Sheep Wool as Biomass: Identifying the Material and Its Reclassification from Waste to Resource

Abstract

1. Introduction

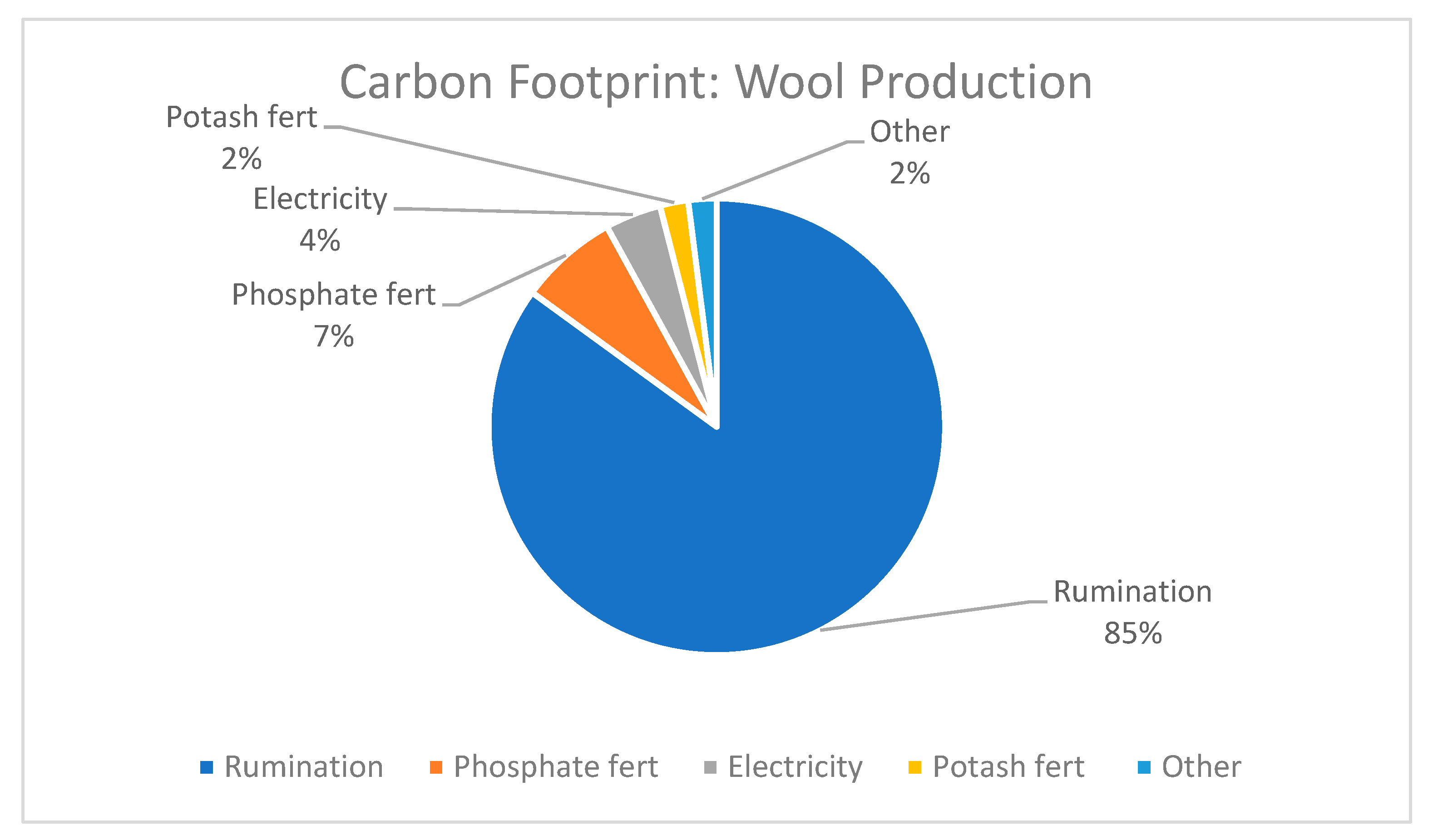

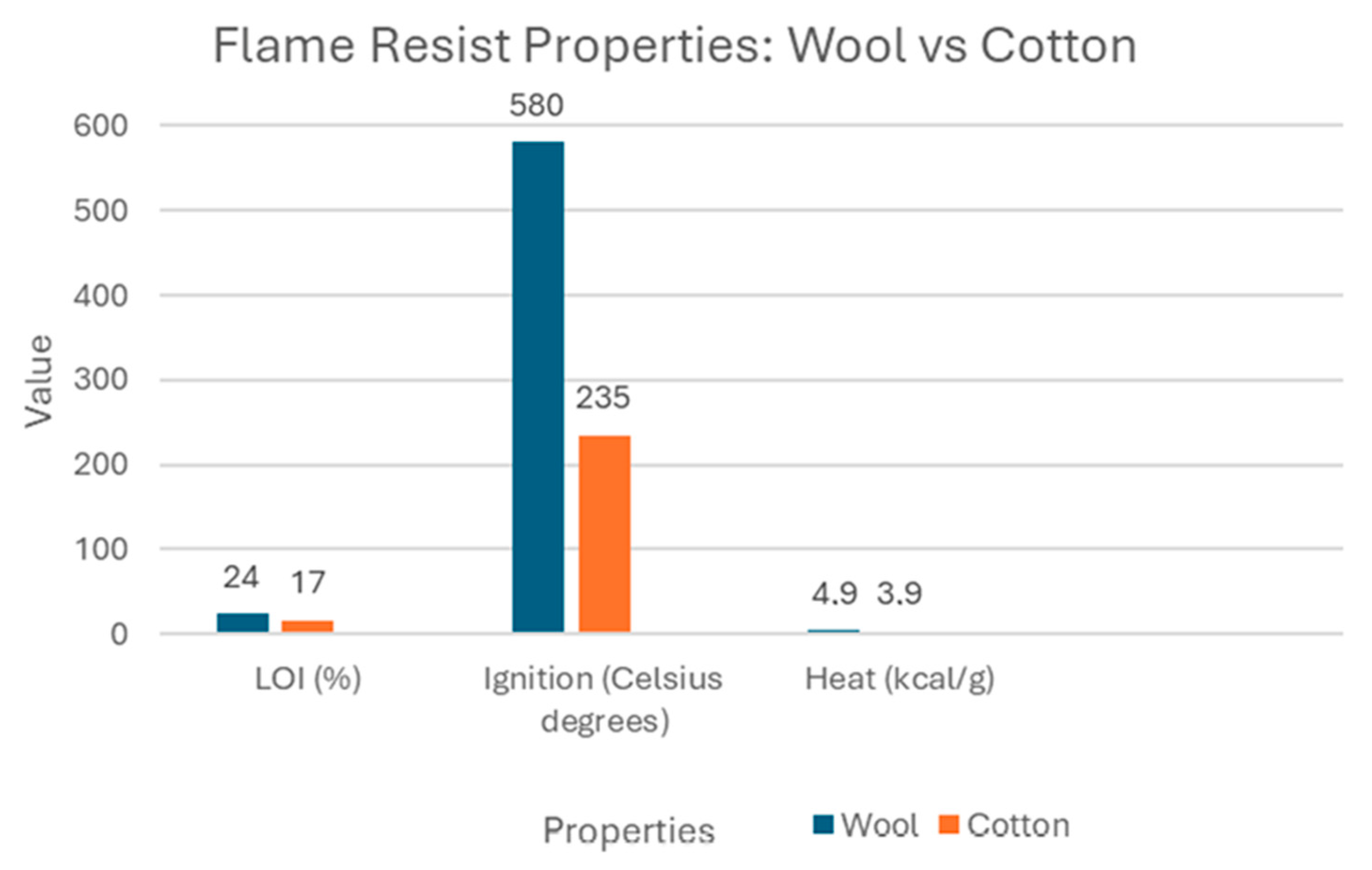

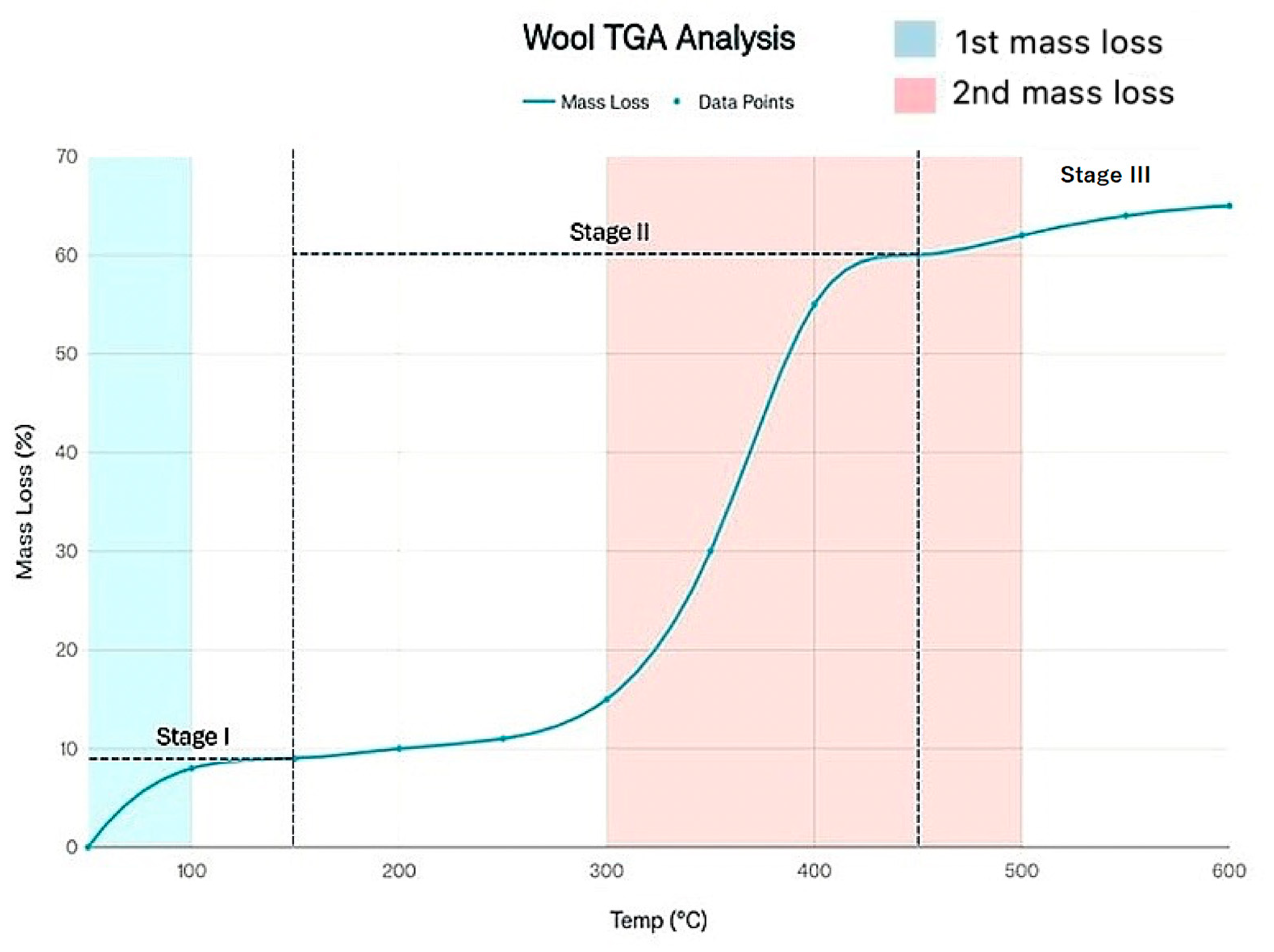

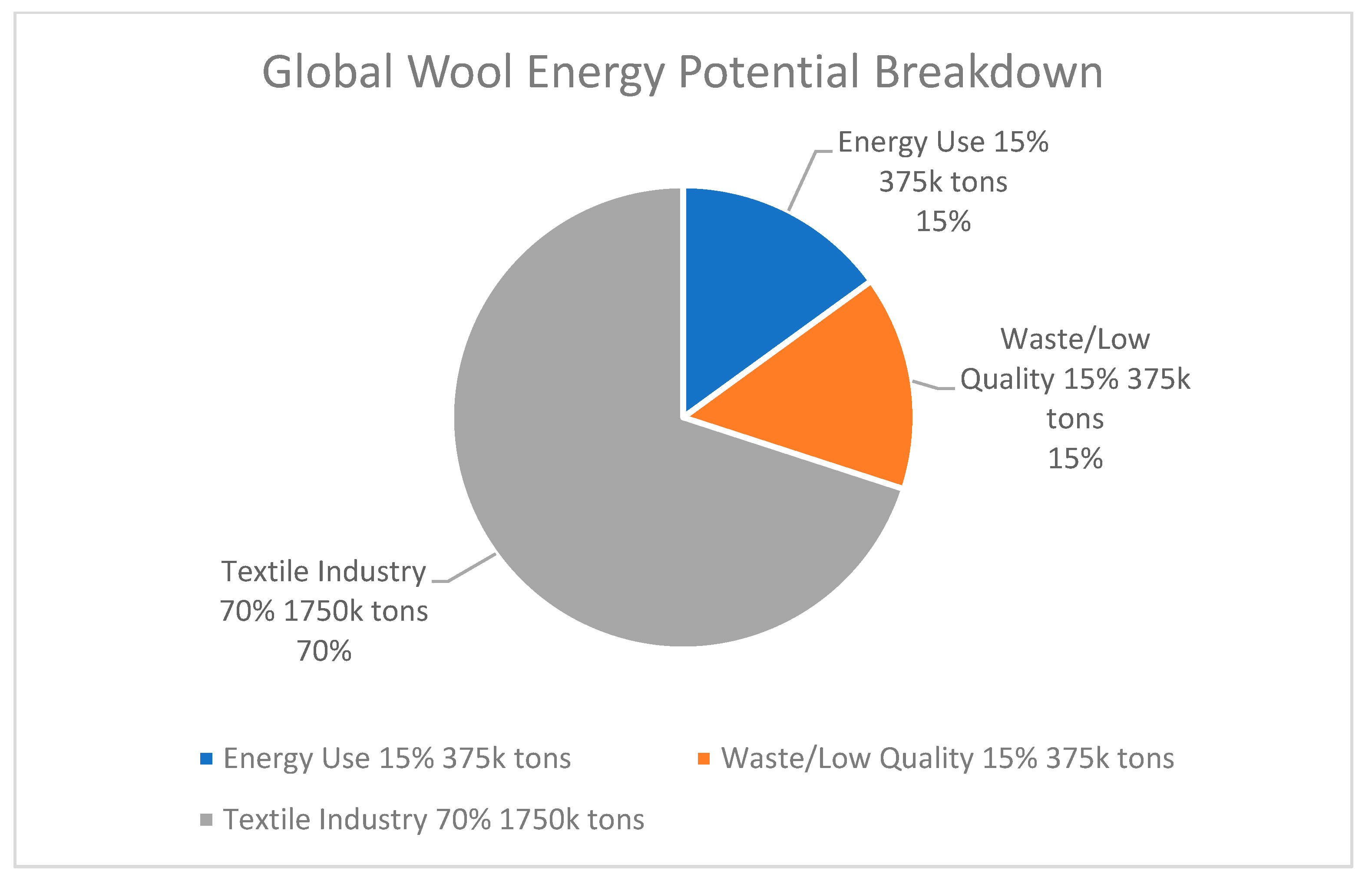

2. Potential of Sheep Wool as Biomass

3. Processing Waste Sheep Wool as a Raw Material with Energy Potential

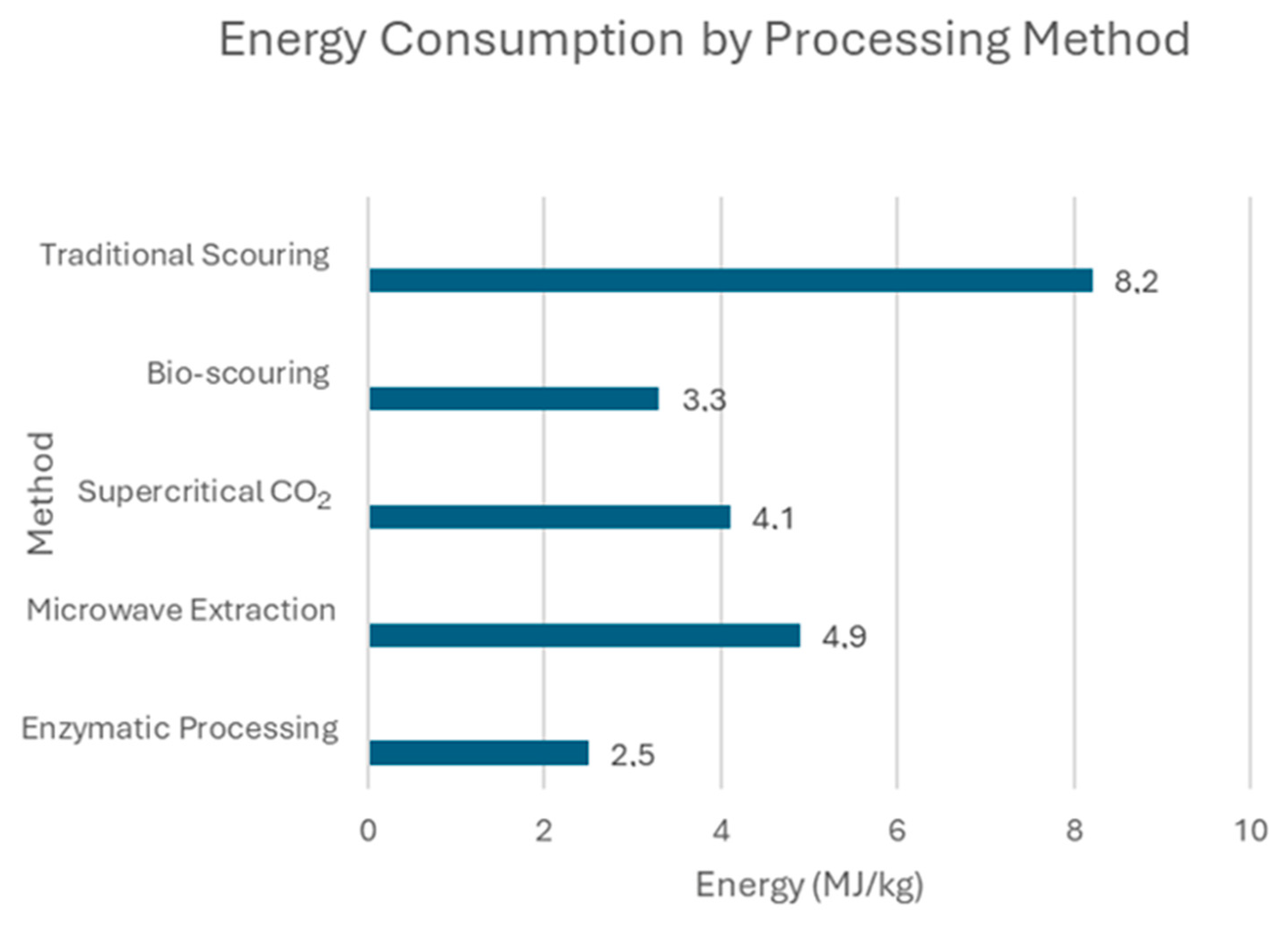

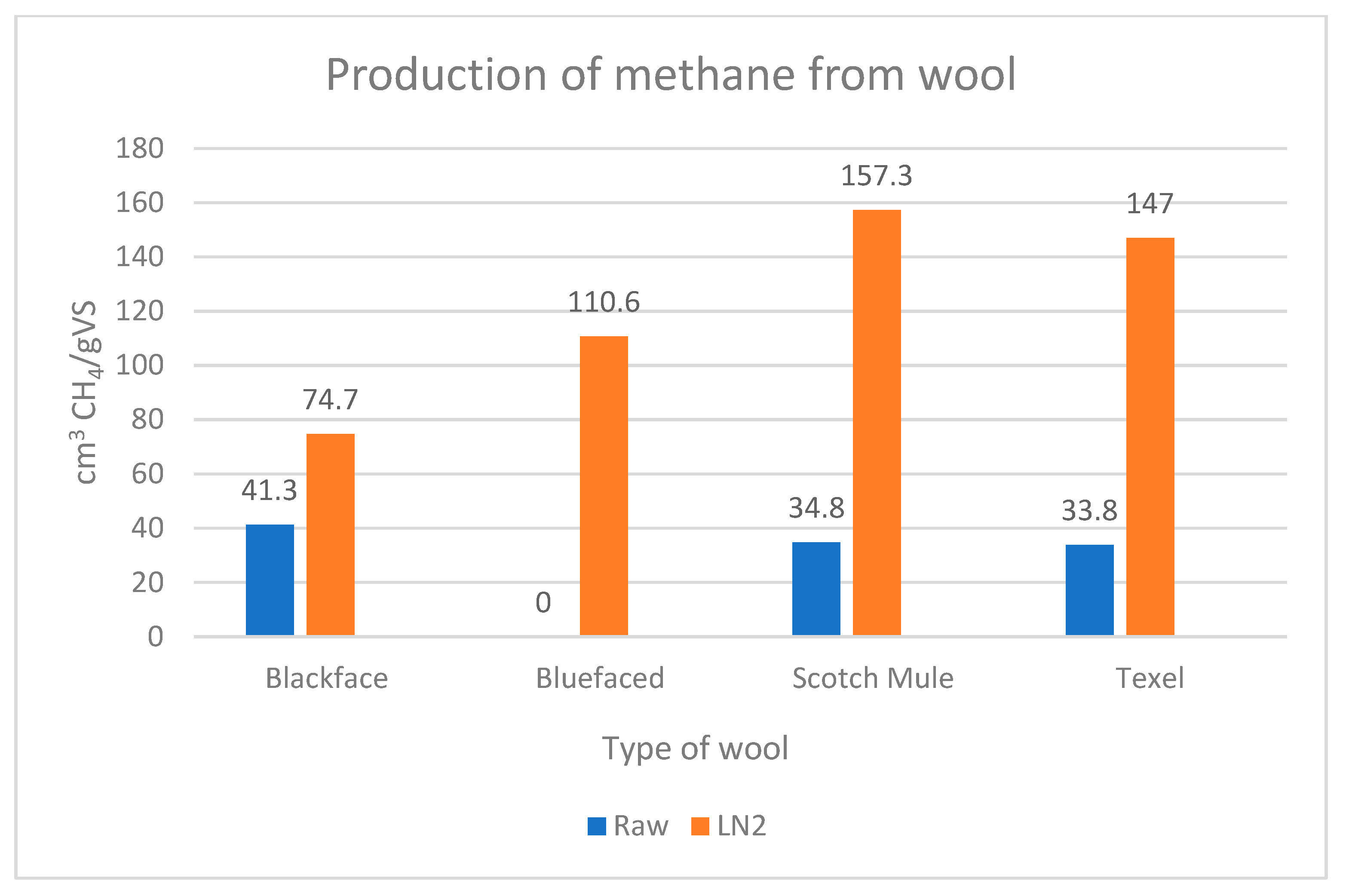

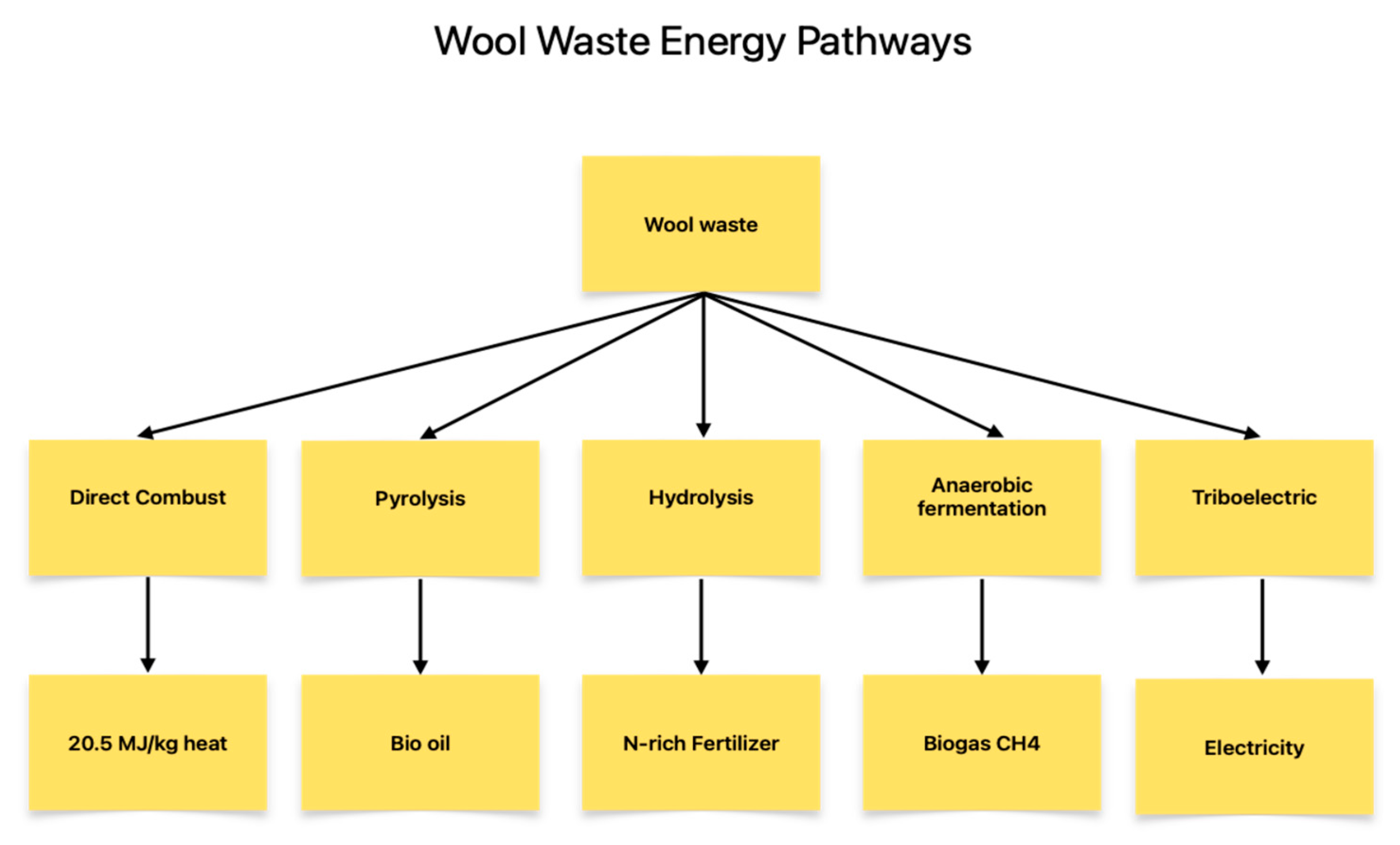

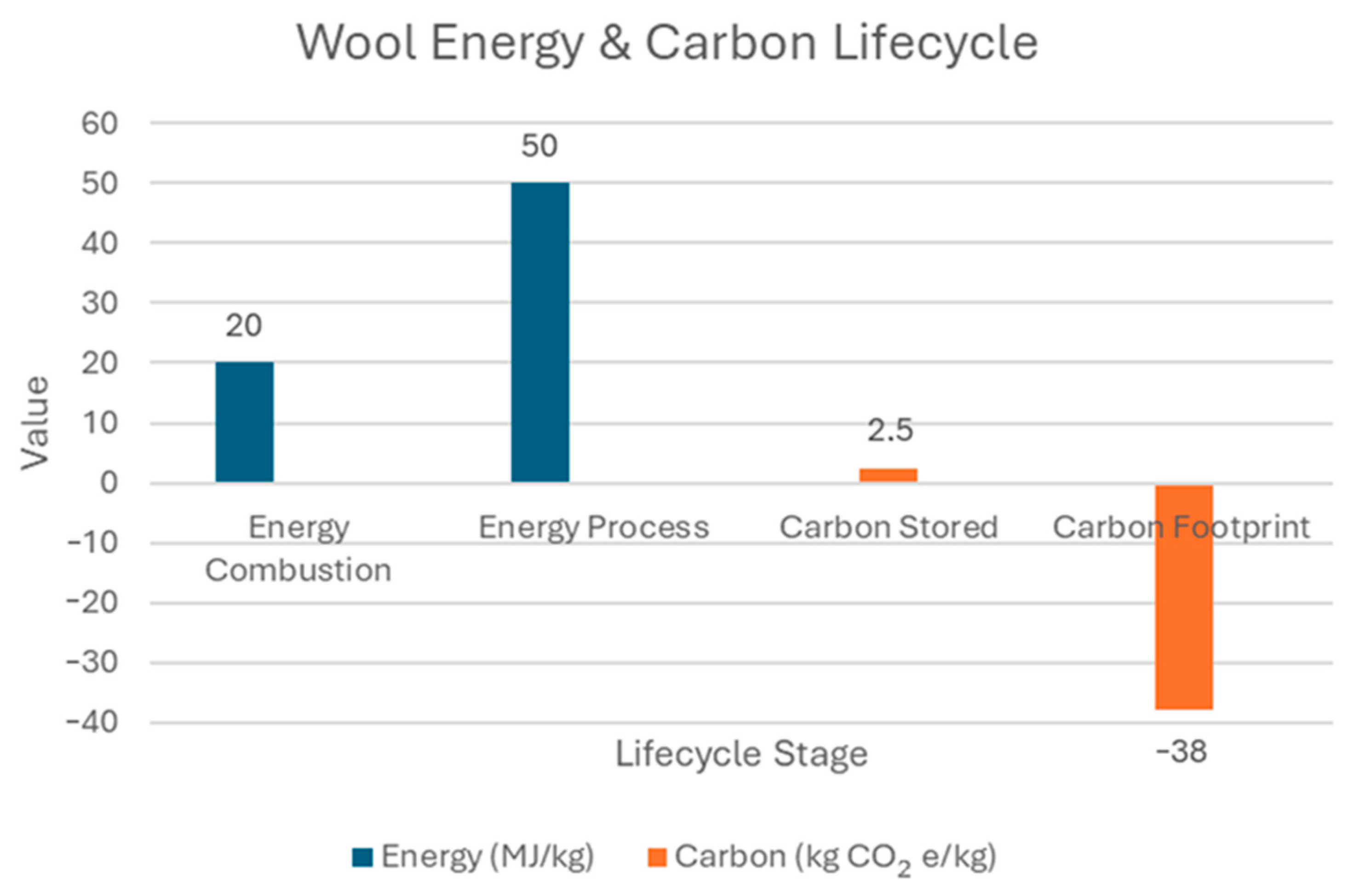

3.1. Sheep Wool Energy Potential and Pre-Processing

3.2. Sheep Wool-Energy Conversion Technologies

4. Market Challenges in the Use of Waste Sheep Wool as Biomass

