Modeling of Roughness Effects on Generic Gas Turbine Swirler via a Detached Eddy Simulation Low-y+ Approach

Abstract

1. Introduction

Research Scope

2. Materials and Methods

2.1. Reference Experimental Data

2.2. Roughness Parameter Selection

2.3. CFD Domains

2.4. DES Setup

2.5. Physics Setup

3. Results and Discussion

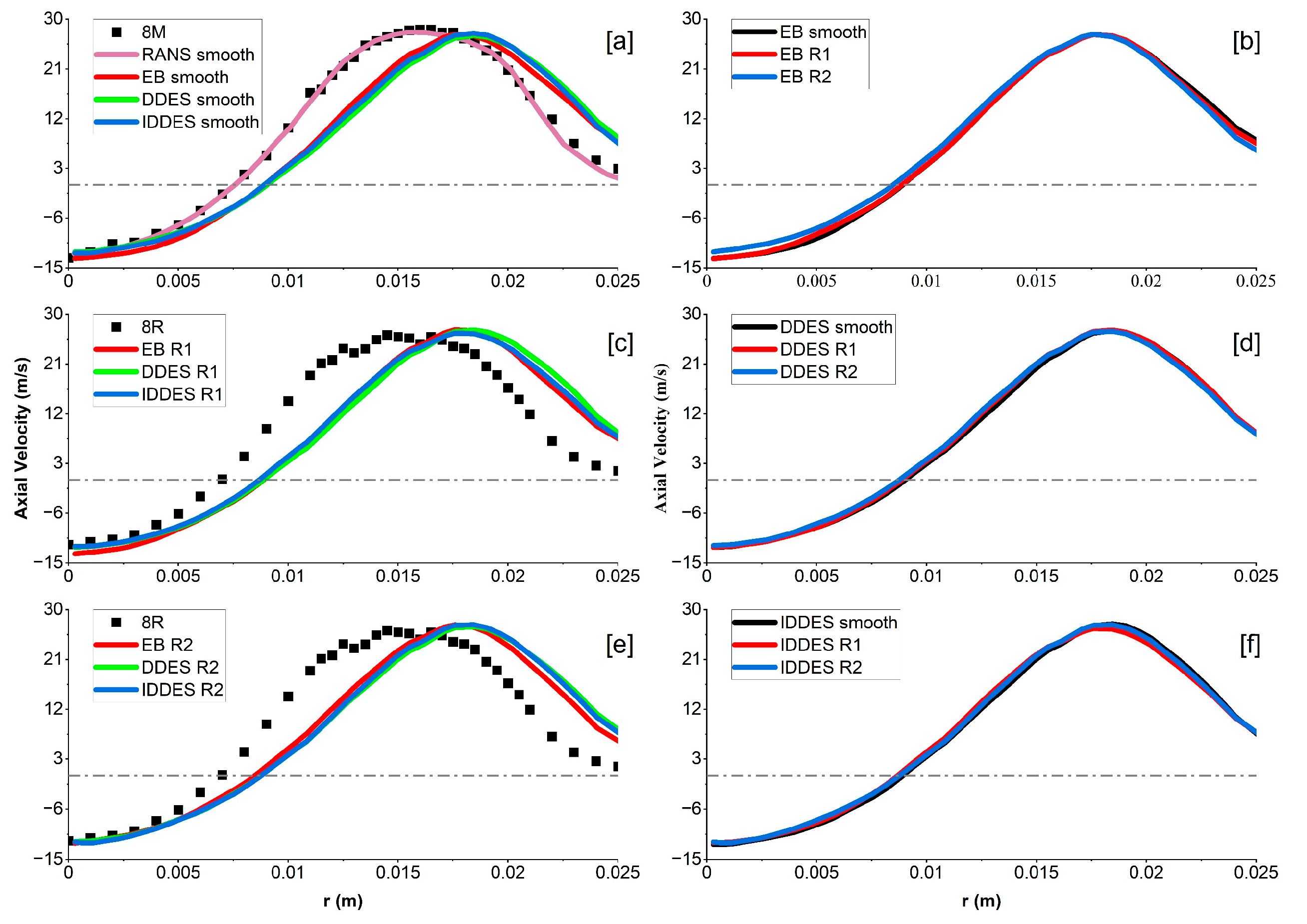

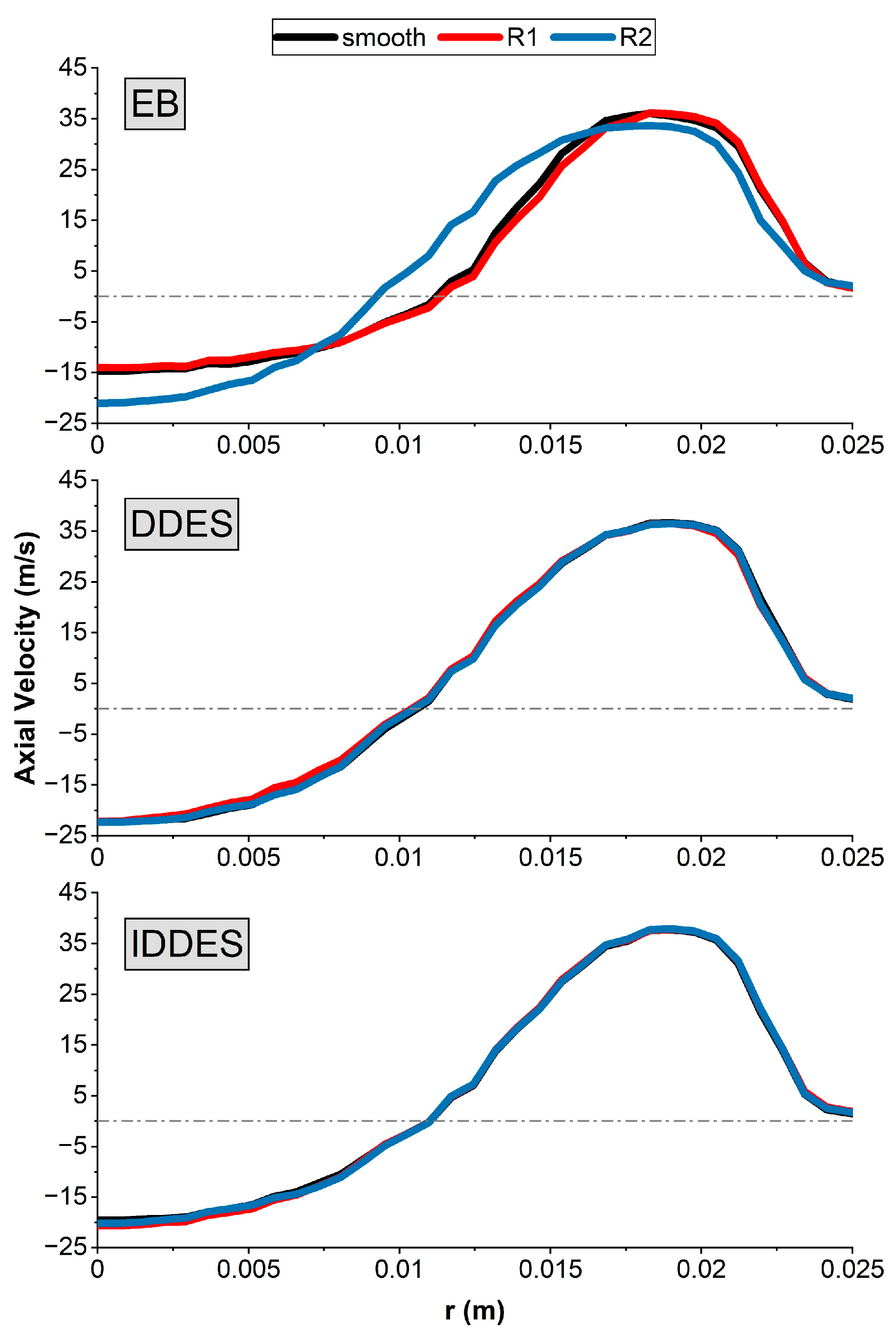

3.1. Velocity Profiles

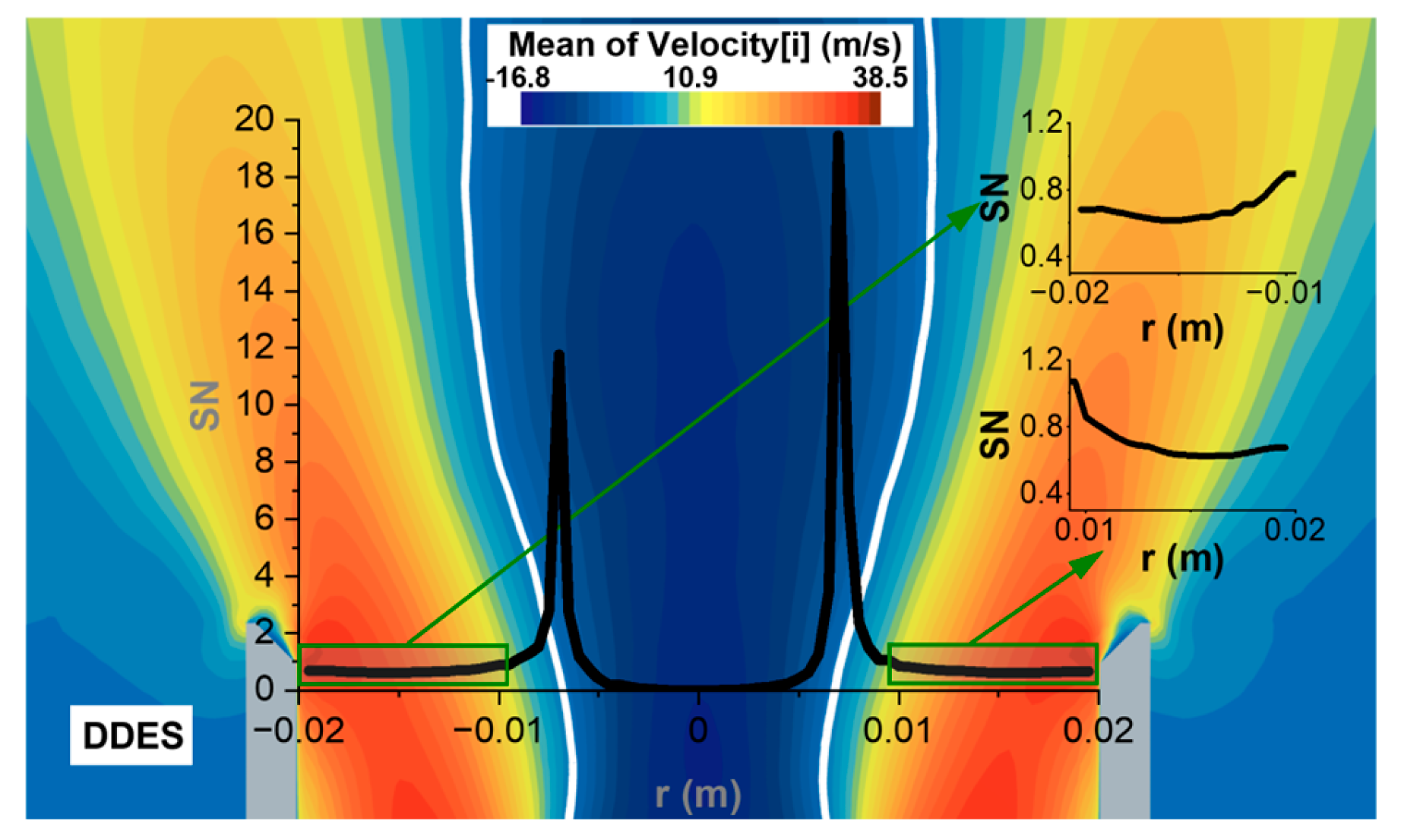

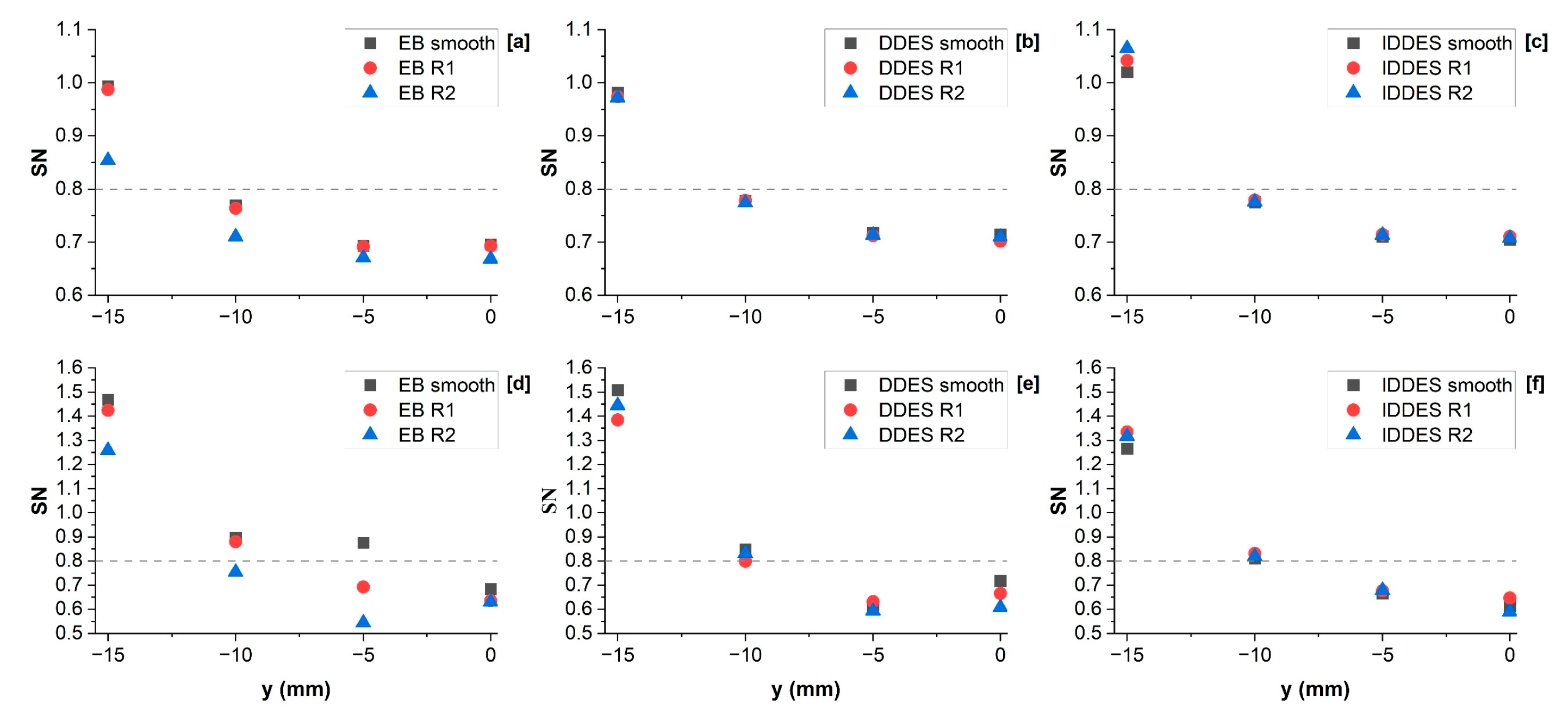

