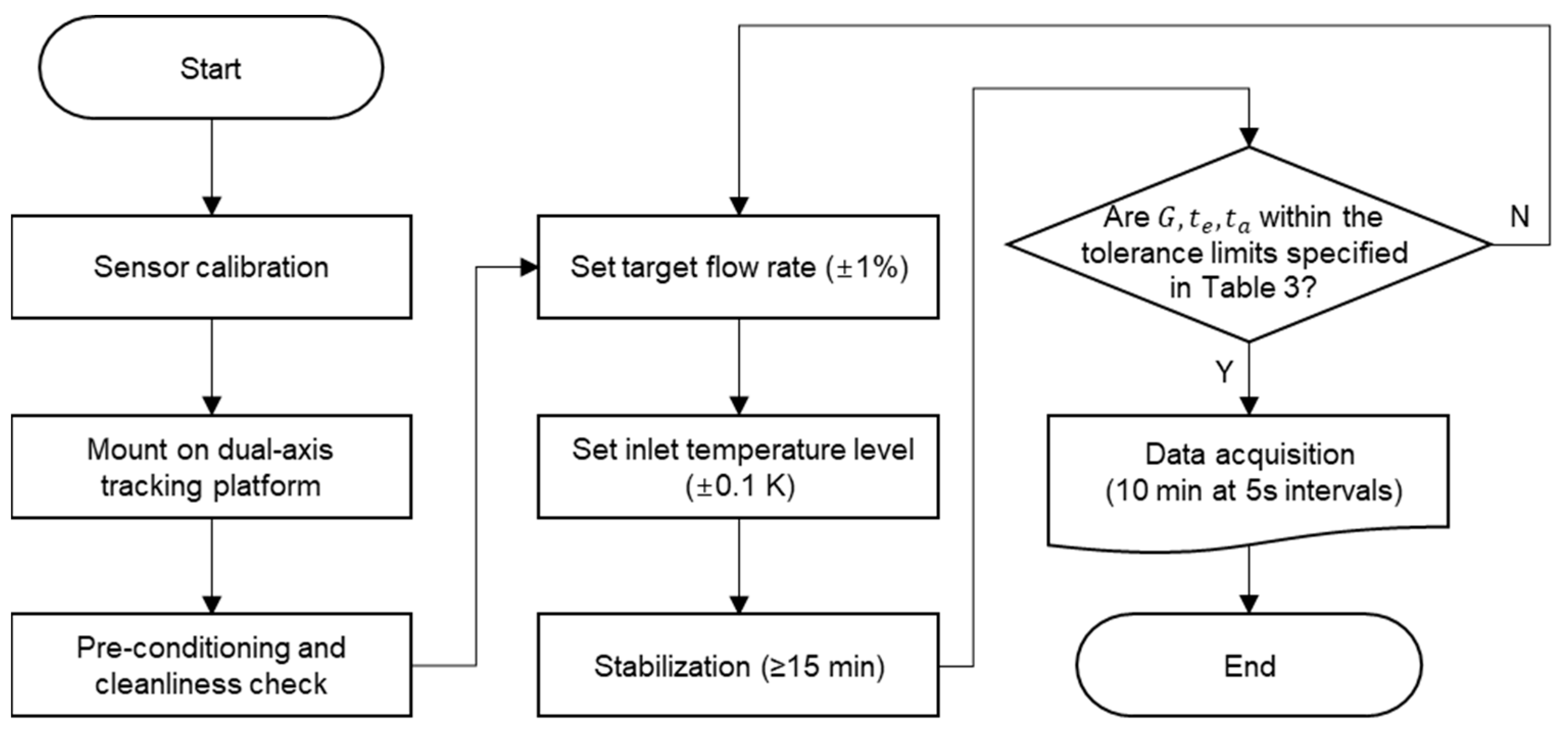

3.2. Experimental Method

3.2.1. Test Conditions

3.2.2. Steady-State Test Procedure

3.3. Instantaneous Efficiency of the Collector

3.4. Modeling of Instantaneous Efficiency

4. Results

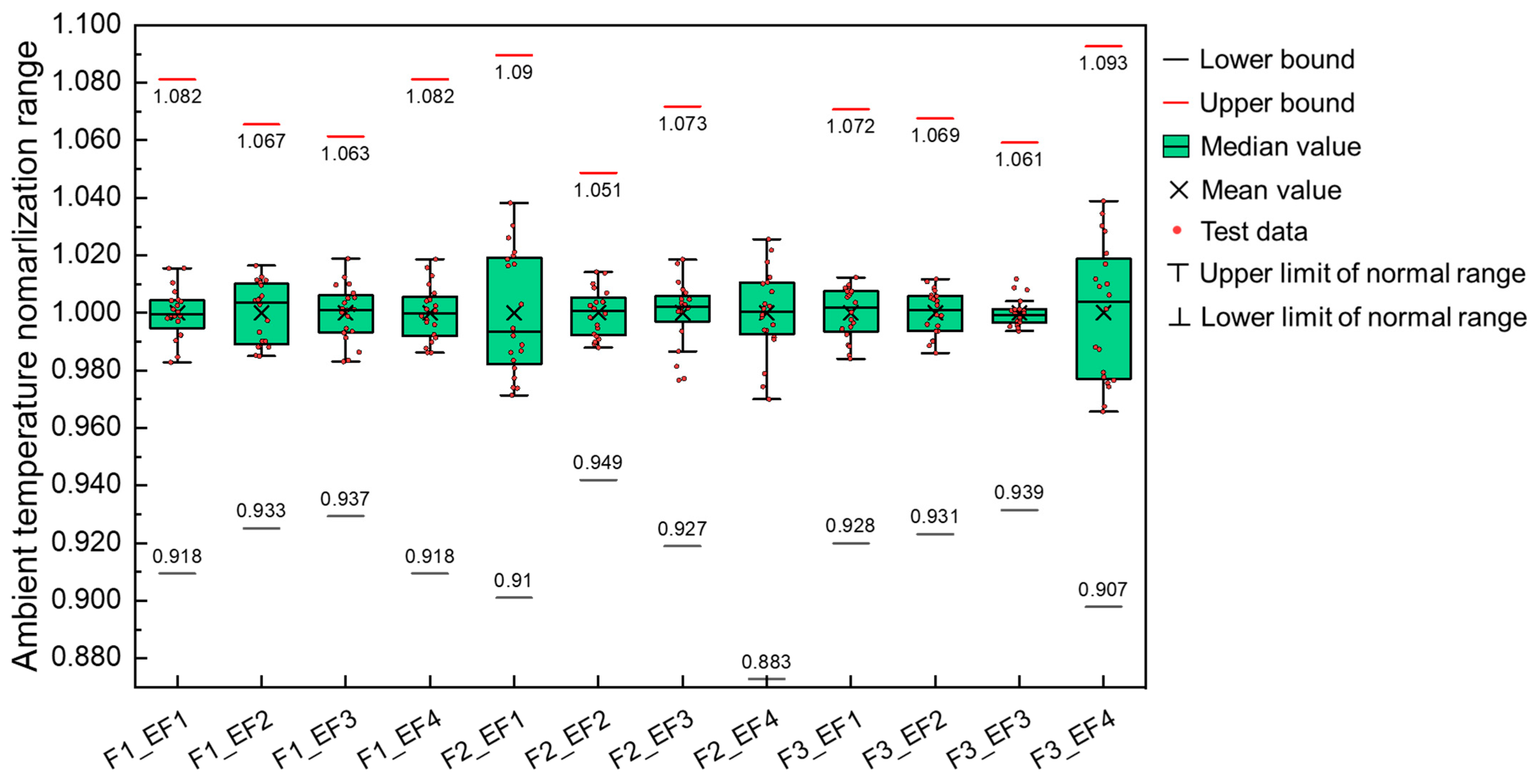

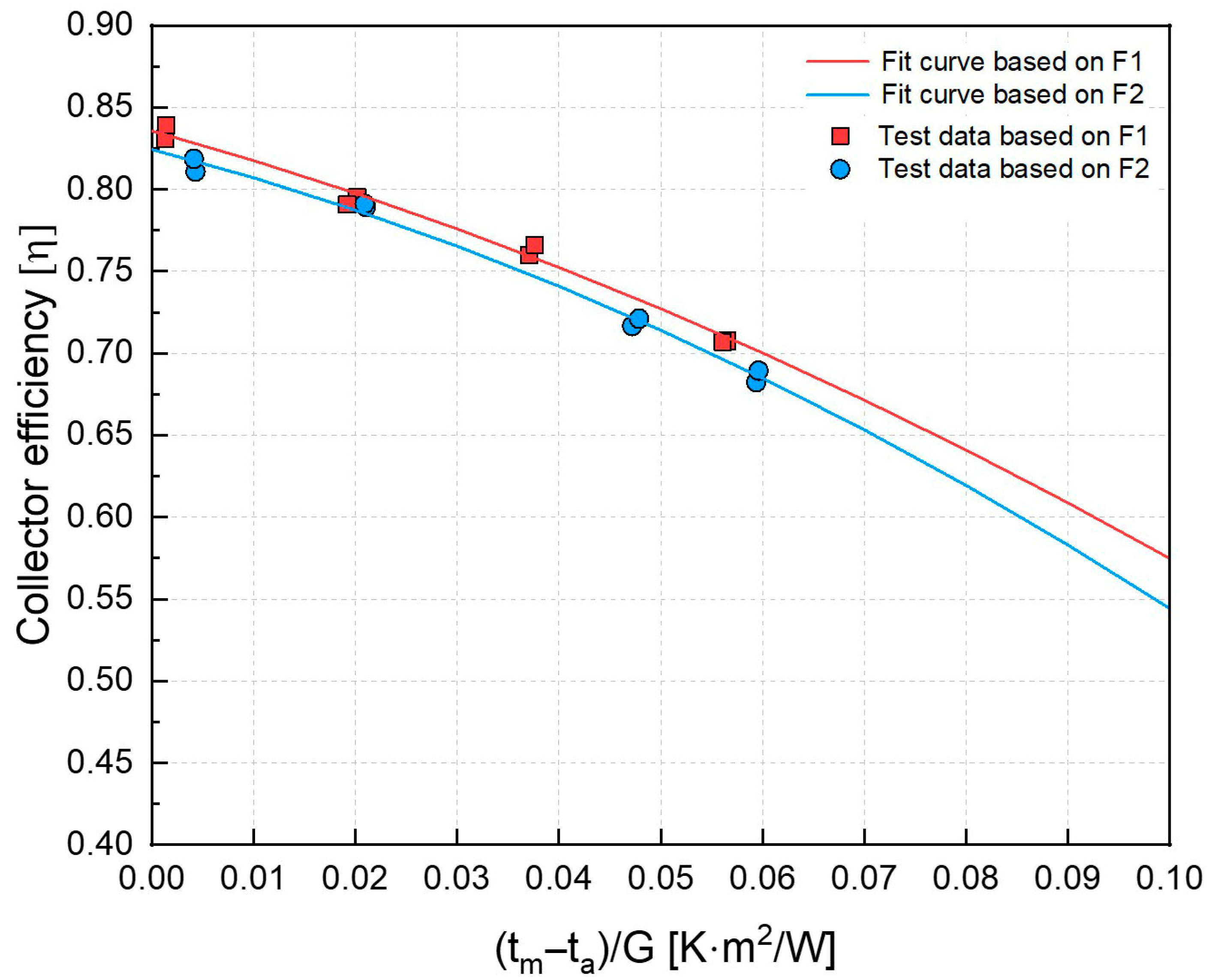

4.1. Collector Efficiency Test Results

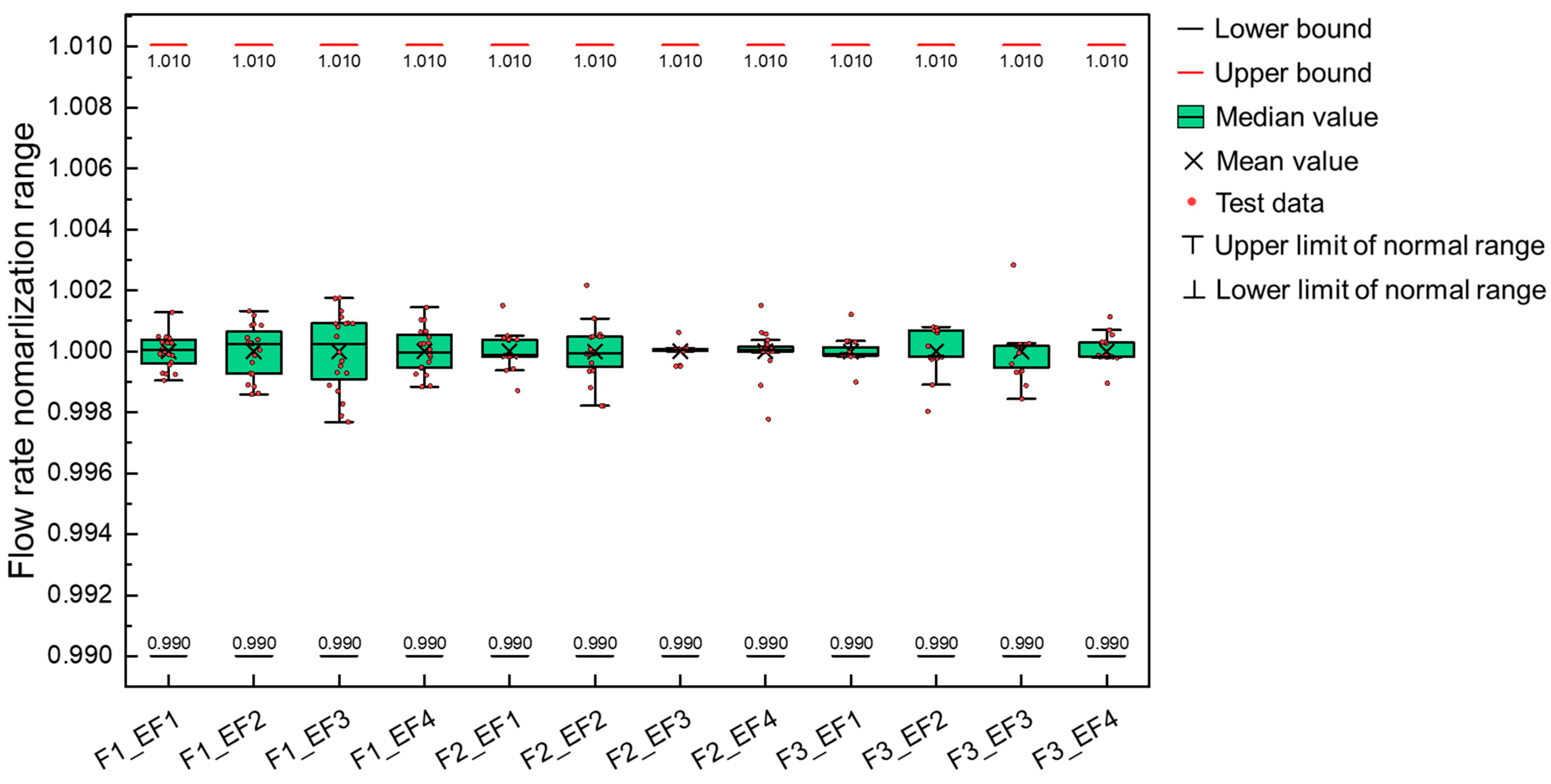

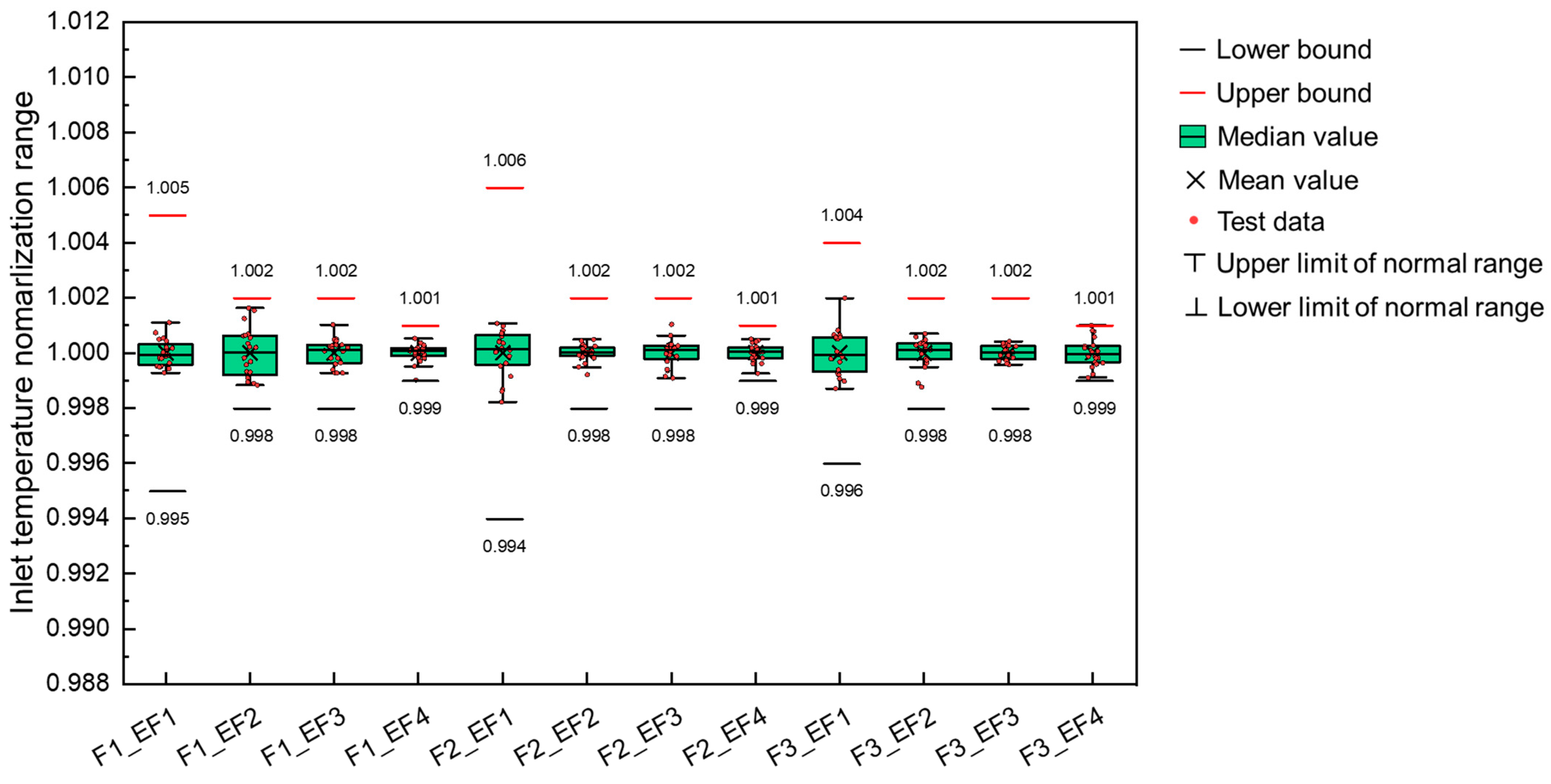

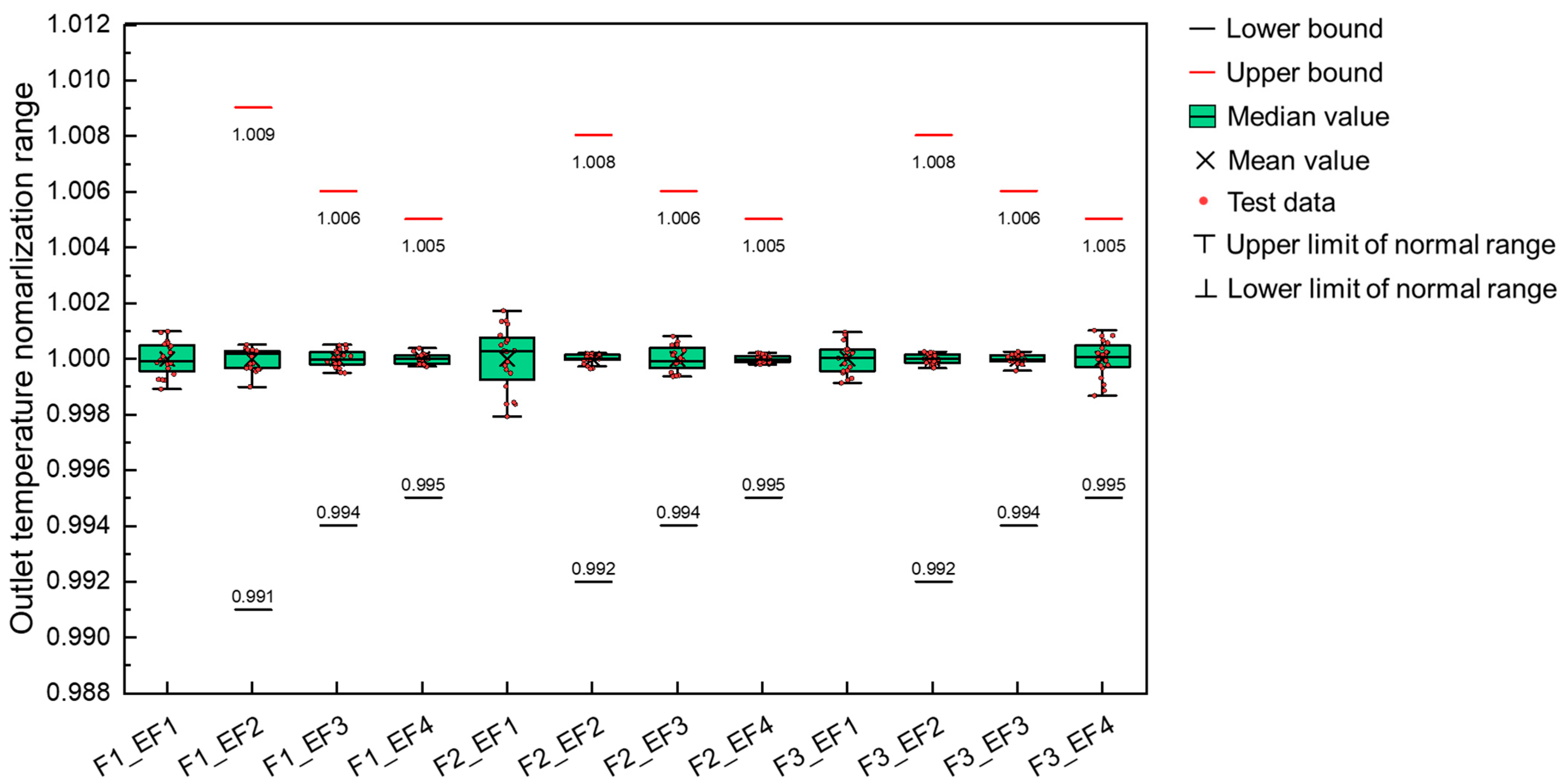

Measurement Data

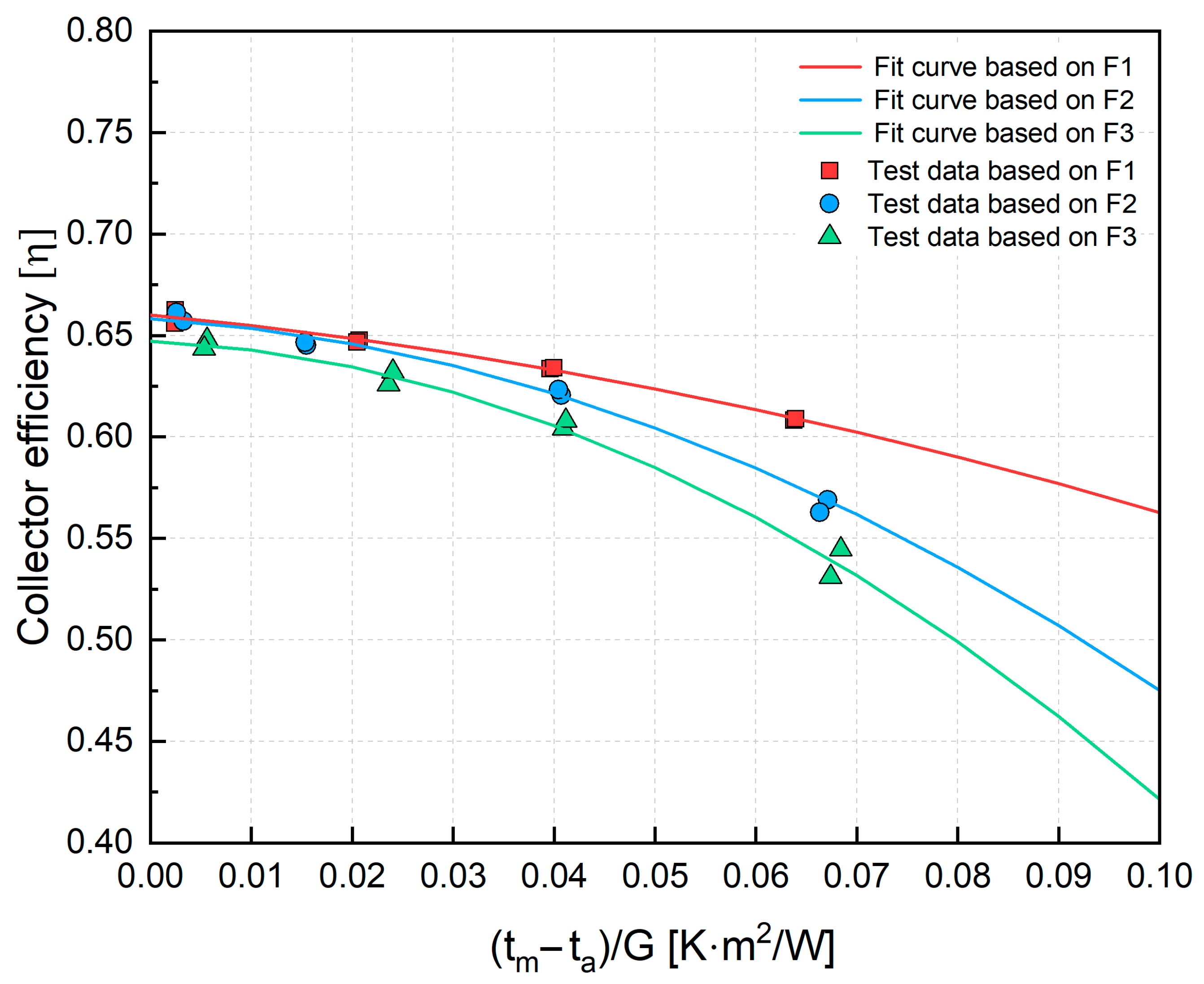

4.2. Instantaneous Efficiency Modeling

Instantaneous Efficiency Model

5. Conclusions

- Thermal output trends and flow rate sensitivity

- Implications for national standards and certification

- Future work

- Study limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Useful power extracted from collector | W |

| Average power extracted from collector | W |

