1. Introduction

Transport has been an integral part of human civilization since its inception. Alongside communication, it constitutes a vital sector of the economy by enhancing the utility of goods through their spatial mobility. Moreover, transport plays a fundamental role in human mobility, thereby influencing personal development, health, and recreational activities. The transport sector is closely interlinked with other economic sectors; its advancement fosters overall economic growth, while underdevelopment in either domain can hinder progress in the other.

Road transport, characterized by its high flexibility, has experienced significant expansion. However, its efficiency is moderate, particularly when considering its substantial environmental impact. This inefficiency stems from the relatively low payload capacity of vehicles, the high energy consumption inherent to road transport, and the considerable capital investment required for constructing transport infrastructure, including roadways, fuel stations, and maintenance facilities. Despite these limitations, road transport remains a critical component of the global economy and plays a pivotal role in European integration, facilitating the free movement of people, goods, and services.

Statistical analyses were specifically conducted for the years 2021 [

1] and 2022 [

2], reflecting the transitional period following the COVID-19 pandemic and the renewed armed conflict in Ukraine commencing on 24 February 2022. Furthermore, in 2021, comprehensive road noise monitoring and acoustic mapping were performed in Poland, with subsequent assessments planned for 2026.

Transport contributes approximately 5% to the European Union’s gross domestic product (GDP) and employs over 10 million individuals across Europe. The transport system is essential for European enterprises and global supply chains. However, transport activities impose significant external costs on society, including greenhouse gas emissions, environmental pollution, noise, road traffic accidents, and congestion.

The European Union’s road transport policy aims to stimulate economic growth by supporting the development of a modern infrastructure network that facilitates safer and more efficient travel. Concurrently, the policy promotes sustainable and digital innovations. Among EU member states, the most extensive motorway networks are observed in Spain (15,860 km), Germany (13,155 km), Italy (6978 km), Portugal (3065 km), the Netherlands (2790 km), Sweden (2185 km), and Hungary (1860 km). Poland’s road network is undergoing systematic expansion; by the end of 2021, the total length of public roads reached approximately 430,000 km. Motorway length increased by 48.3 km compared to 2020, totaling 1760.5 km. This corresponds to 5.6 km of motorway per 1000 km2 of national territory and 4.6 km per 100,000 inhabitants. Expressways (both single and dual carriageways) extended by 246.4 km, reaching 2794.9 km by the end of 2021. In 2022, Poland recorded the highest motorization rate within the EU, with 687 vehicles per 1000 inhabitants, surpassing Luxembourg (681) and Italy (675).

Motorways and expressways in the EU are also heavily utilized for freight transport. In 2022, the total road freight transport volume remained stable relative to 2021, at approximately 1920 billion ton-kilometers (tkm). Poland led in freight transport volume with 385,089 million tkm, followed by Germany (303,948 million tkm) and Spain (266,724 million tkm). Regarding the weight of goods transported, Germany (3,060,964 thousand tons), France (1,631,139 thousand tons), and Poland (1,599,513 thousand tons) ranked highest.

The transport system’s primary vehicle categories include freight vehicles with maximum permissible weights both up to and exceeding 3.5 tons. The largest registrations of vehicles up to 3.5 tons were reported in France (4,868,148), Spain (4,696,170), Germany (3,018,598), Italy (3,774,192), and Poland (2,905,731). For heavy-duty vehicles exceeding 3.5 tons, the highest numbers were observed in Poland (728,465), Germany (530,994), Italy (515,850), Spain (349,197), and France (307,433). Additionally, over 253 million passenger cars are registered across the EU, with the highest concentrations in Germany (48,540,878), France (39,822,723), Italy (38,738,590), Poland (25,869,804), and Spain (24,913,132), collectively accounting for 70% of the EU’s passenger car fleet.

Operational analysis for 2022 indicates a 1.0% increase in international road freight transport performance (measured in ton-kilometers) compared to 2021, representing 25.4% of total EU road freight transport. This segment has demonstrated robust growth since 2021 relative to prior years. Conversely, cabotage transport decreased by 8.9%, while national transport and cross-trade operations each declined marginally by 0.1% in the same period.

In Poland, revenue generated from road transport services across all transport units increased by 9.8% in 2021 compared to 2020, reaching PLN 201.5 billion. The private sector experienced a 10.1% revenue growth, whereas the public sector’s revenue increased by 7.3%.

In 2021, the road transport sector was predominantly powered by gas/diesel oil (66.5%) and petrol (24.0%). Liquefied petroleum gas (LPG) constituted a minor share of fuel consumption in this sector, accounting for approximately 2%, with considerable variation in its use across different countries. The uptake of alternative fuels in road transport has gradually increased, driven by key European Union policies, technological advancements, and evolving consumer preferences. In 2021, renewable energy sources and biofuels comprised 6.4% of actual fuel consumption within the EU road transport sector. Despite a gradual increase over recent years, electricity maintained a marginal role, representing only 0.2% of total consumption.

An analysis of road traffic in Poland was conducted using data from the General Traffic Measurement, the National Traffic Model for the road network, and the Central Statistical Office’s survey on freight vehicle transport activity. In 2021, the total vehicle-kilometers traveled on Poland’s public road network reached 248.6 billion, reflecting an 8.8% increase relative to 2020. Passenger cars dominated traffic, contributing 203.3 billion vehicle-kilometers—also an 8.8% increase over the previous year. Traffic volumes increased for other vehicle categories as well: trucks by 8.4% (including vehicles over 3.5 tons gross vehicle weight by 8.0%), buses by 9.0%, and motorcycles by 8.5%.

Vehicles registered in Poland accounted for 94.2% of total traffic on the national public road network (234.1 billion vehicle-kilometers), while foreign-registered vehicles comprised 5.8% (14.5 billion vehicle-kilometers). Passenger cars predominated in both groups, constituting 82.5% of Polish vehicles and 70.0% of foreign vehicles. Trucks represented the second-largest category, accounting for 15.1% of Polish vehicles and 29.8% of foreign vehicles.

Traffic increased across all road categories in 2021, with the most pronounced growth observed on voivodeship roads (10.7%). The highest traffic volume was recorded on national roads, totaling 98.6 billion vehicle-kilometers—an 8.4% increase compared to 2020.

By the end of 2021, the number of registered passenger cars in Poland reached 25.9 million, marking a 3.0% increase from the previous year. Of these, 21.4 million vehicles were up to 30 years old, representing a 1.8% increase since 2020. The proportion of passenger cars aged up to 5 years slightly decreased from 11.2% in 2020 to 11.1% in 2021, whereas the share of vehicles aged 16–30 years increased marginally from 43.2% to 43.3%, and those over 30 years increased from 16.4% to 17.4%.

The registered truck population (including light trucks) totaled 3.6 million at the end of 2021, a 3.0% increase over the previous year. Among these, 2.8 million vehicles were up to 30 years old. The age distribution of trucks remained consistent with the prior year: 11.5% were up to 5 years old, 37.5% were between 16 and 30 years old, and the proportion of trucks over 30 years increased from 21.9% to 22.6%. Slight increases were noted in trucks with payload capacities below 1.5 tons (from 79.7% in 2020 to 80.0% in 2021) and those with payloads of 10 tons or more (from 4.1% to 4.2%). Regarding engine types, 69.7% of trucks were diesel-powered (compared to 68.8% in 2020), 16.8% utilized gasoline engines (17.4% in 2020), and 4.7% were LPG-powered (4.9% in 2020).

Pollutant emissions from road transport primarily originate from fuel combustion within vehicle engines, as well as from tire and brake pad wear and the resuspension of road surface dust. The magnitude of emissions is influenced by vehicle fleet size and age, road surface conditions, and traffic management. The principal gaseous pollutants emitted by road transport include carbon dioxide (CO2) at 61,362 thousand tons, carbon monoxide (CO) at 288.5 thousand tons, nitrogen oxides (NOₓ) at 204.1 thousand tons, non-methane volatile organic compounds (NMVOCs) at 34.8 thousand tons, and particulate matter (PM) at 20.2 thousand tons. These pollutants exert substantial adverse effects on human health and ecosystems through air quality degradation. In 2020, road transport accounted for approximately 20% of total CO2 emissions, 13% of CO emissions, 34% of NOₓ emissions, 5% of NMVOCs, and 4% of total suspended particulates (TSPs) in Poland.

Despite the implementation of increasingly stringent emission standards for passenger cars, trucks, and buses, as well as ongoing developments in road infrastructure, emissions from road transport remain one of the most critical factors adversely affecting air quality—particularly in densely populated urban areas.

Road traffic constitutes the most significant source of noise pollution for humans, primarily due to its widespread occurrence and persistent impact during both daytime and nighttime hours. Noise monitoring, based on acoustic mapping, revealed that in 2021, road traffic noise posed a substantial threat mainly within urbanized regions and affected an increasing number of residents. Of the nearly 300 km of roads monitored in 2021, approximately 33% exhibited noise levels up to 60 dB (decibels), which corresponds to permissible daytime noise limits for residential areas adjacent to roadways. Conversely, on more than 67% of the monitored roads, noise levels exceeded these regulatory thresholds.

For several years, road traffic noise levels in urban centers have consistently remained high, typically ranging between 70 and 80 dB. In 2021, the highest proportions of streets where noise levels surpassed the maximum permissible value of 60 dB (relative to the total length of monitored streets) were recorded in cities within the voivodeships of Lubelskie, Lubuskie, Łódzkie, and Małopolskie (all at 100%), as well as Dolnośląskie and Warmińsko-Mazurskie (both at 93%). The lowest exceedance rates were observed in Mazowieckie (25%) and Pomorskie (37%).

The substantial volume of vehicles operating on the road network presents significant challenges regarding energy consumption reduction and environmental protection. The adoption of sustainable and innovative transport modes is pivotal to achieving the climate and energy objectives set by both Poland and the European Union. These initiatives primarily aim to support transport systems in addressing their principal—often conflicting—challenges, which include enhancing the competitiveness of the European transport sector vis-à-vis rapidly expanding global markets; improving infrastructure quality; developing modern vehicle technologies; alleviating traffic congestion that impairs road transport efficiency; reducing fossil fuel consumption, notably diesel and petrol; achieving a 60% reduction in emissions by 2050 relative to 1990 levels; and pursuing further emission reductions beyond that target.

The combination of a large vehicle fleet and a relatively underdeveloped network of highways and expressways poses a significant challenge in identifying and implementing technical solutions focused on improving traffic safety, minimizing energy consumption, and mitigating adverse environmental impacts. One potential approach involves the formation of homogeneous and heterogeneous vehicle platoons with optimized structural configurations, inter-vehicle spacing, and speeds, supported by advanced vehicle fleet control and management systems.

The type of platoon—homogeneous or heterogeneous—determines significant differences in driving dynamics, safety, energy efficiency, as well as aerodynamic and aeroacoustic performance. Homogeneous platoons, composed of vehicles with similar technical parameters, enable more consistent and predictable driving. Uniform acceleration, braking, and control system responses help reduce speed fluctuations and enhance string stability. Cut-in and cut-out maneuvers are executed more smoothly, and vehicles can maintain shorter, constant gaps. As a result, not only does traffic throughput improve, but so do aerodynamic and aeroacoustic conditions—airflow around the platoon becomes more orderly, reducing drag and leading to substantial fuel or energy savings.

Heterogeneous platoons, composed of vehicles with varying technical parameters such as engine power, acceleration, braking performance, or mass, exhibit non-uniform responses to speed changes, which complicates the maintenance of stable inter-vehicle gaps and increases susceptibility to string instability. Vehicle diversity also affects the execution of cut-in and cut-out maneuvers, leading to temporary slowdowns and fluctuations in traffic flow stability. The flexible spacing required in such platoons limits aerodynamic benefits, while speed variations increase fuel or electric energy consumption and elevate the risk of collisions. From an aerodynamic and aeroacoustic perspective, differences in vehicle body shapes and larger inter-vehicle gaps generate airflow disturbances and vortices, resulting in higher levels of aerodynamic noise, perceptible both inside the vehicles and in the surrounding environment.