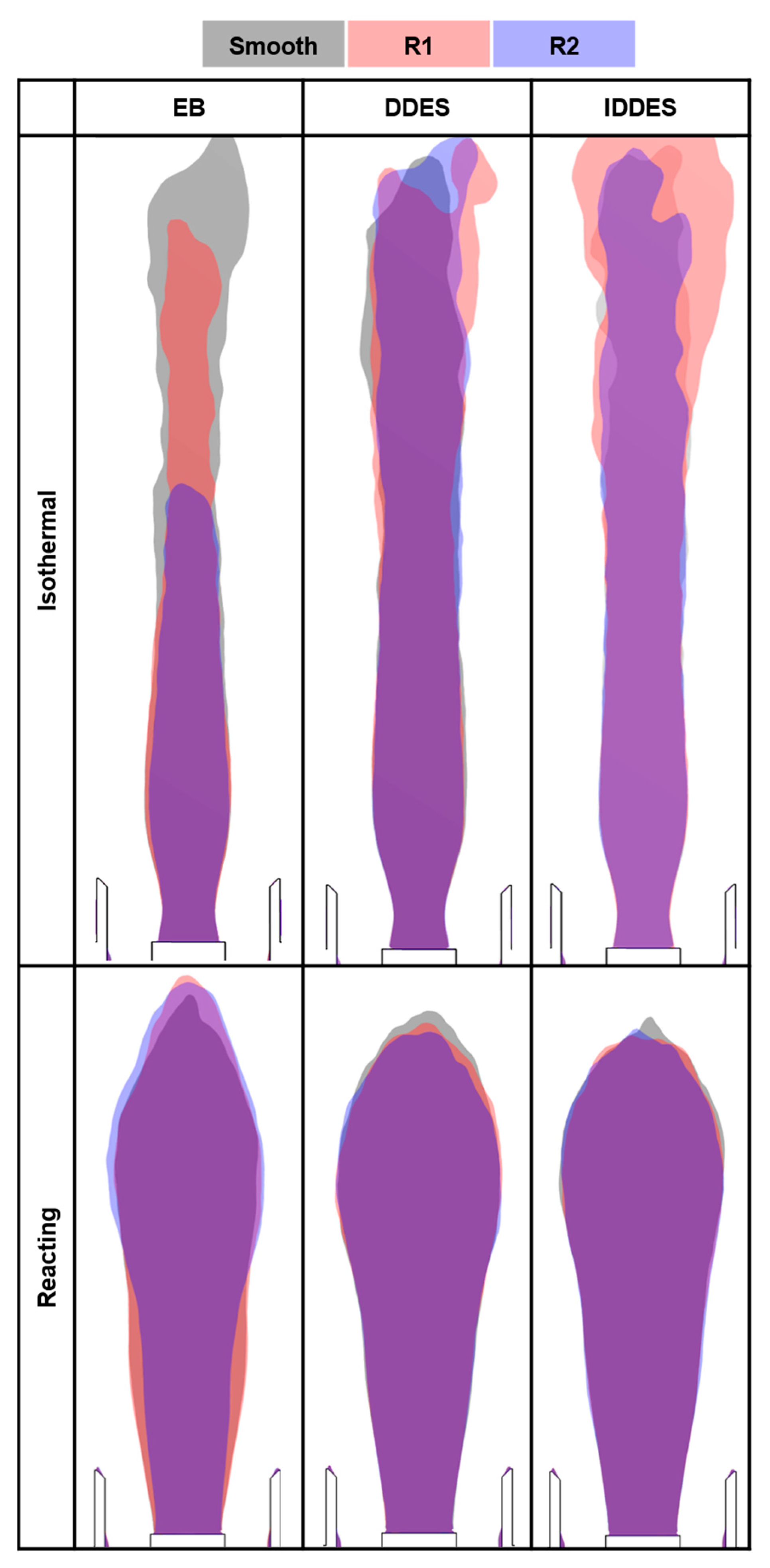

3.2. Swirl Numbers and Recirculation Zones

3.3. Effective and Wall Shear Stress

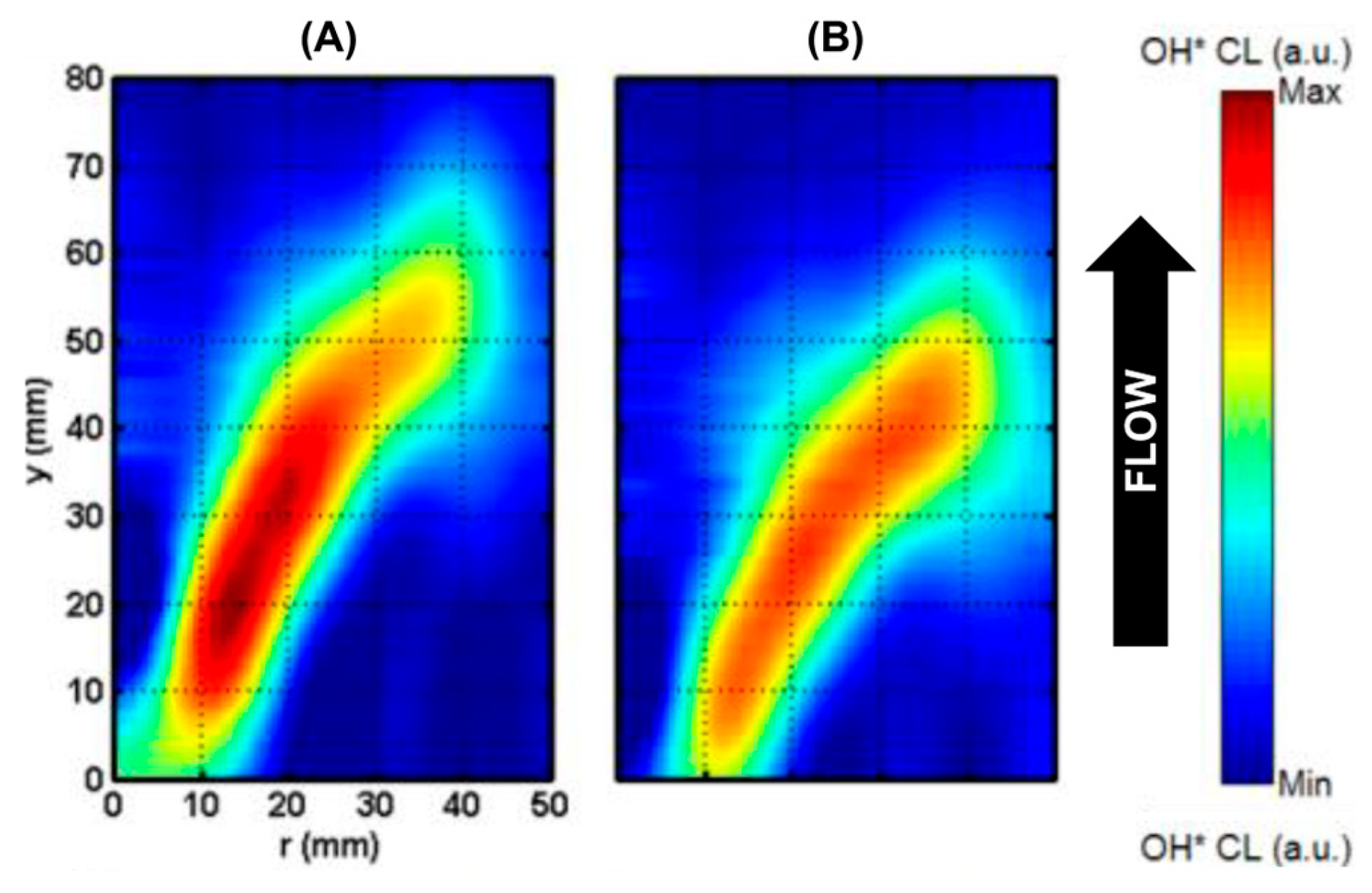

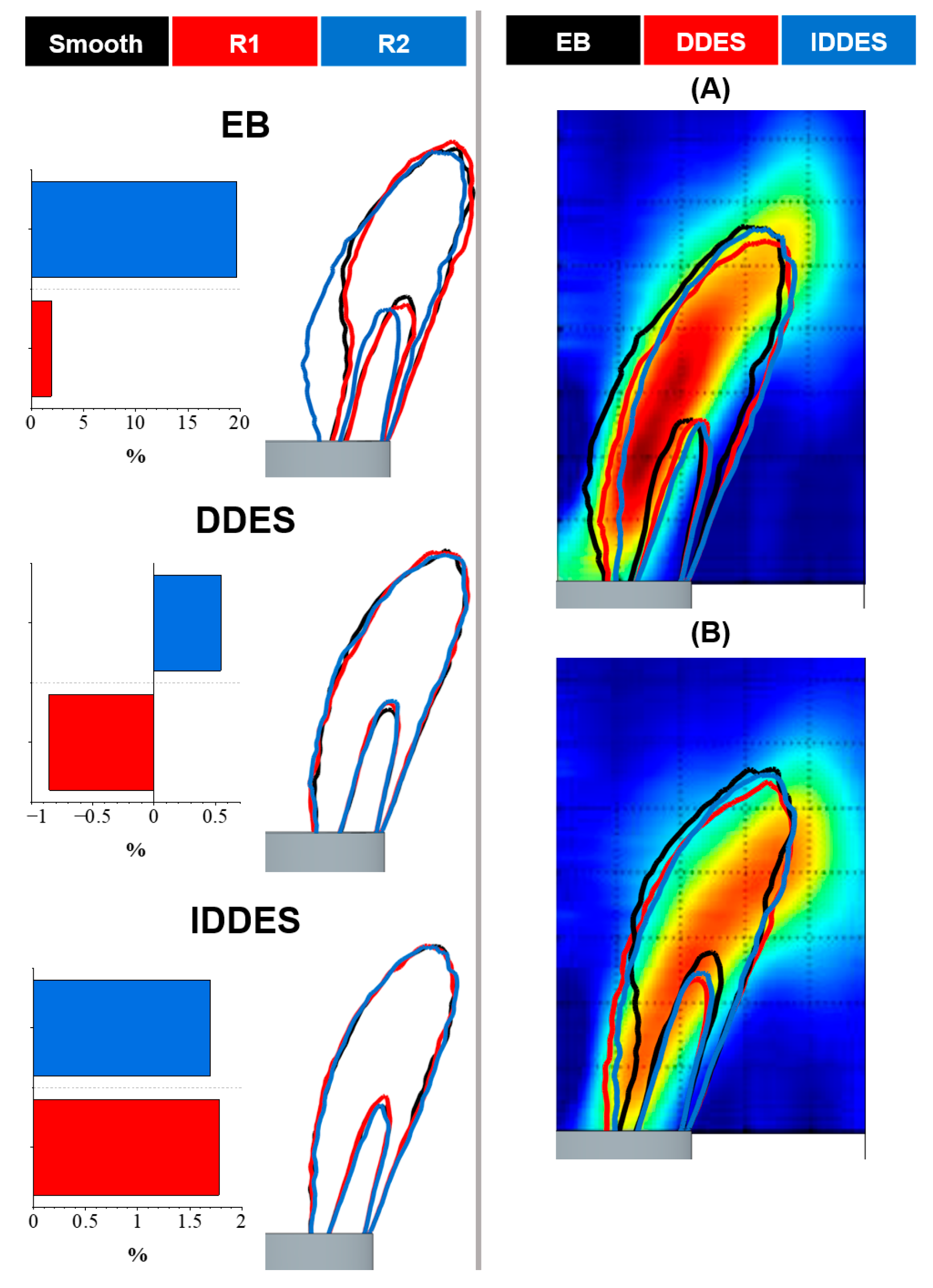

3.4. Flame Location and Characteristics

4. Conclusions

- Of the three DES models investigated, EB exhibited the highest sensitivity to roughness in both isothermal and reacting conditions. This turbulence model should, therefore, be prioritized when employing a low-y+ mesh to capture roughness effects.

- Literature-based ks correlations proved inadequate when coupled with a low-y+ approach. All reacting and isothermal simulations failed to capture meaningful roughness effects. Significant effects were captured only when applying the novel correlation developed in this work ( > 90).

