1. Introduction

The global energy transition is rapidly shifting focus toward renewable and decarbonized solutions that abate greenhouse gas emissions while maintaining reliability and economic feasibility. One of the most promising vectors in this transition is hydrogen [

1], a clean energy carrier capable of decarbonizing hard-to-abate sectors [

2,

3] such as heavy industry, long-haul transportation, and chemical manufacturing [

4,

5,

6,

7]. Among the various hydrogen production pathways, renewable electricity-powered water electrolysis is increasingly regarded as a cornerstone technology for achieving net-zero energy systems in the upcoming years [

8,

9,

10,

11,

12,

13].

Within the available electrolysis technologies mix, Proton Exchange Membrane (PEM) electrolysers offer distinct advantages, including high efficiency and current density, rapid response to load fluctuations, compact design, and relatively low operating temperatures [

14,

15,

16,

17], making them ideal for coupling with variable renewable energy sources such as solar and wind [

18,

19,

20,

21]. However, the economic competitiveness of PEM electrolysis remains constrained by high capital intensiveness, significant electricity prices, and system inefficiencies that limit hydrogen output per unit of energy input [

22].

Simultaneously, the decarbonization of the heating sector, which accounts for nearly half of the final energy consumption in the European Union, presents another critical challenge [

23,

24]. District heating systems, especially in urban environments at the district level, offer a promising platform for delivering sustainable thermal energy by integrating renewable heat sources [

25] as well as industrial waste heat [

26,

27,

28]. The concept of sector coupling, interlinking electricity, heating, and fuel sectors, has emerged as a strategic approach to maximize the efficiency of renewable energy systems and increase system flexibility as well as reliability [

29,

30,

31,

32].

A key opportunity in this context lies in the valorisation of waste heat generated during electrolysis. While Solid Oxide Electrolysis Cells (SOECs) have been extensively studied for waste heat applications due to their high operating temperatures [

33,

34], the potential for recovering low-grade heat from PEM electrolysers has received relatively little attention. PEM electrolysers typically operate between 50 °C and 80 °C and release waste heat at a thermal level that, although insufficient for high-temperature industrial processes, aligns well with the temperature requirements of district heating systems, especially in the residential sector [

35,

36,

37,

38].

Several studies have highlighted the benefits of co-locating electrolysers with end-use sectors or integrating them with renewable generation to reduce transmission losses and increase efficiency [

39]. For instance, Cloete et al. developed a numerical energy system model encompassing electricity and hydrogen generation (both green and blue), transmission, and storage. Their results show how co-locating the electrolysis and the renewable energy production units reduces electricity transmission costs by 50% [

40].

However, most analyses consider electrolysers purely as hydrogen production units, often neglecting the thermal energy released during operation. Moreover, the temperature-dependent behaviour of PEM electrolysers, which affects both hydrogen production efficiency and waste heat availability, is often overlooked in integrated system design [

41,

42,

43]. In particular, comprehensive analyses that assess how operating temperature influences the trade-off between the specific energy consumption and the waste heat recovery potential remain scarce. This omission limits the understanding of how to optimize the PEM electrolyser’s operation in integrated energy systems.

In addition, although recent work has begun to recognize the multi-functionality of electrolysers in Power-to-X systems, where surplus electricity is converted into hydrogen, heat, and other valuable outputs, the body of scientific literature addressing that aspect remains limited.

In detail, a combined modelling and experimental investigation of a 46.5 kWel alkaline electrolyser demonstrated that system efficiency could exceed 90% when incorporating heat recovery strategies [

44]. Similarly, Frank et al. [

45] reported an 18% increase in efficiency, contingent upon the complete utilization of waste heat from a 1 MWel electrolyser. Bilbao [

46] proposed a different strategy, involving an alkaline electrolyser, aiming to enhance overall system efficiency by preheating the feed water. However, a marginal increase (<1%), was observed in overall efficiency due to the comparatively low water consumption rate, approximately 30 times lower than the mass flow rate of the waste heat water, resulting in underutilization of the waste heat potential. Bilbao further suggests that fully exploiting the available waste heat could potentially increase overall efficiency by up to 13%, consistent with findings reported by Buttler and Spliethoff [

47], although the specific mechanisms for heat utilization were not detailed.

Another crucial aspect for assessing the potential of electrolytic-derived waste within district heating networks is represented by the compatibility between the recovered waste heat, the district heating network, and the end-users’ infrastructure within the DH network, i.e., their heat emission system. Depending on the recovered heat thermal level, which, in turn, depends on the stack operating temperature, different emission systems, such as traditional radiators, fan coils, or radiant floor systems, may be more or less suitable. Addressing this interaction between the overall energy system’s components and their thermal compatibility is critical for ensuring technical feasibility and cost-effectiveness as well as for maximizing the value of thermal integration and waste heat recovery.

For that purpose, this work proposes a novel, integrated approach to the recovery and valorisation of waste heat from PEM electrolysers by directly coupling their thermal output with district heating networks and diverse end-user heat emission systems. In contrast to previous research, which has largely remained conceptual and lacks system-level detail, this work uniquely combines thermal, hydraulic, and economic analyses to evaluate the real-world applicability of waste heat recovery. A key innovation lies in the explicit consideration of end-user emission technologies, as a function of the electrolyser’s stack operating temperature, thereby enabling a more precise matching of supply and demand thermal characteristics. Moreover, the study pioneers the use of a reconverted existing DH network as a delivery infrastructure for the recovered heat and, critically, incorporates the revenue from heat sales into the economic model to reduce the levelized cost of hydrogen. This dual-purpose use of the electrolyser, producing both hydrogen and heat, represents a significant advancement in the field, offering a replicable and economically viable pathway for increasing the overall efficiency and financial attractiveness of Power-to-Hydrogen systems. By addressing both the technical and economic barriers previously identified in the literature, this work fills a crucial gap and provides a robust foundation for future implementation of integrated hydrogen-heat energy systems.

