Abstract

Industrial electric drives account for a dominant share of electricity consumption in manufacturing, making their optimal configuration a critical factor for both sustainability and cost reduction. Traditional design approaches based on prototyping and empirical testing are often costly and insufficient for systematically exploring alternative configurations. This study introduces an integrated computational framework that combines digital twin (DT) modeling and virtual commissioning (VC) to enable energy-aware configuration of industrial electric drive systems at early design stages. The methodology employs parameterized component models derived from manufacturer catalog data, implemented in a commercial simulation environment and integrated into an industrial-grade VC platform. Validation is performed on two conveyor-based testbeds, enabling systematic comparison of simulation outputs with physical measurements. The results demonstrate predictive accuracy sufficient to quantify trade-offs in energy consumption, losses, and efficiency across different vendor solutions. Case studies involving belt and strap conveyors highlighted how the framework supports vendor-neutral decision making, revealing nonintuitive optimization trade-offs between minimizing energy consumption and maximizing efficiency. The proposed framework advances sustainable automation by embedding energy analysis directly into commissioning workflows, offering reproducible, scalable, and cross-domain applicability. Its modular design supports transfer to sectors such as renewable energy, transportation, and biomedical mechatronics, where energy efficiency is equally decisive.

1. Introduction

Industrial electric drive systems account for approximately 45% of global electricity consumption and up to 70% within industrial facilities [1]. Their optimal configuration is, therefore, essential for achieving sustainability targets and reducing operating costs. With rising energy prices and stringent environmental regulations, such as the European Green Deal’s target of a 55% reduction in greenhouse gas emissions by 2030 [2], the systematic design of energy-optimized drive systems has become a strategic priority. This challenge spans diverse sectors, from conveyor systems, pumps, and compressors in manufacturing to specialized applications in robotics, renewable energy systems [3,4,5], and biomedical engineering, for example, portable devices, robotic surgery, and advanced prosthetics [6,7,8,9], where energy constraints directly affect performance.

The economic potential of improved industrial drive efficiency is substantial, reinforcing the urgency of adopting simulation-driven approaches. This trend is reinforced by policy and regulatory initiatives, including IEC 60034-30-1 [10] efficiency standards and the extended product approach under the Ecodesign Directive [11]. At the global level, energy-aware drive design directly supports the United Nations Sustainable Development Goals, particularly SDG 7 (affordable and clean energy) and SDG 9 (industry, innovation, and infrastructure) [12].

International policy frameworks have set ambitious energy-reduction targets. These drivers create both challenges and opportunities for manufacturing industries to adopt simulation-based optimization. Traditional design approaches for drive systems have relied heavily on physical prototyping and empirical testing. While effective, these methods are costly, time-consuming, and limited in their ability to systematically evaluate multiple design alternatives. Computational modeling addresses these shortcomings by providing reproducible and scalable analyses. Within this paradigm, two complementary concepts enable systematic exploration: digital twins (DTs), which provide parameterized, reusable models replicating physical and dynamic characteristics of real systems, and virtual commissioning (VC), which validates control software against high-fidelity system models by integrating real control logic, vendor-specific data, and closed-loop testing [13,14,15,16]. Crucially, the synergy between DT (providing high-fidelity component physics) and VC (enabling real-time HIL tests with industrial control) allows for the first-time systematic evaluation of energy consumption and efficiency under dynamic, real-world operating conditions, which is the core focus of this study.

Despite these advancements, existing approaches inadequately integrate DT and VC for energy-aware design of drive systems [17]. Current DT-based approaches typically emphasize generic system modeling without direct industrial applicability, while VC studies focus primarily on functional verification without incorporating detailed energy analysis [18,19]. This methodological gap limits the availability of computational methods for vendor-neutral, energy-aware component selection and system configuration. Bridging this gap is essential for advancing sustainable automation practices.

This study addresses three research questions: (1) How can DT models be effectively integrated with VC platforms to enable energy analysis? (2) What level of predictive accuracy can be achieved using only manufacturer catalog data? (3) How can the framework support vendor-neutral component selection decisions? To answer these questions, an integrated computational framework is introduced. The proposed approach combines parameterized digital twin models with virtual commissioning capabilities to enable quantitative energy analysis of industrial electric drive systems at early design stages.

This study also examines the identified gaps by presenting the first comprehensive framework that integrates detailed DT models of drive components with industrial VC platforms for energy-aware configuration. Unlike prior work focusing on either system-level DT concepts or functional VC validation [17,20,21], this research provides the following: (1) physics-based component models with validated energy predictions, (2) systematic catalog-based parameterization procedures, (3) seamless integration with industrial control hardware, and (4) vendor-neutral evaluation methodology demonstrated on multivendor testbeds. By embedding an energy analysis into established engineering workflows, the proposed approach advances both the scientific understanding of DT-VC integration and its practical applicability for sustainable automation.

The main contributions of this paper are given as follows: (1) a structured methodology for simulation-driven energy optimization of industrial drives, (2) a validated library of parameterized component models enabling vendor-neutral evaluation, (3) seamless integration with industrial VC platforms ensuring practical applicability, and (4) experimental validation on conveyor-based testbeds, demonstrating predictive accuracy and industrial relevance. These contributions advance the state-of-the-art by providing systematic tools for energy-aware drive configuration within established engineering workflows.

The remainder of this article is structured as follows. Section 2 reviews related work on digital twins, virtual commissioning, and energy-aware drive configuration. Section 3 presents the proposed computational framework and DT library. Section 4 provides a detailed mathematical description of the physics-based digital twin models, including the parameterized equations for the inverter, induction motor, and mechanical subsystems. Section 5 describes the integration with an industrial VC platform. Section 6 reports validation results obtained on conveyor-based testbeds. Section 7 applies the framework to case studies in component selection. Section 8 discusses implications and limitations, and Section 9 concludes the paper with directions for future research.

2. Related Work

Contemporary mechatronic system engineering is evolving toward simulation-based digital design, with digital twins and virtual commissioning emerging as key paradigms for accelerating development [20]. This section reviews recent contributions in VC, DT, and energy-aware drive modeling, highlighting current capabilities and limitations that motivate the present research.

2.1. Virtual Commissioning and Limitations

Virtual commissioning is widely recognized as a method for shortening development cycles and improving quality by enabling early-stage testing in risk-free environments. Recent contributions confirm its role in PLC testing, offline commissioning, and operator training, reducing software–hardware integration risks and supporting operator readiness [21,22,23,24,25]. Commercial tools such as Siemens SIMIT, ABB RobotStudio, or EKS RF::Suite, employed for control logic validation and broader system integration [17,26].

However, VC implementations often rely on simplified plant or drive models that omit dynamic and energy-related behavior, limiting realistic evaluation [17,21,27]. Lifecycle-oriented methodologies emphasize parallel development, continuous support, and stakeholder collaboration [23,24,25,28,29], yet the absence of accurate drive-level models restricts energy-aware design. Case studies in rolling mills, robotic cells, and bottling plants demonstrate VC’s potential, although quantitative energy assessments remain scarce [17,22,26,30]. Domain-specific DT software for infrastructure [31] and entity data models for simulation [32] have been proposed, yet energy-aware VC workflows across devices remain underdeveloped. Current practice emphasizes functional and safety validation over energy-related performance metrics, limiting sustainability-driven engineering.

2.2. Digital Twin Challenges

Digital twin technologies extend VC by enabling dynamic synchronization between virtual and physical systems. Research highlights their potential for automated re-commissioning using multibody dynamic models and adaptive control strategies [21]. Applications in electric vehicles and locomotive systems demonstrate their ability to validate energy management strategies and assess design requirements [33,34]. DTs have also been employed to model electrical energy conversion systems, where case studies confirmed their capability to capture dynamic efficiency and operational performance under varying load conditions [35].

Industrial projects further illustrate both achievements and limitations. The EUREKA Clusters initiative delivered methodologies for energy-efficient manufacturing applicable during VC [36], while the AREUS project achieved up to 30% energy savings in KUKA robots through 600 VDC grid integration [37,38,39]. The ongoing SPEAR project developed predictive tools for energy optimization during VC [40,41]. These initiatives demonstrate the industrial relevance of simulation-driven energy optimization, yet they mostly target system-level performance rather than detailed drive-level fidelity.

