Study of Superconducting Fault Current Limiter Functionality in the Presence of Long-Duration Short Circuits

Abstract

1. Introduction

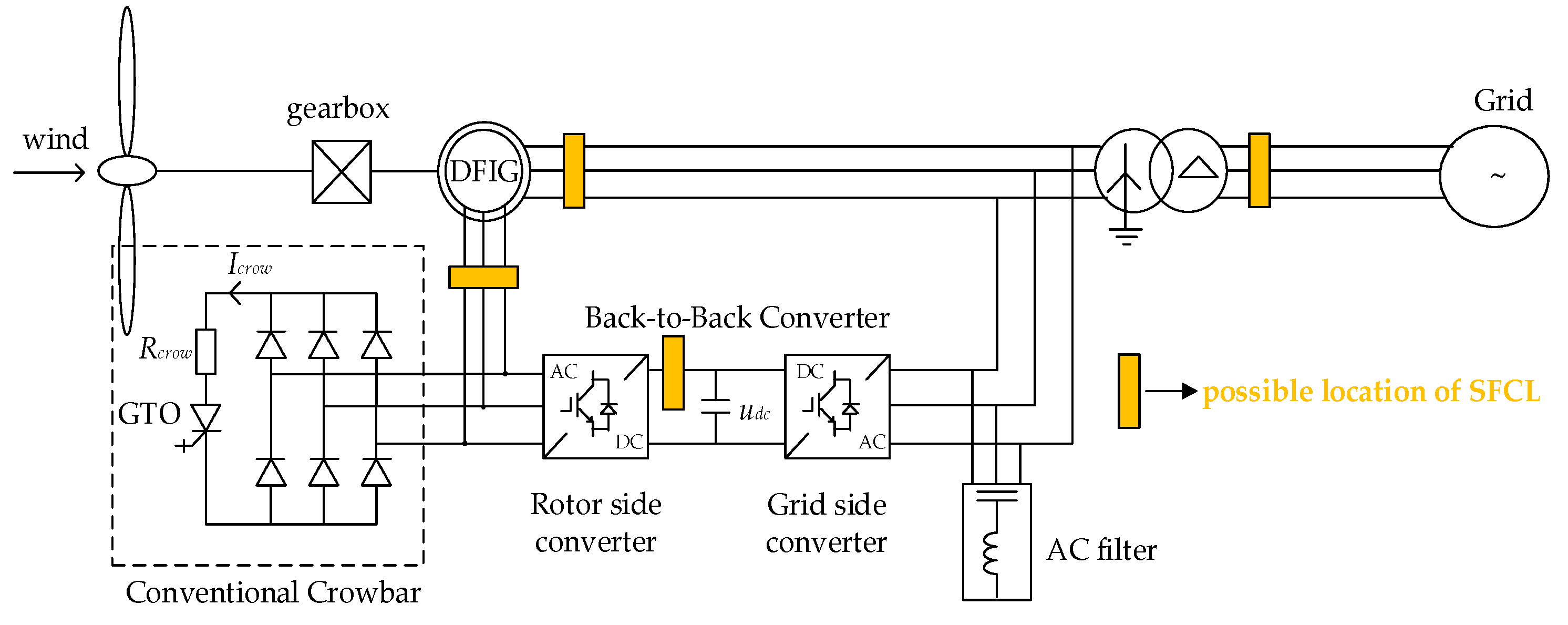

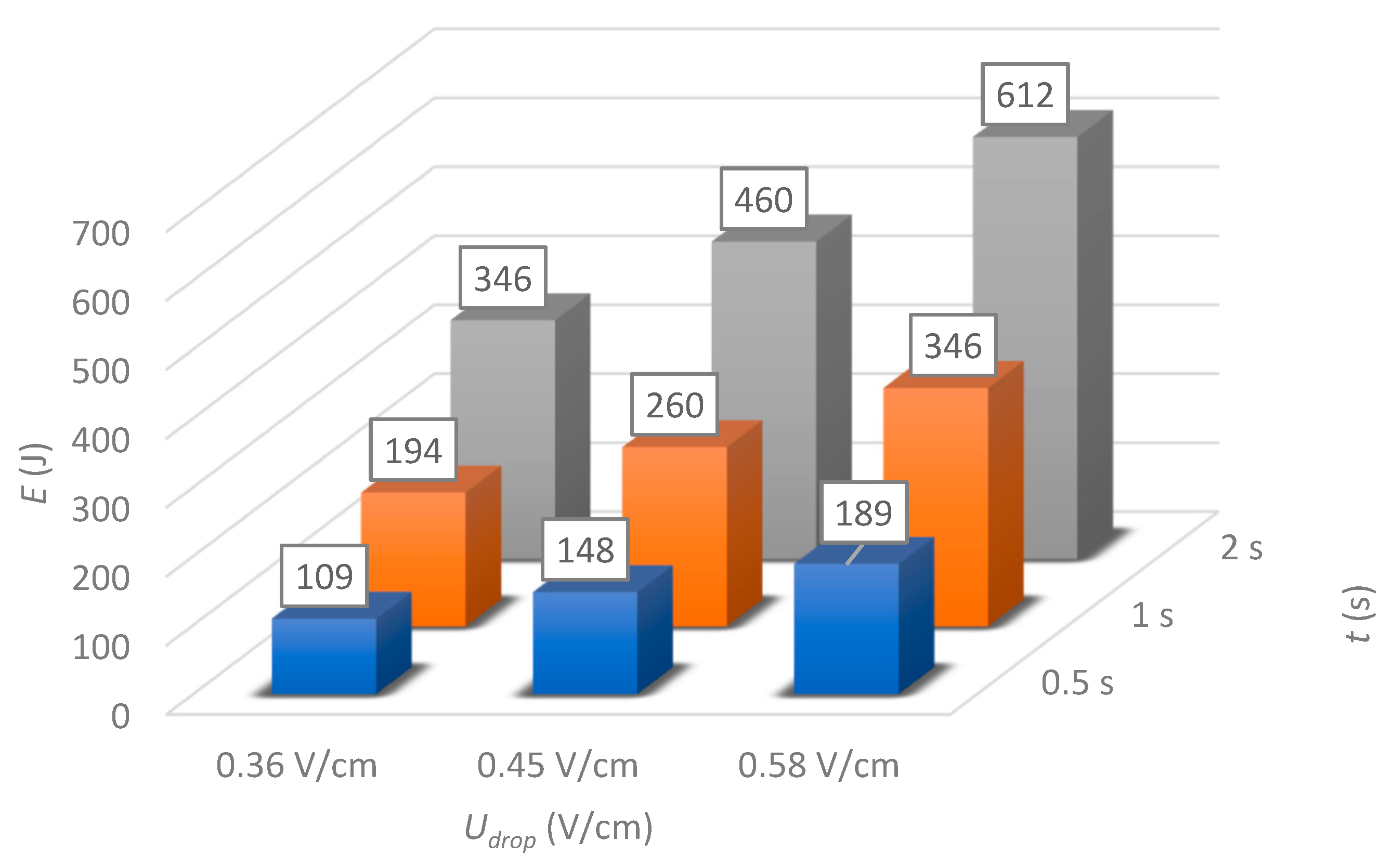

2. Application of SFCL in a Power System with Long Short-Circuit Current Duration

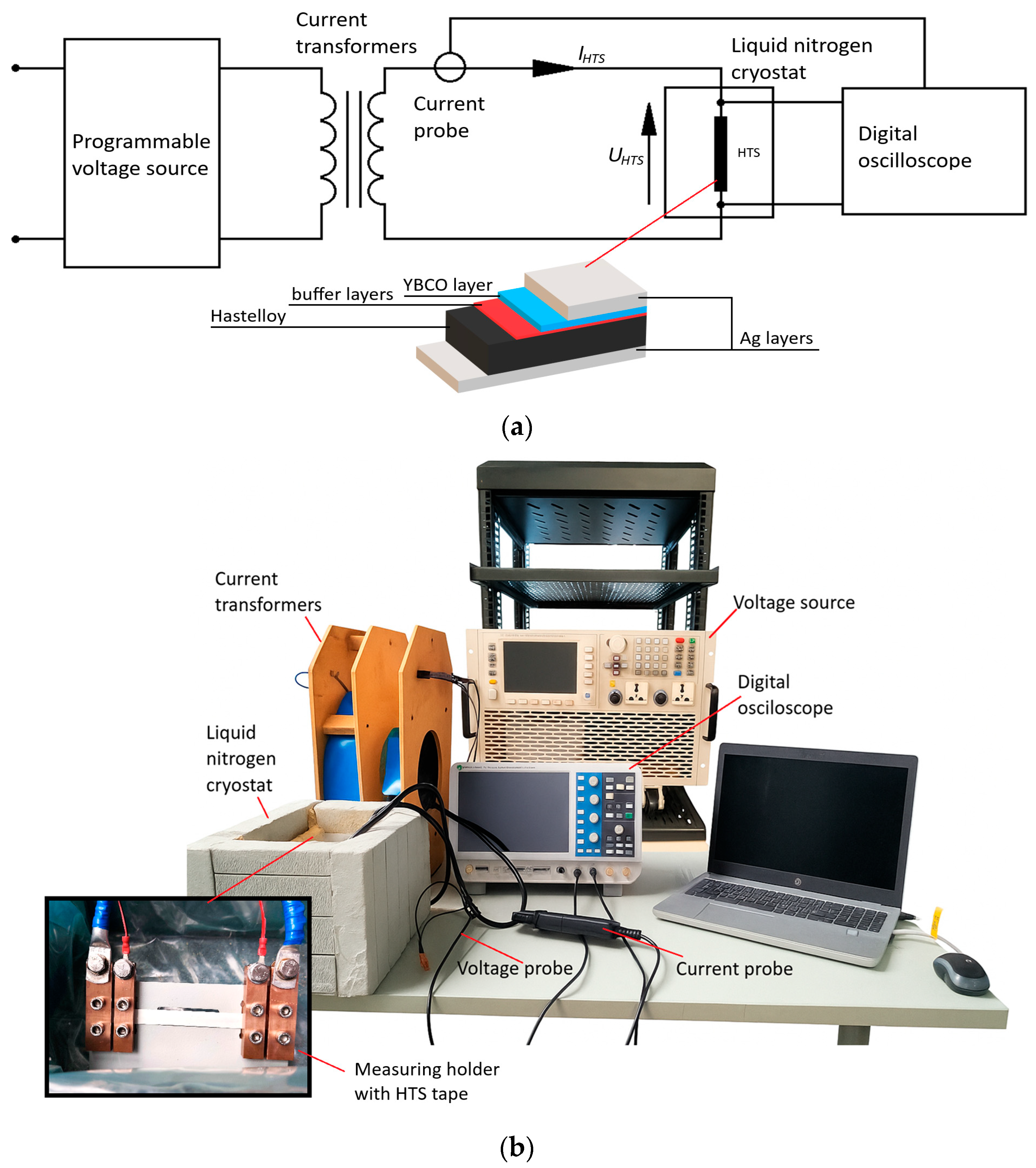

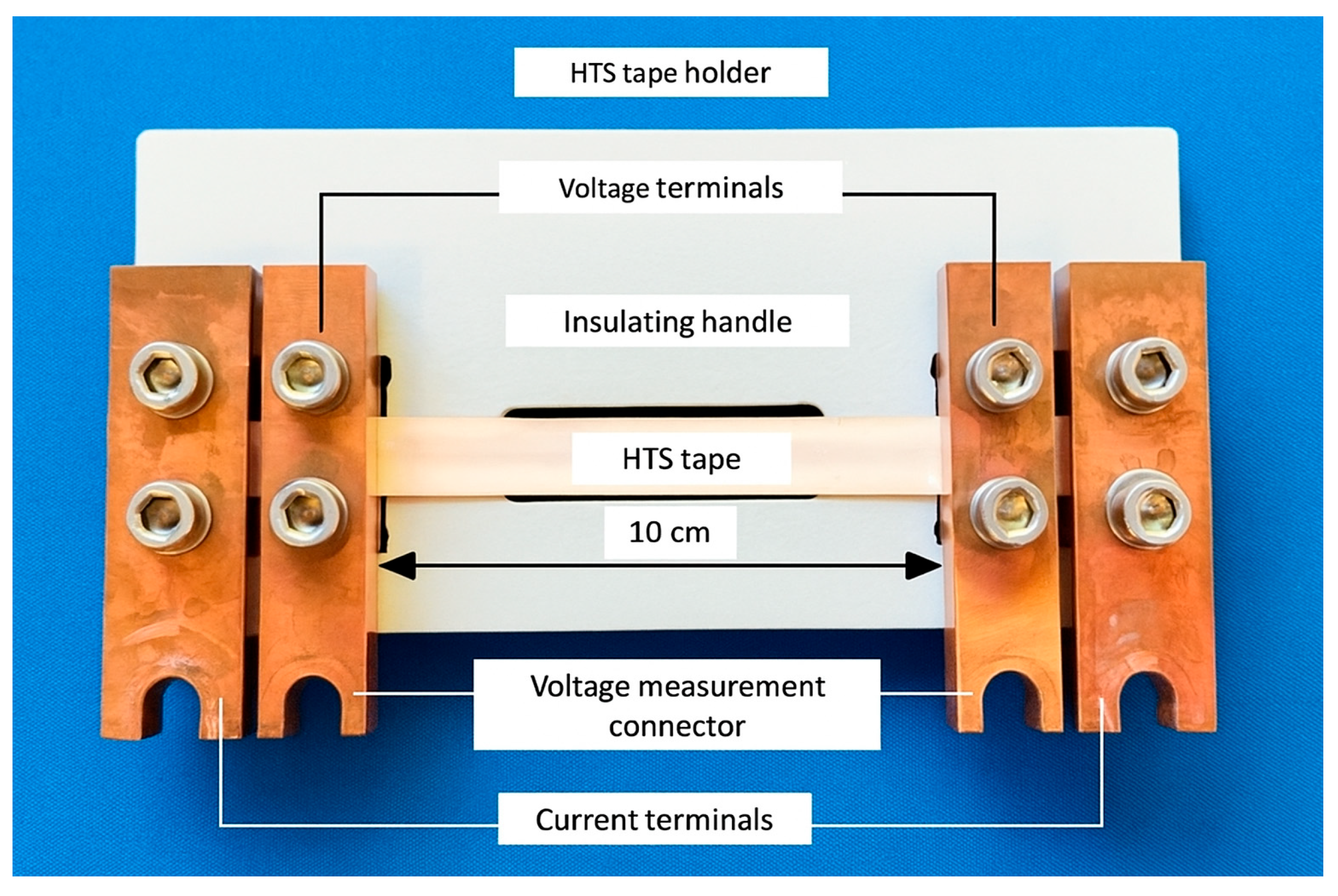

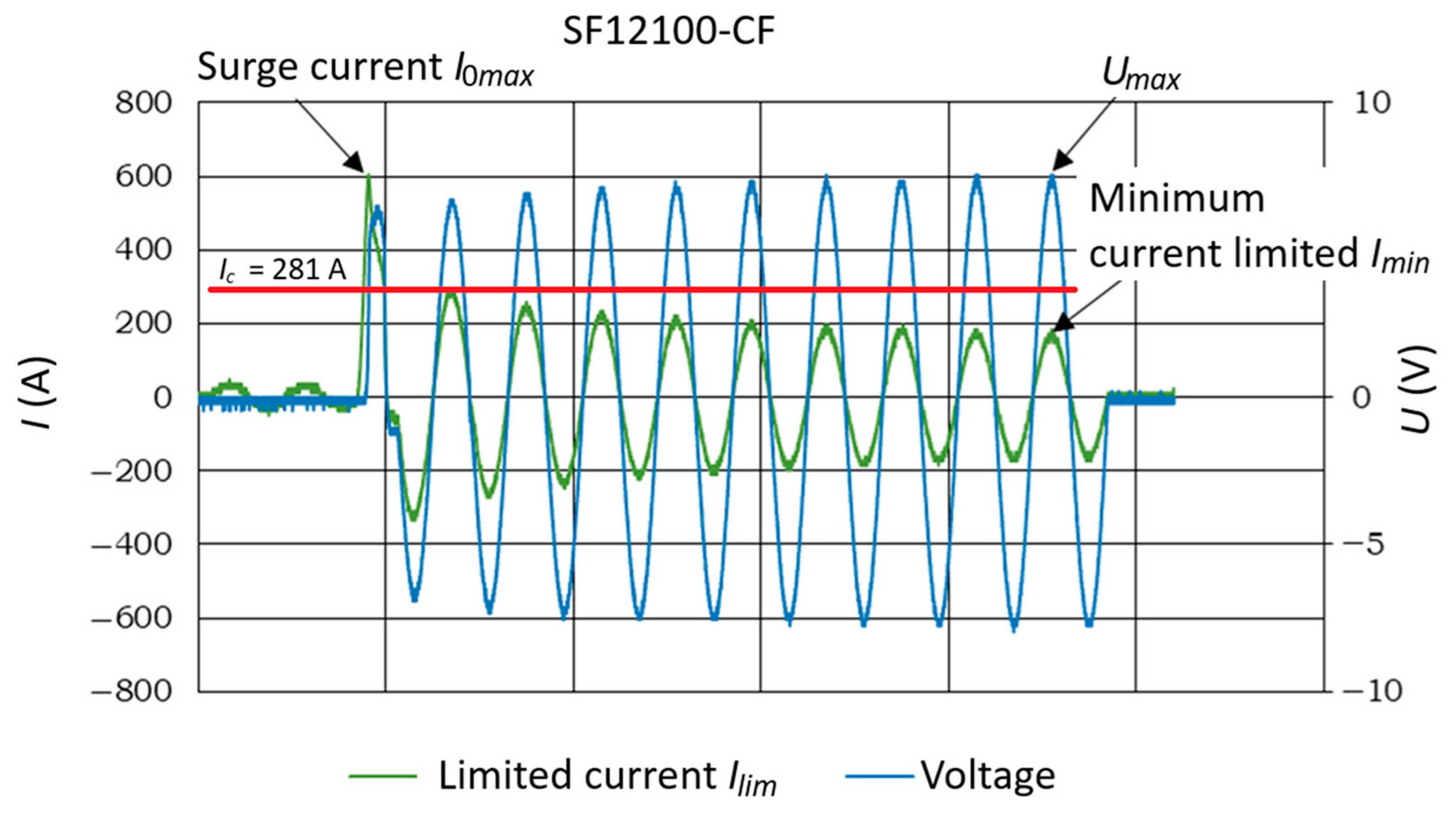