2. Materials and Methods

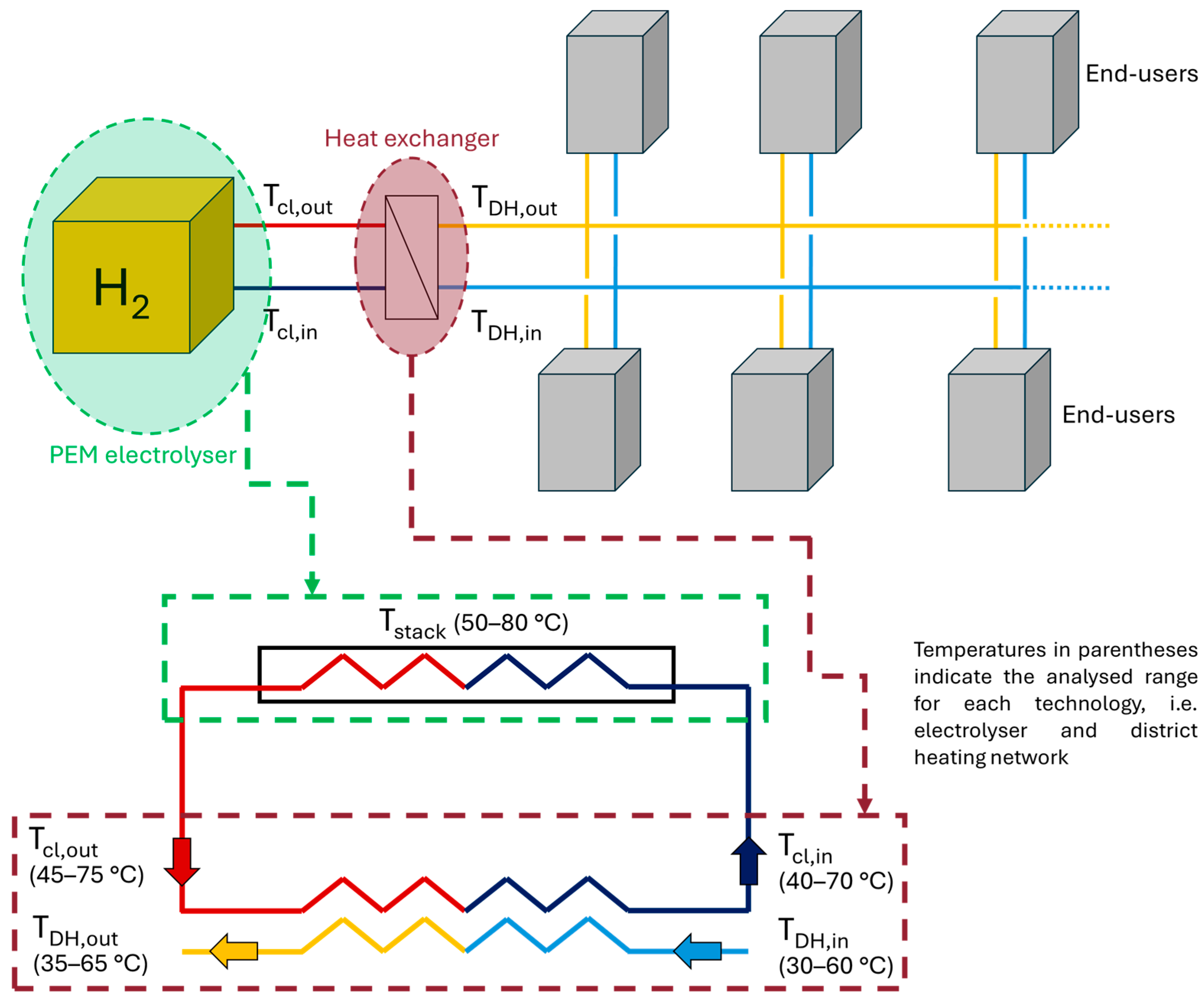

An integrated energy system in which the thermal by-product of hydrogen production via an 850 kW PEM electrolyser is recovered and utilised as a renewable heat source within a district heating (DH) network is assessed in this work. Such a technical scheme, reported in

Figure 1, represents a practical application of energy sector coupling, wherein electricity, hydrogen, and thermal energy domains are interlinked to maximize resource utilisation and enhance overall system sustainability, flexibility, and resilience. The working principle is centred on the dual output of the PEM electrolyser: while its primary function is the production of green hydrogen by means of renewable electricity, due to intrinsic irreversibilities, e.g., electrochemical inefficiencies and thermal losses within the electrolyser stack, the reaction process also generates low-temperature waste heat.

PEM electrolysers generally operate in the temperature range of approximately 50 °C to 80 °C, conditions under which a non-negligible share of the input electrical energy is converted into heat within the system’s coolant circuit. In conventional configurations, that thermal energy is typically dissipated to the environment. In the proposed approach, on the other hand, the waste heat is recovered through a dedicated heat exchanger interfaced with the thermal loop of a DH network. In detail, the heat exchanger transfers thermal energy from the electrolyser’s primary coolant loop to the heat transfer fluid within the district heating network. This configuration ensures both thermal and hydraulic decoupling between the hydrogen production system and the end-use heating systems while enabling effective heat recovery. Lastly, downstream the heat exchanger, the heat transfer fluid supplies heat to the different end-users’ heat emission systems.

The thermodynamic trade-off inherent in this system is governed by the electrolyser’s operating temperature. The system design must therefore balance the dual objectives of maximising hydrogen output and optimising renewable heat recovery, according to contextual energy needs and economic considerations.

2.1. Analytical Model Description

In order to assess the overall performance of such an integrated, sector-coupling energy solution, it is imperative to accurately evaluate the share of electric energy input that is converted into heat due to inefficiencies. Foremost, it is noteworthy that the electrolyser’s performance is heavily dependent on the polarisation curve, which, in turn, hinges on the electrolyser’s stack operating temperature. The first step is to calculate the open circuit voltage, by means of the Nernst equation, which reads as

where

is the reversible cell voltage,

is the universal gas constant,

is the stack operating temperature, and

is the Faraday constant. Moreover,

,

and

represent the partial pressure of hydrogen, oxygen, and water. The reversible cell voltage,

, is also dependent on the stack operating temperature, according to Equation (2).

where

represents the reversible cell voltage at standard temperature and pressure, equal to 1.23 V, and

is the temperature at standard condition, i.e., 298 K.

Notwithstanding this, the real cell voltage can be calculated by adding the contribution of the different overpotential effects, namely activation, diffusion, and ohmic. Those effects are also dependent on the operating temperature. Indeed, Z. Abdin et al. developed a detailed numerical fit model for calculating the real cell voltage of a PEM electrolyser as a function of its thermodynamic operating conditions, merging anode, cathode, membrane, and cell voltage models. From their analysis, it is possible to state that the cell voltage as a function of the stack operating temperature (see Ref. [

48] for the detailed mathematical model), can be computed as follows:

Thereafter, once the actual cell voltage has been calculated, in order to assess the assess the electrolyser’s dissipated thermal power, the thermoneutral voltage must be computed. This latter represents the voltage operating condition under which heat generation from the cell’s components compensates for the heat demand of the electrolysis process. The thermoneutral voltage calculation reads as

where,

represents the enthalpy change of the reaction as a function of the temperature, n is the number of electrons involved in the reaction, i.e., 2, and F is the Faraday constant, equal to 96,485

. The enthalpy change of the reaction is equal to −285.83 kJ/mol under standard conditions; however, as the stack operates at higher thermal level,

must be corrected according to Kirchoff’s law [

49] (see Equation (5)), employed in this work, or by means of numerical fits available in the literature [

50].

where

is the enthalpy change of the reaction as a function of the temperature,

is the enthalpy change of the reaction under standard temperature conditions, and

represents the change in specific heat of the reaction.

