A Capacity Optimization Method of Ship Integrated Power System Based on Comprehensive Scenario Planning: Considering the Hydrogen Energy Storage System and Supercapacitor

Abstract

1. Introduction

1.1. Background

1.2. Literature Review

1.3. Contribution

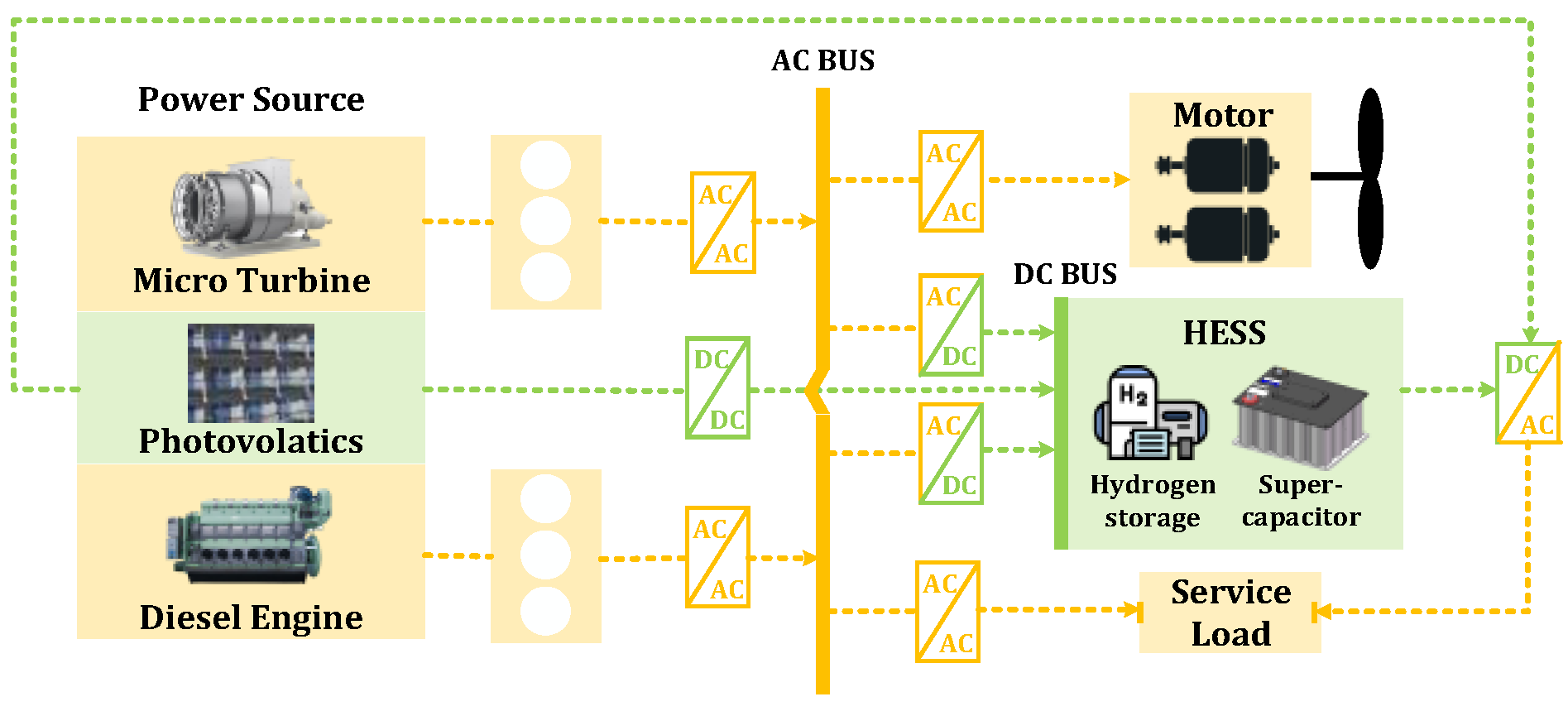

- This paper proposes an improved design for the integrated power system (IPS) of a large cruise ship, incorporating renewable energy and a hybrid energy storage system. The power generation unit comprises a photovoltaic power generation system, diesel engines, and micro gas turbines, while the hybrid energy storage system integrates a hydrogen storage system and a supercapacitor.

- A bi-level optimal power capacity configuration model is established, which integrates planning and operation. The upper layer optimizes the capacity of each power generation unit, aiming to maximize the HEIPS’s Return on Equity (ROE) under COMP. The lower layer allocates the power deficit from the upper layer to the hybrid energy storage systems (HESS), determines the corresponding equipment capacities, and feeds this information back to the upper tier for iterative optimization.

- Within this bi-level framework, we propose an energy control strategy based on time gradient control has been proposed, which takes into account the dynamic response of the load. Additionally, an energy storage power allocation method that considers the characteristics of energy storage devices has been developed. These methods can dynamically adjust the charging and discharging strategy of the energy storage system according to the real-time operating conditions of HESIPS.

2. Modeling and Control of Hybrid Energy Ship Power System

2.1. Subsystem Modeling

2.1.1. Photovoltaic Power Model (PV)

2.1.2. Diesel Engine (DE)

2.1.3. Micro-Gas Turbine (MG)

2.1.4. Hydrogen Energy Storage System

2.1.5. Supercapacitor

2.1.6. Load Model

2.2. Analysis of Hybrid Energy Storage Characteristics

2.3. Energy Storage Power Distribution Method Considering Device Characteristics (ESPD)

- Mode 1 (SC charging normally): when the system meets , SC is charged, the absorbed power is . ( defined as the maximum allowable value of SC charging power, Equation (35)).

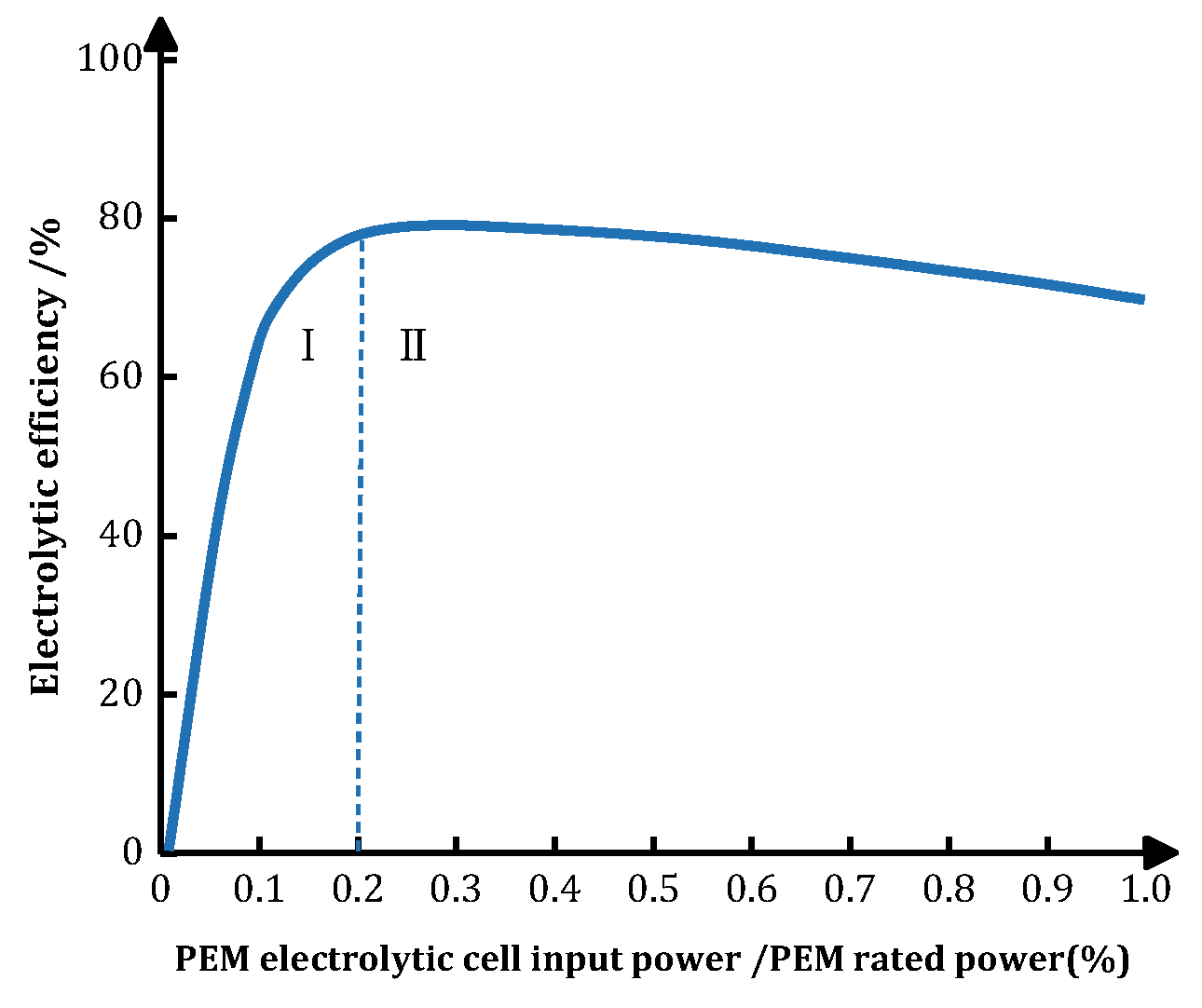

- Mode 2 (SC charging normally, EC operating in the optimal interval): when the system meets , and , SC is charged first . EC absorbs the residual power .