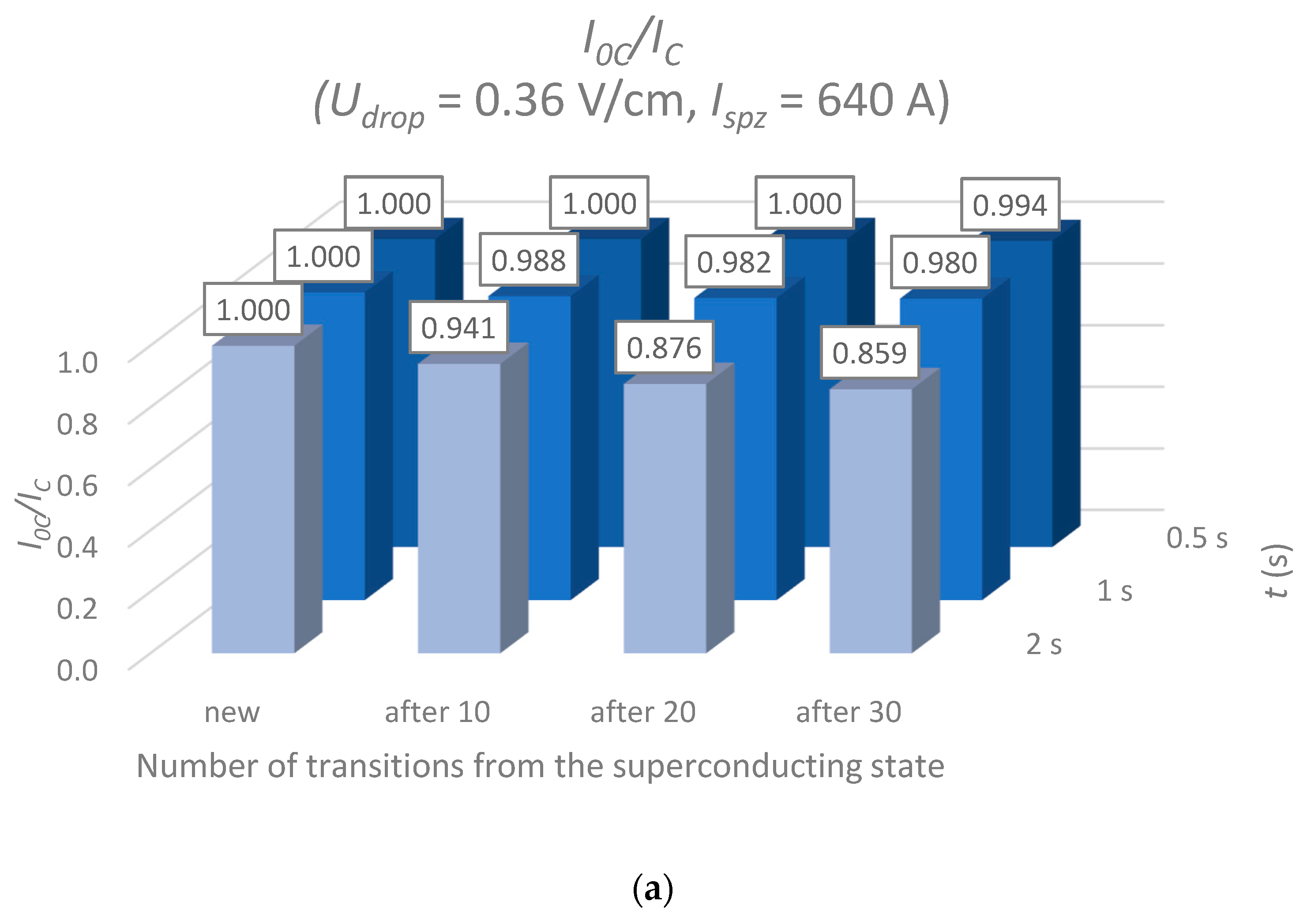

3. Experimental Testing of 2G HTS Tape During Long-Duration Short Circuits

4. Discussion

5. Conclusions

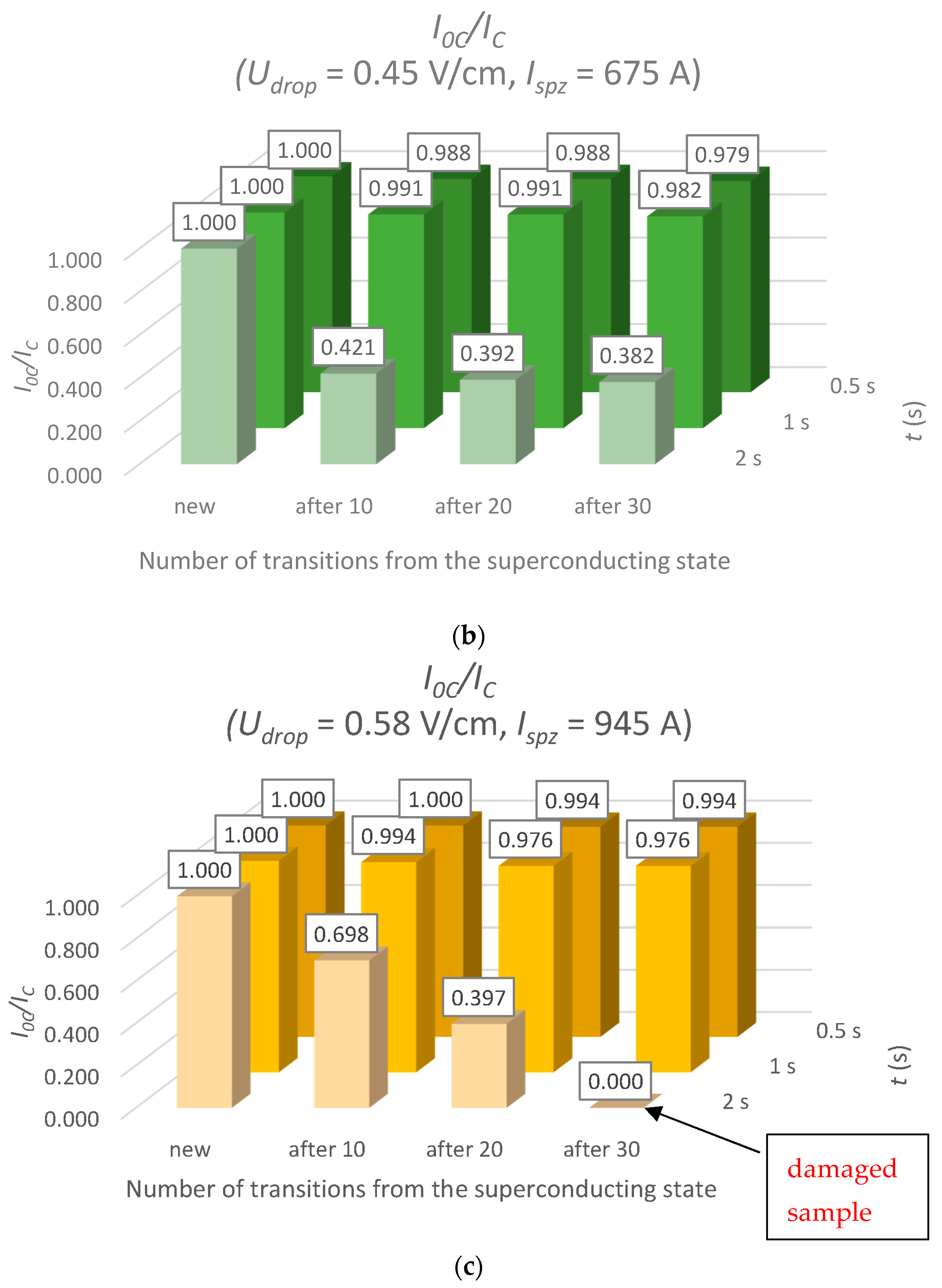

- The operating time of the SFCL in the resistive state constitutes a key functional limitation of the device. The tested HTS tapes exhibit resistance to multiple transitions from the superconducting to the resistive state, provided that the duration of the short-circuit current does not exceed approximately 1 s—note that this time corresponds to the SF12100-CF tape with a thin layer of Ag; for other tape constructions, the safe time must be determined separately. Exceeding this time results in degradation of the critical current value (IC), which may consequently lead to accelerated activation of the SFCL (at lower short-circuit currents) or permanent damage to the tape.

- From the perspective of operational diagnostics, the value of the surge current I0max can be used as an indicator of the deteriorating condition of the HTS tape. A decrease in the value of I0max in successive current-limiting cycles indicates an earlier transition of the tape to the resistive state, which in turn may result from the degradation of the critical current value.

