Physio-Mechanical Properties and Meso-Scale Damage Mechanism of Granite Under Thermal Shock

Abstract

1. Introduction

2. Research Methods

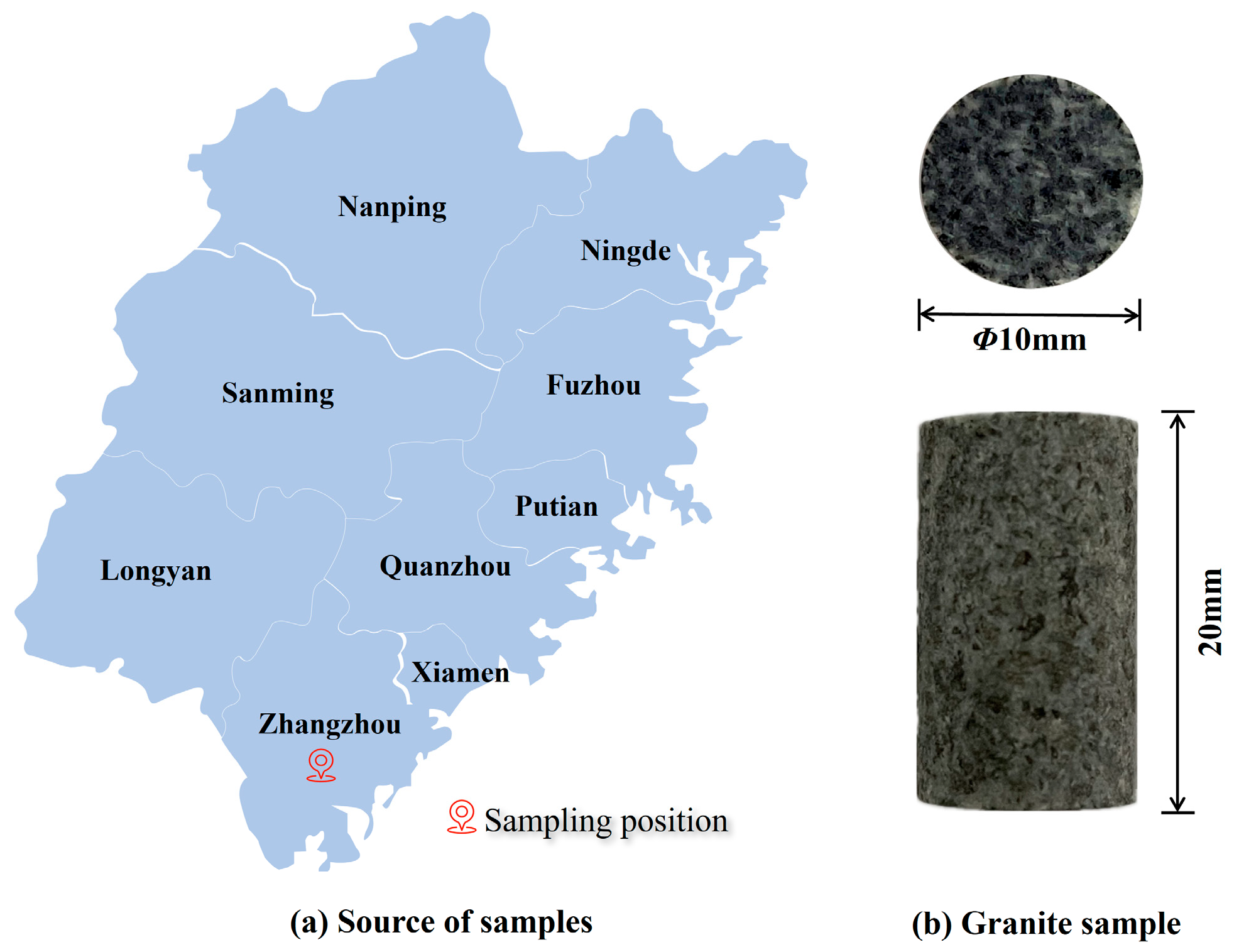

2.1. Experimental SAMPLES

2.2. Thermal Shock Experiments

2.3. Physical and Mechanical Property Tests

2.3.1. Permeability Tests

2.3.2. Uniaxial Compression Tests

2.4. Microstructural Observation Experiments

CT Scanning Experiments

3. Analysis of Physical and Mechanical Properties of Granite Under Thermal Shock

3.1. Mass Change in Granite

3.2. P-Wave Velocity Change in Granite

3.3. Mechanical Properties of Granite Under Thermal Shock

4. Variation in Meso-Structure of Granite Under Thermal Shock

4.1. Analysis of 2D CT Scanning Images

4.2. Analysis of 3D Fracture Reconstruction Models

4.3. Quantitative Characterization and Analysis of Thermally Induced Damage Fractures

4.4. Relationship Between Overall Porosity and Permeability Characteristics of Granite

4.5. Optical Microscopic Characteristics of Thermally Induced Damage Fractures

5. Discussions

5.1. Analysis of Thermal Damage Mechanism of Granite

5.2. Implications for Enhanced Geothermal System Development

6. Conclusions

- (1)