| Aperture area | m2 |

| Hemispherical solar irradiance | W/m2 |

| Collector efficiency based on hemispherical irradiance G | - |

| Mass flow rate of heat transfer fluid | kg/s |

| Temperature difference between fluid outlet and inlet | K |

| Collector inlet temperature | °C |

| Collector outlet temperature | °C |

| Mean temperature of heat transfer fluid | °C |

| Ambient temperature of heat transfer fluid | °C |

| Specific heat capacity of heat transfer fluid at the collector inlet | kJ/(kgK) |

| Coefficient of specific heat capacity, | kJ/(kgK) |

| Coefficient of specific heat capacity, | kJ/(kgK2) |

| Coefficient of specific heat capacity, | kJ/(kgK3) |

| Coefficient of specific heat capacity, | kJ/(kgK4) |

| Coefficient of specific heat capacity, | kJ/(kgK5) |

| Coefficient of specific heat capacity, | kJ/(kgK6) |

| Coefficient of specific heat capacity, | kJ/(kgK7) |

| Peak collector efficiency ( at ) based on hemispherical irradiance G | - |

| First-order heat loss coefficient (EU standard) | W/(m2 K) |

| Second-order heat loss coefficient (EU standard) | W/(m2 K2) |

| First-order heat loss coefficient (ASHRAE standard) | W/(m2 K) |

| Modified temperature difference | (m2 K)/W |

| Test conditions at a flow rate of 0.092 kg/s | |

| Test conditions at a flow rate of 0.067 kg/s | |

| Test conditions at a flow rate of 0.042 kg/s | |

| First inlet temperature condition | |

| Second inlet temperature condition | |

| Third inlet temperature condition | |

| Final inlet temperature condition | |

| Thermal output at flow rates deviated from the reference flow rates (W) | |

| Thermal output under reference flow rate condition (W) | |

| Flow rate under altered conditions (kg/s) | |

| Reference flow rate (kg/s) | |

