Abstract

This review synthesizes recent research on alternative fuels for piston-engine aircraft and related propulsion technologies. Biofuels show substantial promise but face technological, economic, and regulatory barriers to widespread adoption. Among liquid options, biodiesel offers a high cetane number and strong lubricity yet suffers from poor low-temperature flow and reduced combustion efficiency. Alcohol fuels (bioethanol, biomethanol) provide high octane numbers suited to high-compression engines but are limited by hygroscopicity and phase-separation risks. Higher-alcohols (biobutanol, biopropanol) combine favorable heating values with stable combustion and emerge as particularly promising candidates. Biokerosene closely matches conventional aviation kerosene and can function as a drop-in fuel with minimal engine modifications. Emissions outcomes are mixed across studies: certain biofuels reduce NOx or CO, while others elevate CO2 and HC, underscoring the need to optimize combustion and advance second- to fourth-generation biofuel production pathways. Beyond biofuels, hydrogen engines and hybrid-electric systems offer compelling routes to lower emissions and improved efficiency, though they require new infrastructure, certification frameworks, and cost reductions. Demonstrated test flights with biofuels, synthetic fuels, and hydrogen confirm technical feasibility. Overall, no single option fully replaces aviation gasoline today; instead, a combined trajectory—biofuels alongside hydrogen and hybrid-electric propulsion—defines a pragmatic medium- to long-term pathway for decarbonizing general aviation.

1. Introduction

General aviation (GA) encompasses all aviation activities other than commercial airline and military operations, including recreational, training, business, rescue, and agricultural flights. The global GA fleet is estimated to number in the hundreds of thousands of aircraft, making this sector highly significant in terms of safety, accessibility of air transport, and technological innovation [1]. Although general aviation does not account for the largest share of fuel consumption in aviation, its environmental impact is disproportionately high particularly due to emissions of local pollutants around airports and densely populated areas [2]. GA also plays an important role in global transportation, but its development is associated with environmental and public health challenges.

Traditionally used aviation gasoline (AVGAS), while providing a high octane rating and properties necessary for piston engine operation, contains tetraethyl lead (TEL) additives, which contribute to the release of toxic substances into the atmosphere [3]. Studies show, that the combustion of leaded fuels is one of the main sources of lead emissions in airport environments, negatively affecting human health, especially among those living near airports [2,4]. In response to these risks, restrictions and bans on the use of TEL-containing fuels are being gradually introduced, while the market is seeking alternative solutions, including unleaded fuels and biofuels.

Liquid biofuels such as biodiesel, bioethanol, and biomethanol are gaining importance as potential substitutes for conventional fuels, as they can reduce greenhouse gas emissions and mitigate local pollution [5,6]. At the same time, the development of standards and regulatory frameworks remains a key factor in determining their adoption in aviation. Current ASTM and STC regulations allow the use of biofuels only to a limited extent, and the absence of unified standards for piston engines hinders commercialization [7,8].

In parallel with biofuels, other low-emission alternatives are being developed, including hydrogen propulsion technologies and hybrid systems. Hydrogen, when used with fuel cells, offers zero on-site CO2 emissions, but its adoption faces challenges related to storage, transport, and cost [9,10]. Hybrid-electric propulsion, on the other hand, can significantly reduce emissions during critical phases of flight, such as takeoff and landing, while still providing sufficient range [11]. In this context, research on alternative fuels takes on particular importance as part of a broader aviation decarbonization strategy.

This article presents a literature review of existing studies on the use of biofuels in piston engines, their impact on performance parameters and exhaust emissions, and the prospects for their application in general aviation. The review also includes the alternative propulsion systems, such as hydrogen and hybrid propulsion.

2. Fuels Used in Aircraft Piston Engines

The most commonly used fuel in aircraft piston engines is aviation gasoline (AVGAS). Piston engines operate on the same principle as automotive spark-ignition engines, but they have higher performance requirements, which necessitates the use of high-octane fuels [3]. Although more aircraft worldwide are powered by aviation gasoline than by jet fuel, the AVGAS market remains relatively small due to the limited size of these aircraft and, consequently, their low fuel consumption [3].

AVGAS is a mixture of C4–C9 hydrocarbons, primarily isoalkanes, including iso-octanes such as 2,2,4-trimethylpentane. It also contains numerous additives, including anti-knock agents (tetraethyl lead, TEL), antioxidants (e.g., 2,6-di-tert-butyl-4-methylphenol), anti-icing agents (diethylene glycol monomethyl ether), antistatic additives (Stadis 450), and dyes [12]. Currently, two main grades of aviation gasoline remain in widespread use: AVGAS 100 and its modified, lower-lead version AVGAS 100LL. AVGAS 100LL is certified under ASTM D910 and UK DEF STAN, authorizing its use in small aircraft worldwide [8]. In addition to these two main grades, other variants exist, such as 100VLL (very low lead) and unleaded alternatives like UL82 and UL87. Table 1 presents the specifications of the mentioned fuels [3]. The column “Distillation 10 vol%” indicates the temperature under standard test conditions at which 10% of the total fuel sample has distilled [12].

Table 1.

Specifications of aviation gasoline [3,13].

A study conducted in North Carolina in 2022 [2], demonstrated that the combustion of aviation gasoline containing tetraethyl lead is one of the primary sources of atmospheric lead emissions. The highest emissions occur during aircraft take-off, landing, and taxiing, with lead concentrations being most pronounced in the immediate vicinity of airports [2,14]. Epidemiological studies have shown elevated blood lead levels in children living within 1.5 km of airport boundaries [2]. Lead is a neurotoxin that adversely affects the human body, particularly the cardiovascular system. Prolonged exposure to lead can result in chronic illnesses and even death [4,15].

In response to the risks associated with the combustion of TEL-containing fuels, many countries have undertaken measures aimed at eliminating lead from general aviation [8,16]. For this reason, intensive efforts are underway to implement unleaded substitutes that could be used without the need for engine modifications. Examples of such fuels include UL91 and UL82 [8]. Parameters such as dry vapor pressure equivalent (DVPE) and final boiling point (FBP) play a crucial role in this context, as they affect factors such as ease of engine start at low temperatures and overall combustion efficiency.

Growing environmental awareness and regulatory pressure are gradually phasing out traditional TEL-containing AVGAS grades. This creates opportunities for unleaded fuels and alternative solutions, including blends with bio-components, which can significantly reduce CO2 and other pollutant emissions.

3. Biofuels for Piston Engines

It should be noted that the biofuels discussed in this article are not currently used as aviation fuels. However, they may represent a potential alternative for piston engines after appropriate modifications, adjustment of operational parameters, or in accordance with manufacturers’ guidelines.

3.1. Biodiesel

Biodiesel is primarily produced through the transesterification of vegetable oils or animal fats using methanol or ethanol in the presence of a basic catalyst (e.g., NaOH, KOH). The reaction products are fatty acid methyl or ethyl esters (FAME) and glycerol as a by-product [17,18]. Alternatively, enzymatic methods or heterogeneous catalysts are increasingly employed, which help reduce purification costs and energy consumption [19]. Feedstock sources include rapeseed, soybean, and palm oils, as well as waste oils and algae [17].