A recent review emphasized the role of DTs in industrial energy management, identifying classification schemes, challenges, and future directions, particularly regarding the integration of monitoring and optimization functions [42]. Nevertheless, their use in drive systems remains largely conceptual, with limited integration into industrial workflows. Practical aspects such as calibration and tuning of motor–inverter subsystems for energy optimization are rarely addressed, which weakens the connection between DT-based simulations and industrial drive engineering.

Beyond industrial automation, DT frameworks have also been explored in healthcare. Shu et al. [6] demonstrated real-time synchronization between patient anatomy and tool motion in skull base surgery, while Vallée [7] and Mone [8] discussed their broader role in biomedical systems. Additionally, Corral-Acero et al. [43] introduced a cardiac digital twin enabling precision cardiology, showing how simulation–data integration can transform patient-specific decision making. Although outside of the energy domain, these cases illustrate the methodological transferability of DT concepts.

Most current implementations provide system-level synchronization but insufficient coverage of drive-level energy performance—a decisive factor in industrial automation. The reviews confirm that, while DTs are increasingly adopted in domains such as smart grids and renewable energy [44], their deployment in industrial drive engineering remains exploratory. This mismatch between the high potential of DT frameworks and their limited application underscores the need for approaches that couple adaptive, model-based DTs with real-time data. Recent advances suggest that such integration can enhance resilience, improve fault tolerance, and increase operational flexibility in power systems [45].

2.3. Drive Modeling and Energy Efficiency

High-fidelity models of electric drives capture nonlinearities, component-level losses, and control dynamics, offering valuable insights into performance under diverse operating conditions [46,47,48]. Modular simulation environments and catalog-based parameterization procedures enable systematic validation of inverters, motors, and mechanical subsystems [49]. Despite these advances, such models are typically developed in isolation, without systematic integration into VC or DT workflows.

Studies on energy efficiency have quantified consumption profiles, regenerative braking, and hybrid storage strategies [46,50,51]. Recent analyses also highlight the dominant role of industrial drives in global energy demand [24,25,28]. Yet these insights are seldom embedded into VC/DT environments, which limits their impact on virtual validation and energy-aware system configuration.

Bridging these two domains—i.e., the precision of high-fidelity drive models and the systemic perspective of energy-efficiency studies—offers significant potential. Their integration into VC/DT frameworks could enable multilevel optimization, where component-level dynamics inform system-level energy management. This convergence would strengthen the role of digital twins in industrial drive engineering by linking detailed physical modeling with actionable strategies for energy-aware decision support.

2.4. Applications in Automation

VC and DT have been widely applied to automation tasks such as PLC code debugging, virtual equipment selection, and early-stage system configuration. These applications reduce commissioning risks and enable hardware-in-the-loop testing [33,52]. Advanced case studies demonstrate improvements in reliability, quality assurance, and system flexibility through integrated simulation and control validation [17,21,26].

A methodology based on virtual commissioning demonstrated improvements in scheduling reactive to machine breakdowns within flow shop manufacturing systems, enhancing makespan performance via DT-supported planning [53]. Separately, a design method employing DT for PLC control systems enabled high-fidelity validation of controller logic and significantly shortened commissioning time in a multistorey elevator prototype [54].

DT frameworks applied to hybrid vehicles with energy storage and modular system simulations have yielded measurable improvements in energy efficiency and battery life [33,34]. However, existing implementations still focus mainly on functional validation and operational flexibility, offering limited support for systematic, energy-oriented evaluation of electric drive systems. Given the growing industrial demand for lifecycle-based energy assessments, VC and DT frameworks must evolve to explicitly integrate energy-aware modeling and evaluation.

2.5. Research Gaps

The limitations identified across VC, DT, drive modeling, and automation applications converge into several critical research gaps. Analysis of existing literature, summarized in Table 1, reveals four primary gaps that this research addresses:

Table 1.

Summary of related work on VC, DT, and energy-aware drive modeling.

- Integration gap. VC implementations lack embedded energy modeling capabilities, while energy-efficient drive models remain isolated from commissioning platforms.

- Fidelity gap. Current DT frameworks provide system-level modeling without the component-level drive detail necessary for accurate energy prediction.

- Validation gap. Limited experimental validation of energy predictions in industrial settings, with most studies relying on simulation-only verification.

- Application gap. Absence of vendor-neutral evaluation frameworks that enable systematic comparison of drive alternatives.

These gaps establish the need for the unified framework presented in this paper, which integrates high-fidelity drive models with industrial VC platforms while maintaining practical applicability through catalog-based parameterization.

3. Proposed Methodology

This section introduces a structured, simulation-driven methodology for the energy-aware configuration of industrial electric drive systems. The framework integrates digital twin modeling, virtual commissioning, and systematic validation, establishing a reproducible workflow that links early-stage system design with industrial applicability. The overall process is organized into five sequential stages (Figure 1), which include:

Figure 1.

Information and decision flow within the proposed simulation-based methodology for energy-aware configuration of industrial electric drive systems.

- Development of parameterized component models,

- Integration into a standardized simulation environment,

- Evaluation of energy-related performance indicators,

- Validation against measurements from physical testbeds,

- A decision-support layer.

The methodology addresses Industry 4.0 priorities and sustainability requirements by incorporating energy efficiency assessment directly into digital engineering workflows. The novelty lies in combining parameterized DT component models, validated against physical testbeds, with a vendor-neutral VC environment. This hybrid integration ensures not only functional verification but also quantitative energy analysis at the design stage, providing a transparent, reproducible, and vendor-independent evaluation that ensures scalability across different applications.

3.1. Model Development

The framework employs a modular digital twin modeling approach representing the key components of industrial electric drive systems. This approach facilitates the creation of a reusable library of models for typical drive components, enabling engineers to benchmark alternative hardware solutions transparently across manufacturers.

The developed DT models cover the inverter, induction motor, shaft, gearbox, rolling bearings, load, and encoder. Parameterization is derived exclusively from manufacturer catalog data, ensuring broad applicability without requiring proprietary information. Where necessary, catalog data are refined through empirical measurements to improve fidelity.

A detailed mathematical description of each subsystem, including the governing equations, parameterization procedures, and implementation details, is presented in Section 4. This comprehensive modeling foundation ensures both predictive accuracy and industrial applicability of the proposed framework.

3.2. Simulation Environment

DT models are implemented in the EKS RF::ViPer VC environment. Standardized operating scenarios—including acceleration and deceleration profiles, conveyor tasks, and scalar control strategies with linear or quadratic voltage amplification—reflect typical intralogistics operations. Embedding DT models in the VC platform extends the methodology beyond pure simulation, enabling hardware-in-the-loop testing and control validation using industrial PLCs.

3.3. Evaluation

Simulation outputs are evaluated with energy-related indicators to assess the performance of alternative hardware and control strategies. These metrics provide a quantitative basis for comparing different configurations under realistic operating conditions. The analyzed indicators include total energy consumption, energy losses, and overall efficiency, which are used to evaluate both absolute energy demand and relative performance.

3.4. Model Validation

Model accuracy is established through systematic comparison with measurements obtained from two physical conveyor-based testbeds. Both long-duration and transient operating profiles are executed under identical boundary conditions in simulation and experiment to ensure a direct comparison of energy consumption time series. Validation is quantified using a set of standard accuracy indicators—mean error, mean absolute error, root mean square error, and mean absolute scaled error—along with energy-specific error metrics, such as absolute and relative energy deviations. This dual validation, covering both signal accuracy and cumulative energy consumption, reinforces predictive reliability and enhances the industrial relevance of the models.

3.5. Decision-Support Layer

The framework incorporates a decision-support layer that synthesizes validated simulation results into actionable engineering insights. Key performance indicators include total energy consumption, component-specific losses, and overall system efficiency. These indicators provide a quantitative basis for ranking hardware alternatives and assessing the impact of control strategies. By structuring validated results into a reusable knowledge base, the framework supports vendor-neutral decision making and facilitates the inclusion of sustainability metrics in industrial design workflows.

In summary, the proposed computational framework provides a complete pathway from component modeling to decision support, ensuring both scientific rigor and industrial applicability. The modular architecture enables extension to emerging domains while maintaining core energy optimization capabilities.

4. Modeling of Electric Drive Systems

This section provides the mathematical and functional descriptions of the digital twin models developed for the proposed methodology. The subsystem models cover the inverter, induction motor, gearbox, and rolling bearings.