| Correction factor for thermal output difference due to flow rate variation | |

| CSP | Concentrated Solar Power |

| PVT | Photovoltaic-Thermal |

| ETC | Evacuated Tube Solar Collector |

| KOLAS | Korea Laboratory Accreditation Scheme |

| ISO | International Organization for Standardization |

| IEC | International Electrotechnical Commission |

| ILAC | International Laboratory Accreditation Cooperation |

| EN | European Norm |

| ASHRAE | The American Society of Heating, Refrigerating and Air-conditioning Engineers |

| KS | Korea Industrial Standards |

| B | Letter classification of mechanical engineering |

| TRNSYS | Transient System Simulation Tool |

| PCM | Phase change material |

| Class A | Highest-performance pyranometer classification |

| Class B | Intermediate-performance pyranometer classification |

| WGET | Water in glass evacuated tube collector |

| UpET | U-pipe evacuated tube collector |

References

- IPCC. Climate Change 2023: Synthesis Report. Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar]

- IRENA. World Energy Transitions Outlook 2021: 1.5 °C Pathway; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Sigrist, R. Le Capteur Solaire de Horace-Benedict de Saussure: Genese d’une Science Empirique; Jullien: Geneva, Switzerland, 1993. [Google Scholar]

- Evangelisti, L.; De Lieto Vollaro, R.; Asdrubali, F. Latest advances on solar thermal collectors: A comprehensive review. Renew. Sustain. Energy Rev. 2019, 114, 109318. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Chow, T.T. A review on photovoltaic/thermal hybrid solar technology. Appl. Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- ILAC. ILAC Mutual Recognition Arrangement (MRA). International Laboratory Accreditation Cooperation. 2021. Available online: https://ilac.org (accessed on 7 September 2025).