Owing to the rapid development of science and technology, as well as proposed regulatory changes in the EU and in the world’s most advanced countries, intensive research is being conducted on homogeneous and heterogeneous platoons. A fundamental transformation is expected with the introduction of the 6G standard and the adoption of advanced methods and techniques based on artificial intelligence, modern powertrains, and control systems. Selected studies in this field will be presented in the subsequent sections of this work.

The authors focused on numerical aerodynamic and aeroacoustic analyses of heterogeneous platoons and their impact on fuel consumption and environmental effects. The main contributions of this work are summarized below. Within the scope of the study:

Aerodynamic analyses were performed on 54 developed and implemented geometric–numerical models of heterogeneous platoons, composed of combinations of passenger cars, light commercial vehicles, and heavy trucks.

Fuel consumption was determined for individual vehicles as well as for all 54 heterogeneous platoon combinations at three different speeds and three inter-vehicle distances.

Aeroacoustic analyses were conducted at three speeds using the Ffowcs Williams–Hawkings analogy and geometric methods for nine selected configurations of heterogeneous platoon models and individual vehicles.

Additionally, for speeds ranging from 50 to 140 km/h, at 10 km/h intervals, the percentage fuel consumption of selected heterogeneous platoon models was estimated in comparison with vehicles driving outside the platoon, along with their acoustic impact on the environment, using geometric methods.

2. Selected Aspects of Vehicle and Vehicle Platoon Aerodynamics and Aeroacoustics

2.1. History of Road Vehicle Aerodynamics

The history of road vehicle aerodynamics dates back to the late 19th century [

3]. Early designers often drew inspiration from shapes proven in marine engineering and airship design. The earliest known vehicle designed with aerodynamic efficiency in mind was the electric car built by Camille Jenatzy, which featured a torpedo-shaped body. This vehicle was the first to exceed 100 km/h, achieving a record speed of 105.9 km/h on 29 April 1899. In 1913, at the behest of Count Marco Ricotti, a vehicle with an airship-inspired design was constructed on an Alfa Romeo chassis, incorporating a fully enclosed passenger cabin.

Significant advancements in vehicle aerodynamics occurred following World War I. Beginning in 1919, Rumpler, renowned for the “Rumpler Taube” aircraft, developed several vehicles he termed “tear-drop shaped cars.” When viewed from above, these vehicles resembled airfoils. To optimize the otherwise narrow streamlined tail section, Rumpler positioned the engine at the rear of the vehicle. In 1922, wind tunnel tests on a 1:7.5 scale model were conducted at the Aerodynamic Laboratory in Göttingen. Results indicated that the drag of the Rumpler vehicle was approximately one-third that of contemporary competitors. However, minimizing aerodynamic drag was not Rumpler’s principal design objective; promotional materials from the era emphasized that his car generated substantially less dust and mud than others. Wind tunnel testing of the original Rumpler car in 1979 yielded a drag coefficient (Cd) of 0.28 and a frontal area (A) of 2.57 m2. Notably, such a low drag coefficient was not matched in production vehicles until decades later, exemplified by the 1986 Opel Omega. The aerodynamic performance of the Rumpler car is especially remarkable considering its fully exposed wheels.

Contemporaneous to Rumpler, Jaray initiated aerodynamic vehicle design research, publishing an article entitled “The Streamlined Car, a New Shape for the Automobile Body.” In 1938, wind tunnel testing of Jaray’s designs—initially started by Klemperer in 1921–1922—was resumed under Ludwig Prandtl’s supervision in Göttingen. Jaray’s vehicle body featured two horizontal profiles: a primary main profile and a secondary profile starting from the base of the windshield. Consistent with Jaray’s design principles, the secondary profile had a rounded top, resulting in the so-called “Lange car” shape. Model testing demonstrated a drag coefficient as low as 0.14, with subsequent measurements on a 1:5 scale model by the author and collaborators confirming values near 0.16. These models, however, did not include details such as chassis components, wheel arches, or window recesses.

In 1939, the French manufacturer Mauboussin adopted a similar aerodynamic approach for the “Mistral,” which was based on an airfoil-shaped outline but featured a vertical trailing edge. A prominent rear “fin” enhanced stability in crosswinds at the expense of interior space.

In the early 1930s, Lay conducted systematic aerodynamic studies at the University of Michigan, modifying front and rear vehicle geometries to isolate aerodynamic phenomena. His research revealed a strong interaction between flow fields at the vehicle’s front and rear. The low drag observed in long-tailed models was contingent upon flow adherence over the front body surface. However, Lay’s segmented model, constructed from assembled parts with parallel sidewalls and sharp corners, exhibited high drag, limiting the applicability of his findings.

Similar insights were previously reported by Dornier in 1920, based on measurements of airfoil sections with truncated trailing edges. In 1934, engineer Wunibald Kamm introduced the “Kamm-back” design, which truncated the vehicle’s long tapered tail. This approach offered increased rear interior volume while maintaining a reduced drag coefficient. The low drag was attributed to attached flow that separated at the vehicle’s rear over a significantly reduced cross-sectional area.

The first passenger car featuring a Kamm-type rear was the “Everling,” built in 1938. Wunibald Kamm subsequently developed several “K-type” vehicles, culminating in the refined K5 model, which was suitable for series production. However, plans for mass production were halted by the outbreak of World War II in 1939.

The “streamlined shapes” of automobile bodies developed in the early 20th century were infrequently employed in mass vehicle production. During that period, fuel consumption was not prioritized over aesthetic considerations and prevailing styling trends. However, the 1973 oil crisis marked a pivotal shift in design priorities. The reduction in oil supply, escalating fuel prices, and growing concerns regarding the depletion of natural resources underscored the critical importance of reducing aerodynamic drag in vehicle design. Consequently, the late 1970s and 1980s are recognized as a breakthrough era for the mass production of aerodynamic vehicles. Leading automotive manufacturers, including Audi, BMW, Volkswagen, Citroën, Opel, SAAB, and Ford, dedicated efforts to refining streamlined body geometries. Notable reductions in drag coefficients (C

d) were achieved during this period; for example, the Volkswagen Passat’s Cd decreased from 0.41 in 1978 to 0.27 in 1996, while the 1989 Opel Calibra attained a C

d of 0.26, and the 1982 Citroën GSA X3 exhibited a C

d of 0.34 [

4,

5,

6].

2.2. State of the Art

Research aimed at drag reduction continues to advance, employing a variety of strategies. Aerodynamic resistance can be minimized through both shape optimization and the integration of auxiliary body components. Elsayed [

7] investigated three methods for enhancing vehicle aerodynamics: the installation of a horizontal rear roof spoiler, the modification of the roof surface with specialized grooves, and the addition of vertical side fins at window level. These interventions yielded reductions in aerodynamic drag force of 15.87%, 19.82%, and 22.67%, respectively. Vedrtnam et al. [

8] explored passive aerodynamic devices, utilizing vortex generators (VGs) and a rear spoiler to manipulate airflow around the vehicle. Twenty-six configurations were examined, with varying wing angles, VG applications, and crosswind directions. The most effective configuration produced a drag coefficient reduction of up to 68.18%.

A comprehensive discussion, along with the presentation of results concerning the potential reduction in vehicle aerodynamic drag and drag coefficients, is provided in [

9]. The authors presented various solutions aimed at minimizing aerodynamic drag in heavy-duty vehicles. It was emphasized that approximately 75% of the total aerodynamic drag generated by road trains is associated with the trailer or semi-trailer, which justifies intensive research efforts to minimize this effect. The publication identifies several structural components affecting the aerodynamics of heavy-duty vehicles and presents the potential fuel savings resulting from their implementation. Among other aspects, roof deflectors and fairings, the front bumper, windshield, external mirrors, and the possibility of replacing them with camera-based systems were discussed. Attention was also drawn to the significant influence of the vehicle underbody shape, chassis and axle enclosures, as well as wheel covers and aerodynamic mudflaps.

The research results showed that a rear deflector can reduce aerodynamic drag during flat-road driving at 90 km/h by approximately 2%, side skirts by 3.4%, and their combined use can achieve a reduction of around 6.5%. In addition to passive solutions, the Plasma Stream technology was presented, based on active airflow control using plasma actuators developed at the University of Notre Dame. This system demonstrates high efficiency and enables fuel consumption reductions of 7–10% at speeds exceeding 100 km/h.

Intensive research and development efforts are ongoing to develop novel solutions employing both passive and active systems to reduce the aerodynamic drag coefficient in electric vehicles, including passenger cars and trucks. A notable example is provided by Tesla, as reported in a study on the Tesla Semi truck [

10]. Simulations were carried out using computational fluid dynamics (CFD) methods, with the geometric model encompassing the cabin shape, windshield, side fairings, and trailer. Tests were conducted at typical highway speeds (80 km/h and 100 km/h) under flow conditions representative of unobstructed open environments. The results of the numerical analyses demonstrated a significant reduction in the aerodynamic drag coefficient to a value of C

d = 0.339.

Active aerodynamic systems have been described by Piechna [

11], who presented intelligent technologies that adapt aerodynamic characteristics dynamically in response to vehicle speed. Additional parameters such as acceleration, yaw angle, steering angle, and brake pressure are also incorporated. These adaptive systems aim to enhance aerodynamic efficiency, contributing to decreased fuel consumption, improved safety, and greater driving comfort.

A comprehensive review of contemporary drag reduction methodologies was conducted by Szodrai [

12], covering both passive and active aerodynamic enhancements. The study focused on two vehicle categories: hatchbacks and notchbacks. An alternative approach to road vehicle aerodynamics was proposed by Kurec et al. [

13], who analyzed an active aerodynamic braking system. By deploying strategically positioned plates on the hood and roof of a passenger vehicle, additional aerodynamic forces were generated to increase drag and downforce. The enhanced drag serves to decelerate the vehicle, while increased downforce improves traction, thereby augmenting driving safety.

The aforementioned studies primarily address drag reduction at the level of individual vehicles, achieved via modifications to body geometry and the implementation of passive or active aerodynamic systems. A fundamentally different approach involves exploiting the aerodynamic wake generated behind vehicles to reduce drag without altering the vehicles themselves. This strategy focuses on optimizing the aerodynamics of vehicle groups, or platoons. A vehicle platoon consists of multiple road vehicles traveling consecutively in a single lane, maintaining uniform speed and prescribed inter-vehicle distances. When all vehicles in a platoon share identical body types, the platoon is classified as homogeneous; if the vehicles differ in body type, the platoon is heterogeneous.

Aerodynamic interactions between vehicles have been investigated extensively over many years. These studies vary with respect to vehicle geometries analyzed, inter-vehicle spacing, and platoon speeds. Zabat et al. [

14] examined homogeneous platoons composed of two to four passenger cars. The experiments were conducted in a wind tunnel using scaled models, each vehicle measuring 0.6 m in length, with inter-vehicle distances ranging from zero to three vehicle lengths. Drag coefficients were measured at an airflow velocity of 25 m/s. Schito et al. [

15] analyzed homogeneous platoons of one to six vehicles, each 4 m in length, focusing primarily on the drag coefficient. Tests were performed at three inter-vehicle spacings: 2, 3, and 4 m. The same study also investigated three heterogeneous platoons configured as truck–hatchback–sedan, van–hatchback–sedan, and sedan–hatchback–van. Each platoon consisted of three vehicles with differing body types, maintaining spacings between 0.5 and 3 m. The test velocity was set at 30 m/s. In all configurations, the greatest reduction in drag coefficient was observed for the vehicle positioned centrally within the platoon; notably, in every case, the middle vehicle was the smallest.

Le Good et al. [

16] performed scaled wind tunnel tests on homogeneous platoons comprising two to five passenger vehicles. At sufficiently small inter-vehicle distances, an adverse effect was noted: an increase in aerodynamic drag induced by platoon formation. The majority of research has focused on platoons exclusively composed of heavy-duty vehicles. Browand et al. [

17] conducted on-road experiments with two trucks at spacing intervals from 3 to 10 m and speeds of 88.5 km/h. Fuel consumption decreased by 5–10% for the lead vehicle and by 10–12% for the following vehicle. Lammert et al. [

18] carried out similar on-road tests in 2014, examining the influence of both inter-vehicle spacing (6 to 22.5 m) and platoon speed on fuel consumption reduction. Humphreys et al. [

19], in 2016, investigated a homogeneous platoon of two trucks and additionally examined the effect of lateral offset of one vehicle from the centerline on aerodynamic drag.