4.1. Inverter Model

The created inverter model is designed to encapsulate the primary functions essential for control and energy analysis within industrial environments. These functions include sophisticated speed profile management, positioning, scalar control strategies, and the calculation of energy-related parameters.

4.1.1. Speed Profile Generator

The model incorporates three industrial ramp types (rectangular, trapezoidal, and smoothed with corresponding angular acceleration waveforms). The dynamic ramp time is calculated via the speed change factor defined as:

where is the speed change factor [1], is the setpoint speed value [rpm], is the actual speed value [rpm], and is the nominal speed of the motor connected to the inverter [rpm].

The total time required for speed change is calculated via the following:

where is the time required to change the motor speed to the setpoint value [s], is the initial rounding time of the speed profile [s], is the defined motor acceleration time [s], is the defined motor deceleration time [s], and is the final rounding time of the speed profile [s].

The maximum angular acceleration , required to achieve the nominal speed within the defined ramp time, is calculated using:

where is the angular acceleration required to reach nominal speed within the ramp time [rad/s2], and is the cycle time of the implemented speed profile generation algorithm [s].

The actual angular acceleration , dependent on the current segment of the speed profile, is determined by:

where is the actual angular acceleration [rad/s2], and is the currently realized fragment of the speed profile [s].

Finally, the actual speed is calculated using the following result:

4.1.2. Positioning Algorithm

The positioning model calculates the required angular distance or linear displacement necessary for deceleration, based on the speed profile’s acceleration characteristics, i.e.,

where is the angular distance required to reach the setpoint value [rad], and

where is the linear displacement required to reach the setpoint value [m] and is the rotating arm radius [m].

4.1.3. Scalar Control Algorithms

The models implement linear control. The motor supply frequency is calculated for both strategies using [55]:

where is the actual output current frequency from the inverter [Hz] and is the power supply network frequency [Hz].

For linear scalar control, the output voltage is determined by the following relationship:

where is the actual output voltage from the inverter [V], is the RMS voltage of the power supply network [V], and is the voltage boost value at zero speed [V].

4.1.4. Inverter Efficiency and Power Consumption

The inverter’s efficiency is determined by the ratio of output power to input power [56]:

where is the inverter efficiency [%], is the output power of the inverter to the motor [W], and is the power drawn by the inverter from the network [W].

The total electrical power consumption from the grid is calculated as the sum of standby power and power loss, based on the motor’s power consumption [55]:

where is the actual power drawn from the supply network by the inverter [W], is the stand-by power drawn by the inverter [W], and is the actual power drawn by the motor connected to the inverter [W].

4.2. Induction Motor Model

The motor model provides crucial electrical and mechanical parameters, focusing on efficiency and power factor, both of which are parameterized using catalog data.

4.2.1. Motor Efficiency and Power Factor

Motor efficiency is calculated by the ratio of mechanical output power to electrical input power [57], i.e.,

where is the electric motor efficiency [%], is the mechanical power value at the motor output [W], and is the electrical power value at the motor input [W].

Using manufacturer catalog data points (for full, 3/4, and 1/2 load), the actual motor efficiency is approximated by a logarithmic fit:

where is the actual motor efficiency [%], is the coefficient a for the logarithmic fit of efficiency [1], is the actual motor load (ratio of output power to nominal value) [1], and is the coefficient b for the logarithmic fit of efficiency [1].

The motor’s power factor is similarly defined and approximated by a logarithmic fit based on catalog data:

where is the actual motor power factor [1], is the coefficient a for the logarithmic fit of power factor [1], and is the coefficient b for the logarithmic fit of power factor [1].

4.2.2. Motor Power Consumption

The electrical power consumed by the motor is the core output for energy analysis. It is calculated by linking the required mechanical power (load, acceleration, and friction power) to the motor efficiency [55]:

where is the actual electrical power drawn by the induction motor [W], is the actual load power of the motor at rest [W], is the actual power required for motor speed change (acceleration/deceleration) [W], is the actual power required to overcome friction forces (e.g., in gearbox, bearings) [W], and is the actual motor efficiency [%].

4.3. Mechanical Subsystems

The mechanical part of the drive system was divided into three key subsystems: gearbox, rolling bearings, and load. Each was modeled separately to capture energy losses and reflected inertia.

4.3.1. Gearbox

The gearbox model calculates the output speed and output power based on the gear ratio i and efficiency . The output speed is as follows [58]:

where is the gearbox output speed [rpm], is the actual motor shaft speed (gearbox input) [rpm], and is the gearbox ratio [1]. Gearbox efficiency is approximated using a logarithmic fit to the manufacturer’s data points:

where is the gearbox efficiency determined in the created model [%], is the coefficient a for the logarithmic fit of efficiency [1], is the coefficient b for the logarithmic fit of efficiency [1], and is the gearbox startup efficiency [%].

4.3.2. Rolling Bearings

Two catalog-based models are implemented to estimate friction torque M, which defines the friction loss power in Equation (15). These models require only catalog data.

- Standard conditions model. Friction torque M is calculated by the equivalent dynamic load P and the friction coefficient μ [59], i.e.,where is the bearing friction torque [Nm], is the equivalent dynamic bearing load [N], is the bearing friction coefficient [1], and is the bearing bore diameter [m].

- Non-standard conditions model. A more detailed model separates the friction torque into load-independent and load-dependent components [59,60]:where the load-independent component depends on viscosity and bearing size :where is the manufacturer-supplied coefficient (type, size, and lubricant) [1], is the bearing pitch diameter [m], is the kinematic viscosity of the lubricant [m2/s], and is the actual shaft speed (gearbox output) [rpm]. The load-dependent component is calculated using the equivalent static load :where is the manufacturer-supplied coefficient (type, size, static load) [1] and is the equivalent static bearing load [N].

4.3.3. Load and Reflected Inertia

Accurate calculation of the reflected inertia is essential for dynamic and acceleration power calculations Pacc.

- Load mounted on the gearbox output (e.g., rotating buffer). Reflected inertia is calculated using [61]:where is the reflected inertia [kg⋅m2], is the inertia of the tool/load on the gearbox output [kg⋅m2], is the gearbox efficiency [%], and is the gearbox ratio [1].

- Conveyor systems. Reflected inertia is calculated using two drive shafts and the mass of the belt/straps [62]:where is the inertia of the drive shaft connected to the gearbox output [kg⋅m2], is the inertia of the drive shaft not connected to the gearbox output [kg⋅m2], is the radius of the conveyor drive shafts [m], and is the mass of the belt/straps conveyor [kg].

5. Experimental Setup and Validation Environment

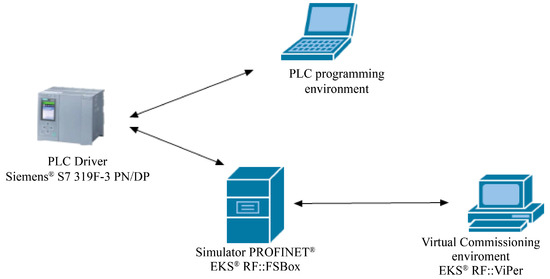

The proposed methodology was validated using a hybrid infrastructure that combined physical conveyor-based testbeds and a virtual commissioning environment based on the RF::Suite platform (Figure 2). This section describes the hardware and software architecture employed in the study, demonstrating its role in ensuring reproducibility and industrial relevance.

Figure 2.

Developed framework based on a modular structure consisting of four levels.

5.1. Physical Testbeds

Two conveyor installations were used to obtain reference measurements and to assess the predictive accuracy of the digital twin models. Both testbeds were jointly developed by PROPOINT S.A. and the Silesian University of Technology and equipped with industrial-grade components.

5.1.1. Belt Conveyor System

The primary test stand (Figure 3) is a belt conveyor composed of three independent conveyor lines, each representing a complete drive system with distinct characteristics. The configuration enables parallel testing under identical load conditions, facilitating direct performance comparison. Each motor is coupled with a gearbox and transmits torque to a belt roller with a diameter of 45 mm and a mass of 3.1 kg. The rollers are mounted on SKF ball bearings, and each system is equipped with a SICK encoder to provide accurate position and speed feedback. This installation served as the main experimental platform for model validation.

Figure 3.

Test stand with a belt conveyor.