- Mode 3 (SC charging partially, EC operating in the optimal interval): when the system meets , and . EC absorbs the power first and SC is charged second .

- Mode 4 (SC charging normally, EC operating outside the optimal interval): when the system meets , , SC is charged first . EC absorbs the residual power .

- Mode 5 (SC discharging normally): when the system meets , SC is charged, the absorbed power is ( defined as the maximum allowable value of SC charging power, Equation (35)).

- Mode 6 (SC and FC discharging normally): when the system meets , SC is charged first, and the absorbed power is . FC is then discharged .

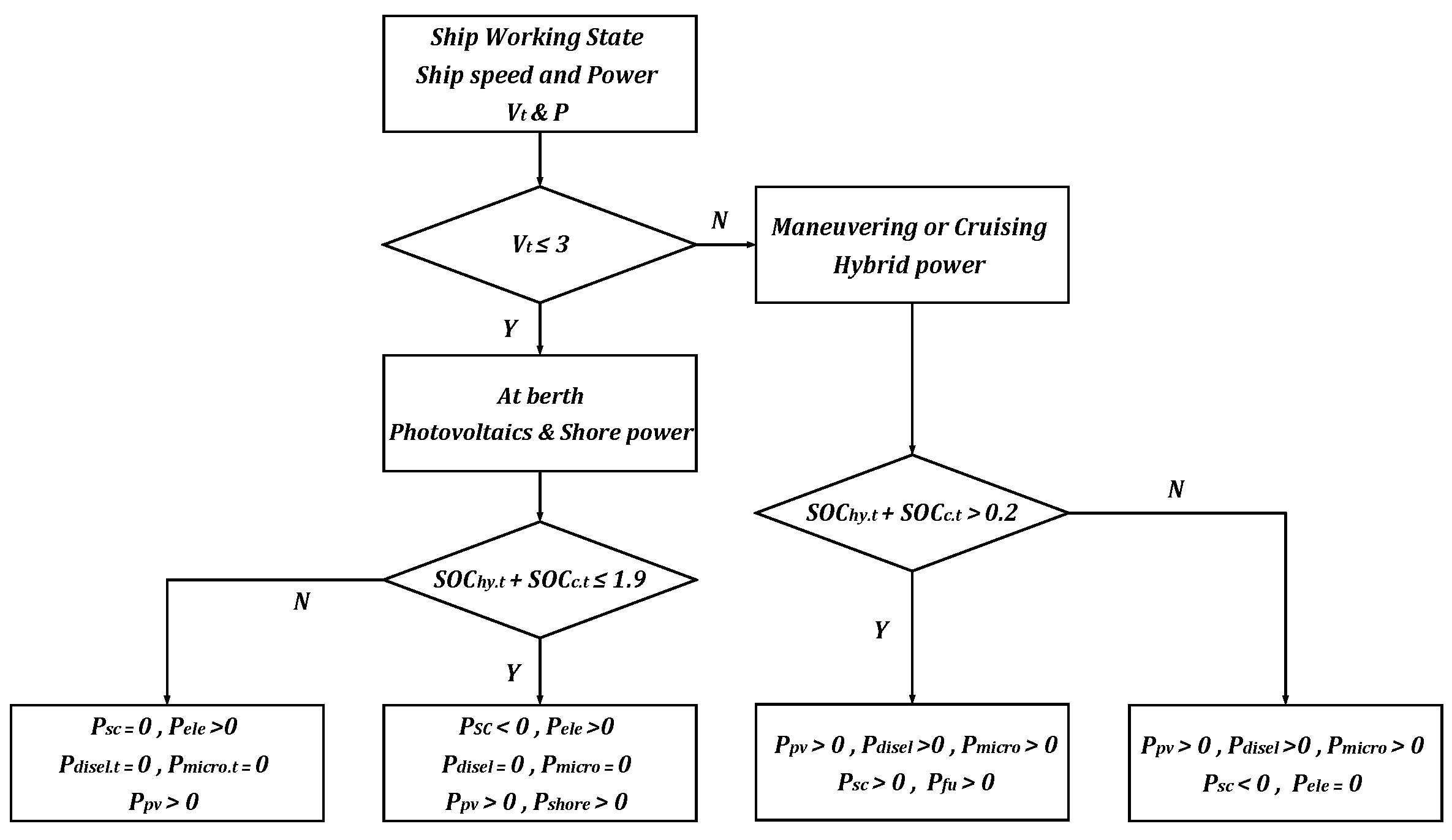

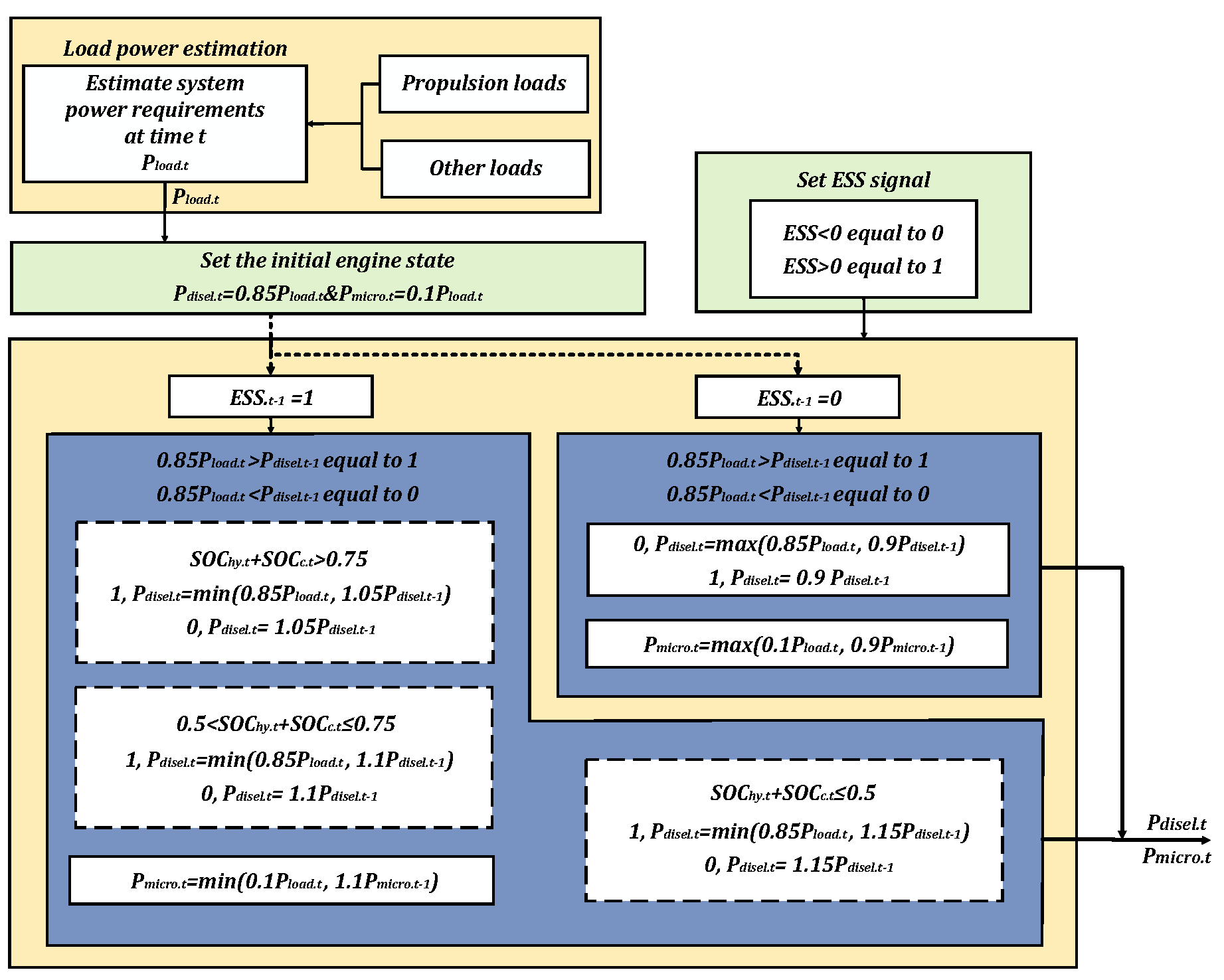

2.4. EMS Based on Time Gradient Control and Considering Dynamic Load Response

3. Optimization Model

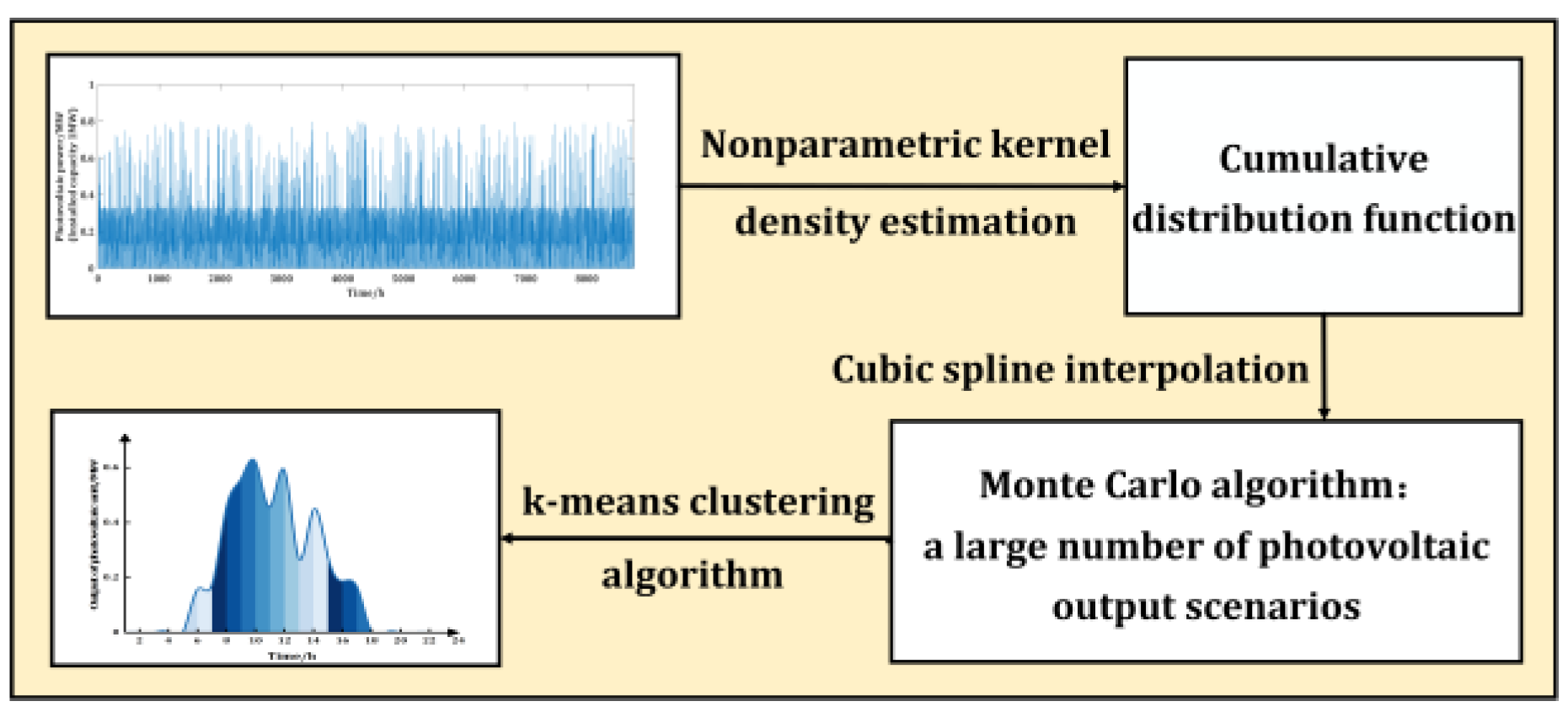

3.1. Comprehensive Scenario Planning Model (COMP)

- Utilizing historical PV output data spanning m days (with a sampling interval of 1 h), a Gaussian kernel function was chosen to produce the probability density function for PV output during each time period within a 24 h cycle, employing the nonparametric kernel density estimation technique [28].

- 2.

- Based on the probability density function for each period of PV output, we obtain the cumulative distribution function , and set .

- 3.

- The cumulative distribution function values for each time period are sampled, and the cubic spline interpolation method is applied to determine the corresponding PV output values for each time period based on their cumulative probabilities. Subsequently, Monte Carlo simulation is employed to generate a vast number of PV output scenarios.

- 4.