- To ensure the safe operation of SFCL in applications such as systems with DFIGs, it is first necessary to determine the safe operating time for the applied HTS tape based on experimental tests and analyses. Subsequently, it is recommended to implement a modified protection strategy that enables the detection and clearance of a fault in a time shorter than the established safe time (which, in the case of the tested HTS tape, was approximately 1 s). If this is not feasible, the SFCL should be automatically bypassed using a conventional fault current limiter once the permissible operating time is exceeded. Such an approach will allow the limiter to maintain continuous operation while avoiding the exceedance of the endurance limits of the HTS tape.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dias, D.H.N.; Sotelo, G.G.; Dias, F.J.M.; Rocha, L.M.M.; Matins, F.G.R.; Sass, F.; Polasek, A. Characterization of a Second Generation HTS Coil for Electrical Power Devices. IEEE Trans. Appl. Supercond. 2015, 25, 4601304. [Google Scholar] [CrossRef]

- Zhang, Y.; Lehner, T.F.; Fukushima, T.; Sakamoto, H.; Hazelton, D.W. Progress in Production and Performance of Second Generation (2G) HTS Wire for Practical Applications. IEEE Trans. Appl. Supercond. 2014, 24, 7500405. [Google Scholar] [CrossRef]

- Morandi, A.; Trevisani, L.; Fabbi, M.; Martini, L.; Bocchi, M. Superconducting transformer: Key design aspects for power applications. J. Phys. Conf. Ser. 2008, 97, 012318. [Google Scholar] [CrossRef]

- Hajiri, G.; Berger, K.; Trillaud, F.; Lévêque, J.; Caron, H. Impact of Superconducting Cables on a DC Railway Network. Energies 2023, 16, 776. [Google Scholar] [CrossRef]

- Peng, S.; Cai, C.; Cai, J.; Zheng, J.; Zhou, D. Optimum Design and Performance Analysis of Superconducting Cable with Different Conductor Layout. Energies 2022, 15, 8893. [Google Scholar] [CrossRef]

- Tsotsopoulou, E.; Dyśko, A.; Hong, Q.; Elwakeel, A.; Elshiekh, M.; Yuan, W.; Booth, C.; Tzelepis, D. Modelling and Fault Current Characterization of Superconducting Cable with High Temperature Superconducting Windings and Copper Stabilizer Layer. Energies 2020, 13, 6646. [Google Scholar] [CrossRef]

- Wojtasiewicz, G.; Janowski, T.; Kozak, S.; Kozak, J.; Majka, M.; Kondratowicz-Kucewicz, B. Experimental investigation of the model of superconducting transformer with the windings made of 2G HTS tape. IEEE Trans. Appl. Supercond. 2012, 22, 5500504. [Google Scholar] [CrossRef]

- Staines, M.P.; Jiang, Z.; Glasson, N.; Buckley, R.G.; Pannu, M. High-temperature superconducting (HTS) transformers for power grid applications. In Superconductors in the Power Grid: Materials and Applications; Woodhead Publishing: Cambridge, UK, 2015; pp. 367–397. [Google Scholar]

- Manusov, V.Z.; Nazarov, M.K. Design and Perspectives for Innovative Application of Power Transformers with a Superconducting Winding. In Proceedings of the 14th International Scientific-Technical Conference on Actual Problems of Electronic Instrument Engineering (APEIE), Novosibirsk, Russia, 2–6 October 2018; pp. 290–294. [Google Scholar]

- Liu, Y.; Grilli, F.; Cao, J.; Li, L.; Zhang, C.; Wang, M.; Xu, F.; Lin, J.; Noe, M. An Electromagnetic Design of a Fully Superconducting Generator for Wind Application. Energies 2021, 14, 7811. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, L.; Wu, X.; Shan, F.; Chen, L.; Liu, S.; Zheng, Z.; Zhu, L.; Wang, J.; Zhai, Y. Review of Offshore Superconducting Wind Power Generation for Hydrogen Production. Energies 2025, 18, 1889. [Google Scholar] [CrossRef]

- Liu, B.; Badcock, R.; Shu, H.; Fang, J. A Superconducting Induction Motor with a High Temperature Superconducting Armature: Electromagnetic Theory, Design and Analysis. Energies 2018, 11, 792. [Google Scholar] [CrossRef]

- Hara, S.; Iwami, Y.; Kawasaki, R.; Matsumoto, T.; Shirai, Y.; Shiotsu, M.; Kobayashi, H.; Naruo, Y.; Nonaka, S.; Inatani, Y.; et al. Development of Liquid Hydrogen Cooling System for a Rotor of Superconducting Generator. IEEE Trans. Appl. Supercond. 2021, 31, 5202505. [Google Scholar] [CrossRef]

- Jacob, T.; Buchholz, A.; Noe, M.; Weil, M. Comparative Life Cycle Assessment of Different Cooling Systems for High-Temperature Superconducting Power Cables. IEEE Trans. Appl. Supercond. 2022, 32, 4802805. [Google Scholar] [CrossRef]

- Marchevsky, M. Quench Detection and Protection for High-Temperature Superconductor Accelerator Magnets. Instruments 2021, 5, 27. [Google Scholar] [CrossRef]

- Iwakuma, M.; Funaki, K.; Takeo, M.; Yamafuji, K. Quench protection of superconducting transformers. IEEE Trans. Magn. 1991, 27, 2080–2083. [Google Scholar] [CrossRef]

- Rao, V.V.; Kar, S. Superconducting Fault Current Limiters—A Review. Indian J. Cryog. 2011, 36, 14–25. [Google Scholar]

- Yadav, S.; Bharati, K.; Tewari, V. Sperconducting Fault Current Limiter—A Review. Int. J. Appl. Eng. Res. 2019, 14, 2. [Google Scholar]

- Nagarathna, M.C.; Murthy, H.V.; Shashikumar, R. A Review on Super Conducting Fault Current Limiter (SFCL) in Power System. Int. J. Eng. Res. Gen. Sci. 2015, 3, 485–489. [Google Scholar]

- Noe, M.; Steurer, M. High-temperature superconductor fault current limiters: Concepts, applications, and development status. Supercond. Sci. Technol. 2007, 20, R15. [Google Scholar] [CrossRef]

- Elshiekh, M.E.; Mansour, D.-E.A.; Azmy, A.M. Improving Fault Ride-Through Capability of DFIG-Based Wind Turbine Using Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2013, 23, 5601204. [Google Scholar] [CrossRef]

- Zou, Z.C.; Chen, X.Y.; Li, C.S.; Xiao, X.Y.; Zhang, Y. Conceptual Design and Evaluation of a Resistive-Type SFCL for Efficient Fault Ride Through in a DFIG. IEEE Trans. Appl. Supercond. 2016, 26, 5600209. [Google Scholar] [CrossRef]

- Chen, L.; Li, G.; Chen, H.; Ding, M.; Zhang, X.; Li, Y.; Xu, Y.; Ren, L.; Tang, Y. Investigation of a Modified Flux-Coupling-Type SFCL for Low-Voltage Ride-Through Fulfillment of a Virtual Synchronous Generator. IEEE Trans. Appl. Supercond. 2020, 30, 5601006. [Google Scholar] [CrossRef]

- Yin, J.; Chen, Z.; Qian, W.; Zhou, S. A Virtual Synchronous Generator Low-Voltage Ride-Through Control Strategy Considering Complex Grid Faults. Appl. Sci. 2025, 15, 1920. [Google Scholar] [CrossRef]