5.1.2. Strap Conveyor System

The second test stand (Figure 4) is a strap conveyor, providing alternative mechanical characteristics while maintaining electrical compatibility with the validated drive models. The main structural difference is the use of two V-belts instead of a flat belt, combined with 125 mm pulleys mounted on each shaft. This modification increased the effective shaft mass to 5.8 kg, altering the load characteristics while maintaining compatibility with the drive systems. This alternative mechanical configuration provided mechanical variability, allowing evaluation of the generalization capabilities of the DT models.

Figure 4.

Test stand with a strap conveyor.

5.2. Data Acquisition and Control Infrastructure

Both conveyor systems were operated via Siemens S7 series programmable logic controllers (PLCs). The data acquisition system captures electrical parameters at a 2 kHz sampling rate and mechanical variables at 100 Hz, ensuring adequate resolution for both steady-state and transient analysis. Time synchronization between measurement channels maintains phase coherence with accuracy better than 1 ms. A standardized OPC-based interface was employed to collect electrical signals (voltage, current, and power) and mechanical responses (speed and position). Synchronized logging ensured comparability between datasets from virtual and physical setups, enabling systematic model validation.

5.3. Virtual Commissioning Environment

A VC environment was established using RF::ViPer, part of the RF::Suite platform, to bridge the gap between model-based simulation and real-world control execution. The VC architecture implements deterministic real-time execution with guaranteed cycle times, essential for accurate energy prediction under dynamic operating conditions. The setup included the RF::FSBox hardware device, which emulated Profinet communication in real time, making it indistinguishable to the PLC whether the connected devices were simulated or physical. A Siemens S7-319F-3 PN/DP PLC (Siemens AG, Nuremberg, Germany) was integrated into the VC workstation, enabling execution of IEC 61131-3 [63] compliant control logic in a realistic setting (Figure 5). This configuration enabled seamless interaction between the digital twin models and industrial-grade control hardware.

Figure 5.

Topology of the VC station used in the research.

The VC setup validated both functional accuracy and timing behavior of the control logic. Running the control on a physical PLC exposed the logic to real cycle times and network latencies, providing a realistic assessment of the energy performance of both the drive systems and the associated control strategies.

5.4. Integrated Framework Summary

The combination of two conveyor testbeds and RF::ViPer-based virtual commissioning created a comprehensive validation environment. This tri-level architecture ensures consistency across modeling, simulation, and experimental validation while maintaining industrial relevance. The platform demonstrates scalability from component-level testing to system-wide evaluation.

The framework established a closed loop between model-based studies and physical experimentation. Simulation results were directly comparable with measurements from the conveyor stations, while the VC layer enabled pre-validation of control programs before deployment. This integration reduced commissioning risks, minimized hardware reconfiguration efforts, and ensured transferability of the methodology to larger-scale industrial systems.

6. Experimental Validation and Results

The validation procedure was conducted on modular, component-based digital twin models of industrial electric drive systems. Validation experiments followed a structured protocol designed to assess model accuracy across diverse operating conditions representative of industrial applications. Each drive was decomposed into its key subsystems—inverter, induction motor, shaft, gearbox, rolling bearings, load, and encoder—represented by parameterized models derived from manufacturer catalog data. This DT-based representation ensured reusability.

The modular architecture provided systematic reusability across applications and consistent transfer between platforms, ensuring reproducibility, scalability, and industrial portability. Structured validation experiments were performed using two conveyor-based testbeds. The validation focused on energy consumption predictions under scalar control strategies. Systematic comparison of simulation outputs with experimental measurements assessed the accuracy of the proposed models in reproducing real-world drive behavior.

6.1. Validation Methodology

The validation methodology employs a comprehensive set of statistical indicators to assess both instantaneous accuracy and cumulative energy prediction performance. The following four quality indicators were used to validate electric drive system models in terms of electrical energy consumption:

- mean error to capture overall bias in energy predictions:where is the number of measurement samples taken [1], is the current value of the electrical energy consumed from the grid by the inverter model [W], and is the current value of the electrical energy taken from the grid by the actual inverter [W];

- mean absolute error to provide a straightforward measure of average deviation:

- mean absolute scaled error as a scale-independent statistic suitable for comparing across models and operating conditions:

- root mean square error , which penalizes larger deviations and thus reflects sensitivity to transient peaks in the energy profiles:

To strengthen the methodological foundation of the validation, the selected statistical indicators are grounded in best practices from simulation-model validation literature. Hora and Campos [64] provide a comprehensive review of performance criteria for simulation models and emphasize that error-based and scale-independent measures should be combined to capture complementary aspects of model fidelity. The simultaneous use of , , , and ensures that both systematic bias and random fluctuations are assessed. This choice aligns with established model evaluation guidelines [65], where multiple complementary criteria are recommended to achieve a balanced assessment of model performance.

Additionally, electrical energy consumption was measured for both the physical drive system and its simulated counterpart. The following indicators were employed to evaluate the obtained values:

- absolute error:where is the amount of measured electrical energy consumed in the propulsion system model [Wh], and is the amount of measured electrical energy expended in the actual propulsion system [Wh],

- relative error:

Measurements were conducted over a period of 3600 s, with a sampling interval of 0.5 s, resulting in 7200 samples (i.e., n = 7200). For all the tests presented in Section 6.2.1, Section 6.2.2 and Section 6.2.3, an identical cycle of setpoint speed changes was applied. The setpoint speed was updated every 30 s, taking values of 0, 200, 400, 600, 800, or 1200 rpm.

6.2. Results

6.2.1. Influence of Speed Profile Generator Settings on Electrical Energy Consumption

The effect of the speed profile generator settings on system-level electrical energy consumption was evaluated. Two distinct acceleration profiles were tested to assess model sensitivity to dynamic operating conditions. Both a rectangular ramp and a trapezoidal ramp were applied, with acceleration and deceleration times of 10 s and 30 s, respectively. A linear scalar control algorithm with a boost voltage of 0 V was employed.

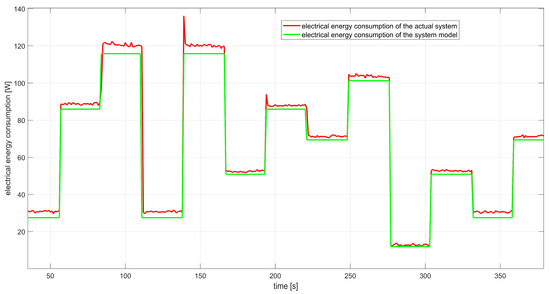

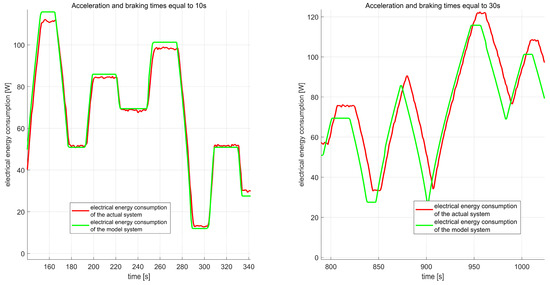

The first configuration evaluated incorporated a Siemens SINAMICS inverter. Representative waveforms are shown in Figure 6 (rectangular ramp) and Figure 7 (trapezoidal ramp).

Figure 6.

Electrical energy consumption profile over time for validating the drivetrain system model with a Siemens SINAMICS inverter, using a rectangular ramp.

Figure 7.

Electrical energy consumption profile over time for validating the drivetrain system model with a Siemens SINAMICS inverter, using a trapezoidal ramp with acceleration and deceleration times of 10 s (left-hand side) and 30 s (right-hand side).

The quality indicator values are presented in Table 2, while the measured electrical energy consumption is summarized in Table 3. The results demonstrate a strong correlation between simulated and measured values, with relative errors consistently below acceptable thresholds for industrial applications.

Table 2.

Quality indicator values for validating the drive system model with a Siemens SINAMICS frequency inverter under different speed profile generator settings.

Table 3.

Electrical energy consumption of a drive system with a Siemens SINAMICS inverter under different speed profile generator configurations.

For the SEW system, corresponding indicators are reported in Table 4 and energy values in Table 5. The analysis revealed that rectangular ramps produced higher instantaneous errors due to rapid power transitions, while trapezoidal profiles yielded smoother energy trajectories with improved prediction accuracy.

Table 4.

Quality indicator values for validating a drive system with an SEW inverter under different speed profile generator settings.

Table 5.