Lastly, the thermal power dissipated in the electrolysis process,

, is calculated according to Equation (6).

where

, equal to 0.3 A/cm

2, represents the current density and A represents the active area, equal to 7400 cm

2, while

and

represent the real cell voltage and the thermoneutral voltage, respectively, and

is the number of cells, equal to 210.

2.2. Economic and Environmental Metrics

In order to assess the potential cost-effectiveness of the Power-to-Gas and Power-to-Heat sector coupling strategy proposed in this work, the levelized cost of hydrogen (LCOH) is employed as the main techno-economic evaluation metric. In detail, the LCOH is calculated according to Equation (7).

where, referring to the electrolysis unit,

(CAPital EXpenditure) represents the initial investment cost,

(OPerational EXpenditure) represents the operation and maintenance costs, and

, calculated according to Equation (8), details the capital recovery factor.

where

represents the discount rate, equal to 3.71%, and

represents the electrolyser’s lifetime, equal to 10 years. Moreover,

represents the electrolyser’s full-load hours, and

represents the district heating network full-load hours. In detail, the former is set at 3500 h, representing the full-load hours for combined wind and PV in Italy; the latter is set to vary between 1000 and 2500 h, in 500 h steps, in order to encompass all potential climate zones in Italy [

51], in order to provide a comprehensive overview of the country’s outdoor environmental conditions. Moreover,

details the electrolyser-dissipated thermal power, i.e., the thermal power available at the district heating network, and

represents the heat price for the end users. In detail, that value is set to vary, specifically between 50 EUR/MWh

th and 150 EUR/MWh

th, in 50 EUR/MWh

th steps, for identifying potential thresholds between the levelized cost of heat values hailing from different heat production systems.

In this work, the investment cost associated with the district heating network was not accounted for, as it was assumed that the proposed strategy could simultaneously offer a potentially virtuous pathway for linking the Power-To-Heat and the Power-To-Gas strategies, as well as an approach for reconverting existing networks.

In addition, the environmental aspect of the proposed approach was evaluated in terms of CO

2 emissions reduction. For that purpose, a different heat generation system was assumed for each heat emission system. In detail, referring to radiators, it was assumed that the heat generation system consists of a natural gas boiler with a 90% efficiency. On the other hand, it was assumed that both fan coils and radiant floors are supplied by heat pumps, with COPs of 3 and 5, respectively. Obviously, as the electrolysis unit is powered by RES, the waste heat resulting from the electrochemical conversion is characterised by a null carbon footprint. Having said this, the calculation for the CO

2 emissions reduction reads as

where H represents the available thermal energy, while

and

are the efficiency and the CO

2 emission factor, relative to the heat generation system, respectively. Referring to the carbon dioxide emission factor, a value of 0.201 was assumed for natural gas, while 0.3196 was assumed for electricity.

The final techno-economic assumptions employed in the calculation of the evaluation metrics are reported in

Table 1.

3. Results and Discussion

The Power-to-Heat and Power-to-Gas coupling strategy proposed in this work allows for a comprehensive assessment of the electrolysis unit performance as well as the district heating network and heat emission systems coupling. These aspects hinge on the electrolyser’s operating temperature.

3.1. Temperature Impact on Electrolytic Performance

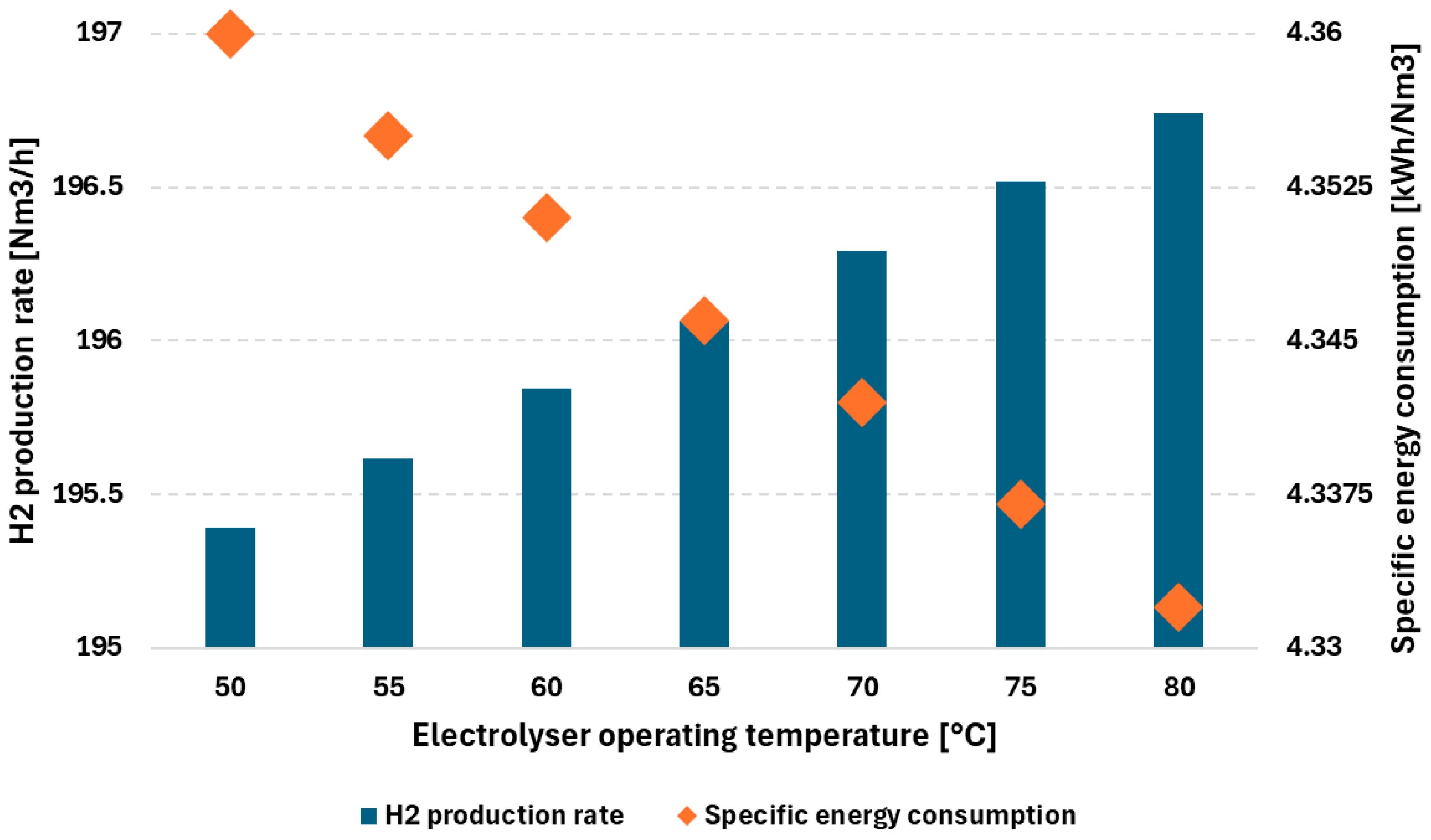

In detail, referring to the electrolytic energy performance and conversion rate, expressed as specific energy consumption and hydrogen production rate, their dependence on the electrolyser’s thermal level is depicted in

Figure 2.

