3.1. Exploratory Data Analysis

This section details the exploratory data analysis of key operational variables, including well flowrate, pump head pressure, suction pressure, power consumption, and operating frequency. Individual and joint analyses across Wells A–E identified patterns and correlations to inform subsequent modeling.

3.1.1. Results of Well A

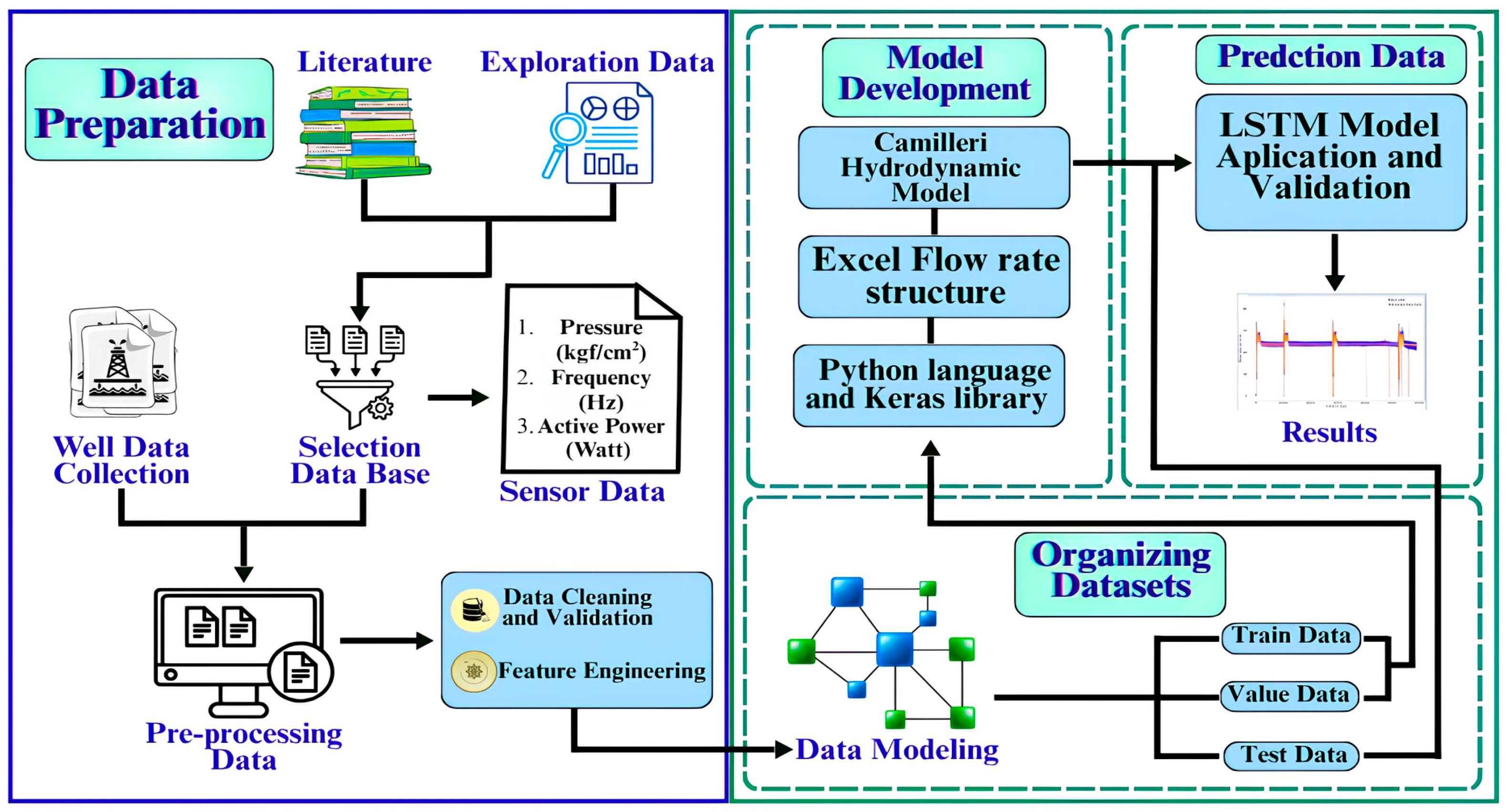

An exploratory data analysis for Well A was performed on key operational variables, including active power, frequency, suction and wellhead pressures, and the flowrate estimated from the hydrodynamic model by [

33]. These variables were examined using detailed graphical representations to evaluate their temporal behavior and interrelationships. This analysis is critical, as the behavior of these parameters directly impacts predictive model performance and aligns with the physical relationships in the referenced hydrodynamic framework.

Figure 4 and

Figure 5 present this detailed graphical analysis for Well A.

Figure 4 presents the temporal behavior of critical operational parameters for Well A, including active power, frequency, suction pressure, and head pressure. The data demonstrate characteristic patterns of operational stability, with clearly distinguishable periods of steady-state production interspersed with brief interruptions attributable to operational interventions. These transient events are consistently followed by rapid system recovery, indicating robust operational management protocols.

The active power profile (

Figure 4a) exhibits remarkable stability during normal operation, maintaining values between 20 and 22 kW, which confirms consistent electrical supply to the pumping system. The observed sharp declines to near-zero values represent controlled shutdown events, likely implemented as part of pressure management protocols or maintenance procedures. The immediate restoration of power levels following these events suggests an automated protection system is effectively maintaining operational integrity.

Frequency measurements (

Figure 4b) directly correlate with the active power behavior, demonstrating stable operation at approximately 55 Hz during production periods. The synchronous drops in frequency with power interruptions confirm coordinated system shutdowns. The precise maintenance of target frequency during active periods indicates excellent regulation by the variable frequency drive (VFD) and stable power supply conditions.

Suction pressure dynamics (

Figure 4c) reveal characteristic operational signatures, with baseline values around 40 kgf/cm

2 during normal flow conditions. The dramatic pressure surges exceeding 80 kgf/cm

2 during shutdown periods represent expected hydrodynamic responses to flow interruption, where reservoir energy accumulates at the pump intake. The consistent return to baseline values following system restart demonstrates effective pressure management.

Head pressure measurements (

Figure 4d) show stable operation within the 6–8 kgf/cm

2 range, indicating proper downstream flow control. The absence of extreme pressure excursions during shutdown events suggests effective pressure dissipation mechanisms in the delivery system. The minor pressure fluctuations observed during system restart represent normal transient behavior as the pump re-establishes equilibrium between suction and discharge conditions.

Collectively, these parameters paint a comprehensive picture of Well A’s operational profile, characterized by extended periods of stable production punctuated by brief, controlled interruptions. The system’s rapid recovery following these events and the maintenance of all parameters within expected operational ranges demonstrate effective field management practices and robust equipment performance. This behavior pattern is consistent with modern production wells employing automated protection systems and routine maintenance protocols. The data quality and consistency support their use for further analytical modeling and performance optimization studies.

