Design and Experimental Validation of a Cluster-Based Virtual Power Plant with Centralized Management System in Compliance with IEC Standard

Abstract

1. Introduction

- Proposing a scalable cluster-based VPP architecture with a centralized energy management system;

- Developing a control strategy for managing power export and import using LCU and VMS;

- First applied in Indonesia, conducting comprehensive experimental verification of key performance indicators, including response time, adjustment rate, and accuracy, in accordance with IEC TS 63189-1:2023;

- Validating the impact of power exchange in small-scale VPP on the frequency and voltage of the large-scale interconnected grid system.

2. Materials and Methods

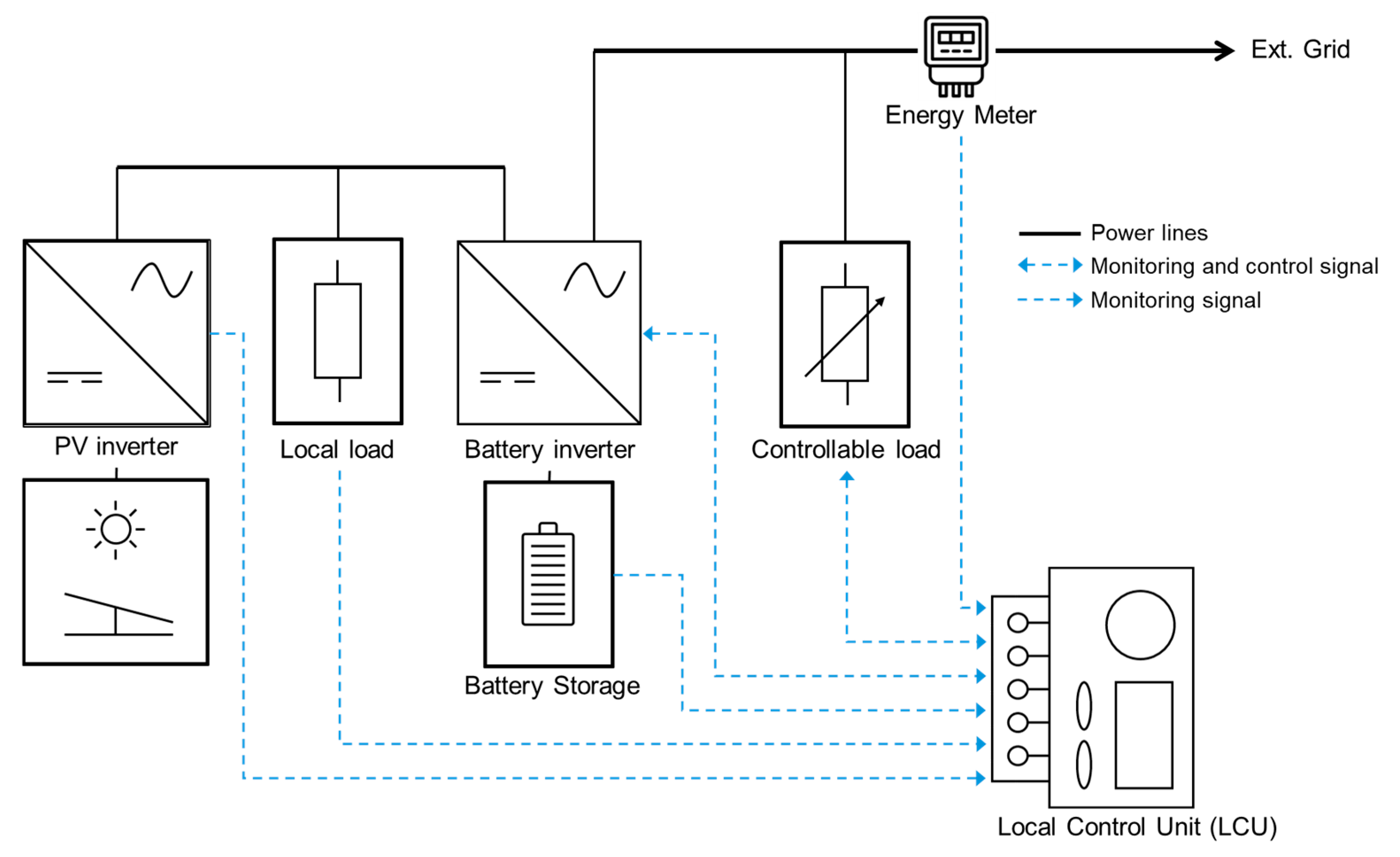

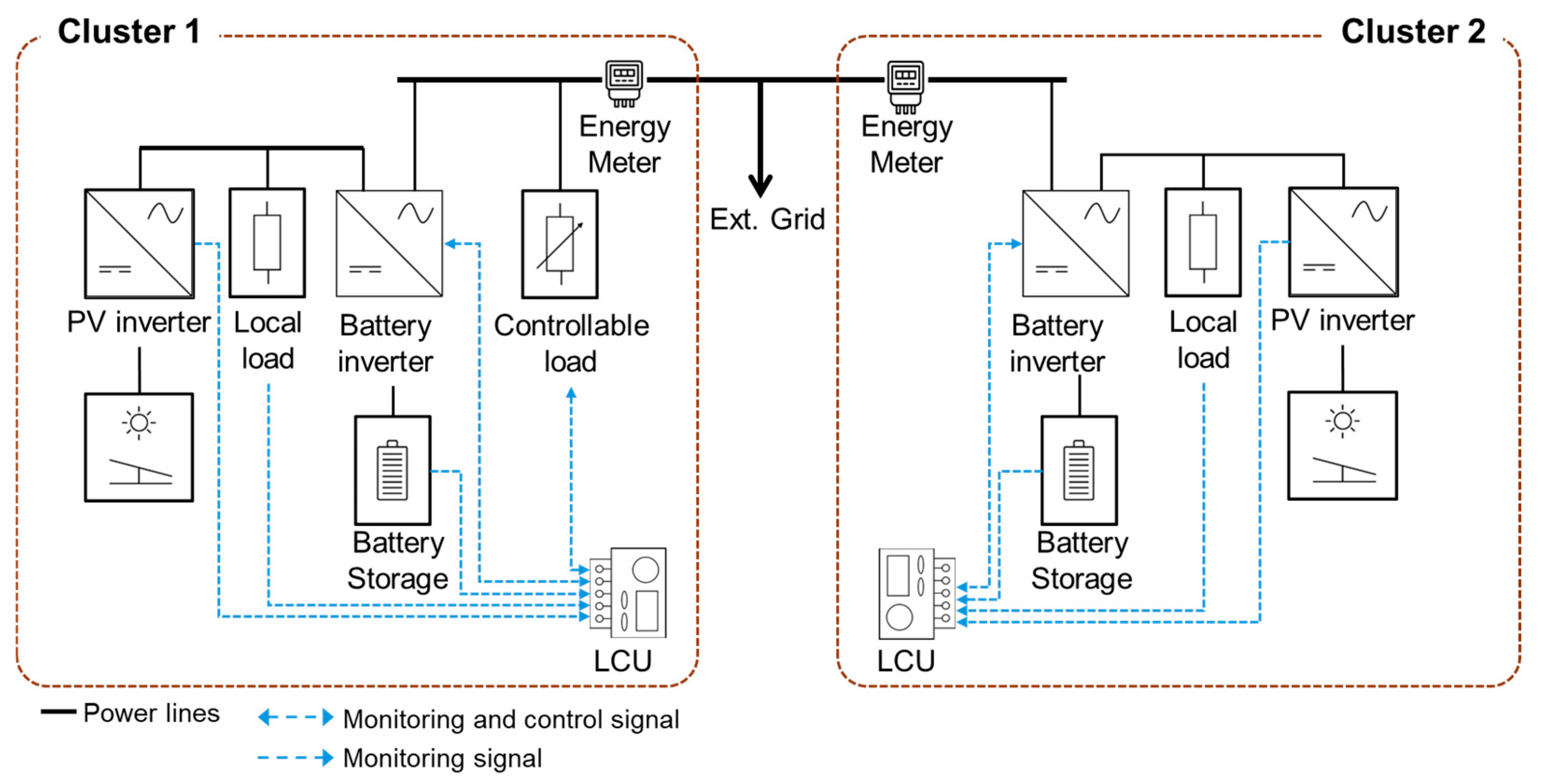

2.1. System Components

2.1.1. PV Systems

2.1.2. BESS

2.1.3. Controllable Load

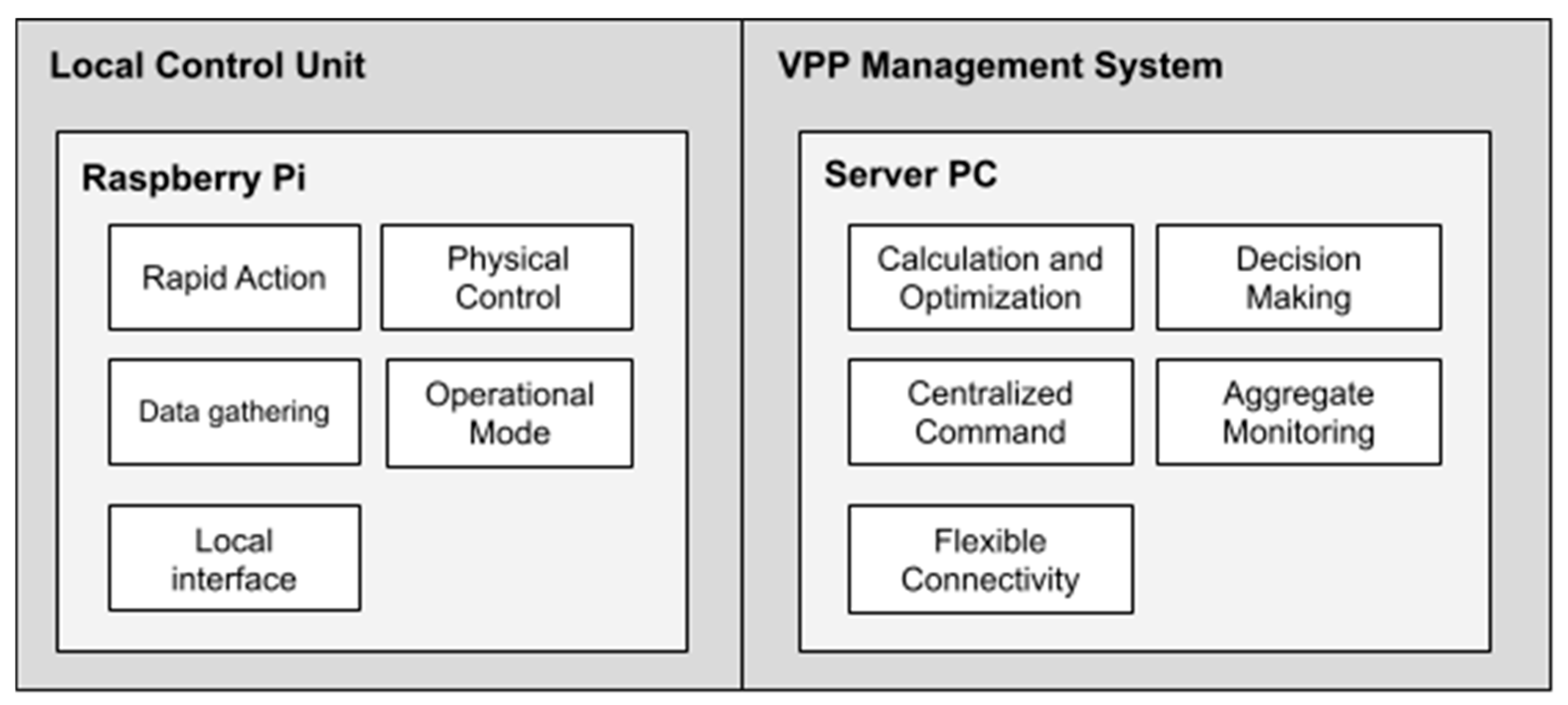

2.1.4. LCU

2.1.5. VMS

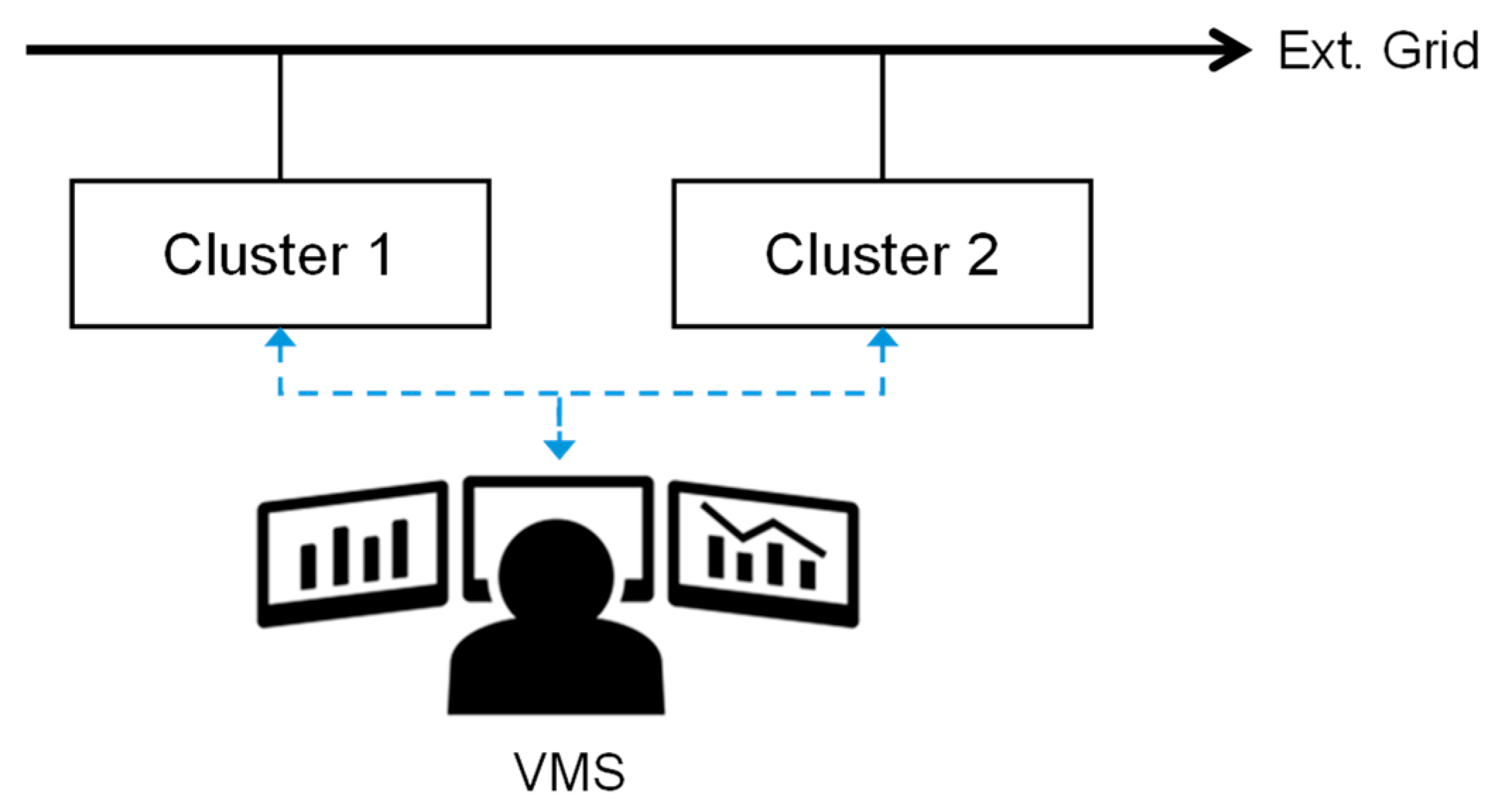

2.2. System Architecture

2.3. Control and Management Strategy

2.3.1. Control Strategy

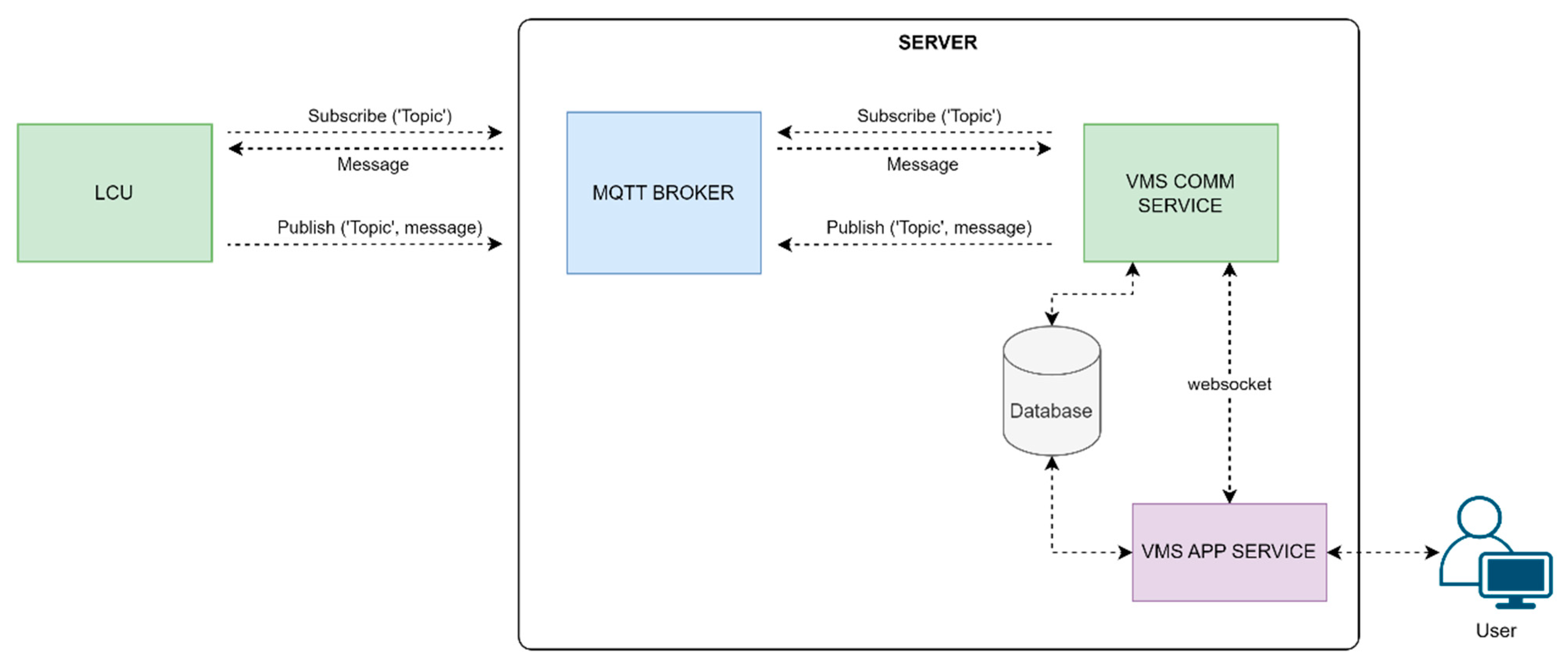

2.3.2. Communication Interfaces

2.3.3. Aggregation Management

3. Experimental Setup

3.1. Hardware Specification

3.2. Testing Scenario

- Continuous mode: Power exchange between the cluster and the external grid is permissible even without a request by the VMS. Also called normal mode.

- Limited mode: Power exchange between the cluster and the external grid is prohibited unless explicitly requested by the VMS.

3.3. IEC TS 63189-1:2023 Testing Parameter

3.3.1. Response Time Parameter

- tresponse time represents the time interval between the receipt of a setpoint signal and the moment the actual system output reaches the commanded setpoint value.

- t0 is the timestamp marking the issuance of the setpoint signal.

- t1 is the timestamp indicating the first occurrence where the actual system response equals the setpoint.

3.3.2. Adjusment Rate Parameter

3.3.3. Adjusment Accuracy Parameter

- n1 = The number of instances in which the actual value matches the setpoint value