Both trends are linear with respect to the electrolyser operating temperature; however, while the hydrogen production rate increases with the electrolysis thermal level, the specific energy consumption decreases (see

Figure 2). Indeed, as is well recognized, as stack temperature increases, the electrochemical efficiency of the electrolyser improves due to enhanced ionic conductivity and reaction kinetics. This aspect is reflected by a lower specific energy consumption per unit of hydrogen produced.

Explicitly, as the electrolyser’s operating temperature rises from 50 °C to 80 °C, the electrolyser’s specific energy consumption only drops by 1%, which symmetrically corresponds to a 1% increase in its hydrogen production rate. In detail, the unit’s specific energy consumption decreases from 4.36 kWh/Nm3 to 4.332 kWh/Nm3, while the hydrogen production rate increases from 195.4 Nm3/h to 196.7 Nm3/h. Thus, the operating temperature exerts a notably low effect on the hydrogen production and electrochemical conversion aspects.

On the other hand, the electrolysis thermal level holds a crucial role in terms of heat recovery and heat emission systems coupling. In detail,

Figure 3 shows how such an improvement in hydrogen production rate, yielding from a greater stack operating temperature, is accompanied by a reduction in the amount of recoverable waste heat, as a greater share of the input energy is converted into chemical form. Conversely, at lower operating temperatures, while the electrolyser operates with slightly lower hydrogen production efficiency, a larger fraction of input energy is released as heat, increasing the thermal recovery potential for the DH network.

Specifically, in

Figure 3, the available heat is expressed as a fraction of the stack power, which was considered constant in the calculation. By applying the aforementioned increase in the electrolyser’s operating temperature, the heat availability drops by 3%, from 0.196 to 0.19. The reason for this behaviour can be deduced from analysing the trends reported in

Figure 2. In detail, it is noteworthy that as the electrochemical unit’s thermal level rises, its specific energy consumption lowers, entailing higher conversion efficiency. As a result of this greater electricity-to-hydrogen conversion efficiency, the share of electricity converted into heat must decrease, resulting in reduced heat availability (see

Figure 3).

3.2. Matching Electrolyser Operation and District Heating Networks

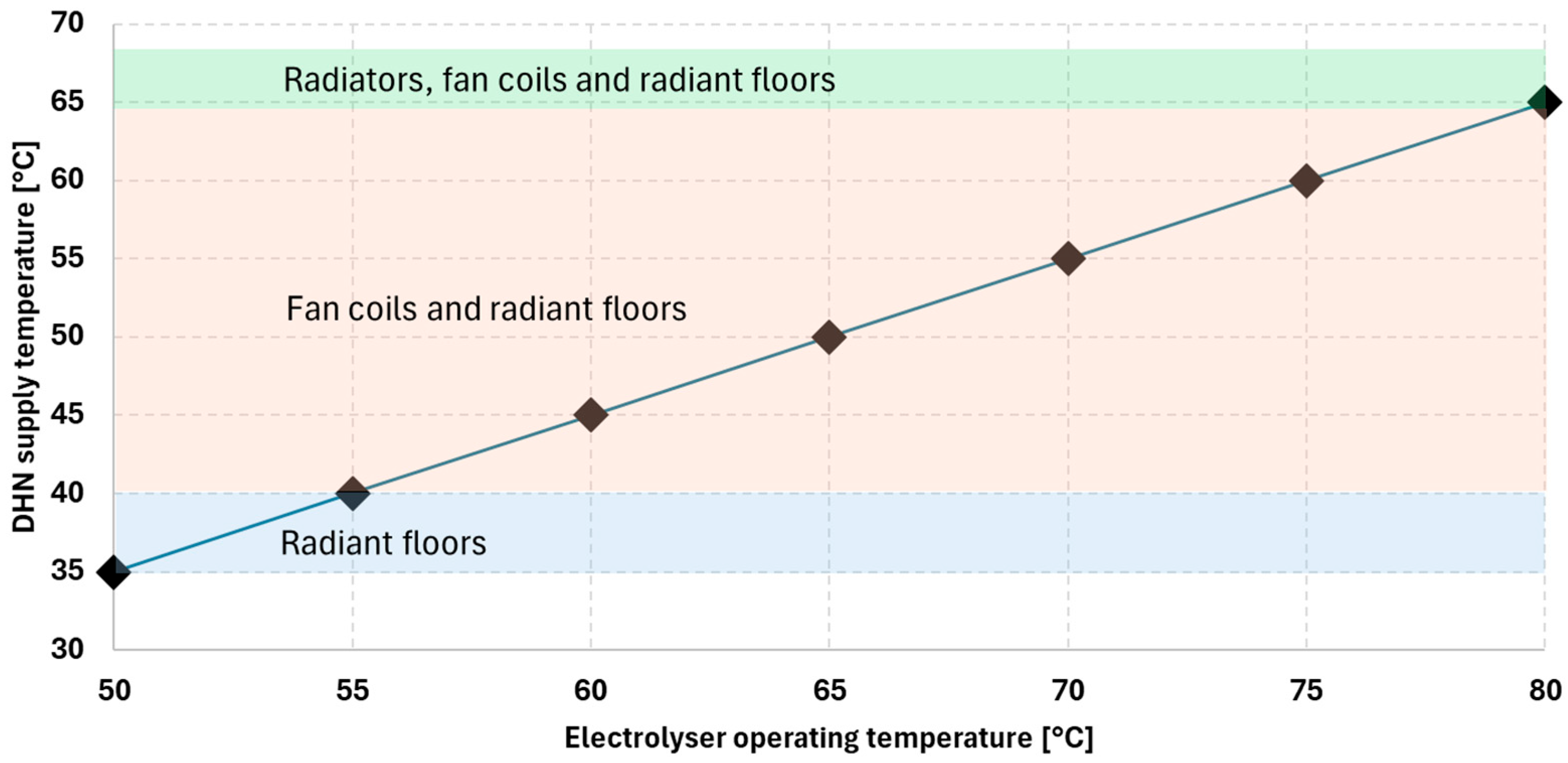

Having said this, it is imperative to further detail the available heat by considering its thermal level in order to understand its potential coupling with existing heat emission systems downstream the district heating network. Specifically, the considered heat emissions systems encompass all commercially available technologies, namely radiators, fan coils, and radiant floors. Such analysis, depicted in

Figure 4, was performed by linking the electrolyser’s operating temperature with the supply temperature of the district heating network and the heat emission systems.