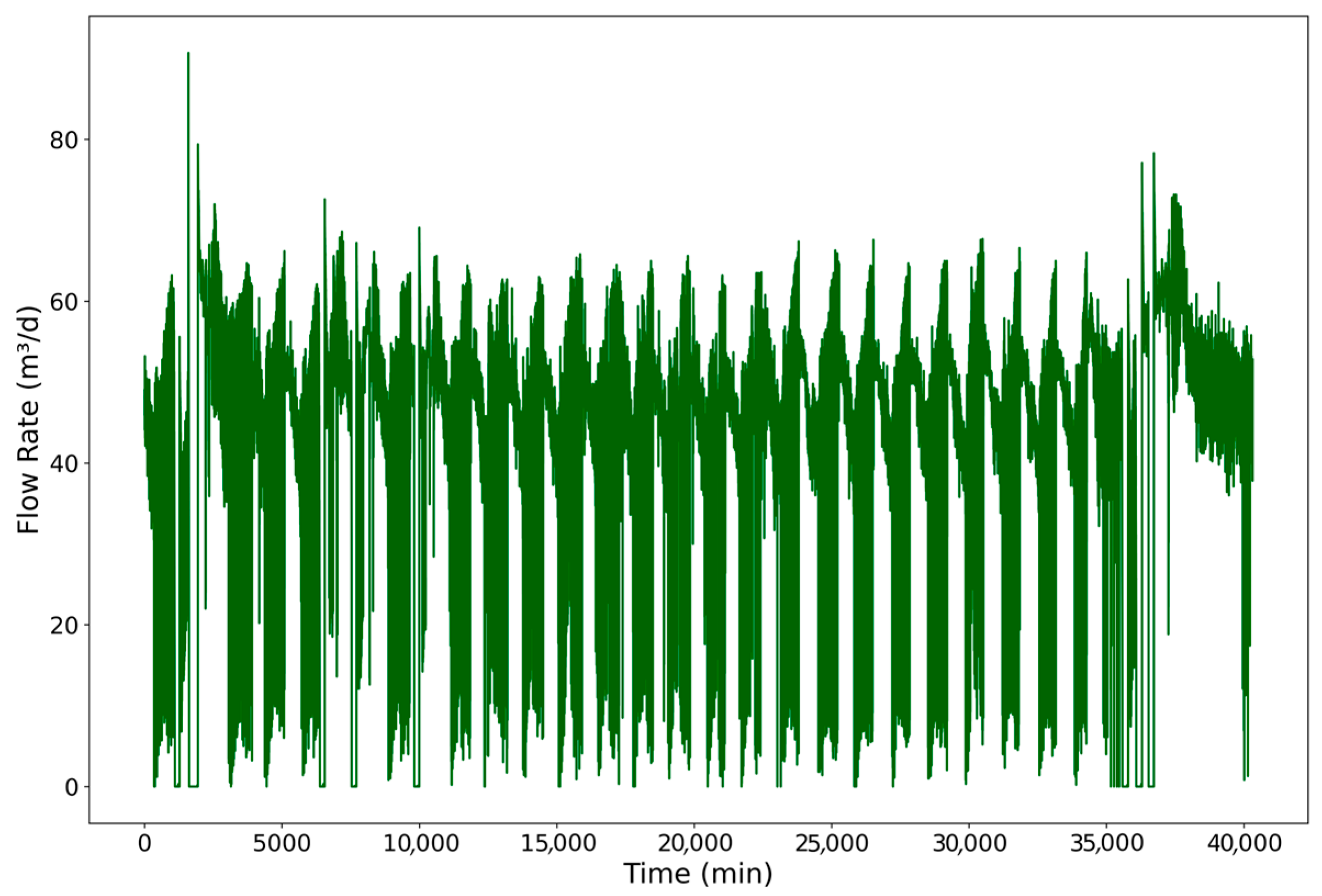

The flowrate data from Well A, presented in

Figure 5, exhibits characteristic operational patterns that merit detailed examination. The temporal profile demonstrates stable production conditions with flowrates consistently maintained within a well-defined operational range, punctuated by periodic interruptions. During normal operation, the flowrate stabilizes around 50 m

3/d, reflecting optimal reservoir deliverability and pump performance. The observed fluctuations show an amplitude of approximately ±10–15%, indicating moderate but expected variability in production conditions.

Sharp drops to zero flow are observed at regular intervals, approximately every 18,000 to 20,000 min, typically lasting 1000 to 1500 min. These patterns suggest planned shutdowns for operational maintenance or pressure control. Each interruption is followed by a rapid recovery to baseline production levels, indicating effective restart protocols. The absence of gradual decline prior to these events reinforces the interpretation of controlled, non-emergency shutdowns.

Moreover, the stability of flowrates between shutdown events reflects consistent reservoir pressure support and effective operation of the artificial lift system. This behavior is consistent with established production management practices in which periodic interruptions are employed to preserve long-term well integrity and maximize well recovery performance following operational interruptions. The high quality of the data, demonstrated by clear signal continuity and the absence of measurement artifacts, provides a robust and reliable foundation for subsequent production analyses and predictive modeling.

3.1.2. Results of Well B

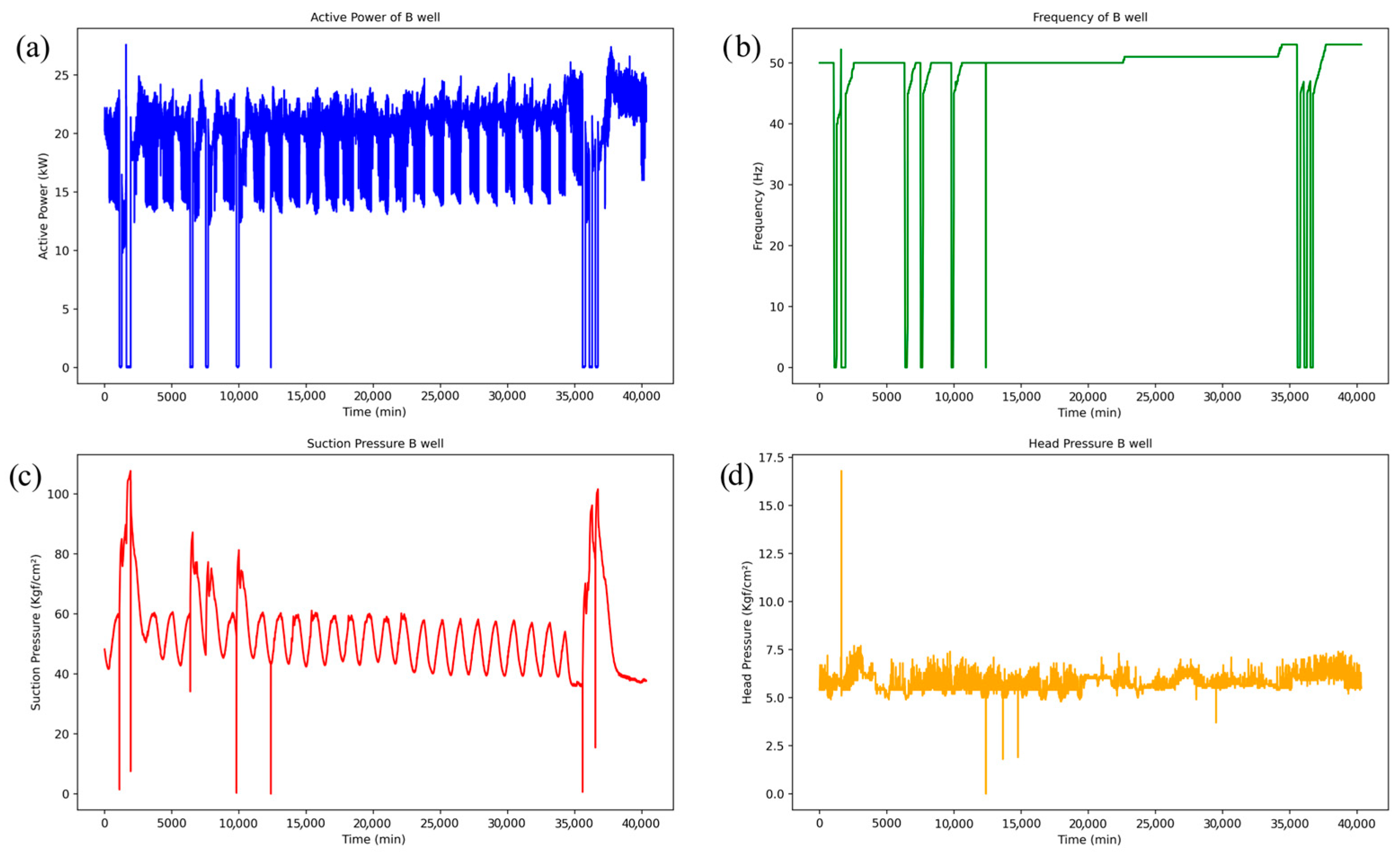

Figure 6 and

Figure 7 present the operational variables for Well B, which exhibit a markedly different behavior compared to Well A. While Well A’s operation is characterized by relative stability, Well B demonstrates significant operational instability, as evidenced by cyclical fluctuations in its data.

The wellbore configuration for Well B features a packer set below the Electric Submersible Pump (ESP), with a 350 m lower tubing section extending further downhole. The prevailing hypothesis suggests that gas accumulates in the lower section of the tubing annulus. Periodically, this trapped gas is believed to reach the intake of the production tubing below the packer. Such an event would cause a rapid increase in the gas volume fraction at the pump’s suction, consequently impairing its performance. This phenomenon provides a compelling explanation for the cyclical patterns observed in Well B’s pressure, power, and production data, which manifest with a consistent periodicity, particularly upon pump startup.

The operational behavior of Well B, detailed in the accompanying figures, presents a stark contrast to the stable conditions observed in Well A. The time-series data for active power (

Figure 6a), frequency (

Figure 6b), suction pressure (

Figure 6c), and head pressure (

Figure 6d) collectively illustrate an operation characterized by severe instability and periodic cycles. The active power exhibits pronounced fluctuations, which correspond directly to extreme volatility in the suction pressure. Crucially, the frequency plot reveals that these unstable periods culminate in repeated, systematic shutdowns of the pump, where the operational frequency drops to 0 Hz before restarting. This pattern confirms that the well operates under transient conditions, a behavior that directly results in the cyclical flowrate presented in

Figure 7.