Electrical energy consumption of a drive system with an SEW inverter under different speed profile generator settings.

For the NORD system, results are summarized in Table 6 and Table 7, confirming that the modeling approach maintains accuracy across different manufacturer implementations despite variations in internal control algorithms.

Table 6.

Quality indicator values for validating a drive system with a NORD inverter under different speed profile generator configurations.

Table 7.

Electrical energy consumption of a drive system with a NORD inverter under different speed profile generator settings.

6.2.2. Influence of Positioner Settings on Electrical Energy Consumption

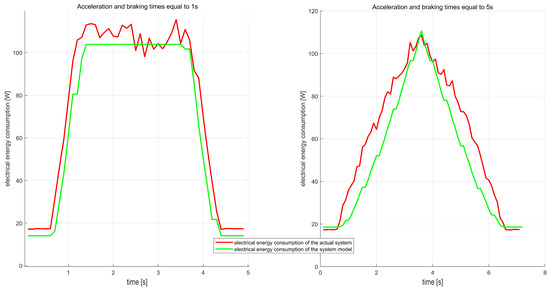

An investigation of the positioner settings (set speeds and acceleration/deceleration times) was conducted using linear control with a boost voltage of 0 V and the Siemens SINAMICS system from Test Stand No. 2.

A linear displacement of 0.85 m was executed, with two acceleration/deceleration times (1 s and 5 s). The corresponding waveforms are shown in Figure 8 (465 rpm) and Figure 9 (930 rpm).

Figure 8.

Time course of electrical energy consumption during the validation of the positioning process for a drive system model with a Siemens SINAMICS inverter, using a setpoint speed of 465 rpm and acceleration/deceleration times of 1 s (left-hand side) and 5 s (right-hand side).

Figure 9.

Time course of electrical energy consumption during the validation of the positioning process for a drive system model incorporating a Siemens SINAMICS inverter, using a setpoint speed of 930 rpm and acceleration/deceleration times of 1 s (left-hand side) and 5 s (right-hand side).

The corresponding quality indicators are reported in Table 8, with energy values in Table 9. The results confirm a close agreement between simulation and experiment, although errors increased slightly with longer ramp times.

Table 8.

Quality indicators for a Siemens SINAMICS drive system under varying positioner settings.

Table 9.

Energy consumption of a Siemens SINAMICS drive system for various positioner settings.

6.2.3. Influence of Scalar Control Algorithm Settings on Electrical Energy Consumption

Analysis of scalar control algorithm settings examined both linear and quadratic algorithms, each with boost voltages of 0 V and 40 V. This investigation addresses the practical need to optimize control parameters for specific load characteristics. A rectangular ramp was used throughout. Quadratic scalar control was available only in the Siemens SINAMICS inverter (Test Stand No. 1); therefore, this configuration was exclusively evaluated. The corresponding quality indicators are presented in Table 10, and the measured consumption values in Table 11.

Table 10.

Quality indicator values for the validation of a drive system with a Siemens SINAMICS inverter for various scalar control algorithm configurations.

Table 11.

Electrical energy consumption of a drive system with a Siemens SINAMICS inverter for different configurations of the scalar control algorithm.

6.3. Analysis

The validation results confirm that the proposed modular DT modeling approach provides accurate predictions of energy consumption in industrial drive systems. The achieved accuracy levels confirm the framework’s suitability for engineering decision support in component selection and system optimization. The key insights include:

- trapezoidal acceleration profiles improve both energy efficiency and prediction accuracy compared with rectangular profiles,

- model accuracy degrades gracefully with increasing acceleration times, maintaining industrial applicability,

- quadratic control strategies show potential advantages for specific load profiles, warranting further investigation.

All the validation results were achieved using only publicly available catalog data, demonstrating the practical applicability of the methodology without requiring proprietary manufacturer information. The close agreement with experimental results demonstrates the feasibility of this universal, transferable methodology for energy-aware modeling and validation of industrial drive systems.

6.4. Cross-Vendor Comparative Analysis

The validation experiments enabled systematic comparison of predictive accuracy across drive systems from three manufacturers: Siemens SINAMICS (Siemens AG, Munich, Germany), SEW MOVITRAC (SEW-EURODRIVE GmbH & Co KG, Bruchsal, Germany), and NORD NORDAC (Getriebebau NORD GmbH & Co. KG, Bargteheide, Germany). Table 12 summarizes the aggregated error metrics across all operating scenarios, providing quantitative evidence of the framework’s vendor-neutral applicability.

Table 12.

Aggregated validation metrics for energy consumption prediction across drive systems from three manufacturers under various operating scenarios.

Predictive accuracy across vendors: Relative error () remained below 6.3% for all the vendors across speed profile scenarios, with NORD exhibiting the highest overall accuracy (4.90% average REen_con), followed by Siemens (5.42%) and SEW (6.29%). These values fall significantly within acceptable engineering tolerances for early-stage design decisions, where prediction errors below 10% are typically considered sufficient for component selection and energy budgeting. Trapezoidal acceleration profiles with a ramp time of 10 s consistently yielded the highest prediction accuracy across all the vendors (REen_con < 5% for Siemens and SEW, 5.76% for NORD). This improved accuracy stems from the smoother velocity transitions inherent in trapezoidal profiles, which more closely match the logarithmic efficiency approximations embedded in the component models.

Vendor-specific characteristics: An analysis of the error distributions revealed distinct vendor-specific patterns:

- –

- Siemens SINAMICS. Demonstrated the highest accuracy for trapezoidal profiles with short ramp times (REen_con = 2.49%) but exhibited larger errors for extended deceleration periods (REen_con = 10.04% with a ramp of 30 s). This behavior suggests that the catalog-based efficiency model slightly underestimates thermal losses during prolonged low-speed operation.

- –

- SEW MOVITRAC. Showed relatively uniform prediction accuracy across ramp types (REen_con range: 2.92–11.14%), with the largest deviation occurring during rectangular ramp profiles. The higher baseline error (compared with other vendors) likely reflects differences in internal control algorithms not fully captured by standard scalar control models.

- –

- NORD NORDAC. Exhibited consistently good accuracy for standard speed profiles (REen_con < 6.3%) but displayed increased sensitivity to ramp duration. The variability may stem from more aggressive energy optimization features in NORD’s firmware, which introduce nonlinearities not accounted for in the simplified scalar control model.

Positioning task performance: Positioning tests (conducted exclusively on Siemens hardware) revealed accuracy degradation with increasing speed setpoints and longer deceleration times. At 465 rpm, prediction errors remained modest (REen_con = 2.32–5.82%) but escalated significantly at 930 rpm (REen_con = 9.27–15.42%). This degradation correlates with the increased dynamic contribution of acceleration power Pacc, where small errors in reflected inertia estimation compound during rapid speed changes.

Scalar control strategy impact: Comparison of linear and quadratic control algorithms (Table 10) demonstrated that quadratic control with zero voltage boost achieved the best prediction accuracy (REen_con = 2.93%), closely matching the logarithmic efficiency parameterization. Introduction of a voltage boost of 40 V increased prediction error for both strategies (8.59% for linear and 4.23% for quadratic), indicating that low-speed boost behavior—though empirically included in the model—exhibits vendor-specific transient effects not fully captured by steady-state catalog data.

Implications for component selection: The vendor-neutral validation confirms that the catalog-based parameterization approach maintains predictive reliability across manufacturer-specific implementations, despite inherent differences in internal control strategies, switching frequencies, and thermal management. The achieved accuracy levels (average REen_con < 7%) support the framework’s applicability for the following.

Early-stage vendor comparison: Quantitative ranking of alternative drive solutions with confidence intervals suitable for procurement decisions. Energy budgeting: system-level consumption estimates with margins appropriate for capacity planning and utility contract negotiations.

Control strategy optimization: Comparative evaluation of acceleration profiles and scalar control parameters to minimize energy consumption within cycle time constraints.

The framework’s limitations become apparent primarily during high-speed positioning tasks (>900 rpm) with rapid decelerations, where dynamic effects dominate and catalog-based steady-state assumptions degrade. For applications requiring sub-5% prediction accuracy under such conditions, the incorporation of vendor-specific dynamic models or empirical correction factors will be necessary.

Nevertheless, the results demonstrate that physics-based component modeling with catalog parameterization provides a robust foundation for vendor-neutral energy assessment, advancing the state-of-the-art in simulation-driven industrial automation design.