In 2018, several studies addressed vehicle platoons. Siemon [

20] investigated a homogeneous platoon of four trucks as well as a heterogeneous platoon also composed of four trucks differing in cargo type. Vohra [

21] conducted experiments with two- and three-truck platoons. Gnatowska and Sosnowski [

22] studied platoons based on vehicles modeled with Ahmed body geometry.

Jaffar et al. [

23] employed machine learning techniques to predict drag coefficients of vehicle platoons. Their research focused on homogeneous platoons of two, three, and four vehicles, applying five algorithms: support vector regression, polynomial regression, linear regression, and two neural network models. Experimental data from [

24] served as the training dataset. Additionally, Computational Fluid Dynamics (CFD) simulations were conducted for the same platoon configurations. The study demonstrated the utility of supervised learning as a complementary approach for analyzing vehicle aerodynamic properties.

Kaluva et al. [

25] analyzed drag coefficients for two types of homogeneous platoons: autonomous transport minibuses (Dynamic Autonomous Road Transit, DART) and notchback passenger cars. Aerodynamic parameters were evaluated for individual vehicles and for platoons of two to seven vehicles. CFD simulations were performed using ANSYS Fluent Academic Research with an unstructured mesh. Results showed an average drag coefficient reduction of 23% for the DART platoon and 24% for the passenger car platoon.

Robertson et al. [

26] reported experimental research on homogeneous platoons using 1:20 scale truck models to simulate convoys of eight vehicles. The setup replicated vehicle motion relative to the ground. Three inter-vehicle distances—0.5, 1, and 1.5 vehicle lengths—were tested at 25 m/s. At the smallest spacing, an average drag coefficient reduction per vehicle of 48% was achieved. He et al. [

27] performed similar simulations on homogeneous platoons using the Detached Eddy Simulation (DES) turbulence model to analyze flow behavior and aerodynamic coefficients. Their results aligned well with experimental data.

Despite the considerable benefits demonstrated by the aforementioned studies, it is essential to consider existing legal regulations. The provisions of the Polish Road Traffic Act [

28] dated 20 June 1997, impose specific restrictions on the operation of vehicle platoons. Article 32, paragraph 1, stipulates the maximum number of vehicles permitted in a convoy: the number of passenger cars traveling in an organized platoon shall not exceed ten vehicles, whereas for trucks, the limit is five vehicles. According to the traffic code, a van may be classified into one of two categories depending on its intended use: it is categorized as a passenger car if designed to transport up to nine persons, or as a mixed-use vehicle (cargo-passenger) if structurally intended to carry cargo and between four and nine persons, including the driver. Accordingly, the maximum number of vans permitted in an organized convoy may be either ten or five vehicles, respectively.

A separate regulation defines the allowable inter-vehicle distance. Article 19, paragraph 2, section 3 of the Road Traffic Act mandates that the driver “maintain a distance sufficient to avoid collision in the event of braking or stopping of the vehicle ahead.” Section 3, applicable to non-urban areas, requires that vehicle combinations exceeding seven meters in length “maintain a distance from the preceding motor vehicle sufficient to allow other overtaking vehicles to safely enter the gap between them.” Section 3a specifies the minimum permissible distance between vehicles on motorways and expressways: this distance, expressed in meters, must be no less than half the numerical value of the vehicle’s speed in kilometers per hour.

The previously cited studies indicate that aerodynamic drag reduction is achievable only at inter-vehicle distances shorter than those permitted under the current “Road Traffic Act.” A potential solution may reside in the deployment of modern intelligent systems that facilitate vehicle control and inter-vehicle communication. One such system is the Vehicle-to-Vehicle (V2V) communication system, which enables vehicles within a convoy to maintain precisely defined spacing. This capability is primarily realized through the synchronized acceleration and braking of all vehicles. A convoy operating under such systems is commonly referred to as a “platoon”.

The principal advantages of platooning include increased fuel efficiency [

29,

30], reduced emissions of harmful pollutants [

31,

32], enhanced driving comfort and traffic flow [

33], decreased road space utilization [

34,

35,

36], and improved road safety [

37,

38,

39]. Owing to these benefits, numerous international projects have been initiated that exploit the platooning concept. Initiatives such as Safe Road Trains for the Environment (SARTRE) [

40,

41] and the Grand Cooperative Driving Challenge (GCDC) [

40] primarily focus on heterogeneous vehicle platoons, whereas PATH [

40,

42], KONVOI [

43], Energy ITS [

40], SCANIA [

40], COMPANION [

44], and the European Truck Platoon Challenge (ETPC) target homogeneous platoons predominantly composed of trucks.

Directions for future research and near-term developments in platooning have been outlined by Sivanandham et al. [

45]. Beyond emphasizing the substantial advantages of organized road transport, the authors highlight current limitations impeding the widespread adoption of these technologies. Another intensively explored research area involves the implementation of advanced control and communication systems for truck platoons. The most widely utilized controller currently is the Cooperative Adaptive Cruise Control (CACC) system—an enhanced variant of Adaptive Cruise Control (ACC). Existing CACC systems employ short-range wireless communication [

46]; however, ongoing research investigates alternative communication protocols, including Wi-Fi [

47], LTE and 5G [

48,

49,

50], as well as cloud computing technologies [

51]. Reference [

52] provides a comprehensive characterization of selected CACC controllers. In recent years, numerous novel approaches have been proposed for vehicle communication and automated control system design, including consensus-based controllers [

53,

54], model predictive control [

55,

56], sliding mode control [

57,

58,

59,

60,

61,

62], and adaptive controllers [

63,

64].

In recent years, issues related to the formation of vehicle convoys—comprising both automated and autonomous vehicles (CAVs—Connected and Automated Vehicles) and conventional human-driven vehicles (HDVs—Human-Driven Vehicles)—have attracted increasing attention from the scientific community. Control strategies for such mixed traffic platoons have been widely studied; however, most research has focused on fixed-structure formations, where the spatial arrangement of CAVs and HDVs is predetermined. Representative configurations examined in the literature include HDV-HDV-CAV [

65], CAV-HDV-...-HDV-CAV [

66], HDV-CAV-HDV [

67], HDV-CAV-HDV-CAV-HDV [

68], and CAV-CAV-...-CAV-HDV [

69].

Nevertheless, the structural configuration of a convoy and the spatial positioning of CAVs within the platoon play a critical role, significantly affecting traffic safety, energy efficiency, and the overall throughput of the transportation system, as shown in studies [

70,

71,

72]. Additionally, the dynamics of platoon formation—particularly in response to highway and urban traffic conditions—have also been addressed in recent research [

73,

74,

75].

This topic has been further investigated in subsequent studies. Jin et al. [

76] examined the influence of CAV positioning on energy efficiency and traffic throughput in mixed vehicle platoons by analyzing three scenarios: a random distribution of CAVs and HDVs, an alternating configuration, and a layout in which all CAVs are concentrated in the central segment of the platoon. In a related study, Li et al. [

77] assessed the impact of platoon formation on stability, utilizing an objective function optimization framework for three CAV arrangement patterns: uniform, random, and clustered.

Both studies assumed homogeneous and predefined spatial distributions of CAVs and HDVs. However, in real-world traffic environments, vehicle fleet heterogeneity and the stochastic behavior of HDV drivers introduce complex interactions that may considerably affect the performance of mixed platoons. This issue was addressed in [

78], where the authors proposed a heterogeneous platoon model comprising both CAVs and HDVs. Their findings demonstrated that platoon formation structure substantially influences both energy efficiency and traffic throughput—variations in formation configuration resulted in changes in energy consumption ranging from 1.24% to 26.27%, and in traffic throughput from 0.49% to 29.47%.

The development of efficient driving strategies for mixed vehicle platoons encompasses, among other aspects, the optimization of longitudinal and lateral trajectories for the entire vehicle ensemble. Under highway conditions, the trajectories of autonomous vehicles (CAVs—Connected and Automated Vehicles) are formulated by incorporating the heterogeneous behaviors of conventional human-driven vehicles (HDVs—Human-Driven Vehicles), including variations in driving styles [

65], lane-changing maneuvers [

79], and on-ramp merging processes [

80].

Owing to the increased complexity of urban environments—characterized by factors such as traffic signalization and fluctuating traffic density—the management of mixed vehicle platoons in urban scenarios presents considerable challenges. In response, Wang et al. [

81] and Shi et al. [

66] proposed control frameworks for mixed traffic at signalized intersections, targeting the minimization of both energy consumption and travel time. It is important to note, however, that these investigations primarily focused on optimizing CAV trajectories while neglecting the influence of HDV presence within the objective function. As a result, the potential for energy consumption reduction in fully mixed platoons remains substantially underutilized.

To address this gap, Yang et al. [

82], Wang et al. [

67], and Li et al. [

68] developed eco-driving strategies for mixed platoons that explicitly consider the effect of CAV driving behavior on the dynamics and energy consumption of trailing HDVs. These methodologies aim to improve the overall energy efficiency of the entire platoon.

In the realm of platoon control, novel strategies have been introduced based on centralized, distributed, and hybrid control architectures. A notable example is the switching control strategy termed Cooperative Adaptive Cruise Platoon Control (CACPC), which primarily focuses on maintaining stability and robustness against disturbances during dynamic controller transitions [

83]. Concurrently, Quadri et al. [

84] developed PLATO, a dynamic multi-platoon management system leveraging 5G communication technologies and edge computing architectures. This system synergistically integrates the benefits of centralized and distributed control paradigms, facilitating reliable real-time management of a large fleet of platoons.

Furthermore, Zhang et al. concentrated on the design of robust control methodologies, emphasizing behavioral stability and resilience to stochastic disturbances. Their management of heterogeneous platoons employed a Robust Model Predictive Control (RMPC) framework [

85], ensuring system adaptability under varying operational conditions.

Recent literature reports also indicate considerable research interest in the areas of maintaining constant time gaps between vehicles in a platoon, simultaneous coordination of vehicle motion within the platoon (car-following), data transmission scheduling, precise trajectory tracking, maintaining constant curvilinear spacing, and coordinated linear velocity, as well as their impact on fuel efficiency and driving comfort. These issues are discussed in detail in the studies presented below.

Study [

86] addresses the determination of the time headway necessary to ensure robust string stability in platoons of connected and autonomous vehicles in the presence of V2V communication disturbances. The influence of noise in the acceleration signal transmitted from the preceding vehicle on the effectiveness of the Constant Time Headway Policy (CTHP) was analyzed. A control model was developed, utilizing both onboard sensor measurements and data from the wireless network. Conditions for controller gains and the minimum allowable time gap were derived, ensuring system stability in the presence of signal noise.

In the study [

87], a new approach for joint platoon coordination and data transmission scheduling in cooperative vehicle–infrastructure systems (CVISs) using mobile edge computing (MEC) is presented. A two-level approach was proposed, comprising a mobility optimization layer to enhance fuel efficiency and a vehicle-to-infrastructure (V2I) communication layer for reliable data transmission scheduling. The developed models enable fuel consumption minimization and improved communication reliability by considering platoon mobility, channel characteristics, and application requirements. Simulation results showed that the proposed method reduces the platoon’s fuel consumption per time slot by 16.4% while improving communication reliability by a factor of 1.31 compared to conventional approaches.

The article [

88] presents a novel method for platooning connected autonomous vehicles (CAVs) on curved roads, combining a longitudinal regulator based on deep reinforcement learning (DRL) with a nonlinear lateral controller. The DRL agents learn the optimal acceleration by iteratively interacting with an effective lateral controller. The use of distributed control and vehicle-to-vehicle (V2V) communication enables efficient cooperation among multiple vehicles, rapid adaptation to environmental changes, and maintenance of optimal trajectories, constant gaps, and driving comfort. Numerical experiments demonstrated the effectiveness of the method under various scenarios, including lane changes by the platoon and left turns at roundabouts.