In aviation, biodiesel is notable for its good lubricity and high cetane number, which promote ignition; however, its use is limited by low oxidative stability and high viscosity at low temperatures [18].

3.2. Bioethanol

Bioethanol is mainly produced by fermenting simple sugars (glucose, fructose) derived from agricultural feedstocks such as sugarcane, corn, sugar beets, or cereals [5,6,20]. Second-generation bioethanol, produced from lignocellulosic materials such as straw, wood, and agricultural residues is gaining importance. This process involves hydrolysis of cellulose and hemicellulose to fermentable sugars, followed by fermentation using yeast or genetically engineered microorganisms [6]. Work is also ongoing on third-generation bioethanol, produced from algal biomass with high photosynthetic efficiency [5]. Bioethanol has a high octane number but a low heating value and high hygroscopicity, limiting its use in pure form [20].

3.3. Biomethanol

Biomethanol can be produced from synthesis gas (CO + H2) obtained Via gasification of biomass, municipal waste, or sewage sludge [6,21]. Alternatively, anaerobic fermentation can be used, followed by conversion of biogas (CH4 + CO2) to syngas Via steam or dry reforming. Methanol synthesis typically occurs at 50–100 bar and 200–300 °C using a copper-based catalyst [21]. Recently, biotechnological processes utilizing autotrophic microorganisms for CO2 conversion have also been developed [6]. As an aviation fuel, biomethanol has a low cetane number and low viscosity but exhibits very clean combustion and strong CO2 reduction potential [6].

3.4. Biopenatnol

Pentanol can be produced Via both biotechnological and chemical methods. Fermentative production relies on microorganisms capable of synthesizing higher alcohols from glucose, starch, or lignocellulose into C3-C5 alcohols [22]. Alternatively, hydroformylation of butenes (oxo-synthesis) produces aldehydes that are subsequently hydrogenated to alcohols. Increasingly, pentanol production from algal biomass and lignocellulosic waste is being considered. Pentanol has a higher heating value and lower volatility than ethanol or methanol, making it more similar to conventional aviation fuels [22].

3.5. Biobutanol

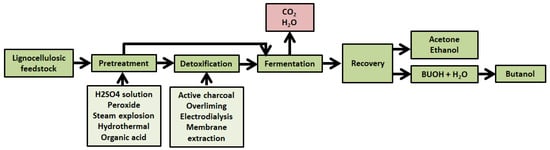

Biobutanol is most commonly obtained through ABE (acetone-butanol-ethanol) fermentation using Clostridium acetobutylicum strains [23,24,25]. In the classical method, a mixture of three products is produced, with butanol accounting for approximately 20% of the total volume. Modern technologies rely on microbial metabolic engineering, which increases process yield and reduces acetone production [23]. Alternative pathways include catalytic conversion of syngas to butanol, as well as biotechnological utilization of lignocellulosic waste and algae [25]. Biobutanol has a high heating value, good miscibility with gasoline, and lower hygroscopicity than ethanol, making it one of the most promising biofuels for aviation [24]. Figure 1 illustrates the biobutanol production process.

Figure 1.

Schematic diagram of the biobutanol production process [23].

3.6. Biopropanol

Biopropanol can be produced through carbohydrate fermentation using genetically modified yeasts and bacteria that enhance C3 alcohol yield. Alternatively, catalytic conversion of glycerol (a biodiesel by-product) to propanol Via hydrogenation is also possible [19,26]. Experimental studies focus on the use of waste and agricultural feedstocks, which can reduce production costs. Its energy properties are superior to those of ethanol; however, production processes are less technologically mature and remain in the research phase [26].

3.7. Bio-Kerosene

Bio-kerosene is most commonly produced through hydroprocessing of vegetable oils and fats (Hydroprocessed Esters and Fatty Acids, HEFA). This process involves hydrogenation and hydrocracking, resulting in paraffinic hydrocarbons similar to conventional Jet A-1 fuel [27]. Alternative pathways include FT-SPK (Fischer–Tropsch Synthetic Paraffinic Kerosene), synthesized from syngas, and ATJ (Alcohol-to-Jet), in which alcohols (ethanol, butanol) are dehydrated and oligomerized into hydrocarbons [28]. An interesting approach is also lipid ozonolysis cracking, which produces bio-kerosene from vegetable oils and algae [28]. Due to its similarity to Jet A-1 fuel, bio-kerosene has the greatest potential as a “drop-in” fuel for aircraft engines.

3.8. Bio-Oil

Bio-oil obtained from the catalytic pyrolysis of tyre waste is a complex liquid mixture rich in organic compounds, primarily aromatic hydrocarbons, aliphatic hydrocarbons, and oxygenated species. This bio-oil is produced by thermally decomposing tyre waste in an inert atmosphere, typically at temperatures around 500 °C, using catalysts such as zeolites to enhance the yield and quality of the liquid products [29]. The catalytic pyrolysis process not only increases the liquid yield but also improves the quality of the bio-oil by reducing its oxygen content and enhancing its calorific value. The presence of catalysts facilitates the breakdown of complex polymeric structures in tyres, leading to the formation of lighter, more volatile compounds that are more suitable for further processing or direct utilization as fuels [29]. Characterization of the bio-oil is typically performed using techniques like pyrolysis-gas chromatography-mass spectrometry (Py-GC-MS), which allows for the detailed analysis of its chemical composition. This analytical approach helps in identifying the specific compounds present, understanding their distribution, and assessing the potential applications of the bio-oil in various energy and chemical sectors [29].

Table 2 presents approximate elemental composition of previously mentioned biofuels.

Table 2.

Approximate elemental composition of biofuels.

4. Physicochemical Requirements of Alternative Aviation Fuel

4.1. Standards and Regulations

The development of alternative fuels for piston engines, as in the case of jet engines, is closely linked to regulations and certification processes. Currently, ASTM D910 (ASTM D910; Standard Specification for Leaded Aviation Gasolines, ASTM International, West Conshohocken, PA, USA, 2017) and ASTM D7547 (ASTM D7547; Standard Specification for Hydrocarbon Unleaded Aviation Gasoline, ASTM International, West Conshohocken, PA, USA, 2023) standards specify the requirements for leaded and unleaded aviation gasoline, but there are no direct standards yet for biofuels intended for piston engines. The use of liquid biofuels such as biodiesel, bioethanol, or biobutanol is only possible under Supplemental Type Certificates (STC). In the United States, STCs must be approved by the FAA (Federal Aviation Administration), and in Europe by EASA (European Union Aviation Safety Agency). Furthermore, the use of such fuel blends requires an individual compliance assessment for each engine type [8].

A broader regulatory framework for alternative aviation fuels exists in ASTM D7566 (ASTM D7566; Standard Specification for Aviation Turbine Fuels Containing Synthesized Hydrocarbons. ASTM International: West Conshohocken, PA, USA, 2018), developed for sustainable aviation fuels for turbine engines containing biocomponents (e.g., FT-SPK, HEFA-SPK, ATJ-SPK). In the future, this standard may be extended to fuels intended for piston engines; currently, however, it is limited to applications in jet aviation [7,30].

Regarding the use of hydrogen, dedicated ASTM standards for its application in piston aviation do not yet exist. However, conceptual work is underway by the FAA and EASA on certification roadmaps for general aviation [9].