7. Case Studies: Simulation-Based Component Selection

Simulation experiments supporting component selection for two representative conveyor applications were conducted. These case studies demonstrate the framework’s capability to provide quantitative decision support for real-world engineering problems. The study employed identical drive systems available at the test benches, using a linear scalar control algorithm without a voltage boost in all the tests. Acceleration and deceleration ramps of 1 s ensured comparability.

The following quality indicators were computed:

- energy consumption, :where is the electrical energy consumption [Wh], is the number of measurement samples taken [1], is the current value of electrical energy consumed by the system [W], and is the time constant of the simulator [s].

- energy losses, :where is the electrical energy losses [Wh], and is the current value of the electrical energy needed to overcome all the frictional forces, i.e., bearings and gearbox [W];

- energy efficiency, :where is the energy efficiency, understood as the percentage of energy losses in total electrical energy consumption [%].

Here, while measurements on physical test stands were feasible, additional validation metrics (5) and (6) were also used.

7.1. Application 1—Belt Conveyor

The first case study considered a belt conveyor supplying components to a robot. This application represents typical pick-and-place operations in automated assembly lines. The cycle lasted 60 s, during which the robot removed four components (Figure 10). Both the physical test bench and validated simulation models were employed.

Figure 10.

Assumed process to deliver four components to the robot.

The results in Table 13 compare electrical energy consumption across systems. Simulation predictions closely matched experimental measurements, validating the framework’s applicability for comparative analysis.

Table 13.

Electrical energy consumption of the belt conveyor using electric drive systems available at Test Stand No. 1.

An analysis of the energy efficiency indicators (Table 14) revealed that the SEW drive system achieved optimal performance through combined minimization of energy consumption and maximization of efficiency. This dual optimization suggests inherent design advantages for the specific load profile. This result demonstrates the framework’s capability for identifying energy-optimal component configurations.

Table 14.

Quality indicator values obtained for the belt conveyor simulator using components from Test Stand No. 1.

7.2. Application 2—Strap Conveyor

The second case study investigated a strap conveyor delivering components to a robot. The modified mechanical configuration introduces different inertial and frictional characteristics, testing model adaptability. The cycle was again 60 s with four transfers (Figure 10). Both simulation and physical test benches were used, applying the same scalar control and 1 s ramps. The results presented in Table 15 show that simulations based on estimates maintained the accuracy despite the altered mechanical configuration, demonstrating model robustness.

Table 15.

Electrical energy consumption of the strap conveyor using electric drive systems available at Test Stand No. 2.

An analysis of the energy efficiency indicators (Table 16) revealed distinct optimization trade-offs compared with the belt conveyor. While SEW minimized total energy consumption, NORD achieved superior efficiency, illustrating that optimal component selection depends on prioritized performance metrics. These findings indicate that optimal solutions depend on whether the objective is the minimization of energy demand or the maximization of efficiency.

Table 16.

Quality indicator values for the strap conveyor simulation using components from Test Stand No. 2.

7.3. Comparative Analysis

The two case studies demonstrate that simulation-based methods enable vendor-neutral evaluation of drive systems. The framework reveals nonintuitive trade-offs between performance metrics that would be difficult to identify through conventional selection methods, i.e.,

- For the belt conveyor, convergent optimization where a single solution (SEW) dominates both objectives,

- For the strap conveyor, divergent optimization requires explicit prioritization between energy minimization and efficiency maximization.

These results highlight the importance of application-specific evaluation rather than relying on generic performance ratings. The framework provides quantitative evidence for component selection decisions, supporting both technical and economic justification. The proposed methodology, thus, provides a robust foundation for energy-aware decision support in industrial drive system selection.

8. Discussion

The experimental validation and case studies confirm the practical utility of the integrated DT–VC framework for energy-aware configuration of electric drives. Beyond numerical agreement, the results have broader methodological and industrial implications.

8.1. Methodological Contributions

This study introduces four key methodological advances that extend the state-of-the-art in energy-aware automation engineering:

1. Comprehensive component-level DT modeling: Unlike system-level abstractions common in prior work [66], the proposed framework provides detailed physics-based models of drive subsystems—inverters (Section 4.1), motors (Section 4.2), gearboxes (Section 4.3.1), bearings (Section 4.3.2). These models incorporate:

- Nonlinear efficiency characteristics derived from manufacturer catalogs, approximated through logarithmic fits that maintain computational efficiency while capturing load-dependent behavior,

- Dynamic acceleration profiles with jerk limitation, enabling realistic motion trajectory planning that is essential for accurate transient energy prediction.

- Load-dependent mechanical losses accounting for both speed-dependent and load-dependent friction torque components in rolling bearings, addressing a gap noted in prior VC implementations [17,27],

This granularity enables accurate energy prediction under transient operating conditions—particularly during acceleration, deceleration, and positioning tasks—which are essential for industrial decision making but are rarely achieved in existing VC implementations.

2. Seamless DT-VC integration: The framework bridges the gap between academic modeling and engineering practice by embedding high-fidelity DT models within industrial VC platforms (Section 5.3). This integration maintains the following:

- Deterministic real-time execution with guaranteed cycle times compatible with industrial PLC scan rates (typically 10–50 ms),

- Hardware-in-the-loop capability through RF::FSBox emulation of Profinet communication, enabling physical PLC execution indistinguishable from connection to real drives,

- Compatibility with IEC 61131-3 compliant control logic, ensuring that validated programs transfer directly to production systems without modification.

This practical integration addresses a limitation repeatedly emphasized in recent reviews [17,66], where VC tools often rely on simplified plant models that omit energy-related dynamics.

3. Catalog-based parameterization methodology: Reliance on publicly available manufacturer data—efficiency maps at 50%, 75%, and 100% load, rated power factors, nominal speeds, and mechanical ratings—ensures wide applicability without requiring proprietary information [67,68]. The logarithmic fitting procedures provide systematic parameter extraction from sparse catalog data, enabling model construction for arbitrary vendor components. Validation results (Section 6) demonstrate that this approach maintains prediction accuracy below 10% across three manufacturers (Table 12), confirming its industrial viability. This methodology enhances reproducibility across platforms and supports technology transfer to industries with limited access to detailed component specifications.

4. Vendor-neutral evaluation capability: The modular model library enables systematic benchmarking of drive systems from multiple manufacturers under identical operating conditions (Section 7). Case studies on belt and strap conveyors revealed nonintuitive optimization trade-offs: SEW minimized energy consumption in the belt conveyor application (0.90 Wh vs. 1.23 Wh for Siemens), while NORD achieved superior efficiency in the strap conveyor (50.0% vs. 39.8% for Siemens). These findings—quantified through simulation and validated against experimental measurements with relative errors below 7%—demonstrate that optimal component selection depends on application-specific performance priorities rather than generic efficiency ratings. This capability addresses the long-recognized challenge of objective component comparison [42] and supports data-driven procurement decisions based on quantified energy metrics rather than marketing claims.

These contributions collectively advance simulation-driven drive engineering by providing validated tools that combine scientific rigor with industrial applicability, enabling energy-aware decision making at early design stages where configuration changes are most cost-effective.

8.2. Industrial Relevance and Transferability

The modular structure of the framework ensures adaptability across diverse industrial domains. While validated on conveyor-based testbeds, the workflow can be extended to pumping stations, HVAC systems, and machine tools [69,70]. Beyond industrial automation, comparable methods are increasingly employed in renewable energy and transportation applications, such as wind turbine optimization or electric vehicle drive selection [71,72,73]. Comparable integration challenges arise in domains characterized by stringent energy constraints. In mobile robotics [74], battery capacity directly limits operational time, while in biomedical mechatronics, prosthetic and rehabilitation exoskeletons must reconcile functional performance with strict power limitations [75,76,77]. Similar approaches can support battery-powered prostheses or rehabilitation devices, where energy efficiency directly impacts usability [78]. In medical robotics, advanced energy management strategies can be virtually tested under standardized cycles, enabling refinement of design before physical deployment [79].

8.3. Limitations and Validity Considerations

Several limitations should be acknowledged. Validation was performed under relatively simple duty cycles, while industrial environments often involve variable loads, reversals, and thermal effects not fully captured here [80,81]. The current focus on scalar control excludes advanced strategies such as field-oriented or predictive control [82,83]. Furthermore, catalog data vary in detail and completeness between vendors, which may reduce fidelity in specific cases. Long-term factors such as temperature-dependent degradation or mechanical wear were not modeled, which may affect predictive accuracy over extended lifecycles [81].