- Korea Institute of Energy Research (KIER). Certificate of Accreditation–KOLAS Internationally Accredited Testing Laboratory (No. KT203). In Korea Laboratory Accreditation Scheme (KOLAS); Korea Institute of Energy Research (KIER): Daejeon, Republic of Korea, 2025. [Google Scholar]

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standardization and International Electrotechnical Commission: Geneva, Switzerland, 2017.

- ISO 9806:2025; Solar Energy—Solar Thermal Collectors—Test Methods. International Organization for Standardization: Geneva, Switzerland, 2025.

- KS B 8295:2023; Solar Thermal Collectors (Flat Plate, Evacuated-Tube, Fixed Concentrating Type). Korea Standardization Agency: Eumseong-gun, Republic of Korea, 2023.

- EN 12975-2:2006; Thermal Solar Systems and Components—Solar Collectors—Part 2: Test Methods. European Committee for Standardization: Brussels, Belgium, 2006.

- ANSI/ASHRAE Standard 93-2010 (RA 2014); Methods of Testing to Determine the Thermal Performance of Solar Collectors. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): Atlanta, GA, USA, 2014.

- Víg, P.; Seres, I.; Vladár, P. Improving efficiency of domestic solar thermal systems by a flow control. Sol. Energy 2021, 230, 779–790. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Q.; Fan, R.; Lin, X.; Yu, Y. Effects of thermal mass and flow rates on forced- circulation solar hot water system: Comparison of water-in-glass and U-pipe evacuated-tube solar collectors. Sol. Energy 2013, 98, 290–301. [Google Scholar] [CrossRef]

- Farhadi, S.; Atrian Seresht, H.; Aghakhani, H.; Baghapour, B. Performance prediction of heat pipe evacuated tube solar collectors: Analytical modeling and data-driven machine learning/ANN approach with developing web application. Energy 2025, 321, 135512. [Google Scholar] [CrossRef]

- KNREC (Korean New & Renewable Energy Center). KS-Based National Certification Overview for Renewable Energy Equipment (in Korean). 2025. Available online: https://www.knrec.or.kr/biz/introduce/new_cert/intro_energyks.do?gubun=A (accessed on 24 September 2025).

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide: Global Market Development and Trends 2023, Detailed Market Figures 2022; IEA Solar Heating & Cooling Programme; AEE—Institute for Sustainable Technologies: Gleisdorf, Austria, 2024. [Google Scholar] [CrossRef]

- Plaza Gomariz, F.; Cejudo López, J.M.; Domínguez Muñoz, F. An analysis of low flow for solar thermal system for water heating. Sol. Energy 2019, 179, 67–73. [Google Scholar] [CrossRef]

- Razika, I.; Nabila, I.; Madani, B.; Zohra, H.F. The effects of volumetric flow rate and inclination angle on the performance of a solar thermal collector. Energy Convers. Manag. 2014, 78, 931–937. [Google Scholar] [CrossRef]

- Talib, M.A.; Eidan, A.A.; Tawfeeq, A.H.; AL-Fatlawe, F.M.K. Effect of changing the water flow rate on the efficiency of hybrid PVT uncovered collectors without glass: Numerical study. CFD Lett. 2024, 16, 91–104. [Google Scholar] [CrossRef]

- Nugroho, R.; Idrusalhamid, M.; Lubis, A. Investigation of the fluid flow rates effect on the characteristics and performance of evacuated tube solar collector in a parallel-series arrangement. Int. J. Mech. Prod. Eng. 2021, 9. Available online: https://www.iraj.in/journal/journal_file/journal_pdf/2-725-16251239377-11.pdf (accessed on 9 October 2025).

- Elsheniti, M.B.; Kotb, A.; Elsamni, O. Thermal performance of a heat-pipe evacuated-tube solar collector at high inlet temperatures. Appl. Therm. Eng. 2019, 154, 315–325. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Song, W.; Li, T.; Wang, D.; Liu, Y. Optimization and thermal performance of U-type evacuated tube solar collector filled with phase change material. Energy Rep. 2022, 8, 6126–6138. [Google Scholar] [CrossRef]

- Kumar, A.; Said, Z.; Bellos, E. An up-to-date review on evacuated tube solar collectors. J. Therm. Anal. Calorim. 2021, 145, 2873–2889. [Google Scholar] [CrossRef]

- KS B ISO 9060:2018; Specification and Classification of In-Struments for Measuring Hemispherical Solar and Direct Solar Radiation. Korea Industrial Standards: Seoul, Republic of Korea, 2018.

- Tekir, M.; Taskesen, E.; Gedik, E.; Arslan, K.; Aksu, B. Effect of constant magnetic field on Fe3O4-Cu/water hybrid nanofluid flow in a circular pipe. Heat Mass Transf. 2022, 58, 707–717. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

| Author | Analysis Method | Collector Type | Metric | Main Findings |

|---|---|---|---|---|

| Plaza Gomariz et al. [19] | Experiment and simulation (TRNSYS) | Flat plate collector (serpentine type) | Solar fraction (%) Useful energy gain (kWh/year) Hours of operation (h/year) Pump energy consumption (kWh/year) Investment cost (€) | Higher flow slightly increases efficiency and solar fraction, but differences are minimal. Low-flow extends operation time and reduces pump power (11–34%). Initial cost is ~11% lower, with 14–18 years payback for high-flow. |

| Razuja et al. [20] | Experiment | Flat plate collector (covered) | Collector efficiency (%) Storage tank temperature (K) Temperature difference(K) | At 1.033 kW/m2 and 0° tilt, efficiency increases linearly with flow rate (η = 0.68Qv + 49.79, R2 = 0.9898). Efficiency also rises linearly with inclination angle from 0° to 60° (η = 0.43α + 53.07, R2 = 0.967). However, horizontal operation (0°) is more effective for water heating (higher storage temperature). Temperature difference is larger at low flow, but high flow is more effective for efficiency. |

| Talib et al. [21] | Simulation (CFD: ANSYS) | PVT collector(uncovered) | Panel temperature (K) Collector efficiency (%) Outlet temperature (K) | Increasing flow reduces panel temperature, increases efficiency, and slightly raises outlet temperature. Maximum efficiency of 95% is achieved at 0.03 kg/s. Efficiency improvement is due to increased heat absorption, with heat transfer proportional to flow rate. Higher flow enhances heat removal, lowering panel temperature and improving performance. |