- High temperature and cooling shock cause the deterioration of the physical and mechanical properties of granite. When the heat treatment temperature ranges from 20 °C to 450 °C, the attenuation rate of the P-wave velocity of granite after liquid nitrogen cooling shock increases linearly. In this stage, relatively few thermally induced damage cracks are generated, the change in mechanical properties is not obvious, and granite exhibits brittle failure characteristics. When the heat treatment temperature exceeds 450 °C, the attenuation rate of the P-wave velocity of granite increases sharply, its mechanical properties deteriorate significantly, the rock gradually transitions to ductile failure, and the degree of fragmentation increases.

- (2)

- The porosity of granite meso-structure is positively correlated with the heat treatment temperature. The heterogeneous distribution of rock minerals and the difference in thermal expansion between different mineral particles lead to the random distribution of thermal damage cracks, and the number and density of thermal damage cracks gradually increase with the increase in heat treatment temperature. Under the high temperature of 600 °C or above, the internal cracks in granite gradually expand and penetrate, and a fracture network is formed, and quartz undergoes α-β phase transformation and expands in volume, which promotes the further expansion of thermal damage cracks.

- (3)

- Under the influence of different cooling rates, the mechanical response and meso-damage of rocks are different, especially for high-temperature rocks over 450 °C, the connectivity and permeability of cracks in granite are significantly improved under the condition of liquid nitrogen cooling, which also reflects that liquid nitrogen cooling has a good application prospect in the reservoir fracturing and permeability enhancement reconstruction of EGS system. Liquid nitrogen can be injected into deep high-temperature rock mass in a planned way to form a temperature gradient, which will generate thermal stress inside the rock, induce mineral particles to shrink, weaken the degree of cementation, initiate and develop fractures, and finally improve the fracture connectivity and reservoir permeability of deep rock mass.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, D.J.; Zhang, C.Y.; Ji, Y.L.; Zhao, X.G.; Zhao, Z.H.; He, M.C. Permeability evolution of rough fractures in Gonghe granite subjected to cyclic normal stress at elevated temperatures: Experimental measurements and analytical modeling. Rock Mech. Rock Eng. 2024, 57, 11301–11318. [Google Scholar] [CrossRef]

- Wang, J.M.; Zhang, P.; Bu, M.H.; Luan, Z.L.; Wang, S.G. Mechanical behavior of granite subjected to thermal treatment: Insight from experiment and numerical simulation. Bull. Eng. Geol. Environ. 2023, 82, 400. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhang, W.; Ma, F.; Lin, W.J.; Liang, J.Y.; Zhu, X. Overview on hydrothermal and hot dry rock researches in China. China Geol. 2018, 1, 273–285. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Fan, D.J.; Elsworth, D.; He, M.C.; Zhao, X.G.; Zhu, C.; Zhang, H. Mechanisms of stress- and fluid-pressure-driven fault reactivation in Gonghe granite: Implications for injection-induced earthquakes. Int. J. Rock Mech. Min. Sci. 2024, 174, 105642. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, L.C.; Liu, J.; Ranjith, P.G.; Gao, F.; Cai, C.Z.; Xie, H.P. Experimental study on the effect of heating and liquid nitrogen-cooling cyclic treatment on mechanical properties and fracturing characteristics of granite. Int. J. Rock Mech. Min. Sci. 2024, 176, 105691. [Google Scholar] [CrossRef]

- Yuan, Y.; Zheng, K.; Wang, C.; Zhao, Y.; Bi, J. Thermal damage and acoustic emission characteristics of high-temperature granite under liquid nitrogen cooling. Nat. Resour. Res. 2025, 34, 581–597. [Google Scholar] [CrossRef]

- Rong, G.; Sha, S.; Li, B.; Chen, Z.H.; Zhang, Z.Y. Experimental investigation on physical and mechanical properties of granite subjected to cyclic heating and liquid nitrogen cooling. Rock Mech. Rock Eng. 2021, 54, 2383–2403. [Google Scholar] [CrossRef]

- Jin, P.H.; Hu, Y.Q.; Shao, J.X.; Zhao, G.K.; Zhu, X.Z.; Li, C. Influence of different thermal cycling treatments on the physical, mechanical and transport properties of granite. Geothermics 2019, 78, 118–128. [Google Scholar] [CrossRef]

