Abstract

Directive (EU) 2024/3019 on urban wastewater treatment requires municipal wastewater treatment plants (WWTPs) to achieve energy neutrality by 2045. This study assessed the energy efficiency of a WWTP in central Poland over eight years (2015–2022), considering influent variability, electricity use and cost, and biogas recovery. The facility served 41,951–44,506 inhabitants, with treated wastewater volumes of 3.08–3.93 million m3/year and a real population equivalent (PE) of 86,602–220,459. Over the study period, the specific energy demand remained stable at 0.92–1.20 kWh/m3 (average 1.04 ± 0.09 kWh/m3), equivalent to 17.4–36.3 kWh/PE∙year. Energy efficiency indicators (EEIs) per pollutant load removed averaged 1.12 ± 0.28 kWh/kgBODrem, 0.53 ± 0.12 kWh/kgCODrem, 1.18 ± 0.36 kWh/kgTSSrem, 12.1 ± 1.5 kWh/kgTNrem, and 62.3 ± 11.7 kWh/kgTPrem. EEI per cubic meter of treated wastewater proved to be the most reliable metric for predicting energy demand under variable influent conditions. Electricity costs represented 4.48–13.92% of the total treatment costs, whereas co-generation from sludge-derived biogas covered 18.1–68.4% (average 40.8 ± 13.8%) of the total electricity demand. Recommended pathways to energy neutrality include co-digestion with external substrates, improving anaerobic digestion efficiency, integrating photovoltaics, and optimizing electricity use. Despite fluctuations in influent quality and load, the ultimate effluent quality consistently complied with legal requirements, except for isolated cases of exceeded phosphorus levels.

1. Introduction

It is estimated that WWTPs account for approximately 1% of the total national electricity consumption in EU Member States [1]. At the same time, the overall electricity consumption by WWTPs in Europe is about 27 TWh/year [2]. In Poland, municipal WWTPs consume approximately 1.4 TWh/year of electricity [3]. Achieving the required high efficiency of pollutant removal necessitates the use of an increasing number of devices, which in turn leads to higher energy consumption in individual processes. This energy is derived predominantly from non-renewable sources, and its production contributes to atmospheric pollution. For this reason, reducing the energy intensity of wastewater treatment processes and increasing the share of renewable energy sources is of critical importance [4].

Several energy efficiency indicators (EEIs) are applied in WWTPs today. However, they often lack consistent interpretability, which complicates cross-facility comparisons. Based on literature review and data resolution, three key categories of EEIs can be defined: those based on treated wastewater quantity (EEIQ), population equivalent (EEIPE), and removed pollutant load (EEIL). The EEIL typically refers to organic matter expressed as biochemical oxygen demand over 5 days (BOD) and chemical oxygen demand (COD) [1,3,4]. Currently, the most commonly used indicators are EEIQ and EEIPE, referenced to the average annual quantity and quality of wastewater. The EEIQ is mostly used to compare WWTPs fed with influents of similar composition, whereas EEIPE enables broader comparisons across different wastewater types (municipal, industrial, domestic). While EEIPE usually focuses on organic matter removal, it can also be applied for nitrogen and phosphorus removal, provided that PEs are recalculated from unit nutrient loads. However, PE conversion factors vary across countries [1]. The EEIPE takes no account of treatment effectiveness, which makes it less precise in estimating pollutant-specific energy costs. Instead, it primarily informs about the annual energy consumed per PE served. In contrast, EEIL, which allows for computing energy demand per unit of pollutant removed, appears to be a more accurate and outcome-focused indicator—relevant in both organic matter and nutrient removal. However, this approach requires precise quantitative and qualitative measurements of wastewater, which increases the costs and labor-intensiveness of such calculations. Additionally, use of chemical dosing and precipitation for pollutant removal—whether before the main treatment process (e.g., in primary clarifiers) or after biological treatment—may bias obtained values. This is because dosing of agents such as polyelectrolytes for suspended solids removal or chemical phosphorus precipitation increases chemical consumption and the amount of chemical sludge produced, but only minimally affects the electricity demand of treatment processes [5,6]. For this reason, EEIL should relate specifically to processes where electrical energy plays a key role.

The published literature data on electricity consumption in WWTPs worldwide demonstrates substantial variability and lacks consistency. Numerous authors have provided literature-based syntheses, enabling comparative assessments across a wide range of facilities [1,7,8,9,10]. Their findings indicate that WWTP energy consumption depends on, among other things, influent quality and quantity, facility size, process technology applied, commissioning or modernization year (affecting equipment and automation level). A general trend observed is that larger WWTPs (serving higher PE) exhibit a lower unit energy demand [1,10]. Recent advances, including energy-efficient technologies and automation, have also enabled modern WWTPs to achieve lower energy consumption levels. WWTP energy demand across regions is also substantially affected by electricity prices, which, when high, encourage efficiency measures [1] and demand regulatory frameworks to be met.

The adoption of instruments such as the European Union Urban Wastewater Treatment Directive 91/271/EEC [11] or the United States Clean Water Act [12] has enabled significant advances in wastewater treatment technologies worldwide. More recently, Directive (EU) 2024/3019 [13] requires WWTPs serving at least 10,000 PE to achieve energy neutrality by 2045. This goal implies that their own energy demand must be fully covered through renewable sources. The Directive explicitly promotes biogas utilization and wastewater heat recovery, fostering the integration of energy-efficient and climate-neutral processes. Achieving such neutrality, however, requires thorough analyses of current WWTP energy balances.

So far, most reported EEIs have been presented as average annual values expressed per cubic meter or per population equivalent, typically calculated for a single year. However, variability of EEIs within a given facility over multiple years remains unexplored. There is a lack of information on how the quantity and quality of influent wastewater affect the energy demand of a particular WWTP, which generally operates with a specific, usually stable, technological setup and equipment. This is important, as the obtained EEI values can be strongly dependent on the timing of the energy audit for a given facility, and may vary considerably—not due to the actual energy efficiency of treatment processes, but rather as a result of temporary fluctuations in influent quantity and quality. Moreover, there is still a lack of literature data concerning specific energy consumption per kg of removed nitrogen or phosphorus. Equally important are actual treatment costs and the contribution of electricity expenditures. Therefore, the objectives of this study were to (1) characterize influent quantity and quality, including long-term PE fluctuations during 2015–2022; (2) analyze the impact of these variations on EEIs; (3) quantify electricity consumption in a municipal wastewater treatment; (4) determine actual treatment costs and the share of electricity costs; (5) evaluate the potential for biogas-based energy recovery from sewage sludge; and (6) assess the treatment efficiency of the mechanical and biological stages. The research was conducted at a municipal WWTP utilizing the University of Cape Town (UCT)-activated sludge process, which is recognized as an advanced method for nutrient removal and an energy-efficient configuration, making it particularly relevant in the context of analyzing energy demand and costs in municipal wastewater treatment plants.