4.1. Challenges and Limitations in Waste Sheep Wool Processing

4.2. Comparison of Wool with Other Biomass Sources

5. Conclusions and Prospects for Development

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, A.; Agrawal, A. Recent Trends in Solid Waste Management Status, Challenges, and Potential for the Future Indian Cities—A Review. Curr. Res. Environ. Sustain. 2020, 2, 100011. [Google Scholar] [CrossRef]

- Wilson, D.C.; Velis, C.A. Waste Management—Still a Global Challenge in the 21st Century: An Evidence-Based Call for Action. Waste Manag. Res. J. A Sustain. Circ. Econ. 2015, 33, 1049–1051. [Google Scholar] [CrossRef]

- Valenti, F.; Parlato, M.C.M.; Pecorino, B.; Selvaggi, R. Enhancement of Sustainable Bioenergy Production by Valorising Tomato Residues: A GIS-Based Model. Sci. Total Environ. 2023, 869, 161766. [Google Scholar] [CrossRef] [PubMed]

- Molik, E.; Kosiek, A.; Potocka, A. Wpływ Długości Dnia Na Sekrecję Prolaktyny i Parametry Biologiczne Wełny Owczej. Wiad. Zootech. 2019, 2, 43–47. [Google Scholar]

- Górecki, R.S.; Górecki, M.T. Utilization of Waste Wool as Substrate Amendment in Pot Cultivation of Tomato, Sweet Pepper, and Eggplant. Pol. J. Env. Stud. 2010, 19, 1083–1087. [Google Scholar]

- Piróg, J.; Komosa, A. Influence of Substrate and Cultivar on Quantity and Quality of Greenhouse Tomato Yield. Acta Agrophysica 2006, 7, 699–707. [Google Scholar]