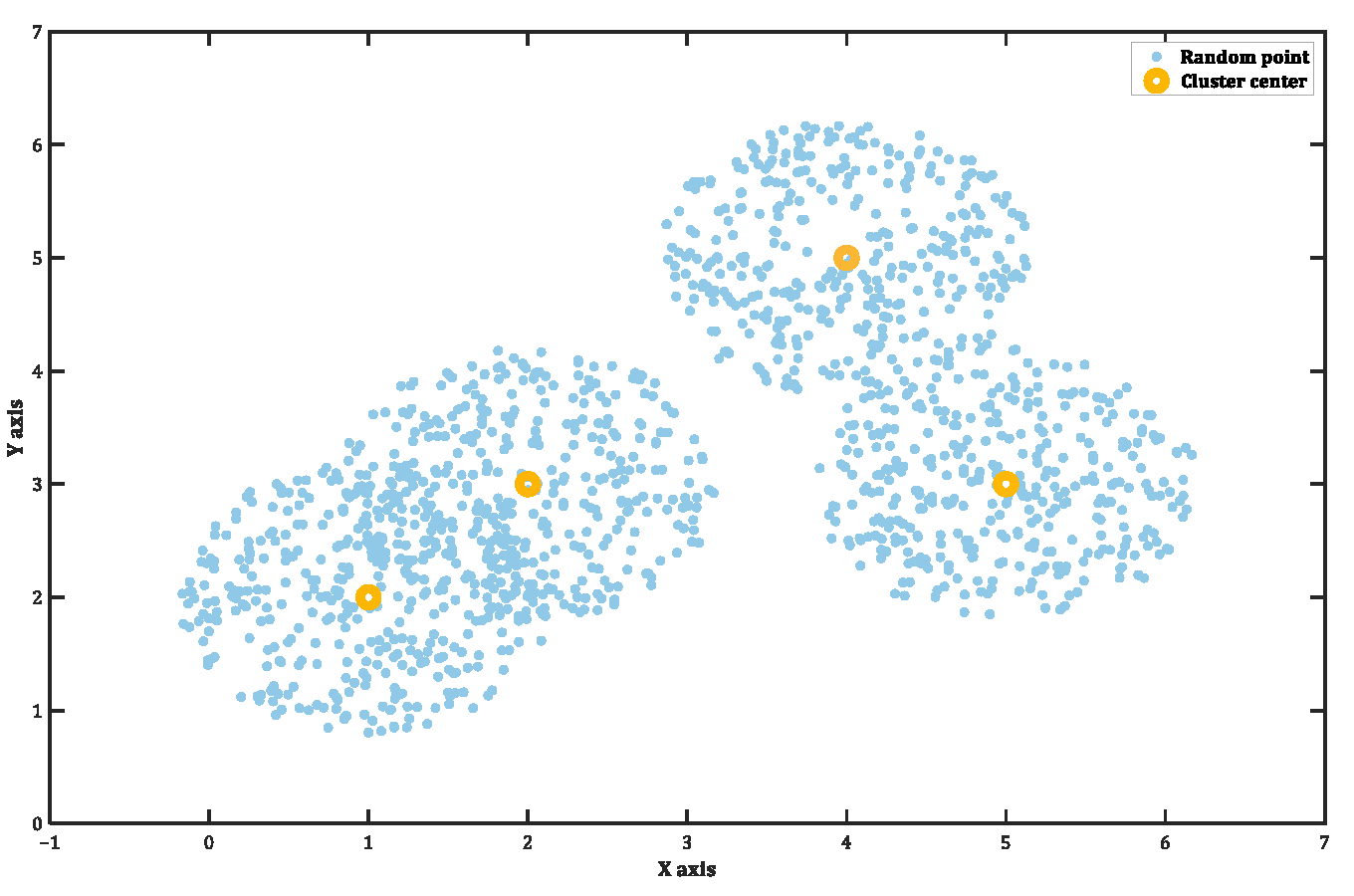

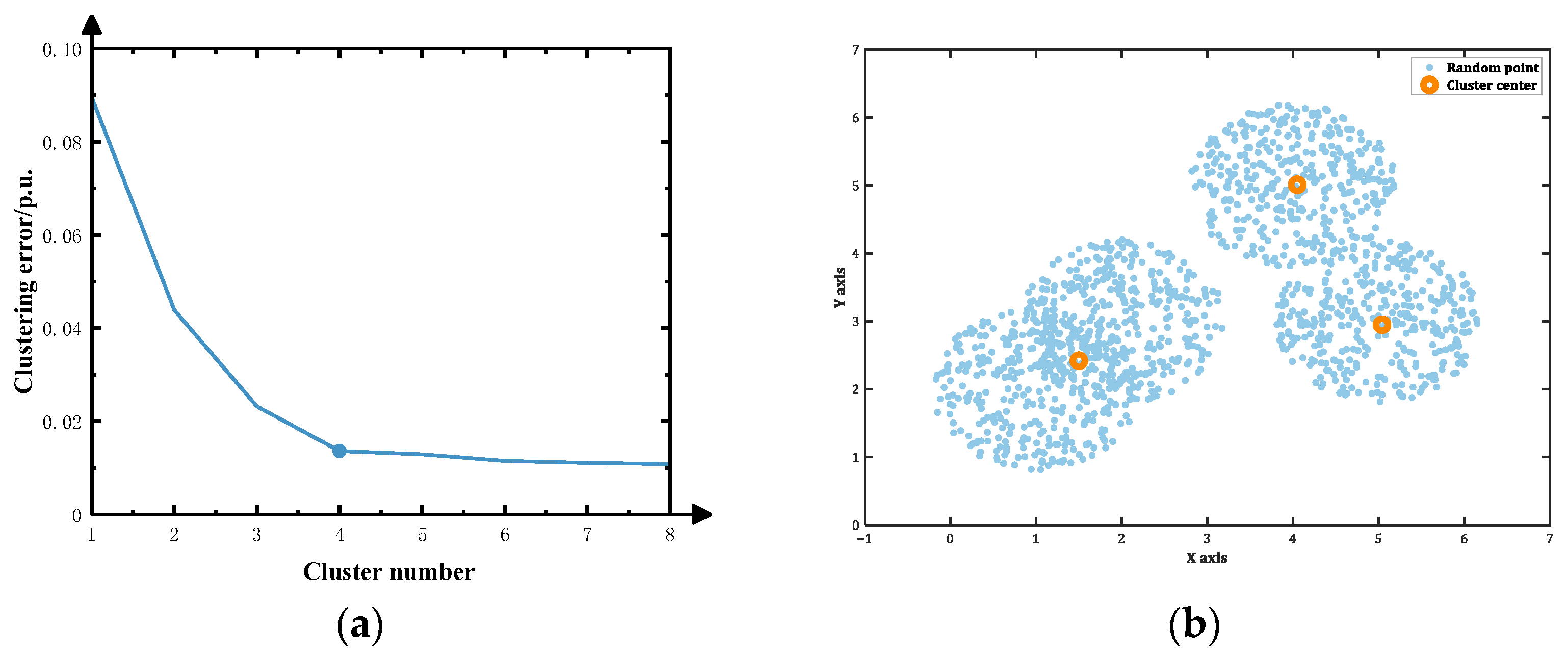

- Before clustering the sampled data, it is essential to determine the optimal number of clusters. This selection is pivotal for the subsequent optimization process, significantly impacting both the calculation speed and the rationality of capacity planning. Therefore, the accuracy of the method used to determine the optimal number of clusters must be rigorously tested. The testing methodology is shown in Appendix A.

- 5.

- The algorithm that demonstrates higher accuracy in step 4 is utilized to ascertain the optimal number of clusters. Subsequently, the K-means clustering algorithm is employed to reduce the large-scale scenarios simulated in step 3 and to calculate the probability of each scenario. Since this algorithm is not the primary focus of this paper, the specific clustering steps are omitted here for brevity.

3.2. A Bi-Level Capacity Optimization Model

3.2.1. Upper Objective Function

3.2.2. Lower Objective Function

3.2.3. Power Balance Constraint

3.2.4. EC Constraint

3.2.5. EC Optimal Operating Interval Constraint

3.2.6. FC Power Constraint

3.2.7. SC Power Constraint

3.2.8. Ship Emission Constraint

3.2.9. Capacity Constraint

3.3. Solution of the Collaborative Optimal Model of Bi-Level

3.3.1. Improved Particle Swarm Optimization (IPSO)

- Tolerance-based search direction adjustment mechanism (TSDM)

- Define the population stagnation state: If the individual best fitness of all particles does not improve in a certain iteration, the population is considered to have entered a stagnation state.

- 2.

- Tolerance Counter (): The variable tolerance of the population is denoted by , which is initialized to 0. If no improvement is achieved by all particles after one iteration, the parameter can be updated as .

- 3.

- Calculate the direction adjustment probability : is an increasing function based on , which is used to quantify the necessity of adjusting the search direction.

- Self-learning-based candidate generation strategy (SLCG)

| Algorithm 1: Self-learning-based candidate generation strategy |

| 1:for each dimension j from 1 to J do 2: Generate a random number of rand ( ) between [0, 1]; 3: if > rand ( ) then 4: ; 5: else 6: randomly select two and from the swarm; 7: if then 8: ; 9: else 10: ; 11: end if 12: end if 13: end for |

- Curve-increasing strategy

3.3.2. IPSO Based on Dynamic Programming (DP-IPSO)

- a.

- Define state variable (reflecting the temporal dynamics of the system): State variables need to cover all core parameters associated with constraints. Therefore, define .

- b.

- Define decision variables (corresponding to real-time power allocation) : Decision variables need to be directly related to the capacity optimization goal of PSO to avoid meaningless decisions. Therefore, let .

- c.

- DP state transition equation (integrating all timing constraints): Equations (2)–(5), Equations (28)–(39).

3.3.3. Bi-Level Capacity Optimization Based on DP-IPSO Algorithm

| Algorithm 2: Solution algorithm of the bi-level capacity optimal model |

| 1: System configuration. |

| 2: Set equipment capacity parameters |

| 3: Set power operating parameters . |

| 4: Set EEOI parameters . |

| 5: Upper layer initialization: set algorithm parameters . |

| 6: Population initialization is performed according to DP. |

| 7: Lower layer initialization: set algorithm parameters . |

| 8: for % Corresponding to each particle in the upper layer do |

| 9: for % Number of scenarios do |

| 10: Generate initial power sequence based on EMS and upper layer capacity constraints. |

| 11: end for |

| 12: end for |

| 13: Main loop |

| 14: Upper IPSO iteration |

| 15: for do |

| 16: for do |

| 17: Lower IPSO iteration |

| 18: for do |

| 19: for do |

| 20: for do |

| 21: Update the lower individual optimal and global optimal |

| 22: end for |

| 23: Accumulate the weighted fuel cost of scenario s. |

| 24: end for |

| 25: end for |

| 26: Calculate upper layer fitness (ROE). |

| 27: Update the upper individual optimal and global optimal. |

| 28: Upper particle update (integration of TSDM + SLCG mechanism and Curves-increasing strategy). |