2. Materials and Methods

Figure 1 presents experimental design of this study, which analyzed the operation of a municipal WWTP over the period of 2015–2022. The research included the assessment of influent and effluent quantity and quality, the evaluation of electricity consumption using EEIs, and the analysis of treatment costs based on operational data provided by the WWTP operator. The facility, located in central Poland, employs an activated sludge treatment system configured as a UCT process. It receives wastewater from municipal collectors as well as septage delivered by vacuum trucks to a designated receiving station. This septage originates from sealed tanks and septic systems associated with domestic wastewater treatment plants. In addition to municipal wastewater, the WWTP also accepts industrial wastewater, and to some extent, stormwater and snowmelt from a combined sewerage system as well as infiltration from the sanitary sewerage network. The treated effluent is discharged into a river. The actual PE during the analyzed period ranged from 220,459 to 86,602, and the flow of treated wastewater ranged from 3,930,268 to 3,083,863 m3/year (the table in Section 3.1). All wastewater treatment processes are automated and monitored through a Supervisory Control and Data Acquisition (SCADA) system. Any operational disturbances are visualized in the Main Control Room and the Thermal Sludge Utilization Plant Control Room, ensuring continuous supervision and immediate response to irregularities. A simplified technological scheme with marked sampling points is presented in Figure S1. The total installed power of the treatment system amounts to 767.05 kW (216.05 kW for the mechanical treatment stage and 551.00 kW for the biological treatment stage).

Figure 1.

Block diagram of the conducted research.

2.1. Mechanical Treatment Stage

The mechanical treatment line consists of a bar screen with 34 mm spacing and a washer–compactor (5.5 kW); a pumping station equipped with four screw pumps (Qmin = 0.151 m3/s, Qmax = 0.330 m3/s, 18.5/28.0 kW each); and three coarse screens with 3 mm spacing (2.2 kW each). Fractions separated on both types of screens, after screw press processing (Q = 1.0–1.5 m3/h, 4.5 kW), are sanitized and transported off-site. The flow continues into two grit chambers (Q = 925 m3/h, V = 300 m3, 5.3 kW each), equipped with aeration systems supplied by two blowers (Q = 200 m3/h, 11.0 kW each). The separated mineral fraction is transferred to a sand separator (Q = 1.5 t/h, 1.65 kW), after which the sand is deposited in containers and managed off-site. The final step of the pre-treatment entails two primary clarifiers (Vmin = 540 m3, Vmax = 596 m3, 2.2 kW each). This section also included a supernatant pumping station (Q = 42.8 m3/h, H = 4.3 m H2O, 6.0 kW). The mechanical stage is separated from the biological stage by an intermediate pumping station (Q = 624 m3/h, H = 6.3 m H2O, 45 kW) that conveys wastewater to a distribution chamber (V = 106 m3), which divides the flux into three parallel trains leading to the UCT biological reactors (Figure S1).

2.2. Biological Treatment Stage

The activated sludge reactors enable nitrification, denitrification, and enhanced biological phosphorus removal. The total volume of the activated sludge chambers is 13,920 m3, and the system consists of dedicated compartments for dephosphatation, nitrification, denitrification, and mixing. In total, 18 mixers of 3.0 kW each and 3 mixers of 7.5 kW each are installed, supported by 12 pumps of 7.5 kW each. Oxygen supply to the aerobic compartments is provided by fine-bubble aeration systems consisting of plate diffusers mounted on the tank floors. Aeration is delivered by four blowers installed in the blower hall: two centrifugal blowers (110 kW each, Q = 2500–6500 Nm3/h) and two rotary blowers (69.5 kW each, Q = 2800 Nm3/h). The dissolved oxygen concentration in the nitrification chambers is maintained at 2.0 ± 0.5 mgO2/L. Following the biological treatment, wastewater flows into six secondary clarifiers (two per biological reactor, V = 4560 m3 each). This section also includes a pumping system for floating materials separated in the secondary clarifiers (Q = 5–20 m3/h, 3.0 kW) (Figure S1).

2.3. Sludge Treatment System

Primary sludge from the clarifiers is directed to a gravity thickener, with supernatant recycled upstream of the primary clarifiers. Waste-activated sludge, after polymer addition, is mechanically thickened in decanter centrifuges to a dry solids content of about 5–6%. The thickened primary sludge, excess sludge, as well as fats collected in the grit chamber and primary clarifiers are conveyed to the sludge digestion facility. The WWTP operates based on two closed anaerobic digesters with an active volume of 2000 m3 each, where mesophilic anaerobic digestion takes place at 37–38 °C with a retention time of 28–30 days. After digestion, sludge is mechanically dewatered by centrifuges, stabilized with quicklime, and then applied for agricultural use off-site.

The biogas generated (59–66% CH4, 33–40% CO2, 0.002–0.007% H2S, and trace amounts of N2 and O2; heating value 22.5–23.5 MJ/m3) is dried, desulfurized, and subsequently used in a cogeneration unit (HE-SEC-500/547-LG500-B, Horus-Energia Sp. z o.o., Sulejówek, Poland, 2013) to produce both electricity and heat. Excess biogas is stored in a dedicated gas holder. The recovered heat is utilized for digester heating, building heating, and staff facilities. Electricity generated from biogas, combined with power imported from the grid, meets the plant’s overall electricity demand. Temporary electricity surpluses are exported to the national grid (Figure S2).

2.4. Physicochemical Analyses and Measurements

Physicochemical analyses of raw, mechanically treated, and biologically treated wastewater were performed by an accredited laboratory as part of statutory monitoring. Parameters analyzed included biochemical oxygen demand (BOD, ISO standard PN-EN 1899-2:2002 [14]), chemical oxygen demand (COD, PN-ISO 15705:2005 [15]), total suspended solids (TSS, PN-EN/872:2007+Ap1:2007 [16]), total nitrogen (TN, PN-73/C-04576/14 [17]), and total phosphorus (TP, PN-EN ISO 6878:2006 p.8 + Ap1:2010 + Ap2:2010 [18]). Sampling frequency was approximately once per week (2015–2021) and once every two weeks (2022). Wastewater samples were collected for analyses before the bar screen (raw wastewater), from the distribution chamber (mechanically treated wastewater), and from the secondary clarifier effluent (treated wastewater discharged to the river).