The potential connection between the district heating network and the heat emission terminals, either direct or with an intermediate heat exchanger for heat degradation, can be identified by three different coloured zones, specifically, a light blue one representing a connection with radiant floors, a light orange one, indicating the addition of fan coils, and a light green one, denoting the inclusion of radiators.

Indeed, for an electrolyser operating temperature up to 55 °C, radiant floors represent the only potential heat emission system connection with an electrolytic waste heat-powered district heating network. The light-blue band does not exceed an electrolyser operating temperature of 55 °C due to the recommended water supply temperature for radiant floors being lower than 45 °C [

52,

53].

Having said this, for electrolysis units operating at higher thermal level, an intermediate heat exchanger for heat level degradation should be considered for employing radiant floors as a heat emission system. Indeed, for higher electrolyser operating temperature, namely between 55 °C and 80 °C, fan coils can also be considered as a potential heat emission terminal. In detail, these terminals are typically fed with water at 45–50 °C, despite some manufacturers allowing a maximum feed temperature of 70 °C [

54]. In the latter case, however, the operating thermal level of low-temperature electrolysis systems is not sufficient for generating such a high temperature level for the district heating network and, in turn, for the end users. This limitation stems from the typical PEM electrolyser operating temperature ranging between 50 °C and 80 °C.

Lastly, for an electrolyser operating temperature equal to 80 °C, the only possible direct connection is represented by radiators. Indeed, the typical feed and return water temperature of these heat emission terminals are 75 °C and 65 °C, respectively, despite Z. Liu et al. having reported a feed temperature for radiators as low as 55 °C [

55].

Figure 4 shows how the thermal level for commercially available electrolysers and heat emission terminals can provide a synergistic coupling between waste heat derived from cooling electrolysis units and low-temperature district heating networks. Such a virtuous waste heat utilization pathway could be pivotal for aiding residential heating demand decarbonization based on direct electrification strategies.

3.3. Impact on CO2 Emissions

From an environmental perspective,

Figure 5 illustrates the potential CO

2 emission reduction achieved through the integration of PEM electrolysis waste heat recovery into district heating networks across the various building heat emission systems considered, as a function of both stack operating temperature (50–80 °C) and heating full-load hours (1000–2500).

Firstly, referring to radiators, due to their high-temperature requirements, employing the PEM-produced recovered heat is only feasible at a 80 °C stack operating temperature, the upper limit of typical PEM electrolyser operation. In such a condition, the CO2 emission reduction scales linearly with heating full-load hours, ranging from 36.21 tCO2/year at 1000 h to 90.52 tCO2/year at 2500 h. These significant values reflect the potential displacement of natural gas boiler use, assumed to operate at 90% efficiency, by 100% renewable waste heat.

In contrast, fan coils, which operate effectively at moderate temperatures (typical water feed temperature of 45 °C), exhibit emissions reductions starting at 55 °C. For instance, at 55 °C and 2500 h, the avoided emissions reach 35.32 kg CO2/year, slightly decreasing with increasing stack temperature due to the inverse relationship between electrolyser efficiency and available waste heat. Indeed, as aforementioned, as the temperature rises, the specific energy consumption drops; thus, hydrogen output increases, and less residual heat is available. This trade-off is crucial in optimizing thermal valorisation strategies. Related to the heat generation system, heat pumps with a COP equal to three were assumed for powering fan coils. Hence, displacing such systems yields less CO2 savings per unit of recovered heat compared to gas boilers but remains beneficial due to the fully renewable origin of the recovered thermal energy.

In the end, radiant floors, operating at low supply temperatures (typically fed by water at 35 °C), can accept waste heat from all investigated stack temperatures, starting from 50 °C. This compatibility makes them the most universally adaptable solution in thermal integration with PEM electrolysers. The emissions reduction in this case ranges from 10.36 kg CO2/year (1000 h, 80 °C) to 26.61 kg CO2/year (2500 h, 50 °C). Notably, the trend for radiant floors is opposite to that of hydrogen production: lower stack temperatures result in greater available heat and thus higher CO2 savings, which is particularly relevant given the high COP (assumed equal to five) of heat pumps typically employed in these systems, which makes the offset electricity consumption smaller but still non-negligible when replaced by waste heat.

These findings emphasize a systemic trade-off between electrolyser performance and thermal recovery potential. At higher operating temperatures, hydrogen production becomes more efficient (i.e., lower specific energy consumption), reducing the thermal losses and thus the available waste heat. Conversely, at lower operating temperatures, despite marginally higher energy demand per unit hydrogen, greater heat is released, enhancing district heating integration potential. Therefore, the optimal operating strategy must balance hydrogen economics (e.g., LCOH) and decarbonization impact via heat valorisation.

From a broader climate policy standpoint, this dual valorisation pathway, encompassing green hydrogen production and waste heat recovery, represents a synergistic opportunity for decarbonizing both the energy and building sectors simultaneously. Especially in urban areas with district heating infrastructure, and in colder climate zones with extended heating seasons (e.g., 2500 h/y), these systems can be tailored to maximise waste heat recovery, reduce fossil-based heating, and approach net-zero emissions. Additionally, it is important to highlight that since the waste heat from the electrolyser is entirely renewable, as it is a by-product of RES-powered electrolysis, its use carries zero carbon emissions, making it a climate-neutral thermal input. When appropriately deployed, it can replace more carbon-intensive heating options, aligning with EU and global net-zero targets while also reinforcing the strategic role of hydrogen in integrated energy systems.