Promising results from research on advanced technical solutions in control systems, communication, and artificial intelligence, together with anticipated changes in traffic regulations and the implementation of 6G communication, suggest that future roads will host not only homogeneous but also heterogeneous vehicle platoons, currently being tested on research proving grounds and selected road sections. The deployment of 6G communication technology, as presented in the studies listed below, is particularly promising.

Article [

89] analyzes the advantages of edge computing over traditional cloud computing in critical applications requiring ultra-low latency and high reliability, such as drone networks, autonomous vehicles, telesurgery, and Augmented Reality (AR). Edge intelligence enables local processing of large datasets and complex tasks in near real time, thereby mitigating latency and data storage challenges. A case study on 6G-based edge intelligence demonstrates a significant improvement in communication latency (10–100 μs) compared to 5G (<5 ms) and 4G (<10 ms). These solutions demonstrate the potential of 6G networks to provide efficient, secure, and mobile computing infrastructure while highlighting open research challenges in this area.

Study [

90] discusses the architecture, communication, resource allocation, key features, and application examples, as well as technological and non-technological challenges. It identifies key requirements and future research directions for the development of 6G Autonomous Intelligent Transportation Systems (6G-AITSs).

Article [

91] presents the concept of traffic flow optimization in autonomous vehicle networks using 6G communication technology. The proposed approach eliminates traditional traffic lights by employing vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication, supported by multi-agent reinforcement learning. The results of theoretical analyses indicate a 40–50% reduction in intersection waiting times, a 50–70% decrease in the probability of accidents, and a 35% reduction in the carbon footprint. The ultra-low latency and high scalability of 6G enable support for up to 10,000 vehicles per km

2.

Another aspect related to the environmental impact of road transport is the noise it generates. According to the research conducted by Helfer [

92], aerodynamic noise becomes comparable in magnitude to tire noise at speeds of approximately 120 km/h for passenger cars and 80 km/h for delivery vehicles.

In study [

93], Bergamini et al. performed simulation research using Computational AeroAcoustics (CAA). The mathematical models were based on Lighthill’s acoustic analogy. The investigated geometries featured a trapezoidal shape with a flat front and a rear end inclined at a 50-degree angle. Results from CFD simulations were incorporated into the Ffowcs Williams–Hawkings equation to determine the generated aerodynamic noise. For model validation, a CFD simulation of a two-dimensional cylindrical object was conducted and compared with existing literature data. The second stage of validation involved a wind tunnel experiment.

Tsai et al. [

94] conducted an aeroacoustic analysis of a car equipped with a rear spoiler. An unstructured mesh was employed in the CFD study. Airflow simulation around the vehicle was performed in two phases: initially, steady-state calculations using the k-ε Renormalization Group (RNG) turbulence model, followed by unsteady-state computations using the steady-state results as initial conditions. The objective was to identify the optimal rear spoiler configuration regarding aerodynamic noise and forces.

To analyze the acoustic pressure level around an Ahmed body geometry, Duncan et al. [

95] applied the Lattice Boltzmann Method as implemented in the PowerFLOW software. The unsteady-state simulation was conducted using the Very Large Eddy Simulation (VLES) model, with model discretization performed via the software’s integrated meshing tool.

The authors of this study have been conducting research over several years, initially focusing on simplified models and currently addressing complex vehicle platoon structures. The research began with a simplified vehicle geometry widely recognized in the scientific community as the Ahmed body. In the work presented in [

96], key characteristics and parameters of the numerical mesh were defined, alongside the selection of appropriate initial and boundary conditions and computational models. For steady-state simulations, the k-ω SST turbulence model was employed. Subsequent unsteady-state analyses were performed using the Large Eddy Simulation (LES) model with a time step of 10

−5 s. During the model validation process, computed quantities were compared with experimental data and numerical results from the literature. Vortex structures in the aerodynamic wake, velocity profiles in the symmetry plane, and values of drag and lift coefficients were analyzed. The unsteady-state simulations also enabled aeroacoustic analysis of the Ahmed body geometry, applying the Ffowcs Williams–Hawkings equations to determine the acoustic field at discrete points surrounding the vehicle model.

The study reported in [

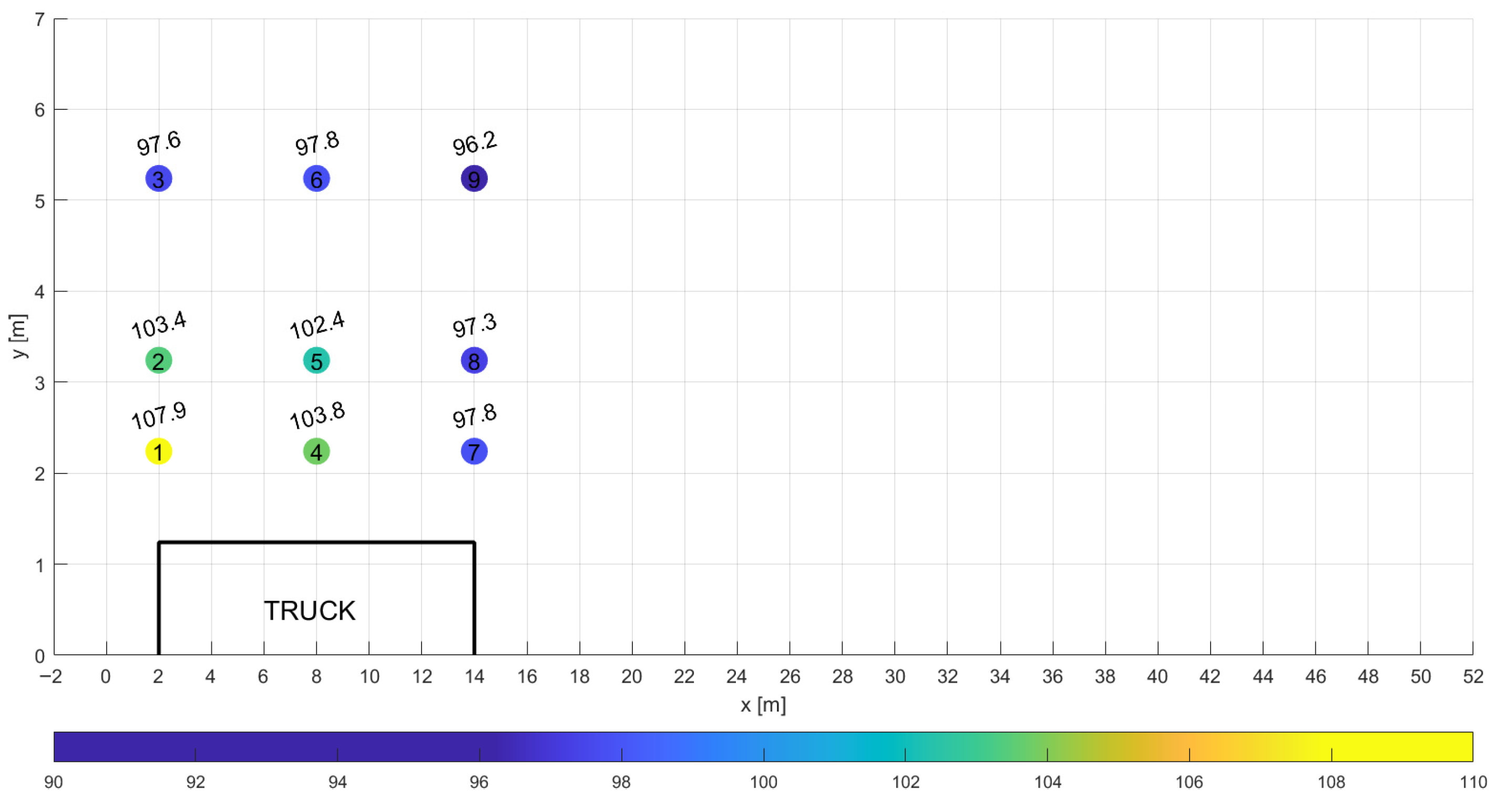

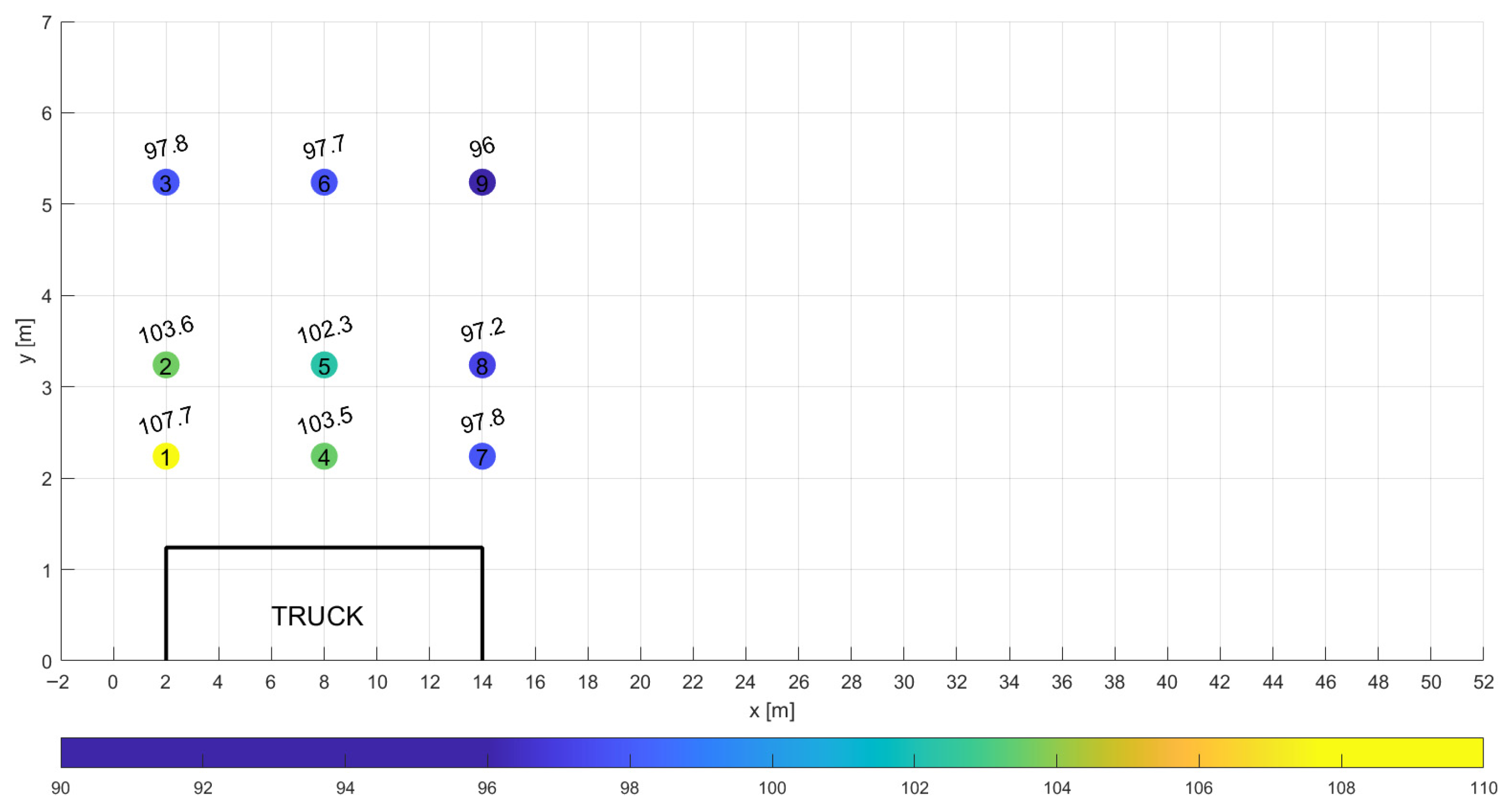

97] presents simulation results for a vehicle platoon consisting of three identical truck models traveling at a uniform speed of 90 km/h. The modeling employed a previously developed truck model, arranged into platoons with three distinct inter-vehicle distances. The study defined key numerical mesh parameters and applied appropriate boundary and initial conditions along with validated turbulence models. Analyses included investigation of drag and lift coefficients, as well as distribution of the overall sound pressure level. Several figures illustrate velocity, pressure, and turbulence intensity distributions around the analyzed truck platoons.

