Leakage Current Equalization via Thick Semiconducting Coatings Suppresses Pin Corrosion in Disc Insulators

Abstract

1. Introduction

2. Materials and Methods

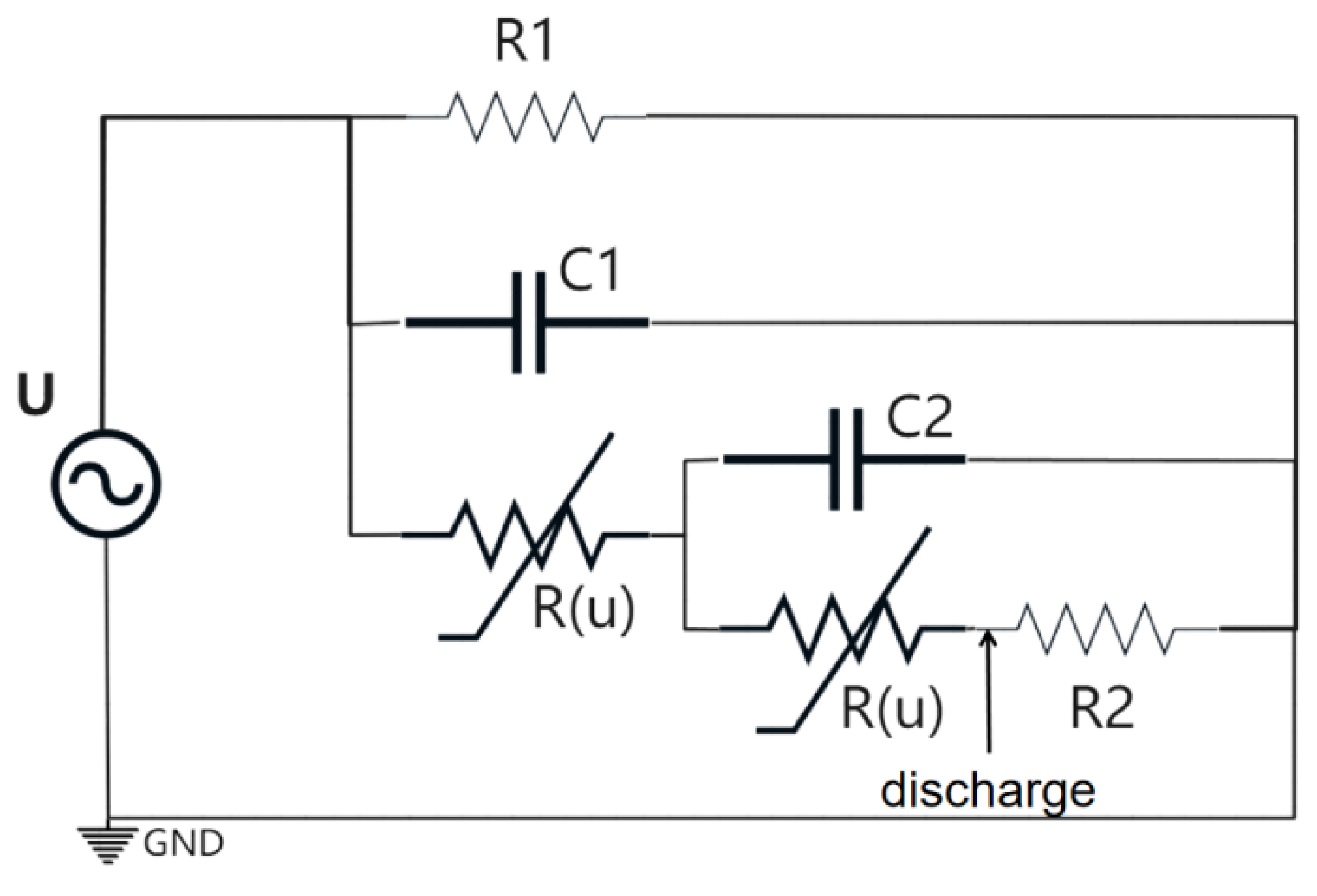

2.1. Simulation of Leakage Current of Porcelain Insulator

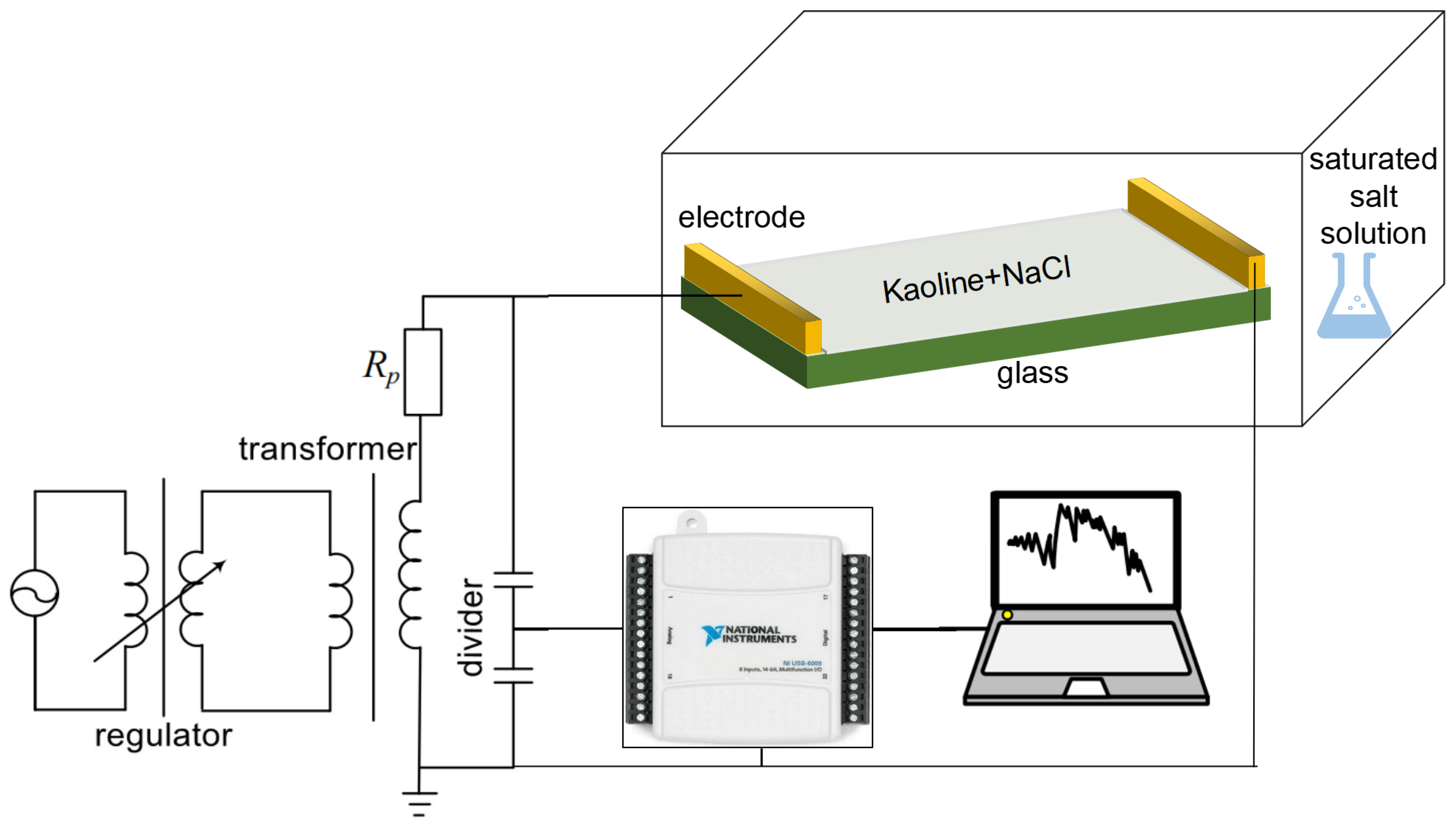

2.2. Measurement of Leakage Current

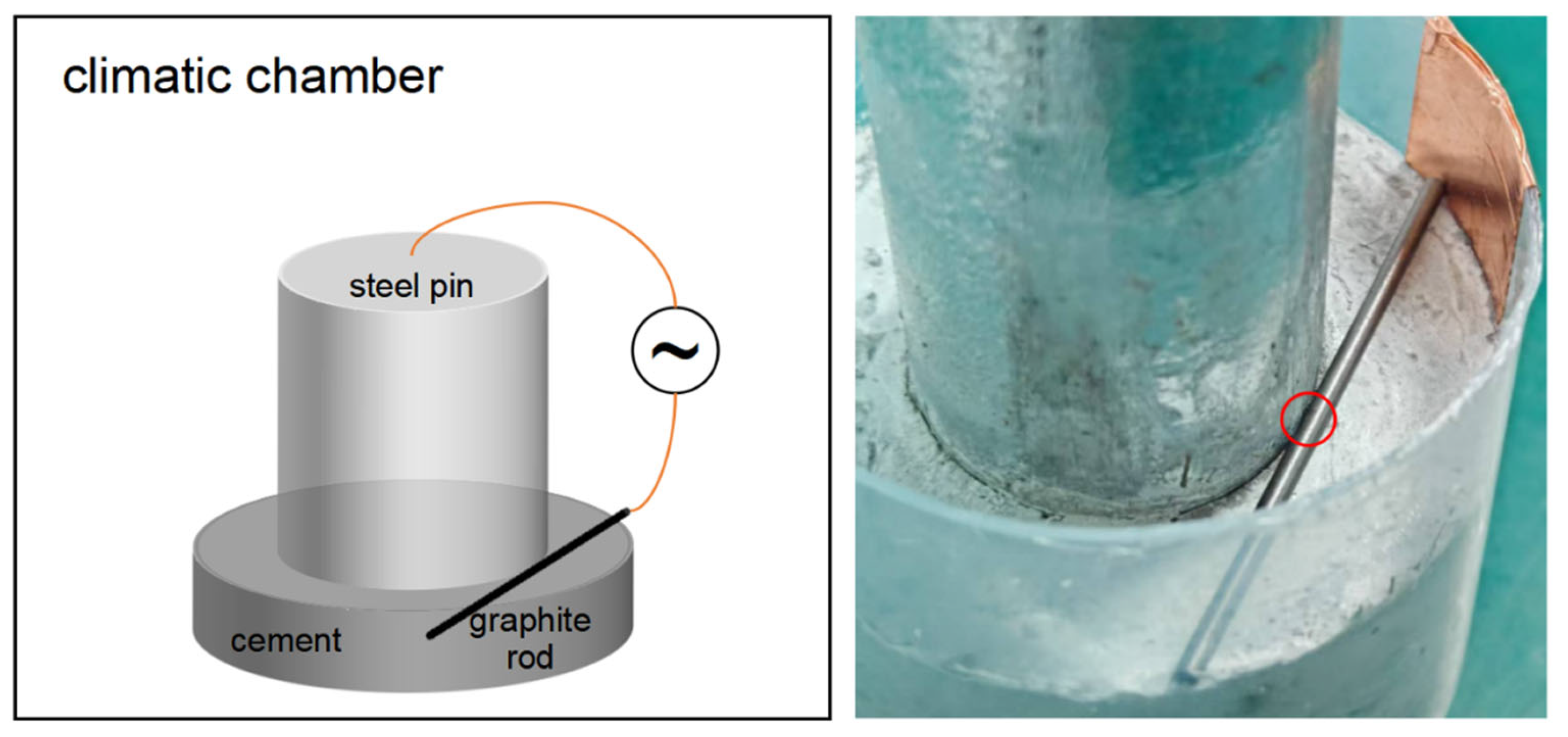

2.3. Accelerated Corrosion Test with Leakage Current

2.4. Simulation of Leakage Current Mitigation Using Semiconducting Coating