- n0 = The total number of setpoint commands issued

4. Results and Discussion

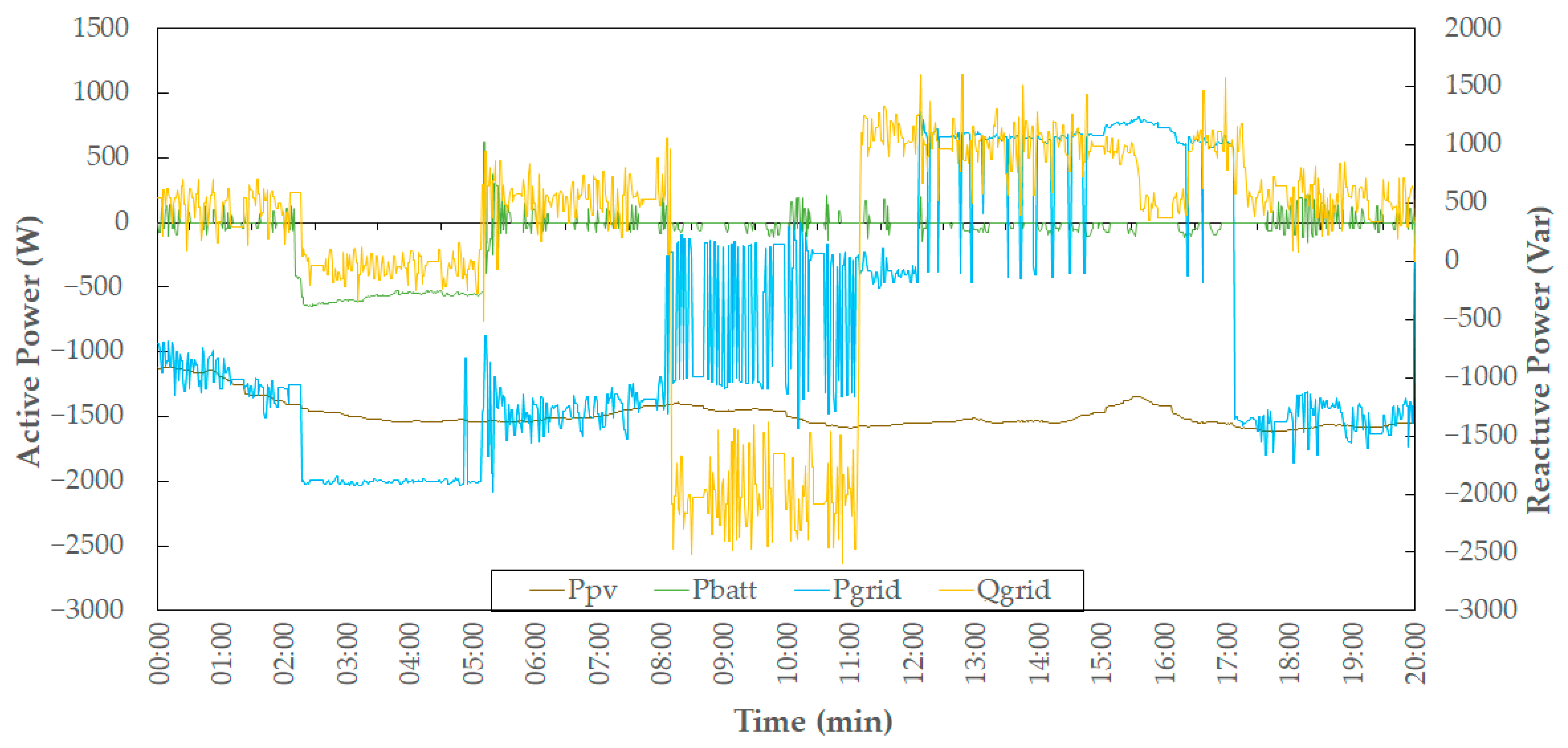

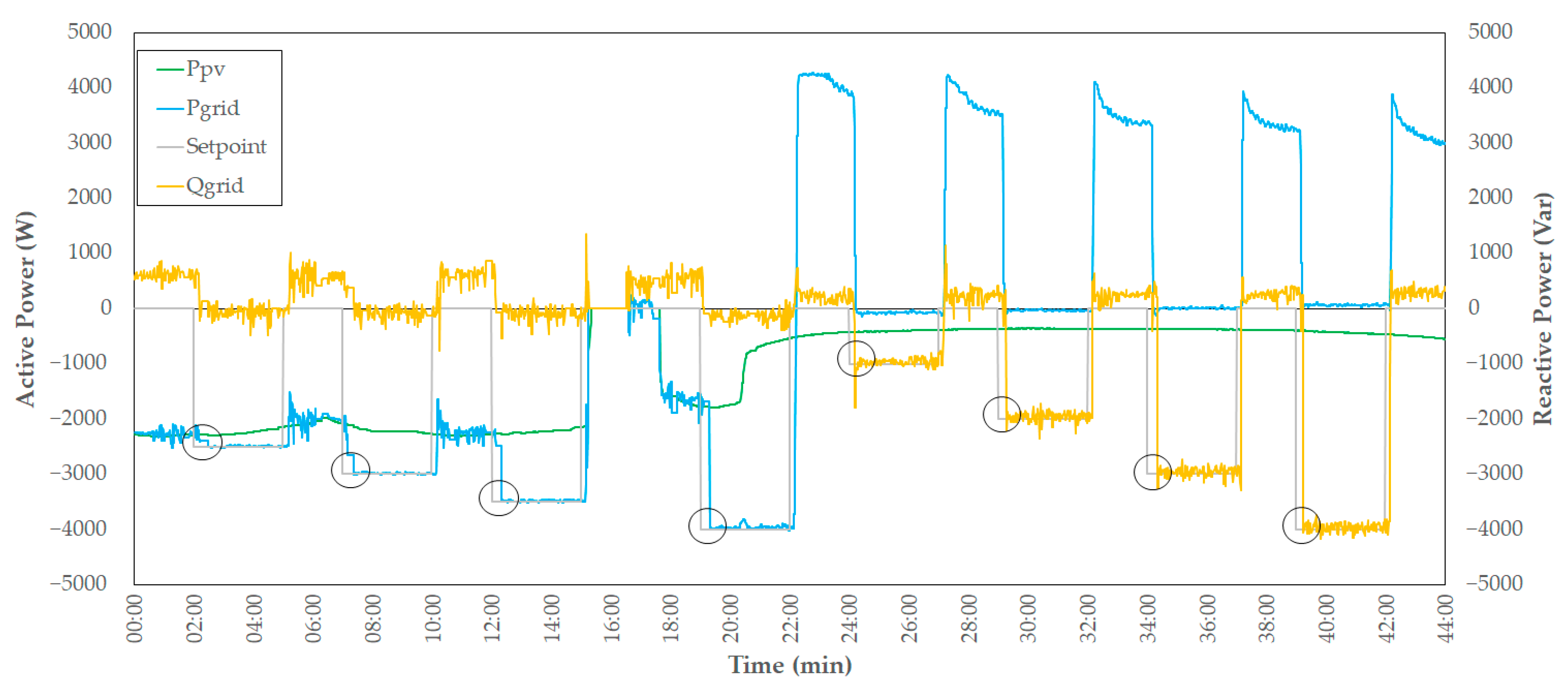

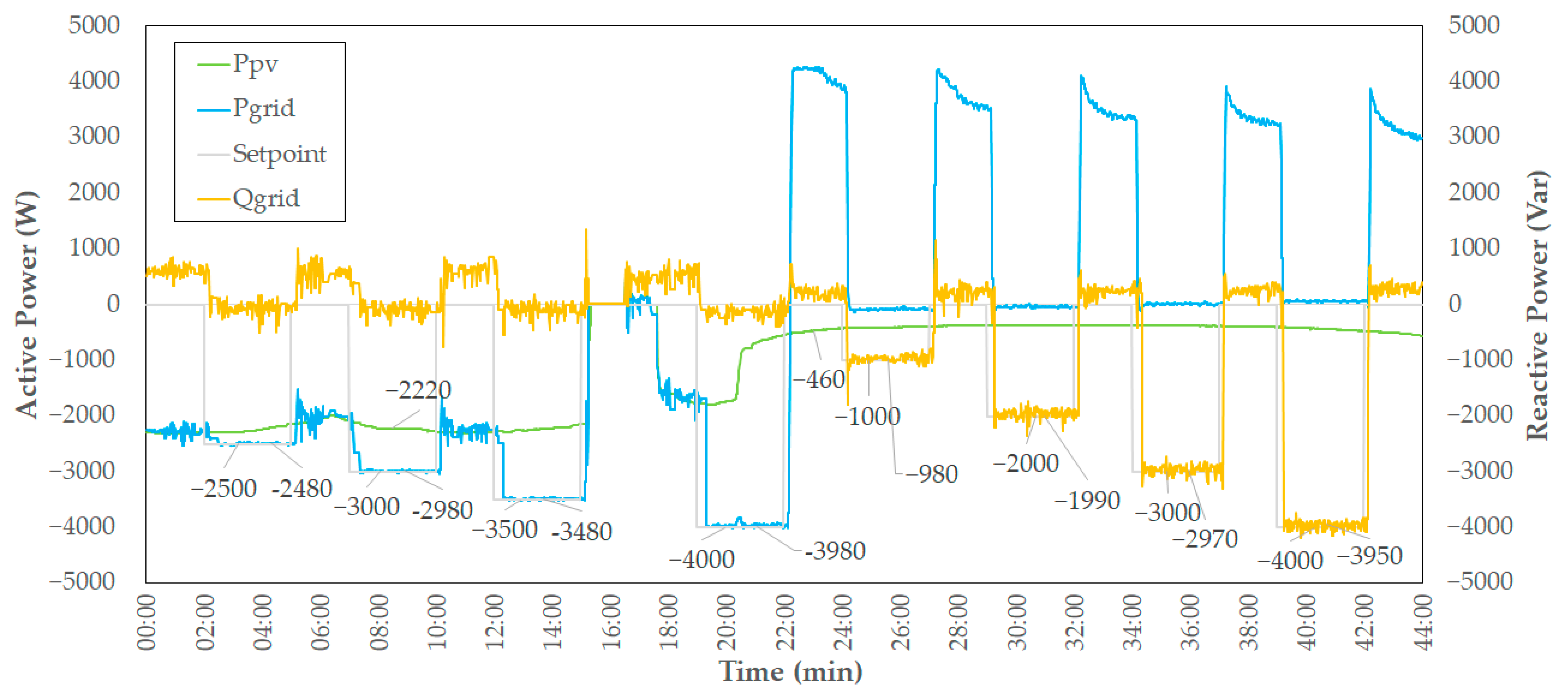

4.1. Continuous Mode (Normal)

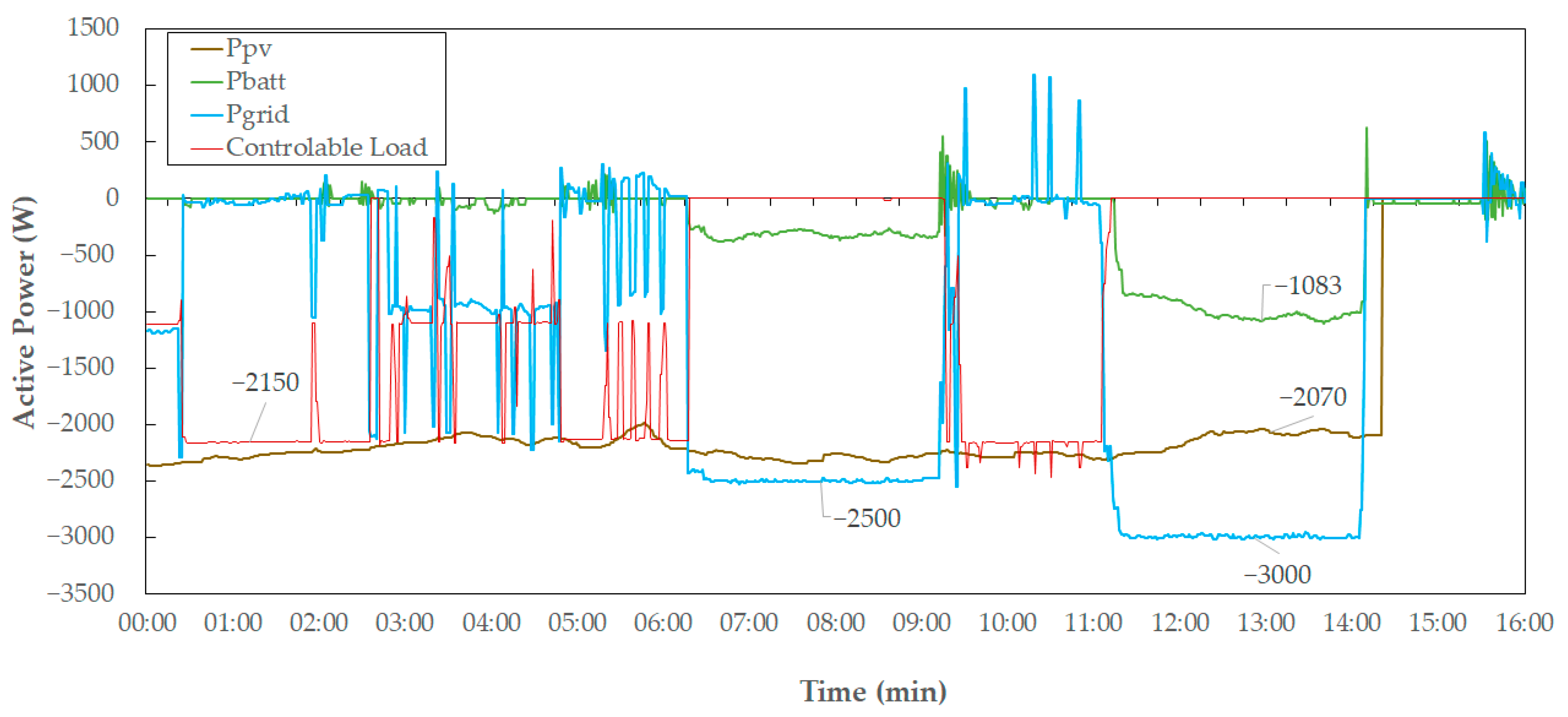

4.2. Limited Mode

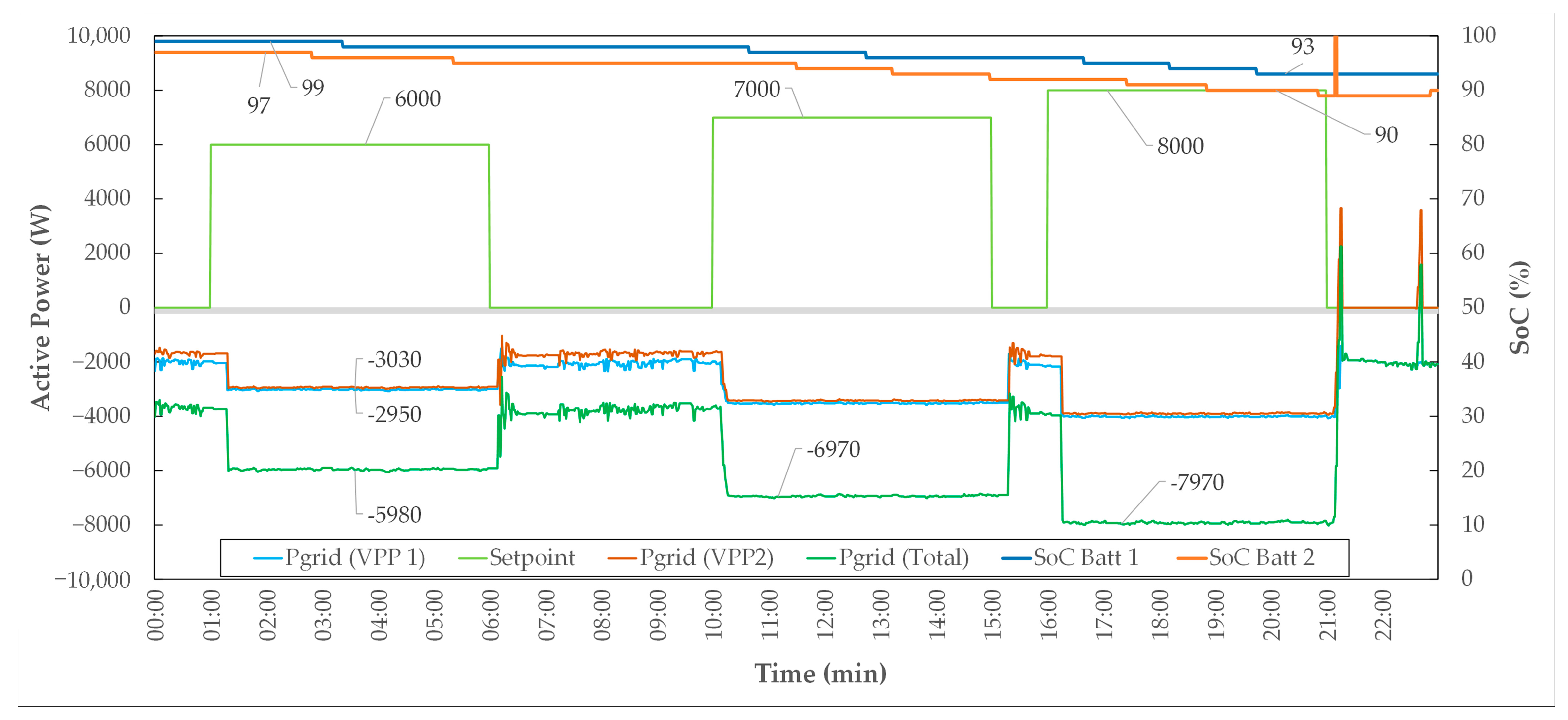

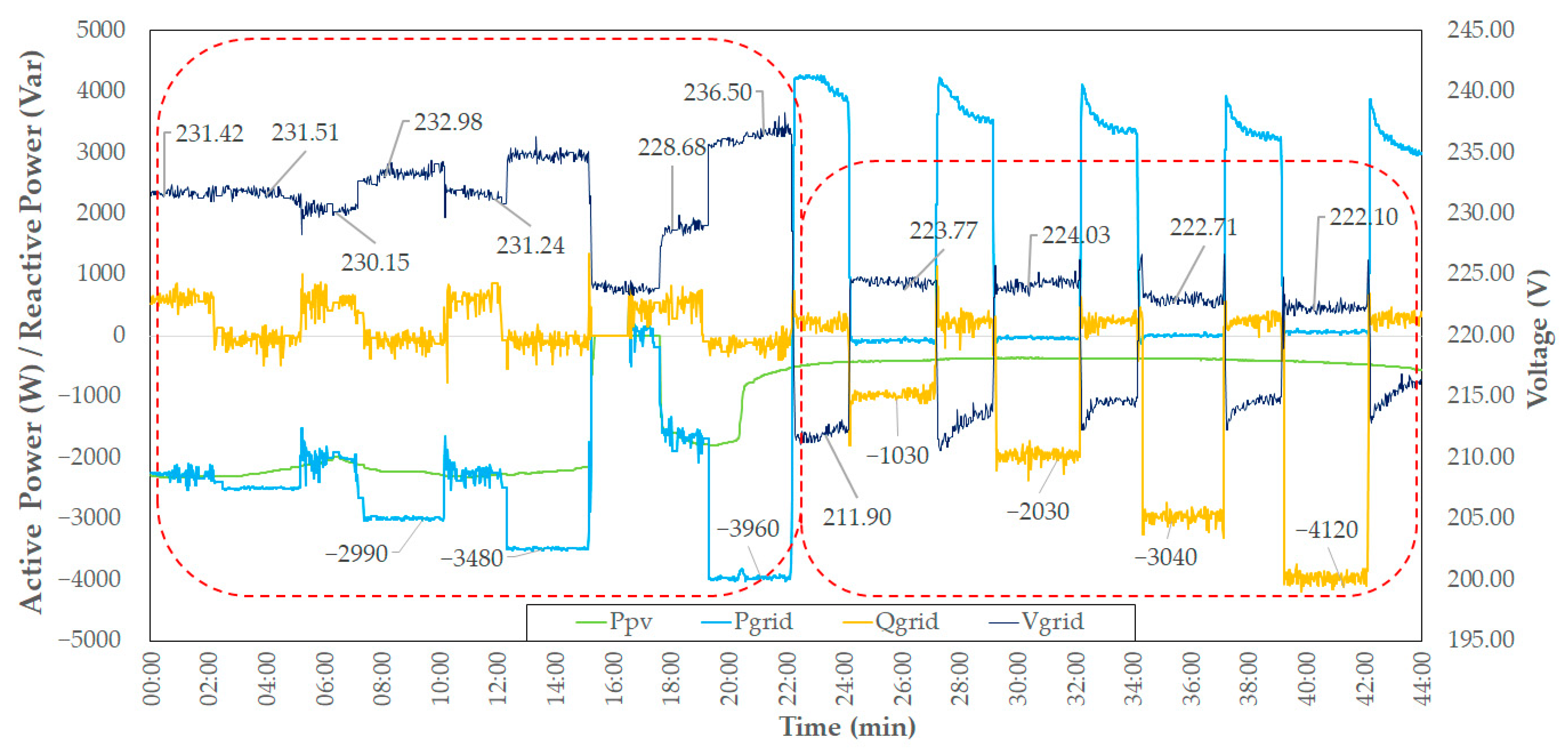

4.3. Aggregation

4.4. Response Time

4.5. Adjustment Accuracy

4.6. Adjustment Rate

4.7. Frequency Regulation

4.8. Voltage Control

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gong, X.; Wang, X.; Cao, B. On Data-Driven Modeling and Control in Modern Power Grids Stability: Survey and Perspective. Appl. Energy 2023, 350, 121740. [Google Scholar] [CrossRef]