- Zhou, L.; Zhu, Z.; Oterkus, E.; Oterkus, S.; Xu, H. Research on the effects of heating and cooling processes on the mechanical properties of yellow rust granite. Geohazard Mech. 2023, 1, 231–243. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, W.Q.; Zhu, Y.M.; Huang, Z. Effect of high temperatures on the thermal properties of granite. Rock Mech. Rock Eng. 2019, 52, 2691–2699. [Google Scholar] [CrossRef]

- Guo, P.Y.; Zhang, P.; Bu, M.H.; Wang, J.M.; Zheng, X.; He, M.C. Microcracking behavior and damage mechanism of granite subjected to high temperature based on CT-GBM numerical simulation. Comput. Geotech. 2023, 159, 105385. [Google Scholar] [CrossRef]

- Li, Z.H.; Wong, L.N.Y.; Teh, C.I. Influence of thermal and mechanical loading on development of microcracks in granite. Rock Mech. Rock Eng. 2020, 53, 2035–2051. [Google Scholar] [CrossRef]

- Liu, Z.X.; Wu, Y.; Li, X.Z.; Huang, Z.; Lin, J.; Pan, X.H. Effects of thermal treatment on the macroscopic physical properties and microstructure of Beishan fine grained granite. Bull. Eng. Geol. Environ. 2022, 81, 190. [Google Scholar] [CrossRef]

- Tian, W.L.; Yang, S.Q.; Elsworth, D.; Wang, J.G.; Li, X.Z. Permeability evolution and crack characteristics in granite under treatment at high temperature. Int. J. Rock Mech. Min. Sci. 2020, 134, 104461. [Google Scholar] [CrossRef]

- Xiao, P.; Li, X.N.; Li, Y.; Tang, Y.D.; Ge, X.F.; Qin, Y.; Tian, H.; Zheng, J. Experimental technique for modeling multi-field coupled transport in multi-fracture geothermal reservoirs. Energies 2025, 18, 18549. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, L.H.; Yu, J.; Li, X.Z.; Yang, L.N.; Xue, S.; Zhang, K. The sensitivity of mechanical properties and pore structures of Beishan granite to large variation of temperature in nuclear waste storage sites. Environ. Sci. Pollut. Res. 2023, 30, 75195–75212. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wu, Y.; Mu, P.; Zhang, C.; Li, X. Meso-damage mechanism and physico-mechanical properties of Zhangzhou granite subjected to water-cooling treatment after elevated temperatures. Geothermics 2025, 131, 103397. [Google Scholar] [CrossRef]

- Goman, M.E.; Li, G.C.; Bader, S.; Elkarmoty, M.; Ismael, M. Damage evolution of Granodiorite after heating and cooling treatments. Minerals 2021, 11, 779. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.M. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Bu, M.H.; Zhang, P.; Guo, P.Y.; Wang, J.M.; Luan, Z.L.; Jin, X. Deterioration of equivalent thermal conductivity of granite subjected to heating-cooling treatment. J. Rock Mech. Geotech. Eng. 2024, 16, 4229–4246. [Google Scholar] [CrossRef]

- Qin, Y.; Tian, H.; Xu, N.X.; Chen, Y. Physical and mechanical properties of granite after high-temperature treatment. Rock Mech. Rock Eng. 2020, 53, 305–322. [Google Scholar] [CrossRef]

- Fan, L.F.; Gao, J.W.; Du, X.L.; Wu, Z.J. Spatial gradient distributions of thermal shock-induced damage to granite. J. Rock Mech. Geotech. 2020, 12, 917–926. [Google Scholar] [CrossRef]

- Lin, W.J.; Chen, X.Y.; Gan, H.N.; Yue, G.F. Geothermal, geological characteristics and exploration direction of hot dry rocks in the Xiamen bay-Zhangzhou basin, southeastern China. Acta Geol. Sin. 2020, 94, 2066–2077. (In Chinese) [Google Scholar] [CrossRef]

- Yuan, H.W.; Jing, T.Y.; Yin, Y.L.; Wei, S.C.; Gan, H.N.; Zhao, W.T.; Zhang, J. Geothermal model and development area of a fault-controlled geothermal zone along the Fujian coastal area of southeastern China. Nat. Gas Ind. B 2024, 11, 28–41. [Google Scholar] [CrossRef]

- Yao, S.S.; Wang, Q.; Bai, Y.F.; Li, H.Z. A practical gas permeability equation for tight and ultra-tight rocks. J. Nat. Gas. Sci. Eng. 2021, 95, 104215. [Google Scholar] [CrossRef]

- Sundaram, D.; Svidró, J.T.; Diószegi, A.; Svidró, J. Measurement of Darcian Permeability of foundry sand mixtures. Int. J. Cast Met. Res. 2021, 34, 97–103. [Google Scholar] [CrossRef]