The actual PE was calculated based on Equation (1) [1]:

where ADWF is the average wastewater flow (m3/year), CBOD5 is the annual mean BOD5 concentration (g O2/m3), and 60 g BOD5/PE is the adopted unit load.

Electric energy indicators (EEIs) were determined according to Equations (2)–(4) [1]:

The wastewater volume was determined using continuous flow measurements at the effluent discharge to the river, obtained from a stationary flowmeter OCM Pro CF, model OCP-M3W0INA30 (Nivus Sp. z o.o., Gdynia, Poland, 2020).

The volume of sludge intended for the final management was calculated based on the quantity of waste transferred for agricultural utilization after anaerobic digestion.

Electricity consumption was determined from utility bills for grid-purchased electricity, meter readings from the main transformer station of the WWTP, and electricity generation records from the co-generation unit, measured by an electricity meter located in the thermal sludge utilization plant switchboard.

3. Results and Discussion

The analyzed facility represents a municipal WWTP operating based on the activated sludge process, performing both wastewater treatment and sewage sludge management through anaerobic methane fermentation. The assessment of pollutant removal efficiency, electricity consumption and generation, as well as treatment costs, was carried out over eight years and included 1143 wastewater samples (381 samples of raw wastewater, 381 samples of mechanically treated wastewater, and 381 samples of treated effluent). This provided the baseline data necessary for evaluating the potential to achieve energy neutrality in this type of facility.

3.1. Wastewater Flow and PE

The results obtained demonstrate high stability and flexibility of the analyzed system, which enabled the required treatment efficiency to be maintained under variable influent quantity and quality. Table 1 presents the wastewater flow and actual PE, calculated using Equation (1).

Table 1.

Wastewater flow and actual PE in 2015–2022.

Although the number of inhabitants remained relatively constant throughout 2015–2022, both the treated wastewater volume and the actual PE showed a distinct downward trend. PE represents the pollution load equivalent of wastewater, expressed relative to the unit organic load typically generated per person per day. Conventionally, this is assumed to be 60 g BOD5 per capita. PE proves useful in comparing WWTPs that treat mixed wastewater, with variable contributions from households, industries, and services [19]. The highest PE was noted in 2019, with the subsequent years showing a marked decline. Since the number of inhabitants did not decrease significantly (Table 1), the PE drop cannot be attributed to urban depopulation. Rather, it was likely driven by reduced industrial wastewater inflow. In 2019, a total of 3,745,319 m3 of wastewater was treated, compared to 3,083,863 m3 in 2022—a decrease of 18%. Correspondingly, BOD load also showed a decline (Table 2), reflecting lower discharges from the local brewery and a change in the production profile at the local dairy industry, which were the main sources of industrial wastewater.

Table 2.

Quality of raw (I), mechanically treated (II), and biologically treated (III) wastewater over the study period (mean ± SD; min–max; n = number of samples per category).

3.2. Efficiency of Removal of Organic Matter and Suspended Solids

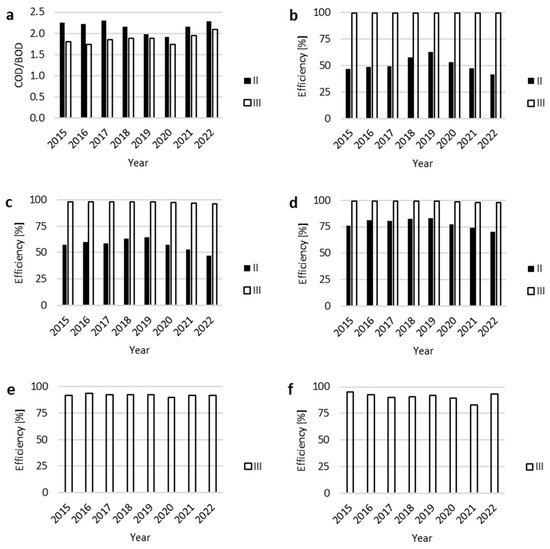

The characteristics of raw wastewater significantly affect treatment processes and, consequently, electricity consumption in WWTPs [20]. The analyzed wastewater exhibited large variations in both instantaneous and annual average quality parameters. Influent BOD ranged from 320 to 3370 mgO2/L, COD from 775 to 5452 mgO2/L, TSS from 60 to 3990 mg/L, TN from 61 to 156 mg N/L, and TP from 6 to 43 mg P/L (Table 2). The COD/BOD ratio is an important indicator of biodegradability, reflecting the proportion of organic compounds readily biodegraded compared to those requiring chemical oxidation or advanced treatment. Despite the high variability in influent composition over the study period, the wastewater could be classified as readily biodegradable, with COD/BOD ratios of 1.9–2.3 (Figure 2a) [21]. This ratio enabled a high efficiency of organic matter removal via activated sludge treatment and ensured sufficient biodegradable organic carbon to support biological denitrification and phosphorus removal without the need for external carbon supplementation [22,23].

Figure 2.

COD/BOD ratio (a) and pollutant removal efficiencies of BOD (b), COD (c), TSS (d), TN (e), and TP (f) after mechanical (II) and biological (III) treatment compared to raw wastewater.

TSS represents the total concentration of suspended and floating solids, including both organic and inorganic particles. Inorganic solids are largely removed in the early stages of treatment (grit chambers and primary clarifiers). In this facility, organic suspended solids are desirable due to the integrated removal of nitrogen and phosphorus, as they provide carbon essential for maintaining appropriate C:N:P ratios. In contrast, excessive organic matter retention in grit chambers could hinder the management of separated sand.

The mechanical treatment (screens, aerated grit chambers, primary clarifiers) achieved removal efficiencies of 42–63% for BOD, 47–64% for COD, and 70–83% for TSS (Figure 2b–d), which is consistent with values recorded for typical municipal WWTPs [24]. The COD/BOD ratio decreased only slightly to 1.7–2.1 after primary treatment (Figure 2a). The subsequent biological treatment delivered high efficiency and ensured compliance with effluent standards despite influent variability. Annual average effluent concentrations were 3.63–7.03 mgO2/L (BOD), 42.6–62.4 mgO2/L (COD), and 7.7–15.7 mg/L (TSS) (Table 2), all below legal thresholds (BOD < 15 mg/L, COD < 125 mg/L, TSS < 35 mg/L) [25]. The low TSS in the final effluent indicated no secondary contamination from activated sludge flocs, confirming both proper secondary clarifier performance and good sludge settleability.