- Banasaz, S.; Ferraro, V. Keratin from Animal By-Products: Structure, Characterization, Extraction and Application—A Review. Polymers 2024, 16, 1999. [Google Scholar] [CrossRef]

- Parlato, M.; Valenti, F.; Midolo, G.; Porto, S. Livestock Wastes Sustainable Use and Management: Assessment of Raw Sheep Wool Reuse and Valorization. Energies 2022, 15, 3008. [Google Scholar] [CrossRef]

- Bianco, I.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of Worsted and Woollen Processing in Wool Production: ReviWool® Noils and Other Wool Co-Products. J. Clean. Prod. 2023, 415, 137877. [Google Scholar] [CrossRef]

- Chukwunonso Ossai, I.; Shahul Hamid, F.; Hassan, A. Valorisation of Keratinous Wastes: A Sustainable Approach towards a Circular Economy. Waste Manag. 2022, 151, 81–104. [Google Scholar] [CrossRef]

- Pekhtasheva, E.; Neverov, A.; Kubica, S.; Zaikov, G. Biodegradation and Biodeterioration of Some Natural Polymers. Chem. Chem. Technol. 2012, 6, 263–280. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Porto, S.M.C. Organized Framework of Main Possible Applications of Sheep Wool Fibers in Building Components. Sustainability 2020, 12, 761. [Google Scholar] [CrossRef]

- Janíček, M.; Massányi, M.; Kováčik, A.; Halo, M.; Tirpák, F.; Blaszczyk-Altman, M.; Albrycht, M.; Stawarz, R.; Halo, M.; Massányi, P. Content of Biogenic Elements in Sheep Wool by the Regions of Slovakia. Biol. Trace Elem. Res. 2025, 203, 1886–1897. [Google Scholar] [CrossRef]