| Nugroho et al. [22] | Simulation (Matlab) | Evacuated tube collector | Outlet temperature (K) Thermal output (kW) Collector efficiency (%) | Higher flow increases efficiency and heat absorption but decreases outlet temperature. Maximum efficiency of ~68.65% is achieved at 4.72 kg/s (800 W/m2). Highest outlet temperature of 87.5 °C occurs at the minimum flow rate (1.6 kg/s). Optimal flow depends on the objective (temperature gain vs. efficiency improvement). |

| Elsheniti et al. [23] | Experiment and simulation (Matlab) | Evacuated tube collector (heat pipe) | Outlet temperature (K) Thermal output (kW) Collector efficiency (%) | Considering thermal capacity improves prediction accuracy (max error 12.5% → 4.4%). Higher flow increases efficiency but lowers outlet temperature, while lower flow does the opposite. Beyond certain flow and irradiance conditions, adding more tubes has no further effect on efficiency. At 0.01 kg/s and 800 W/m2, outlet temperature stops rising after ~150 tubes (≈119 °C). Efficiency decreases as tube number increases (e.g., 42% → 27% for 15 → 150 tubes). |

| Vig et al. [14] | Experiment and simulation (TRNSYS) | Evacuated tube collector (heat pipe) | Collector efficiency (%) Daily collected heat (kWh), Temperature difference (K) | Higher flow increases efficiency but saturates above 2.5 kg/min (maximum ≈ 86%). High flow is more effective when storage temperature is low and solar irradiance is high. |

| Gao et al. [15] | Experiment and simulation (TRNSYS) | Evacuated tube collector (water in glass, U-pipe) | Useful energy delivered to storage(kWh/m2) Collector efficiency (%) Pump operation hour(h) | Thermal mass must be considered; neglecting it causes large simulation errors. WGETsc stores 25–35% less useful energy than UpETsc due to large internal volume (~30 L/m2). Pump operation: 736 h/year (UpETsc) vs. 397 h/year (WGETsc). Optimal flow: 20–60 kg/h·m2 (WGETsc), 20–40 kg/h·m2 (UpETsc). |

| Li et al. [24] | Experiment and simulation (CFD: ANSYS) | Evacuated tube collector (U-type, with aluminum fins and embedded PCM) | Collector efficiency (%) Outlet temperature (K) Hot water supply duration (min) PCM Liquid fraction (%) | Applying PCM (323 K) reduces peak HTF temperature by ~7.4 K and extends hot water supply time by 160 min. High flow shortens hot water duration and lowers PCM liquid fraction despite higher temperature output. |

| Present study | Experiment | Evacuated tube collector (heat pipe) | Collector efficiency (%) Thermal output(W) Empirical flow rate correction factor (-) | Thermal output increases by ~6% as flow rises (0.042 → 0.092 kg/s). High flow enhances heat removal but raises external losses. Output shows non-linear dependence on flow (α ≈ 0.05–0.08). |

| Component | Specification |

|---|---|

| Type | Evacuated tube solar collector (double-glass, heat pipe type) |

| Dimensions | Width: 1720 mm, Height: 1990 mm |

| Area | Gross area: 3.42 m2, Aperture area: 2.10 m2 |

| Design specifications | |

| Operating temperature | (−20 to 120) °C/Optimal: (10 to 85) °C |

| Working fluid flow rate | (0.01 to 0.04) kg/s/Optimal: (0.018 to 0.037) kg/s |

| Manifold | |

| Outer casing | Material: Aluminum, Thickness: 1.8 mm, Dimensions: 1720 mm × 156 mm |

| Main pipe | Heat transfer pipe: Copper (Outer Ø 37 mm, Thickness: 1.0 mm, Length: 1800 mm, Qty: 1) Connector: Copper (Outer Ø 27 mm, Thickness: 1.2 mm) |

| Insulation | Primary: Rock wool, Thickness: 20 mm, Heat resistance: 410 °C Secondary: Polyurethane, Thickness: 40 mm, Heat resistance: 120 °C |

| Absorber unit | |

| Transparent cover | Material: Double borosilicate glass, Thickness: 1.8 mm, Outer Ø 58 mm, Inner Ø 47 mm, Length: 1800 mm, Qty: 21 |

| Absorber plate | Material: Aluminum, Thickness: 1.6 mm, Width: 47 mm, Length: 1721 mm, Qty: 21, Coating: Selective absorber coating |

| Heat pipe | Condensation section: Copper Ø 24 mm, Thickness: 1.0 mm, Length: 95 mm, Qty: 21 Evaporation section: Copper Ø 8 mm, Thickness: 0.6 mm, Length: 1705 mm, Qty: 21 |

| Reflector | None |

| Equipment | Standard Requirements | Available Equipment Specification |

|---|---|---|

| Pyranometer | Class B pyranometer as defined in KS B ISO 9060 | Class A pyranometer as defined in KS B ISO 9060 |

| Temperature sensors | Measurement uncertainty within 0.1 K; high resolution of ±0.02 K required for detecting temperature variations over time Outdoor air temperature: accuracy of 1 K and uncertainty within 0.5 K | Collector and ambient temperature sensors Standard uncertainty: 0.045 K Resolution: 0.01 K |

| Flow meter | Accuracy within ±1% of the mass flow rate measured per hour; calibration must cover the full range of flow and temperature used in collector testing | Calibration range: (2–20) kg/min Deviation: (−0.56% to 0.53%) |

| Parameter | Tolerance from Average Value |

|---|---|

| Global irradiance on collector plane | ±50 W/m2 |

| Ambient temperature (outdoor test) | ±1.5 K |

| Mass flow rate of working fluid | ±1% |

| Inlet fluid temperature | ±0.1 K |

| Outlet fluid temperature | ±0.4 K |

| Test Date | Solar Irradiance | Mass Flow Rate | Ambient Temperature | Inlet Temperature | Outlet Temperature |