Research described in [

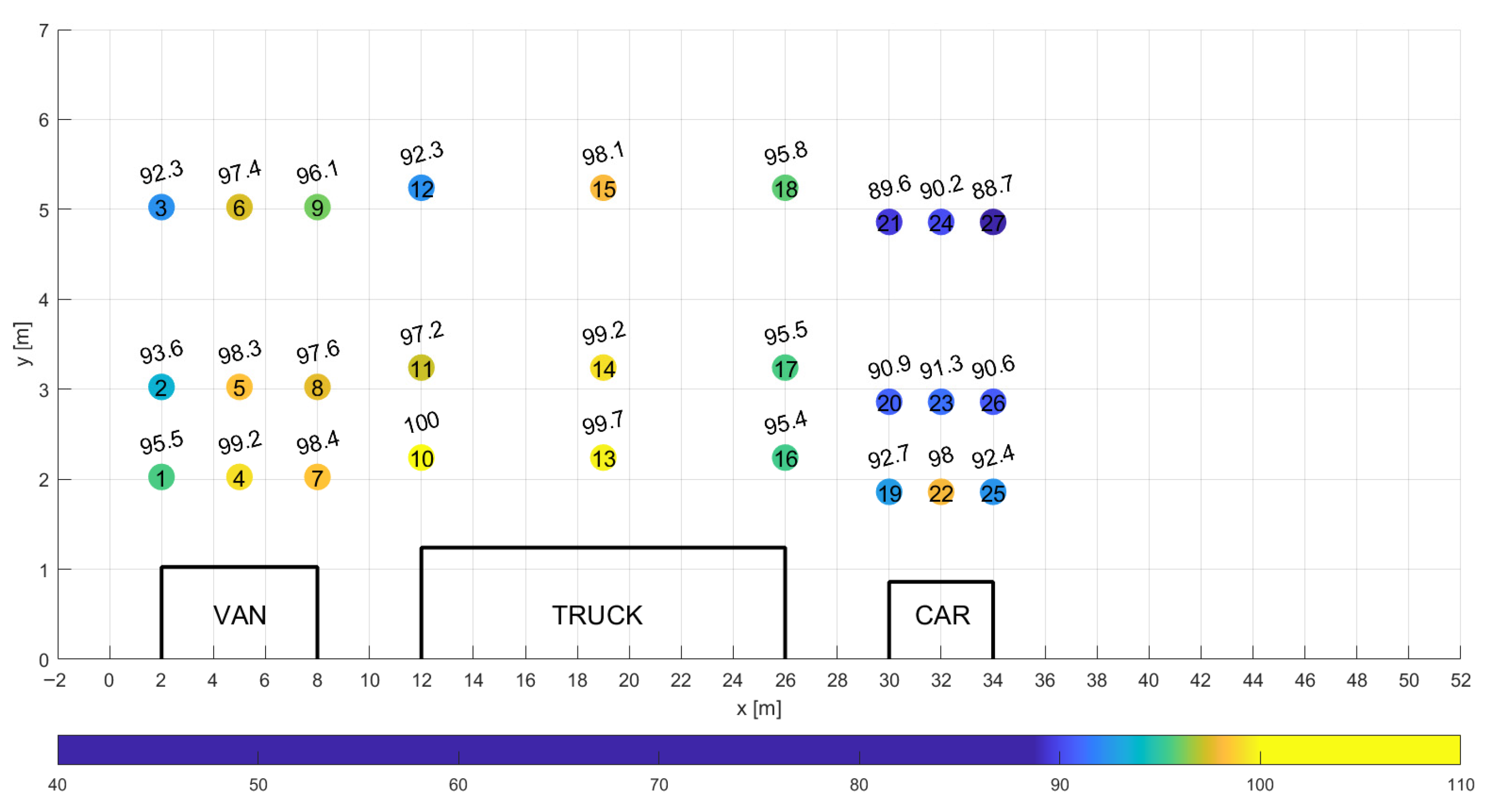

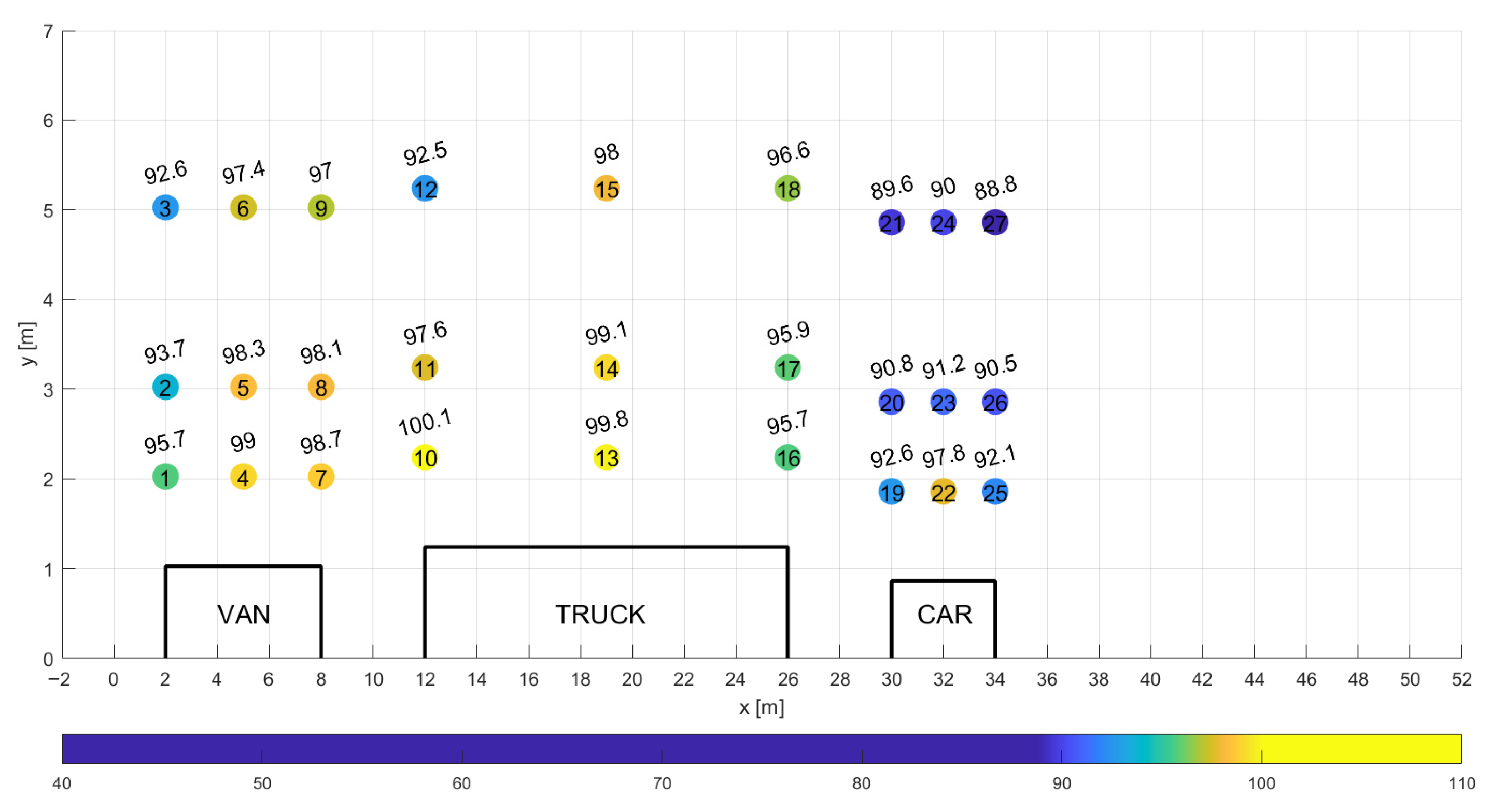

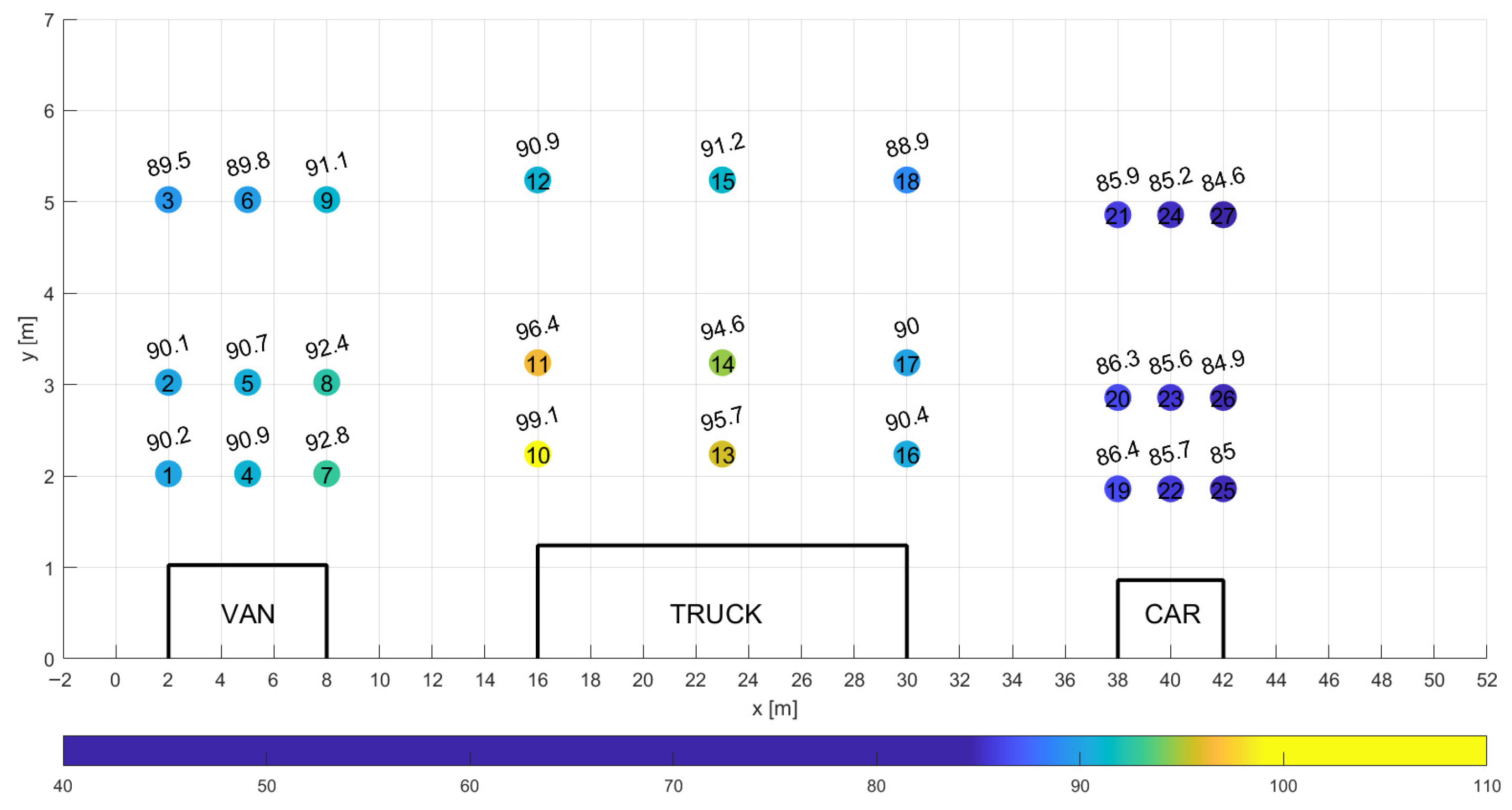

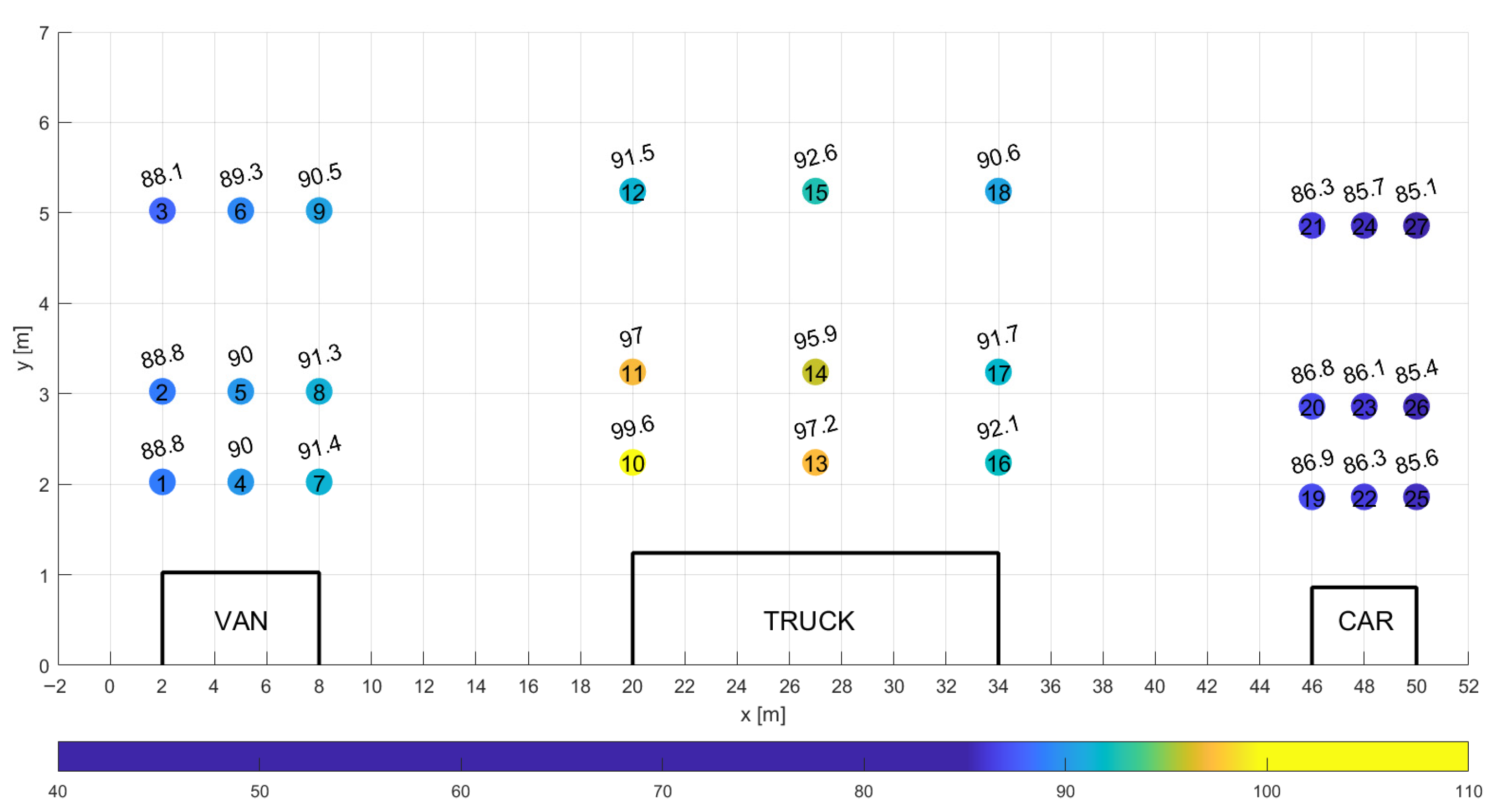

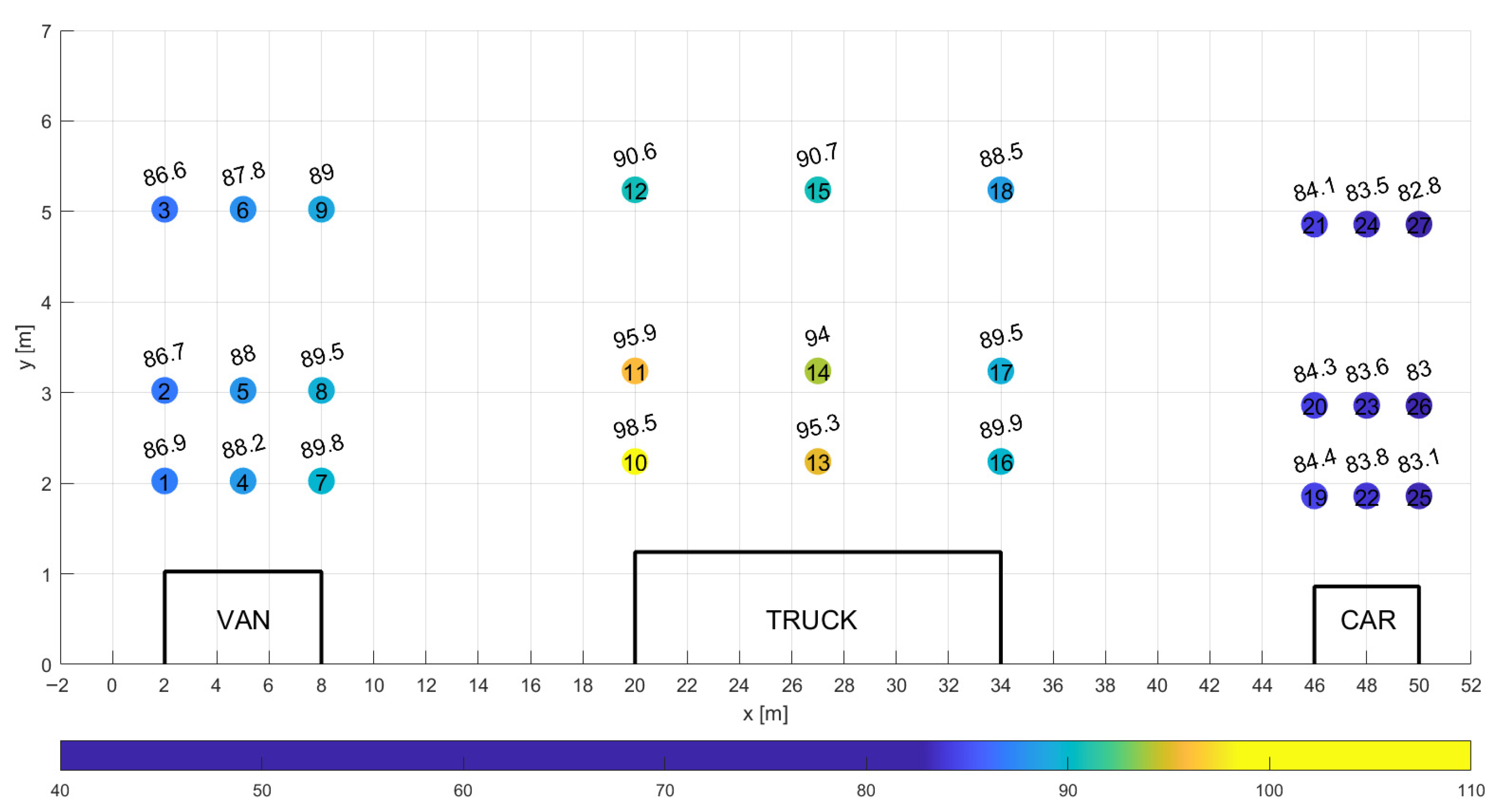

98] focused primarily on highly detailed modeling of structured meshes used for simulations of individual vehicles and heterogeneous platoons, consisting of three distinct vehicle types: a passenger car, a van, and a truck. The study specified numerical mesh features and parameters, boundary and initial conditions, and computational models. The principal aim was to develop universal models enabling future studies of platoons with arbitrary vehicle numbers, configurations, inter-vehicle distances, and speeds. Velocity fields, streamlines, pressure distributions, and turbulence kinetic energy dissipation were graphically presented for the heterogeneous platoons. Additionally, overall sound pressure levels were calculated at selected points within the computational domain.

In study [

3], a comprehensive process for modeling aerodynamic and aeroacoustic phenomena in different vehicle platoons—both homogeneous and heterogeneous—was presented. Digital models were developed, and fuel consumption was assessed for various platoon configurations, along with their environmental impacts. Studies [

99,

100] introduced novel Acoustic Environment Management Systems employing Geographic Information Systems (GISs), which integrate graphical information with textual data stored in databases. The system incorporated information on the effects of road, rail, industrial, municipal, and aircraft noise on urban residents. Its development involved thousands of acoustic measurements conducted in the Kraków metropolitan area, followed by the creation and validation of acoustic models. Upon completion, the system was implemented and has since been systematically updated and further enhanced. Additional improvements were achieved through studies [

101,

102,

103], which enabled the determination of optimal travel routes across the Kraków metropolitan area, taking into account, among others, acoustic criteria. Graph-based algorithms, genetic algorithms, and neural networks were applied for this purpose. The research currently being carried out by the authors, as well as that planned for the future, is expected to significantly enrich this system with elements of an Intelligent Transportation System (ITS).

The primary objective of the study was to develop and execute 54 numerical models of heterogeneous vehicle platoons, varying in vehicle composition, traveling at three speeds: 50 km/h, 90 km/h, and 140 km/h, and at three inter-vehicle distances: 4 m, 8 m, and 12 m. Each platoon comprised three vehicles of differing body types: a small passenger car (Audi A3), a medium-sized delivery van (Fiat Ducato, model L3H2), and a large truck (Mercedes-Benz Actros F with trailer).