- Qudaisat, M.; Alipour, A. Future-Proofing Energy Infrastructure Resilience with Distributed Energy Resources. Dev. Built Environ. 2025, 23, 100696. [Google Scholar] [CrossRef]

- Adham, M.; Keene, S.; Bass, R.B. Distributed Energy Resources: A Systematic Literature Review. Energy Rep. 2025, 13, 1980–1999. [Google Scholar] [CrossRef]

- Amiruddin, A.; Dargaville, R.; Gawler, R. Optimal Integration of Renewable Energy, Energy Storage, and Indonesia’s Super Grid. Energies 2024, 17, 5061. [Google Scholar] [CrossRef]

- Sulaeman, I.; Simatupang, D.P.; Noya, B.K.; Suryani, A.; Moonen, N.; Popovic, J.; Leferink, F. Remote Microgrids for Energy Access in Indonesia—Part i: Scaling and Sustainability Challenges and a Technology Outlook. Energies 2021, 14, 6643. [Google Scholar] [CrossRef]

- Morstyn, T.; Farrell, N.; Darby, S.J.; McCulloch, M.D. Using Peer-to-Peer Energy-Trading Platforms to Incentivize Prosumers to Form Federated Power Plants. Nat. Energy 2018, 3, 94–101. [Google Scholar] [CrossRef]

- Kaiss, M.; Wan, Y.; Gebbran, D.; Vila, C.U.; Dragičević, T. Review on Virtual Power Plants/Virtual Aggregators: Concepts, Applications, Prospects and Operation Strategies. Renew. Sustain. Energy Rev. 2025, 211, 115242. [Google Scholar] [CrossRef]