- Hawkins, D.P.; Ragnarsdóttir, K.V. The Cu, Mn and Zn Concentration of Sheep Wool: Influence of Washing Procedures, Age and Colour of Matrix. Sci. Total Environ. 2009, 407, 4140–4148. [Google Scholar] [CrossRef]

- Patkowska-Sokoła, B.; Dobrzański, Z.; Osman, K.; Bodkowski, R.; Zygadlik, K. The Content of Chosen Chemical Elements in Wool of Sheep of Different Origins and Breeds. Arch. Anim. Breed. 2009, 52, 410–418. [Google Scholar] [CrossRef]

- Cholewinska, P.; Michalak, M.; Wyrostek, A.; Czyż, K. Badanie Impedancji, Ciepłochronności i Naprężenia Zrywającego Wełny Jednolitej i Mieszanej. Wiad. Zootech. 2018, 56, 62–67. [Google Scholar]

- Szatkowski, P.; Suchrowiec, K.; Tadla, A.; Flis, Z.; Szatkowska, M.; Molik, E. Możliwości Zastosowania Wełny Owczej Jako Elementu Kompozytu Nawozowego. Przegląd Hod. 2021, 6, 9–12. [Google Scholar]

- Kaynak, E.; Üreyen, M.E.; Koparal, A.S. Flammability and Thermal Degradation Behaviour of Wool/Polyamide 6.6 Blends. Tekst. Ve Mühendis 2020, 27, 22–30. [Google Scholar] [CrossRef]

- Golański, M. Potencjał Zastosowania Produktów Organicznych w Budownictwie. Przegląd Bud. 2011, 82, 80–87. [Google Scholar]

- Fiore, V.; Di Bella, G.; Valenza, A. Effect of Sheep Wool Fibers on Thermal Insulation and Mechanical Properties of Cement-Based Composites. J. Nat. Fibers 2020, 17, 1532–1543. [Google Scholar] [CrossRef]

- Korjenic, A.; Klarić, S.; Hadžić, A.; Korjenic, S. Sheep Wool as a Construction Material for Energy Efficiency Improvement. Energies 2015, 8, 5765–5781. [Google Scholar] [CrossRef]

- Kim, N.K.; Bhattacharyya, D. Development of Fire Resistant Wool Polymer Composites: Mechanical Performance and Fire Simulation with Design Perspectives. Mater. Des. 2016, 106, 391–403. [Google Scholar] [CrossRef]

- Subasinghe, A.; Somashekar, A.A.; Bhattacharyya, D. Effects of Wool Fibre and Other Additives on the Flammability and Mechanical Performance of Polypropylene/Kenaf Composites. Compos. B Eng. 2018, 136, 168–176. [Google Scholar] [CrossRef]

- Mroczka, K.; Ożóg, S. Analiza Mikroskopowa SEM Wybranych Włókien Stosowanych w Przemyśle Włókienniczym. Ann. Univ. Paedagog. Cracoviensis Stud. Tech. 2010, 3, 129. [Google Scholar]

- Rippon, J.A. The Structure of Wool. In The Coloration of Wool and Other Keratin Fibres; Wiley: Hoboken, NJ, USA, 2013; pp. 1–42. [Google Scholar]

- Bhavsar, P.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Mossotti, R.; Rovero, G.; Giansetti, M.; Tonin, C. Superheated Water Hydrolysis of Waste Wool in a Semi-Industrial Reactor to Obtain Nitrogen Fertilizers. ACS Sustain. Chem. Eng. 2016, 4, 6722–6731. [Google Scholar] [CrossRef]

- Brock, P.M.; Graham, P.; Madden, P.; Alcock, D.J. Greenhouse Gas Emissions Profile for 1 Kg of Wool Produced in the Yass Region, New South Wales: A Life Cycle Assessment Approach. Anim. Prod. Sci. 2013, 53, 495. [Google Scholar] [CrossRef]

- Sarkar, S.; Lal, B.; Gautam, P.; Bhatt, R.S.; Sahoo, A. Comparing Carbon Footprints of Sheep Farming Systems in Semi-Arid Regions of India: A Life Cycle Assessment Study. PLoS ONE 2024, 19, e0292066. [Google Scholar] [CrossRef]

- Peri, P.L.; Rosas, Y.M.; Ladd, B.; Díaz-Delgado, R.; Martínez Pastur, G. Carbon Footprint of Lamb and Wool Production at Farm Gate and the Regional Scale in Southern Patagonia. Sustainability 2020, 12, 3077. [Google Scholar] [CrossRef]

- Skodras, G.; Grammelis, P.; Basinas, P.; Kakaras, E.; Sakellaropoulos, G. Pyrolysis and Combustion Characteristics of Biomass and Waste-Derived Feedstock. Ind. Eng. Chem. Res. 2006, 45, 3791–3799. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, Z.; Zaman, F.; Huang, Y.; Guan, Y. Detection and Kinetic Simulation of Animal Hair/Wool Wastes Pyrolysis toward High-Efficiency and Sustainable Management. Waste Manag. 2021, 131, 305–312. [Google Scholar] [CrossRef]

- Petek, B.; Marinšek Logar, R. Management of Waste Sheep Wool as Valuable Organic Substrate in European Union Countries. J. Mater. Cycles Waste Manag. 2021, 23, 44–54. [Google Scholar] [CrossRef]

- Schoen, E.J.; Bagley, D.M. Biogas Production and Feasibility of Energy Recovery Systems for Anaerobic Treatment of Wool-Scouring Effluent. Resour. Conserv. Recycl. 2012, 62, 21–30. [Google Scholar] [CrossRef]

- Kuzmanova, E.; Zhelev, N.; Akunna, J.C. Effect of Liquid Nitrogen Pre-Treatment on Various Types of Wool Waste Fibres for Biogas Production. Heliyon 2018, 4, e00619. [Google Scholar] [CrossRef]

- Ruiz, B.; Fuente, E.; Pérez, A.; Taboada-Ruiz, L.; Sanz, J.M.; Calvo, L.F.; Paniagua, S. Employment of Conventional and Flash Pyrolysis for Biomass Wastes from the Textile Industry with Sustainable Prospects. J. Anal. Appl. Pyrolysis 2023, 169, 105864. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Flores-Sahagun, T.; Arizaga, G.G.C.; Franco, T.S.; Tanobe, V.d.A. Surface Modification Treatment Methods of Wool. In Wool Fiber Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 71–105. [Google Scholar]

- Iglesias, M.S.; Sequeiros, C.; García, S.; Olivera, N.L. Eco-Friendly Anti-Felting Treatment of Wool Top Based on Biosurfactant and Enzymes. J. Clean. Prod. 2019, 220, 846–852. [Google Scholar] [CrossRef]

- Vujasinović, E.; Tarbuk, A.; Pušić, T.; Dekanić, T. Bio-Innovative Pretreatment of Coarse Wool Fibers. Processes 2022, 11, 103. [Google Scholar] [CrossRef]