The study aimed to determine aerodynamic drag forces for individual vehicles and total drag for the platoons, drag coefficients and their percentage reductions, average fuel consumption and corresponding percentage reductions for individual vehicles, and total fuel consumption for heterogeneous platoons. For the most favorable platoon configurations, distributions of A-weighted sound pressure levels were also to be determined.

The simulations utilized the k-ω SST turbulence model, Large Eddy Simulation (LES), and the Ffowcs Williams–Hawkings acoustic analogy. CFD computations were performed at the Cyfronet Academic Computer Centre in Kraków using the Prometheus supercomputer and Ansys Fluent software. Additional verification was conducted using the NMPB-Routes-2008 method [

104] and ISO 9613-2 standard [

105,

106] via SoundPlan software 8.2 and 9.1. The developed models and analysis results will support further research on acoustic and aerodynamic phenomena related to moving road vehicles, contributing to the so-called “active layer” of the Integrated Acoustic Environment Management System for the Royal Capital City of Kraków—currently under development by the authors [

3,

99,

100,

101,

102,

103]—as well as applications within Intelligent Transportation Systems (ITSs).

Given that this work was conducted over a period of three years, a variety of computational environments and software packages were utilized, including Ansys Academic Research, CATIA V5 Student Edition, CATIA Academic License Program, SoundPlan 8.2 and 9.1 Research & Education License, and MATLAB Academic Research. The authors have had, and continue to have, access to the latest research and educational versions of these software packages.

3. Materials and Methods

3.1. Geometrical and Numerical Model

Aerodynamic phenomena associated with vehicle motion can be effectively analyzed through simulation-based studies. Computational Fluid Dynamics (CFD) is a field that focuses on solving fluid flow problems using numerical methods. When the parameters of interest—such as fluid velocity, pressure, or density—vary over time, the simulations are categorized as unsteady-state (transient) analyses. While unsteady simulations provide a more realistic representation of fluid behavior, they are computationally expensive due to the necessity of extremely small time steps and substantial computational resources.

In scenarios where temporal variations in flow parameters are not critical, steady-state simulations are employed. These models assume time-invariant conditions and provide time-averaged values of the analyzed parameters, thereby reducing computational effort. Depending on the nature of the flow domain, numerical simulations can be divided into two categories. Internal flow analyses pertain to fluid motion within geometries enclosed by solid boundaries—for example, flows through pipelines, tanks, or HVAC systems. In contrast, external flow simulations concern fluid motion around bodies immersed in an unbounded environment, where the computational domain is defined by artificial boundaries rather than physical walls. Typical examples include aerodynamic analyses of aircraft, buildings, and road vehicles. The present study focuses on external flow phenomena, specifically airflow around road vehicles.