The production flowrate of Well B, as illustrated in the provided figure, is characterized by significant instability and severe transient behavior. The data clearly shows a distinct cyclical pattern where production periodically ceases entirely, with the flowrate dropping to zero m3/d. During the operational phases between these interruptions, the flowrate remains highly volatile, fluctuating rapidly within a wide band, generally between approximately 40 and 70 m3/d. This cyclical start–stop behavior, which persists with a consistent periodicity throughout the monitored timeframe, confirms a non-steady-state production regime and highlights profound operational challenges for this well.

The presence of these severe, transient operational states is of particular importance to this study for two main reasons. First, such challenging conditions serve as a rigorous test for assessing the robustness and predictive accuracy of the proposed LSTM network. A model that performs effectively under these adverse real-world dynamics demonstrates strong potential to support production management and enhancing operational decision-making. Second, this scenario highlights the capability of the hybrid modeling approach to generate accurate forecasts even when physical sensors might fail or provide erroneous readings, as long as the well remains operational. This ability to maintain predictive oversight during intermittent sensor failure is critical for ensuring operational continuity and enabling proactive intervention.

3.1.3. Results of Well C

Wells C–E are completely different from wells A and B. They have only two things in common: they are offshore wells and equipped with ESP. While wells A and B are located in the Northeast region of Brazil, wells C–E are located in the Southeast region of Brazil. In addition, wells A and B have reduced oil and gas production with several operational problems. Wells C–E, on the other hand, have high production and high efficiency, with rare shutdowns, and it can be said that there is a team of engineers working preventively to avoid failures and production shutdowns.

The graphs below and the following sections show results from wells C–E that differ greatly from the results seen so far from wells A and B. Consistent with the analysis performed on the preceding wells, an exploratory data analysis was conducted for Well C. This analysis encompassed the primary operational variables: active power, operating frequency, suction pressure, wellhead pressure, and flowrate.

Figure 8 and

Figure 9 provide a detailed graphical representation of these data.

The graphs in

Figure 8 show the behavior of key operational parameters for Well C: active power (

Figure 8a), frequency (

Figure 8b), suction pressure (

Figure 8c), and head pressure (

Figure 8d). The data indicate a system operating predominantly under stable conditions, with occasional interruptions likely due to planned events or transient disturbances.

Active power (

Figure 8a) remains stable around 1000 kW, reflecting a high-capacity pumping system with consistent energy input. Five distinct drops to nearly zero occur, typical of automated safety shutdowns, scheduled maintenance, or brief power losses. Their short duration and rapid recovery suggest controlled stoppages rather than equipment failures.

Frequency (

Figure 8b) closely follows the power trend, staying near 53 Hz during normal operation. Reductions in frequency coincide with power drops, confirming the pump’s variable frequency drive was off or reset. The near-constant frequency indicates full or near-full pump speed, consistent with high-volume production.

Suction pressure (

Figure 8c) is steady at 78–80 kgf/cm

2, with transient spikes above 100 kgf/cm

2 after shutdowns, likely from fluid accumulation at the pump intake during stoppages. This is typical when reservoir pressure is substantial and the artificial lift system temporarily ceases, allowing pressure to build before restart.

Head pressure (

Figure 8d) is generally stable at 120 kgf/cm

2, with minor acceptable fluctuations. Significant drops to zero align with shutdowns, while a sharp spike above 170 kgf/cm

2 near the final stoppage may result from pressure wave reflection or downstream backpressure on restart.

Overall, Well C demonstrates continuous, high-throughput performance with brief, well-managed interruptions. The synchronization between power, frequency, and pressure confirms a well-tuned control system, while suction pressure spikes during downtime match established ESP operational principles. This stability supports optimized uptime, effective maintenance scheduling, and sustained production integrity.

The flowrate of Well C, illustrated in

Figure 9, demonstrates a remarkably stable and continuous production profile over an extended operational period. The production rate holds at a consistent, positive value, indicative of a highly controlled, steady-state system. Therefore, aside from these identifiable data artifacts, Well C exhibits exceptional operational stability with no significant production volatility.

3.1.4. Results of Well D

Following the same analytical approach applied to previous wells, Well D underwent comprehensive exploratory data analysis. The evaluation included key operational parameters such as active power consumption, operating frequency, intake pressure, discharge pressure, and production flowrate. These variables are illustrated in

Figure 10 and

Figure 11 through detailed temporal trend visualizations.

The operational behavior of Well D is detailed in

Figure 10, which presents the time-series data for active power, frequency, suction pressure, and head pressure. Under normal conditions, the well demonstrates a highly stable and high-capacity operational profile. The active power is consistently maintained near 1050 kW, while the frequency is stable at approximately 54 Hz, reflecting steady Variable Frequency Drive operation. This stability is mirrored in the pressure readings, with suction pressure holding steady at around 82–85 kgf/cm

2 and head pressure at 112–115 kgf/cm

2, indicating consistent reservoir inflow and efficient pump performance. Notably, immediately following these shutdowns, the suction pressure spikes sharply to over 100 kgf/cm

2. This behavior is characteristic of fluid column buildup at the pump intake when flow ceases in a well with strong reservoir support. Concurrently, the head pressure dips, reflecting the complete cessation of flow.

In summary, Well D operates as a well-regulated and high-efficiency system whose infrequent interruptions are handled in a predictable and controlled manner. The clear coupling between power, frequency, and pressure dynamics during these events underscores a responsive control system. The observed pressure spikes during shutdowns highlight the system’s sensitivity and the importance of real-time monitoring to prevent mechanical strain or hydraulic imbalances. These findings suggest that while the well benefits from robust artificial lift and reservoir support, the proper management of shutdown and startup sequences is critical for preserving equipment integrity and ensuring long-term production continuity.

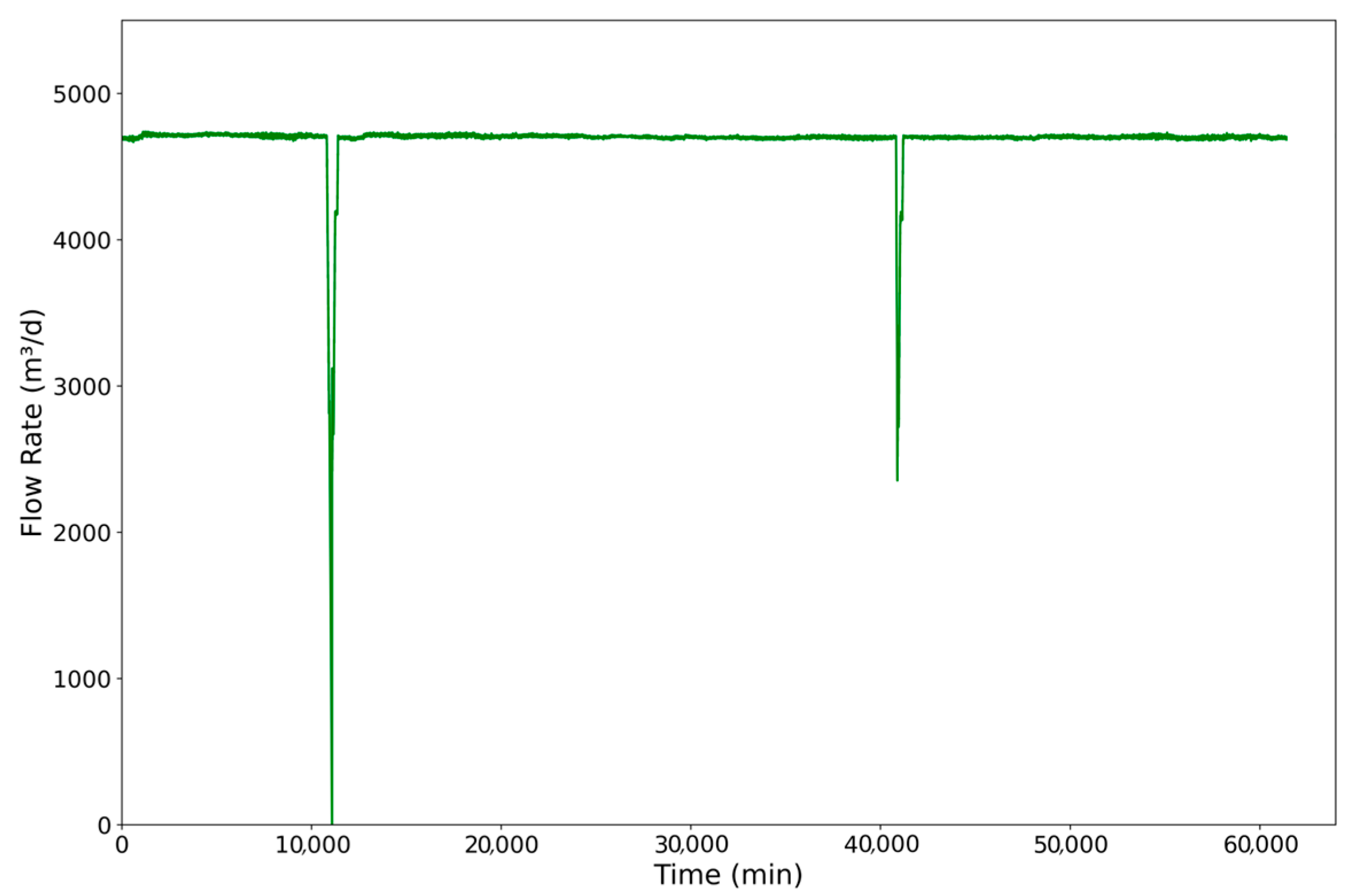

The flowrate for Well D (

Figure 11) is characterized by a highly stable and consistent production profile, maintained at approximately 4900 m

3/d for most of the operational period. This steady output reflects effective artificial lift, reliable reservoir inflow, and a well-regulated control system.