- Fambri, G.; Lombardi, G.; Badami, M.; Chiaramonti, D. Energy Assessment of a Slow Pyrolysis Plant for Biochar and Heat Cogeneration. Chem. Eng. Trans. 2024, 109, 571–576. [Google Scholar] [CrossRef]

- Buelvas, A.; Quintero-Coronel, D.A.; Vanegas, O.; Ortegon, K.; Bula, A.; Mesa, J.; González-Quiroga, A. Gasification of Solid Biomass or Fast Pyrolysis Bio-oil: Comparative Energy and Exergy Analyses Using AspenPlus®. Eng. Rep. 2024, 6, e12825. [Google Scholar] [CrossRef]

- Ryšavý, J.; Čespiva, J.; Kuboňová, L.; Dej, M.; Szramowiat-Sala, K.; Molchanov, O.; Niedzwiecki, L.; Yan, W.-M.; Thangavel, S. Co-Gasification of Pistachio Shells with Wood Pellets in a Semi-Industrial Hybrid Cross/Updraft Reactor for Producer Gas and Biochar Production. Fire 2024, 7, 87. [Google Scholar] [CrossRef]

- Zoccola, M.; Montarsolo, A.; Mossotti, R.; Patrucco, A.; Tonin, C. Green Hydrolysis as an Emerging Technology to Turn Wool Waste into Organic Nitrogen Fertilizer. Waste Biomass Valorization 2015, 6, 891–897. [Google Scholar] [CrossRef]

- Vilas-Boas, A.C.M.; Tarelho, L.A.C.; Oliveira, H.S.M.; Silva, F.G.C.S.; Pio, D.T.; Matos, M.A.A. Valorisation of Residual Biomass by Pyrolysis: Influence of Process Conditions on Products. Sustain. Energy Fuels 2024, 8, 379–396. [Google Scholar] [CrossRef]

- Kabir, M.M.; Forgács, G.; Sárvári Horváth, I. Enhanced Methane Production from Wool Textile Residues by Thermal and Enzymatic Pretreatment. Process Biochem. 2013, 48, 575–580. [Google Scholar] [CrossRef]

- Marchelli, F.; Rovero, G.; Curti, M.; Arato, E.; Bosio, B.; Moliner, C. An Integrated Approach to Convert Lignocellulosic and Wool Residues into Balanced Fertilisers. Energies 2021, 14, 497. [Google Scholar] [CrossRef]

- Zago, S.; Scarpetta-Pizo, L.C.; Zagal, J.H.; Specchia, S. PGM-Free Biomass-Derived Electrocatalysts for Oxygen Reduction in Energy Conversion Devices: Promising Materials. Electrochem. Energy Rev. 2024, 7, 1. [Google Scholar] [CrossRef]

- Salamanca-Valdivia, M.A.; Cardenas-Herrera, L.; Barreda-Del-Carpio, J.E.; Moscoso-Apaza, G.M.; Garate-de-Davila, R.E.; Munive-Talavera, C.A. Production of Biogas in a Dry Anaerobic Digestion Reactor of Residues Generated in the Processing of Sheep and Alpaca Wool. In Proceedings of the 2021 10th International Conference on Renewable Energy Research and Application (ICRERA), Istanbul, Turkey, 26 September 2021; IEEE: New York, NY, USA, 2021; pp. 152–154. [Google Scholar]

- Marzeddu, S.; Cappelli, A.; Paoli, R.; Ambrosio, A.; Decima, M.A.; Boni, R.; Romagnoli, F. LCA Sensitivity Analysis of an Energy-Biochar Chain from an Italian Gasification Plant: Environmental Trade-Offs Assessment. Conect. Int. Sci. Conf. Environ. Clim. Technol. 2023, 63. [Google Scholar] [CrossRef]

- Marzeddu, S.; Cappelli, A.; Ambrosio, A.; Décima, M.A.; Viotti, P.; Boni, M.R. A Life Cycle Assessment of an Energy-Biochar Chain Involving a Gasification Plant in Italy. Land 2021, 10, 1256. [Google Scholar] [CrossRef]

- Arfelli, F.; Tosi, C.; Ciacci, L.; Passarini, F. Life Cycle Assessment of a Wood Biomass Gasification Plant and Implications for Syngas and Biochar Utilization. Energies 2024, 17, 2599. [Google Scholar] [CrossRef]

- Bianco, I.; Gerboni, R.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of MWool® Recycled Wool Fibers. Resources 2022, 11, 41. [Google Scholar] [CrossRef]

- Fatemeh, D.; Niloofar, E. Production of Valuable Nanoparticles from Waste Protein Fibres. Curr. Trends Fash. Technol. Text. Eng. 2017, 1, 17–19. [Google Scholar] [CrossRef]

- Brebu, M.; Spiridon, I. Thermal Degradation of Keratin Waste. J. Anal. Appl. Pyrolysis 2011, 91, 288–295. [Google Scholar] [CrossRef]

- Zeng, D.; Dou, Y.; Li, M.; Zhou, M.; Li, H.; Jiang, K.; Yang, F.; Peng, J. Wool Fiber-Derived Nitrogen-Doped Porous Carbon Prepared from Molten Salt Carbonization Method for Supercapacitor Application. J. Mater. Sci. 2018, 53, 8372–8384. [Google Scholar] [CrossRef]

- Chen, B.; Tang, Y.; Song, D. Dispatch Method of Township Industrial Park Integrated Energy System Considering Power to Ammonia and Biomass Waste Energy Conversion. In Proceedings of the 2024 IEEE 8th Conference on Energy Internet and Energy System Integration (EI2), Shenyang, China, 29 November 2024; IEEE: New York, NY, USA, 2021; pp. 468–473. [Google Scholar]

- Liu, Y.; Xu, X.; Liu, Y.; Liu, J.; Hu, W.; Yang, N.; Jawad, S.; Wei, Z. Operational Optimization of a Rural Multi-Energy System Supported by a Joint Biomass-Solid-Waste-Energy Conversion System and Supply Chain. Energy 2024, 312, 133528. [Google Scholar] [CrossRef]

- Li, X.; Sun, L.; Zhang, J.; Li, X.; Yang, Y.; Zhu, L.; Zhang, Y.; Wang, L. Carbon Footprint of Wool at Cradle to Farm-Gate Stage in Victoria, Australia. AATCC J. Res. 2024, 11, 37–46. [Google Scholar] [CrossRef]

- Hearle, J.W.S. A Critical Review of the Structural Mechanics of Wool and Hair Fibres. Int. J. Biol. Macromol. 2000, 27, 123–138. [Google Scholar] [CrossRef]

- Wang, H.; Guo, S.; Zhang, C.; Qi, Z.; Li, L.; Zhu, P. Flame Retardancy and Thermal Behavior of Wool Fabric Treated with a Phosphorus-Containing Polycarboxylic Acid. Polymers 2021, 13, 4111. [Google Scholar] [CrossRef] [PubMed]