3.3. Efficiency of Nitrogen Removal

The UCT reactor is designed for integrated carbon, nitrogen, and phosphorus removal via sequential passage through dedicated zones with different oxygen conditions [26]. Nitrogen removal begins with nitrification, where organic nitrogen and ammonium are oxidized under aerobic conditions by nitrifying microorganisms [27]. Aeration of activated sludge reactors usually represents the most energy-intensive unit process [3]. In this WWTP, two rotary blowers (2 × 69.5 kW) and two centrifugal blowers (2 × 110 kW) ensured sufficient oxygen supply. However, prior to 2015, only one centrifugal blower was in operation, and it did not provide adequate oxygen under high loading conditions. In May 2020, a blower failure led to insufficient nitrogen removal, with effluent TN reaching 58.20 mg N/L (Table 2). Following this incident, a second centrifugal blower was installed in 2021, after which effluent quality improved significantly.

Effective nitrification enabled subsequent denitrification under anoxic conditions in the presence of easily biodegradable organics [28]. Over the study period, the adopted configuration ensured a high nitrogen removal efficiency of 89.7–93.4% (Figure 2e), despite influent TN variations of 61–156 mg N/L. The average effluent TN concentration ranged from 6.81 ± 1.57 mg N/L to 9.60 ± 8.40 mg N/L (Table 2), confirming effective ammonification, nitrification, and denitrification. Further technological improvements should focus on optimizing aeration to reduce energy demand for oxygen supply, thereby lowering treatment costs.

3.4. Efficiency of Phosphorus Removal

Phosphorus removal performance was insufficient (Figure 2f). Effluent TP concentrations often failed to meet legal requirements (TP < 1.0 mg P/L) [25]. Average effluent TP ranged from 0.96 ± 0.76 to 2.67 ± 2.06 mg P/L during 2015–2022 (Table 2). Phosphorus was removed solely via biological enhanced phosphorus removal (EBPR). Insufficient EBPR performance likely stemmed from irregular activated sludge functioning. Polyphosphate-accumulating organisms (PAOs), responsible for EBPR, are highly sensitive to operational conditions, including concentrations of dissolved oxygen and nitrates, and the presence of adequate organic substrates [29]. Increasing monitoring of these parameters in activated sludge chambers, as well as responding to changes in real time, could enhance the biological efficiency of phosphorus removal; however, it would involve investment costs and higher operational expenses associated with continuous monitoring. Moreover, maintaining EBPR efficiency requires appropriate management of excess sludge. Achieving the required parameters for effective biological phosphorus removal is particularly challenging when there is large variability in the quality and quantity of incoming raw wastewater, as was the case in this study (Table 1 and Table 2).

Interestingly, TP concentrations determined after the mechanical treatment were often higher than those in raw wastewater (Table 2), likely due to phosphorus release from excess sludge supernatant recycled upstream of the primary clarifiers. To enhance phosphorus removal, many WWTPs implement chemical precipitation with iron or aluminum salts, which should be considered in the analyzed facility [30]. Introducing chemical precipitation may improve phosphorus removal, but it leads to increased production of chemical sludge, which affects the efficiency of anaerobic digestion and may potentially reduce energy recovery from biogas [5,6]. Moreover, this solution increases chemical consumption, while having only a minimal impact on overall energy demand.

3.5. Electricity Demand and Treatment Costs

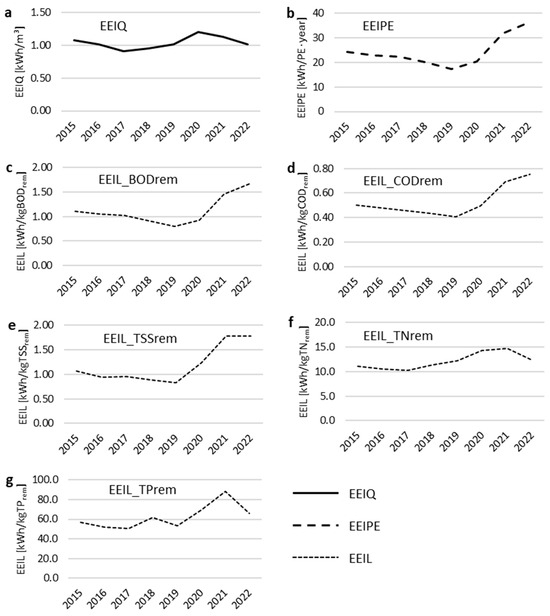

Analysis of EEI changes indicates that EEIQ proved to be the most reliable predictor of electricity demand at the studied WWTP (Figure 3a). Despite considerable variation in raw wastewater characteristics, EEIQ remained relatively stable, ranging from 0.92 to 1.20 kWh/m3, with an average of 1.04 ± 0.09 kWh/m3. This finding suggests that increases in influent volume directly translated into higher electricity demand. According to literature data, EEIQ in Poland ranges from 0.3 to 1.0 kWh/m3, depending on the treatment technology [3]. Wang et al. [7] reported values of 0.13–0.6 kWh/m3 in WWTPs located in the USA, Germany, and China. Likewise, Trapote et al. [31] analyzed 90 Spanish WWTPs and reported values of 0.28–2.52 kWh/m3. Other references cited power consumption between 0.3 and 2.1 kWh/m3 of treated wastewater in the EU and between 0.41 and 0.87 kWh/m3 in the USA, depending on treatment level, facility size, and topography [32,33].

Figure 3.

Changes in EEIs over the study period: EEIQ (a); EEIPE (b); and EEIL for BOD (c), for COD (d), for TSS (e), for TN (f), and for TP (g).