- Marinescu, B.; Gomis-Bellmunt, O.; Dörfler, F.; Schulte, H.; Sigrist, L. Dynamic Virtual Power Plant: A New Concept for Grid Integration of Renewable Energy Sources. IEEE Access 2022, 10, 104980–104995. [Google Scholar] [CrossRef]

- Liu, J.; Hu, H.; Yu, S.S.; Trinh, H. Virtual Power Plant with Renewable Energy Sources and Energy Storage Systems for Sustainable Power Grid-Formation, Control Techniques and Demand Response. Energies 2023, 16, 3705. [Google Scholar] [CrossRef]

- Abdelkader, S.; Amissah, J.; Abdel-Rahim, O. Virtual Power Plants: An In-Depth Analysis of Their Advancements and Importance as Crucial Players in Modern Power Systems. Energy Sustain. Soc. 2024, 14, 52. [Google Scholar] [CrossRef]

- Moghadam, M.; Ghaffarzadeh, N.; Tahmasebi, M.; Pasupuleti, J. Virtual Power Plant Management with Hybrid Energy Storage System. Unconv. Resour. 2025, 5, 100107. [Google Scholar] [CrossRef]

- Zhong, W.; Chen, J.; Liu, M.; Murad, M.A.A.; Milano, F. Coordinated Control of Virtual Power Plants to Improve Power System Short-Term Dynamics. Energies 2021, 14, 1182. [Google Scholar] [CrossRef]

- Sarmiento-Vintimilla, J.C.; Torres, E.; Larruskain, D.M.; Pérez-Molina, M.J. Applications, Operational Architectures and Development of Virtual Power Plants as a Strategy to Facilitate the Integration of Distributed Energy Resources. Energies 2022, 15, 775. [Google Scholar] [CrossRef]

- Morteza Rahimiyan, L.B. Real-Time Energy Management of a Smart Virtual Power Plant. IET Gener. Transm. Distrib. 2018, 13, 2015–2023. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, H.; Wang, T.; Zhang, S.; Wu, X.; Wang, H. Blockchain-Based Decentralized Energy Management Platform for Residential Distributed Energy Resources in a Virtual Power Plant. Appl. Energy 2021, 294, 117026. [Google Scholar] [CrossRef]

- Setiawan, A.; Jufri, F.H.; Dzulfiqar, F.; Samual, M.G.; Arifin, Z.; Angkasa, F.F.; Aryani, D.R.; Garniwa, I.; Sudiarto, B. Opportunity Assessment of Virtual Power Plant Implementation for Sustainable Renewable Energy Development in Indonesia Power System Network. Sustainability 2024, 16, 1721. [Google Scholar] [CrossRef]

- Soto, E.A.; Bosman, L.B.; Wollega, E.; Leon-Salas, W.D. Analysis of Grid Disturbances Caused by Massive Integration of Utility Level Solar Power Systems. Eng 2022, 3, 236–253. [Google Scholar] [CrossRef]

- Callegaro, L.; Konstantinou, G.; Rojas, C.A.; Avila, N.F.; Fletcher, J.E. Testing Evidence and Analysis of Rooftop PV Inverters Response to Grid Disturbances. IEEE J. Photovolt. 2020, 10, 1882–1891. [Google Scholar] [CrossRef]

- Esfahani, M.; Alizadeh, A.; Cao, B.; Kamwa, I.; Xu, M. Bridging Theory and Practice: A Comprehensive Review of Virtual Power Plant Technologies and Their Real-World Applications. Renew. Sustain. Energy Rev. 2025, 222, 115929. [Google Scholar] [CrossRef]

- Xie, Y.; Zhang, Y.; Lee, W.J.; Lin, Z.; Shamash, Y.A. Virtual Power Plants for Grid Resilience: A Concise Overview of Research and Applications. IEEE/CAA J. Autom. Sin. 2024, 11, 329–343. [Google Scholar] [CrossRef]

- Elkhatib, M.; Johnson, J.; Schoenwald, D. Virtual Power Plant Feedback Control Design for Fast and Reliable Energy Market and Contingency Reserve Dispatch. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 2969–2974. [Google Scholar] [CrossRef]

- IEC TS 63189-1; Virtual Power Plants—Part 1: Architecture and Functional Requirements. IEC: Geneva, Switzerland, 2023.

- Alves, F.; Ribeiro, R.; Petiz, M.; Abbasi, A.; Carvalho, P.; Faia, R.; Faria, P.; Vaie, Z.; Rodrigues, R. Virtual Power Plant Optimization Service-Benchmark of Solvers. In Proceedings of the 2024 19th Conference on Computer Science and Intelligence Systems (FedCSIS), Belgrade, Serbia, 8–11 September 2024; pp. 279–287. [Google Scholar] [CrossRef]

- Häberle, V.; Tayyebi, A.; He, X.; Prieto-Araujo, E.; Dörfler, F. Grid-Forming and Spatially Distributed Control Design of Dynamic Virtual Power Plants. IEEE Trans. Smart Grid 2024, 15, 1761–1777. [Google Scholar] [CrossRef]

- Abbasi, A.; Alves, F.; Ribeiro, R.A.; Sobral, J.L.; Rodrigues, R. Optimizing Virtual Power Plants with Parallel Simulated Annealing on High-Performance Computing. Smart Cities 2025, 8, 47. [Google Scholar] [CrossRef]

- Ju, L.; Lv, S.S.; Li, Y.; Li, Y.; Qi, X.; Li, G.; Zhang, F. Two-Stage Scheduling Optimization Model and Benefit Allocation Strategy for Virtual Power Plant Clusters Aggregated by Multidimensional Information Indicators. Renew. Energy 2025, 240, 122245. [Google Scholar] [CrossRef]

- Wu, C.; Fang, L.; Yang, T.; Zhang, F.; Qiu, Y. Virtual Power Plant Response Strategy Considering Dynamic Aggregation of Different Flexible Resources. J. Phys. Conf. Ser. 2024, 2774, 012044. [Google Scholar] [CrossRef]

- Oladimeji, O.; Ortega, A.; Sigrist, L.; Marinescu, B.; Thomas, V. Adaptive High-Performance Optimization Tool for Real-Time Operation of Renewable-Based Virtual Power Plants. IEEE Access 2025, 13, 11479–11493. [Google Scholar] [CrossRef]

- Chatzistylianos, E.S.; Psarros, G.N.; Papathanassiou, S.A. Export Constraints Applicable to Renewable Generation to Enhance Grid Hosting Capacity. Energies 2024, 17, 2588. [Google Scholar] [CrossRef]

- Mihalič, F.; Truntič, M.; Hren, A. Hardware-in-the-Loop Simulations: A Historical Overview of Engineering Challenges. Electronics 2022, 11, 2462. [Google Scholar] [CrossRef]

- Qais, M.; Kirli, D.; Moroshko, E.; Kiprakis, A.; Tsaftaris, S. A Virtual Power Plant for Coordinating Batteries and EVs of Distributed Zero-Energy Houses Considering the Distribution System Constraints. J. Energy Storage 2025, 106, 114905. [Google Scholar] [CrossRef]

- Sun, Z.; Lu, T. Collaborative Operation Optimization of Distribution System and Virtual Power Plants Using Multi-Agent Deep Reinforcement Learning with Parameter-Sharing Mechanism. IET Gener. Transm. Distrib. 2024, 18, 39–49. [Google Scholar] [CrossRef]