- For identical kₛ values, roughness effects were more pronounced under reacting conditions, suggesting that correlations may need to be fluid and chemistry-specific.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ε | Energy Dissipation Rate |

| ∆t | Time Step |

| ∆x | Distance Across a Cell |

| µ | Dynamic Viscosity |

| 8G | Grit-Blasted ALM Swirler, Sg = 0.8 |

| 8M | Machined Swirler, Sg = 0.8 |

| 8R | “Raw” ALM Swirler, Sg = 0.8 |

| AM | Additive Manufacturing |

| BLF | Boundary Layer Flashback |

| CFD | Computational Fluid Dynamics |

| Co | Courant Number |

| DDES | Delayed Detached Eddy Simulation |

| DES | Detached Eddy Simulation |

| EB | Elliptic Blending |

| ftt | Flow-Through Time |

| HPGSB-2 | High-Pressure Generic Swirl Burner (Mk. II) |

| HPOC | High-Pressure Optical Chamber |

| IDDES | Improved Delayed Detached Eddy Simulation |

| k | Turbulent Kinetic Energy |

| ks | Equivalent Sand-Grain Roughness |

| L0 | Integral Length Scale |

| LDA | Laser Doppler Anemometry |

| ṁ | Mass Flowrate |

| P | Burner Ambient Pressure |

| Q | Mesh Quality Indicator for DES |

| r | Radial Coordinate |

| Roughness Parameter | |

| Ra | Arithmetic Average Surface Roughness |

| RANS | Reynolds-Averaged Navier–Stokes Equations |

| Rnozzle | Swirler Nozzle Radius (20 mm) |

| Rq | RMS Surface Roughness |

| Rz | Ten-Point Mean Surface Roughness |

| R1 | Transitionally Rough Simulations |

| R2 | Fully Rough Simulations |

| Sconv | Conventional Swirl Number |

| Sg | Geometric Swirl Number |

| SLM | Selective Laser Melting |

| SN | Swirl Number |

| SRS | Scale Resolving Simulation |

| T1 | Inlet Temperature |

| ū | Mean Nozzle Exit Axial Velocity |

| U | Velocity Magnitude |

| u* | Velocity Scale |

| Ux | Axial Velocity |

| Uθ | Tangential Velocity |

| ρ | Density |

| φ | Equivalence Ratio |

| y | Axial Coordinate |

| τ | Wall Shear Stress |

References

- Dutta, B.; Babu, S.; Jared, B.H. Science, Technology and Applications of Metals in Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Srinivasan, D.; Ananth, K. Recent Advances in Alloy Development for Metal Additive Manufacturing in Gas Turbine/Aerospace Applications: A Review. J. Indian Inst. Sci. 2022, 102, 311–349. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. Additive Manufacturing for the Manufacture of Gas Turbine Engine Components: Literature Review and Future Perspectives. In Volume 6: Ceramics; Controls, Diagnostics, and Instrumentation; Education; Manufacturing Materials and Metallurgy, Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Navrotsky, V.; Graichen, A.; Brodin, H. Industrialisation of 3D printing (additive manufacturing) for gas turbine components repair and manufacturing. VGB PowerTech 2015, 12, 48–52. [Google Scholar]

- Durocher, A.; Fan, L.; Francolini, B.; Füri, M.; Bourque, G.; Sirois, J.; May, D.; Bergthorson, J.M.; Yun, S.; Vena, P. Characterization of a Novel Additive Manufacturing Micromix Nozzle Burning Methane to Hydrogen. J. Eng. Gas Turbines Power 2024, 146, 051009. [Google Scholar] [CrossRef]

- Andersson, O.; Graichen, A.; Brodin, H.; Navrotsky, V. Developing Additive Manufacturing Technology for Burner Repair. J. Eng. Gas Turbines Power 2017, 139, 031506. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int. J. Adv. Manuf. Technol. 2013, 67, 2743–2751. [Google Scholar] [CrossRef]

- Spierings, A.B.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar] [CrossRef]

- Bacchewar, P.B.; Singhal, S.K.; Pandey, P.M. Statistical modelling and optimization of surface roughness in the selective laser sintering process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 35–52. [Google Scholar] [CrossRef]

- Shinonaga, T.; Kobayashi, H.; Okada, A.; Tsuji, T. Surface smoothing of additively manufactured Ti-6Al-4V alloy by combination of grit blasting and large-area electron beam irradiation. Int. J. Adv. Manuf. Technol. 2023, 127, 5127–5137. [Google Scholar] [CrossRef]

- Tyagi, P.; Goulet, T.; Riso, C.; Garcia-Moreno, F. Reducing surface roughness by chemical polishing of additively manufactured 3D printed 316 stainless steel components. Int. J. Adv. Manuf. Technol. 2019, 100, 2895–2900. [Google Scholar] [CrossRef]

- Giuliani, F.; Paulitsch, N.; Cozzi, D.; Görtler, M.; Andracher, L. An Assessment on the Benefits of Additive Manufacturing Regarding New Swirler Geometries for Gas Turbine Burners. In Volume 4A: Combustion, Fuels, and Emissions, Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Runyon, J.; Giles, A.; Marsh, R.; Pugh, D.; Goktepe, B.; Bowen, P.; Morris, S. Characterization of Additive Layer Manufacturing Swirl Burner Surface Roughness and Its Effects on Flame Stability Using High-Speed Diagnostics. J. Eng. Gas Turbines Power 2020, 142, 041017. [Google Scholar] [CrossRef]

- Ebi, D.; Bombach, R.; Jansohn, P. Swirl flame boundary layer flashback at elevated pressure: Modes of propagation and effect of hydrogen addition. Proc. Combust. Inst. 2021, 38, 6345–6353. [Google Scholar] [CrossRef]