3.4. Impact on the Levelised Cost of Hydrogen

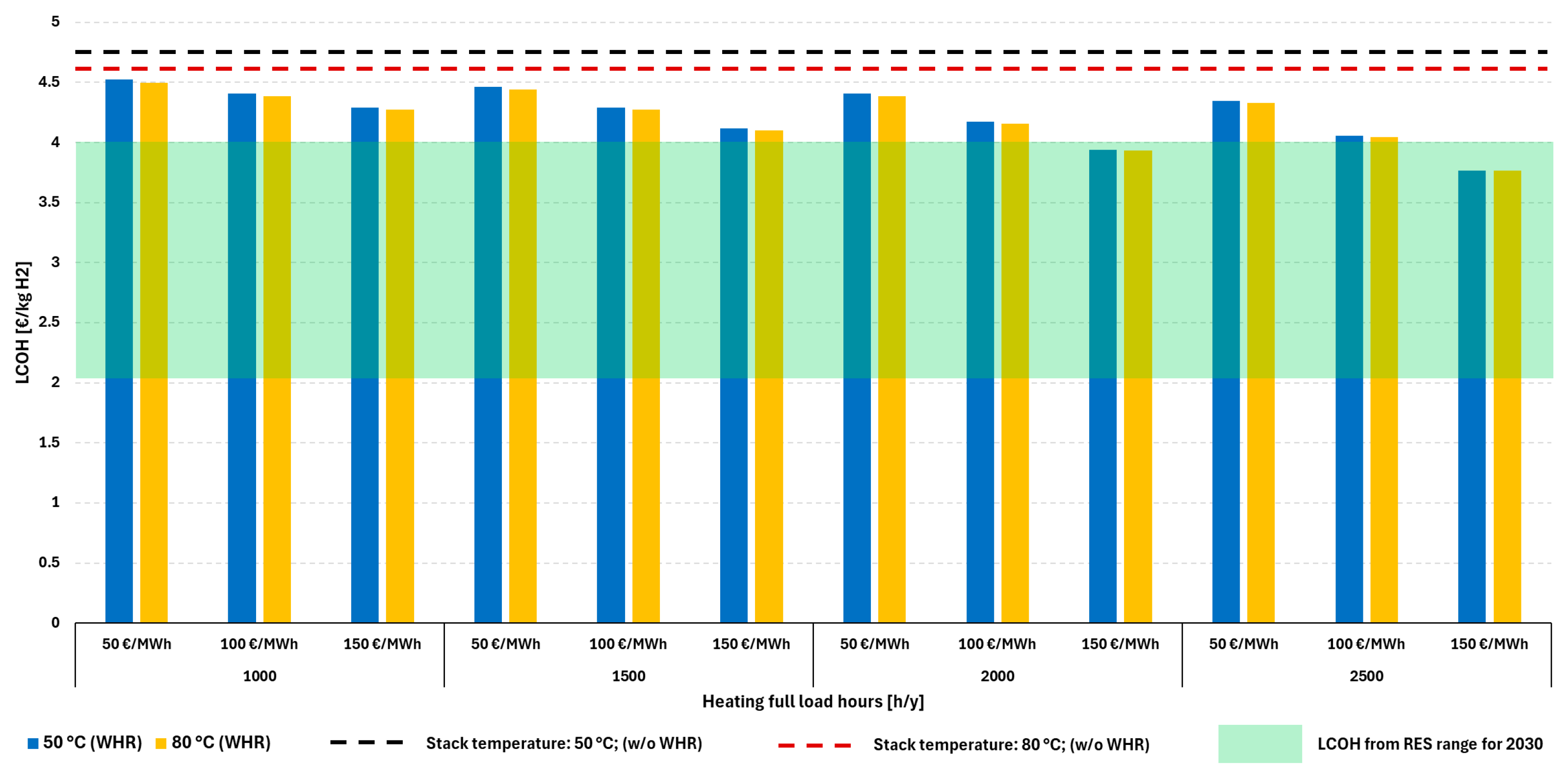

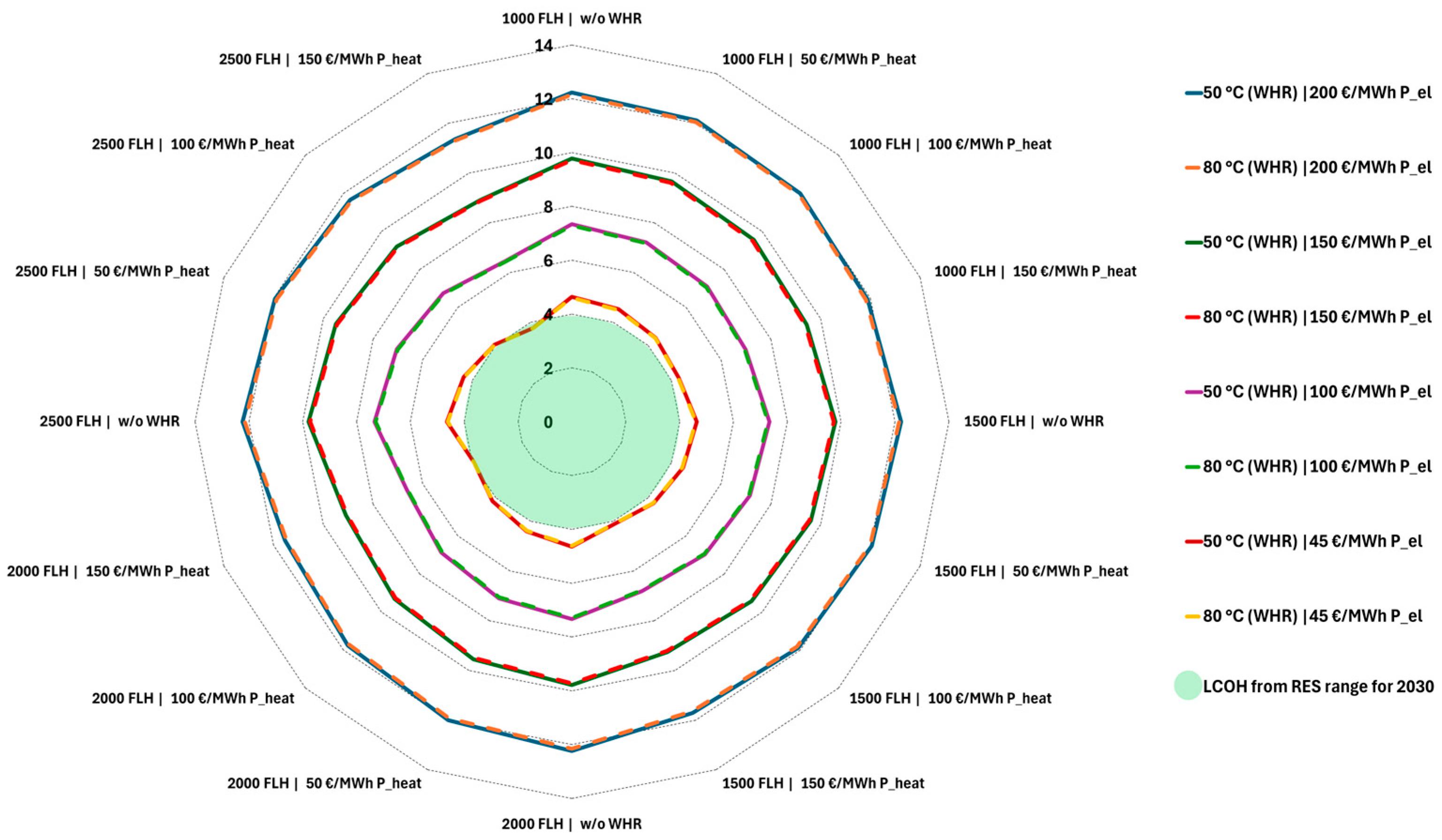

Lastly, in

Figure 6, the results of the detailed numerical evaluation of the LCOH, the main enabler for a green hydrogen-driven energy transition towards 100% renewable energy systems, are detailed. Such an analysis encompasses the PEM electrolyser stack operating temperature (ranging from 50 °C to 80 °C), the heating full-load hours (FLH) (1000 to 2500 h), and the heat selling prices (50 to 150 EUR/MWh).