The study considers three vehicle types, each representing a distinct body category: a passenger car, a delivery van, and a heavy-duty truck. These vehicle geometries are employed both for individual aerodynamic simulations and for simulations of vehicle platoons consisting of three units. A platoon comprising vehicles of identical body types is referred to as homogeneous, whereas a platoon composed of different body types is referred to as heterogeneous.

In all three geometric models, the key features that influence aerodynamic performance—primarily body shape—were retained. However, to reduce mesh complexity and improve discretization quality, several simplifications were introduced. These include the omission of side mirrors, antennas, wheel arches, as well as detailed underbody structures such as cooling systems, drivetrain components, and exhaust assemblies.

Figure 1 presents an isometric view of the developed vehicle models: passenger car, delivery van, and truck.

The passenger car used in the study is a 1998 Audi A3, a hatchback commonly found in Central Europe. This specific model was selected due to its availability to the authors. The vehicle dimensions are as follows: length—4.152 m, width—1.72 m, and height—1.42 m. The cataloged drag coefficient for this model is Cd = 0.31. The frontal area projected onto a plane perpendicular to the direction of airflow is Acar = 1.95 m2.

The van used in the analysis is a Fiat Ducato, model L3H2. The vehicle measures 6.00 m in length, 2.05 m in width, and 2.564 m in height. For the 2014 model, the drag coefficient is Cd = 0.31. The frontal area perpendicular to the airflow is Avan = 4.57 m2.

The truck configuration includes a tractor unit represented by the Mercedes-Benz Actros F, equipped with a roof fairing, and a standard trailer. The total length of the truck is 14.00 m, with a width of 2.48 m and a height of 4.00 m. Drag coefficient values for similar vehicle configurations have been reported in the literature: C

d = 0.542 in the study by Hariram et al. [

107], C

d = 0.554 in Landman et al. [

108], and C

d = 0.563 in Skrucany et al. [

109]. The frontal area projected perpendicularly to the flow direction for the truck is A

truck = 9.30 m

2.

All vehicle models were developed using CATIA V5 software. Both surface and solid modeling modules were employed to accurately reproduce the vehicle geometries.

The assumptions defined in the mathematical model could only be satisfied within sufficiently small regions of the domain. Therefore, the computational domain was subdivided into finite volumes. The discretized form of the partial differential equations, expressed as a system of equations, was solved using the Finite Volume Method (FVM) implemented in the ANSYS Fluent software.

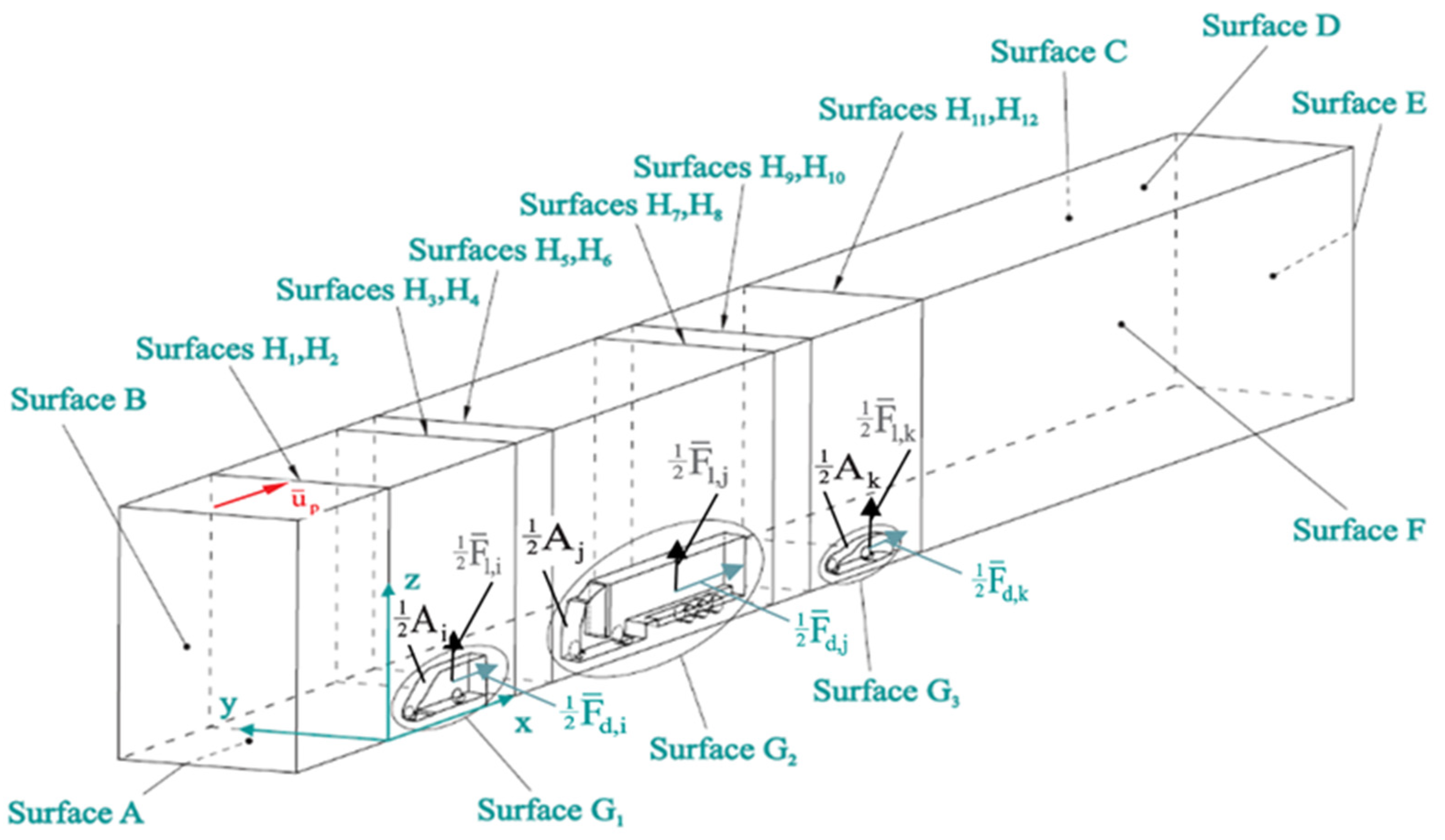

A schematic representation of the airflow model around the vehicle platoon, developed for aerodynamic analysis, is shown in

Figure 2. The figure includes simplified geometries of the three vehicles and highlights the surfaces used to define the boundary conditions.

To reduce the total number of finite volumes, a symmetry plane was introduced in the model. As a result, the projected surface areas of the vehicles onto the plane perpendicular to the flow direction, as well as the aerodynamic forces, represent half of their actual values. The total side force, after accounting for the mirrored configuration, is zero.

The computational domain was constructed using modular blocks, with the number of elements (in millions) varying depending on the inter-vehicle spacing: inlet block—4.09, van block—33.3, intermediate block—from 3.29 to 9.79, truck block—63.3, second intermediate block—from 3.29 to 9.79, passenger car block—28.28, and outlet block—10.51. A structured mesh topology was applied.

For all analyzed configurations, the non-dimensional wall distance parameter y+ did not exceed a value of 1, indicating adequate resolution of the near-wall flow region. Furthermore, a transitional (inflation) layer was applied, consisting of 15 layers with a growth rate of 1.15 between successive layers. The mesh quality, assessed by the minimum orthogonal quality metric, remained above 0.1 in all cases, ensuring the required level of numerical accuracy for reliable simulation results.

Figure 2 presents the following designations: the bottom plane (surface A) represents the road surface. In the computational models, this surface moves in the direction opposite to the actual motion of the vehicles, with an absolute velocity u

p equal to the velocity of the vehicle platoon u

veh.

Surface B, located at the domain inlet, defines the inlet boundary condition. A constant velocity—depending on the analyzed case—of 13.89 m/s, 25 m/s, or 38.89 m/s was applied, corresponding to vehicle speeds of 50 km/h, 90 km/h, and 140 km/h, respectively. A uniform airflow was subjected to an initial disturbance described by the turbulence intensity parameter III.

Surfaces C and D correspond to the lateral boundaries of the domain, where a zero-gradient condition was applied to all considered physical variables. The rear plane (Surface E) defines the outlet boundary condition, where a reference static pressure of zero was specified.

To reduce the total number of computational elements, model symmetry was employed. A symmetry boundary condition was applied on Surface F. The surfaces of the vehicle bodies were labeled as G1 through G3 and treated as no-slip walls (flow velocity at the wall surface equal to zero).

The computational blocks were connected via interface planes labeled H1 to H12. The numerical mesh on these interfaces was matched across adjoining blocks to ensure grid continuity and maintain numerical consistency throughout the domain.

A comprehensive mathematical formulation of the boundary conditions, expressed as Equations (A1)–(A26), is provided in detail in reference [

98].

3.2. Mathematical Model

In this section, a comprehensive methodology and the mathematical models employed to determine pressures, velocities, aerodynamic drag forces, as well as A-weighted sound pressure levels and fuel consumption, are presented. The study utilized the finite volume method implemented in Ansys Fluent. This software enables the numerical solution of partial differential equations governing the motion of fluid particles. The fundamental equations of fluid mechanics are the continuity Equation (1) and the momentum Equation (2) [

110]. Solving these equations requires the adoption of an additional hypothesis regarding viscosity.

Years of accumulated experience, along with numerous studies reported in [

3,

96,

97,

98], demonstrate the effectiveness of the k-ω SST model, which belongs to the group of RANS (Reynolds-Averaged Navier–Stokes) models, and was employed in this work for steady-state calculations. For unsteady simulations, the Large Eddy Simulation (LES) approach [

3] was applied. The simulations assumed a viscous, Newtonian, and incompressible fluid, while gravitational effects were neglected.

Using the Ffowcs Williams–Hawkings (FW-H) Equations (3)–(3D) [

111], acoustic pressure was determined at selected points, and the corresponding A-weighted sound pressure levels were subsequently calculated. For the analysis of the acoustic field, unsteady numerical simulations were conducted using the Large Eddy Simulation (LES) approach. Due to the low Mach number (Ma ≤ 0.075), the acoustic calculations were carried out using Farassat’s method [

112,

113]. In the following part of the study, aerodynamic drag forces were evaluated for both individual vehicles and vehicle convoys. Drag coefficients, percentage reductions in drag coefficients, average fuel consumption, and percentage reductions in fuel consumption for individual vehicles were also calculated, along with the total fuel consumption for heterogeneous vehicle convoys.

u—air velocity vector

p—pressure

ρ0—air density

—stress tensor

To determine the acoustic field around vehicles and vehicle platoons, the Ffowcs Williams–Hawkings analogy (3–7) was used [

111]. The physical quantity of interest is the acoustic pressure p′.

Ffowcs Williams–Hawkings equation:

where

ui—fluid velocity component in the xi direction

un—fluid velocity component normal to the surface f

vi—surface velocity component in the xi direction

vn—surface velocity component normal to the surface f

Tij—Lighthill turbulence stress tensor

Pij—compressible stress tensor

H(f)—Heaviside function

δ(f)—Dirac delta function

δij(f)—Kronecker delta

c0—speed of the sound

ρ0—density fluctuation

The obtained time-dependent pressure values were utilized to calculate the sound pressure level according to Equation (8) [

114], followed by the determination of the A-weighted sound pressure level and the equivalent A-weighted sound pressure level in accordance with Equation (9) [

114].

where

p′—pressure fluctuation

p

ref = 2 × 10

−5 [Pa]—reference acoustic pressure.

where

pA—acoustic pressure corrected according to the A-weighted frequency response

pref—reference acoustic pressure,

T—the time interval for which the equivalent A-weighted sound level is determined.

The drag coefficient C

d is calculated according to Equation (10) [

4,

115] based on the viscous and pressure forces acting on the vehicles.

where

Fd—acting drag force

ρp—air density

A—frontal area of the vehicle,

u—relative air velocity.