- Ding, S.; Huang, K.; Han, Y.; Valiev, D. Numerical study of the influence of wall roughness on laminar boundary layer flashback. Phys. Rev. Fluids 2021, 6, 023201. [Google Scholar] [CrossRef]

- Al-Fahham, M.; Hatem, F.A.; Alsaegh, A.S.; Valera Medina, A.; Bigot, S.; Marsh, R. Experimental Study to Enhance Resistance for Boundary Layer Flashback in Swirl Burners Using Microsurfaces. In Volume 4A: Combustion, Fuels and Emissions, Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; American Society of Mechanical Engineers: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Bons, J.P. A review of surface roughness effects in gas turbines. J. Turbomach. 2010, 132, 021004. [Google Scholar] [CrossRef]

- Lu, M.-H.; Liou, W.W. Assessment of Two Low-Reynolds-Number k-e Models in Turbulent Boundary Layers with Surface Roughness. J. Spacecr. Rocket. 2007, 44, 1307–1316. [Google Scholar] [CrossRef]

- Krasilnikov, V.; Skjefstad, V.S.; Koushan, K.; Rambech, H.J. A Calibration Study with CFD Methodology for Self-Propulsion Simulations at Ship Scale. J. Mar. Sci. Eng. 2023, 11, 1342. [Google Scholar] [CrossRef]

- McClain, S.T.; Hodge, B.K.; Bons, J.P. Predicting Skin Friction and Heat Transfer for Turbulent Flow Over Real Gas Turbine Surface Roughness Using the Discrete Element Method. J. Turbomach. 2004, 126, 259–267. [Google Scholar] [CrossRef]

- Aupoix, B. Revisiting the Discrete Element Method for Predictions of Flows Over Rough Surfaces. J. Fluids Eng. 2016, 138, 031205. [Google Scholar] [CrossRef]

- Bons, J.P.; McClain, S.T.; Wang, Z.J.; Chi, X.; Shih, T.I. A Comparison of Approximate Versus Exact Geometrical Representations of Roughness for CFD Calculations of cf and St. J. Turbomach. 2008, 130, 021024-1. [Google Scholar] [CrossRef]

- Kapsis, M.; He, L.; Li, Y.S.; Valero, O.; Wells, R.; Krishnababu, S.; Gupta, G.; Kapat, J.; Schaenzer, M. Multiscale Parallelized Computational Fluid Dynamics Modeling Toward Resolving Manufacturable Roughness. J. Eng. Gas Turbines Power 2020, 142, 021001. [Google Scholar] [CrossRef]

- Stripf, M.; Schulz, A.; Bauer, H.-J. Modeling of Rough-Wall Boundary Layer Transition and Heat Transfer on Turbine Airfoils. J. Turbomach. 2008, 130, 021003. [Google Scholar] [CrossRef]

- Siemens Digital Industries Software. Simcenter STAR-CCM+ User Guide, version 2021.1; Siemens Digital Industries Software: Plano, TX, USA, 2021. [Google Scholar]

- Runyon, J.; Marsh, R.; Bowen, P.; Pugh, D.; Giles, A.; Morris, S. Lean methane flame stability in a premixed generic swirl burner: Isothermal flow and atmospheric combustion characterization. Exp. Therm. Fluid Sci. 2018, 92, 125–140. [Google Scholar] [CrossRef]

- Pugh, D.; Bowen, P.; Valera-Medina, A.; Giles, A.; Runyon, J.; Marsh, R. Influence of steam addition and elevated ambient conditions on NOx reduction in a staged premixed swirling NH3/H2 flame. Proc. Combust. Inst. 2019, 37, 5401–5409. [Google Scholar] [CrossRef]

- Chigier, N.A.; Bee’r, J.M. Velocity and Static-Pressure Distributions in Swirling Air Jets Issuing From Annular and Divergent Nozzles. J. Basic Eng. 1964, 86, 788–796. [Google Scholar] [CrossRef]

- Roux, S.; Lartigue, G.; Poinsot, T.; Meier, U.; Bérat, C. Studies of mean and unsteady flow in a swirled combustor using experiments, acoustic analysis, and large eddy simulations. Combust. Flame 2005, 141, 40–54. [Google Scholar] [CrossRef]

- Wang, S.; Yang, V.; Hsiao, G.; Hsieh, S.-Y.; Mongia, H.C. Large-eddy simulations of gas-turbine swirl injector flow dynamics. J. Fluid Mech. 2007, 583, 99–122. [Google Scholar] [CrossRef]

- Cebeci, T.; Bradshaw, P. Momentum Transfer in Boundary Layers; Hemisphere Publishing Corp.: Washington, DC, USA, 1977. [Google Scholar]

- Blocken, B.; Stathopoulos, T.; Carmeliet, J. CFD simulation of the atmospheric boundary layer: Wall function problems. Atmos. Environ. 2007, 41, 238–252. [Google Scholar] [CrossRef]

- Adams, T.; Grant, C.; Watson, H. A Simple Algorithm to Relate Measured Surface Roughness to Equivalent Sand-grain Roughness. Int. J. Mech. Eng. Mechatron. 2012, 1, 66–71. [Google Scholar] [CrossRef]

- Barlow, D.N.; Kim, Y.W. Effect of Surface Roughness on Local Heat Transfer and Film Cooling Effectiveness; American Society of Mechanical Engineers: Houston, TX, USA, 1995. [Google Scholar]

- Castellani, S.; Nassini, P.C.; Andreini, A.; Meloni, R.; Pucci, E.; Valera-Medina, A.; Morris, S.; Goktepe, B.; Mashruk, S. Numerical Modeling of Swirl Stabilized Lean-Premixed H2–CH4 Flames with the Artificially Thickened Flame Model. J. Eng. Gas Turbines Power 2024, 146, 061019. [Google Scholar] [CrossRef]