8.4. Comparison with Existing Approaches

Unlike conventional VC implementations that emphasize functional testing [84,85], this framework embeds energy analysis as a primary design criterion. Compared with data-driven DT approaches requiring extensive operational datasets [86], the catalog-based strategy offers broader transferability and avoids the cold-start problem. In this respect, the present study complements existing tools by enabling reproducible, vendor-neutral energy benchmarking at early design stages.

8.5. Future Research Directions

Future work should extend the framework to advanced control strategies, such as field-oriented or predictive control [87], and incorporate thermal and degradation models for higher-fidelity predictions [88]. Automated design-space exploration, for example, through machine learning or evolutionary algorithms [89,90,91,92], could transform the framework from a comparison tool into a full optimization platform, similar to data-driven design methods for electric machines [93]. Integration with lifecycle-oriented DT ecosystems, such as those driven by prognostics and health management for industrial assets, would further enhance the framework’s industrial impact [94]. Finally, establishing standardized validation metrics for energy-oriented DT/VC studies would enhance cross-study comparability and support industrial adoption [95].

9. Conclusions

This paper has offered a simulation-based methodology combining digital twin modeling and virtual commissioning for energy-aware configuration of industrial electric drive systems. The presented approach enables systematic evaluation of energy consumption, losses, and efficiency at early design stages, addressing a long-standing methodological gap in automation practice.

The proposed approach was validated on conveyor-based testbeds equipped with drives from multiple vendors, confirming predictive accuracy under diverse operating conditions. Case studies on belt and strap conveyors demonstrated that different vendors can exhibit significantly different trade-offs between energy consumption and efficiency, underscoring the importance of systematic, vendor-neutral evaluation.

While developed for intralogistics applications, the modular architecture ensures scalability and transferability across industrial and cross-domain contexts, including renewable energy systems, transportation drives, and biomedical mechatronics. By embedding energy-awareness into VC workflows, the methodology supports reliable commissioning while strengthening sustainable decision making in component selection.

Future research will primarily focus on two key areas: extending the framework’s capabilities and enhancing its industrial applicability. The former involves the development of higher-fidelity digital twins for drive systems, based on extended measurement campaigns, as well as the integration of advanced control strategies and multilevel optimization algorithms for automated component selection. The latter will incorporate these models into lifecycle-oriented digital shadow frameworks to enable predictive maintenance and long-term energy monitoring. Additionally, broader validation campaigns and collaboration with standardization bodies will be essential for establishing energy-focused benchmarks and accelerating their adoption across industries.

Author Contributions

Conceptualization, S.B. (Szymon Bysko); formal analysis, S.B. (Szymon Bysko); funding acquisition, S.B. (Szymon Bysko); investigation, S.B. (Szymon Bysko); methodology, S.B. (Szymon Bysko); resources, S.B. (Szymon Bysko); software, S.B. (Szymon Bysko); validation, S.B. (Sara Bysko) and T.B.; visualization, S.B. (Sara Bysko); writing—original draft preparation, S.B. (Sara Bysko); writing—review & editing, S.B. (Sara Bysko) and T.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Centre for Research and Development, Poland, grant “Development of energy-efficient, adaptive robotic cells with Industry 4.0 features, dedicated to the creation of a modular, freely complex and interconnected set of production machines or stand-alone operation”, No. POIR.01.01.01-00-1032/19. The Article Processing Charge was financed under the European Funds for Silesia 2021–2027 Program co-financed by the Just Transition Fund—project entitled “Development of the Silesian biomedical engineering potential in the face of the challenges of the digital and green economy (BioMeDiG)”. Project number: FESL.10.25-IZ.01-07G5/23.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

This work has been supported by the Polish Ministry of Science and Higher Education under internal grant No. 02/040/BK_25/1070 from the Silesian University of Technology.

Conflicts of Interest

Author Szymon Bysko was employed by the company PROPOINT S.A., R&D Department. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- International Energy Agency. World Energy Outlook 2024: Industrial Motor Systems; IEA Publications: Paris, France, 2024; Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 10 August 2025).

- European Commission. The European Green Deal: Delivering the EU’s 2030 Climate Targets; COM/2023/379 Final; European Commission: Brussels, Belgium, 2023; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2023:379:FIN (accessed on 10 August 2025).

- Mawson, V.J.; Hughes, B.R. The development of modelling tools to improve energy efficiency in manufacturing processes and systems. J. Manuf. Syst. 2019, 51, 95–105. [Google Scholar] [CrossRef]

- Diaz, J.L.; Ocampo-Martinez, C. Energy efficiency in discrete-manufacturing systems: Insights, trends, and control strategies. J. Manuf. Syst. 2019, 52, 131–145. [Google Scholar] [CrossRef]

- Lima, R.C.C.; de Oliveira, L.A.V.; da Silva, S.P.P.; Santos, J.D.d.A.; Caetano, R.G.D.; Freitas, F.N.C.; de Oliveira, V.S.; Bonifácio, A.d.F.; Filho, P.P.R. A new proposal for energy efficiency in industrial manufacturing systems based on machine learning techniques. J. Manuf. Syst. 2024, 77, 1062–1076. [Google Scholar] [CrossRef]

- Shu, H.; Liang, R.; Li, Z.; Goodridge, A.; Zhang, X.; Ding, H.; Nagururu, N.; Sahu, M.; Creighton, F.X.; Taylor, R.H.; et al. Twin-S: A digital twin for skull base surgery. Int. J. CARS 2023, 18, 1077–1084. [Google Scholar] [CrossRef]

- Vallée, A. Digital twin for healthcare systems. Front. Digit. Health 2023, 5, 1253050. [Google Scholar] [CrossRef]

- Mone, G. Biomedical Digital Twins. Commun. ACM 2023, 66, 9–11. [Google Scholar] [CrossRef]

- Han, D.; Qian, D.; Yan, G.; Kuang, S.; Wen, R.; Xiang, S. Optimization of transcutaneous energy transmission system suitable for implanted devices. J. Phys. Conf. Ser. 2024, 2787, 012003. [Google Scholar] [CrossRef]

- IEC 60034-30-1:2014; Rotating Electrical Machines—Part 30-1: Efficiency Classes of Line Operated AC Motors (IE Code). International Electrotechnical Commission (IEC): Geneva, Switzerland, 2014.

- European Commission. Ecodesign and Energy Labelling Working Plan 2022–2024; SWD/2022/0101 Final; European Commission: Brussels, Belgium, 2022; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=SWD:2022:101:FIN (accessed on 10 August 2025).

- United Nations. Transforming our World: The 2030 Agenda for Sustainable Development; A/RES/70/1; United Nations: New York, NY, USA, 2015; Available online: https://sdgs.un.org/2030agenda (accessed on 10 August 2025).

- Striffler, N.; Voigt, T. Concepts and trends of virtual commissioning—A comprehensive review. J. Manuf. Syst. 2023, 71, 664–680. [Google Scholar] [CrossRef]

- Liu, Z.; Suchold, N.; Diedrich, C. Virtual commissioning of automated systems. In Automation; Kongoli, F., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 131–148. [Google Scholar] [CrossRef]

- Koo, L.; Park, C.; Lee, C.; Park, S.; Wang, G. Simulation framework for the verification of PLC programs in automobile industries. Int. J. Prod. Res. 2014, 49, 4925–4943. [Google Scholar] [CrossRef]

- Krystek, J.; Alszer, S.; Bysko, S. Virtual commissioning as the main core of Industry 4.0—Case study in the automotive paint shop. In Intelligent Systems in Production Engineering and Maintenance ISPEM 2018; Burduk, A., Chlebus, E., Nowakowski, T., Tubis, A., Eds.; Springer: Wroclaw, Poland, 2019; pp. 370–379. [Google Scholar]

- Gasiyarov, V.R.; Bovshik, P.A.; Loginov, B.M.; Karandaev, A.S.; Khramshin, V.R.; Radionov, A.A. Substantiating and Implementing Concept of Digital Twins for Virtual Commissioning of Industrial Mechatronic Complexes Exemplified by Rolling Mill Coilers. Machines 2023, 11, 276. [Google Scholar] [CrossRef]