The overall production profile confirms that Well D is a robust, high performing well that operates under optimized conditions. The system demonstrates resilience, with rapid recovery from transient disturbances and no signs of long-term performance degradation. The sharp, controlled nature of the full shutdown suggests a proactive operational intervention or an automated fault response, rather than a gradual decline from reservoir depletion or equipment failure. These observations indicate a sophisticated level of automation and control governing the well’s operation.

3.1.5. Results of Well E

Consistent with the methodology applied to the previous wells, Well E underwent a systematic exploratory data analysis. The investigation focused on key performance indicators, including electrical power input, pump operating frequency, suction pressure, discharge pressure, and volumetric flowrate.

Figure 12 and

Figure 13 present the complete dataset through graphical representations that illustrate the temporal behavior of each parameter.

The operational data for Well E, presented in

Figure 12, illustrates a system defined by exceptional stability and highly predictable performance. During the extensive monitoring period, the active power is consistently maintained at approximately 1050 kW (

Figure 12a), driven by a stable operational frequency of around 54 Hz (

Figure 12b). This steady energy input and constant pump speed result in a remarkably stable suction pressure of about 80 kgf/cm

2 (

Figure 12c) and a constant head pressure near 115 kgf/cm

2 (

Figure 12d). This uniformity across all parameters points to a highly efficient and well-regulated artificial lift system operating under ideal steady-state conditions with consistent reservoir inflow.

This stable operational profile is punctuated by two isolated, transient events. These events are characterized by an instantaneous drop in frequency and a corresponding cessation of power consumption. Simultaneously, the head pressure falls to zero as the pump stops generating hydraulic work, while the suction pressure experiences a sharp upward spike. This inverse behavior, characterized by a sudden rise in suction pressure upon shutdown, is a classic signature of fluid column buildup at the pump intake in a well with strong reservoir support. It confirms that the reservoir continues to supply fluid even when the pump is inactive, causing a rapid pressure increase within the wellbore.

In summary, the operational data for Well E depict a high-performance, well-controlled system with highly predictable behavior. The rare interruptions do not indicate chronic instability or degradation but rather coordinated shutdowns, likely planned interventions or automated protective trips. This profile suggests management by a sophisticated control system, providing a valuable baseline of optimal performance essential for advanced anomaly detection, predictive maintenance, and overall asset management.

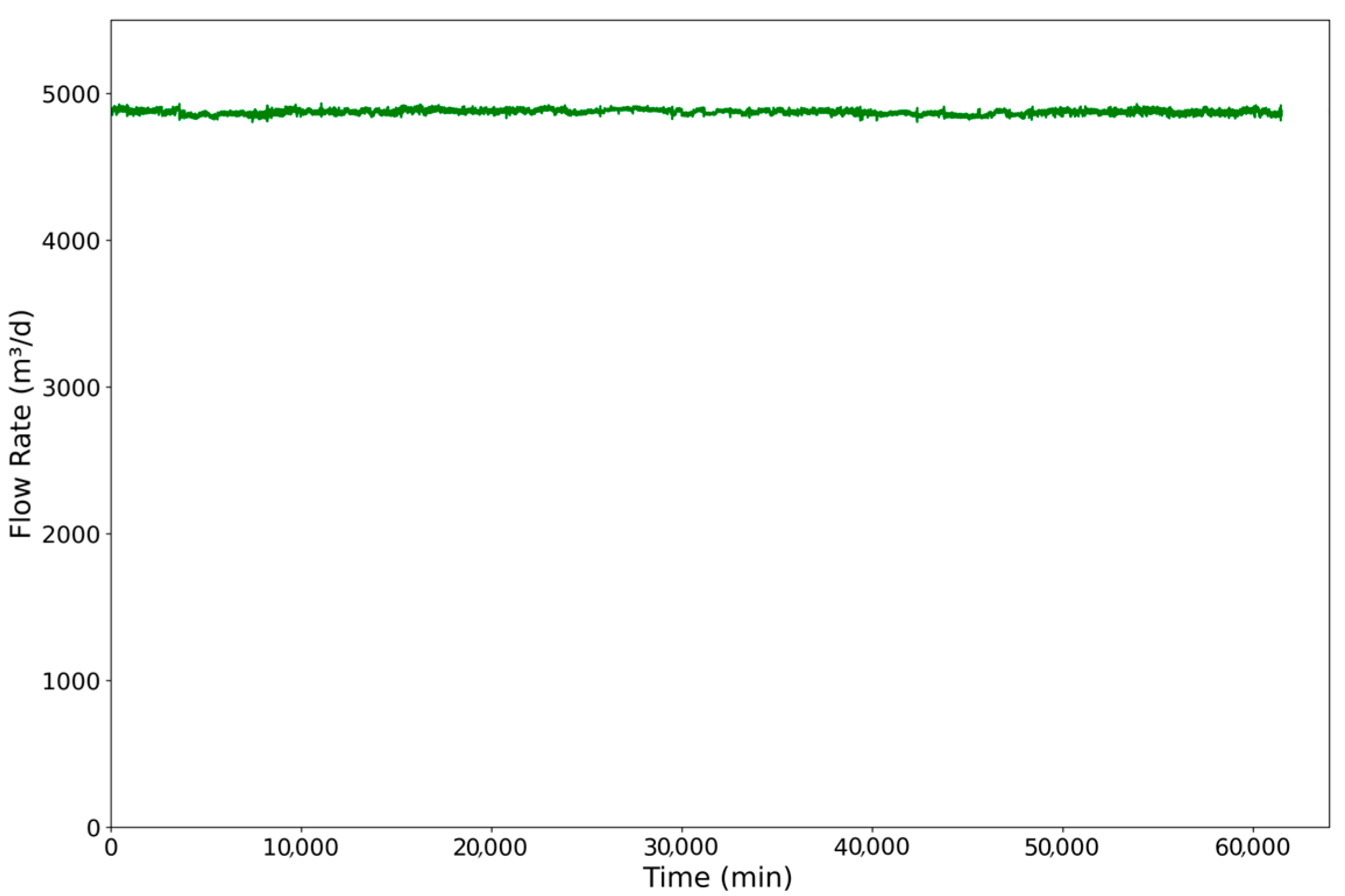

The flowrate profile for Well E, presented in

Figure 13, demonstrates exceptional operational stability and high production output. For the vast majority of the monitored period, the well maintains a consistent and uniform flowrate of approximately 4850 m

3/d. This remarkable consistency is a direct reflection of the steady power and frequency applied to the Electric Submersible Pump (ESP), as analyzed previously, and is indicative of a highly optimized and well-regulated artificial lift system operating with stable reservoir inflow.

3.1.6. Pearson Correlation Across Wells A Through E

To quantitatively investigate the linear interdependencies among key operational variables, a Pearson correlation analysis was conducted for each of the five wells (A through E). This statistical method assesses the strength and direction of a linear association between two continuous variables, providing quantitative insight into the distinct operational dynamics of each system. The resulting correlation matrices, presented in

Table 3, are particularly valuable for interpreting the cyclical and unstable behaviors previously identified in certain wells and for comparing these dynamics across the different production environments.

A comprehensive analysis of the linear relationships between key operational variables was performed for all five wells using the Pearson correlation coefficient. The resulting matrices, presented in

Table 3, provide a quantitative framework for comparing the distinct operational dynamics of each system. This approach allows for a more objective characterization of the relationships between parameters, such as flow rate and power, than is possible through narrative descriptions alone, thereby substantiating previous qualitative assessments of system stability.