Indicators related to organic matter concentration—namely EEIPE (Figure 3b) and EEIL for BOD (Figure 3c), COD (Figure 3d), and TSS (Figure 3e)—showed similar trends, though with different absolute values. The average specific energy demand was 1.119 ± 0.277 kWh/kgBODrem, 0.528 ± 0.118 kWh/kgCODrem, and 1.184 ± 0.363 kWh/kgTSSrem. This corresponded to per capita annual energy use of 17–36 kWh/PE∙year, with a mean of 24 ± 6 kWh/PE∙year. According to current technology levels, state-of-the-art WWTPs typically consume 20–45 kWh/PE∙year, although older plants may use up to twice this amount [33,34]. Vaccari et al. [10] reported that specific electricity demand per PE depended strongly on WWTP size, reaching 23 kWh/PE∙year for plants with capacity >100,000 PE; 42 kWh/PE∙year for plants serving 10,000–100,000 PE; 48 kWh/PE∙year for 2000–10,000 PE; and 76 kWh/PE∙year for small installations (<2000 PE). When comparing different WWTPs, EEIPE proved to be a better benchmark than EEIQ, mainly because rainfall and infiltration significantly influence wastewater flows. Plants receiving proportionally high infiltration flows may appear artificially more energy-efficient when evaluated on a volumetric basis. In such cases, pollutant-load-based indicators are more reliable. Literature data show that EEIL for COD can vary considerably, reaching 3.01, 1.54, 1.02, 0.82, and 0.69 kWh/kgCODrem, in facilities with capacities ranging from <2000 PE to >100,000 PE [1]. These and other studies consistently confirm that large WWTPs (>100,000 PE) are typically the most energy-efficient [35].

Moreover, Longo et al. [1] compared energy consumption and showed that it differs depending on class size, technology applied, or the country where the analysis is conducted. In terms of technology, energy use was found to be 0.57 kWh/kgCODrem (conventional activated sludge; 31 analyzed facilities), 0.74 kWh/kgCODrem (aerated ponds; 83 facilities), 1.00 kWh/kgCODrem (unspecified secondary treatment; 45 facilities), 1.20 kWh/kgCODrem (biological nutrient removal—of which UCT systems were included in the cited study; 88 facilities), 1.30 kWh/kgCODrem (extended aeration; 73 facilities), and 2.91 kWh/kgCODrem (membrane bioreactor; 8 facilities). The values obtained in this study, ranging from 0.41 to 0.76 kWh/kgCODrem (Figure 3d), classify the analyzed facility as having high energy efficiency.

In contrast, EEIL calculated for TSS is seldom applied as a benchmarking tool, because if suspended solid removal was the sole treatment objective, it could be achieved at minimal energy cost using only sedimentation tanks and filters. In integrated systems, where the primary aim is the combined removal of carbon, nitrogen, and phosphorus, TSS reduction occurs as a secondary effect. Nevertheless, in this study, EEIL was also reported for TSS to provide a basis for future methodological evaluation of its practical usefulness.

The removal of nitrogen and phosphorus required considerably higher energy inputs, averaging 12.14 ± 1.55 kWh/kgTNrem (Figure 3f) and 62.26 ± 11.69 kWh/kgTPrem (Figure 3g). Although EEIL values are frequently reported for organic matter (BOD, COD) in activated sludge systems, they are less commonly presented for TN and TP [4]. Żyłka et al. [3,36] reported EEIL values in sequencing batch reactors at 52.90 kWh/kgTNrem and 141.26 kWh/kgTPrem. Panepinto et al. [37] obtained a value of 14.66 kWh/kgTNrem for a municipal WWTP treating 615,000 m3/day, whereas Chiavola et al. [38] reported only values for ammonium nitrogen removal (5.5–24.5 kWh/kgN-NH3rem). In turn, Lackner et al. [39], based on a survey among operators of 14 full-scale partial nitritation/anammox sequencing batch reactors, obtained EEIL values ranging from 0.8 to 1.92 kWh/kgNrem. These results, however, refer to the treatment of wastewater with high ammonium nitrogen concentration, a low C:N ratio, and elevated temperatures. For similar wastewaters and technology, Wett et al. [40] reported a value of 4.0 kWh/kgNrem.

The presented results and literature data demonstrate how the type of wastewater and the applied technology can generate varying energy demands. This also makes direct comparisons between facilities and the imposition of specific allowable EEI values difficult in practice.

Throughout the study period, sludge production steadily decreased, leading to lower biogas yields and reduced electricity generation. This decline was linked to both smaller wastewater volumes and lower organic loads. As illustrated in Figure 3a, reduced influent volumes corresponded with a lower energy demand, which was consistent with the stable EEIQ value. In 2020, a seven-month co-generation unit failure caused electricity production from biogas to fall to barely 689 MWh, forcing the WWTP to purchase 3120 MWh from the grid.

Despite complete digestion of sewage sludge, the share of biogas-derived electricity in total WWTP demand ranged from 18.1% to 68.4%, with a mean of 40.8 ± 13.8% (Table 3). These figures align with literature values, which indicate that sewage sludge digestion typically supplies 35% [41], 52.2% [42], 64% [43] or up to 74.3% [44] of WWTP electricity demand. Achieving full energy neutrality would therefore require higher biogas output, potentially through co-digestion of sewage sludge with external substrates [43]. This option, however, depends on substrate availability, purchase and transport costs, and post-digestion sludge management, which may pose economic and technical challenges [45,46]. Alternatively, anaerobic digestion efficiency could be enhanced by pretreatment methods, such as sludge disintegration [47]. Another option would be to deploy renewable energy sources, for instance, photovoltaic systems, to further support energy independence [48]. However, this strategy requires significant land area for installation and energy storage systems, which incur additional costs and replacement over time.

Table 3.

Electricity consumption and costs incurred at the studied WWTP (conversion from PLN to USD based on 3.64 PLN/USD rate of exchange).

In 2022, the total electricity consumption was 3147 MWh. Although not the highest in absolute terms, the cost impact was substantial due to exceptionally high electricity prices (Table 4). If all electricity had been purchased from the grid, annual costs would have reached USD 678,606.62 (PLN 2,470,128.10). Owing to biogas-based production, the WWTP saved USD 223,267.80 (PLN 812,694.80). The more than threefold increase in electricity price per MWh in 2022 stemmed from the surge in energy carrier prices, including natural gas, caused by the global geopolitical instability. As of August 2025, electricity purchase prices remain around USD 145.60/MWh (PLN 530/MWh) [49]. Electricity costs and potential savings from achieving energy neutrality have thus become one of the critical investment criteria when upgrading WWTPs [50].

Table 4.

Unit costs of wastewater treatment per m3, pollutant removal, and energy (conversion from PLN to USD based on 3.64 PLN/USD rate of exchange).