4.2. Physicochemical Properties

The physicochemical properties of biofuels (Table 2) play a key role in their application, as they influence both combustion processes and operational safety. One of the fundamental parameters is density, which determines the mass of fuel injected and its volume in fuel systems. Biodiesel has a relatively high density of approximately 870 kg/m3, which affects its energy content and lubricating properties [18]. For bio-derived alcohols such as bioethanol and biomethanol, the density is lower, at 785 kg/m3 for bioethanol and 795 kg/m3 for biomethanol [5,6]. The density of biopropanol and biobutanol ranges from 805 to 810 kg/m3, while pentanol has a density of 815 kg/m3 [24,26,31]. Bio-kerosene exhibits a density of 795 kg/m3, comparable to conventional aviation fuels [32].

Another important parameter for engine operation is the cetane number, which determines the fuel’s tendency to autoignite. Biodiesel exhibits a high cetane number of 50, ensuring stable and complete combustion in piston engines [18]. In contrast, alcohols have significantly lower cetane numbers: bioethanol ranges from 4 to 23, biomethanol approximately 5, biopropanol 12, and biobutanol 25 [5,6,20,26].

Kinematic viscosity affects the lubrication of fuel system components and the atomization process. Biodiesel has a relatively high viscosity of 4.1 mm2/s [17]. Alcohols display lower viscosities: bioethanol 1.2–1.5 mm2/s, biomethanol 0.755 mm2/s, pentanol 2.89 mm2/s, biopropanol 2.801 mm2/s, and biobutanol 3.64 mm2/s, which facilitates atomization but may limit lubricating properties [5,6,20,21,24,26,31]. Bio-kerosene has a viscosity of 1.679 mm2/s [32].

Lower heating value (LHV) determines fuel efficiency. Biodiesel has an LHV of 37.5 MJ/kg, pentanol 35.06 MJ/kg, biobutanol 33.1 MJ/kg, biopropanol 30.6 MJ/kg, bioethanol 41.24 MJ/kg, and biomethanol the lowest at 19.66 MJ/kg [5,6,20,26,31]. The high heating values of bioethanol and biodiesel may translate into more efficient power generation in aircraft piston engines.

Another critical parameter in fuel studies is the flash point. Biodiesel exhibits a high flash point above 160 °C [18]. Alcohols have significantly lower flash points: bioethanol 12–20 °C, biomethanol 11 °C, biopropanol 15 °C, biobutanol 28.8 °C, and pentanol 138 °C (boiling point) [20,21,24,26,31].

4.3. Impact on Aircraft Piston Engine Performance

The use of biofuels in aircraft piston engines is associated with numerous changes in combustion processes, engine performance parameters, and exhaust emissions. Their impact depends both on the physicochemical properties of the fuel and the selected engine operating parameters. Table 3. presents the impact of biofuels on selected performance parameters of aviation piston engines.

Table 3.

Physicochemical properties of biofuels [5,6,18,20,21,24,26,30].

In the case of biodiesel, studies have shown that the effective power during its combustion is slightly lower than when using diesel fuel, resulting in higher specific fuel consumption (SFC) and lower thermal efficiency (ETE) [18]. The combustion characteristics depend on load and engine speed. Under full-load operation, the contribution of combustion during the pilot injection phase is similar to that of diesel, while under partial-load conditions, biodiesel burns more slowly in the pilot phase, favoring incomplete combustion. During the main injection phase, due to complete evaporation, biodiesel combusts faster, and the maximum heat release rate (HRR) can be higher than that of diesel. Characteristics of biodiesel combustion include a faster burning rate, shorter combustion duration, and an earlier CA50 (crank angle at 50% mass fraction burned) point in the engine cycle. At high engine speeds, biodiesel ignition delay is similar to diesel, whereas under low-load conditions, the difference increases in favor of biodiesel [18]. Other studies confirm that electronic injection systems facilitate precise fuel dosing, and appropriate selection of operating points and propeller settings can reduce BSFC (Brake Specific Fuel Consumption). Notably, Camelina-based biodiesel has shown reduced fuel consumption and favorable emission characteristics [17].

Alcohols such as bioethanol, biomethanol, biobutanol, and biopropanol have high octane numbers, allowing their use in high-compression engines, improving efficiency and reducing knocking [5]. Due to their oxygen bonds, they emit lower NOx and soot compared to fossil fuels [6]. Increased ethanol content in fuel blends used in aviation engines does not significantly affect maximum power, but reduces CO and UHC emissions, while increasing CO2 and NOx emissions [20]. These effects result from the higher oxygen content in the fuel and different combustion dynamics. However, high-ethanol fuels may pose operational challenges, such as phase separation or vapor lock, which can limit the aircraft’s operational ceiling. One proposed solution is the use of multi-point injection systems with separate delivery of low- and high-ethanol fuels [20].

Biobutanol exhibits different combustion characteristics compared to diesel, due to higher resistance to autoignition and greater volatility, combustion occurs mainly in the premixed mode, facilitating the use of PPCI (Premixed Charge Compression Ignition) and HCCI (Homogeneous Charge Compression Ignition) strategies. Studies have shown the potential to achieve low NOx and smoke emissions with efficiency comparable to diesel engines, albeit with increased fuel consumption due to lower heating value [24]. In blends with conventional fuels, biobutanol provides higher thermal efficiency, lower CO and soot emissions, but higher NOx emissions compared to gasoline [26]. In blends with RP-3 fuel, it shows the greatest potential as an alternative to aviation gasoline.

Biopropanol in fuel blends improves engine efficiency more than ethanol, and CO and soot emissions are significantly lower than for gasoline. However, NOx emissions are variable and depend on the blend composition and operating conditions [26].

For bio-kerosene, studies indicate that injection conditions (fuel and ambient pressure) significantly affect atomization and combustion. Adding 20% ethanol to bio-kerosene improves atomization characteristics and may be considered an optimal solution for aviation applications [32].

The reported values in Table 4 are averaged ranges from multiple studies and should be interpreted as typical trends rather than exact measurements. Actual results depend on engine type, operating conditions, and blend ratio.

Table 4.

Impact of biofuels on selected performance parameters of aviation piston engines compared to conventional fuels [5,6,17,18,20,24,26,32].

5. Feedstock Used for Biofuels Production

5.1. Biofuels Generations

There are four generations of biofuels, differing in feedstock type and technological complexity [6]. First-generation biofuels are primarily produced from edible agricultural feedstocks, which are widely available and relatively easy to process chemically. Commonly used crops include sugar- and starch-rich plants such as corn, wheat, barley, sugarcane, and sugar beets. These feedstocks allow ethanol production through fermentation, a well-established and widely applied technological process [5,6]. This generation also includes oilseed crops, such as rapeseed, soybean, palm, and sunflower. Oils extracted from these sources can be converted into biodiesel (FAME) Via esterification, exhibiting fuel properties similar to conventional aviation kerosene [6,21]. Additionally, first-generation biofuels include animal fats, which can supplement biodiesel production, especially in terms of reducing feedstock costs and utilizing waste [27]. To be efficient, oil crops typically require an oil content of 20–45% of dry matter, which allows for sufficient yield during transesterification [33].