| 29: end for |

| 30: . |

| 31: end for |

| 32: Output solutions and . |

4. Results and Discussion

4.1. Scenario Generation Results and Correlation Comparative Analysis

4.1.1. Scenario Generation Results Based on COMP

4.1.2. Comparative Analysis of Scenarios Generated Using Empirical Distribution (Specifically, the Beta Distribution)

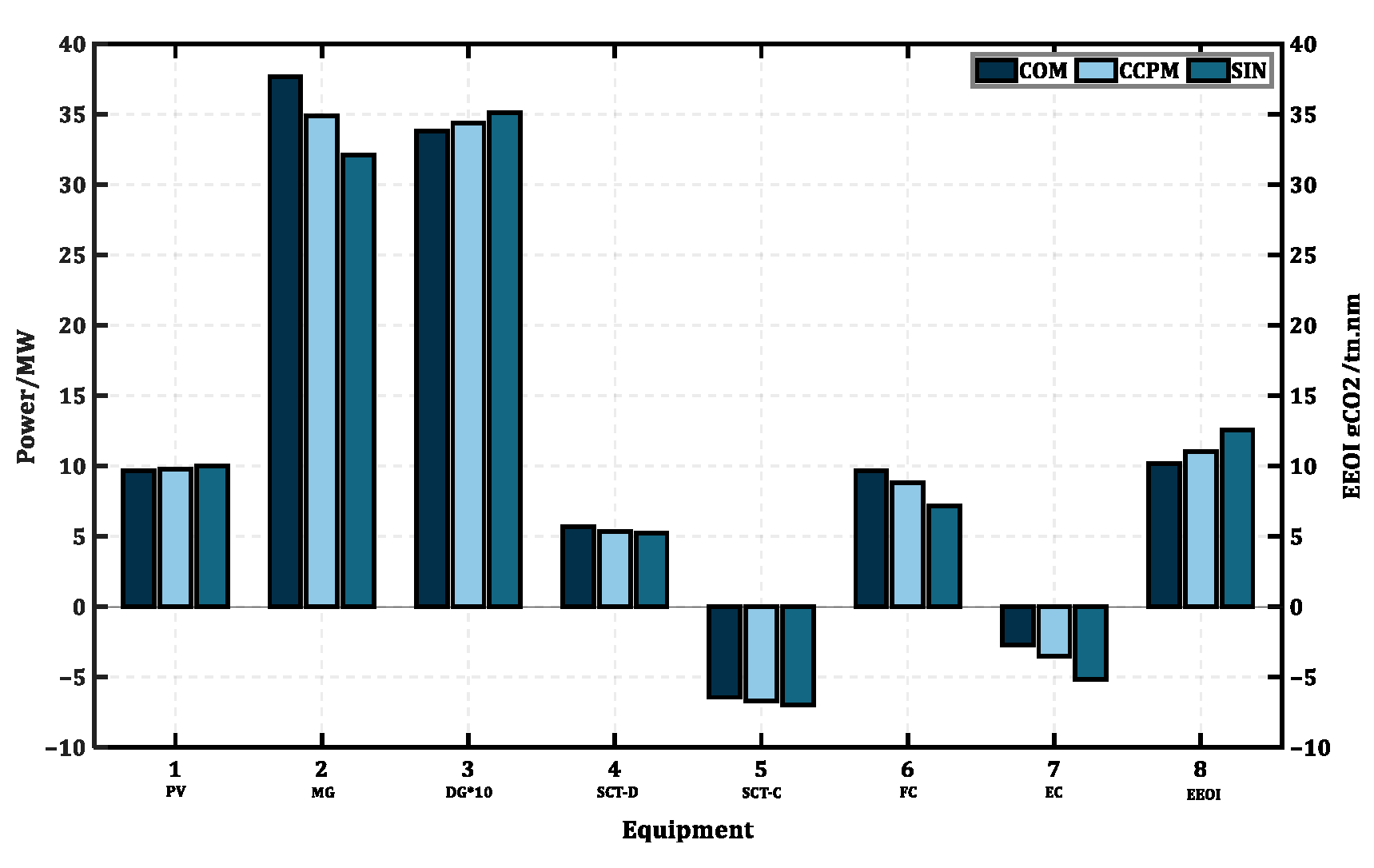

4.2. Optimization Results and Correlation Analysis

4.2.1. Power Capacity Configuration Results and Related Comparative Analysis

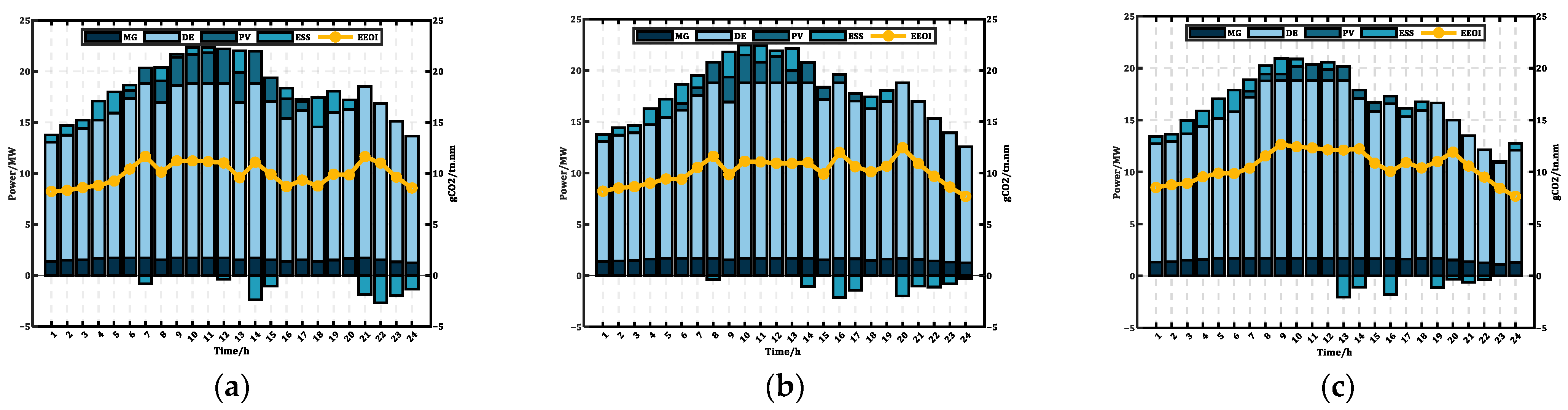

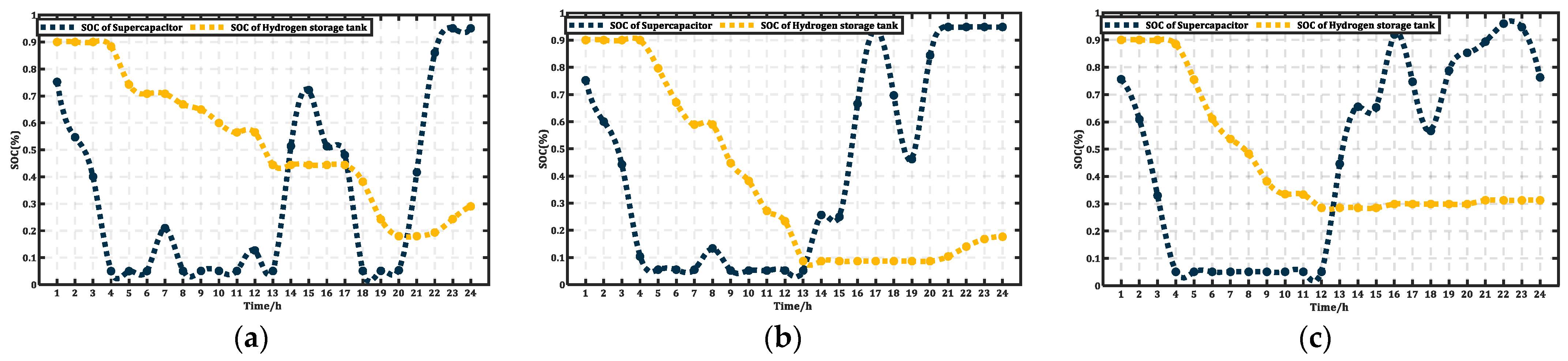

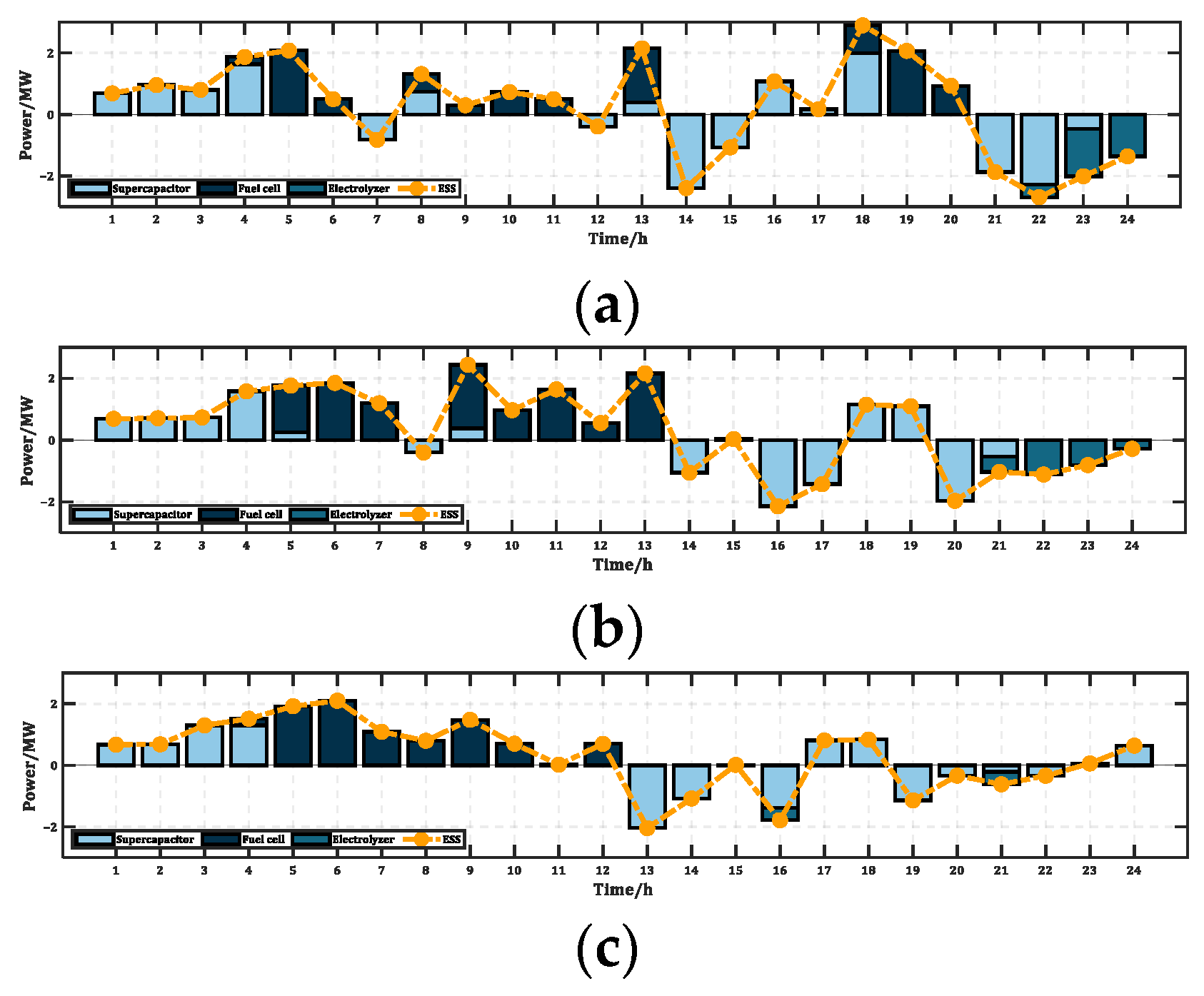

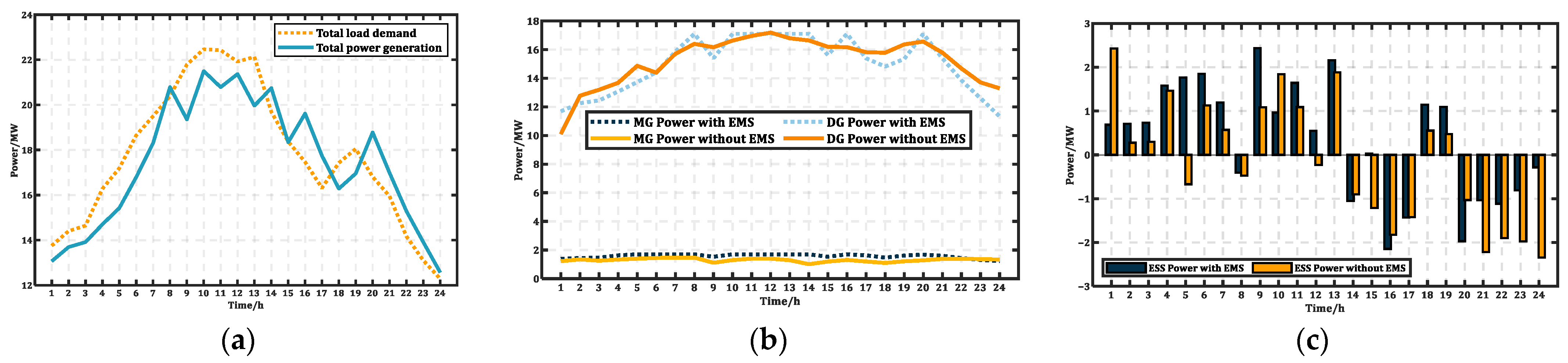

4.2.2. Analysis of Typical Scenarios and Working Conditions

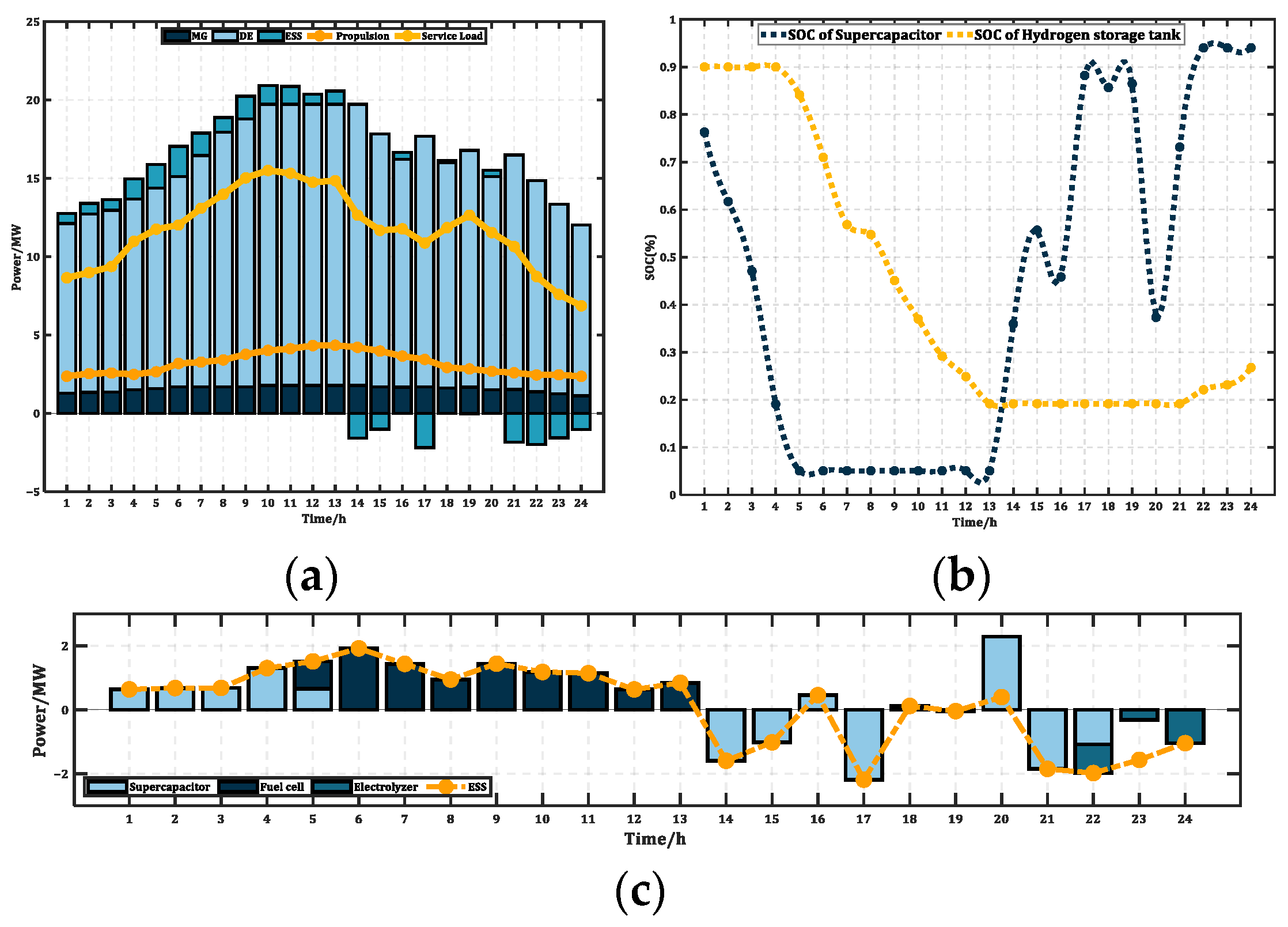

4.3. Ship Berthing Status Analysis

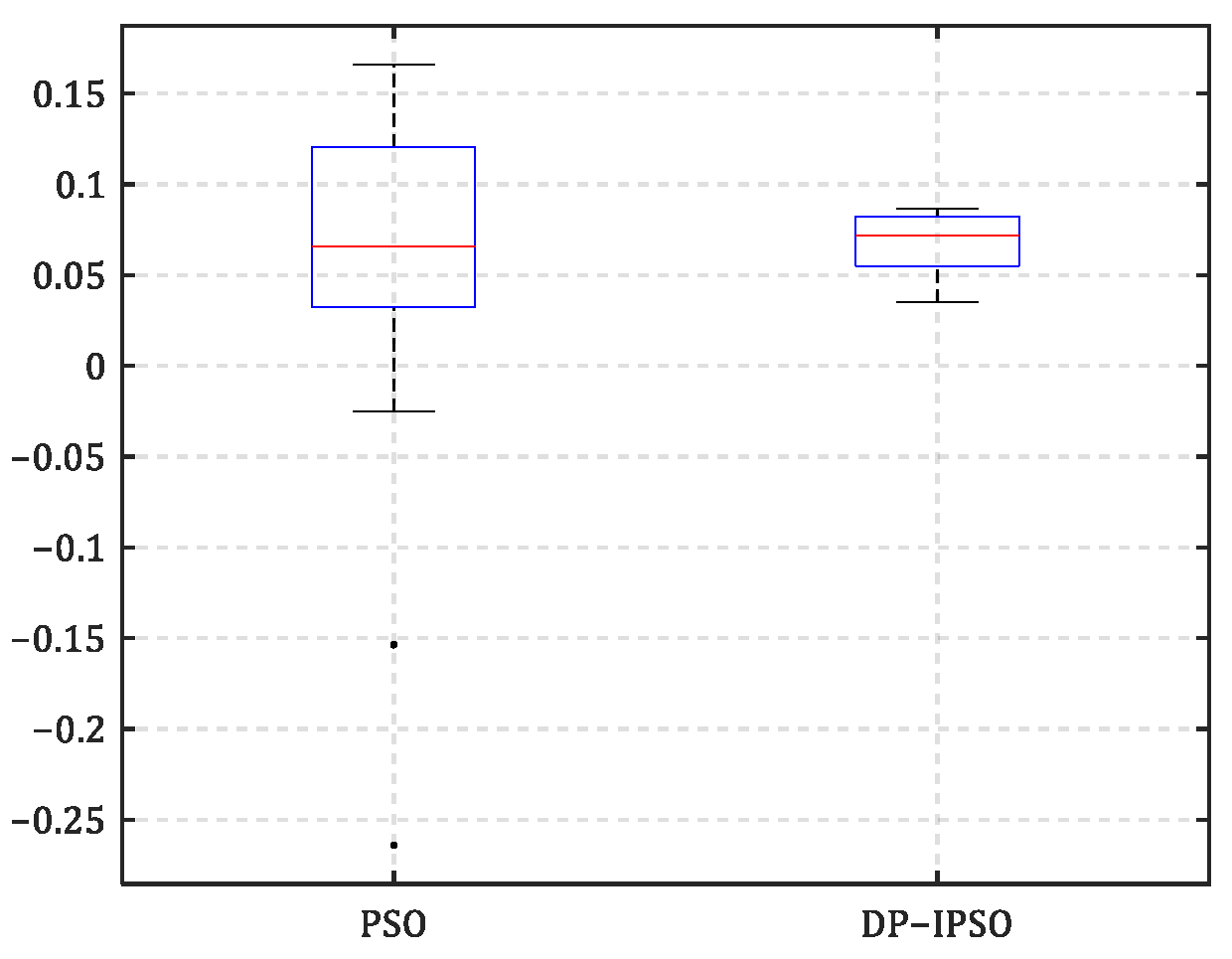

4.4. Algorithm Stability Comparison

5. Conclusions

- The proposed method converts uncertain PV power into a set of comprehensive scenarios, which are then integrated into the optimization function. This approach leads to capacity allocation that avoids equipment redundancy, maintains a degree of conservatism, and demonstrates strong environmental performance. Case studies demonstrate that even in the worst-case scenario, the cruise ship can still sail normally.

- The EMS presented in Section 2.4 is feasible and reasonable and can effectively reduce fuel consumption by 1.64% (per day).

- Engine load response and power ramping affect the engine’s transient maximum output power, which in turn affects ESS power. To maintain system reliability while using traditional engines for load tracking, the ESS capacity must be expanded. This expansion is necessary to compensate for the power gap between the generation equipment and the load demand.

- While EC has a relatively low utilization rate compared to SC and FC in terms of power dispatch, its ability to absorb power in real time and with high security makes it one of the excellent options for investors, whether during long voyages, while at anchor, or in the event of a sudden power outage when DE cannot keep up. Furthermore, EC can provide significant long-term benefits.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HESIPS | Hybrid energy ship integrated power system |

| HESS | Hybrid energy storage systems |

