Experimental Investigation of Partial Flue Gas Recirculation During Load Changes in a 1 MWth SRF-Fired CFB Combustor

Abstract

1. Introduction

2. Experimental Section

2.1. Layout of 1 MWth Pilot Plant

2.2. Materials

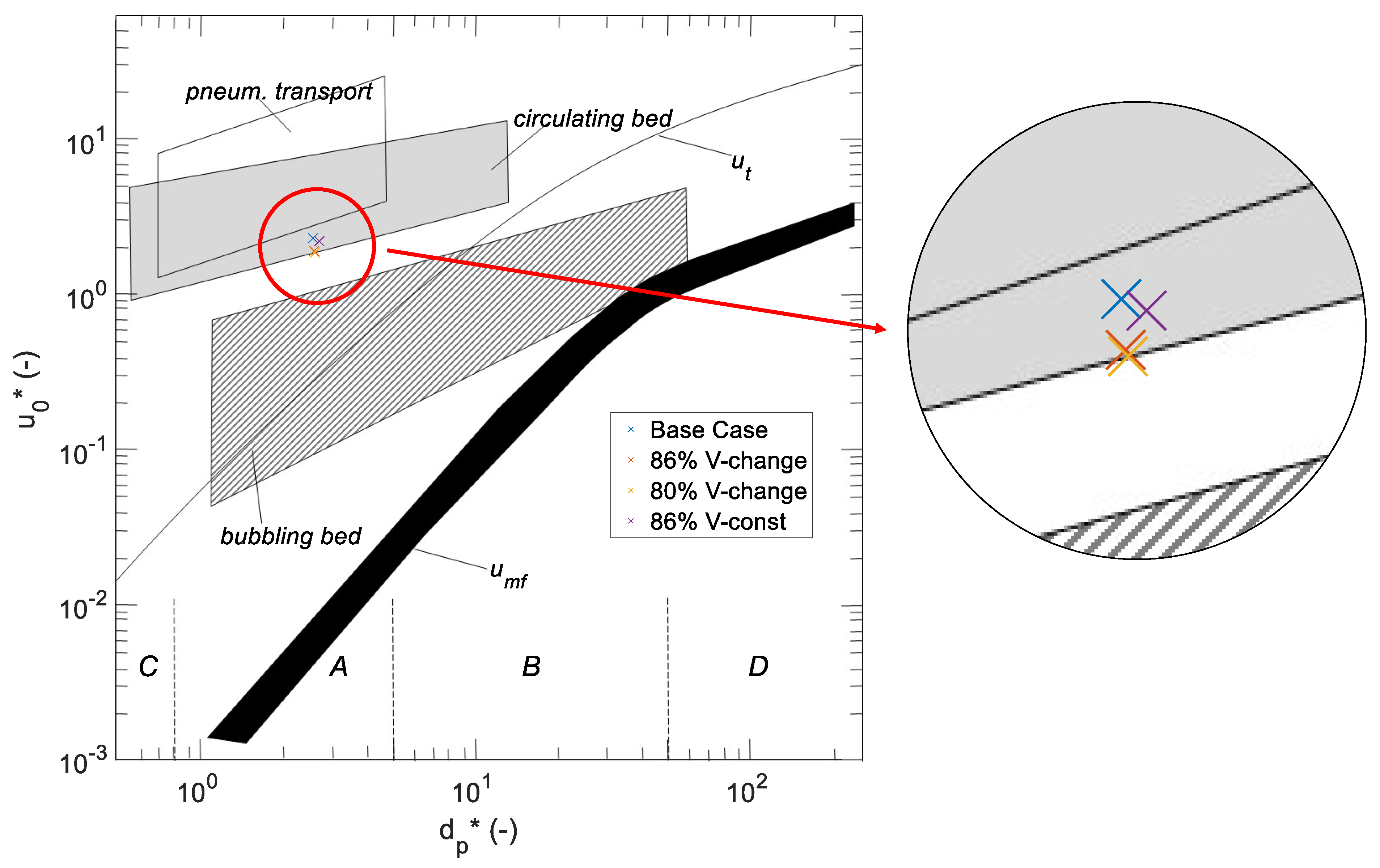

2.3. Operating Conditions

2.4. Load Step Methodology

- Calculating the oxygen demand for the reduced load based on the full-load equivalence ratio (λ)

- Adjusting the air supply composition to maintain the same λ value

- Replacing a proportion of the fresh air with recirculated flue gas while keeping the total volumetric fluidization rate equivalent to that at 100% load