3. Results and Discussion

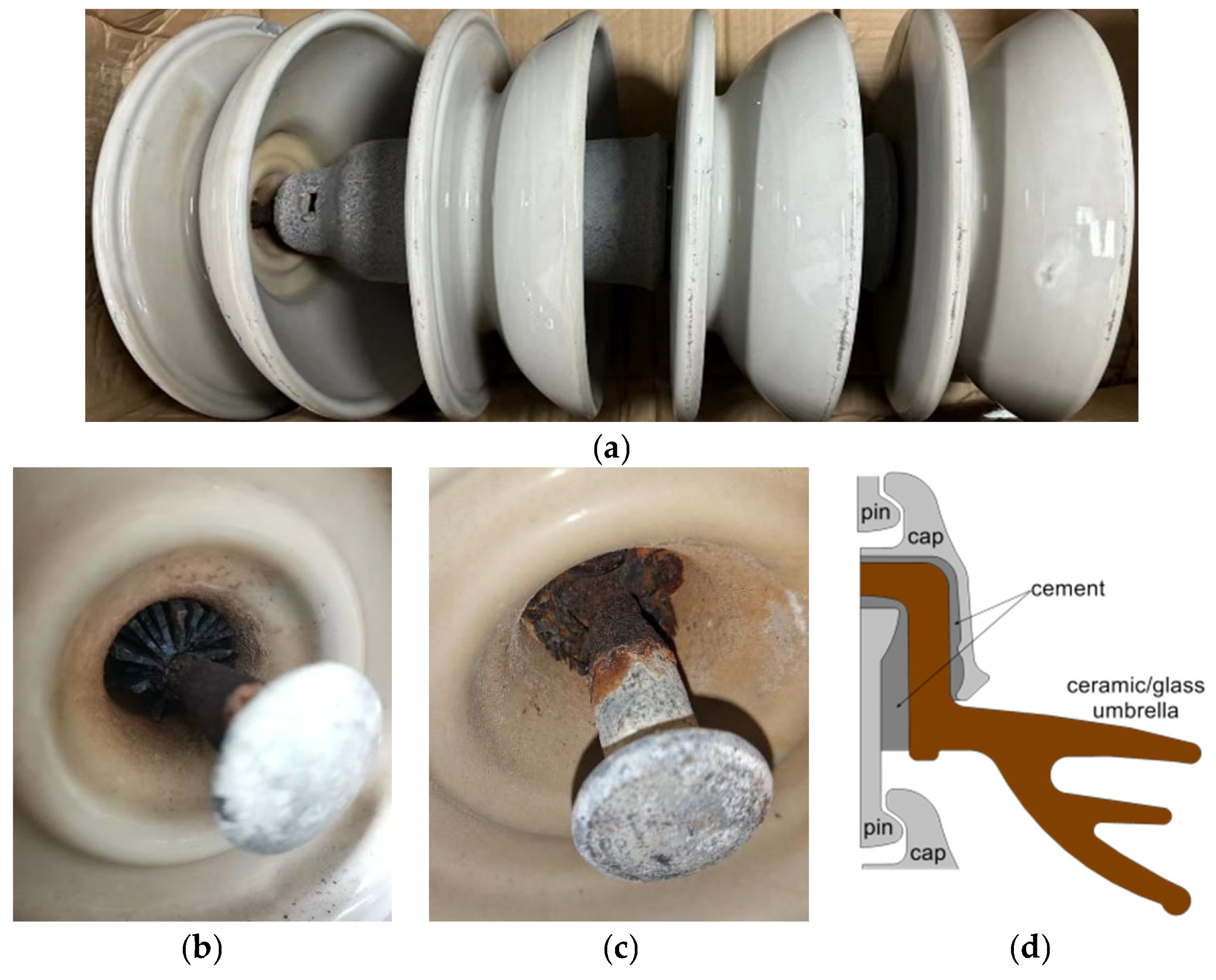

3.1. Case Analysis of Broken Strings

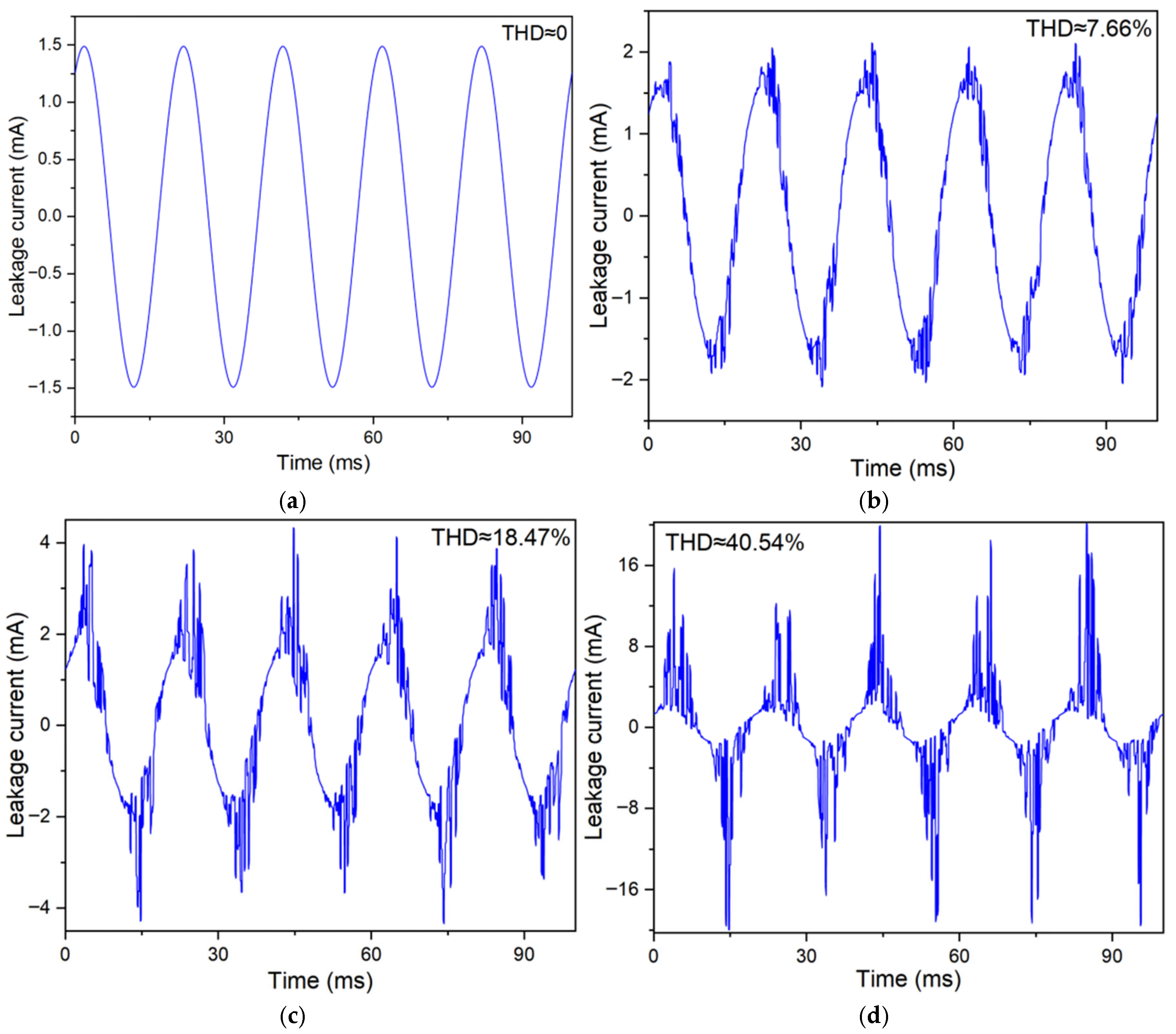

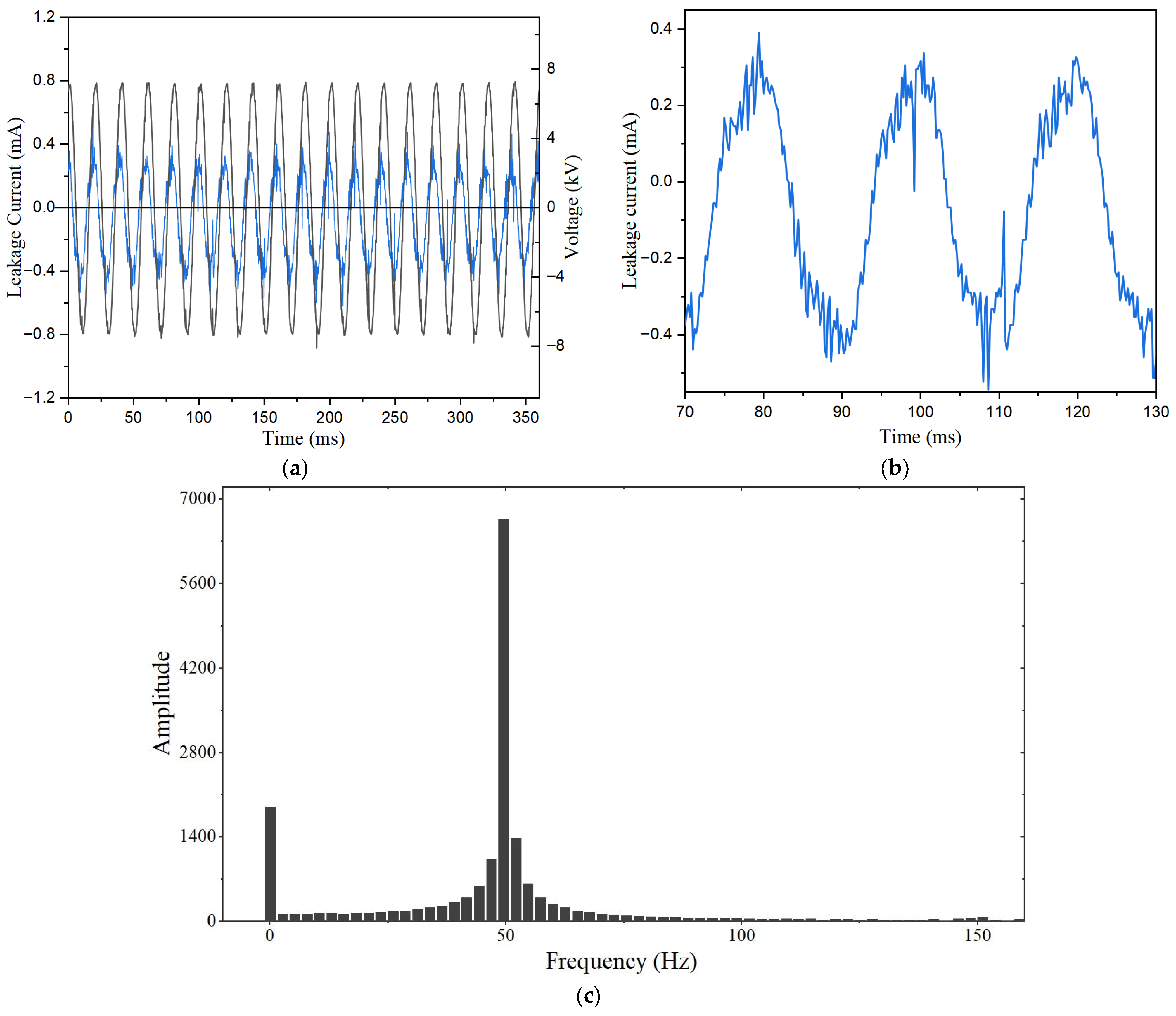

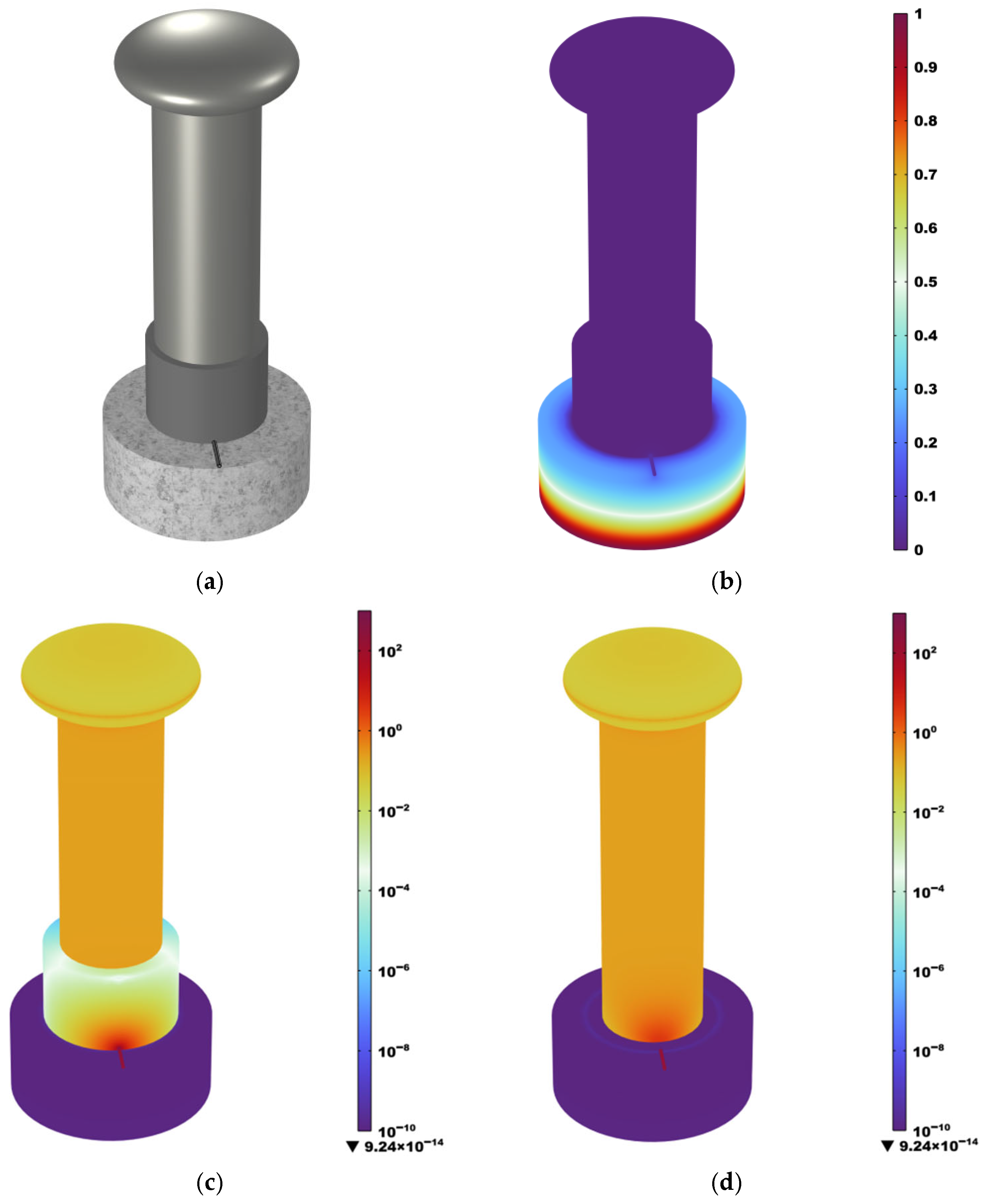

3.2. Results of Leakage Current Simulation and Measurement

3.3. Results of Accelerated Corrosion Test

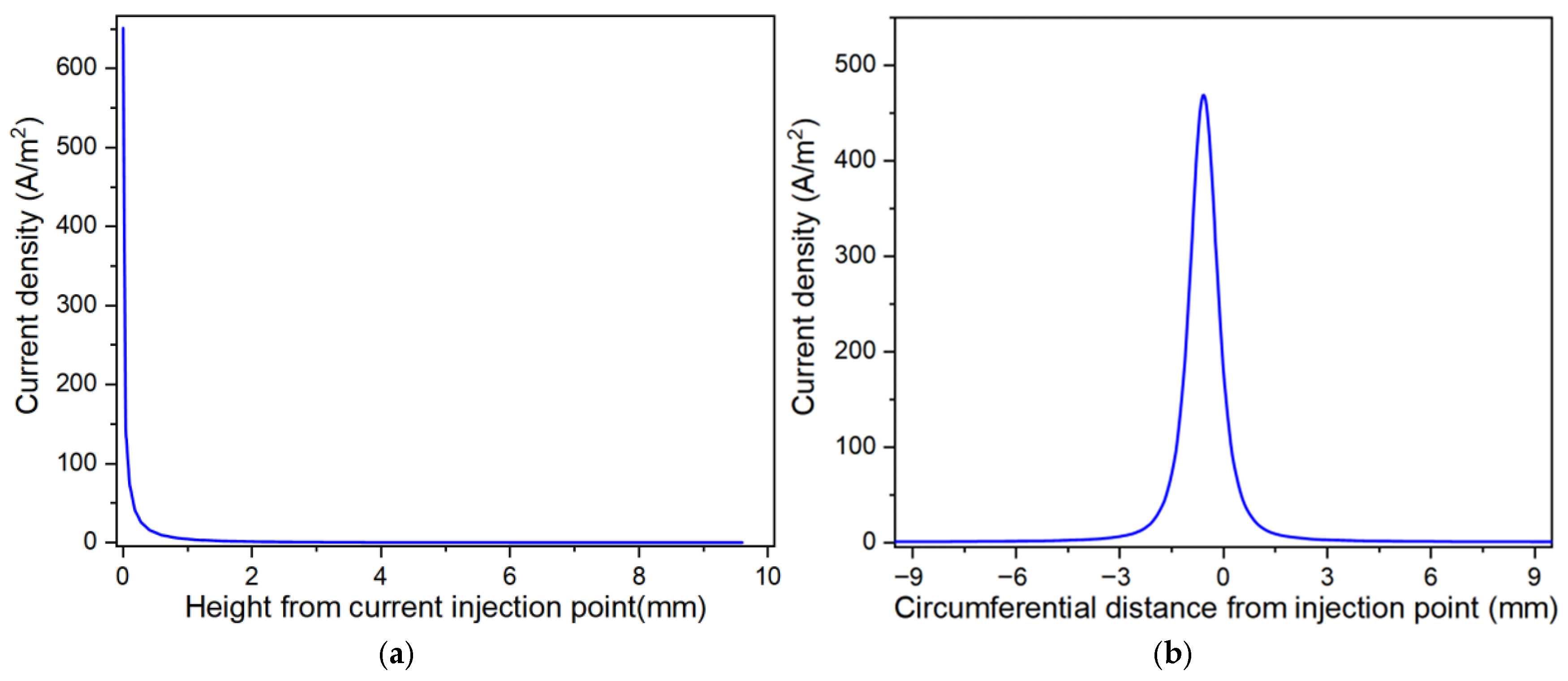

3.4. Results of Current Density Distribution and Mitigation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kluss, J.; Chalaki, M.R.; Whittington, W.; Rhee, H.; Whittington, S.; Yadollahi, A. Porcelain