This analysis is crucial in assessing the benefits of waste heat valorisation from PEM electrolysis within integrated energy systems, particularly through its coupling with low-temperature district heating networks.

Firstly, the LCOH results show that for a PEM electrolyser operating without heat recovery, i.e., excluding any valorisation of waste heat, the cost remains significantly higher than desired future benchmarks. Specifically, for a stack temperature equal to 50 °C, the LCOH reaches 4.640 EUR/kg H2, while at 80 °C, due to improved conversion efficiency and lower specific energy consumption, the levelized cost slightly decreases to 4.611 EUR/kg H2. Such a marginal reduction, corresponding to approximately 0.63%, underscores the benefit of higher operating temperatures for electrochemical performance while also highlighting the limited economic competitiveness of standalone PEM electrolysis under current techno-economic assumptions, especially when not integrated with additional value streams.

Conversely, referring to configurations featuring waste heat recovery and valorisation, the data reported in

Figure 6 clearly demonstrate that the levelized cost of hydrogen decreases monotonically with increasing stack temperature, across all combinations of FLH and heat selling price. This trend arises from the intrinsic thermodynamic behaviour of PEM electrolysis. Specifically, higher operating temperatures entail the greater electrochemical conversion efficiency of water into hydrogen, thereby reducing the specific energy consumption. As a result, more hydrogen can be produced per unit of electric energy input, with the latter notably representing the dominant cost driver in electrolytic hydrogen production. Thus, although the amount of recoverable waste heat decreases with increasing temperature, the reduction in electricity-related costs more than compensates for the loss in thermal-driven revenue, according to the price assumed in this work.

Across all operating conditions, the LCOH reaches its lowest value at the highest stack operating temperature, i.e., 80 °C, and for the most favourable heat valorisation scenario, namely 2500 heating full-load hours and 150 EUR/MWh of heat price. Under such techno-economic conditions, the LCOH drops to approximately 3.77 EUR/kg H2, representing a substantial improvement compared to the base case with no heat recovery. In contrast, the least favourable case, i.e., 50 °C stack temperature, 1000 heating full-load hours, and a heat price of 50 EUR/MWh, yields an LCOH of approximately 4.52 EUR/kg H2, revealing a difference of approximately 0.75 EUR/kg H2, which corresponds to a 17% reduction. Those results highlight the utmost importance of recovering and valorising waste heat, especially considering the significant economic leverage it can provide.

In addition, it is valuable to point out that the LCOH sensitivity to heat price increases with the number of heating full-load hours. Specifically, at 1000 FLH, increasing the heat price from 50 to 150 EUR/MWh results in a reduction in LCOH ranging between 0.23 and 0.25 EUR/kg H2 across the entire temperature range considered. Conversely, at 2500 heating FLH, the same variation in heat price yields an LCOH reduction of up to 0.58 EUR/kg H2, more than double the impact observed at 1000 FLH. Such a difference indicates a strong synergy between operating time and heat valorisation potential, reinforcing the importance of aligning electrolyser operation with heating demand profiles to maximise economic benefits.

Moreover, the absolute LCOH values approach the threshold of economic viability for renewable hydrogen, namely the 2–4 EUR/kg H2 target range projected by the International Energy Agency (IEA) for renewable hydrogen production by 2030. Such a threshold has been widely recognized as critical for enabling the large-scale adoption of green hydrogen across industrial and energy sectors.

3.5. Sensitivity Analysis

In order to deepen the techno-economic evaluation, a sensitivity analysis was carried out by increasing the electricity price, from the optimistic value of 45 EUR/MWh up to 200 EUR/MWh, while simultaneously accounting for the influence of electrolyser operating temperature, heating full-load hours, and the valorisation of waste heat into a district heating network. Through such a comprehensive evaluation (see

Figure 7), it is possible to determine how fluctuations in one of the most critical cost drivers, i.e., electricity price, affect the levelized cost of hydrogen (LCOH) and how synergistic effects with waste heat recovery (WHR) can mitigate these impacts.

In detail, the data demonstrate that at the highest electricity price considered (200 EUR/MWh), the LCOH values exceed 12 EUR/kg H2 under all configurations, even when waste heat recovery is incorporated and monetised at varying heat prices. For instance, at 50 °C with 1000 heating full-load hours and WHR, the LCOH drops from 12.23 EUR/kg H2 without valorisation to 12.00 EUR/kg H2 at a heat price of 100 EUR/MWh and 11.88 EUR/kg H2 at 150 EUR/MWh. At 80 °C under the same conditions, the corresponding range spans from 12.16 EUR/kg H2 to 11.82 EUR/kg H2, confirming that, at such high electricity prices, waste heat recovery valorisation can only marginally attenuate the overwhelming electricity-driven cost pressure.

At intermediate electricity prices (150 EUR/MWh), the LCOH falls into the range of approximately 9.78 to 8.91 EUR/kg H2 depending on operating temperature, heating full-load hours, and heat price. For example, at 50 °C and 2500 FLH, the LCOH decreases from 9.78 EUR/kg H2 without WHR to 9.20 EUR/kg H2 at a 100 EUR/MWh heat price and 8.91 EUR/kg H2 at a 150 EUR/MWh heat price. At 80 °C, the corresponding values are slightly lower, ranging from 9.72 EUR/kg H2 without valorisation to 8.88 EUR/kg H2 at the highest monetisation of heat. These results illustrate that WHR becomes increasingly relevant at moderate electricity prices, providing a reduction of nearly 0.9 EUR/kg H2 in optimal conditions, which can be decisive when aiming to close the gap in achieving competitive hydrogen production targets.

At a 100 EUR/MWh electricity price, LCOH values decline significantly, into the 7.3–6.4 EUR/kg H2 range. For instance, at 50 °C with 2500 FLH, the LCOH is 7.33 EUR/kg H2 without WHR, dropping to 6.75 EUR/kg H2 at a 100 EUR/MWh heat price and further to 6.46 EUR/kg H2 at 150 EUR/MWh. At 80 °C, under the same configuration, the LCOH reaches a minimum of 6.44 EUR/kg H2. This demonstrates that longer utilisation periods and higher heat valorisation systematically improve system economics. Furthermore, the difference between 50 °C and 80 °C operation is modest but systematic, with higher operating temperatures producing slightly lower LCOH values due to improved hydrogen output per unit of electricity, albeit at the expense of lower recoverable heat. This trade-off highlights the intricate balance between hydrogen productivity and thermal valorisation in integrated energy systems.