3. Results and Discussion

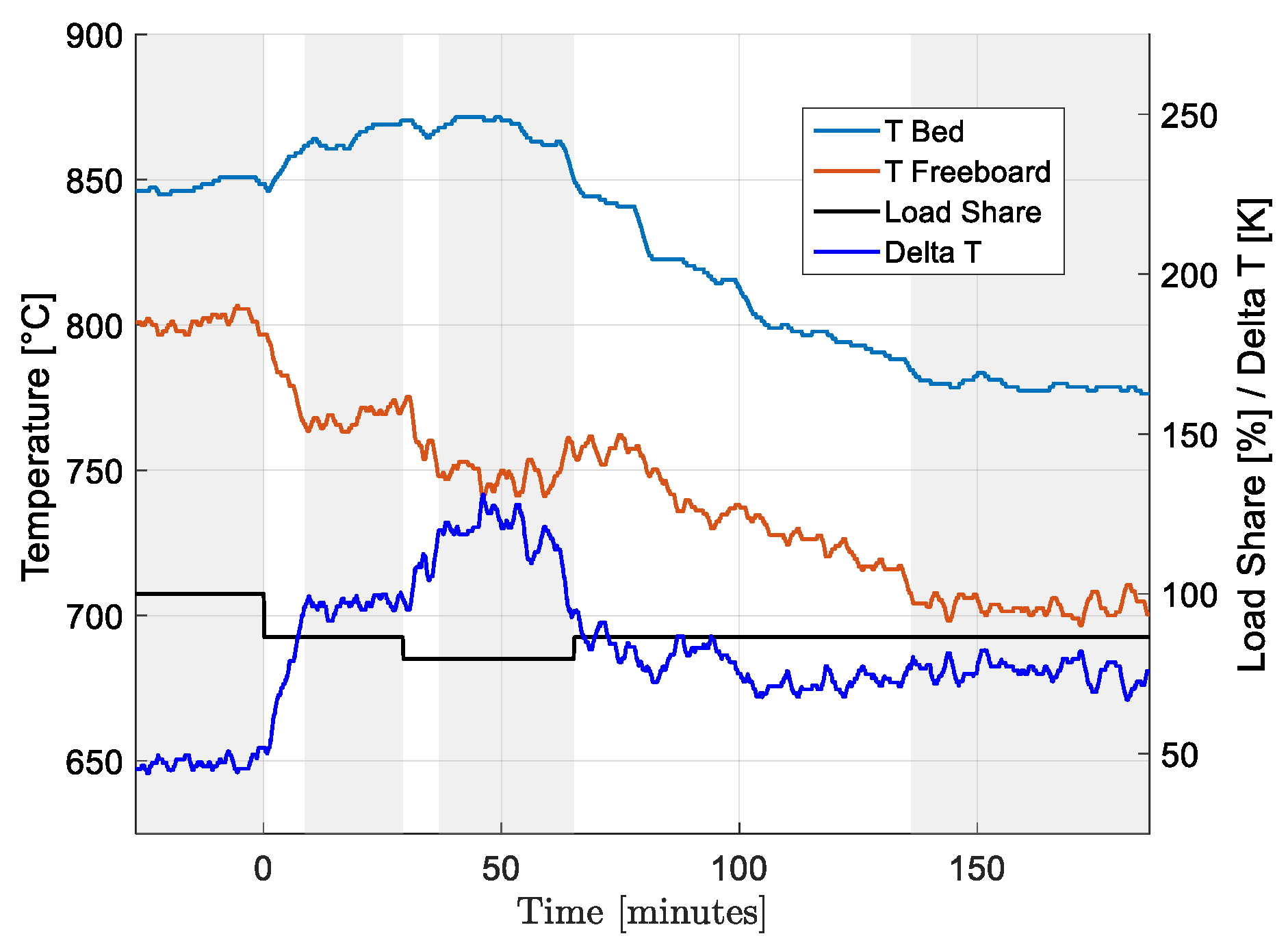

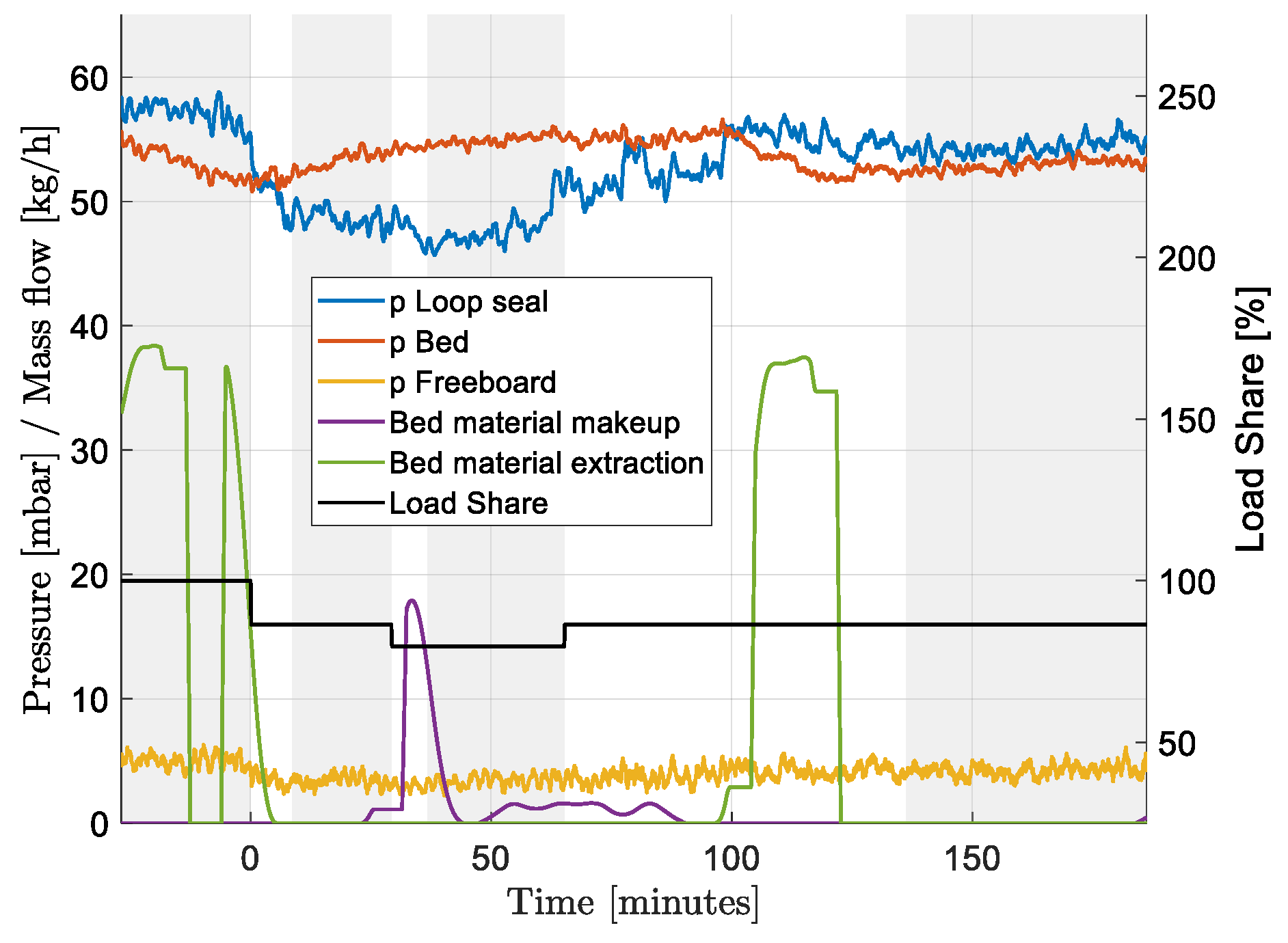

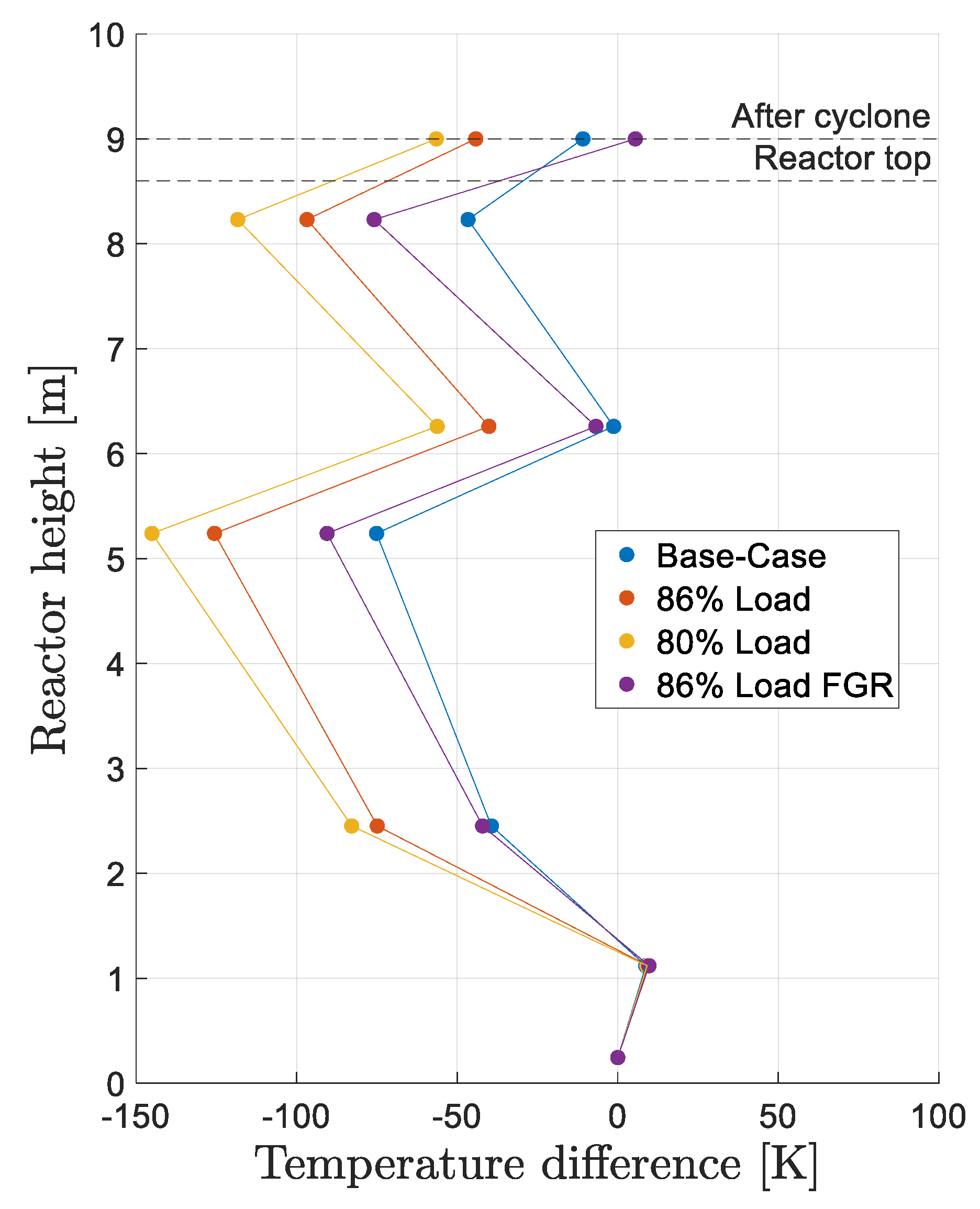

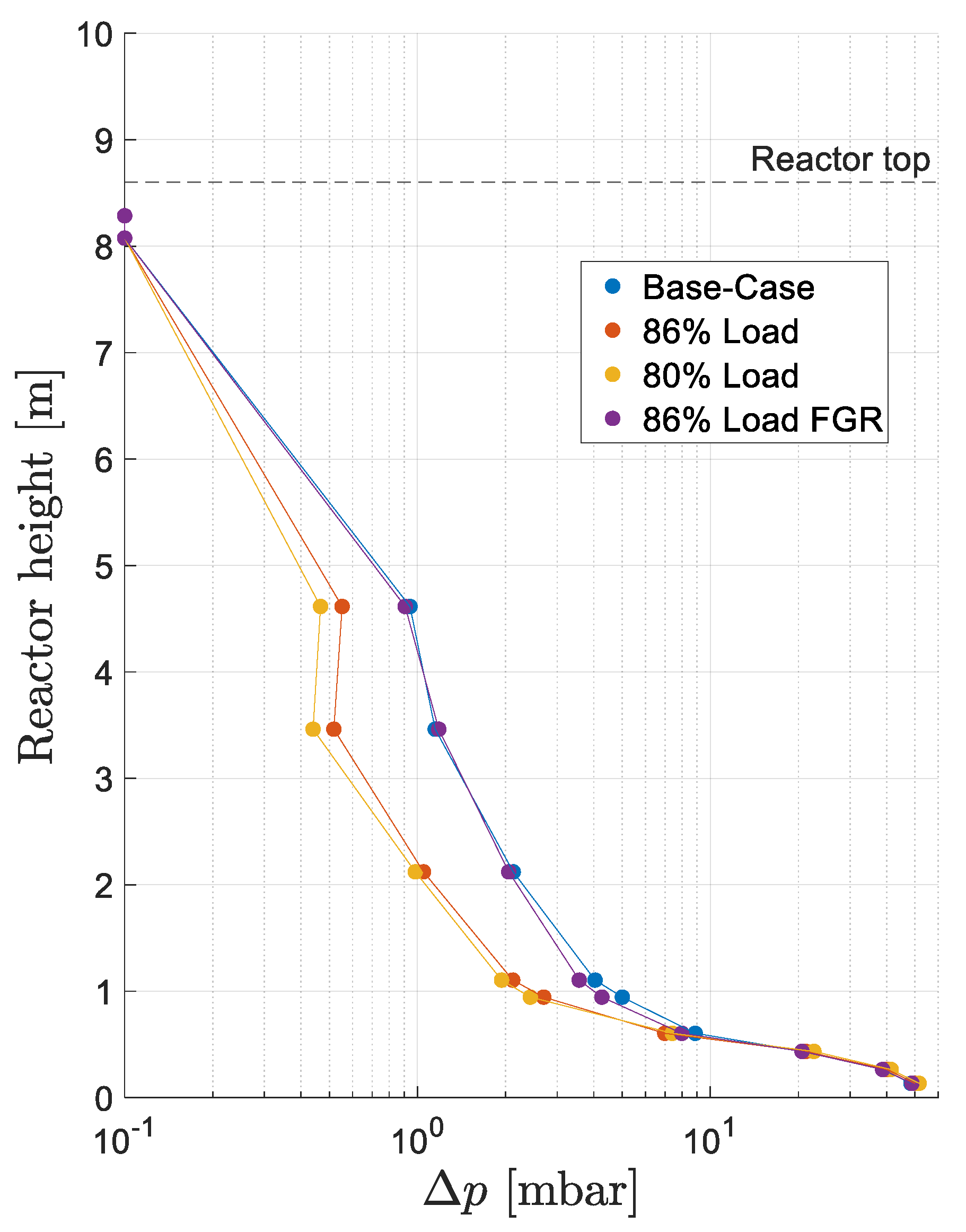

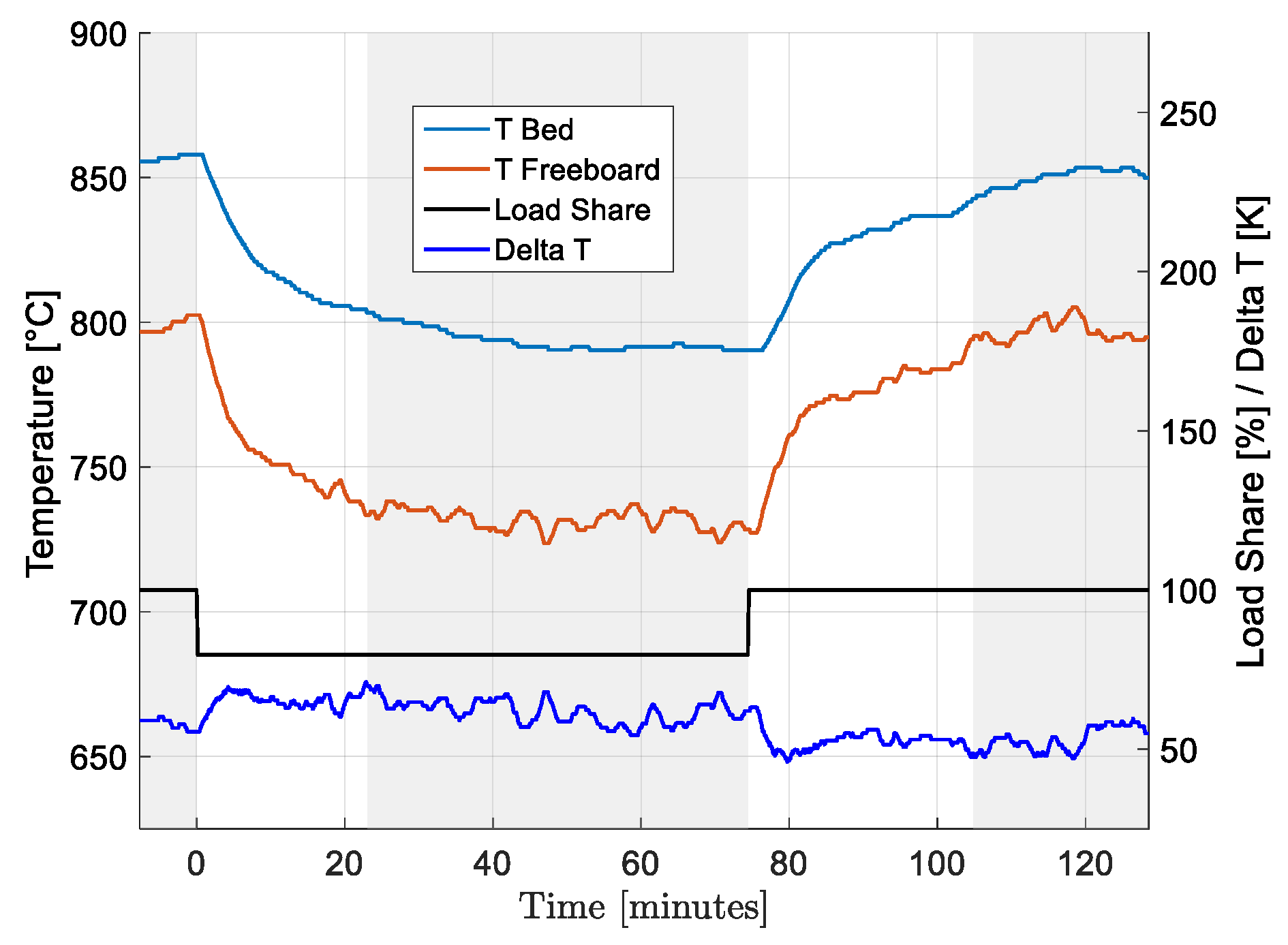

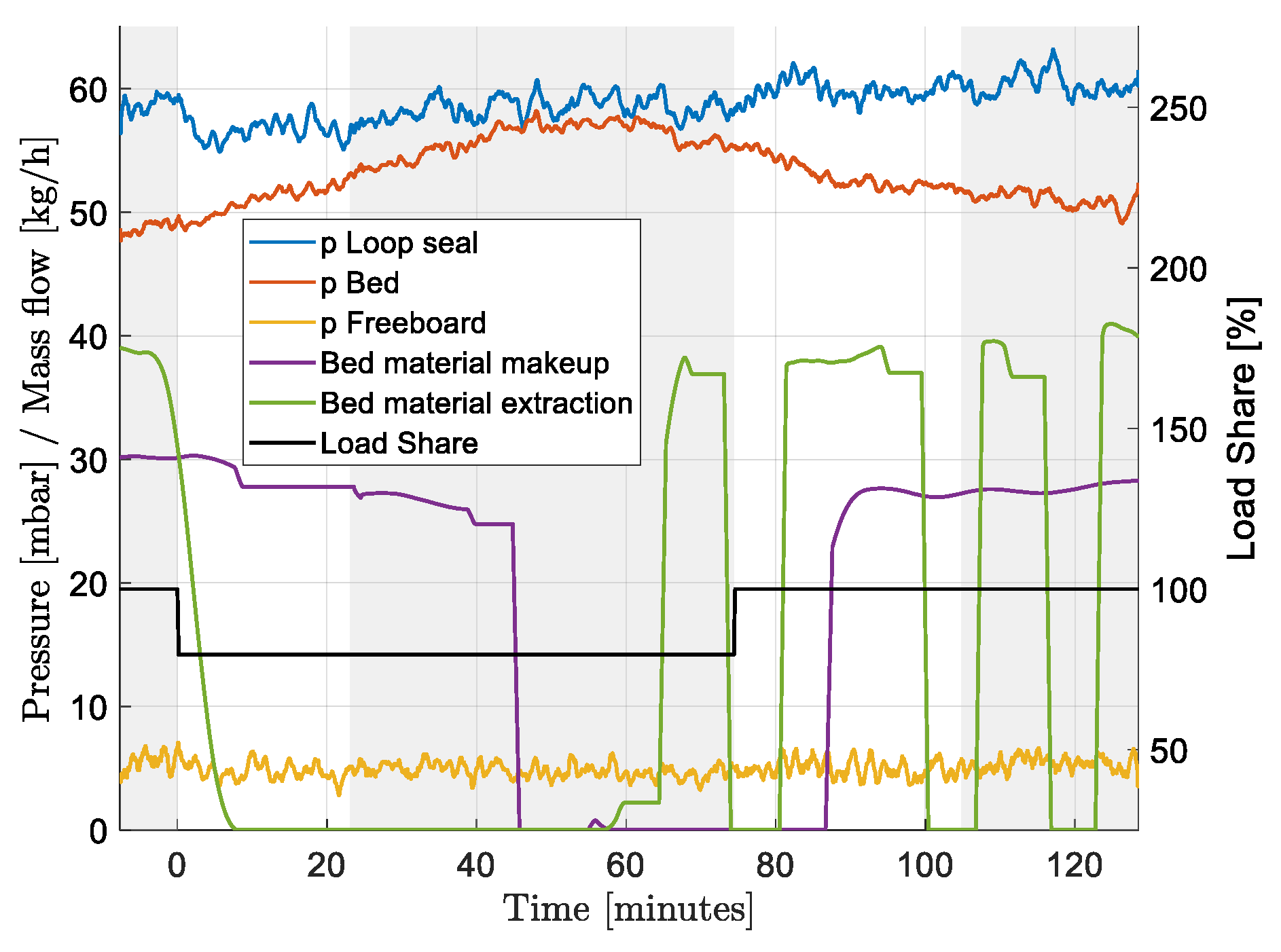

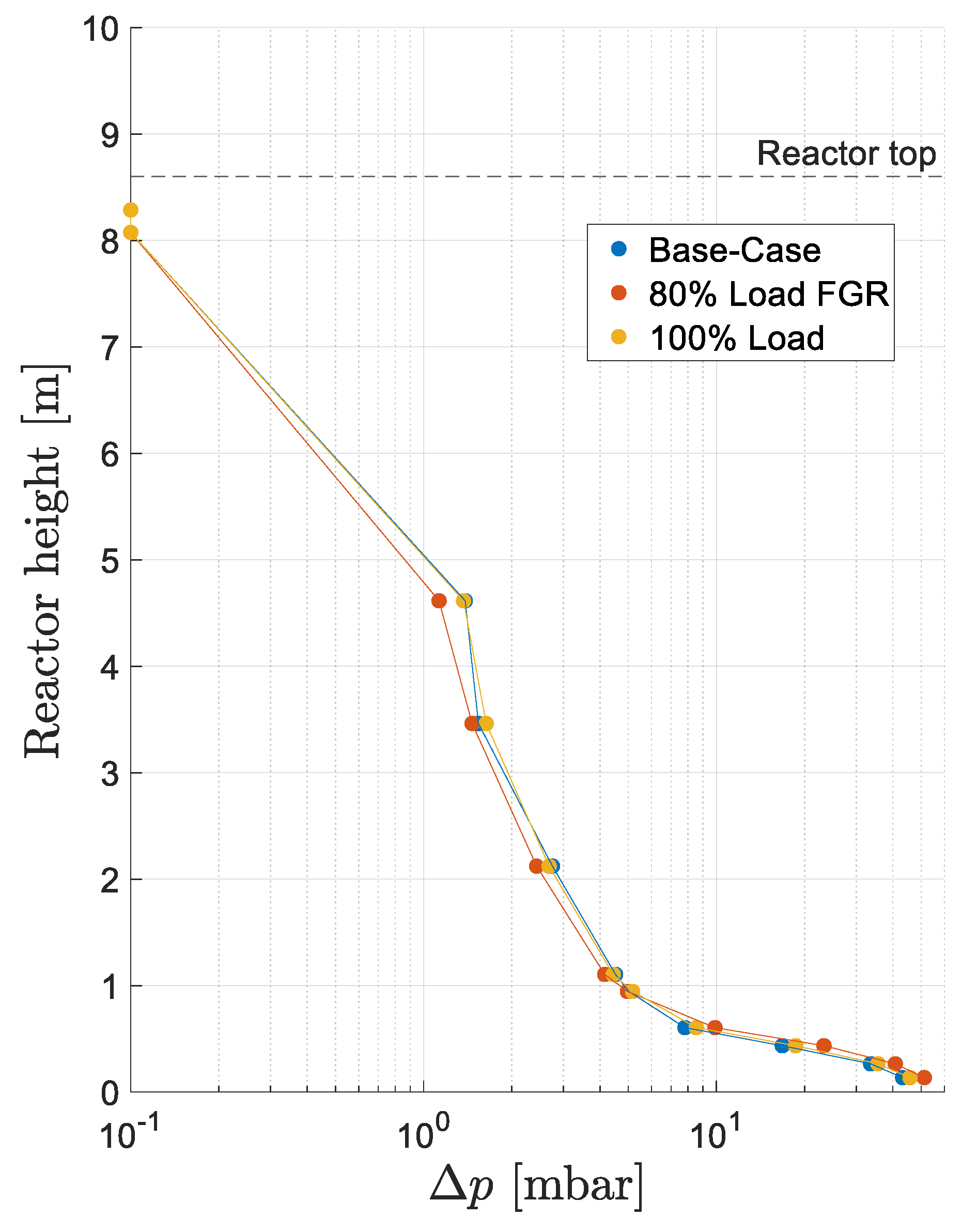

3.1. Load Step Test Period 1

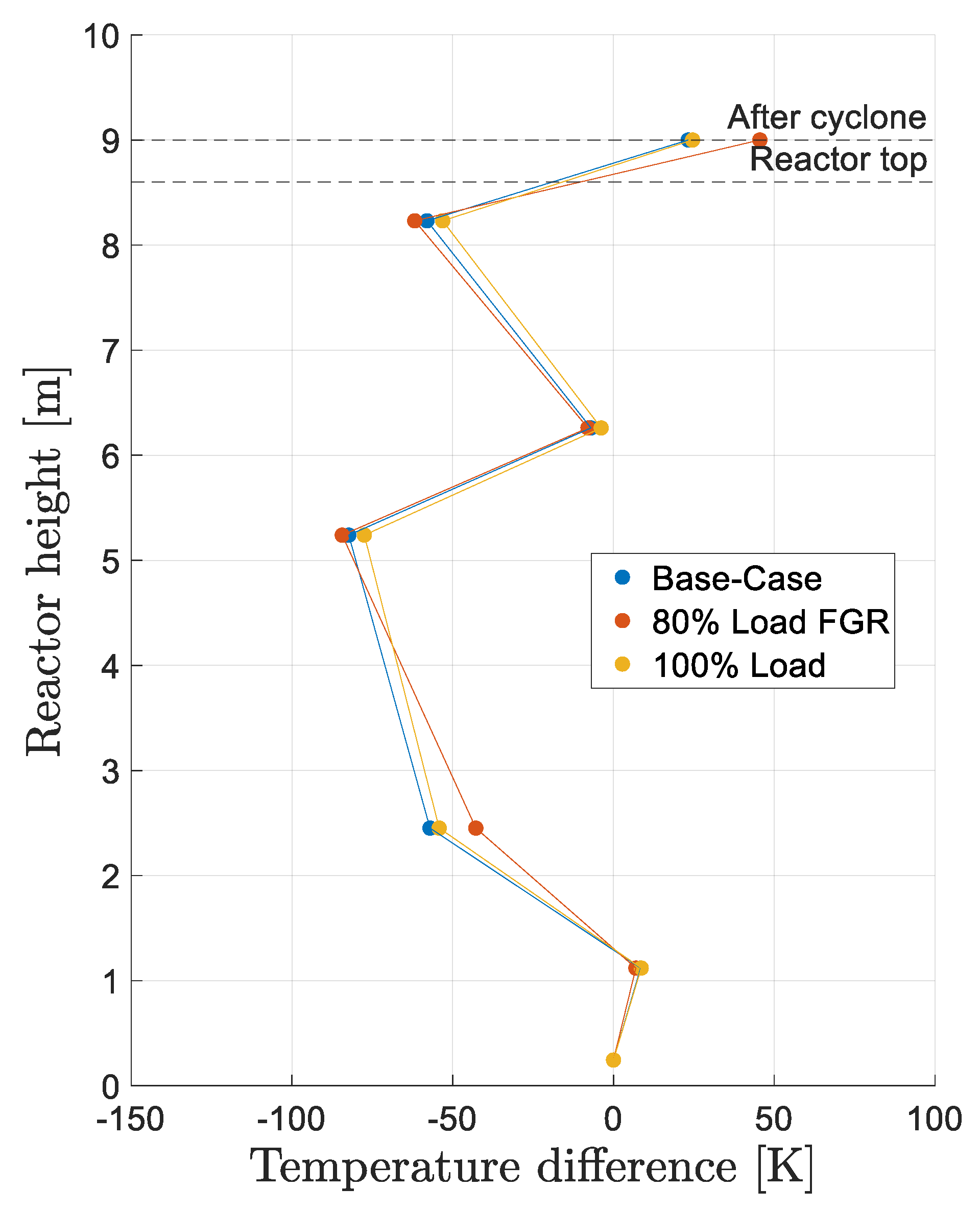

3.2. Load Step Test Period 2–Partial FGR

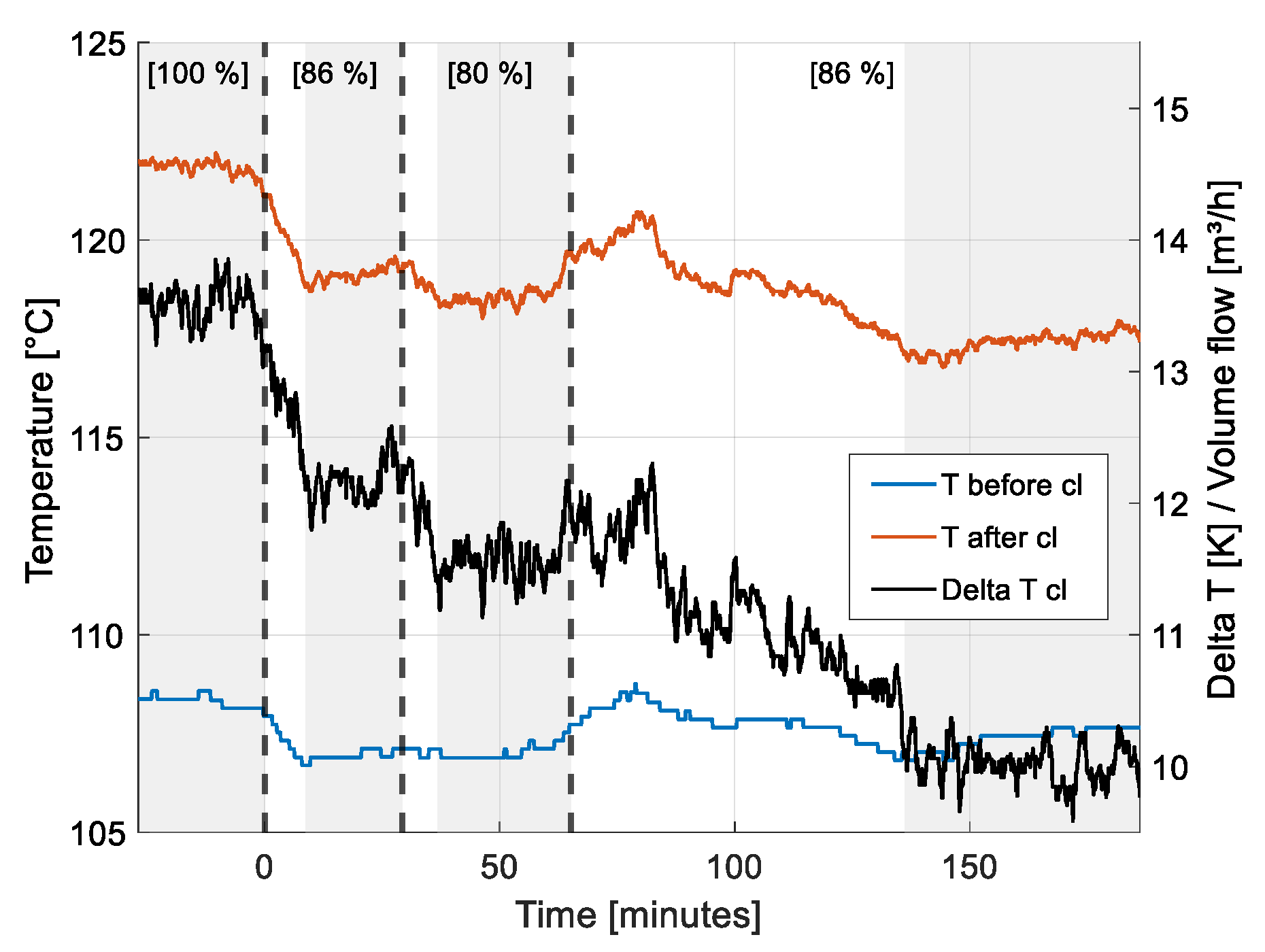

3.3. Investigation of Heat Extraction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Lyu, J.; Yue, G. A review on research and development of CFB combustion technology in China. Powder Technol. 2023, 414, 118090. [Google Scholar] [CrossRef]