The results clearly differentiate between stable and volatile production environments. For the wells exhibiting high stability, particularly Well E, the analysis reveals near-perfect positive correlations between flow rate, active power, and frequency (r ≈ 1.00), alongside a very strong negative correlation with suction pressure (r = −0.91). This quantifies a highly predictable and efficient system, where increases in power and frequency translate directly into increased output and a corresponding decrease in suction pressure. Similarly, Wells C and D demonstrate strong positive correlations between active power, frequency, and wellhead pressure (e.g., for Well C, r = 0.92 and r = 0.88, respectively), confirming a consistent and stable operational signature. The strong negative correlation between active power and suction pressure observed in these wells (r = −0.71 for Well C) is another robust indicator of stable pump performance.

In stark contrast, the correlation matrices for Wells A and B numerically confirm their previously described instability. For Well A, while a strong positive relationship exists between flow rate and frequency (r = 0.80), the correlations with suction pressure (r = −0.07) and wellhead pressure (r = 0.10) are negligible. This quantitatively demonstrates a decoupling of the pump’s output from the system’s pressure dynamics, a hallmark of operational volatility likely caused by phenomena such as gas slugging. Well B exhibits similar behavior, with a significantly weaker relationship between flow rate and frequency (r = 0.57) compared to the other wells, and minimal correlation with pressure variables.

By tabulating the Pearson coefficients for all wells, it becomes possible to move beyond qualitative labels like “stable” or “unstable” and objectively quantify these differences. For instance, the stark contrast between the flow rate-suction pressure correlation in Well E (r = −0.91) and Well A (r = −0.07) provides a precise, data-driven measure of their relative stability. This comparative quantification strengthens the analysis by transforming narrative observations into empirical evidence, enabling a more rigorous assessment of each well’s unique operational dynamics.

3.2. LSTM Results

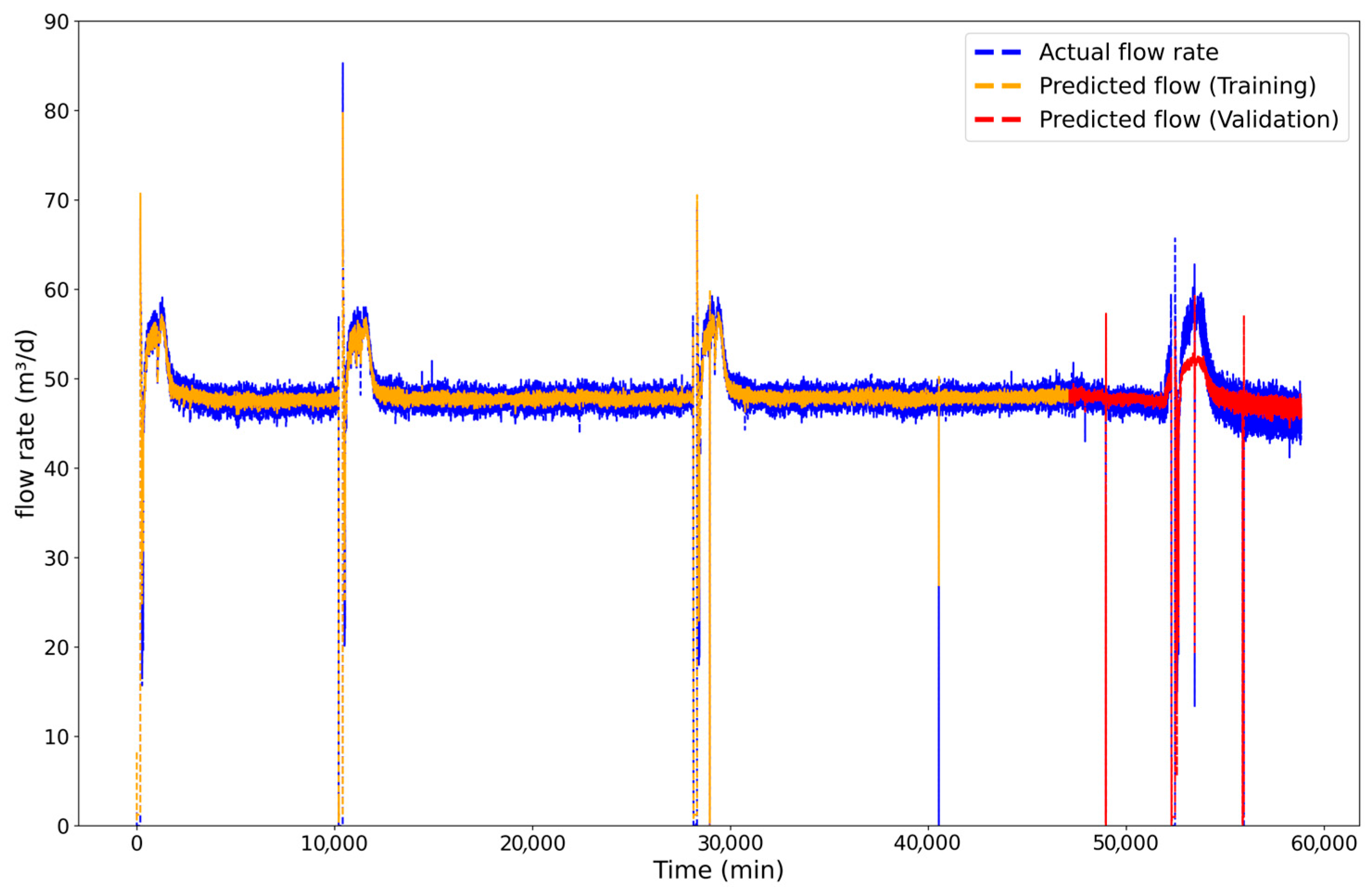

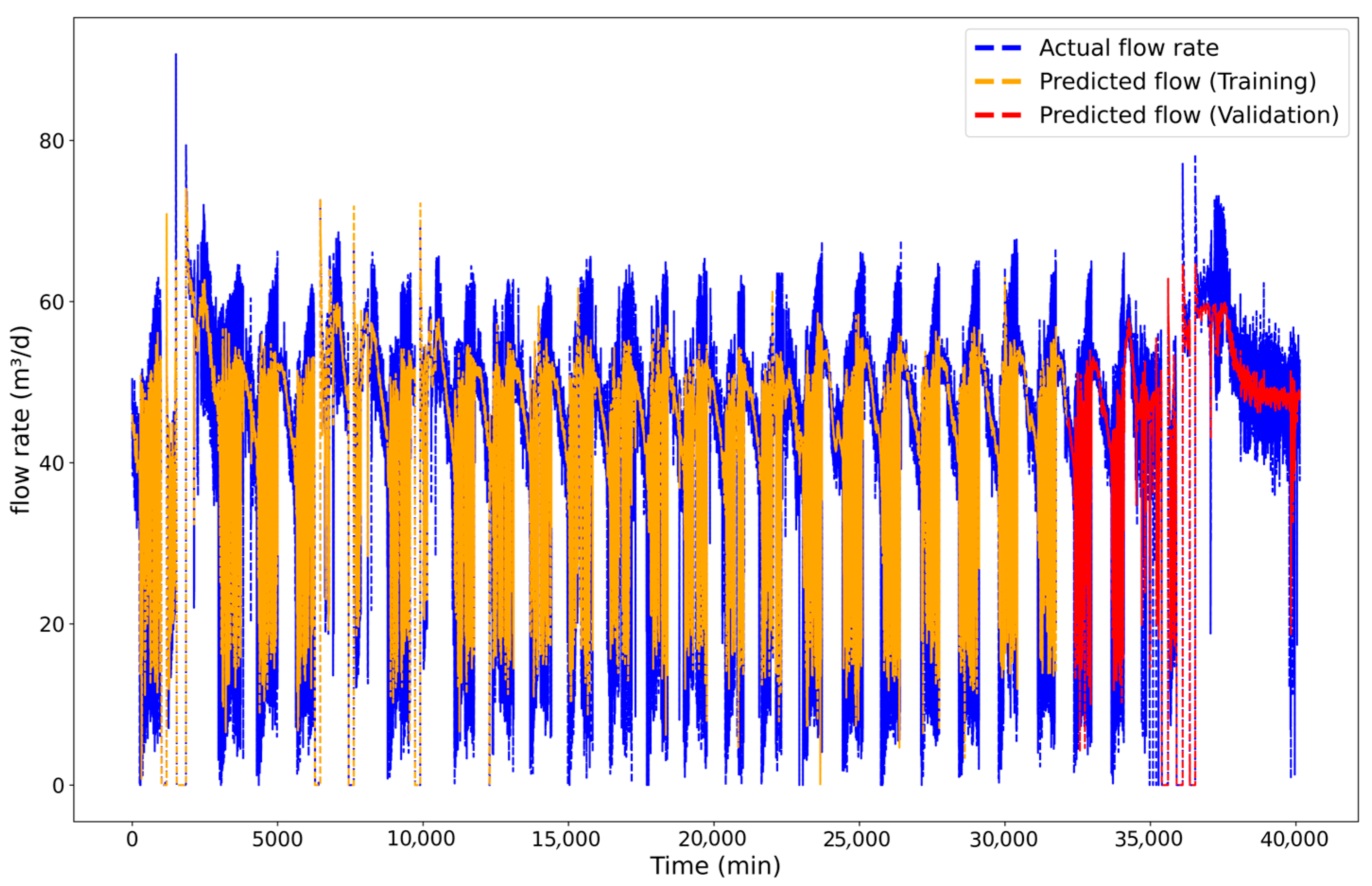

3.2.1. LSTM Results to the A Well

After the initial data analysis, a Long Short-Term Memory (LSTM) network was built to forecast Well A’s flowrate using past values for one-step-ahead predictions. The model employed two hidden layers with a 30% dropout to prevent overfitting. The Adam optimizer was utilized with a Mean Squared Error (MSE) loss function, a batch size of 16, and the model was trained for 100 epochs. The final architecture consists of 16,337 trainable parameters. To assess generalization, the minute-by-minute dataset was split, reserving the final segment for validation. LSTM forecast results for Well A are shown in