Second-generation biofuels utilize non-edible and waste feedstocks, avoiding competition with food production. This group includes lignocellulosic materials such as straw, wood residues, miscanthus, and bagasse. These feedstocks require more advanced processes, including enzymatic hydrolysis, pyrolysis, gasification, or hydrorefining, to produce liquid fuels suitable for combustion in aircraft engines [6,27]. The suitability of lignocellulosic feedstocks depends strongly on their composition. Lignocellulosic biomass typically contains 35–55% cellulose, 20–40% hemicellulose, and 10–25% lignin. High lignin content (more than 25%) can limit enzymatic hydrolysis and reduce fermentation efficiency [34,35]. Important types also include industrial and municipal waste, such as used cooking oils and waste fats, which can be processed into biodiesel meeting ASTM and DEF STAN standards [28]. In research studies, some of these feedstocks have been used as components of blended alternative fuels, including bio-kerosene produced from waste fats [28].

Third-generation biofuels focus on microalgae and macroalgae, which have high lipid productivity relative to cultivation area and can be grown under conditions unsuitable for conventional agriculture. Algae are a valuable source of hydrocarbons and oils suitable for conversion into biodiesel and bio-kerosene [7,17,27]. Lipid content in microalgae can range from 20% up to 60–70% of dry biomass, depending on species and cultivation conditions, often surpassing oil content on terrestrial crops [35]. In scientific literature, algae are tested both as pure oils and in blends with conventional aviation fuels, allowing evaluation of their effects on combustion, particulate emissions, and fuel stability [17].

Fourth-generation biofuels are based on innovative technological processes, including genetically modified organisms and artificial photosynthesis. Feedstocks in this group include microorganisms such as yeasts, bacteria, or cyanobacteria, capable of producing ethanol, butanol, or hydrocarbons through fermentation and biosynthesis [24]. Oleaginous yeasts used in this generation are considered suitable if they accumulate more than 20% lipids in their dry biomass, which makes lipid recovery and fuel production economically viable [34,36]. In addition, power-to-liquid technologies are being developed, using renewable hydrogen and captured carbon dioxide as substrates to produce liquid aviation fuels with a neutral CO2 balance [7].

5.2. Feedstocks Used in Experimental Studies

A literature analysis shows that experimental studies on piston engines most commonly use:

- Biodiesel (FAME) derived from vegetable oils (camelina, jatropha, soybean) and animal fats [17,18],

- Bio-jet fuel from vegetable oils, produced Via triglyceride conversion [37],

- Bioethanol and biomethanol as additives to aviation gasoline [5],

- Pentanol and biobutanol, used in blends with aviation kerosene [22],

- Bio-kerosene produced from waste fats Via hydrorefining and ozonolysis [28,32],

- Algae as a biodiesel source in piston engine studies [17].

In experimental research, feedstocks with well-characterized chemical and energy properties dominate, such as vegetable oils, alcohols (ethanol, butanol), and waste animal fats. Third- and fourth-generation feedstocks, including algae and genetically modified microorganisms, remain largely experimental but show significant potential for sustainable piston-engine aviation in the future [7,17,27,28].

6. Alternative Propulsion in General Aviation

6.1. Hydrogen Propulsion

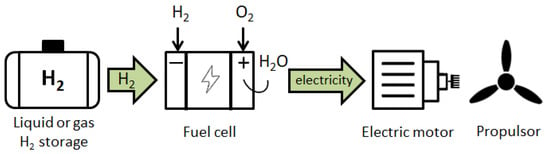

Hydrogen is considered one of the key solutions enabling the long-term decarbonization of general aviation, and indeed the entire aviation industry [10,11]. Its primary advantage is zero carbon dioxide emissions during combustion or conversion in fuel cells, which significantly distinguishes it from fossil fuels and most biofuels [38]. However, the use of hydrogen poses a number of technological challenges, including storage, transport, and operational safety [39]. The IATA (International Air Transport Association) report describes two main methods for extracting energy from hydrogen and using it to power aircraft. One involves reversing the electrolysis process and recombining hydrogen with oxygen to produce water and electricity. This occurs in a fuel cell, which operates similarly to a battery, converting chemical energy into electrical energy. The electricity generated in this process can then be used to power an electric motor in a fully electric or hybrid aircraft. Using hydrogen provides three times more energy per kilogram than kerosene-based fuel [10].

However, the literature emphasizes that hydrogen can be used in general aviation in three main forms:

- as a fuel for piston and turbine engines in combustion systems,

- in a dual-fuel configuration, where it supplements traditional aviation fuel,

Figure 2. Hydrogen fuel cells to power electric aircraft (based on [10]).

Figure 2. Hydrogen fuel cells to power electric aircraft (based on [10]).

A particularly interesting concept is the hydrogen-kerosene dual-fuel engine, which enables a gradual increase in the share of hydrogen energy without completely abandoning the existing fuel infrastructure. Research by Reitmayr and Hofmann [11] has shown that an appropriate hydrogen injection strategy allows not only for up to 50% CO2 reduction but also for improved engine energy efficiency [11].

The first demonstration flights of aircraft powered by liquid and compressed hydrogen were a significant step. The DLR Antares H2, H2FLY HY4, and ZeroAvia Do228 projects demonstrated the technical feasibility of hydrogen propulsion in general aviation [39,40,41]. At the same time, regulatory roadmaps from EASA, FAA, and CAA (Civil Aviation Authority) indicate that certification and commercialization of hydrogen-powered general aviation aircraft will be possible in the 2035–2040 timeframe [9]. The IATA report, however, emphasizes the need for significant investments in airport infrastructure and the development of cryogenic hydrogen storage technologies [10]. At the same time, fuel cell-based solutions are being developed, which can power electrical systems in light sports and training aircraft [38,42]. Due to high energy conversion efficiency and the lack of local emissions, this concept is particularly attractive in areas with restrictive environmental regulations.

6.2. Electric and Hybrid Propulsion

Electric motors represent another important direction in the development of alternative aircraft propulsion systems. Their main advantages include structural simplicity, high efficiency, and the absence of exhaust emissions [1]. However, a key limitation lies in the low energy density of batteries compared to liquid fuels. Even the most advanced energy storage systems cannot provide a flight range and endurance comparable to conventional combustion engines [1,39]. Consequently, there is growing interest in hybrid configurations that combine electric propulsion with combustion or turbine engines. Such solutions allow for fuel consumption and emission reduction during the most environmentally sensitive flight phases (take-off and landing), while still maintaining longer range capabilities [11].

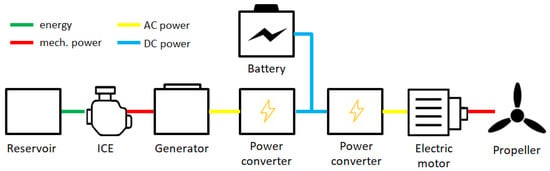

The literature distinguishes three main types of such systems:

- series hybrids,

- parallel hybrids,

- series–parallel hybrids [38,43].