- Ember. Electricity Data Explorer. Available online: https://ember-energy.org/data/electricity-data-explorer/ (accessed on 18 June 2025).

- Climate Action Tracker. CAT Net Zero Target Evaluations. Available online: https://climateactiontracker.org/global/cat-net-zero-target-evaluations/ (accessed on 26 June 2025).

- IPCC. 2023: Climate Change 2023: Synthesis Report. Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Lee, H., Romero, J., Eds.; IPCC: Geneva, Switzerland; 184p. [CrossRef]

- Kubik, M.L.; Coker, P.J.; Barlow, J.F. Increasing thermal plant flexibility in a high renewables power system. Appl. Energy 2015, 154, 102–111. [Google Scholar] [CrossRef]

- Pan, E.; Yu, J.; Zhang, S.; Nie, Y.; Li, Q. Retrospective Analysis of the Effect of Hering’s Law on Outcomes of Surgical Correction of Ptosis. Ann. Plast. Surg. 2018, 80, 242–244. [Google Scholar] [CrossRef]

- Liu, G.; Zhu, Y.; Huang, Z. Dynamic Economic Dispatch with Wind Power Penetration Based on Non-Parametric Kernel Density Estimation. Electr. Power Compon. Syst. 2020, 48, 333–352. [Google Scholar] [CrossRef]

- Li, W.; Ren, H.; Chen, P.; Wang, Y.; Qi, H. Key Operational Issues on the Integration of Large-Scale Solar Power Generation—A Literature Review. Energies 2020, 13, 5951. [Google Scholar] [CrossRef]

- Li, S.; Ma, Z.; Zhang, X.; Wang, K.; Zhou, Q.; Zhang, J.; Chen, W. Analysis and evaluation of short-term wind power interval forecast error based on K-means clustering. J. Phys. Conf. Ser. 2021, 1983, 12091. [Google Scholar] [CrossRef]