Insulation—Defining the Underlying Mechanism of Failure. High Volt. 2019, 4, 81–88. [Google Scholar] [CrossRef]

- Kim, T.; Lee, Y.-J.; Sanyal, S.; Woo, J.-W.; Choi, I.-H.; Yi, J. Mechanism of Corrosion in Porcelain Insulators and Its Effect on the Lifetime. Appl. Sci. 2020, 10, 423. [Google Scholar] [CrossRef]

- Wang, C.; Qin, G. Corrosion of Underground Infrastructures under Metro-Induced Stray Current: A Review. Corros. Commun. 2024, 14, 23–38. [Google Scholar] [CrossRef]

- Huang, Z.; Feng, C.; Wang, J.; Liu, W.; Xie, Y. Research on Metal Corrosion Mechanism and Inhibition Measures of Transmission and Distribution Equipment in Hunan. IOP Conf. Ser. Earth Environ. Sci. 2021, 621, 012035. [Google Scholar] [CrossRef]

- Salem, A.A.; Lau, K.Y.; Rahiman, W.; Abdul-Malek, Z.; Al-Gailani, S.A.; Rahman, R.A.; Al-Ameri, S. Leakage Current Characteristics in Estimating Insulator Reliability: Experimental Investigation and Analysis. Sci. Rep. 2022, 12, 14974. [Google Scholar] [CrossRef] [PubMed]