| ROE | Return on Equity |

| PV | Photovoltaic cell |

| DE | Diesel engine |

| MG | Photo-gas turbine |

| EC | Electrolytic cell |

| FC | Fuel cell |

| SC | Supercapacitor |

| HSE | Hydrogen storage equipment |

| ESPD | Energy storage power distribution method |

| EMS | Energy management strategy |

| SOC | State of charge |

| EEOI | Energy Efficiency Operation Indicator |

| DP | Dynamic programming |

| DP-IPSO | An improved particle swarm optimization algorithm integrated with dynamic programming |

| COMP | COMP |

| SP | Stochastic Planning |

| ROP | Robust Planning |

Appendix A

References

- United Nations Conference on Trade and Development. Review of Maritime Transport 2020 [EB/OL]. Available online: https://unctad.org/publication/review-maritime-transport-2020 (accessed on 8 June 2025).

- 2022 Guidelines for the Development of a Ship Energy Efficiency Management Plan (SEEMP). Available online: https://www.imorules.com/MEPC346_78ANN.html (accessed on 8 June 2025).

- Tadros, M.; Ventura, M.; Soares, C.G. Review of current regulations, available technologies, and future trends in the green shipping industry. Ocean Eng. 2023, 280, 114670. [Google Scholar] [CrossRef]

- Dimopoulos, G.G.; Stefanatos, I.C.; Kakalis, N.M.P. Exergy analysis and optimisation of a marine molten carbonate fuel cell system in simple and combined cycle configuration. Energy Convers. Manag. 2016, 107, 10–21. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, J.; Yan, X.; Li, Q.; Long, T. A design and experimental investigation of a large-scale solar energy/diesel generator powered hybrid ship. Energy 2018, 165, 965–978. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, W.; Zhuo, J. Quantum-PSO based system stabilizer optimization for shipboard power system. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016. [Google Scholar]

- Gaber, M.; El-Banna, S.H.; Eldabah, M.; Hamad, M.S. Model and control of naval ship power system by the concept of all-electric ships based on renewable energy. In Proceedings of the 2019 21st International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 17–19 December 2019. [Google Scholar]

- Huang, X.; Sun, S. Application of wind power generation technology in ships. In Proceedings of the 2022 IEEE Asia-Pacific Conference on Image Processing, Electronics and Computers (IPEC), Dalian, China, 14–16 April 2022. [Google Scholar]