- Basu, P. Combustion of coal in circulating fluidized-bed boilers: A review. Chem. Eng. Sci. 1999, 54, 5547–5557. [Google Scholar] [CrossRef]

- Lockwood, T. Techno-economic analysis of PC versus CFB combustion technology. IEA Clean Coal Cent. 2013. [Google Scholar]

- Miller, B.G. Clean Coal Engineering Technology [Recurso Electrónico]; Butterworth-Heinemann: Waltham, MA, USA, 2011. [Google Scholar]

- Suraniti, S.L.; Nsakala, N.y.; Darling, S.L. Alstom oxyfuel CFB boilers: A promising option for CO2 capture. Energy Procedia 2009, 1, 543–548. [Google Scholar] [CrossRef]

- Kunii, D.; Levenspiel, O. Circulating fluidized-bed reactors. Chem. Eng. Sci. 1997, 52, 2471–2482. [Google Scholar] [CrossRef]

- Kunii, D.; Levenspiel, O. Fluidization Engineering; Butterworth-Heinemann: Boston, MA, USA, 1991. [Google Scholar]

- Nowak, W.; Mirek, P. Circulating fluidized bed combustion (CFBC). In Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification; Elsevier: Amsterdam, The Netherlands, 2013; pp. 701–764. [Google Scholar]

- Oka, S. Fluidized Bed Combustion; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Lecomte, T.; de La Fuente, J.; Neuwahl, F.; Canova, M.; Pinasseau, A.; Jankov, I.; Brinkmann, T.; Roudier, S.; Delgado, S.L. Best Available Techniques (BAT) Reference Document for Large Combustion Plants: Industrial Emissions Directive 2010/75/EU; Publications Office of the European Union: Luxembourg, 2017.