Over the study period, the WWTP achieved cumulative savings of USD 814,452.29 (PLN 2,964,606.35) due to the biogas-based power generation. If the facility were capable of producing its entire electricity demand internally, additional savings could amount to USD 1,426,710.95 (PLN 5,193,227.86).

Comparing wastewater treatment costs across regions is inherently difficult, particularly with regard to sewage tariffs, as electricity costs represent only one element of total expenses. The overall cost of treating 1 m3 of wastewater includes transport and collection, chemical and material use, sludge management, infrastructure maintenance, technical and administrative services, and environmental fees associated with effluent discharge [51,52]. At the analyzed facility, the cost of treating 1 m3 of wastewater ranged between USD 1.00 and 1.58 (PLN 3.64–5.75), which corresponded to the unit pollutant removal costs presented in Table 4. These costs are subject to significant variability depending on staff wages, prices of chemicals and energy, and environmental charges.

A much more important parameter is the share of electricity in the total treatment costs. Assuming that all electricity had been purchased from the power grid at the prevailing tariffs of a given period, this share ranged from 4.48% to 13.92% of the total cost of treating 1 m3 of wastewater. The higher the purchase price of 1 MWh, the greater this share became. According to literature data, electricity typically accounts for a larger proportion of the total treatment cost in other regions of the world, i.e., 26.3% as reported by Li et al. [53] for three WWTPs in China, 25–40% based on U.S. studies [54], and 20–40% according to Castellet and Molinos-Senante [55].

4. Conclusions

The presented data demonstrate considerable variability in both the quantity and quality of municipal wastewater at a single WWTP over a relatively short period of only eight years. At the same time, the wastewater exhibited high biodegradability (COD/BOD = 2.2 ± 0.1), including after mechanical treatment (COD/BOD = 1.9 ± 0.1), where removal efficiencies averaged 51 ± 6% for BOD, 58 ± 5% for COD, and 78 ± 4% for TSS. The overall treatment performance ensured final effluent quality compliant with the regulatory standards, i.e., BOD < 15 mg/L, COD < 125 mg/L, TSS < 35 mg/L, and TN < 10 mg/L. Occasional instances of TP concentrations surpassing the limit of 1 mg P/L were observed. The large variability in influent wastewater quality and volume also led to significant fluctuations in EEI values. However, EEI calculated per cubic meter of treated wastewater exhibited the highest stability, as energy consumption changed proportionally with the treated wastewater. For this reason, this indicator appears to be the best choice for determining the energy efficiency of this type of facility and for comparing its values with reference standards. Over the study period, EEIQ averaged 1.04 ± 0.09 kWh/m3, EEIPE 24 ± 6 kWh/PE∙year, and EEIL equaled 1.12 ± 0.28 kWh/kgBODrem, 0.53 ± 0.12 kWh/kgCODrem, 1.18 ± 0.6 kWh/kgTSSrem, 12.1 ± 1.5 kWh/kgTNrem, and 62.3 ± 11.7 kWh/kgTPrem. Although the analyses are based on a robust time series, the implementation of predictive modeling techniques (such as machine learning or multivariate regression) should be applied in future studies of this type. Directive (EU) 2024/3019 of the European Parliament and of the Council of 10 December 2024 on urban wastewater treatment establishes the requirement for WWTPs serving at least 10,000 PE to achieve energy neutrality by 2045 [13]. This implies that wastewater treatment facilities will need to ensure not only regulatory compliance regarding effluent quality but also long-term stability in energy demand, supplied increasingly from renewable sources, despite fluctuations in influent quantity and composition. In the present study, electricity production from biogas generated on-site covered only 18.1–68.4% of the total electricity demand of the facility, with an average of 40.8 ± 13.8%. These results are consistent with literature data. At the same time, electricity expenditures accounted for 4.48–13.92% of the total treatment cost per 1 m3 of wastewater. To improve the share of renewable energy in energy supply in the future, WWTPs should consider pretreatment of substrates, co-digestion with other organic materials, or the adoption of alternative solutions such as photovoltaic systems.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/en18195277/s1, Figure S1: Block technological diagram of the wastewater line at the municipal wastewater treatment plant (A–C: sampling points for wastewater analyses). Figure S2: Block technological diagram of the sludge line at the wastewater treatment plant.

Author Contributions

Conceptualization, A.M. and R.L.; methodology, A.M. and R.L.; validation, W.J. and J.R.; formal analysis, A.M., R.L., J.R. and W.J.; investigation, R.L. and A.M.; resources, R.L.; data curation, A.M. and R.L.; writing—original draft preparation, A.M. and R.L.; writing—review and editing, A.M. and R.L.; visualization, A.M. and R.L.; supervision, J.R. and W.J.; project administration, A.M.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded in the framework of Project No. 29.610.023-110 of the University of Warmia and Mazury in Olsztyn, Poland.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Materials. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Longo, S.; d’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.M.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and Diagnosis of Energy Consumption in Wastewater Treatment Plants. A State of the Art and Proposals for Improvement. Appl. Energy 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- Torregrossa, D.; Schutz, G.; Cornelissen, A.; Hernández-Sancho, F.; Hansen, J. Energy Saving in WWTP: Daily Benchmarking under Uncertainty and Data Availability Limitations. Environ. Res. 2016, 148, 330–337. [Google Scholar] [CrossRef]

- Żyłka, R.; Karolinczak, B.; Dąbrowski, W. Structure and Indicators of Electric Energy Consumption in Dairy Wastewater Treatment Plant. Sci. Total Environ. 2021, 782, 146599. [Google Scholar] [CrossRef]

- Rodziewicz, J.; Mielcarek, A.; Bryszewski, K.; Janczukowicz, W.; Kłobukowska, K. Energy Consumption for Nutrient Removal from High-Nitrate and High-Phosphorus Wastewater in Aerobic and Anaerobic Bioelectrochemical Reactors. Energies 2022, 15, 7251. [Google Scholar] [CrossRef]

- Kindzierski, W.B.; Hrudey, S.E. Effects of Phosphorus Removal Chemicals upon Methane Production during Anaerobic Sludge Digestion. Can. J. Civ. Eng. 1986, 13, 33–38. [Google Scholar] [CrossRef]

- Ghyoot, W.; Verstraete, W. Anaerobic Digestion of Primary Sludge from Chemical Pre-Precipitation. Water Sci. Technol. 1997, 36, 357–365. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Y.; Keller, A.A.; Li, X.; Feng, S.; Dong, Y.; Li, F. Comparative Analysis of Energy Intensity and Carbon Emissions in Wastewater Treatment in USA, Germany, China and South Africa. Appl. Energy 2016, 184, 873–881. [Google Scholar] [CrossRef]