Figure 14.

The model demonstrates a high degree of accuracy in reproducing the well’s behavior. The training curve (orange) (

Figure 14) very closely tracks the actual flowrate during the stable operational periods around 48 m

3/d. More importantly, it successfully identifies the timing of the sharp, transient shutdown events, although it naturally smooths the prediction and does not capture the full magnitude of these instantaneous drops. The validation curve (red) confirms the model’s robust performance on unseen data. It accurately predicts the baseline flow and successfully adapts to the more volatile production phase near the end of the timeline, showcasing the model’s ability to generalize. The overall success is quantified by the close alignment of the mean observed flowrate (47.65 m

3/d) and the mean predicted flowrate (47.38 m

3/d). The model’s slightly lower dispersion (predicted standard deviation of 5.97 m

3/d vs. observed 6.30 m

3/d) is characteristic of this type of forecasting and confirms a well-fitted yet non-overfit model.

Table 4 provides a detailed statistical summary of the LSTM model’s forecasting performance for Well A. The table presents a quantitative comparison of the key statistical metrics for the Observed flowrate (m

3/d), the model’s Predicted flowrate (m

3/d), and the resulting model error, which is detailed through the analysis of the Residuals (m

3/d).

The descriptive statistics presented in

Table 4 provide a detailed quantitative evaluation of the LSTM model’s performance for Well A, assessing its accuracy, bias, and reliability. An analysis of the central tendency reveals an exceptionally well-calibrated model. The mean predicted flowrate of 47.49 m

3/d is in very close agreement with the mean observed flowrate of 47.77 m

3/d. This alignment results in a mean residual of just −0.03 m

3/d, indicating a negligible average bias and suggesting the model does not systematically over or underpredict production. This finding is further reinforced by the median (50th percentile) residual, which is also −0.03 m

3/d, confirming that the central point of the error distribution is effectively zero. This analysis is based on a consistent sample size across all metrics, ensuring the statistical integrity of the comparison.

Beyond its accuracy in predicting the average, the model also demonstrates a strong ability to capture the data’s inherent variability. The standard deviation of the predicted flowrate (5.57 m3/d) closely mirrors that of the observed data (5.82 m3/d), showing that the model successfully reproduces the magnitude of typical fluctuations. The low standard deviation of the residuals (1.30 m3/d) further confirms that prediction errors are tightly clustered and not widely dispersed. A more granular look at the error distribution via percentiles reveals that 75% of all absolute errors are under 0.92 m3/d, a threshold considered highly acceptable for operational forecasting and a strong indicator of the model’s reliability under normal conditions.

Despite its high overall accuracy, the analysis of extreme values highlights the model’s primary limitation: handling abrupt, non-continuous shutdown events. While the model correctly identifies shutdowns (minimum observed flow of 0.00 m

3/d), its minimum prediction of −0.36 m

3/d is physically unrealistic, likely an artifact of overshooting during a rapid drop. Similarly, the model tends to underpredict the highest production peaks, with a predicted maximum of 79.73 m

3/d compared to the observed 85.30 m

3/d. The largest prediction error (a maximum residual of 67.96 m

3/d) corresponds to one of these shutdown events. In summary,

Table 4 confirms the model for Well A is highly accurate and robust for continuous operations, but its performance at the edges of the operational envelope reveals opportunities for future refinement, such as specific training on transient events.

3.2.2. LSTM Results to the B Well

Following a similar methodology to Well A, an LSTM network was developed for Well B to perform one-period-ahead flowrate forecasting, using its past values as input. However, given the highly complex and unstable operational behavior of Well B previously discussed, a more robust network architecture was required to capture its dynamics, the results of which are presented in

Figure 15. The model for Well B was therefore constructed with three hidden layers and a 30% dropout rate across all layers, totaling 184,129 trainable parameters, a significant increase in complexity compared to the model for Well A. Consistent with the previous network, the Adam optimizer and Mean Squared Error (MSE) loss function were employed, with a batch size of 16 and a training duration of 100 epochs. The input data, sourced from a hydrodynamical model at one-minute intervals, was partitioned by reserving 10% of the total data for the validation set.

A detailed examination of the results, as depicted in

Figure 15, reveals key aspects of the model’s performance. During the training phase, the predicted flow (orange curve) effectively captures the periodic structure of the actual production. The model accurately predicts the general shape, frequency, and amplitude of the production cycles. The primary discrepancy lies in the model’s handling of the abrupt, complete shutdowns. While it anticipates the sharp declines in flow, it often smooths the prediction and fails to capture the instantaneous drops to exactly zero. This is an expected outcome, as such sudden events possess a stochastic quality that is inherently difficult for a deterministic model to perfectly forecast. Critically, the validation phase (red curve) confirms the model’s robustness.

The network continues to accurately predict the cyclical pattern on unseen data, demonstrating that it has successfully learned the underlying physical process rather than merely overfitting to the training data. This result is highly significant, as it highlights the model’s potential for providing valuable operational forecasts even for highly unstable and challenging wells.

Table 5 provides a detailed statistical summary of the LSTM model’s forecasting performance for Well B. The table presents a quantitative comparison of the key statistical metrics for the Observed flowrate (m

3/d), the model’s Predicted flowrate (m

3/d), and the resulting model error, which is detailed through the analysis of the Residuals (m

3/d).

The descriptive statistics in

Table 5 provide a critical evaluation of the LSTM model’s performance on Well B, a system defined by significant operational instability. At first glance, the central tendency suggests a well-calibrated model, as the mean predicted flowrate (43.22 m

3/d) is very close to the observed mean (43.43 m

3/d), resulting in a minimal average bias of −0.28 m

3/d. However, this metric is misleading.

The reason for this high magnitude of error is evident in the system’s dispersion. The observed flowrate has a very large standard deviation of 14.944 m3/d, quantitatively confirming the extreme variability of the production cycles previously identified. While the model captures a portion of this variability (predicted std dev of 12.197 m3/d), the high standard deviation of the residuals (8.596 m3/d) proves that the prediction errors themselves are large and widely dispersed.

The model’s limitations are most apparent at the operational extremes. Although it successfully predicts the frequent shutdowns to zero flow, it severely underpredicts the production peaks, forecasting a maximum of only 73.975 m

3/d compared to the observed 90.700 m

3/d. The maximum residual is a substantial 79.400 m

3/d, highlighting a major prediction failure during an extreme flow surge or system restart. In conclusion,

Table 5 illustrates that while the LSTM model is well-centered, its predictive precision for Well B is fundamentally constrained by the well’s physical instability. The high error dispersion and failure to capture extreme peaks are not necessarily model flaws but rather a reflection of challenging, non-stationary dynamics. This underscores that for such volatile systems, standard accuracy metrics can be deceptive, and more advanced approaches, such as hybrid models or the inclusion of event-based features, are required to improve forecast reliability.