- Pratomosiwi, F. Electrical Equivalent Circuit of Ceramic Insulators with RTV Silicone Rubber Coating and Computer Simulation of Leakage Currents. WSEAS Trans. Circuits Syst. 2009, 8, 360–369. [Google Scholar]

- Segall, S.M.; Bahgat, H.; Gudino, E.; Boudreault, J.P.; Khattar, C.; Chen, S. Challenges in Implementing SP21424-2018 AC Corrosion Criteria. In Proceedings of the CORROSION 2021, AMPP: Virtual Conference, Salt Lake City, UT, USA, 19–30 April 2021; pp. 1–14. [Google Scholar]

- Galimberti, C.E. Corrosion of Lead by Alternating Current. Corros. Eng. Dig. 1965, 14, 212–218. [Google Scholar] [CrossRef]

- Han, Y.; Xia, Y.; Chen, X.; Sun, L.; Liu, D.; Ge, X. Effect of Rare Earth Lanthanum-Cerium Doping on Corrosion Behavior of Zinc-Aluminum-Magnesium Hot-Dip Galvanizing Coatings Used for Transmission Towers. Anti-Corros. Methods Mater. 2018, 65, 131–137. [Google Scholar] [CrossRef]

- Vagramyan, A.T.; Sutyagina, A.A. The Effect of Alternating Current on the Electrodeposition of Nickel. Russ. Chem. Bull. 1953, 1, 399–402. [Google Scholar] [CrossRef]

- Zhang, J.; Ji, S.; Ou, X. Representation Method of Insulator Pollution Degree Based on Leakage Current Fundamental Resistive Component. High Volt. Appar. 2010, 46, 29–33+39. [Google Scholar] [CrossRef]

- Fu, C.; Hu, J.; Yang, D.; Yang, B.; Shuang, K.; Zhao, J.; Han, E.; Ke, W. Survey on Soil Corrosion of Grounding Grid of Power Substations in Hainan Island. Corros. Sci. Prot. Technol. 2017, 29, 97–102. [Google Scholar]