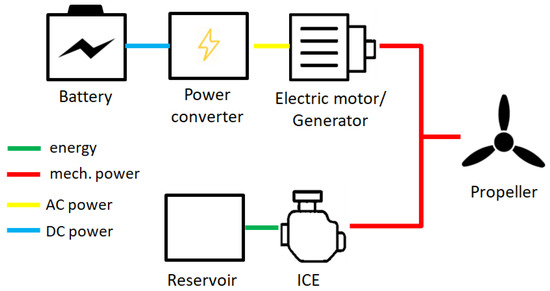

In a series configuration (Figure 3), the combustion engine does not directly drive the propeller but instead generates electrical energy that powers the electric motors driving the propeller. This approach provides greater flexibility in selecting combustion engine parameters, enables optimization of its operation within the range of maximum efficiency and minimal emissions, and allows for energy recuperation during flight [38,43].

Figure 3.

Series hybrid-electric architecture (based on [44]).

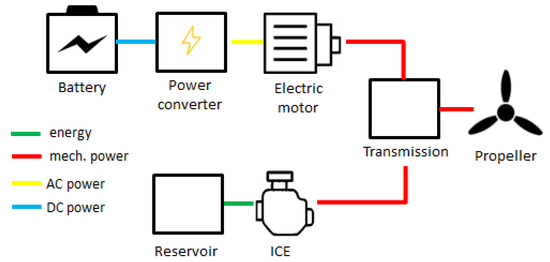

In a parallel configuration (Figure 4), both the combustion engine and the electric motor can drive the propeller simultaneously. This solution allows for flexible use of both energy sources depending on the flight phase: the electric motor can support take-off and climb, while the combustion engine operates during cruise, where it achieves its highest efficiency. This type of propulsion also enables an immediate switch to fully electric operation in the event of combustion engine failure, thereby enhancing operational safety [38,43]. According to researches, parallel hybrid-electric architecture can improve ascent performance up to 56% and decrease the fuel consumption by 6% [41].

Figure 4.

Parallel hybrid-electric architecture (based on [44]).

Series-parallel hybrids (Figure 5) combine the advantages of both previous configurations. The combustion engine can either drive the propeller directly or generate electrical energy for the electric motors. This allows for maximum operational flexibility and the possibility to optimize engine performance in different flight phases, which is particularly important in ultralight and light training aircraft, where safety and cost-efficiency are top priorities [38,43].

Figure 5.

Series-parallel (mixed) hybrid-electric architecture (based on [44]).

In practice, the implementation of hybrid propulsion systems requires careful integration of all components. Research has highlighted the necessity of conducting a detailed reliability analysis to ensure the safe operation of the system in flight [38].

7. Emissions from Alternative Aviation Fuels

Emissions from aircraft engines are a significant area of research in reducing the environmental impact of air transport. Consequently, there is growing interest in low-carbon fuels that can replace conventional aviation fuels, helping to reduce greenhouse gas emissions and local pollutants. The aim of scientific research in this field is to identify fuels with the greatest ecological potential, while ensuring both energy efficiency and operational safety.

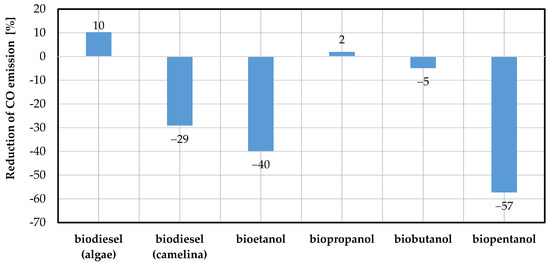

Figure 6 presents the reduction of carbon monoxide (CO) emissions for various biofuels compared with diesel fuel and gasoline. It can be observed that algal biodiesel results in about a 10% reduction in emissions, while camelina biodiesel leads to a 29% increase [17]. Even higher increases were recorded for alcohols: bioethanol—40%, biopentanol—57%, and to a lesser extent biobutanol—5%. Only biopropanol shows a slight reduction in carbon monoxide emissions, at around 2% [19].

Figure 6.

Reduction In CO emission from various biofuels compared to diesel and gasoline [17,19].

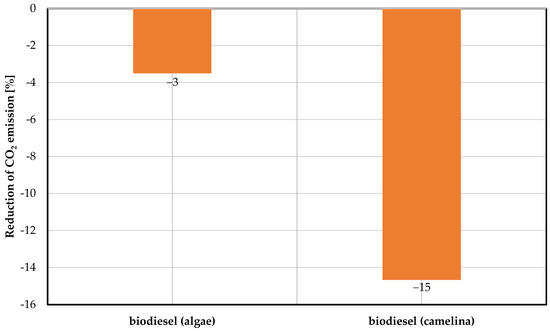

Figure 7 shows the changes in carbon dioxide (CO2) emissions from two types of biodiesel compared with diesel fuel. The results are rather unfavorable: algal biodiesel causes a 3% increase in emissions, while camelina biodiesel results in a 15% increase [17].

Figure 7.

Reduction in emission of CO2 from biodiesel compared to diesel [17].

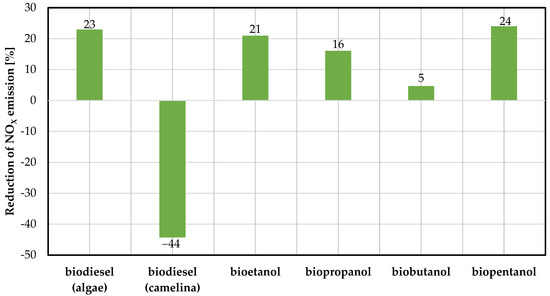

Figure 8 presents the reduction of nitrogen oxides (NOx) emissions for various biofuels compared with conventional fuels. The greatest improvements were observed for algal biodiesel (23%) and bioethanol (21%) [17,19]. Biopropanol and biopentanol showed reductions of 16% and 24%, respectively [19,26]. In contrast, camelina biodiesel led to a 44% increase in NOx emissions [17].

Figure 8.

Reduction of NOx emission from various biofuels compared to diesel and gasoline [17,19,26].

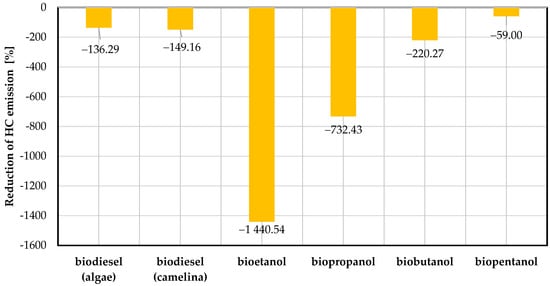

In the case of hydrocarbon (HC) emission reduction (Figure 9), the results clearly indicate highly unfavorable effects of using biofuels in this regard. For algal and camelina biodiesel, HC emissions increase by 136% and 149%, respectively, while for alcohols the values are even higher: bioethanol—1440%, biopropanol—732%, biobutanol—220%, and biopentanol—590% [17,19,26].

Figure 9.

Reduction In HC emission from various biofuels compared to diesel and gasoline [17,19,26].