- Wakeel, M.; Chen, B.; Hayat, T.; Alsaedi, A.; Ahmad, B. Energy Consumption for Water Use Cycles in Different Countries: A Review. Appl. Energy 2016, 178, 868–885. [Google Scholar] [CrossRef]

- Gude, V.G. Energy and Water Autarky of Wastewater Treatment and Power Generation Systems. Renew. Sustain. Energy Rev. 2015, 45, 52–68. [Google Scholar] [CrossRef]

- Vaccari, M.; Foladori, P.; Nembrini, S.; Vitali, F. Benchmarking of Energy Consumption in Municipal Wastewater Treatment Plants—A Survey of over 200 Plants in Italy. Water Sci. Technol. 2018, 77, 2242–2252. [Google Scholar] [CrossRef]

- Directive-91/271-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/1991/271/oj/eng (accessed on 26 August 2025).

- Summary of the Clean Water Act | US EPA. Available online: https://www.epa.gov/laws-regulations/summary-clean-water-act (accessed on 26 August 2025).

- Directive-EU-2024/3019-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/2024/3019/oj/eng (accessed on 26 August 2025).

- PN-EN 1899-2:2002; Water Quality—Determination of Biochemical Oxygen Demand after n Days (BOD5)—Part 2: Undiluted Samples. Polish Committee for Standardization: Warsaw, Poland, 2002.

- PN-ISO 15705:2005; Water Quality—Determination of the Chemical Oxygen Demand Index (ST-COD)—Small-Scale Sealed-Tube Method. Polish Committee for Standardization: Warsaw, Poland, 2005.

- PN-EN 872:2007 + Ap1:2007; Water Quality—Determination of Suspended Solids—Method by Filtration Through Glass-Fibre Filters. Polish Committee for Standardization: Warsaw, Poland, 2007.

- PN-73/C-04576/14; Water and Wastewater—Determination of Total Nitrogen Content. Polish Committee for Standardization: Warsaw, Poland, 1973.

- PN-EN ISO 6878:2006 + Ap1:2010 + Ap2:2010; Water Quality—Determination of Phosphorus—Ammonium Molybdate Spectrometric Method. Polish Committee for Standardization: Warsaw, Poland, 2010.

- Rodziewicz, J.; Pesta, J.; Janczukowicz, W.; Mielcarek, A. The Influence of Pandemic Lockdowns on Municipal Wastewater Quality as a Consequence of Not Discharging Food Waste from Restaurants. Appl. Sci. 2023, 13, 8875. [Google Scholar] [CrossRef]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Chenel, S.; Marín-Navarro, D.; Moreira, M.T.; Feijoo, G. Eco-Efficiency Analysis of Spanish WWTPs Using the LCA + DEA Method. Water Res. 2015, 68, 651–666. [Google Scholar] [CrossRef]

- Wei, G.; Wei, T.; Li, Z.; Wei, C.; Kong, Q.; Guan, X.; Qiu, G.; Hu, Y.; Wei, C.; Zhu, S.; et al. BOD/COD Ratio as a Probing Index in the O/H/O Process for Coking Wastewater Treatment. Chem. Eng. J. 2023, 466, 143257. [Google Scholar] [CrossRef]

- Zhang, B.; Ning, D.; Yang, Y.; Van Nostrand, J.D.; Zhou, J.; Wen, X. Biodegradability of Wastewater Determines Microbial Assembly Mechanisms in Full-Scale Wastewater Treatment Plants. Water Res. 2020, 169, 115276. [Google Scholar] [CrossRef] [PubMed]

- Janczukowicz, W.; Rodziewicz, J.; Czaplicka, K.; Kłodowska, I.; Mielcarek, A. The Effect of Volatile Fatty Acids (VFAs) on Nutrient Removal in SBR with Biomass Adapted to Dairy Wastewater. J. Env. Sci. Health A Tox Hazard. Subst. Environ. Eng. 2013, 48, 809–816. [Google Scholar] [CrossRef] [PubMed]

- Nowobilska-Majewska, E.; Bugajski, P. The Analysis of the Amount of Pollutants in Wastewater after Mechanical Treatment in the Aspect of Their Susceptibility to Biodegradation in the Treatment Plant in Nowy Targ. J. Ecol. Eng. 2019, 20, 135–143. [Google Scholar] [CrossRef]

- Dz.U. 2014 Poz. 1800 (Journal of Laws of 2014, Item 1800). (Ang. Regulation of the Minister of the Environment of 18 November 2014 on the Conditions for Introducing Wastewater into Water or Soil and on Substances Particularly Harmful to the Aquatic Environment.). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20140001800 (accessed on 20 August 2025).

- Vaiopoulou, E.; Aivasidis, A. A Modified UCT Method for Biological Nutrient Removal: Configuration and Performance. Chemosphere 2008, 72, 1062–1068. [Google Scholar] [CrossRef]

- Welz, P.J.; Thobejane, M.P.; van Blerk, G.N. Ammonium Oxidizing Bacterial Populations in South African Activated Sludge Wastewater Treatment Plants. Water Environ. Res. 2023, 95, e10945. [Google Scholar] [CrossRef]

- Dai, H.; Sun, Y.; Wan, D.; Abbasi, H.N.; Guo, Z.; Geng, H.; Wang, X.; Chen, Y. Simultaneous Denitrification and Phosphorus Removal: A Review on the Functional Strains and Activated Sludge Processes. Sci. Total Environ. 2022, 835, 155409. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Houweling, D.; Dold, P. Biological Nutrient Removal in Municipal Wastewater Treatment: New Directions in Sustainability. J. Environ. Eng. 2012, 138, 307–317. [Google Scholar] [CrossRef]

- Preisner, M.; Smol, M. Investigating Phosphorus Loads Removed by Chemical and Biological Methods in Municipal Wastewater Treatment Plants in Poland. J. Environ. Manag. 2022, 322, 116058. [Google Scholar] [CrossRef]

- Trapote, A.; Albaladejo, A.; Simón, P. Energy Consumption in an Urban Wastewater Treatment Plant: The Case of Murcia Region (Spain). Civ. Eng. Environ. Syst. 2014, 31, 304–310. [Google Scholar] [CrossRef]