Based on the drag coefficient values C

d,i for individual vehicles in the platoon obtained from simulation studies, and the drag coefficient value C

d for a single vehicle, the reduction in the drag coefficient was calculated according to Equation (11) [

116].

where

Cd—drag coefficient of a single vehicle

Cd,i—drag coefficient of the i-th vehicle in the platoon.

The amount of fuel consumed during driving is a function of numerous variables, including vehicle speed, forces acting on the vehicle, engine efficiency, drivetrain efficiency, and the type of fuel used. Assuming that the vehicles travel on a flat road at a constant velocity, the total resistance force is primarily composed of aerodynamic drag and rolling resistance [

5]. To estimate the average fuel consumption K

avg Equation (12), as presented in studies [

117,

118], was employed.

where

Pr—power required to overcome rolling resistance

Pa—power required to overcome aerodynamic drag

—calorific value of the fuel

uveh—vehicle speed

—engine efficiency

—drivetrain efficiency

—fuel density.

The power required to overcome motion resistance can be calculated using the following Formulas (13) and (14) [

5]:

where

Fd—drag force,

Fr—rolling resistance force

uveh—vehicle speed.

The aerodynamic drag coefficient primarily depends on the shape of the vehicle, and for full-size vehicles, its value changes only slightly with speed [

5]. For the analyzed vehicles, the aerodynamic drag force was calculated at speeds of 50, 90, and 140 km/h.

The weight of the passenger car and the van corresponds to vehicles loaded to three-quarters of their maximum gross weight. For the truck, the calculations were based on the maximum permissible gross vehicle weight, which, for a five-axle vehicle combination (a two-axle truck and a three-axle trailer), is 40,000 kg, in accordance with the Regulation of the Minister of Infrastructure on the technical conditions of vehicles and the scope of their necessary equipment.

The rolling resistance coefficient was assumed as kr = 0.009 [

3,

119], and the gravitational acceleration was taken as g = 9.81 m/s

2. For the most commonly used radial tires, the rolling resistance coefficient remains constant for speeds up to 140 km/h [

5]. Due to the low lift coefficient values for the individual vehicles, its influence on rolling resistance was neglected. The rolling resistance force for each vehicle was calculated using Equation (15) [

5].

where

kr—rolling resistance coefficient,

M—vehicle mass

g—gravitational acceleration.

The percentage reduction in fuel consumption of the

i-th vehicle, ΔK

i was estimated based on the method presented in [

5], and can be expressed by Equation (16). For the calculations, it was assumed that the vehicles travel at a constant speed u

veh, the drag coefficient changes to C

d,i due to aerodynamic interactions between vehicles, and the engine efficiency remains constant.

where

ΔCd,i—percentage reduction in the drag coefficient of the i-th vehicle in the platoon

Fd—drag force of the vehicle traveling outside the convoy

Fr,i—rolling resistance force of the i-th vehicle

The total aerodynamic drag force of all vehicles in the platoon, F

d,c was calculated using Equation (17) [

3].

where F

d,i—drag force of the

i-th vehicle in the platoon.

Using the average fuel consumption values of individual vehicles operating outside the platoon K

avg (

Table A3), the percentage reduction in fuel consumption ΔK

i and Equation (18) [

3], the average fuel consumption of each vehicle in the platoon K

avg,i was determined. Subsequently, to calculate the total fuel consumption of all vehicles in the platoon K

c per 100 km traveled, the average fuel consumption values K

avg,i were summed according to Equation (19) [

3].

where

Kavg—average fuel consumption per 100 km of a vehicle outside the platoon

ΔK

i—percentage reduction in fuel consumption by the

i-th vehicle in the platoon.

where

Kavg,i—average fuel consumption per 100 km by the i-th vehicle in the platoon.

All additional information regarding the individual vehicles used in the calculations is provided in

Appendix A,

Table A1,

Table A2 and

Table A3.

Table A1 presents data on vehicle mass, calculated aerodynamic drag values at various speeds, and rolling resistance values. The parameter values utilized for calculating the average fuel consumption of the vehicles are listed in

Table A2. The fuel calorific value Q

w was adopted in accordance with the Regulation of the Minister of Climate [

120], while the fuel density was based on the Announcement of the Minister of Energy [

121]. Engine efficiency and drivetrain efficiency were adopted following references [

3,

117].

Table A3 shows the calculated average fuel consumption for a passenger car, van, and truck at three different speeds. These results were subsequently used to evaluate the fuel consumption reduction for vehicles operating in heterogeneous platoons composed of a passenger car, van, and truck.

4. Analysis of Drag Force and Fuel Consumption Reduction in Heterogeneous Vehicle Platoons

A key aspect of the present study is the explicit consideration of heterogeneity within vehicle platoons. Unlike homogeneous formations, heterogeneous platoons consist of vehicles with markedly different dimensions, masses, aerodynamic characteristics, and powertrains. These differences substantially affect energy consumption and pollutant emissions, as the aerodynamic interactions, drag reduction potential, and overall dynamics vary depending on the specific vehicle composition. To account for these effects, the study includes both passenger cars and heavy-duty trucks with a total length of up to 14 m. This approach allowed for the investigation of how variations in vehicle geometry, speed, and inter-vehicle distance influence fuel consumption, environmental emissions, and acoustic performance. By integrating these heterogeneous features into the computational framework, the analysis captures realistic mixed-traffic conditions and provides insights that are directly applicable to modern road transport systems.

After developing the models and conducting simulation studies, an analysis of drag force and fuel consumption reduction was performed for various configurations of heterogeneous vehicle platoons.

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9 in

Appendix B present the results for heterogeneous platoons composed of three vehicles in each of the six possible configurations.

The first column in each table specifies the convoy speed, with analyses conducted at three speeds: 50, 90, and 140 km/h. The second column indicates the inter-vehicle spacing, ranging from 4 to 12 m. The third column details the vehicle sequence within the platoon—for instance, in

Table A4, the platoon configuration consists of a van leading, followed by a truck in the middle, and a passenger car at the rear.

Columns 4 through 7 present the computed aerodynamic parameters: the drag force F

d,i acting on the i-th vehicle in the platoon, the drag coefficient C

d,i for the i-th vehicle, the calculated reduction in drag coefficient ΔC

d,i, the percentage reduction in fuel consumption ΔK

i, and the average fuel consumption per 100 km for the i-th vehicle in the platoon K

avg,i. Values of drag force reduction and fuel consumption reduction for all heterogeneous vehicle column configurations are provided in the

Appendix B (

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9).

Analysis of the results shown in

Table A4 for the van–truck–car configuration revealed an increase in drag force ranging from 620.74 to 5753.14 N, and a corresponding increase in total fuel consumption from 32.33 to 73.41 L/100 km. The drag coefficient C

d,i ranged from 0.088 to 0.277 for the van, 0.455 to 0.495 for the truck, and 0.170 to 0.322 for the passenger car. Drag coefficient reduction ΔC

d,i varied between 3.82% and 69.44% for the van, 13.46% and 20.45% for the truck, and from −2.55% to 45.86% for the passenger car. Percentage reductions in fuel consumption ΔK

i ranged from 1.4% to 56.96% for the van, 2.14% to 9.3% for the truck, and −1.61% to 29.77% for the passenger car.

Similarly, analysis of

Table A5 for the van–car–truck configuration showed drag force values between 654.64 and 5822.85 N and total fuel consumption between 32.72 and 73.01 L/100 km. The drag coefficient C

d,i ranged from 0.230 to 0.291 for the van, 0.378 to 0.508 for the truck, and 0.137 to 0.250 for the passenger car. The drag coefficient reduction ΔC

d,i ranged from −1.04% to 20.14% for the van, 11.19% to 19.93% for the truck, and 20.38% to 56.37% for the passenger car. Percentage reductions in fuel consumption ΔK

i varied between −0.38% and 16.52% for the van, 2.34% and 11.23% for the truck, and 12.88% to 44.40% for the passenger car.

The analysis of the results presented in

Table A6 for the car–van–truck vehicle configuration revealed a significant increase in drag force ranging from 654.63 to 5979.49 N, along with a corresponding increase in total fuel consumption from 32.72 to 77.13 L/100 km. The drag coefficient C

d,i, ranged between 0.113 and 0.280 for the van, 0.456 and 0.518 for the truck, and 0.232 and 0.380 for the passenger car. The drag reduction ΔC

d,i varied from 2.78% to 62.15% for the van, 9.44% to 20.28% for the truck, and −21.02% to 59.72% for the passenger car. The percentage reduction in fuel consumption ΔK

i ranged from 2.28% to 50.98% for the van, 1.88% to 11.53% for the truck, and −16.94% to 19.25% for the passenger car.

The analysis of

Table A7 for the car–truck–van configuration indicated an increase in drag force from 763.27 to 6204.36 N and fuel consumption from 33.52 to 77.58 L/100 km. The drag coefficient C

d,i ranged from 0.214 to 0.298 for the van, 0.507 to 0.549 for the truck, and 0.137 to 0.372 for the passenger car. The drag reduction ΔC

d,i ranged between −3.47% and 25.69% for the van, 4.02% to 11.36% for the truck, and −18.47% to 56.37% for the passenger car. Fuel consumption reduction ΔK

i varied from −1.28% to 21.07% for the van, 0.68% to 6.57% for the truck, and −14.89% to 44.40% for the passenger car.

According to

Table A8, for the truck–car–van configuration, drag force increased from 775.89 to 6254.47 N, with fuel consumption rising from 33.54 to 76.09 L/100 km. Drag coefficients ranged from 0.238 to 0.264 for the van, 0.561 to 0.579 for the truck, and 0.143 to 0.254 for the passenger car. Drag reduction ΔC

d,i spanned 8.33% to 17.36% for the van, −1.22% to 2.80% for the truck, and 19.11% to 54.46% for the passenger car. Fuel consumption reduction ΔK

i ranged from 4.85% to 13.95% for the van, −0.18% to 1.62% for the truck, and 8.38% to 31.57% for the passenger car.

For the truck–van–car configuration (

Table A9), drag force increased from 775.93 to 6117.45 N, with fuel consumption ranging from 33.50 to 74.47 L/100 km. Drag coefficients varied between 0.225 and 0.247 for the van, 0.530 and 0.577 for the truck, and 0.163 and 0.221 for the passenger car. Drag reduction ΔC

d,i ranged from 14.24% to 21.88% for the van, −0.87% to 7.34% for the truck, and 29.62% to 48.09% for the passenger car. The percentage reduction in fuel consumption ΔK

i ranged from 5.75% to 17.94% for the van, −0.13% to 4.25% for the truck, and 13.01% to 31.31% for the passenger car.

In 8 out of 54 cases considered (three speeds × three vehicle spacings), the lowest total aerodynamic drag force F

d,c among the six analyzed vehicle configurations was observed for the van–truck–passenger car platoon, highlighted in green in

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9. At 90 km/h and 12 m spacing, the lowest total drag force occurred for the passenger car–van–truck configuration. The lowest average fuel consumption values K

avg,i were recorded for six configurations with the van–truck–car (V–T–C) sequence (

Table A4), two with the van–car–truck (V–C–T) sequence (

Table A5), and one with the truck–van–car (T–V–C) sequence (

Table A9), marked in red in the respective tables.

Table 1,

Table 2 and

Table 3 display vehicle platoon structures based on the position occupied by each vehicle within the convoy. For each analyzed speed and vehicle position, the most and least favorable platoon structures regarding fuel consumption reduction were identified. “Position” refers to the location of the analyzed vehicle in the platoon, while “Structure” denotes the sequence of vehicles. The following abbreviations are used: C—passenger car, V—van, T—truck.

For the passenger car (

Table 1), the highest percentage fuel consumption reduction was achieved with configurations C–T–V and V–C–T, both at 4-m spacing and 140 km/h, resulting in a reduction of ΔK

i = 44.40%. Conversely, the C–V–T configuration at 12 m spacing showed the least favorable outcome, with an estimated fuel consumption increase of 16.94%. For the van (

Table 2), the greatest fuel savings occurred in the V–T–C configuration at 140 km/h and 4-m spacing, with ΔK