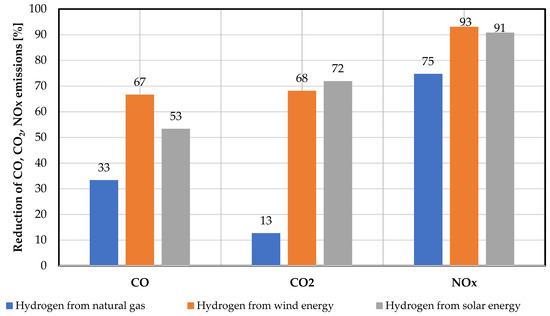

Figure 10 presents the reduction of carbon monoxide (CO), carbon dioxide (CO2), and nitrogen oxides (NOx) emissions when using hydrogen produced from various sources, compared with gasoline. Hydrogen produced from natural gas allows for a Reduction In CO by 33%, CO2 by 13%, and NOx by 75% [38]. Even more favorable results were obtained for hydrogen from renewable energy sources. For wind-derived hydrogen, the reductions are 67% for CO, 68% for CO2, and 93% for NOx, while for solar-derived hydrogen, the reductions are 53%, 72%, and 91%, respectively [38].

Figure 10.

Reduction in gaseous compounds emissions from different feedstock Hydrogen compared to gasoline [38].

8. The Alternative Fuel Market for General Aviation

In the face of increasing pressure to reduce greenhouse gas emissions, biofuels for piston aviation engines are becoming an important element of general aviation decarbonization strategies. Their development enables not only a reduction in CO2 emissions but also a decrease in other gaseous pollutants and particulate matter.

Biodiesel is one of the most widely used biofuels in general aviation. Produced mainly from vegetable oils or animal fats, it can be used in piston engines either in pure form or blended with conventional diesel fuel. World Energy is a leader in biodiesel production, manufacturing over 200 million gallons annually, with a portion allocated for aviation use [45].

In general aviation, bioethanol is primarily used in blends with conventional fuel, enabling the reduction in harmful emissions. LanzaJet, a company specializing in ethanol-to-aviation fuel conversion technology, launched its first commercial facility in 2024 in Soperton, Georgia, USA, with a production capacity of 9 million gallons of aviation fuel per year [46].

Cobalt Technologies, in collaboration with Albemarle Corporation and the Naval Air Warfare Center Weapons Division (NAWCWD), is conducting research on converting biobutanol into aviation fuels. Experimental production in Baton Rouge, Louisiana, allowed for the assessment of biobutanol’s potential in aviation applications [47].

In general aviation, unleaded fuels are standard. Many countries have banned the use of leaded fuels, which has contributed to the development of alternative solutions such as UL94 and UL100. Companies, including Shell Aviation, offer unleaded fuels compliant with international standards, suitable for use in a wide range of aircraft [48].

The development of the biofuel market in general aviation faces several key challenges [39]:

- Feedstock availability—increasing competition for feedstocks across different transport sectors affects price stability and biomass availability.

- Production costs—particularly for SAF (Sustainable Aviation Fuels), used in jet engines, biofuel prices are currently at least twice as high as conventional aviation fuels, limiting widespread adoption.

- Regulations—diverse regulations in different regions, such as ReFuelEU Aviation, may restrict the use of agricultural feedstocks and affect market development.

- Infrastructure—the lack of adequate production and distribution facilities for biofuels, especially SAF, requires significant investment.

9. Test Flights

The development of alternative fuels in aviation has extended beyond laboratory and simulation studies. Since the early 21st century, test and demonstration flights have been conducted using biofuels and synthetic fuels in piston-engine aircraft and light experimental designs.

One of the earliest examples of practical biofuel use in general aviation was the Brazilian Embraer EMB-202 Ipanema, which, starting in 2004, regularly operated on bioethanol as its primary fuel. This was the first certified production aircraft powered by ethyl alcohol, widely used in agricultural aviation in South America [49]. In 2008, test flights with a Cessna 152 using ethanol-AVGAS blends were carried out in the United States. The studies demonstrated the aircraft’s safe operation in cruise flight, although differences in fuel consumption and combustion characteristics were noted compared to conventional 100LL AVGAS [50].

In Europe, test flights were also conducted using the synthetic biofuel Zero Petroleum. In 2021, the RAF (Royal Air Force) flew a light Ikarus C42 aircraft entirely powered by synthetic AVGAS SynAvGas, produced from hydrogen and carbon dioxide. This event was widely recognized as a breakthrough example of CO2-neutral fuel technology [51].

In recent years, hydrogen-powered flights have gained increasing significance. Although not directly linked to biofuels, they fall under the broader category of alternative aviation fuels. In 2009, the first crewed flight of the Antares DLR-H2 glider, powered by a hydrogen fuel cell, took place [42]. In 2016, the German company H2FLY’s HY4 aircraft flew using compressed hydrogen, and in 2023, an upgraded version completed its first flight using liquid hydrogen [40]. Also in 2023, ZeroAvia conducted a test flight with a modified Dornier 228 equipped with a hydrogen fuel cell hybrid system, marking the largest hydrogen-powered aircraft to date [41].

These test flights using bioethanol, biodiesel, synthetic fuels, and hydrogen demonstrate that alternative fuels can be successfully applied in piston engines. While many of these experiments were demonstrative in nature, they provided crucial data for the further development of biofuel technologies in aviation.

10. Future Developments in Aviation Fuels

The development of fuels for general aviation is progressing along several key pathways: the elimination of lead from AVGAS, exploration of bio-based and synthetic alternatives, and, over the longer term, the adoption of hydrogen and hybrid propulsion systems [2,3,7,8]. Reducing CO2 emissions and eliminating toxic substances, particularly lead from 100LL fuel, is a central priority, as lead exposure poses significant health risks [2,4]. Unleaded alternatives provide near-term solutions by maintaining required engine performance while removing toxic lead [3,8].

Although some current research investigates alcohol blends and biofuels, these remain largely experimental in piston engines due to technical challenges [5,19,26]. Second- and third-generation biofuels derived from agricultural waste or microorganisms are more promising and represent an important step toward sustainable GA operations [7,30]. For turbine-powered aircraft, SAFs certified under ASTM standards, including alcohol-to-jet fuels, are already in commercial use, but their properties are not fully compatible with piston engines, reinforcing the need for tailored solutions in GA [12,46].

Looking forward, hydrogen- and hybrid-based propulsion technologies are emerging as key avenues for decarbonization. Dual-fuel hydrogen–kerosene engines and hydrogen-electric aircraft demonstrate potential to significantly reduce emissions in GA [11,38,41]. However, high production costs, safety considerations, and insufficient refueling infrastructure remain major barriers to widespread adoption [9,10,39].

The future of GA fuels will depend on the coordinated deployment of unleaded fuels, biofuels, and hydrogen technologies, supported by regulatory frameworks and infrastructure development. Continued investments in SAF production from local waste, experimental hydrogen systems, and hybrid propulsion will be critical for achieving sustainable, low-emission general aviation.

11. Conclusions

The conducted literature review and analysis of research findings indicate that biofuels for piston-engine aircraft hold significant potential as alternative fuels, yet their application still faces technological, economic, and regulatory challenges. Biodiesel stands out with a high cetane number and good lubricating properties, but its use is limited by high viscosity at low temperatures and lower combustion efficiency [18]. Bioethanol and biomethanol offer high octane numbers, which favor operation in high-compression engines, but their hygroscopic nature and operational risks, such as phase separation, restrict their applicability [5,6,17]. Biobutanol and biopropanol, due to higher heating values and stable combustion characteristics, are considered among the most promising fuels [24,26]. Biokerosene, closely resembling conventional aviation kerosene, can serve as a “drop-in” fuel, requiring minimal engine modifications [27,28].