- Naderi, S.B.; Davari, P.; Zhou, D.; Negnevitsky, M.; Blaabjerg, F. A Review on Fault Current Limiting Devices to Enhance the Fault Ride-Through Capability of the Doubly-Fed Induction Generator Based Wind Turbine. Appl. Sci. 2018, 8, 2059. [Google Scholar] [CrossRef]

- Zou, Z.-C.; Xiao, X.-Y.; Liu, Y.-F.; Zhang, Y.; Wang, Y.-H. Integrated Protection of DFIG-Based Wind Turbine with a Resistive-Type SFCL Under Symmetrical and Asymmetrical Faults. IEEE Trans. Appl. Supercond. 2016, 26, 5603005. [Google Scholar] [CrossRef]

- Zheng, Z.-X.; Huang, C.-J.; Yang, R.-H.; Xiao, X.-Y.; Li, C.-S. A Low Voltage Ride Through Scheme for DFIG-Based Wind Farm with SFCL and RSC Control. IEEE Trans. Appl. Supercond. 2019, 29, 5601005. [Google Scholar] [CrossRef]

- Ou, R.; Xiao, X.-Y.; Zou, Z.-C.; Zhang, Y.; Wang, Y.-H. Cooperative Control of SFCL and Reactive Power for Improving the Transient Voltage Stability of Grid-Connected Wind Farm with DFIGs. IEEE Trans. Appl. Supercond. 2016, 26, 5402606. [Google Scholar] [CrossRef]

- Lee, H.Y.; Asif, M.; Park, K.H.; Lee, B.W. Feasible Application Study of Several Types of Superconducting Fault Current Limiters in HVDC Grids. IEEE Trans. Appl. Supercond. 2018, 28, 5601205. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Asif, M.; Park, K.-H.; Lee, B.-W. Assessment of appropriate SFCL type considering DC fault interruption in full-bridge modular multilevel converter HVDC system. Phys. C Supercond. Appl. 2019, 563, 1–6. [Google Scholar] [CrossRef]

- Xi, J.; Pei, X.; Song, W.; Niu, L.; Liu, Y.; Zeng, X. Integration of superconducting fault current limiter with solid-state DC circuit breaker. Int. J. Electr. Power Energy Syst. 2023, 145, 108630. [Google Scholar] [CrossRef]

- Reddy, S.R.P.; Kar, S.; Rajashekara, K. Resistive SFCL Integrated Ultra-Fast DC Hybrid Circuit Breaker for Subsea HVDC Transmission Systems. In Proceedings of the 2021 IEEE Industry Applications Society Annual Meeting (IAS), Vancouver, BC, Canada, 10–14 October 2021; pp. 1–6. [Google Scholar]

- Suarez, P.; Alvarez, A.; Ceballos, J.M.; Perez, B. Loss and Transition Studies of Shunted Free-Stabilized YBCO Tape for SFCL Applications. IEEE Trans. Appl. Supercond. 2011, 21, 1267–1270. [Google Scholar] [CrossRef]

- Kwon, N.Y.; Kim, H.S.; Kim, K.L.; Yim, S.W.; Kim, H.-R.; Hyun, O.-B.; Kim, H.M.; Lee, H.G. Influence of stabilizer thickness on over-current test of YBCO-coated conductors. Supercond. Sci. Technol. 2009, 22, 045033. [Google Scholar] [CrossRef]

- Amaro, N.; Souc, J.; Vojenciak, M.; Pina, J.M.; Martins, J.; Ceballos, J.M.; Gomory, F. AC Losses and Material Degradation Effects in a Superconducting Tape for SMES Applications. In Proceedings of the 5th IFIP WG 5.5/SOCOLNET Doctoral Conference on Computing, Electrical and Industrial Systems, DoCEIS 2014, Costa de Caparica, Portugal, 7–9 April 2014. [Google Scholar]

- Yazaki, S.; Karasawa, A.; Kotoyori, T.; Ishiyama, A.; Miyahara, N. Critical Current Degradation in High-Temperature Superconducting Tapes Caused by Temperature Rise. IEEE Trans. Appl. Supercond. 2013, 23, 4602304. [Google Scholar] [CrossRef]

- Dongdong, L. A combined protection and control strategy to enhance the LVRT capability of a wind turbine driven by DFIG. In Proceedings of the 2nd IEEE International Symposium on Power Electronics for Distributed Generation Systems, Hefei, China, 16–18 June 2010. [Google Scholar]

- El-Sattar, A.A.; Saad, N.H.; El-Dein, S. Dynamic response of doubly fed induction generator variable speed wind turbine under fault. Electr. Power Syst. Res. 2008, 78, 1240–1246. [Google Scholar] [CrossRef]

- Erlich, I.; Wrede, H.; Feltes, S. Dynamic behavior of DFIG-based wind turbines during grid faults. IEEJ Trans. Ind. Appl. 2008, 128, 396–401. [Google Scholar] [CrossRef]

- Rusiński, J. Impact of Superconducting Fault Current Limiter on the Distributed Energy Source Work. IET Gener. Transm. Distrib. 2017, 12, 310–317. [Google Scholar] [CrossRef]

- Hansen, A.D.; Michalke, G. Fault ride-through capability of DFIG wind turbines. Renew. Energy 2007, 32, 1594–1610. [Google Scholar] [CrossRef]

- Wessels, C.; Fuchs, F.W. Fault ride through of DFIG wind turbines during symmetrical voltage dip with crowbar or stator current feedback solution. In Proceedings of the Energy Conversion Congress and Exposition (ECCE), Atlanta, GA, USA, 12–16 September 2010. [Google Scholar]

- Morren, J.; De Haan, S.W.H. Short-circuit current of wind turbines with doubly fed induction generator. IEEE Trans. Energy Convers. 2007, 22, 174–180. [Google Scholar] [CrossRef]

- Petersson, A.; Lundberg, S.; Thiringer, T. A DFIG wind turbine ride-through system. Influence on the energy production. Wind Energy 2005, 8, 251–263. [Google Scholar] [CrossRef]

- Seman, S.; Iov, F.; Niiranem, J.; Arkkio, A. Comparison of simulations for variable-speed wind turbine transient analysis. Int. J. Energy Res. 2006, 30, 713–728. [Google Scholar] [CrossRef]

- Sun, T.; Chen, Z.; Blaabjerg, F. Voltage recovery of grid-connected wind turbines with DFIG after a short-circuit fault. In Proceedings of the 35th Annual IEEE Power Electronics Specialists Conference, Aachen, Germany, 20–25 June 2004. [Google Scholar]

- IEC 60255; Standard for Electrical Relays. The International Electrotechnical Commission (IEC): Geneva, Switzerland, 1989.