- Aamand, L.E.; Leckner, B.; Andersson, S. Formation of nitrous oxide in circulating fluidized-bed boilers. Energy Fuels 1991, 5, 815–823. [Google Scholar] [CrossRef]

- Andries, J.; Becht, J.; Hoppesteyn, P. Pressurized fluidized bed combustion and gasification of coal using flue gas recirculation and oxygen injection. ENERGY Convers. Manag. 1997, 38, S117–S122. [Google Scholar] [CrossRef]

- Błaszczuk, A. Effect of flue gas recirculation on heat transfer in a supercritical circulating fluidized bed combustor. Arch. Thermodyn. 2015, 36, 61–83. [Google Scholar] [CrossRef][Green Version]

- Kullendorff, A.N.; Jansson, B.G.; Olofsson, J.I. Controlling Thermal Transmission Rate at a Fast Fluidized Bed Reactor. US4,813,381 (A), 21 March 1989. [Google Scholar]

- Gao, M.; Hong, F.; Liu, J. Investigation on energy storage and quick load change control of subcritical circulating fluidized bed boiler units. Appl. Energy 2017, 185, 463–471. [Google Scholar] [CrossRef]

- Gao, M.; Hong, F.; Liu, J.; Chen, F. Investigation on the energy conversion and load control of supercritical circulating fluidized bed boiler units. J. Process Control. 2018, 68, 14–22. [Google Scholar] [CrossRef]

- Hong, F.; Chen, J.; Wang, R.; Long, D.; Yu, H.; Gao, M. Realization and performance evaluation for long-term low-load operation of a CFB boiler unit. Energy 2021, 214, 118877. [Google Scholar] [CrossRef]

- Zhang, F.; Xue, Y.; Li, D.; Wu, Z.; He, T. On the Flexible Operation of Supercritical Circulating Fluidized Bed: Burning Carbon Based Decentralized Active Disturbance Rejection Control. Energies 2019, 12, 1132. [Google Scholar] [CrossRef]

- Hong, F.; Wang, R.; Song, J.; Gao, M.; Liu, J.; Long, D. A performance evaluation framework for deep peak shaving of the CFB boiler unit based on the DBN-LSSVM algorithm. Energy 2022, 238, 121659. [Google Scholar] [CrossRef]

- Stefanitsis, D.; Nesiadis, A.; Nikolopoulos, A.; Nikolopoulos, N. Simulation of a circulating fluidized bed power plant integrated with a thermal energy storage system during transient operation. J. Energy Storage 2021, 43, 103239. [Google Scholar] [CrossRef]

- Hu, X.; Zhou, T.; Li, C.; Zhang, M.; Zhu, S.; Yang, H. Investigation on the dynamic characteristics under load regulation in CFB boiler with whole loop model. Chem. Eng. Sci. 2024, 287, 119784. [Google Scholar] [CrossRef]

- Peters, J.; Langner, E.; Ströhle, J.; Epple, B. Acceleration of Load Changes by Controlling the Operating Parameters in CFB Co-Combustion. Front. Energy Res. 2021, 9, 677950. [Google Scholar] [CrossRef]

- Hong, F.; Chen, J.; Zhang, Z.; Wang, R.; Gao, M. Time Series Risk Prediction Based on LSTM and a Variant DTW Algorithm: Application of Bed Inventory Overturn Prevention in a Pant-Leg CFB Boiler. IEEE Access 2020, 8, 156634–156644. [Google Scholar] [CrossRef]

- Peters, J.; Alobaid, F.; Epple, B. Operational Flexibility of a CFB Furnace during Fast Load Change—Experimental Measurements and Dynamic Model. Appl. Sci. 2020, 10, 5972. [Google Scholar] [CrossRef]

- Alobaid, F.; Peters, J.; Epple, B. Experimental measurements for Polish lignite combustion in a 1 MWth circulating fluidized bed during load changes. Energy 2021, 228, 120585. [Google Scholar] [CrossRef]

- Peters, J.; May, J.; Ströhle, J.; Epple, B. Flexibility of CFB Combustion: An Investigation of Co-Combustion with Biomass and RDF at Part Load in Pilot Scale. Energies 2020, 13, 4665. [Google Scholar] [CrossRef]

- Alobaid, F.; Kuhn, A.; Nguyen, N.M.; Johnen, B.; Peters, J.; Epple, B. Numerical and experimental study of co-combustion of refuse-derived fuels in a circulating fluidized bed during load change. Front. Energy Res. 2022, 10, 969780. [Google Scholar] [CrossRef]

- European Investment Bank. Managing Refuse-Derived and Solid Recovered Fuels: Best Practice Options for EU Countries; European Investment Bank: Luxembourg, 2024. [Google Scholar]

- ISO 21640:2021; Solid Recovered Fuels—Specification and Classes. CEN (European Committee for Standardization): Brussels, Belgium, 2021.

- Bajić, B.Ž.; Dodić, S.N.; Vučurović, D.G.; Dodić, J.M.; Grahovac, J.A. Waste-to-energy status in Serbia. Renew. Sustain. Energy Rev. 2015, 50, 1437–1444. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Andrade, R.V.; Leme, M.M.V.; del Olmo, O.A. Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. ENERGY Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Bui, M.; Fajardy, M.; Dowell, N.M. Thermodynamic Evaluation of Carbon Negative Power Generation: Bio-energy CCS (BECCS). Energy Procedia 2017, 114, 6010–6020. [Google Scholar] [CrossRef]

- Wienchol, P.; Szlęk, A.; Ditaranto, M. Waste-to-energy technology integrated with carbon capture—Challenges and opportunities. Energy 2020, 198, 117352. [Google Scholar] [CrossRef]

- Mishra, A.; Kumar, M.; Medhi, K.; Thakur, I.S. Biomass energy with carbon capture and storage (BECCS). In Current Developments in Biotechnology and Bioengineering: Chapter 17–Biomass Energy with Carbon Capture and Storage (BECCS); Elsevier: Amsterdam, The Netherlands, 2020; pp. 399–427. [Google Scholar]

- Gough, C.; Upham, P. Biomass energy with carbon capture and storage (BECCS or Bio-CCS). Greenh. Gases 2011, 1, 324–334. [Google Scholar] [CrossRef]

- Ling, J.L.J.; Yang, W.; Park, H.S.; Lee, H.E.; Lee, S.H. A comparative review on advanced biomass oxygen fuel combustion technologies for carbon capture and storage. Energy 2023, 284, 128566. [Google Scholar] [CrossRef]

- Wagland, S.T.; Kilgallon, P.; Coveney, R.; Garg, A.; Smith, R.; Longhurst, P.J.; Pollard, S.J.T.; Simms, N. Comparison of coal/solid recovered fuel (SRF) with coal/refuse derived fuel (RDF) in a fluidized bed reactor. Waste Manag. 2011, 31, 1176–1183. [Google Scholar] [CrossRef] [PubMed]

- Maj, I.; Kalisz, S.; Wejkowski, R.; Pronobis, M.; Gołombek, K. High-temperature corrosion in a multifuel circulating fluidized bed (CFB) boiler co-firing refuse derived fuel (RDF) and hard coal. Fuel 2022, 324, 124749. [Google Scholar] [CrossRef]

- Kuhn, A.; Langner, E.; Hülsbruch, D.; Barišić, V.; Ströhle, J.; Epple, B. Experimental investigation of fuel conversion characteristics during co-combustion of solid recovered fuel and coal in a 1 MWth circulating fluidized bed reactor. Fuel 2024, 385, 133828. [Google Scholar] [CrossRef]

- Jayanarasimhan, A.; Pathak, R.M.; Shivapuji, A.M.; Rao, L. Tar Formation in Gasification Systems: A Holistic Review of Remediation Approaches and Removal Methods. ACS Omega 2024, 9, 2060–2079. [Google Scholar] [CrossRef]