From an emissions perspective, research results are mixed. Some biofuels enable reductions in NOx or CO, as seen with algal biodiesel or bioethanol, while others increase CO2 and HC emissions, challenging their ecological benefits [17,19,26]. Therefore, a key direction for further work involves optimizing combustion processes and developing advanced production technologies for second-, third-, and fourth-generation biofuels.

Beyond biofuels, alternative propulsion technologies are gaining importance. Hydrogen engines and hybrid-electric propulsion systems show great potential in reducing emissions and improving energy efficiency, though their full implementation requires infrastructure development, new certification standards, and cost reductions in production and operation. Test flights using bioethanol, biodiesel, synthetic fuels, and hydrogen demonstrate that practical application of alternative energy sources in aviation is feasible and technically achievable.

In summary, biofuels and other alternative fuels are not yet full substitutes for aviation gasoline but are a crucial component in the transition toward sustainable aviation. Their development, supported by international regulations, technological innovation, and infrastructure investment, could significantly reduce greenhouse gas emissions and local pollutants in the future. In the medium- and long-term perspective, the combination of biofuels, hydrogen propulsion, and hybrid systems defines the pathway for decarbonizing general aviation.

Author Contributions

Conceptualization, P.K.-P., R.J. and A.Z.; methodology, P.K.-P. and R.J.; validation, P.K.-P., R.J. and A.Z.; formal analysis, F.M. and P.K.-P.; investigation, F.M.; resources, F.M.; data curation, F.M. and P.K.-P.; writing—original draft preparation, F.M.; writing—review and editing, P.K.-P.; visualization, P.K.-P. and F.M.; supervision, P.K.-P. and R.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Frazer-Nash Consultancy. Decarbonising General Aviation—Understanding the Carbon Footprint of General Aviation; Frazer-Nash Consultancy: Leatherhead, UK, 2022. [Google Scholar]

- Klemick, H.; Guignet, D.; Bui, L.T.; Shadbegian, R.; Milani, C. Cardiovascular mortality and leaded aviation fuel: Evidence from piston-engine air traffic in North Carolina. Int. J. Environ. Res. Public Health 2022, 19, 5941. [Google Scholar] [CrossRef]

- Bishop, G.J.; Elvers, B. Aviation gasoline (Avgas). In Handbook of Fuels: Energy Sources for Transportation; Wiley: Hoboken, NJ, USA, 2021; pp. 529–531. [Google Scholar]

- Lamas, G.A.; Ujueta, F.; Navas-Acien, A. Lead and cadmium as cardiovascular risk factors: The burden of proof has been met. J. Am. Heart Assoc. 2021, 10, e018692. [Google Scholar] [CrossRef]

- Awad, O.I.; Mamat, R.; Ali, O.M.; Sidik, N.C.; Yusaf, T.; Kadirgama, K.; Kettner, M. Alcohol and ether as alternative fuels in spark ignition engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 2586–2605. [Google Scholar] [CrossRef]

- Bergthorson, J.M.; Thomson, M.J. A review of the combustion and emissions properties of advanced transportation biofuels and their impact on existing and future engines. Renew. Sustain. Energy Rev. 2015, 42, 1393–1417. [Google Scholar] [CrossRef]

- Christian, J.A., II. Feasibility of Second and Third Generation Biofuel in General Aviation: A Research Report and Analysis. McNair Sch. Res. J. 2014, 1, 4. [Google Scholar]

- Kumar, T.; Mohsin, R.; Ghafir, M.F.A.; Kumar, I.; Wash, A.M. Review of alternative fuel initiatives for leaded aviation gasoline (AVGAS) replacement. Chem. Eng. Trans. 2018, 63, 175–180. [Google Scholar]

- EASA; FAA; UK CAA. H2 Certification Roadmap; EASA: Cologne, Germany, 2024. [Google Scholar]

- IATA. Hydrogen for Aviation: A Future Decarbonization Solution for Air Travel? IATA: Montreal, QC, Canada, 2025. [Google Scholar]

- Reitmayr, C.; Hofmann, P. Strategies to increase hydrogen energy share of a dual-fuel hydrogen–kerosene engine for sustainable general aviation. Hydrogen 2025, 6, 17. [Google Scholar] [CrossRef]

- ASTM D7566-2018; Standard Specification for Aviation Turbine Fuels Containing Synthesized Hydrocarbons. ASTM International: West Conshohocken, PA, USA, 2018.

- D910-17a; Standard Specification for Leaded Aviation Gasolines. ASTM International: West Conshohocken, PA, USA, 2017.

- U.S. Environmental Protection Agency (EPA), Office of Research and Development, National Center for Environmental Assessment. Integrated Science Assessment for Lead; Research Triangle Park, NC, USA. 2013; EPA/600/R-10/075F.; US Environmental Protection Agency: Washington, DC, USA, 2013. [Google Scholar]

- Navas-Acien, A. Lead and Cardiovascular Mortality: Evidence Supports Lead as an Independent Cardiovascular Risk Factor; NCEE Working Paper 2021-03; US Environmental Protection Agency: Washington, DC, USA, 2021. [Google Scholar]

- Ziulkowski, D.J. Collective Knowledge on Aviation Gasolines; College of Technology Directed Projects; Paper 43; Purdue University: West Lafayette, IN, USA, 2011. [Google Scholar]

- Groenewegen, J.R.; Sidhu, S.; Hoke, J.; Wilson, C.; Litke, P. The performance and emissions effects of utilizing heavy fuels and algae-based biodiesel in a port-fuel-injected small spark ignition internal combustion engine. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July—3 August 2011; p. 5807. [Google Scholar]

- Liu, R.; Zhao, W.; Wang, Z.; Liu, X. Investigation on performance and combustion of compression ignition aviation piston engine burning biodiesel and diesel. Aircr. Eng. Aerosp. Technol. 2021, 93, 384–393. [Google Scholar] [CrossRef]

- Qian, Y.; Chen, F.; Zhang, Y.; Tao, W.; Han, D.; Lu, X. Combustion and regulated/unregulated emissions of a direct injection spark ignition engine fueled with C3–C5 alcohol/gasoline surrogate blends. Energy 2019, 174, 779–791. [Google Scholar] [CrossRef]

- Frank, D.; Neubauer, G.; Bauer, C.; Kallo, J.; Willich, C. Exhaust emission measurements from a spark-ignition engine using fuels with different ethanol content for aircraft applications. ACS Omega 2022, 7, 29923–29933. [Google Scholar] [CrossRef]

- Merkisz, J.; Pielecha, I. Alternatywne Paliwa i Układy Napędowe Pojazdów; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 2004. [Google Scholar]

- Chen, L.; Mohsin, R.; Xiao, J. Combustion analysis of an aviation compression ignition engine burning pentanol–kerosene blends under different injection timings. Energy Fuels 2017, 31, 9429–9437. [Google Scholar] [CrossRef]

- Da Silva Trindade, W.R.; dos Santos, R.G. Review on the characteristics of butanol, its production and use as fuel in internal combustion engines. Renew. Sustain. Energy Rev. 2017, 69, 642–651. [Google Scholar] [CrossRef]