- IEEE C37.112-2018; IEEE Standard for Inverse-Time Characteristics Equations for Overcurrent Relays. IEEE: Piscataway, NJ, USA, 2019. [CrossRef]

- Hajdasz, S.; Kempski, A.; Solak, K.; Marc, M.; Rusinski, J.; Szczesniak, P. Critical Current Degradation in HTS Tapes for Superconducting Fault Current Limiter under Repeated Overcurrent. Appl. Sci. 2023, 13, 4323. [Google Scholar] [CrossRef]

- Surdacki, P. The Quench Parameter Analysis of YBCO and MgB2 Superconducting Wires. Electrotech. Rev. 2014, 90, 16–19. [Google Scholar]

- Available online: https://www.superpower-inc.com/specification.aspx (accessed on 15 December 2023).

- Kar, S.; Rao, V.V. Step-by-step design of a single phase 3.3 kV/200 A resistive type superconducting fault current limiter (R-SFCL) and cryostat. Phys. C Supercond. Its Appl. 2018, 550, 107–116. [Google Scholar] [CrossRef]

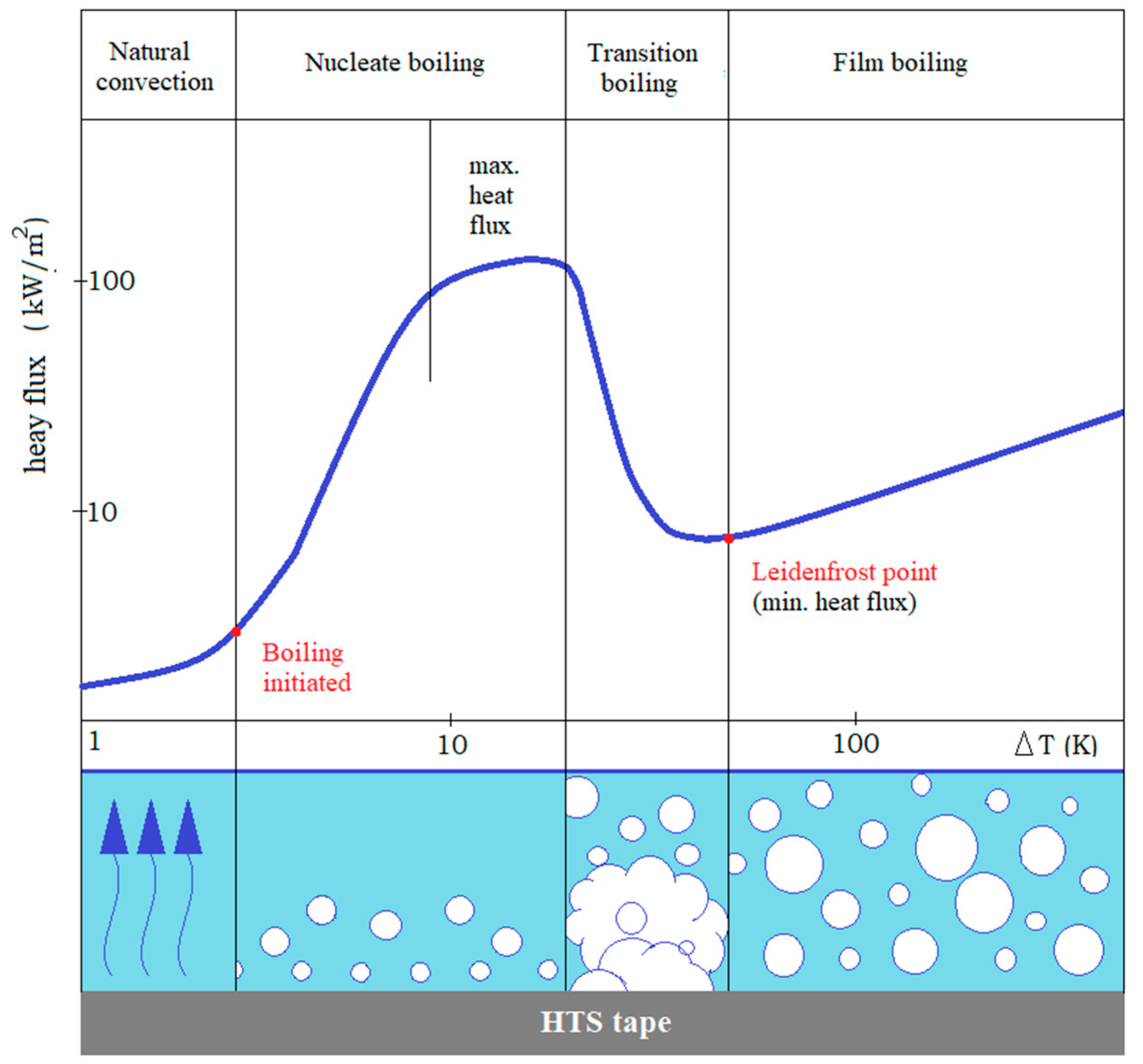

- Buchmuller, I. Influence of Pressure on Leidenfrost Effect; Technische Universität: Darmstadt, Germany, 2014. [Google Scholar]

- Talari, V.; Behar, P.; Lu, Y.; Haryadi, E.; Liu, D. Liedenfrost drops on micro/nanostructured surfaces. Front. Energy 2018, 12, 22–42. [Google Scholar] [CrossRef]