- Yang, X.; Sun, P.; Yang, C. Multi-Objective Optimization of Capacity of Hybrid Energy Storage Device for Ship Electric Propulsion System. Navig. China 2018, 41, 9–14. [Google Scholar]

- Lai, W.; Zhi, Z. Research on Capacity Configuration of Electric Push Ship Energy Storage System. In Proceedings of the 2021 IEEE China Automation Congress (CAC), Beijing, China, 22–24 October 2021. [Google Scholar]

- Wen, S.; Lan, H.; Yu, D.C.; Fu, Q.; Hong, Y.; Yu, L.; Yang, R. Optimal sizing of hybrid energy storage sub-systems in PV/diesel ship power system using frequency analysis. Energy 2017, 140, 198–208. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Zhao, Y.; He, T.; Zeng, H. Optimization design of hybrid energy storage capacity configuration for electric ship. Energy Rep. 2024, 11, 887–894. [Google Scholar] [CrossRef]

- Wu, S.; Li, T.; Xu, F.; Chen, R.; Zhou, X.; Wang, B. Configuration size optimization of gas-electric hybrid power systems on ships considering energy density and engine load response. Energy Convers. Manag. 2024, 301, 118069. [Google Scholar] [CrossRef]

- Wu, N.; Zhang, F.; Zhang, F.; Jiang, C.; Lin, J.; Xie, S.; Zhao, Y. An integrated multi-objective optimization, evaluation, and decision-making method for ship energy system. Appl. Energy 2024, 373, 123917. [Google Scholar] [CrossRef]

- Fang, S.; Wang, Y.; Gou, B.; Xu, Y. Toward future green maritime transportation: An overview of seaport microgrids and all-electric ships. IEEE Trans. Veh. Technol. 2019, 69, 207–219. [Google Scholar] [CrossRef]

- Ju, C.; Wang, P.; Goel, L.; Xu, Y. A two-layer energy management system for microgrids with hybrid energy storage considering degradation costs. IEEE Trans. Smart Grid 2017, 9, 6047–6057. [Google Scholar] [CrossRef]

- Fang, S.; Xu, Y.; Li, Z.; Zhao, T.; Wang, H. Two-step multi-objective management of hybrid energy storage system in all-electric ship microgrids. IEEE Trans. Veh. Technol. 2019, 68, 3361–3373. [Google Scholar] [CrossRef]

- HassanzadehFard, H.; Tooryan, F.; Collins, E.R.; Jin, S.; Ramezani, B. Design and optimum energy management of a hybrid renewable energy system based on efficient various hydrogen production. Int. J. Hydrogen Energy 2020, 45, 30113–30128. [Google Scholar] [CrossRef]