- Han, X.; Yang, Z.; Wang, M.; Tjong, J.; Zheng, M. Clean combustion of n-butanol as a next generation biofuel for diesel engines. Appl. Energy 2017, 198, 347–359. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y.; Liu, D. Bio-butanol as a new generation of clean alternative fuel for SI and CI engines. Renew. Energy 2020, 147, 2494–2521. [Google Scholar] [CrossRef]

- Liu, G.; Ruan, C.; Li, Z.; Huang, G.; Zhou, Q.; Qian, Y.; Lu, X. Investigation of engine performance for alcohol/kerosene blends as in spark-ignition aviation piston engine. Appl. Energy 2020, 268, 114959. [Google Scholar] [CrossRef]

- Koistinen, K.; Upham, P.; Bögel, P. Stakeholder signalling and strategic niche management: The case of aviation biokerosene. J. Clean. Prod. 2019, 225, 72–81. [Google Scholar] [CrossRef]

- Liu, J.; Robles Molina, E.; Mosier, N.S. Sustainable biokerosene from lipids using efficient ozone cracking. Biofuel Res. J. 2025, 12, 2412–2431. [Google Scholar] [CrossRef]

- Jerzak, W.; Wądrzyk, M.; Sieradzka, M.; Magdziarz, A. Valorisation of tyre waste from a vulcanisation plant by catalytic pyrolysis–Experimental investigations using pyrolysis–gas chromatography–mass spectrometry and drop-tube–fixed-bed reactor. Energy Convers. Manag. 2024, 313, 118642. [Google Scholar] [CrossRef]

- Kurzawska-Pietrowicz, P.; Jasiński, R. A review of alternative aviation fuels. Energies 2024, 17, 3890. [Google Scholar] [CrossRef]

- Chen, L.; Hu, X.; Wang, J.; Yu, Y. Impacts of alternative fuels on morphological and nanostructural characteristics of soot emissions from an aviation piston engine. Environ. Sci. Technol. 2019, 53, 4667–4674. [Google Scholar] [CrossRef]

- Song, L.; Liu, T.; Fu, W.; Lin, Q. Experimental study on spray characteristics of ethanol–aviation kerosene blended fuel with a high-pressure common-rail injection system. J. Energy Inst. 2018, 91, 203–213. [Google Scholar] [CrossRef]

- Shaigani, P.; Awad, D.; Redai, V.; Fuchs, M.; Haack, M.; Mehlmer, N.; Brueck, T. Oleaginous yeasts- substrate preference and lipid productivity: A view on the performance of microbial lipid producers. Microb. Cell Factories 2021, 20, 220. [Google Scholar] [CrossRef] [PubMed]

- Segers, B.; Nimmegeers, P.; Spiller, M.; Tofani, G.; Jasiukaitytė-Grojzdek, E.; Dace, E.; Kikas, T.; Marchetti, J.M.; Rajić, M.; Yildiz, G.; et al. Lignocellulosic biomass valorisation: A review of feedstocks, processes and potential value chains and their implications for the decision-making process. RSC Sustain. 2024, 2, 3730–3749. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Sun, P.; Peng, C. A review on renewable energy: Conversion and utilization of biomass. Smart Mol. 2024, 2, e20240019. [Google Scholar] [CrossRef]

- Matouk, A.M.; Abu-Elreesh, G.M.; Abdel-Rahman, M.A.; Desouky, S.E.; Hashem, A.H. Response surface methodology and repeated-batch fermentation strategies for enhancing lipid production from marine oleaginous Candida parapsilosis Y19 using orange peel waste. Microb. Cell Factories 2025, 24, 16. [Google Scholar] [CrossRef]

- Cessna. Strong Warning Against Use of Ethanol in Fuels. General Aviation News, 6 July 2010. Available online: https://generalaviationnews.com/2010/07/06/cessna-issues-strong-warning-against-use-of-ethanol-in-fuels/ (accessed on 19 August 2025).

- Donateo, T.; Bonatesta, A.G.; Ficarella, A.; Lecce, L. Energy consumption and saved emissions of a hydrogen power system for ultralight aviation: A case study. Energies 2024, 17, 3272. [Google Scholar] [CrossRef]

- International Chamber of Shipping. Aviation Faces Capital and Infrastructure Challenges for Future Fuels. Available online: https://www.ics-shipping.org/news-item/aviation-faces-capital-and-infrastructure-challenges-for-future-fuels/ (accessed on 24 August 2025).

- H2FLY. H2FLY and Partners Complete World’s First Piloted Flight of Liquid-Hydrogen-Powered Electric Aircraft. Available online: https://www.h2fly.de/2023/09/07/h2fly-and-partners-complete-worlds-first-piloted-flight-of-liquid-hydrogen-powered-electric-aircraft/ (accessed on 24 August 2025).

- ZeroAvia. Dornier 228 Hydrogen-Electric First Flight. Available online: https://zeroavia.com/do228-first-flight/ (accessed on 24 August 2025).

- DLR. Antares DLR-H2 Fuel-Cell-Powered Aircraft (Image Page). Available online: https://www.dlr.de/en/images/2013/2/antares-dlr-h2-fuel-cell-powered-aircraft_9601 (accessed on 24 August 2025).

- Donateo, T.; Spada Chiodo, L. Design and reliability analysis of a series/parallel hybrid system with a rotary engine for safer ultralight aviation. Appl. Sci. 2023, 13, 4155. [Google Scholar] [CrossRef]

- Gaspari, F.; Trainelli, L.; Rolando, A.; Perkon, I. Concept of Modular Architecture for Hybrid Electric Propulsion of Aircraft; MAHEPA: Ajdovščina, Slovenia, 2017. [Google Scholar]

- Fortune Business Insights. Top Aviation Fuel Companies. Available online: https://www.fortunebusinessinsights.com/blog/top-aviation-fuel-companies-10714 (accessed on 24 August 2025).

- U.S. Department of Energy, Bioenergy Technologies Office. World’s First Ethanol-to-Jet Fuel Plant Paves Way for Commercial Production of SAF. Available online: https://www.energy.gov/eere/bioenergy/articles/worlds-first-ethanol-jet-fuel-plant-paves-way-commercial-production-saf (accessed on 24 August 2025).

- Advanced Biofuels USA. Cobalt and the Naval Air Warfare Center Team Up to Produce a Renewable Jet Fuel from Bio-n-Butanol. Available online: https://advancedbiofuelsusa.info/cobalt-and-the-naval-air-warfare-center-team-up-to-produce-a-renewable-jet-fuel-from-bio-n-butanol (accessed on 24 August 2025).

- Shell Aviation. Aviation Fuel. Available online: https://www.shell.com/business-customers/aviation/aviation-fuel.html (accessed on 24 August 2025).

- Simple Flying. Embraer Ipanema Aircraft Guide. Available online: https://simpleflying.com/embraer-ipanema-aircraft-guide/ (accessed on 24 August 2025).

- Compton, T.J. Flight Performance Testing of Ethanol/100LL Fuel Blends During Cruise Flight. Ph.D. Thesis, Baylor University, Waco, TX, USA, 2008. [Google Scholar]

- CHIP. Lot na Syntetycznym Paliwie RAF. Available online: https://www.chip.pl/2021/11/lot-na-syntetycznym-paliwie-raf (accessed on 20 August 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).