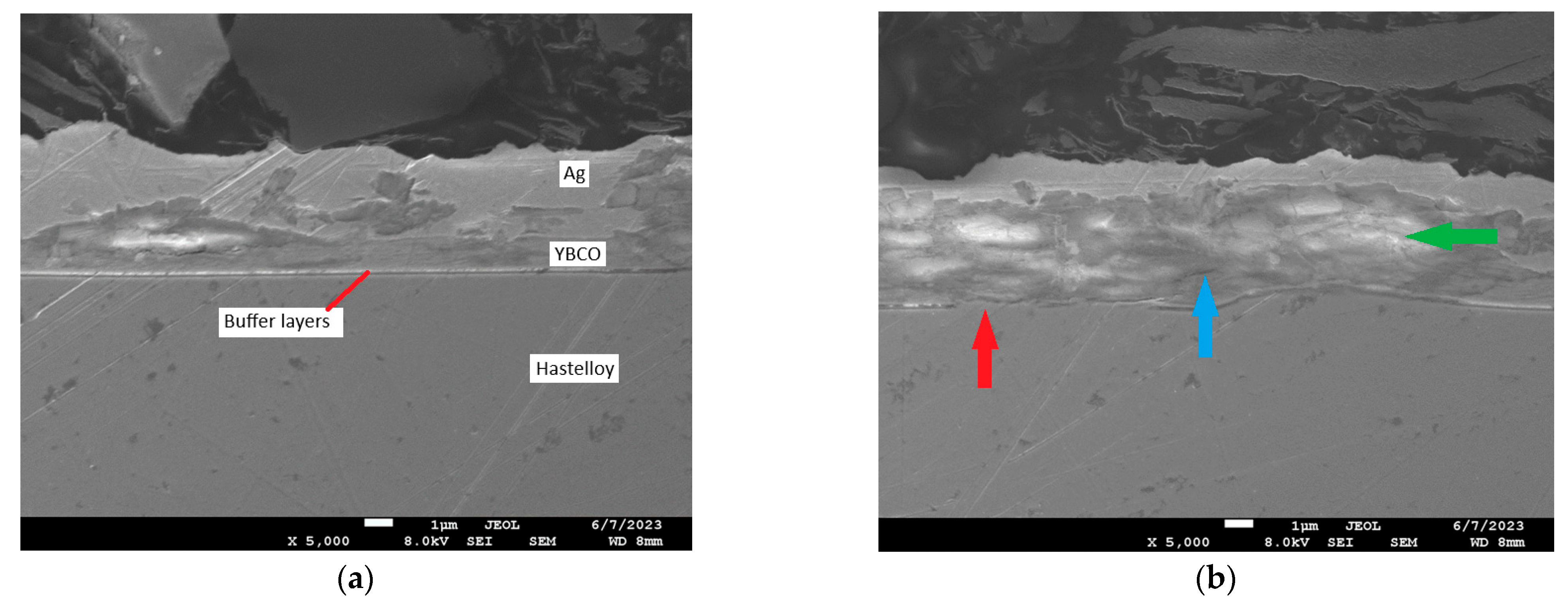

- Hajdasz, S.; Kempski, A.; Arkusz, K.; Szczesniak, P. The Identification of Microstructural Changes in High-Temperature Superconducting Tapes for Superconducting Fault Current Limiters. Appl. Sci. 2024, 14, 9520. [Google Scholar] [CrossRef]

- Zhou, Y.-H.; Park, D.; Iwasa, Y. Review on progresses and challenges of key mechanical issues in high-field superconducting magnets. Natl. Sci. Rev. 2023, 10, nwad001. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Duranti, M.; Swenson, C.A.; Li, P.; Ye, L.; Zhang, X.; Shen, T. Degradation of REBCO coated conductors due to a combination of epoxy impregnation, thermal cycles, and quench: Characteristics and a method of alleviation. J. Appl. Phys. 2020, 128, 173903. [Google Scholar] [CrossRef]

- Kozak, J. Effect of Tape Insulation on Recovery Time of a Conduction-Cooled Resistive Superconducting Fault Current Limiter. Energies 2024, 17, 3350. [Google Scholar] [CrossRef]

- Li, M.; Chen, Y. An Asymmetric Stabilizer Layer Structure of REBCO Superconducting Tapes for Resistive Superconducting Fault Current Limiters. Cryogenics 2024, 138, 103791. [Google Scholar] [CrossRef]

- Chen, B.; Li, J.; Xu, M.; Gao, S. Modeling of HTS High-Current Stacked Conductors with Defective Tapes in Different Locations. Phys. C Supercond. Its Appl. 2023, 606, 135431. [Google Scholar] [CrossRef]

| Relay Characteristic | Equation |

|---|---|

| Standard Inverse (SI) | |

| Very Inverse (VI) | |

| Extremely Inverse (EI) |

| Tape | SF12100-CF |

|---|---|

| the thickness of the silver layer | 2 μm |

| width | 12 mm |

| thickness | 0.105 mm |

| substrate thickness (Hastelloy) | 0.1 mm |

| minimum critical current ICmin (77 K) | 281 A |

| length of the tested tape | 10 cm |

| I0max (A) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t (s) | Udrop = 0.36 V/cm | Udrop = 0.45 V/cm | Udrop = 0.58 V/cm | |||||||||

| New | After 10 | After 20 | After 30 | New | After 10 | After 20 | After 30 | New | After 10 | After 20 | After 30 | |

| 0.5 | 480.0 | 480.0 | 480.0 | 476.6 | 523.3 | 496.6 | 496.6 | 496.6 | 536.6 | 536.6 | 533.3 | 533.3 |

| 1 | 476.6 | 473.3 | 473.3 | 433.0 | 520.0 | 510.0 | 510.0 | 513.3 | 543.3 | 540.0 | 533.3 | 533.3 |

| 2 | 470.0 | 400.0 | 373.0 | 366.0 | 520.0 | 386.6 | 370.0 | 363.0 | 550.0 | 380.0 | 366.6 | - * |

| Imin (A) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t (s) | Udrop = 0.36 V/cm | Udrop = 0.45 V/cm | Udrop = 0.58 V/cm | |||||||||

| New | After 10 | After 20 | After 30 | New | After 10 | After 20 | After 30 | New | After 10 | After 20 | After 30 | |

| 0.5 | 120.0 | 123.3 | 123.3 | 123.3 | 126.6 | 130.0 | 130.0 | 130.0 | 130.0 | 126.6 | 126.6 | 130.0 |

| 1 | 113.3 | 116.6 | 116.6 | 113.3 | 113.3 | 113.3 | 113.3 | 113.3 | 106.6 | 106.6 | 106.6 | 106.6 |

| 2 | 96.7 | 96.7 | 96.7 | 96.7 | 106.6 | 100.0 | 96.7 | 96.7 | 106.6 | 106.6 | 106.6 | - * |

| Umax (V) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t (s) | Udrop = 0.36 V/cm | Udrop = 0.45 V/cm | Udrop = 0.58 V/cm | |||||||||

| New | After 10 | After 20 | After 30 | New | After 10 | After 20 | After 30 | New | After 10 | After 20 | After 30 | |

| 0.5 | 3.5 | 3.6 | 3.5 | 3.6 | 4.4 | 4.3 | 4.4 | 4.3 | 5.4 | 5.3 | 5.4 | 5.3 |

| 1 | 3.6 | 3.6 | 3.6 | 3.6 | 4.5 | 4.5 | 4.5 | 4.5 | 5.8 | 5.7 | 5.6 | 5.7 |

| 2 | 3.6 | 3.6 | 3.6 | 3.6 | 4.7 | 4.8 | 4.7 | 4.7 | 5.7 | 5.7 | 5.7 | - * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajdasz, S.; Kempski, A.; Solak, K.; Rusinski, J. Study of Superconducting Fault Current Limiter Functionality in the Presence of Long-Duration Short Circuits. Energies 2025, 18, 5302. https://doi.org/10.3390/en18195302

Hajdasz S, Kempski A, Solak K, Rusinski J. Study of Superconducting Fault Current Limiter Functionality in the Presence of Long-Duration Short Circuits. Energies. 2025; 18(19):5302. https://doi.org/10.3390/en18195302

Chicago/Turabian StyleHajdasz, Sylwia, Adam Kempski, Krzysztof Solak, and Jacek Rusinski. 2025. "Study of Superconducting Fault Current Limiter Functionality in the Presence of Long-Duration Short Circuits" Energies 18, no. 19: 5302. https://doi.org/10.3390/en18195302

APA StyleHajdasz, S., Kempski, A., Solak, K., & Rusinski, J. (2025). Study of Superconducting Fault Current Limiter Functionality in the Presence of Long-Duration Short Circuits. Energies, 18(19), 5302. https://doi.org/10.3390/en18195302