- Xiang, Y.; Yang, X. An ECMS for multi-objective energy management strategy of parallel diesel electric hybrid ship based on ant colony optimization algorithm. Energies 2021, 14, 810. [Google Scholar] [CrossRef]

- Xu, L.; Wen, Y.; Luo, X.; Lu, Z.; Guan, X. A modified power management algorithm with energy efficiency and GHG emissions limitation for hybrid power ship system. Appl. Energy 2022, 317, 119114. [Google Scholar] [CrossRef]

- Xu, L.; Luo, X.; Wen, Y.; Wu, T.; Wang, X.; Guan, X. Energy management of hybrid power ship system using adaptive moth flame optimization based on multi-populations. IEEE Trans. Power Syst. 2023, 39, 1711–1727. [Google Scholar] [CrossRef]

- Schwager, P.; Tiede, L.; Scholz, T.; Gehrke, K.; Vehse, M. Efficiency analysis and performance modelling of a photovoltaic system for cruise ship cabins with battery storage using direct current distribution networks. Int. J. Electr. Power Energy Syst. 2025, 164, 110447. [Google Scholar] [CrossRef]

- Villagra, A.; Millet, P. An analysis of PEM water electrolysis cells operating at elevated current densities. Int. J. Hydrogen Energy 2019, 44, 9708–9717. [Google Scholar] [CrossRef]

- Deng, Z.; Jiang, Y. Optimal sizing of a wind-hydrogen system under consideration of the efficiency characteristics of electrolysers. Renew. Energy Resour. 2020, 38, 259–266. (In Chinese) [Google Scholar]

- Wei, F.; Sui, Q.; Lin, X.; Li, Z.; Chen, L.; Zhao, B.; Owolabi, S.A. Energy control scheduling optimization strategy for coal-wind-hydrogen energy grid under consideration of the efficiency features of hydrogen production equipment. Proc. CSEE 2018, 38, 1428–1439. [Google Scholar]

- Faber, J.; Hanayama, S.; Zhang, S.; Pereda, P.; Comer, B.; Hauerhof, E. Fourth IMO GHG Study; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Mavromatidis, G.; Orehounig, K.; Carmeliet, J. Design of distributed energy systems under uncertainty: A two-stage stochastic programming approach. Appl. Energy 2018, 222, 932–950. [Google Scholar] [CrossRef]

- Bai, K.; Gu, J.; Peng, H.; Zhu, B. Optimal allocation for multi-energy complementary microgrid based on scenario generation of wind power and photovoltaic output. Autom. Electr. Power Syst. 2018, 42, 133–141. [Google Scholar]

- Kanellos, F.D.; Prousalidis, J.M.; Tsekouras, G.J. Control system for fuel consumption minimization–gas emission limitation of full electric propulsion ship power systems. Proc. Inst. Mech. Eng. Part M J. Eng. 2014, 228, 17–28. [Google Scholar] [CrossRef]

- Shang, C.; Srinivasan, D.; Reindl, T. Economic and environmental generation and voyage scheduling of all-electric ships. IEEE Trans. Power Syst. 2015, 31, 4087–4096. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, H.; Li, K.; Lin, Z.; Yang, J.; Shen, X.L. A hybrid particle swarm optimization algorithm using adaptive learning strategy. Inf. Sci. 2018, 436, 162–177. [Google Scholar] [CrossRef]

- Kroniger, D.; Madlener, R. Hydrogen storage for wind parks: A real options evaluation for an optimal investment in more flexibility. Appl. Energy 2014, 136, 931–946. [Google Scholar] [CrossRef]

- IMO. Studies on the Feasibility and Use of LNG as a Fuel for Shipping; International Maritime Organization: London, UK, 2017; Available online: https://www.uncclearn.org/resources/library/studies-on-the-feasibility-and-use-of-lng-as-a-fuel-for-shipping/ (accessed on 8 June 2025).

- Akhavan-Hejazi, H.; Mohsenian-Rad, H. Energy storage planning in active distribution grids: A chance-constrained optimization with non-parametric probability functions. IEEE Trans. Smart Grid 2016, 9, 1972–1985. [Google Scholar]

- Ning, C.; You, F. Data-driven stochastic robust optimization: General computational framework and algorithm leveraging machine learning for optimization under uncertainty in the big data era. Comput. Chem. Eng. 2018, 111, 115–133. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Liu, Y.; Xu, L.; Ma, T.; Xu, W. Shape clustering algorithm of typical load curves based on adaptive piecewise aggregate approximation. Autom. Electr. Power Syst. 2019, 43, 110–118. [Google Scholar]

| Upper-level optimization variables | , |

| Lower-level optimization variables |

| Quantity | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Equipment | PV | MG | DE | EC | HSE | FC | SC |

| Cost/MWh | 382,361 | 550,000 | 400,000 | 878,750 | 122,856 | 44,200 | 823,000 |

| Discount rate | 6% | 9.6% | 9.6% | 6% | 6% | 6% | 6% |

| O&M rate (%) | 5 | 1 | 1.5 | 5 | 1 | 5 | 1 |

| Lifetime (years) | 20 | 20 | 20 | 5 | 20 | 5 | 10 |

| Fuel price$/ton | - | 405 | 610 | - | - | - | - |

| Efficiency | - | - | - | 0.75 | 0.95 | 0.65 | 0.95 |

| Parameter | PV | MG | DE | EC | HSE | FC | SC |

|---|---|---|---|---|---|---|---|

| Maximum capacity (MW) | 5 | 2 | 20 | 3 | 30 | 3 | 6 |

| Maximum power (MW) | - | 0.95 | 0.95 | ||||

| Minimum power (MW) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Ramp rate limit | - | +10%, −10% | +20%, −10% | - | - | - | - |

| Parameter | Value |

|---|---|

| Ship load factor | |

| EEOI | |

| Power factor of MG | |

| Power factor of DE | |

| SOC |

| Name | PV | MG | DE | |||||

|---|---|---|---|---|---|---|---|---|

| Capacity (MW) | Cost ($) | Capacity (MW) | Cost ($) | Fuel Cost ($) | Capacity (MW) | Cost ($) | Fuel Cost ($) | |

| COMP | 4.356 | 228,500 | 1.789 | 122,309 | 712,489 | 17.990 | 930,396 | 8,528,447 |

| SP [34] | 4.398 | 230,682 | 1.803 | 123,225 | 690,829 | 18.025 | 931,544 | 8,679,928 |

| ROP [35] | 4.512 | 236,699 | 1.815 | 123,963 | 641,800 | 18.350 | 943,685 | 8,997,744 |

| Name | EC | HSE | FC | SC | ||||

|---|---|---|---|---|---|---|---|---|

| Capacity (MW) | Cost ($) | Capacity (kg) | Cost ($) | Capacity (MW) | Cost ($) | Capacity (MW) | Cost ($) | |

| COMP | 2.027 | 1,270,527 | 579 | 1,693,577 | 2.099 | 73,785 | 5.016 | 2,551,149 |

| SP | 2.004 | 1,256,425 | 593 | 1,733,820 | 2.326 | 78,651 | 5.170 | 2,619,079 |

| ROP | 1.957 | 1,226,340 | 602 | 1,758,802 | 2.474 | 80,255 | 5.198 | 2,633,163 |

| Planning Typology | COMP | SP | ROP |

|---|---|---|---|

| ROE (%) | 8.66 | 7.24 | 5.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, F.; Wang, X.; Zhang, Y.; Chang, S. A Capacity Optimization Method of Ship Integrated Power System Based on Comprehensive Scenario Planning: Considering the Hydrogen Energy Storage System and Supercapacitor. Energies 2025, 18, 5305. https://doi.org/10.3390/en18195305

Jing F, Wang X, Zhang Y, Chang S. A Capacity Optimization Method of Ship Integrated Power System Based on Comprehensive Scenario Planning: Considering the Hydrogen Energy Storage System and Supercapacitor. Energies. 2025; 18(19):5305. https://doi.org/10.3390/en18195305

Chicago/Turabian StyleJing, Fanzhen, Xinyu Wang, Yuee Zhang, and Shaoping Chang. 2025. "A Capacity Optimization Method of Ship Integrated Power System Based on Comprehensive Scenario Planning: Considering the Hydrogen Energy Storage System and Supercapacitor" Energies 18, no. 19: 5305. https://doi.org/10.3390/en18195305

APA StyleJing, F., Wang, X., Zhang, Y., & Chang, S. (2025). A Capacity Optimization Method of Ship Integrated Power System Based on Comprehensive Scenario Planning: Considering the Hydrogen Energy Storage System and Supercapacitor. Energies, 18(19), 5305. https://doi.org/10.3390/en18195305