- Masri, M.N.; Yunus, Z.M.; Warikh, A.R.M.; Mohamad, A.A. Electrical Conductivity and Corrosion Protection Properties of Conductive Paint Coatings. Anti-Corros. Meth Mater. 2010, 57, 204–208. [Google Scholar] [CrossRef]

- Xu, L.Y.; Su, X.; Yin, Z.X.; Tang, Y.H.; Cheng, Y.F. Development of a Real-Time AC/DC Data Acquisition Technique for Studies of AC Corrosion of Pipelines. Corros. Sci. 2012, 61, 215–223. [Google Scholar] [CrossRef]

- Luo, L.; Wang, L.; Guan, Z.; Zhang, F.; Li, L. Influence of Pin Corrosion on Mechanical Characteristic of UHVDC Disc Suspension Insulators and Solutions. IEEE Trans. Dielect. Electr. Insul. 2015, 22, 2242–2251. [Google Scholar] [CrossRef]

- Ren, Z.; Yang, D.; Liu, J.; Ma, Y.; Huo, Z.; Zheng, S. The Protection of 500 kV Substation Grounding Grids with Combined Conductive Coating and Cathodic Protection. Anti-Corros. Methods Mater. 2015, 62, 83–87. [Google Scholar] [CrossRef]

- Rachmawati, R.; Sartika, N.; Meisa Putra, N.R.; Suwarno, S. The Study on Leakage Current Characteristics and Electrical Properties of Uncoated Ceramic, RTV Silicon Rubber Coated Ceramic, and Semiconducting Glazed Outdoor Insulators. Int. J. Electr. Eng. Inform. 2018, 10, 318–336. [Google Scholar] [CrossRef]

- Rahim, N.A.A.; Ranom, R.; Zainuddin, H.; Razak, I.A.W.A. Numerical Simulation of Leakage Current on Conductive Insulator Surface. Int. J. Recent Technol. Eng. 2019, 8, 9487–9492. [Google Scholar] [CrossRef]

- Salhi, R.; Mekhaldi, A.; Teguar, M.; Kherif, O. Impact of Nonlinear Material Integration in 400 kV Composite Insulator on Leakage Current and Electric Field Distribution. In Proceedings of the 2nd National Conference on Electronics, Electrical Engineering, Telecommunications, and Computer Vision, C3ETCV’24, Mila, Algeria, 24–25 November 2024. [Google Scholar]

- IEC 60068-2-78; Environmental Testing—Part 2–78: Tests—Test Cab: Damp Heat, Steady State. IEC: Geneva, Switzerland, 2012.

- Zhang, C.; Zhong, H.; Shen, Z.; Zheng, H.; Yang, Y.; Su, J.; Fu, X. Accelerated Corrosion and Multimodal Characterization of Steel Pins in High-Voltage AC Insulators under Multi-Stress Conditions. Materials 2025, 18, 4218. [Google Scholar] [CrossRef] [PubMed]

- Zhicheng, G.; Yingke, M.; Liming, W.; Ruihai, L.; Hua, W.; Yi, M. Leakage Current and Discharge Phenomenon of Outdoor Insulators. Int. J. Electr. Eng. Inform. 2009, 1, 1–17. [Google Scholar] [CrossRef]

- Cao, B. Study on Novel Method to MeasurePartial Equivalent Salt Deposit Densityon the Surface Ofinsulators; Tsinghua University: Beijing, China, 2016. [Google Scholar]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.-J.; Park, S.-S. Silicone Rubber Composites Reinforced by Carbon Nanofillers and Their Hybrids for Various Applications: A Review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zheng, H.; Shen, Z.; Su, J.; Yang, Y.; Zhong, H.; Fu, X. Leakage Current Equalization via Thick Semiconducting Coatings Suppresses Pin Corrosion in Disc Insulators. Energies 2025, 18, 5246. https://doi.org/10.3390/en18195246

Zhang C, Zheng H, Shen Z, Su J, Yang Y, Zhong H, Fu X. Leakage Current Equalization via Thick Semiconducting Coatings Suppresses Pin Corrosion in Disc Insulators. Energies. 2025; 18(19):5246. https://doi.org/10.3390/en18195246

Chicago/Turabian StyleZhang, Cong, Hongyan Zheng, Zikui Shen, Junbin Su, Yibo Yang, Heng Zhong, and Xiaotao Fu. 2025. "Leakage Current Equalization via Thick Semiconducting Coatings Suppresses Pin Corrosion in Disc Insulators" Energies 18, no. 19: 5246. https://doi.org/10.3390/en18195246

APA StyleZhang, C., Zheng, H., Shen, Z., Su, J., Yang, Y., Zhong, H., & Fu, X. (2025). Leakage Current Equalization via Thick Semiconducting Coatings Suppresses Pin Corrosion in Disc Insulators. Energies, 18(19), 5246. https://doi.org/10.3390/en18195246