- Lin, X.; Lin, X.; Zhong, W.; Zhou, Y. Predictive Operation Optimization of Multi-Energy Virtual Power Plant Considering Behavior Uncertainty of Diverse Stakeholders. Energy 2023, 280, 128130. [Google Scholar] [CrossRef]

- Zhu, X.; Ruan, G.; Geng, H. Optimal Frequency Support from Virtual Power Plants: Minimal Reserve and Allocation. Appl. Energy 2025, 392, 125913. [Google Scholar] [CrossRef]

- Sawilam, M.; Kizilkaya, B.; Taha, A.; Flynn, D.; Imran, M.A.; Ansari, S. Impact of Virtual Power Plants on Grid Stability and Renewable Energy Integration in Smart Cities Using IoT. Energy Rep. 2025, 13, 3312–3323. [Google Scholar] [CrossRef]

- SPLN S3.006-1:2024; Remote Terminal Unit (RTU) and SCADA Gateway Specification Part 1: Transmission. PT PLN (Persero): Jakarta, Indonesia, 2024.

- Manowska, A.; Wycisk, A.; Nowrot, A.; Pielot, J. The Use of the MQTT Protocol in Measurement, Monitoring and Control Systems as Part of the Implementation of Energy Management Systems. Electronics 2023, 12, 17. [Google Scholar] [CrossRef]

- Burgio, A.; Cimmino, D.; Nappo, A.; Smarrazzo, L.; Donatiello, G. An IoT-Based Solution for Monitoring and Controlling Battery Energy Storage Systems at Residential and Commercial Levels. Energies 2023, 16, 3140. [Google Scholar] [CrossRef]

| Study | Focus Area | Limitations | Contribution |

|---|---|---|---|

| [20,21,22,23] | Scalable Clustered VPP Architecture | Limited scalability for large multi-cluster systems | Proposes a hierarchical, scalable, clustered VPP architecture integrating multi-layer optimization |

| [11,25,26] | Real-Time Control Strategies | Inadequate adaptive algorithms to handle operational disturbances | Develops adaptive real-time model predictive control to handle disturbances |

| [27,31,32] | Grid Import/Export Behavior Modelling | Oversimplified models ignore complex grid interactions | Implements accurate grid interaction modelling integrated into VPP optimization |

| [33,34] | Experimental Validation | Validation of results obtained from simulations and models | Practical tests are used to check if the simulated VPP models and control methods work in real conditions. |

| This Work (Proposed) | Integrated scalable VPP architecture with responsive control and experimental validation | - | Provides a holistic framework combining scalable clustered architecture, responsive real-time control, and experimental validation for reliable and practical VPP deployment |

| Cluster 1 | Cluster 2 | |

|---|---|---|

| PV Module | 3.9 kW | 3.9 kW |

| PV Inverter | 3.6 kW | 3 kW |

| Battery Energy Storage | LFP 51.2 V 100 Ah | LFP 51.2 V 100 Ah |

| Battery Inverter | 6 kW | 6 kW |

| LCU | PLC and Raspberry Pi | PLC and Raspberry Pi |

| Controllable load | Max 5 kW | - |

| Local load | Air Conditioner, desktop PC, LAN Server | LCD Screen, 2 laptops, 4 LED Lights |

| Operation Mode | Cluster | Export Injection (P) | Export Injection (Q) | Import Injection (P) |

|---|---|---|---|---|

| Continuous | 1 | 2.5–4 kW | 1–4 kVar | 1–4 kW |

| 2 | ||||

| Limited | 1 | 1–4 kW | ||

| 2 | ||||

| Technical Index | Frequency Regulation | Voltage Control | Reserve Capacity | Congestion Management | |

|---|---|---|---|---|---|

| Response Time | Level 1 | ≤20 s | ≤20 s | ≤1 min | ≤1 min |

| Level 2 | 20 s–1 min | 20 s–1 min | 1 min–1 h | 1 min–1 h | |

| Level 3 | 1 min–5 min | 1 min–5 min | >1 h | >1 h | |

| Adjustment Rate | Level 1 | >20%/min | >100%/min | >10%/min | >10%/min |

| Level 2 | 3–20%/min | 25–100%/min | 1–10%/min | 1–10%/min | |

| Level 3 | 1–3%/min | 10–25%/min | ≤1%/min | ≤1%/min | |

| Adjustment Accuracy | Level 1 | ≤0.5% | ≤3% | ≤1.5% | ≤1.5% |

| Level 2 | 0.5–1% | 3–7% | 1.5–10% | 1.5–10% | |

| Level 3 | 1–1.5% | 7–10% | >10% | >10% | |

| Technical Index | Frequency Regulation | Voltage Control | |||

|---|---|---|---|---|---|

| Standard | Test Results | Standard | Test Results | ||

| Response Time | Level 1 | ≤20 s | 7 s | ≤20 s | 11 s |

| Level 2 | 20 s–1 min | 20 s–1 min | |||

| Level 3 | 1 min–5 min | 1 min–5 min | |||

| Adjustment Accuracy | Level 1 | ≤0.5% | 3% | ≤3% | 6% |

| Level 2 | 0.5–1% | 3–7% | |||

| Level 3 | 1–1.5% | 7–10% | |||

| Adjustment Rate | Level 1 | >20%/min | 103%/min | >100%/min | 80%/min |

| Level 2 | 3–20%/min | 25–100%/min | |||

| Level 3 | 1–3%/min | 10–25%/min | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pramana, P.A.A.; Mulyana, A.C.; Fauziah, K.; Halidah, H.; Sriyono, S.; Munir, B.S.; Margowadi, Y.; Renata, D.A.; Prawitasari, A.; Taradini, A.; et al. Design and Experimental Validation of a Cluster-Based Virtual Power Plant with Centralized Management System in Compliance with IEC Standard. Energies 2025, 18, 5300. https://doi.org/10.3390/en18195300

Pramana PAA, Mulyana AC, Fauziah K, Halidah H, Sriyono S, Munir BS, Margowadi Y, Renata DA, Prawitasari A, Taradini A, et al. Design and Experimental Validation of a Cluster-Based Virtual Power Plant with Centralized Management System in Compliance with IEC Standard. Energies. 2025; 18(19):5300. https://doi.org/10.3390/en18195300

Chicago/Turabian StylePramana, Putu Agus Aditya, Akhbar Candra Mulyana, Khotimatul Fauziah, Hafsah Halidah, Sriyono Sriyono, Buyung Sofiarto Munir, Yusuf Margowadi, Dionysius Aldion Renata, Adinda Prawitasari, Annisaa Taradini, and et al. 2025. "Design and Experimental Validation of a Cluster-Based Virtual Power Plant with Centralized Management System in Compliance with IEC Standard" Energies 18, no. 19: 5300. https://doi.org/10.3390/en18195300

APA StylePramana, P. A. A., Mulyana, A. C., Fauziah, K., Halidah, H., Sriyono, S., Munir, B. S., Margowadi, Y., Renata, D. A., Prawitasari, A., Taradini, A., Kurniawan, A., & Akhmad, K. (2025). Design and Experimental Validation of a Cluster-Based Virtual Power Plant with Centralized Management System in Compliance with IEC Standard. Energies, 18(19), 5300. https://doi.org/10.3390/en18195300