- Wu, H.; Glarborg, P.; Frandsen, F.J.; Dam-Johansen, K.; Jensen, P.A.; Sander, B. Trace elements in co-combustion of solid recovered fuel and coal. Fuel Process. Technol. 2013, 105, 212–221. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, S.; Pan, X.; Chen, J. Experimental study on the load response rate under the dynamic combined combustion of PC coal and CFB coal in a CFB boiler. Fuel 2019, 236, 445–451. [Google Scholar] [CrossRef]

- Song, W.; Tang, Z.; Song, G.; Zhu, J.; Liu, J.; Wang, H.; Zhang, Y. Experimental study on variable load regulation of circulating fluidized bed with high temperature preheated activated fuel. Particuology 2024, 95, 178–188. [Google Scholar] [CrossRef]

- Tang, Z.; Song, G.; Yang, X.; Ji, Z. Research on combustion and emission characteristics of circulating fluidized bed during load changes. J. Energy Inst. 2022, 105, 334–341. [Google Scholar] [CrossRef]

- Neshumayev, D.; Rummel, L.; Konist, A.; Ots, A.; Parve, T. Power plant fuel consumption rate during load cycling. Appl. Energy 2018, 224, 124–135. [Google Scholar] [CrossRef]

- Zhu, S.; Hui, J.; Lyu, Q.; Ouyang, Z.; Liu, J.; Zhu, J.; Zeng, X.; Zhang, X.; Ding, H.; Liu, Y.; et al. Experimental study on pulverized coal combustion preheated by a circulating fluidized bed: Preheating characteristics for peak shaving. Fuel 2022, 324, 124684. [Google Scholar] [CrossRef]

- Hui, J.; Zhu, S.; Zhang, X.; Liu, Y.; Lin, J.; Ding, H.; Su, K.; Cao, X.; Lyu, Q. Experimental study of deep and flexible load adjustment on pulverized coal combustion preheated by a circulating fluidized bed. J. Clean. Prod. 2023, 418, 138040. [Google Scholar] [CrossRef]

- Tang, Z.; Song, G.; Song, W.; Sun, L.; Ji, Z.; Ji, Y.; Zhang, Y. Experimental study on variation characteristics of combustion heat load in circulating fluidized bed under fuel high-temperature preheating modification. J. Energy Inst. 2024, 114, 101610. [Google Scholar] [CrossRef]

- Kuhn, A.; Graf, C.; Ströhle, J.; Epple, B. Experimental Study on Oxyfuel-Combustion of Solid Recovered Fuel using Ilmenite as Bed Material in a 1 MWth Fluidized Bed Reactor. Carbon Capture Sci. Technol. 2025, 15, 100436. [Google Scholar] [CrossRef]

- Kuhn, A.; Graf, C.; Hülsbruch, D.; Ströhle, J.; Epple, B. Oxygen Carrier Aided Combustion (OCAC) of Solid Recovered Fuel (SRF) and coal in a 1 MWth CFB pilot plant using Ilmenite. Appl. Therm. Eng. 2025, 274, 126692. [Google Scholar] [CrossRef]

| Position | Equipment | Measurement Principle | Component | Range | Uncertainty | Unit |

|---|---|---|---|---|---|---|

| Primary fluidization line | Magnos 206 | Paramagnetic | O2 | 0 to 25 | 0.9 | Vol.% |

| Uras 26 | NDIR | CO2 | 0 to 100 | 1.8 | Vol.% | |

| Secondary fluidization line | Magnos 206 | Paramagnetic | O2 | 0 to 25 | 0.9 | Vol.% |

| Uras 26 | NDIR | CO2 | 0 to 100 | 1.8 | Vol.% | |

| Flue gas before HX | Magnos 206 | Paramagnetic | O2 | 0 to 25 | 0.9 | Vol.% |

| Uras 26 | NDIR | CO2 | 0 to 90 | 3.0 | Vol.% | |

| Uras 26 | NDIR | CO | 0 to 5 | 0.15 | Vol.% | |

| Uras 26 | NDIR | NO | 0 to 1000 | ≤25 | ppm | |

| Uras 26 | NDIR | SO2 | 0 to 4000 | ≤100 | ppm | |

| Flue gas after ID fan | Hygrophil H4320 | Psychrometric | H2O | 2 to 100 | 0.9 | Vol.% |

| Operating Point | Load Change | Load Share [%] | Total Fluidization [%] | FGR | T bed [°C] | T Freeboard [°C] | [K] | Bed Feed [kg/h] | Bed Extr. [kg/h] | Duration [min] |

|---|---|---|---|---|---|---|---|---|---|---|

| Base Case 1 | - | 100 | 100 | No | 848 | 801 | 47 | 0.0 | 25.7 | 27 |

| Load Step 1 | Decrease | 86 | 86 | No | 865 | 768 | 97 | 0.3 | 0.0 | 20 |

| Load Step 2 | Decrease | 80 | 80 | No | 867 | 749 | 118 | 1.8 | 0.0 | 28 |

| Load Step 3 | Increase | 86 | 100 | Yes | 779 | 703 | 76 | 0.0 | 0.0 | 50 |

| Base Case 2 | - | 100 | 100 | No | 857 | 799 | 58 | 30.2 | 37.6 | 8 |

| Load Step 4 | Decrease | 80 | 100 | Yes | 794 | 732 | 62 | 11.4 | 6.4 | 51 |

| Load Step 5 | Increase | 100 | 100 | No | 850 | 797 | 53 | 27.7 | 24.0 | 24 |

| Mean | Std | ||

|---|---|---|---|

| Proximate analysis | Moisture [wt% a.r.] | 22.0 | 5.1 |

| Ash [wt%, dry] | 6.6 | 0.6 | |

| Volatiles [wt%, dry] | 85.2 | 0.8 | |

| Fixed Carbon [wt%, dry] (calculated: 100%—Rest) | 8.2 | 0.2 | |

| Ultimate analysis | C [wt%, dry] | 61.7 | 0.7 |

| H [wt%, dry] | 8.5 | 0.1 | |

| N [wt%, dry] | 1.0 | 0.02 | |

| O [wt%, dry] | 21.2 | 0.1 | |

| S [wt%, dry] | 0.1 | 0.03 | |

| Cl [wt%, dry] | 1.0 | 0.2 | |

| LHV (lower heating value) | [MJ/kg, a.r.] | 20.9 | 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuhn, A.; Ströhle, J.; Epple, B. Experimental Investigation of Partial Flue Gas Recirculation During Load Changes in a 1 MWth SRF-Fired CFB Combustor. Energies 2025, 18, 5227. https://doi.org/10.3390/en18195227

Kuhn A, Ströhle J, Epple B. Experimental Investigation of Partial Flue Gas Recirculation During Load Changes in a 1 MWth SRF-Fired CFB Combustor. Energies. 2025; 18(19):5227. https://doi.org/10.3390/en18195227

Chicago/Turabian StyleKuhn, Alexander, Jochen Ströhle, and Bernd Epple. 2025. "Experimental Investigation of Partial Flue Gas Recirculation During Load Changes in a 1 MWth SRF-Fired CFB Combustor" Energies 18, no. 19: 5227. https://doi.org/10.3390/en18195227

APA StyleKuhn, A., Ströhle, J., & Epple, B. (2025). Experimental Investigation of Partial Flue Gas Recirculation During Load Changes in a 1 MWth SRF-Fired CFB Combustor. Energies, 18(19), 5227. https://doi.org/10.3390/en18195227