- Basu, S.; DeMarco, A.W.; He, P. On the Dissipation Rate of Temperature Fluctuations in Stably Stratified Flows. Environ. Fluid Mech. 2021, 21, 63–82. [Google Scholar] [CrossRef]

- Shur, M.L.; Spalart, P.R.; Strelets, M.K.; Travin, A.K. A hybrid RANS-LES approach with delayed-DES and wall-modelled LES capabilities. Int. J. Heat Fluid Flow 2008, 29, 1638–1649. [Google Scholar] [CrossRef]

- Gritskevich, M.S.; Garbaruk, A.V.; Schütze, J.; Menter, F.R. Development of DDES and IDDES Formulations for the k-ω Shear Stress Transport Model. Flow Turbul. Combust. 2012, 88, 431–449. [Google Scholar] [CrossRef]

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.; Bowman, C.T.; Hanson, R.K.; Song, S.; Gardiner, W.C., Jr.; et al. The ‘GRIMech 3.0’ Chemical Kinetic Mechanism. 1999. Available online: http://combustion.berkeley.edu/gri-mech/version30/text30.html (accessed on 5 March 2024).

- Kathrotia, T. Reaction Kinetics Modeling of OH*, CH*, and C2* Chemiluminescence; German Aerospace Center (DLR): Cologne, Germany, 2011. [Google Scholar]

- Burcat, A. Prof. Burcat’s Thermodynamic Data. 2006. Available online: http://garfield.chem.elte.hu/Burcat/burcat.html (accessed on 28 May 2024).

- Panoutsos, C.; Hardalupas, Y.; Taylor, A. Numerical evaluation of equivalence ratio measurement using OH∗ and CH∗ chemiluminescence in premixed and non-premixed methane–air flames. Combust. Flame 2009, 156, 273–291. [Google Scholar] [CrossRef]

- Detomaso, N.; Hok, J.-J.; Dounia, O.; Laera, D.; Poinsot, T. A generalization of the Thickened Flame model for stretched flames. Combust. Flame 2023, 258, 113080. [Google Scholar] [CrossRef]

- Pereira, F.S.; Vaz, G.; Eça, L.; Girimaji, S.S. Simulation of the flow around a circular cylinder at Re = 3900 with Partially-Averaged Navier-Stokes equations. Int. J. Heat Fluid Flow 2018, 69, 234–246. [Google Scholar] [CrossRef]

- Pereira, F.S.; Vaz, G.; Eça, L. Evaluation of RANS and SRS methods for simulation of the flow around a circular cylinder in the sub-critical regime. Ocean Eng. 2019, 186, 106067. [Google Scholar] [CrossRef]

- Vignat, G.; Durox, D.; Candel, S. The suitability of different swirl number definitions for describing swirl flows: Accurate, common and (over-) simplified formulations. Prog. Energy Combust. Sci. 2022, 89, 100969. [Google Scholar] [CrossRef]

- Al-Ajmi, R.; Al-Shaghdari, M.; Goktepe, B.; Psomoglou, I.; Bowen, P. Critical Appraisal of Integrated Computational Fluid Dynamics/Surface Roughness Models for Additive Manufactured Swirl Burners. J. Eng. Gas Turbines Power 2025, 147, 091016. [Google Scholar] [CrossRef]

| Measurement | Ra (µm) | Rq (µm) | Rz (µm) |

|---|---|---|---|

| Nozzle Inner | 8.88 | 10.97 | 53.61 |

| Swirler Base | 11.09 | 14.92 | 78.11 |

| Swirler Curve | 8.31 | 10.29 | 50.01 |

| Swirler Flat Length | 8.59 | 10.64 | 54.06 |

| R1 (mm) | R2 (mm) | R2-8M (mm) |  | |

| Nozzle inner | 0.143 | 1.38 | 0.217 | |

| Swirler base | 0.177 | 1.73 | 0.274 | |

| Swirler curve | 0.133 | 1.30 | 0.104 | |

| Swirler flat length | 0.137 | 1.34 | 0.196 |

| ∆t (s) | ftt (s) | |

|---|---|---|

| Isothermal | 1 × 10−5 | 0.0834 |

| Reacting | 1.25 × 10−5 | 0.069 |

| P (MPa) | T1 (K) | ṁ CH4 (g/s) | ṁ Air (g/s) |

|---|---|---|---|

| 0.11 | 573 | 0.5 | 15.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vivoli, R.; Pugh, D.; Goktepe, B.; Bowen, P.J. Modeling of Roughness Effects on Generic Gas Turbine Swirler via a Detached Eddy Simulation Low-y+ Approach. Energies 2025, 18, 5240. https://doi.org/10.3390/en18195240

Vivoli R, Pugh D, Goktepe B, Bowen PJ. Modeling of Roughness Effects on Generic Gas Turbine Swirler via a Detached Eddy Simulation Low-y+ Approach. Energies. 2025; 18(19):5240. https://doi.org/10.3390/en18195240

Chicago/Turabian StyleVivoli, Robin, Daniel Pugh, Burak Goktepe, and Philip J. Bowen. 2025. "Modeling of Roughness Effects on Generic Gas Turbine Swirler via a Detached Eddy Simulation Low-y+ Approach" Energies 18, no. 19: 5240. https://doi.org/10.3390/en18195240

APA StyleVivoli, R., Pugh, D., Goktepe, B., & Bowen, P. J. (2025). Modeling of Roughness Effects on Generic Gas Turbine Swirler via a Detached Eddy Simulation Low-y+ Approach. Energies, 18(19), 5240. https://doi.org/10.3390/en18195240