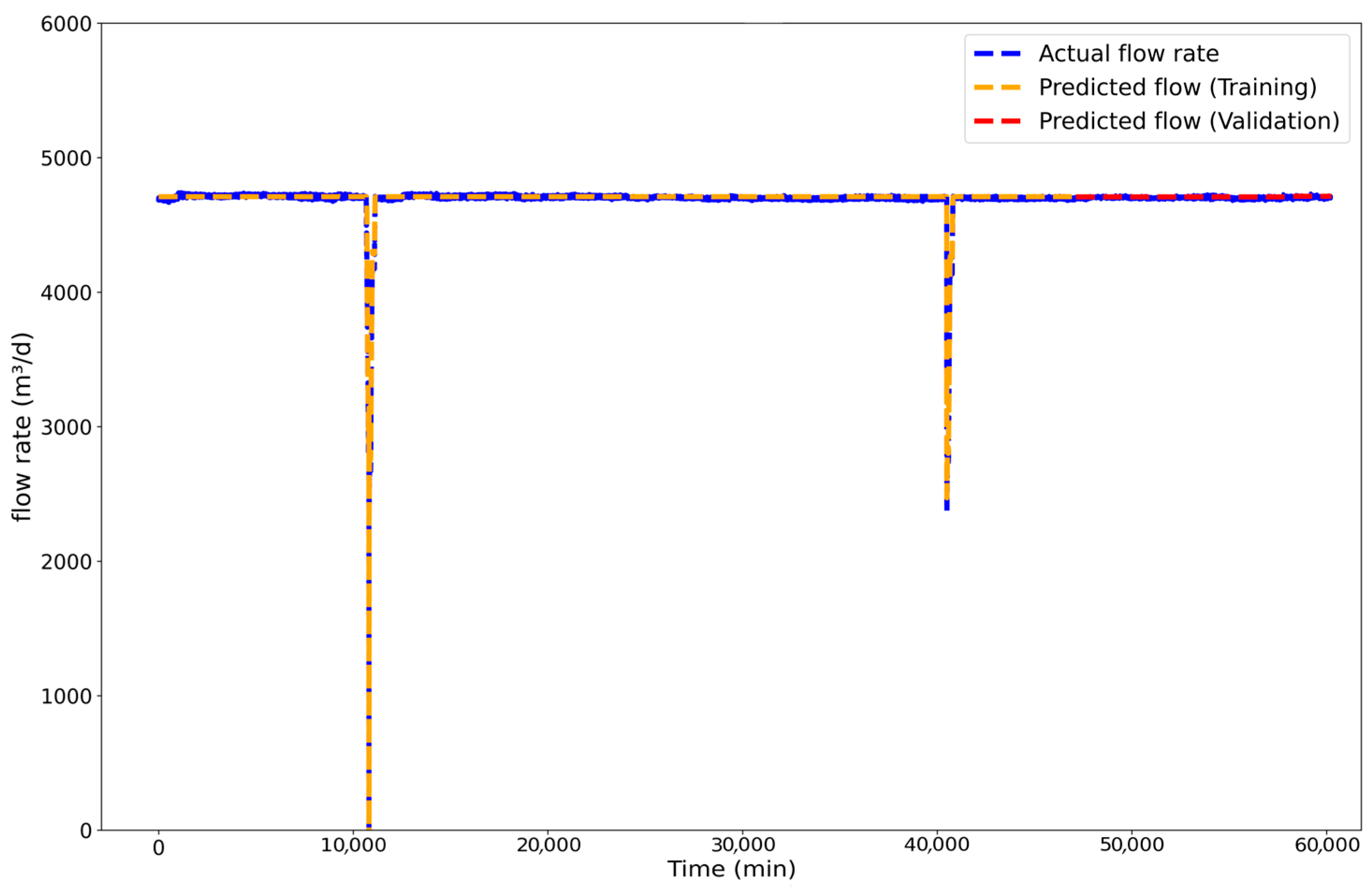

3.2.3. LSTM Results to the C Well

The LSTM model was applied to Well C, with forecast results presented in

Figure 16. The data for Wells C–E were sourced from a field in the southeastern region of Brazil. These wells are more recent and exhibit significantly higher flowrates compared to wells A and B. A network architecture consistent with that used in previous wells was adopted.

The forecast in

Figure 16 shows exceptional accuracy, with predicted flow nearly indistinguishable from the actual rate. The model perfectly captures the stable baseline production of ~4800 m

3/d, maintaining a near-zero error margin during extended steady-state periods. Its performance on transient events, sharp negative peaks, stands out, accurately replicating abrupt drops around the 11,000- and 41,000-min marks.

The LSTM precisely models both the timing and magnitude of these rare but significant deviations, maintaining fidelity from training (orange curve) into validation (red curve) without loss of accuracy. This confirms flawless generalization and the model’s ability to learn Well C’s complete operational signature: a stable system punctuated by predictable shutdowns.

Table 6 presents the statistical summary, comparing observed and predicted flowrates, and detailing residual analysis.

The descriptive statistics in

Table 6 provide a detailed assessment of the predictive model’s performance for Well C, a system known for its highly stable operational behavior. An initial review reveals what appears to be a statistical inconsistency. While the mean predicted flowrate of 4693.54 m

3/d aligns closely with the mean observed value of 4687.47 m

3/d, a difference of just 6.07 m

3/d, the table reports a mean residual of −6.07 m

3/d. Although this value technically reflects the calculation of predicted minus observed, the expectation in a well-calibrated model would be that the mean residual approximates zero, which is largely consistent with the small difference between the means.

An examination of the data’s dispersion further confirms the model’s robust performance. The standard deviations of the observed (166.59 m3/d) and predicted (161.67 m3/d) flowrates are closely aligned, indicating that the model effectively captures the limited variability in Well C’s production. Moreover, the low standard deviation of the residuals (23.20 m3/d) demonstrates that the prediction errors are relatively tight and not widely scattered. The performance under operational extremes is also strong: the maximum predicted flowrate (4710.53 m3/d) closely matches the observed maximum (4739.28 m3/d), and the maximum residual remains within a reasonable bound considering the total output of the well.

The residual represents the instantaneous difference between the model’s forecast and actual data. Positive peaks typically occur after restarts, when production rises sharply but the model has yet to adapt. Conversely, large negative values often arise when the well stops and production falls to zero while the model continues forecasting from prior stable patterns. These deviations introduce brief errors that normalize as the model adjusts, reflecting its response time to sudden operational changes.

Despite the anomaly in the mean residual, evidence from

Table 6 confirms the LSTM’s high accuracy and robustness in forecasting Well C’s flowrate. The model captures the well’s stable production with low error dispersion and minimal deviations under normal conditions. Outlier events are likely linked to transient behaviors and sensor noise or data transmission artifacts, which are inherently difficult to preprocess with complete precision. While minor statistical irregularities may occur, the model’s consistent accuracy supports its suitability for real-time monitoring and operational planning in stable production contexts.

Compared to other wells, Well C’s model delivers superior performance, with lower residuals and more consistent accuracy. Further improvements could include weighted loss functions, expanded training data incorporating slugging cases, and hybrid architectures for extreme-value forecasting. This assessment confirms the model’s reliability while identifying clear paths for optimization.

3.2.4. LSTM Results to the D Well

The analysis of Well D (

Figure 17) presented significant data quality issues, notably a large number of missing values (

NaNs) that required a robust preprocessing stage. Additionally, operational data from Wells D and E displayed subtle, low-amplitude variations that posed a modeling challenge. To capture these fluctuations, the LSTM regressor’s sensitivity was increased tenfold. This fine-tuning enabled the model to learn the underlying stochastic patterns instead of merely predicting averages, ensuring a more faithful representation of the wells’ operational behavior.

The results depicted in

Figure 17 validate the effectiveness of this customized approach, demonstrating the model’s exceptional capability in forecasting the well’s complex, noisy flowrate. Unlike wells with large, distinct events, Well D’s profile is characterized by continuous stochastic fluctuations around a mean of approximately 4900 m

3/d. During the training phase (orange curve), the model excels by closely tracking the actual data’s high-frequency oscillations, indicating that the enhanced sensitivity allowed it to learn the intricate patterns within the noise. This high fidelity is maintained seamlessly throughout the validation phase (red curve), where the model continues to accurately track the unseen fluctuations with no degradation in performance. This robust generalization confirms that the model learned the characteristic signature of the well’s production, underscoring its power not only in predicting major events but also in accurately forecasting fine-grained variations, which is essential for detailed performance monitoring.

Table 7 provides a detailed statistical summary of the LSTM model’s forecasting performance for Well D. The table presents a quantitative comparison of the key statistical metrics for the Observed flowrate (m

3/d), the model’s Predicted flowrate (m

3/d), and the resulting model error, which is detailed through the analysis of the Residuals (m

3/d).

The descriptive statistics presented in

Table 7 offer a quantitative overview of the model’s predictive performance for Well D, a high-capacity and stable production system. The analysis of central tendency reveals an exceptional level of accuracy, with the mean predicted flowrate of 4874.71 m

3/d being nearly identical to the mean observed value of 4874.95 m

3/d. This close agreement is reflected in the mean residual of just 0.23 m

3/d, indicating a negligible positive bias.