- Chen, L.; Chen, K.; Zhang, Z.; Zhang, Y.Y.; Liu, Z.Q.; Huang, Y.H. Macro and micro damage characteristics of Red-bed sandstone in Urumqi under freeze–thaw cycles. Sci. Rep. 2025, 15, 21785. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.F.; Gao, J.W.; Wu, Z.J.; Yang, S.Q.; Ma, G.W. An investigation of thermal effects on micro-properties of granite by X-ray CT technique. Appl. Ther. Eng. 2018, 140, 505–519. [Google Scholar] [CrossRef]

- Wu, X.; Huang, C.; Li, P.; Zhang, S.L.; Xu, Z. Experimental study on evaluation of density, P-wave velocity, thermal conductivity, and thermal diffusion coefficient of granite after thermal treatments by using PCA. Sci. Rep. 2024, 14, 7748. [Google Scholar] [CrossRef]

- Qian, R.P.; Liu, X.L.; Ma, Q.; Feng, G.R.; Bai, J.W.; Guo, J.; Zhang, S.; Wen, X.Z. Effect of water intrusion on mechanical behaviors and failure characteristics of backfill body and coal pillar composite specimens under uniaxial compression. J. Clean. Prod. 2025, 502, 145388. [Google Scholar] [CrossRef]

- Johnson, S.E.; Song, W.J.; Cook, A.C.; Vel, S.S.; Gerbi, C.C. The quartz α↔β phase transition: Does it drive damage and reaction in continental crust? Earth Planet. Sci. Lett. 2021, 553, 116622. [Google Scholar] [CrossRef]

- Costa, A. Permeability-porosity relationship: A reexamination of the Kozeny-Carman equation based on a fractal pore-space geometry assumption. Geophys. Res. Lett. 2006, 33, L02318. [Google Scholar] [CrossRef]

- Safari, M.; Gholami, R.; Jami, M. Developing a porosity-permeability relationship for ellipsoidal grains: A correction shape factor for Kozeny-Carman’s equation. J. Petrol. Sci. Eng. 2021, 205, 108896. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Zhang, Y.H.; Wu, Z.J. Rock strengthening or weakening upon heating in the mild temperature range? Eng. Geol. 2020, 272, 105619. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Sun, Q.; Hao, S.Q.; Geng, J.S.; Lv, C. Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl. Ther. Eng. 2016, 98, 1297–1304. [Google Scholar] [CrossRef]

- Yang, S.Q.; Ranjith, P.G.; Jing, H.W.; Tian, W.L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Chen, C.C.; Chu, P.; Xie, H.P.; Li, M.H.; Li, C.B.; Shang, D.L. Fracture behavior of high-temperature granite subjected to liquid nitrogen cooling: Semi-circular bending test and crack evolution analysis. Theor. Appl. Fract. Mech. 2023, 128, 104100. [Google Scholar] [CrossRef]

- Wu, X.; Huang, Z.; Song, H.; Zhang, S.; Cheng, Z.; Li, R.; Wen, H.; Huang, P.; Dai, X. Variations of physical and mechanical properties of heated granite after rapid cooling with liquid nitrogen. Rock Mech. Rock Eng. 2019, 52, 2123–2139. [Google Scholar] [CrossRef]

- Shao, Z.; Tang, X.; Wang, X. The influence of liquid nitrogen cooling on fracture toughness of granite rocks at elevated temperatures: An experimental study. Eng. Fract. Mech. 2021, 246, 107628. [Google Scholar] [CrossRef]

- Fan, Z.; Parashar, R. Analytical solutions for a wellbore subjected to a non-isothermal fluid flux: Implications for optimizing injection rates, fracture reactivation, and EGS hydraulic stimulation. Rock Mech. Rock Eng. 2019, 52, 4715–4729. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, K.; Wang, J.; Liu, C.; Mu, P.; Wu, Y. Physio-Mechanical Properties and Meso-Scale Damage Mechanism of Granite Under Thermal Shock. Energies 2025, 18, 5366. https://doi.org/10.3390/en18205366

Gao K, Wang J, Liu C, Mu P, Wu Y. Physio-Mechanical Properties and Meso-Scale Damage Mechanism of Granite Under Thermal Shock. Energies. 2025; 18(20):5366. https://doi.org/10.3390/en18205366

Chicago/Turabian StyleGao, Kai, Jiamin Wang, Chi Liu, Pengyu Mu, and Yun Wu. 2025. "Physio-Mechanical Properties and Meso-Scale Damage Mechanism of Granite Under Thermal Shock" Energies 18, no. 20: 5366. https://doi.org/10.3390/en18205366

APA StyleGao, K., Wang, J., Liu, C., Mu, P., & Wu, Y. (2025). Physio-Mechanical Properties and Meso-Scale Damage Mechanism of Granite Under Thermal Shock. Energies, 18(20), 5366. https://doi.org/10.3390/en18205366