|---|---|---|---|---|---|

| W/m2 | kg/s | °C | °C | °C | |

| 11 November 2024 11:39:56 a.m. | 949.1 | 0.0927 | 18.25 | 18.85 | 22.22 |

| 11 November 2024 11:44:56 a.m. | 946.4 | 0.0927 | 18.22 | 18.85 | 22.24 |

| 4 October 2024 1:57:55 p.m. | 1043.8 | 0.0927 | 22.22 | 42.02 | 45.68 |

| 4 October 2024 2:02:55 p.m. | 1038.2 | 0.0927 | 22.62 | 42.07 | 45.70 |

| 4 October 2024 2:59:55 p.m. | 1002.6 | 0.0925 | 23.83 | 61.82 | 65.26 |

| 4 October 2024 3:04:55 p.m. | 993.1 | 0.0924 | 23.85 | 61.82 | 65.24 |

| 24 October 2024 12:29:56 p.m. | 1025.9 | 0.0928 | 18.13 | 81.85 | 85.21 |

| 24 October 2024 12:34:56 p.m. | 1019.7 | 0.0928 | 18.30 | 81.85 | 85.19 |

| 8 November 2024 11:52:26 a.m. | 1022.3 | 0.0674 | 16.39 | 17.23 | 22.22 |

| 8 November 2024 11:57:26 a.m. | 1020.0 | 0.0674 | 17.13 | 17.25 | 22.25 |

| 30 September 2024 2:04:59 p.m. | 1024.4 | 0.0674 | 29.15 | 42.56 | 47.48 |

| 30 September 2024 2:09:59 p.m. | 1020.0 | 0.0674 | 29.38 | 42.55 | 47.47 |

| 31 October 2024 11:49:56 a.m. | 1038.6 | 0.0674 | 20.34 | 60.23 | 65.02 |

| 31 October 2024 11:54:56 a.m. | 1038.9 | 0.0674 | 20.64 | 60.26 | 65.07 |

| 6 November 2024 11:04:56 a.m. | 1036.2 | 0.0674 | 12.94 | 80.31 | 84.68 |

| 6 November 2024 11:09:56 a.m. | 1051.0 | 0.0674 | 12.74 | 80.28 | 84.66 |

| 2 October 2024 1:44:55 p.m. | 1060.0 | 0.0421 | 20.74 | 22.60 | 30.78 |

| 2 October 2024 1:49:55 p.m. | 1063.8 | 0.0421 | 21.02 | 22.62 | 30.78 |

| 2 October 2024 2:44:55 p.m. | 1025.9 | 0.0420 | 21.80 | 42.17 | 49.84 |

| 2 October 2024 2:49:55 p.m. | 1017.2 | 0.0420 | 21.54 | 42.15 | 49.83 |

| 31 October 2024 2:19:56 p.m. | 955.2 | 0.0421 | 24.44 | 60.11 | 66.98 |

| 31 October 2024 2:24:56 p.m. | 947.4 | 0.0421 | 24.54 | 60.11 | 66.98 |

| 7 November 2024 1:39:56 p.m. | 1002.7 | 0.0421 | 16.46 | 80.88 | 87.20 |

| 7 November 2024 1:44:56 p.m. | 997.6 | 0.0421 | 15.79 | 80.83 | 87.28 |

| Condition | ||||

|---|---|---|---|---|

| F1 | −0.4850 | −0.0049 | 0.6602 | 630.4 |

| F2 | −0.3192 | −0.0151 | 0.6583 | 613.2 |

| F3 | −0.2304 | −0.0203 | 0.6472 | 594.8 |

| Condition | Parameter (W) | Parameter (W) | Parameter (W) | (W) |

|---|---|---|---|---|

| F1 | −19.4 | −10.4 | 660.2 | 630.4 |

| F2 | −12.8 | −32.3 | 658.3 | 613.2 |

| F3 | −9.2 | −43.2 | 647.2 | 594.8 |

| Component | Specification |

|---|---|

| Type | Evacuated tube solar collector (double-glass, heat pipe type) |

| Dimensions | Width: 1270 mm, Height: 1950 mm |

| Area | Gross area: 2.48 m2, Aperture area: 1.60 m2 |

| Manifold | |

| Outer casing | Material: Aluminum, Thickness: 2.0 mm, Dimensions: 1950 mm × 146 mm |

| Main pipe | Heat transfer pipe: Copper (Outer Ø 39 mm, Thickness: 2.0 mm, Length: 1950 mm, Qty: 1) Connector: Copper (Outer Ø 22 mm, Thickness: 2.0 mm) |

| Absorber unit | |

| Transparent cover | Material: Double borosilicate glass, Thickness: 1.6 mm, Outer Ø 58 mm, Inner Ø 47 mm, Length: 1800 mm, Qty: 18 |

| Absorber plate | Material: Aluminum, Width: 37 mm, Length: 1800 mm, Qty: 18, Coating: Selective absorber coating |

| Heat pipe | Condensation section: Copper Ø 20 mm, Thickness: 1.0 mm, Length: 70 mm, Qty: 18 Evaporation section: Copper Ø 8 mm, Thickness: 0.6 mm, Length: 1655 mm, Qty: 18 |

| Reflector | None |

| Condition | ||||

|---|---|---|---|---|

| F1 | −1.7326 | −0.0088 | 0.8358 | 741.0 |

| F2 | −1.6108 | −0.0119 | 0.8244 | 727.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-W.; Lee, W.; Lee, K.-h. Thermal Performance of Double-Glass Evacuated Tube Solar Collectors: Flow Rate Variation Under International Standard Testing Conditions. Energies 2025, 18, 5388. https://doi.org/10.3390/en18205388

Kim D-W, Lee W, Lee K-h. Thermal Performance of Double-Glass Evacuated Tube Solar Collectors: Flow Rate Variation Under International Standard Testing Conditions. Energies. 2025; 18(20):5388. https://doi.org/10.3390/en18205388

Chicago/Turabian StyleKim, Deuk-Won, Wangje Lee, and Kyoung-ho Lee. 2025. "Thermal Performance of Double-Glass Evacuated Tube Solar Collectors: Flow Rate Variation Under International Standard Testing Conditions" Energies 18, no. 20: 5388. https://doi.org/10.3390/en18205388

APA StyleKim, D.-W., Lee, W., & Lee, K.-h. (2025). Thermal Performance of Double-Glass Evacuated Tube Solar Collectors: Flow Rate Variation Under International Standard Testing Conditions. Energies, 18(20), 5388. https://doi.org/10.3390/en18205388