- Kabir, M.R.; Halder, D.; Ray, S. Digital Twins for IoT-Driven Energy Systems: A Survey. IEEE Access 2024, 12, 177123–177143. [Google Scholar] [CrossRef]

- Kasper, L.; Birkelbach, F.; Schwarzmayr, P.; Steindl, G.; Ramsauer, D.; Hofmann, R. Toward a Practical Digital Twin Platform Tailored to the Requirements of Industrial Energy Systems. Appl. Sci. 2022, 12, 6981. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, L.; Deng, H.; Qi, Z.; Liang, H. Recent Advances and Future Perspectives of Digital Twins. In Proceedings of the 2023 IEEE International Conference on Control, Electronics and Computer Technology (ICCECT), Jilin, China, 28–30 April 2023; pp. 1563–1566. [Google Scholar] [CrossRef]

- Carlier, R.; Gillis, J.; Rademakers, E.; Borghesan, G.; De Clercq, P.; Ganseman, C.; Stockman, K.; De Kooning, J.D.M. A Digital Twin Framework for Virtual Re-Commissioning of Work-Drive Systems Using CAD-based Motion Co-Simulation. In Proceedings of the 2023 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Seattle, WA, USA, 28–30 June 2023; pp. 119–124. [Google Scholar] [CrossRef]

- Reyes Morales, G.; Sanchez Alonso, R.E.; Mudiki, S.; Salinas Hernandez, A.; Ortega Moody, J.A.; Samudio Cano, A.E. Virtual commissioning of automation of an industrial plant. DYNA 2019, 94, 42–45. [Google Scholar] [CrossRef]

- Oppelt, M.; Urbas, L. Integrated virtual commissioning an essential activity in the automation engineering process: From virtual commissioning to simulation supported engineering. In Proceedings of the 2014 40th Annual Conference of the IEEE Industrial Electronics Society (IECON 2014), Dallas, TX, USA, 29 October–1 November 2014; pp. 2564–2570. [Google Scholar] [CrossRef]

- Kampker, A.; Wessel, S.; Lutz, N.; Reibetanz, M.; Hehl, M. Virtual Commissioning for Scalable Production Systems in the Automotive Industry: Model for evaluating benefit and effort of virtual commissioning. In Proceedings of the 2020 9th International Conference on Industrial Technology and Management (ICITM), Oxford, UK, 11–13 February 2020; pp. 107–111. [Google Scholar] [CrossRef]

- Konstantinov, S.; Assad, F.; Ahmad, B.; Vera, D.A.; Harrison, R. Virtual Engineering and Commissioning to Support the Lifecycle of a Manufacturing Assembly System. Machines 2022, 10, 939. [Google Scholar] [CrossRef]

- Roman, R.; Holubek Radovan, D.S.D. Virtual Commissioning of a Robotic Cell Prior to its Implementation Into a Real Flexible Production System.: Generation of the Robot Offline Programming (OLP) and Validation of the PLC Code. Res. Pap. Fac. Mater. Sci. Technol. Slovak. Univ. Technol. 2018, 42, 42. [Google Scholar] [CrossRef]

- Fratczak, M.; Nowak, P.; Klopot, T.; Czeczot, J.; Bysko, S.; Opilski, B. Virtual commissioning for the control of the continuous industrial processes—Case study. In Proceedings of the 2015 20th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 24–27 August 2015; pp. 1032–1037. [Google Scholar] [CrossRef]

- Shahim, N.; Moller, C. Economic justification of Virtual Commissioning in automation industry. In Proceedings of the 2016 Winter Simulation Conference (WSC), Washington, DC, USA, 11–14 December 2016; pp. 2430–2441. [Google Scholar] [CrossRef]

- Shen, W.; Hu, T.; Yin, Y.; He, J.; Tao, F.; Nee, A. Digital twin based virtual commissioning for computerized numerical control machine tools. In Digital Twin Driven Smart Design; Academic Press: Cambridge, MA, USA, 2020; pp. 289–307. [Google Scholar] [CrossRef]

- Fernández, I.A.; Eguía, M.A.; Echeverría, L.E. Virtual commissioning of a robotic cell: An educational case study. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 820–825. [Google Scholar] [CrossRef]

- Shen, K.; Wang, H. Development of high-efficient asphalt pavement modeling software for digital twin of road infrastructure. Adv. Eng. Softw. 2024, 198, 103786. [Google Scholar] [CrossRef]

- Patzák, B.; Šulc, S.; Šmilauer, V. Towards digital twins: Design of an entity data model in the MuPIF simulation platform. Adv. Eng. Softw. 2024, 197, 103733. [Google Scholar] [CrossRef]

- Ye, Y.; Xu, B.; Zhang, J.; Lawler, B.; Ayalew, B. Reinforcement Learning-Based Energy Management System Enhancement Using Digital Twin for Electric Vehicles. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA, 1–4 November 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Spiryagin, M.; Bernal, E.; Ahmad, S.; Wu, Q.; Cole, C.; Mcsweeney, T. Digital twin framework and platform for zero-emission heavy haul locomotive design and development. Digit. Twins Appl. 2024, 1, 182–197. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Orosz, T.; Demidova, G.L.; Kuts, V.; Rjabtšikov, V.; Vaimann, T.; Kallaste, A. Implementation of Digital Twins for electrical energy conversion systems in selected case studies. Proc. Est. Acad. Sci. 2021, 70, 19–39. [Google Scholar] [CrossRef]

- ITEA4. AVANTI—Test Methodology for Virtual Commissioning of Production Systems, EUREKA Cluster Programme ITEA 2, 2014. Available online: https://itea4.org/project/avanti.html (accessed on 5 September 2025).

- Pellicciari, M.; Avotins, A.; Bengtsson, K.; Lennartson, B.; Berselli, G.; Bey, N.; Meike, D. AREUS—Innovative hardware and software for sustainable industrial robotics. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 1325–1332. [Google Scholar] [CrossRef]

- Grebers, R.; Gadaleta, M.; Paugurs, A.; Senfelds, A.; Avotins, A.; Pellicciari, M. Analysis of the energy consumption of a novel DC power supplied industrial robot. Procedia Manuf. 2017, 11, 311–318. [Google Scholar] [CrossRef]

- KUKAAG. Industrial Intelligence 4.0_Beyond Automation. 2020. Available online: https://www.kuka.com/pl-pl/produkcja-przyszlosci/research-and-development/current-topics-from-the-world-of-research/events/automatica/automatica-2016 (accessed on 5 September 2024).

- SPEAR. Smart Prognosis of Energy with Allocation of Resources. 2021. Available online: https://itea4.org/project/spear.html (accessed on 5 September 2024).

- SPEAR Optimisation Algorithm for Production Processes Now Available as Open Source. 2021. Available online: https://itea4.org/news/spear-optimisation-algorithm-for-production-processes-now-available-as-open-source.html (accessed on 5 September 2024).

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Corral-Acero, J.; Margara, F.; Marciniak, M.; Rodero, C.; Loncaric, F.; Feng, Y.; Gilbert, A.; Fernandes, J.F.; Bukhari, H.A.; Wajdan, A.; et al. The ‘Digital Twin’ to Enable the Vision of Precision Cardiology. IEEE J. Biomed. Health Inf. 2020, 24, 2833–2840. [Google Scholar] [CrossRef] [PubMed]

- Heluany, J.B.; Gkioulos, V. A review on digital twins for power generation and distribution. Int. J. Inf. Secur. 2024, 23, 1171–1195. [Google Scholar] [CrossRef]

- Shen, Z.; Arraño-Vargas, F.; Konstantinou, G. Development of adaptive model-based digital twins for power system resilience. Comput. Electr. Eng. 2025, 125, 2025. [Google Scholar] [CrossRef]

- Arfa Grunditz, E.; Thiringer, T. Characterizing BEV Powertrain Energy Consumption, Efficiency, and Range During Official and Drive Cycles from Gothenburg, Sweden. IEEE Trans. Veh. Technol. 2016, 65, 3964–3980. [Google Scholar] [CrossRef]

- Decker, L.; Förster, D.; Gauterin, F.; Doppelbauer, M. Physics-Based and Data-Enhanced Model for Electric Drive Sizing during System Design of Electrified Powertrains. Vehicles 2021, 3, 512–532. [Google Scholar] [CrossRef]