- Braniša, J.; Koóšová, K.; Porubská, M. Selective Modifications of Sheep Wool Usable in Non-Textile Applications. Polymers 2024, 16, 1380. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Jose, S.; Shanumon, P.S.; Paul, A.; Mathew, J.; Thomas, S. Physico-Mechanical, Thermal, Morphological, and Aging Characteristics of Green Hybrid Composites Prepared from Wool-Sisal and Wool-Palf with Natural Rubber. Polymers 2022, 14, 4882. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Midolo, G.; Porto, S.M.C.; Cascone, G.; Valenti, F. Sheep Wool Waste Availability for Potential Sustainable Re-Use and Valorization: A GIS-Based Model. Agriculture 2024, 14, 872. [Google Scholar] [CrossRef]

- Chaitanya Reddy, C.; Khilji, I.A.; Gupta, A.; Bhuyar, P.; Mahmood, S.; Saeed AL-Japairai, K.A.; Chua, G.K. Valorization of Keratin Waste Biomass and Its Potential Applications. J. Water Process Eng. 2021, 40, 101707. [Google Scholar] [CrossRef]

- Mu, B.; Yu, X.; Yang, Y. Sustainable and Green Process for Recycling Waste Wool Textiles into High-Quality Protein Fibers on a Pilot Scale. Resour. Conserv. Recycl. 2023, 198, 107190. [Google Scholar] [CrossRef]

- Corscadden, K.W.; Biggs, J.N.; Stiles, D.K. Sheep’s Wool Insulation: A Sustainable Alternative Use for a Renewable Resource? Resour. Conserv. Recycl. 2014, 86, 9–15. [Google Scholar] [CrossRef]

- WOOLSHED Project for Interreg Alpine Space. Available online: https://www.alpine-space.eu/project/woolshed/ (accessed on 20 September 2025).

- Ramos, A.; Monteiro, E.; Rouboa, A. Biomass Pre-Treatment Techniques for the Production of Biofuels Using Thermal Conversion Methods—A Review. Energy Convers. Manag. 2022, 270, 116271. [Google Scholar] [CrossRef]

| Element | Content [%] |

|---|---|

| C | 50 |

| N | 15–25 |

| O | 10–25 |

| S | 2–5 |

| H | 6–12 |

| Element | Slovakia 1 | Poland | Greece | Syria |

|---|---|---|---|---|

| Ca | 4065 ± 2340 (729.2–4065) | 1790.0 ± 392.0 | 2900.0 ± 591.0 | 1800.0 ± 351.0 |

| K | 3282 ± 649.7 (2315–3282) | 718.6 ± 307.7 | 643.0 ± 312.9 | 755.0 ± 295.3 |

| Mg | 1009 ± 308.3 (163.8–1009) | 120.8 ± 17.2 | 383.5 ± 65.4 | 590.8 ± 133.5 |

| Na | 969.2 ± 344.7 (194.9–969.2) | 1486.7 ± 234.2 | 2165.0 ± 573.1 | 1745.5 ± 1152.6 |

| Cu | 7.54 ± 2.16 (3.79–7.54) | - | - | - |

| Fe | 71.83 ± 40.06 (17.61–71.83) | - | - | - |

| P | - | 148.0 ± 32.3 | 206.0 ± 49.2 | 284.0 ± 59.8 |

| Processing Technology | Pros | Cons | Approximate Energy Yield | Key Challenges | Technology Readiness Level (TRL) |

|---|---|---|---|---|---|

| Hydrolysis [10,42] | Extracts valuable keratin and amino acids | Requires pre-treatment (chemical/physical/enzymatic | Moderate (e.g., considerable keratin recovery, but energy for processing) | Stability of wool (disulphide bonds) requires effective hydrolysis methods Process optimisation for scale-up | TRL 4–6 (pilot/semi-industrial scales |

| Pyrolysis [35,43] | Produces biochar, bio-oil, and syngas Fast process with thermal decomposition | High energy input for heating Complex product mixture | High (biochar yield 22–47%, bio-oil yield varies 26–60%, depends on conditions) | Controlling product quality Scaling fixed/fluidized/spouted bed reactors | TRL 6–8 (commercial in some biomass applications) |

| Anaerobic Fermentation [34,44] | Produces biogas (methane) as renewable energy Digestate usable as fertiliser | Wool stability reduces biodegradability without pretreatment Long residence times needed | Moderate (Methane yield varies, example ~0.2–0.3 m3 CH4/kg volatile solids | Pretreatment approaches to disrupt wool structure (chemical, enzymatic) Process efficiency | TRL 4–7 (varies, emerging for wool biomass) |

| Parameter | Value | Category |

|---|---|---|

| Calorific value of wool | 20.5 MJ/kg | Energy |

| Calorific value (comparison) | 1.6× wood (shavings) | Energy |

| Calorific value (comparison) | 1.2× wood pellets | Energy |

| Carbon footprint (min) | 14.2 kg CO2-e/kg | Environment |

| Carbon footprint (max) | 52.9 kg CO2-e/kg | Environment |

| Main source of emission | 78.9–93.7% | Environment |

| Stored coal | 1.8 kg CO2-e/kg | Environment |

| Processing energy | 48–52 MJ/kg | Energy |

| Hydrolysis temperature | 170–185 °C | Technology |

| Hydrolysis time | 30–90 min | Technology |

| Hydrolysis efficiency | 2–3 kg hydrolysate/kg of wool | Technology |

| Pyrolysis temperature | 400–600 °C | Technology |

| Ignition temperature | 570–600 °C | Safety |

| EU wool production | ~240,000 tonnes/year | Production |

| Market share in textiles | ~1.2% | Market |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczecina, J.; Szczepanik, E.; Barwinek, J.; Szatkowski, P.; Niemiec, M.; Zhakypbekovich, A.I.; Molik, E. Sheep Wool as Biomass: Identifying the Material and Its Reclassification from Waste to Resource. Energies 2025, 18, 5185. https://doi.org/10.3390/en18195185

Szczecina J, Szczepanik E, Barwinek J, Szatkowski P, Niemiec M, Zhakypbekovich AI, Molik E. Sheep Wool as Biomass: Identifying the Material and Its Reclassification from Waste to Resource. Energies. 2025; 18(19):5185. https://doi.org/10.3390/en18195185

Chicago/Turabian StyleSzczecina, Julita, Ewa Szczepanik, Jakub Barwinek, Piotr Szatkowski, Marcin Niemiec, Alykeev Ishenbek Zhakypbekovich, and Edyta Molik. 2025. "Sheep Wool as Biomass: Identifying the Material and Its Reclassification from Waste to Resource" Energies 18, no. 19: 5185. https://doi.org/10.3390/en18195185

APA StyleSzczecina, J., Szczepanik, E., Barwinek, J., Szatkowski, P., Niemiec, M., Zhakypbekovich, A. I., & Molik, E. (2025). Sheep Wool as Biomass: Identifying the Material and Its Reclassification from Waste to Resource. Energies, 18(19), 5185. https://doi.org/10.3390/en18195185