At the lowest electricity price considered, 45 EUR/MWh, the LCOH approaches levels aligned with medium-term projections for renewable hydrogen, particularly when WHR is maximised. At 50 °C with 2500 FLH, the LCOH falls from 4.64 EUR/kg H2 without WHR to 3.77 EUR/kg H2 at the highest monetised heat price. At 80 °C, the corresponding minimum value is 3.77 EUR/kg H2, underscoring the convergence between the two operating temperatures at high utilisation and under favourable economic conditions for heat recovery. These values are particularly significant because they fall within the 2–4 EUR/kg range forecasted by the International Energy Agency for renewable hydrogen production by 2030, demonstrating that under optimal circumstances, PEM electrolysers integrated with DH networks can realistically attain competitive cost levels. Conversely, without WHR, the same configurations yield 4.64 EUR/kg H2 at 50 °C and 4.61 EUR/kg H2 at 80 °C, values that remain above the upper bound of the IEA forecast, thereby proving that WHR is not a marginal consideration but rather a key enabler of economic feasibility.

In the end, the sensitivity analysis unequivocally shows that electricity price dominates hydrogen production costs, but the monetisation of waste heat through integration with district heating networks provides a tangible and sometimes decisive reduction in the LCOH. At high electricity prices, WHR delivers only modest relief, whereas at moderate to low prices, it enables a downward shift of nearly 1 EUR/kg H2, bringing PEM electrolysers closer to the competitive cost range set by global energy policy benchmarks. Furthermore, the coupling between stack operating temperature and FLH dictates the balance between hydrogen output and available heat, underscoring the systemic character of this integration. Thus, waste heat valorisation represents not just a sustainability benefit but also an economic lever that, when combined with favourable electricity pricing and high utilisation rates, can propel green hydrogen into commercially competitive territory.

3.6. Limitations of the Work and Potential Future Developments

Although this work advances the understanding of waste heat recovery from PEM electrolysers in district heating applications, several aspects remain beyond its current scope and offer opportunities for further refinement. A first limitation lies in the treatment of DHN operating conditions. Indeed, while this work is primarily focused on the coupling of electrolytic-derived waste heat with end-user emission systems, it does not explicitly account for the technical and economic constraints of DHN operation. In detail, since the operating costs of heating networks may be comparable to heat production costs, and permissible operating boundaries can restrict the feasibility of specific technological solutions, a more detailed representation of network dynamics would strengthen the applicability of the proposed approach. Incorporating these elements in future analyses could transform the current conceptual framework into a more comprehensive tool for energy system planning.

Additionally, district heating demand is subject to significant temporal variation, driven by seasonal climatic factors as well as stochastic fluctuations in industrial and technological processes. While this study provides valuable insights under steady-state conditions, it does not yet capture the dynamic performance of the system across an entire heating season. Future work could address this limitation by integrating variable demand profiles and predictive scheduling, thereby enhancing the robustness of the proposed concept under real-world operation. Moreover, the reliability of PEM electrolysers as a continuous heat source for DHNs also warrants further investigation. Given that district heating constitutes a socially significant infrastructure with stringent requirements for supply security, future research should explore redundancy schemes, hybridisation with auxiliary technologies, and reliability metrics tailored to PEM-based heat integration. Such an extension would not only address reliability concerns but also highlight the resilience benefits of combining hydrogen production with district heating.

Lastly, it is noteworthy that district heating systems vary widely in size, structure, and user categories, which may influence both the technical feasibility and economic viability of electrolyser integration. While the general approach adopted in this work has allowed the concept to remain broadly applicable, future studies could refine the analysis by tailoring it to specific system scales and policy frameworks. This would enable the identification of niches where the proposed approach offers the greatest benefit and could serve as a guideline for targeted implementation strategies.

In summary, these limitations point to promising directions for further research, which could transform the proposed concept from a theoretical potential into a practical and robust solution for integrated hydrogen-heat systems.

4. Conclusions

In this work, the integration of PEM electrolysers with district heating (DH) networks was assessed from both techno-economic and environmental perspectives. This multisectoral strategy combines green hydrogen production with the valorisation of low-temperature waste heat, yielding simultaneous benefits in efficiency, competitiveness, and carbon abatement. The findings confirm that waste heat recovery (WHR) is not an ancillary benefit but a central design feature that enhances hydrogen production efficiency and systemic sustainability. By recovering thermal energy that would otherwise be lost, the process supplies a renewable, zero-carbon heat source to urban DH systems, transforming waste into a dispatchable energy vector.

The techno-economic analysis demonstrates that WHR can significantly reduce the levelized cost of hydrogen (LCOH). At 2500 heating full-load hours (FLH) and a heat sale price of 150 EUR/MWh, the LCOH falls from 4.64 to 3.77 EUR/kg H2 at 50 °C (−18.9%) and from 4.61 to 3.77 EUR/kg H2 at 80 °C. These reductions are particularly meaningful given the dominance of electricity costs in hydrogen production and the limited scope for reducing capital expenditure in the short term. Under such favourable conditions, LCOH values align with the International Energy Agency’s 2030 competitiveness range of 2–4 EUR/kg H2, underscoring the strategic importance of WHR in unlocking cost-competitive renewable hydrogen.

From an environmental perspective, substituting conventional heating with recovered waste heat yields substantial CO2 savings. At 80 °C and 2500 FLH, annual reductions reach approximately 90 tonnes compared with natural gas boilers, 34.5 tonnes compared with fan coils powered by heat pumps (COP = 3), and 25.9 tonnes compared with radiant floors powered by high-efficiency heat pumps (COP = 5). These results highlight the broad applicability of the approach across diverse building energy systems and its potential role in accelerating urban decarbonisation.

To deepen the techno-economic evaluation, a sensitivity analysis was performed by varying the electricity price from 45 EUR/MWh to 200 EUR/MWh, while accounting for stack operating temperature, FLH, both with and without WHR. The results confirm that electricity price remains the dominant cost driver: at 200 EUR/MWh, LCOH values increase more than threefold relative to the lowest-price scenario, with WHR offering only marginal relief, at about 3%. At intermediate electricity prices (150 EUR/MWh), WHR becomes increasingly relevant, enabling cost reductions of up to 9% under optimal conditions. At 100 EUR/MWh, LCOH values are reduced by approximately 12% when WHR is incorporated, systematically improving system economics. At the lowest electricity price tested (45 EUR/MWh), WHR lowers costs by around 19%, placing LCOH within the IEA’s projected range for renewable hydrogen by 2030. These results confirm that while electricity cost dominates, WHR provides a tangible lever that can decisively enhance competitiveness at moderate and low prices.

In summary, this study demonstrates that low-temperature WHR from PEM electrolysers constitutes a systemic upgrade rather than a marginal optimisation. It enhances hydrogen competitiveness through new revenue streams, supports the decarbonisation of urban heating, and strengthens the resilience of electrolysis against electricity price volatility. Future hydrogen deployment strategies, especially in regions with established DH infrastructure, should prioritise such integrative configurations to unlock their full potential for both energy system efficiency and climate mitigation.