The model’s ability to capture the system’s stable nature is further confirmed by the dispersion metrics. The standard deviation of the predicted flowrate (13.76 m3/d) is slightly lower than that of the observed data (15.33 m3/d), suggesting the model effectively represents the general variability while smoothing some of the most minor fluctuations. The moderate standard deviation of the residuals (6.36 m3/d) indicates that prediction errors are generally well-contained. This is supported by the analysis of extreme values, which shows that both observed and predicted flowrates operate within a very narrow band, and the maximum absolute error of 73.52 m3/d is considered acceptable for industrial applications. The percentile data further reinforces that the majority of errors fall within a narrow and operationally manageable range.

In summary, the statistical profile in

Table 7 confirms that the predictive model performs with high accuracy and reliability for Well D, effectively mirroring its well-regulated and stable operational conditions. The minimal bias, low residual spread, and excellent alignment of the central tendency all point to a well-calibrated model. The minor deviations and moderate error dispersion are likely concentrated during the rare transient shutdown events characteristic of this well, rather than being a feature of its steady-state performance. Therefore, the model’s predictive quality is confirmed to be robust, consistent, and well-suited for the real-time monitoring, production forecasting, and performance optimization of this stable production system.

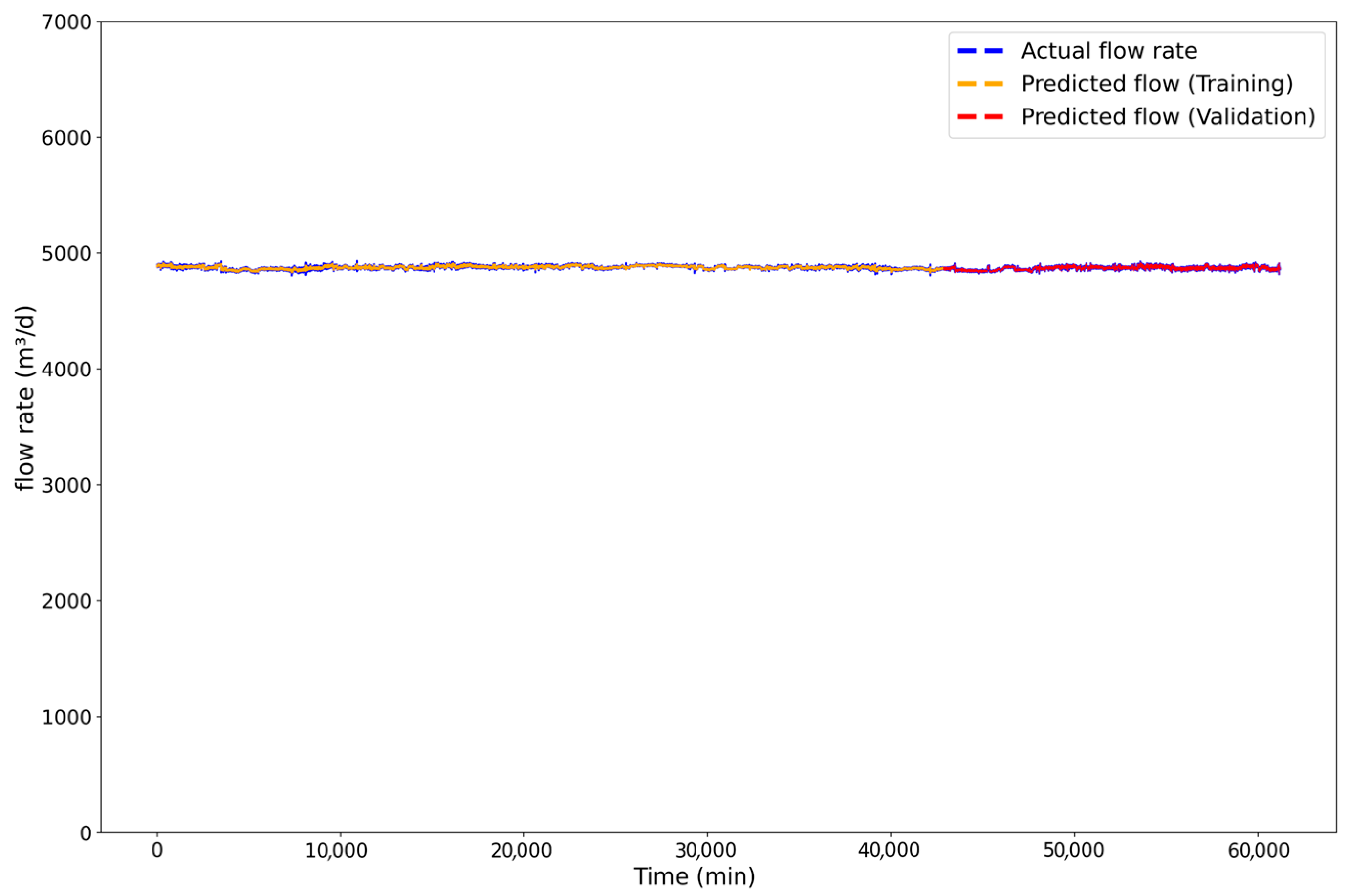

3.2.5. LSTM Results to the E Well

The final application of the LSTM model was on Well E, which represents the pinnacle of operational stability among the wells studied, with its forecasting results presented in

Figure 18. Consistent with the methodology for Wells C and D, the analysis was performed on a representative subset of the large dataset to manage computational demands. Critically, the LSTM regressor’s precision was enhanced by a factor of ten, a crucial adjustment designed to capture the extremely low-amplitude variations characteristic of this well’s highly stable production data. Given the inherent stability of Well E, this analysis serves as a key benchmark to evaluate the model’s maximum potential performance under near-ideal, steady-state conditions.

An examination of the forecast in

Figure 18 reveals a near-perfect prediction, achieving the highest degree of accuracy among all tested wells. This exceptional success can be attributed to two main factors. Firstly, the source data from Well E is inherently stable and predictable, providing a consistent, high-quality pattern for the model to learn. Secondly, the enhanced sensitivity of the LSTM model allowed it to move beyond predicting a simple average and instead learn the fine-grained stochastic texture of the flowrate.

As a result, the predicted flow is almost perfectly superimposed on the actual data, tracking the subtle, noisy fluctuations around the mean of approximately 4800 m3/d with remarkable fidelity. This outstanding performance is consistent across both the training (orange curve) and validation (red curve) phases, demonstrating a flawlessly generalized model. This outcome for Well E serves as a powerful validation of the LSTM methodology, showcasing its capability to achieve near-total accuracy when applied to a well-regulated, stable system and establishing a benchmark for optimal predictive performance.

Table 8 provides a detailed statistical summary of the LSTM model’s forecasting performance for Well E. The table presents a quantitative comparison of the key statistical metrics for the Observed flowrate (m

3/d), the model’s Predicted flowrate (m

3/d), and the resulting model error, which is detailed through the analysis of both the Residuals (m

3/d) and the Absolute Residuals (m

3/d).

The descriptive statistics presented in

Table 8 provide a quantitative summary of the model’s unparalleled predictive performance for Well E, a system previously identified as a benchmark for operational stability. The analysis of central tendency reveals an exceptional concordance between the observed and predicted data. The mean predicted flowrate of 4792.10 m

3/d is virtually identical to the observed mean of 4792.38 m

3/d, resulting in a mean residual of only 0.28 m

3/d, confirming a negligible systematic bias. The high fidelity of the model is further substantiated by the low mean absolute residual of 4.18 m

3/d, indicating that the average magnitude of prediction error is minimal.

An examination of the data’s dispersion further illustrates the model’s precision. The standard deviations of the observed (10.71 m3/d) and predicted (9.10 m3/d) flowrates are closely matched, while the low standard deviation of the residuals (5.59 m3/d) signifies tight error dispersion and high model stability. The analysis of extreme values reveals a singular anomaly within an otherwise impeccable performance. While the maximum and minimum flowrates are closely aligned, the minimum residual registers an extreme negative value of −40.08 m3/d. This is likely attributable to an isolated data acquisition error or a momentary, unmodeled system event.

In summary, the statistical profile in

Table 8 robustly demonstrates the model’s exceptional performance in a stable production environment. The percentile analysis corroborates this, with a near-zero median residual (0.24 m

3/d) and a tight interquartile range, confirming that the vast majority of prediction errors fall within narrow, operationally acceptable margins. This case effectively serves as a quintessential benchmark for forecasting a well-regulated artificial lift system. Aside from the single explained anomaly, all statistical indicators point to a highly reliable and precise forecasting tool. The model’s demonstrated ability to consistently reproduce flow behavior validates its utility for the optimization and real-time monitoring of highly stable production systems and solidifies its role as a reference for evaluating predictive quality in more complex wells.