- Gandiglio, M.; Lanzini, A.; Soto, A.; Leone, P.; Santarelli, M. Enhancing the Energy Efficiency of Wastewater Treatment Plants through Co-Digestion and Fuel Cell Systems. Front. Environ. Sci. 2017, 5, 289034. [Google Scholar] [CrossRef]

- Capodaglio, A.; Olsson, G. Energy Issues in Sustainable Urban Wastewater Management: Use, Demand Reduction and Recovery in the Urban Water Cycle. Sustainability 2019, 12, 266. [Google Scholar] [CrossRef]

- Zessner, M.; Lampert, C.; Kroiss, H.; Lindtner, S. Cost Comparison of Wastewater Treatment in Danubian Countries. Water Sci. Technol. 2010, 62, 223–230. [Google Scholar] [CrossRef]

- Nowak, O.; Enderle, P.; Varbanov, P. Ways to Optimize the Energy Balance of Municipal Wastewater Systems: Lessons Learned from Austrian Applications. J. Clean. Prod. 2015, 88, 125–131. [Google Scholar] [CrossRef]

- Żyłka, R.; Dąbrowski, W.; Malinowski, P.; Karolinczak, B. Modeling of Electric Energy Consumption during Dairy Wastewater Treatment Plant Operation. Energies 2020, 13, 3769. [Google Scholar] [CrossRef]

- Panepinto, D.; Fiore, S.; Zappone, M.; Genon, G.; Meucci, L. Evaluation of the Energy Efficiency of a Large Wastewater Treatment Plant in Italy. Appl. Energy 2016, 161, 404–411. [Google Scholar] [CrossRef]

- Chiavola, A.; Romano, R.; Bongirolami, S.; Giulioli, S. Optimization of Energy Consumption in the Biological Reactor of a Wastewater Treatment Plant by Means of Oxy Fuzzy and ORP Control. Water Air Soil. Pollut. 2017, 228, 1–12. [Google Scholar] [CrossRef]

- Lackner, S.; Gilbert, E.M.; Vlaeminck, S.E.; Joss, A.; Horn, H.; van Loosdrecht, M.C.M. Full-Scale Partial Nitritation/Anammox Experiences—An Application Survey. Water Res. 2014, 55, 292–303. [Google Scholar] [CrossRef] [PubMed]

- Wett, B.; Hell, M.; Nyhuis, G.; Puempel, T.; Takacs, I.; Murthy, S. Syntrophy of Aerobic and Anaerobic Ammonia Oxidisers. Water Sci. Technol. 2010, 61, 1915–1922. [Google Scholar] [CrossRef]

- Szczyrba, P.; Masłoń, A.; Czarnota, J.; Olszewski, K. Analysis of Sewage Sludge and Biogas-Energy Management at the Opole Wastewater Treatment Plant. Inżynieria Ekol. 2020, 21, 26–34. [Google Scholar] [CrossRef]

- Masłoń, A. An Analysis of Sewage Sludge and Biogas Production at the Zamość WWTP. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2020; Volume 47, pp. 291–298. [Google Scholar]

- Masłoń, A.; Czarnota, J.; Szaja, A.; Szulżyk-Cieplak, J.; Łagód, G. The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland. Energies 2020, 13, 6056. [Google Scholar] [CrossRef]

- Masłoń, A. Analysis of Energy Consumption at the Rzeszów Wastewater Treatment Plant. E3S Web Conf. 2017, 22, 00115. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, B.; Yao, F.; He, L.; Chen, F.; Ma, Y.; Shu, X.; Hou, K.; Wang, D.; Li, X. Biogas Production from Anaerobic Co-Digestion of Waste Activated Sludge: Co-Substrates and Influencing Parameters. Rev. Environ. Sci. Biotechnol. 2019, 18, 771–793. [Google Scholar] [CrossRef]

- Peces, M.; Pozo, G.; Koch, K.; Dosta, J.; Astals, S. Exploring the Potential of Co-Fermenting Sewage Sludge and Lipids in a Resource Recovery Scenario. Bioresour. Technol. 2020, 300, 122561. [Google Scholar] [CrossRef]

- Dzido, A.; Walczak, J.; Jankowska, H.; Krawczyk, P.; Özbayram, E.G.; Żubrowska-Sudoł, M. Hydrodynamic Disintegration Effects Assessment by CFD Modelling Integrated with Bench Tests. J. Environ. Manag. 2024, 367, 121948. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, W. Economic and Ecological Assessment of Photovoltaic Systems for Wastewater Treatment Plants in China. Renew. Energy 2022, 191, 852–867. [Google Scholar] [CrossRef]

- Cena Prądu 1 Kwh Dla Firm—Ile Kosztuje w 2025?|Eco Dla Biznesu. Available online: https://ecodlabiznesu.pl/ile-kosztuje-1-kwh-dla-firm/ (accessed on 21 August 2025).

- Ćetković, J.; Knežević, M.; Lakić, S.; Žarković, M.; Vujadinović, R.; Živković, A.; Cvijović, J. Financial and Economic Investment Evaluation of Wastewater Treatment Plant. Water 2022, 14, 122. [Google Scholar] [CrossRef]

- Renzetti, S. Municipal Water Supply and Sewage Treatment: Costs, Prices, and Distortions. Can. J. Econ. 1999, 32, 688. [Google Scholar] [CrossRef]

- Bode, H.; Grünebaum, T. The Cost of Municipal Sewage Treatment–Structure, Origin, Minimization–Methods of Fair Cost Comparison and Allocation. Water Sci. Technol. 2000, 41, 289–298. [Google Scholar] [CrossRef]

- Li, W.; Li, L.; Qiu, G. Energy Consumption and Economic Cost of Typical Wastewater Treatment Systems in Shenzhen, China. J. Clean. Prod. 2017, 163, S374–S378. [Google Scholar] [CrossRef]

- Ateunkeng, J.G.; Boum, A.T.; Bitjoka, L. Enhancement of Energy and Cost Efficiency in Wastewater Treatment Plants Using Hybrid Bio-Inspired Machine Learning Control Techniques. J. Environ. Chem. Eng. 2024, 12, 112496. [Google Scholar] [CrossRef]

- Castellet, L.; Molinos-Senante, M. Efficiency Assessment of Wastewater Treatment Plants: A Data Envelopment Analysis Approach Integrating Technical, Economic, and Environmental Issues. J. Environ. Manag. 2016, 167, 160–166. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).